ES manufacturing G7701L3.0 User Manual

Model No. G7701L3.0

INDUSTRIAL SPRAY GUN

CONTAIN:

Description

Specification and Technical Data

Important Safety Instruction

Instructions for Operation

Maintenance/Storing

Troubleshooting/Repairs

Parts List

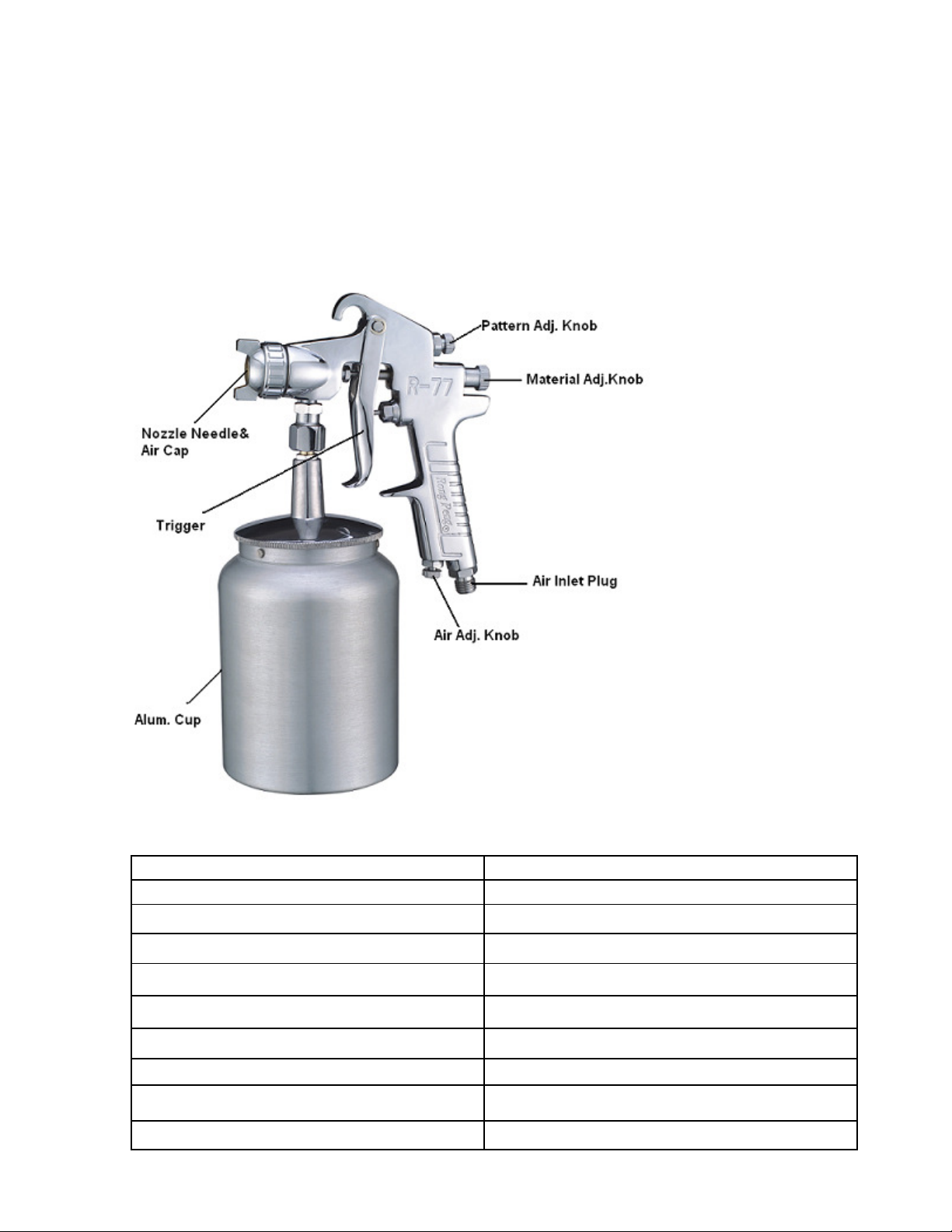

Description

A High pressure spray gun is ideal for refinishing cars or a wide variety of home

improvement projects. This high pressure paint sprayer features air, fluid and fan controls to

offer a wide variety of pattern. It is supplied with a 600 cc suction feed Alum. Cup.

Specifications And Technical Data

1. Name of Parts

2. Technical Data

Item No. G7701L3.0

Air Inlet

Type of Feed

Standard Dia of Nozzle

Optional Dia of Nozzle

Recommended air pressure

Max. pressure of air

Paint Capacity

Avg. Air Consumption

Pattern Width

1/4"

Suction

2.0mm

1.8-2.0-2.5mm

3.0-4.0bar (44 – 58psi)

8.3 bar (120psi)

1000cc

4.2-7.1cfm

180-280mm

- 2 -

4

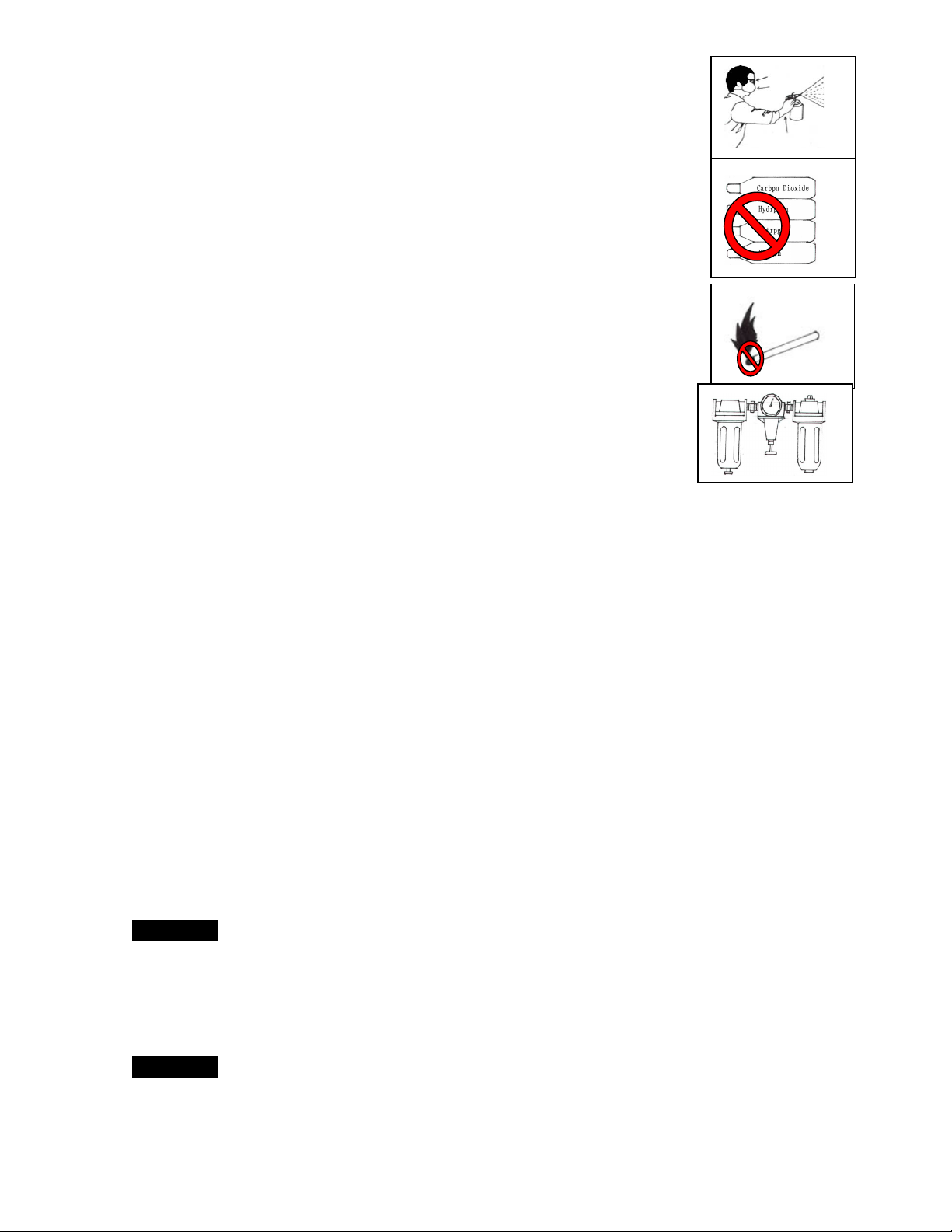

1.For toxic vapors produced by spraying certain materials can create intoxication

and serious damage to health. Always wear safety glasses, gloves and respirator

to prevent the toxic vapor hazard, solvent and pointing paint coming into contact

your eyes or skin. (see fig 1)

2.Never use oxygen, combustible or any other bottle gas as a power source or

would cause explosion and serious personal injury. (see fig 2)

3.Fluid and solvent can be highly flammable or combustible. Pls Use the tool only in

well-ventilated area, and avoid any ignition sources, such as smoking, open

flames and decrial hazard. (see fig 3)

4.Disconnect tool from air supply hose before doing tool maintenance and during

non-operation, for emerge stop and prevention of unintended operation, a ball

valve near the gun to air supply is recommend.

5.Use clean, dry and regulate compressed air rated at 3.0-4.0bar, never exceed

maximum permissive operating pressure 8.3bar (120psi) (see fig 4)

6.Never use homogenate hydrocarbon solvent, which can chemically react with

aluminum and zinc parts and chemically compatible with Alum. and zinc pats.

7.Never point gun at you and others at any time.

8.Before operating the tool, make sure all the screws & caps are securely

tightened in case of leaking;

9. Before painting, make inspection for free movement of trigger and nozzle to insure tool can operate

well.

10.Never modify this tool for any other applications. Only use parts, nozzles and accessories

recommended and accessories recommended by manufactures.

Important Safety Instructions

1

2

3

Instructions For Operation

Preparation

1. After unpacking the product, inspect carefully for any damage that may have occurred during transit.

Make sure to tighten fittings, bolts, etc., before putting unit into service.

2. Thoroughly mix and thin paint in accordance with the paint manufacturer’s instructions. Most

materials will spray readily if thinned properly.

3. Strain material through filter, cheese cloth or a paint strainer.

4. Fill the canister about ¾ full and start the air compressor.

WARNING

5. After Connect the gun to air supply, please make sure that the fluid cap, container and air hose have

been connected tightly with spray gun.

6. Set up a piece of cardboard or other scrap material to use as a target and adjust for best spray

pattern.

WARNING

7. Test the consistency of the material by making a few strokes on a cardboard target. If material still

appears too thick, add a small amount of thinner. THIN WITH CARE! Do not exceed paint

manufacturer’s thinning recommendations.

DO NOT EXCEED Maximum Pressure of Spray Gun or any other parts in the compressor system.

Never aim or spray at yourself or anybody else which would cause serious injury.

Loading...

Loading...