SU7(Haswell) Series

SU7-2212G

Full-Featured Energy Efficient 2-Way Server

Technical Guide

Version: 2.0

COPYRIGHT

Copyright

Copyright © 2014 ESlim Computer Inc. This publication, including all photographs, illustrations and software, is protected under international copyright laws, with all rights

reserved. Neither this technical guide, nor any of the material contained herein, may be

reproduced without the express written consent of the manufacturer. All trademarks and

logos are copyrights of their respective owners.

Version 2.0 / November 25, 2014

Disclaimer

The information in this document is subject to change without notice. The manufacturer

makes no representations or warranties with respect to the contents hereof and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose. Furthermore, the manufacturer reserves the right to revise this publication and to

make changes from time to time in the content hereof without obligation of the manufacturer to notify any person of such revision or changes.

For the latest information and updates please see www.eslim.co.kr

All the illustrations in this technical guide are for reference only and are subject to change

without prior notice.

I

T

ABLE

OF CONTENT

ABLE OF

T

ONTENT

C

About the System

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Tour of the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Front Control Panel LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

LAN Port LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1-1

1-4

1-5

1-5

1-7

1-9

HDD LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Installing Hardware

Safety Measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hard Disk Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the HDD Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the HDD Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid-State Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the SSD Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the SSD Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing a Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-2

2-2

2-3

2-4

2-4

2-5

2-7

2-7

Installing a Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8

II

T

ABLE

OF CONTENT

Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9

2-9

Installing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Removing the Middle Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Installing the Middle Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Removing the Fan Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Installing the Fan Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

SuperCap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Replacing the SuperCap Power Module (RAID Backup Unit) . . . . . . . 2-16

Installing a SuperCap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Expansion Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Removing a PCIe Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Installing a PCIe Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Expansion Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Removing the Expansion Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Installing the Expansion Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

PCIe Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Removing the PCIe Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Installing the PCIe Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Mezzanine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Removing a Mezzanine Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Installing a Mezzanine Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

OCP Mezzanine Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Installing an OCP Mezzanine Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Removing an OCP Mezzanine Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

III

T

ABLE

OF CONTENT

Air Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Removing the Air Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Installing the Air Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Processor Heat Sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Removing the Processor Heat Sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Installing the Processor Heat Sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Removing the Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Installing the Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Memory Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

General Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Memory Population Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Removing a Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Installing a Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Mainboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Removing the Mainboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Installing the Mainboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Hard Disk Drive Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Locating the HDD Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Removing the Backplane (2.5”). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Installing the Backplane (2.5”). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Removing the HDD Backplane (3.5”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Installing the HDD Backplane (3.5”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

SSD Air Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Removing the SSD Air Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Installing the SSD Air Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

IV

T

ABLE

OF CONTENT

SSD Fan Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

Removing a SSD Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

Installing a SSD Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

SSD Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

Removing a SSD Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

Installing a SSD Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

Expander Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Removing an Expander Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Installing an Expander Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

Front Panel Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Removing the Front Panel Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Installing the Front Panel Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

USB Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

Removing the USB Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

Installing the USB Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

BIOS

BIOS Setup Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Page Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering BIOS Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Selection Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Server Platform Setup Utility Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3-1

3-1

3-1

3-2

3-3

3-4

Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Super IO Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SATA Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Port Console Redirection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

V

3-4

3-5

3-7

3-9

T

ABLE

OF CONTENT

Onboard Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

PCI Subsystem Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

CSM Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Trusted Computing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

USB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

IntelRCSetup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Processor Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Advanced Power Management Configuration . . . . . . . . . . . . . . . . . 3-24

Common RefCode Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

QPI Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

IIO Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

PCH Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Server ME Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Runtime Error Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Server Management Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

System Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

View FRU information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

BMC network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

Boot Options Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

UEFI Network Drive BBS Priorities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

Security Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Secure Boot menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

Exit Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

Loading BIOS Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

BIOS Update Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

BIOS Update Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

AFULNX: v2.39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

ME Region Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

BIOS Setting Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

BIOS Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

Clear CMOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-69

Clear Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-69

VI

T

ABLE

OF CONTENT

Server Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

Console Redirection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

Serial Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

Keystroke Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-71

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-71

Interface to Server Management (Optional) . . . . . . . . . . . . . . . . . . . . 3-72

Network BIOS Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

PXE Boot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

Checkpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

Debug Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

Standard Checkpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

ACPI/ASL Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

OEM-Reserved Checkpoint Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-79

BMC

Server Management Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Server System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMC Key Features and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ID Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LAN Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

4-1

4-1

4-1

4-2

4-2

4-2

4-2

4-5

Session and User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Over LAN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platform Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Platform Event Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMC Firmware Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VII

4-5

4-5

4-6

4-6

4-6

4-6

4-6

T

ABLE

OF CONTENT

DOS Recovery Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6

WebUI Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMC Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recovery Process in DOS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recovery Process in Linux System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recovery Process in Windows System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SMASH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7

4-8

4-8

4-8

4-8

4-9

System Level Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

BMC Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Web Graphical User Interface (GUI) for ESMS . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Using the Web GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Dashboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Network Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Sensor Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Event Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Server Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

FRU Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Server Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Server identify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

BIOS POST Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Server Health Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Sensor Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Configuration Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Active Directory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

DNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

LDAP/E-Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Mouse Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

VIII

T

ABLE

OF CONTENT

PEF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

RADIUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Remote Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

SMTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

SOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

SSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

User Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

Virtual Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

UTC Timezone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

LAN Port Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Console Redirection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Server Power Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-73

Maintenance Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-73

BMC Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

BIOS Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

Preserve Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

Restore Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-77

Log Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

User Privilege . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

Connectors and Jumpers

Connectors and Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

5-1

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HDD Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

USB Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCIe SSD Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAS/SATA SSD Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IX

5-1

5-3

5-3

5-5

5-6

5-6

Troubleshooting

T

ABLE

OF CONTENT

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BIOS checkpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intel Memory Reference Code Checkpoints . . . . . . . . . . . . . . . . . . . . .

Hardware Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HDD SMART failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HDD not ready, or server does not see hard disk drive . . . . . . . . . . .

HDD SATA failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motherboard No Boot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motherboard fails single bit ECC Errors. . . . . . . . . . . . . . . . . . . . . . . . . .

Motherboard fails multiple bit error or rebooting . . . . . . . . . . . . . . .

Motherboard fails 1G Ethernet port . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motherboard fails for PXE, 10G Mellanox. . . . . . . . . . . . . . . . . . . . . . . .

Motherboard rebooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-1

6-1

6-2

6-2

6-2

6-2

6-2

6-2

6-3

6-3

6-3

6-4

6-4

Hardware Failure Troubleshooting Matrix . . . . . . . . . . . . . . . . . . . . . . . . .

SOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulatory and Compliance Information

6-5

6-7

X

CONVENTIONS

Conventions

Several different typographic conventions are used throughout this manual. Refer to the

following examples for common usage.

Bold

type face denotes menu items, buttons and application names.

Italic type face denotes references to other sections, and the names of the folders, menus,

programs, and files.

<Enter> type face denotes keyboard keys.

.Warning information appears before the text it references and should not be ignored as

the content may prevent damage to the device.

!

!

WARNING!

Warning information appears before the text it references and should not be ignored as the

content may prevent damage to the device.

CAUTION!

CAUTIONS APPEAR BEFORE THE

APPEAR IN CAPITAL LETTERS AND CONTAIN

TEXT

IT REFERENCES, SIMILAR TO NOTES AND WARNINGS. CAUTIONS, HOWEVER,

VITAL

HEALTH AND SAFETY INFORMATION.

Note:

Highlights general or useful information and tips.

XI

Table 1: Warning and Cautions

CAUTION

Indicates the presence of a hazard that may cause minor personal injury or property damage if the CAUTION is ignored.

WARNING

Indicates the presence of a hazard that may result in serious personal injury if the

WARNING is ignored.

Indicates potential hazard if indicated information is ignored.

Indicates shock hazards that result in serious injury or death if safety instructions

are not followed.

Indicates hot components or surfaces.

Indicates do not touch fan blades, may result in injury.

Remove the system from the rack to disconnect power system.

PRECAUTIONARY MEASURES

Precautionary Measures

Read all caution and safety statements in this document before performing any of the

instructions. To reduce the risk of bodily injury, electrical shock, fire, and equipment damage, read and observe all warnings and precautions in this chapter before installing or

maintaining your system. To avoid personal injury or property damage, before you begin

installing the product, read, observe, and adhere to all of the following instructions and

information. The following symbols may be used throughout this guide and may be

marked on the product and / or the product packaging.

Safety Instructions about your system

In the event of a conflict between the information in this guide and information provided

with the product or on the website for a particular product, the product documentation

takes precedence.

Your system should be integrated and serviced only by technically qualified persons.

You must adhere to the guidelines in this guide and the assembly instructions in related

chapters to ensure and maintain compliance with existing product certifications and

approvals. Use only the described, regulated components specified in this guide. Use of

other products / components will void the UL Listing and other regulatory approvals of

the product, and may result in noncompliance with product regulations in the region(s) in

which the product is sold.

XII

Table 1: Warning and Cautions (Continued)

The enclosure is designed to carry only the weight of the system sled. Do not use

this equipment as a workspace. Do not place additional load onto any equipment

in this system.

Indicates two people are required to safely handle the system.

Restricted Access Location:

The system is intended for installation only in a

Server Room or Computer Room where both these conditions apply:

access can only be gained by SERVICE PERSONS or by USERS who have been

instructed about the reasons for the restrictions applied to the location and

about any precautions that shall be taken; and

access is through the use of a TOOL or lock and key, or other means of security,

and is controlled by the authority responsible for the location.

PRECAUTIONARY MEASURES

Intended Application Uses

This product was evaluated as Information Technology Equipment (ITE), which may be

installed in offices, schools, computer rooms, and similar commercial type locations. The

suitability of this product for other product categories and environments (such as medical,

industrial, residential, alarm systems, and test equipment), other than an ITE application,

may require further evaluation.

Site Selection

The system is designed to operate in a typical office environment. Choose a site that is:

Clean, dry, and free of airborne particles (other than normal room dust).

Well-ventilated and away from sources of heat including direct sunlight and radiators.

Away from sources of vibration or physical shock.

Isolated from strong electromagnetic fields produced by electrical devices.

In regions that are susceptible to electrical storms, we recommend you plug your

system into a surge suppressor and disconnect telecommunication lines to your

modem during an electrical storm.

Provided with a properly grounded wall outlet.

Provided with sufficient space to access the power system, because they serve as the

product's main power disconnect.

Provided with either two independent DC power system or two independent phases

from a single power system.

XIII

Equipment Handling Practices

Reduce the risk of personal injury or equipment damage:

Conform to local occupational health and safety requirements when moving and

lifting equipment.

Use mechanical assistance or other suitable assistance when moving and lifting

equipment.

To reduce the weight for easier handling, remove any easily detachable compo-

nents.

Never lift or move your system soley by the handle on the component.

Power and Electrical Warnings

CAUTION!

M

AKE

!

!

SURE THE SYSTEM IS REMOVED FROM THE

THE BUS

TEM FROM THE POWER SOURCE.

BAR

CAUTION!

TO AVOID RISK OF ELECTRIC SHOCK, DISCONNECT

FROM THE

RACK

BEFORE SERVICING

CLIPS MUST BE DISCONNECTED FROM THE POWER SYSTEM INORDER TO

ALL

CABLING FROM THE SYSTEM AND REMOVE THE SYSTEM

RACK

.

System Access Warnings

PRECAUTIONARY MEASURES

ANY

NON-HOT PLUG COMPONENTS.

FULLY

SEPARATE THE SYS-

CAUTION!

!

TO AVOID PERSONAL INJURY OR PROPERTY DAMAGE, THE FOLLOWING SAFETY INSTRUCTIONS APPLY WHENEVER

ACCESSING THE INSIDE OF THE PRODUCT:

Disconnect from the power source by removing the system from the rack.

Disconnect all cabling running into the system.

Retain all screws or other fasteners when servicing. Upon completion servicing, sercure

with original screws or fasteners.

CAUTION!

!

IF THE SERVER HAS BEEN RUNNING,

CAUTION!

!

UNLESS YOU

VICING.

CAUTION!

!

TO AVOID INJURY DO NOT CONTACT MOVING FAN BLADES. IF YOUR SYSTEM IS SUPPLIED WITH A GUARD OVER THE

FAN, DO NOT OPERATE THE SYSTEM WITHOUT THE FAN GUARD IN PLACE.

ANY

INSTALLED HDD MODULES

ARE

ADDING OR REMOVING A HOT-PLUG COMPONENT, ALLOW THE SYSTEM TO COOL BEFORE SER-

MAY BE

HOT.

XIV

PRECAUTIONARY MEASURES

Rack Mount Warnings

The following installation guidelines are required by UL for maintaining safety compliance

when installing your system into a rack.

The equipment rack must be anchored to an unmovable support to prevent it from tipping when your system or piece of equipment is extended from it. The equipment rack

must be installed according to the rack manufacturer's instructions.

Install equipment in the rack from the bottom up, with the heaviest equipment at the bottom of the rack.

Extend only one piece of equipment from the rack at a time.

You are responsible for installing a main power disconnect for the entire rack unit. This

main disconnect must be readily accessible, and it must be labeled as controlling power to

the entire unit, not just to the system(s).

To avoid risk of potential electric shock, a proper safety ground must be implemented for

the rack and each piece of equipment installed in it.

Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack environment may be greater than room ambient.

Therefore, consideration should be given to installing the equipment in an environment

compatible with the maximum ambient temperature (Tma) specified by the manufacturer.

Reduced Air Flow - Installation of the equipment in a rack should be such that the amount

of air flow required for safe operation of the equipment is not compromised.

Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition is not achieved due to uneven mechanical loading.

Circuit Overloading - Consideration should be given to the connection of the equipment

to the supply circuit and the effect that overloading of the circuits might have on over-current protection and supply wiring. Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern.

Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than direct connections

to the branch circuit (e.g. use of power strips).

XV

PRECAUTIONARY MEASURES

Electrostatic Discharge (ESD)

CAUTION!

!

Always handle boards carefully. They can be extremely sensitive to ESD. Hold boards only

by their edges without any component and pin touching. After removing a board from its

protective wrapper or from the system, place the board component side up on a

grounded, static free surface. Use a conductive foam pad if available but not the board

wrapper. Do not slide board over any surface.

ESD CAN DAMAGE DRIVES, BOARDS, AND OTHER PARTS. W

AT AN ESD WORKSTATION. IF ONE IS NOT

STATIC WRIST STRAP ATTACHED TO CHASSIS GROUND --

WHEN HANDLING PARTS.

Cooling and Airflow

CAUTION!

C

!

AREFULLY

PROPER COOLING AND AIRFLOW, OPERATE THE SYSTEM ONLY WITH THE CHASSIS COVERS* / AIR DUCT INSTALLED.

OPERATING THE SYSTEM WITHOUT THE COVERS / AIR DUCT IN PLACE CAN DAMAGE SYSTEM PARTS . TO INSTALL

THE COVERS* / AIR DUCT:

Check first to make sure you have not left loose tools or parts inside the system.

Check that cables, add-in cards, and other components are properly installed.

Attach the covers* / air duct to the chassis according to the product instructions.

* May not apply to all systems.

E

RECOMMEND THAT YOU PERFORM

AVAILABLE

ROUTE CABLES AS DIRECTED TO MINIMIZE AIRFLOW BLOCKAGE AND COOLING PROBLEMS. FOR

, PROVIDE SOME ESD PROTECTION

ANY

UNPAINTED METAL SURFACE -- ON YOUR SERVER

ALL

PROCEDURES

BY

WEARING AN ANTI-

Please be aware that slots and openings on the front and rear side of the chassis are

designed for ventilation; to make sure reliable operation of your system and to protect it

from overheating, these openings must not be covered or blocked. The openings should

never be covered or blocked by placing the product on a bed, sofa, rug, or other similar

surface. This product should never be placed near or over a radiator or heat register, or in a

built-in installation unless proper ventilation is provided.

Laser Peripherals or Devices

CAUTION!

!

Use certified and rated Laser Class I for Optical Transceiver product.

Heed safety instructions:

any other resource as a reference, pay close attention to the safety instructions. Adhere to

the assembly instructions in this manual to ensure and maintain compliance with existing

product certifications and approvals. Use only the described, regulated components spec-

TO AVOID RISK OF RADIATION EXPOSURE AND / OR PERSONAL INJURY:

Do not open the enclosure of any laser peripheral or device.

Laser peripherals or devices are not serviceable.

Return to manufacturer for servicing.

Before working with the system, whether using this manual or

XVI

PRECAUTIONARY MEASURES

ified in this manual. Use of other products / components will void the UL listing and other

regulatory approvals of the product and will most likely result in non-compliance with

product regulations in the region(s) in which the product is sold.

System power on/off:

To remove power from system, you must remove the system from

rack. Make sure the system is removed from the rack before opening the chassis, adding,

or removing any non hot-plug components.

Hazardous conditions, devices and cables:

Hazardous electrical conditions may be

present on power, telephone, and communication cables. Turn off the system and disconnect the cables attached to the system before opening it. Otherwise, personal injury or

equipment damage can result.

Electrostatic discharge (ESD) and ESD protection:

ESD can damage drives, boards, and

other parts. We recommend that you perform all procedures in this chapter only at an ESD

workstation. If one is not available, provide some ESD protection by wearing an antistatic

wrist strap attached to chassis ground any unpainted metal surface on the server when

handling parts.

ESD and handling boards:

Always handle boards carefully. They can be extremely sensi-

tive to electrostatic discharge (ESD). Hold boards only by their edges. After removing a

board from its protective wrapper or from the server, place the board component side up

on a grounded, static free surface. Use a conductive foam pad if available but not the

board wrapper. Do not slide board over any surface.

Installing or removing jumpers

: A jumper is a small plastic encased conductor that slips

over two jumper pins. Some jumpers have a small tab on top that can be gripped with fingertips or with a pair of fine needle nosed pliers. If the jumpers do not have such a tab,

take care when using needle nosed pliers to remove or install a jumper; grip the narrow

sides of the jumper with the pliers, never the wide sides. Gripping the wide sides can damage the contacts inside the jumper, causing intermittent problems with the function controlled by that jumper. Take care to grip with, but not squeeze, the pliers or other tool used

to remove a jumper, or the pins on the board may bend or break.

General Information

The information about rack and the wording “rack” in this technical guide supports the

organization of Open Compute definition.

The term

described and used in the Open Compute Project definition.

Before servicing this system, it is recommened to read this technical guide completely to

be aware of any safety issues or requirements involved in the servicing of this system.

XVII

Rack

as found in this technical guide referes to the term

Rack

or

Open Rack

as

The power system in this product contains no user-serviceable parts.

Refer servicing only to qualified personnel.

The system is designed to operate in a typical office environment.

Choose a site that is:

Clean and free of airborne particles (other than normal room dust).

Well ventilated and away from sources of heat including direct sunlight.

Away from sources of vibration or physical shock.

Isolated from strong electromagnetic fields produced by electrical devices.

In regions that are susceptible to electrical storms, we recommend you plug

your system into a surge suppressor and disconnect telecommunication lines

to your modem during an electrical storm.

Provided with a properly grounded wall outlet.

Provided with sufficient space to access the power system, because they serve

as the product's main power disconnect.

WARNING!

The system is safety certified as rack-mounted equipment for use in a server room

or computer room, using an approved customer rack.

The enclosure is designed to carry only the weight of the system sled. Do not place

additional load onto any equipment.

Heavy object. Indicates two people are required to safely handle the system.

Assembly Safety Guidelines

PRECAUTIONARY MEASURES

XVIII

PRECAUTIONARY MEASURES

Structure of this guide

Chapter 1: About the System

“This section introduces the system, its different configuration(s) and the main

features.”

Chapter 2: Installing Hardware

“This section provides guidance information to properly service components in

the system.”

Chapter 3: BIOS

“This section provides information regarding the BIOS architecture, BIOS update

utility, server management, checkpoints, and error handling found in the sys-

tem.”

Chapter 4: BMC

“This section provides information and key features of BMC (Baseboard Manage-

ment Controller).”

Chapter 5: Connectors and Jumpers

“This section provides guidance information for the position and configuration of

connectors and jumpers.”

Chapter 6: Troubleshooting

“This section provides a guidance for the troubleshooting of system errors and

hardware failure notification.”

Chapter 7: Regulatory and Compliance Information

“This section provides regulatory and compliance information applicable to this

system.”

XIX

About the System

Chapter 1

This section introduces the system, its different configuration(s) and the main features.

Table 1.1: System Specifications

INTRODUCTION ABOUT THE SYSTEM

SPECIFICATIONS

DESCRIPTION

Form factor

2U rack mount

Chassis dimensions

(W x H x D)

17.6 x 3.44 x 29.33 inches

447 x 87.5 x 745 mm

Processor

Processor type:

Intel® Xeon® processor E5-2600 v3 product family

Max. TDP support:

145W

Number of processors:

2

Internal Interconnect:

6.4 / 8.0 / 9.6 GT/s

Last Level Cache (LLC):

Up to 35 MB

1.1 Introduction

eSlim Haswell SU7-2212G is a general-purpose rackmount server designed for optimal perfor-

mance and power efficiency. It supports up to 1.5 TB highly scalable memory capacity and

up to 12 3.5” or 24 2.5” hot-swappable HDD for complex and demanding workloads, such

as mail-server, database, e-commerce and high-performance computing (HPC).

Greener and More Powerful

Powered by the Intel® Xeon® processor E5-2600 v3 product family and DDR4 mem-

ory technology, the eSlim Haswell SU7-2212G allows owners to upgrade computing per-

formance without overextending power consumption. With ESlim’s enhanced

thermal design, the server can operate under ambient temperatures as high as

40°C. This allows owners to save unnecessary costs associated with datacenter cooling needs and achieve higher data center infrastructure efficiency (DCIE) value.

Full-Featured Design for Demanding Storage and Computing Workload

With 24 dual in-line memory (DIMM) slots, ESlim Haswell SU7-2212G offers non-latency

support to virtualization environments that require the maximum memory capac-

ity. In addition to 12 3.5” or 24 2.5” front-access, hot-swappable HDDs, the SU7-2212G

also has two optional 2.5” PCIe (NVMe) SSD bays and two optional 2.5”

bays on the rear side for extra caching or OS support without sacrificing storage

capacity.

SATA

HDD

Flexible and Scalable I/O options*

eSlim Haswell SU7-2212G provides flexible I/O scalability for today’s diverse data center

application requirements. It features OCP LAN mezzanine card solutions in addition

to dual GbE or 10GbE LAN on Motherboard (LoM). With various controller vendors

and different speed and technology options, customers can choose from GbE to

56GbE bandwidth, copper to fiber-optic cabling, basic Ethernet function to FCoE

and ISCI SAN connectivity. The onboard SAS controller offers multiple eSlim SAS

mezzanine card options with different RAID levels and data transfer bandwidth so

customers can tailor the SAS controller for specific application needs.

Specifications

1-1

Table 1.1: System Specifications (Continued)

ABOUT THE SYSTEM INTRODUCTION

SPECIFICATIONS

DESCRIPTION

Chipset

Intel

®

C610

Memory

Total slots:

24

Capacity: Up to 384GB RDIMM / Up to 768GB LRDIMM

Memory type:

2133 MHz DDR4 RDIMM / LRDIMM

Memory size:

16 GB, 8 GB RDIMM / 32 GB LRDIMM

Storage controller

Onboard (Intel® C610):

10x

SATA

6Gb/s ports

SATA

RAID 0, 1, 10

Optional controller:

ESlim

LSI®

2308 6Gb/s SAS mezzanine, RAID 0, 1, 10

ESlim

LSI®

3008 12Gb/s SAS mezzanine, RAID 0, 1, 10

ESlim

LSI®

2108 6Gb/s RAID mezzanine, RAID 0, 1, 5, 10, RAID 6 with

additional RAID key

ESlim

LSI®

2208 6Gb/s RAID mezzanine, RAID 0, 1, 5, 10, RAID 6 with

additional RAID key

Networking

LOM:

Intel® I350 dual-port 1GbE or Intel® X540 dual-port 10GbE BASE-T

Dedicated 1GbE management port

Optional NIC:

(more options refer to the

AVL)

ESlim Intel® i350 dual-port OCP mezzanine

ESlim Intel® X540 dual-port 10GbE BASE-T OCP mezzanine

ESlim Intel® 82599ES dual-port 10G SFP+ OCP mezzanine

Expansion slots

Riser 1

(default):

One x8 PCIe 3.0 SAS mezzanine slot (CPU0)

One x8 PCIe 3.0, Low profile MD-2 (CPU0)

One x8 PCIe 3.0, Low profile MD-2 (CPU1)

(option 2):

One x16 PCIe 3.0, Low profile MD-2 (CPU0)

One x8 PCIe 3.0, Low profile MD-2 (CPU1)

Riser 2

One x16 PCIe 3.0, FHHL (CPU1)

One x8 PCIe 3.0, FHHL (CPU1)

OCP mezz slot

One x8 PCIe Connector (CPU0)

Storage

12x 3.5" hot-plug HDD/SSD (3.5” HDD SKU)

24x 2.5" hot-plug HDD/SSD (2.5” HDD SKU)

2x optional rear 2.5" PCIe SSD

2x optional rear 2.5"

SATA

HDD/SSD

Onboard storage

2x SATADOM (optional)

Video

Integrated Aspeed AST2400 with 8MB DDR3 video memory

Front I/O

Power/ID/Reset Buttons

LAN/HDD/Status/ID LEDs

2x USB 2.0 ports

1-2

Table 1.1: System Specifications (Continued)

INTRODUCTION ABOUT THE SYSTEM

SPECIFICATIONS

DESCRIPTION

Rear I/O

2x USB 3.0 ports

1x VGA port

1x RS232 serial Port

2x 1 GbE or 10G BASE-T RJ45 port

1x GbE RJ45 management port

1x ID LED

1x Port 80 Debug Port (optional)

Optical drive

NA

TPM

Yes (optional)

Power supply

1 High efficiency redundant hot-plug 750W PSU, 80 Plus Gold (2nd PSU

optional)

Fan

4x dual rotor fans (7+1 redundant)

System management

IPMI v2.0 Compliant, on board

"KVM

over IP" support

Weight (Max. configuration)

26.87 Kg (3.5” HDD SKU)

24.51 Kg (2.5” HDD SKU)

Operating environment

Operating temperature: 5°C to 40°C (41°F to 104°F)

Non-operating temperature: -40°C to 70°C (-40°F to 158°F)

Operating relative humidity: 50% to 85%RH.

Non-operating relative humidity: 20% to 90%RH

1-3

ABOUT YOUR SYSTEM PACKAGE CONTENTS

1.2 Package Contents

(1) SU7-2212G system

(2) processor heat sinks

(1) power supply unit

(1) power cord (optional)

(1) utility CD (Technical Guide included)

(1) rail kit

Note:

For exact shipping contents, contact your ESlim sales representative.

1-4

2 3

A TOUR OF THE SYSTEM ABOUT THE SYSTEM

1.3 A Tour of the System

System Overview

The server is available as a 2.5” and 3.5” HDD configuration.

The 2.5” HDD configuration system overview is displayed in the following image:

1 4 5 6 7

11

10 9 8 4 5 6

Figure 1-1. 2.5” System component overview

1-5

9 HDD assembly

model only)

See

Top Cover

on

page 2-9.

ABOUT THE SYSTEM SYSTEM O

The 3.5” HDD configuration system overview is displayed in the following image:

1 2 3 4 5 6 7

VERVIEW

10 9 8 4 5 6

Figure 1-2. 3.5” System component overview

Table 2: Component Overview

NO. ITEM DESCRIPTION

1 Top front cover Enclosure for hard disk drives bay.

2 Fan modules System fan modules (x4). See

3 DIMM slots DDR4 DIMM slots, 12 per CPU. See

4 Processor

5 PSU assembly Redundant power supply unit assembly.

CPU01 and CPU02 processors with heat sinks on top. See

Sink

on page 2-34.

6 Expansion slots SSD optional expansion bay.

7 Expansion slots PCIe expansion bay.

8 USB board USB ports. See

3.5” model: 12 x hard disk drive assemblies

2.5” model: 24 x hard disk drive assemblies

USB Board

Fan Module

Memory Modules

on page 2-63.

on page 2-13.

on page 2-39.

Processor Heat

10 Front control panel On/Off power button and LED. See

11

Middle top cover

(2.5”

Front Panel Board

on page 2-60.

1-6

2 HDD bays

3 USB board

SYSTEM O

VERVIEW

ABOUT THE SYSTEM

System Front View

1 2 3

Figure 1-3. 2.5” System Front View

1 2 3

Figure 1-4. 3.5” System Front View

Table 3: Front Panel View

NO. NAME DESCRIPTION

1 Front control panel On/Off power button and LED.

12 x 3.5” HDDs

24 x 2.5” HDDs

USB 2.0 ports x 2.

Front panel USB port.

1-7

Table 4: Front Control Panel Definition

NO.

ICON

NAME

DESCRIPTION

1

Power button

with LED

Power on / off

2 Reset button

Soft reset system function

3 ID button

Activates identification event

4 Fault LED

Provides critical and non-critical failure notification

5

HDD access

LED

Hard disk drive access

6 LAN1 LED

LAN access

7 LAN2 LED

LAN access

8 ID LED

Displays when ID button is pressed

ABOUT THE SYSTEM SYSTEM O

Front Control Panel

1

2

3 8

Figure 1-5. Front Control Panel

4

5

6

7

VERVIEW

1-8

SYSTEM O

VERVIEW

ABOUT THE SYSTEM

System Rear View

1 2 3 4

13 12 11

Figure 1-6. System Rear View

Table 5: Rear Panel View

NO. NAME DESCRIPTION

1 Expansion Slot PCIe optional expansion bay.

2 Expansion Slot PCIe expansion bay.

3 Expansion Slot Two PCIe expansion bays.

4 Expansion Slot SAS/SATA optional expansion bay.

5 Power Sub-system Primary power supply unit (PSU1).

6 USB ports USB ports 0 - 1 (2.0 / 3.0)

7 Dedicated NIC Dedicated RJ45 connector

8 NIC1 RJ45 connector

9 NIC2 RJ45 connector

10 COM port A DB9 port (Serial_A) for debug or terminal concentrator

11 VGA connector Maximum display resolution: 1920x1200 32bpp@60Hz (reduced blanking)

12 OCP connector OCP debug connector (optional)

13 Power Sub-system Secondary power supply unit (PSU2)

10 9 8 7 6 5

1-9

Table 6: Front Control Panel LED Behavior

ABOUT THE SYSTEM LED DEFINITIONS

NAME

COLOR

CONDITION

DESCRIPTION

Power LED

Blue

On

System power on

Off

System power off

Identification

Blue

On

Unit selected for identification

Off

No identification request

Fault LED

Amber

Blinking

Critical Failure: critical fan, voltage, temperature state.

Non-Critical Failure: non-critical fan, voltage, temperature

state, CPU thermal trip, DC off

Off

SEL cleared

Last pending warning or error has been de-asserted

HDD Activity

Blue

Blinking

Hard disk drive access (only on board

SATA

port)

Off

No access (non-SAS)

LAN1 LED

Blue

On

Link

Blinking

LAN access (off when there is traffic)

LAN2 LED

Blue

On

Link

Blinking

LAN access (off when there is traffic)

LED Definitions

Front Control Panel LED

1-10

Table 7: RJ45 LED Description

Table 8: HDD Status LED Behavior

LED DEFINITIONS ABOUT THE SYSTEM

CONDITION

L

INK

ACTIVITY

Unplugged

Off

Off

1G active link

On amber

Blinking green

100M active link

On green

Blinking green

10M active link

Off

Blinking green

INDICATION

STATUS LED

FAULT LED

ACTIVE LED

Drive on-line

On blue

Off

On blue: HDD access active

On amber: HDD error

RAID fail, Initial at AC on, RAID

rebuild

LAN Port LEDs

The system mainboard includes an optional 82599EN Ethernet controller and two 1 GbE or

one 10 GbE (optional) ports. Each RJ45 connector has two built-in LEDs. See the following

illustration and table for details.

Speed Activity/Link

PIN 1 location

Figure 1-7. RJ45 LAN port LEDs

HDD LED

Front HDD LED Status Behavior

Active LED

(Right)

Status / Fault

LED (Left)

Figure 1-8. HDD LED Identification

Status / Fault

LED (Top)

Active LED

Bottom)

1-11

Drive on-line

Off

ABOUT THE SYSTEM LED DEFINITIONS

Rear Storage Device LED Status Behavior

1 2 3 4

5 6 7 8

Figure 1-9. Rear Storage Device View

Table 9: Rear Panel View

NO. NAME

1 PCIe Storage Device 0 Status LED

2 PCIe Storage Device 1 Status LED

3 SAS/SATA Storage Device 0 Status LED

4 SAS/SATA Storage Device 1 Status LED

5 PCIe Storage Device 0 Active LED

6 PCIe Storage Device 1 Active LED

7 SAS/SATA Storage Device 0 Active LED

8 SAS/SATA Storage Device 0 Active LED

Table 10: Rear Storage Device LED Behavior

INDICATION STATUS LED ACTIVE LED

On amber: HDD error Blinking blue: HDD access active

Slot empty Off Off

On blue: present

1-12

This page left blank intentionally.

Installing Hardware

Chapter 2

This section provides guidance information to properly service components in the system.

S

AFETY

MEASURES INSTALLING HARDWARE

2.1 Safety Measures

2-1

!

!

!

!

!

!

!

!

!

WARNING!

Always ask for assistance to move or lift the system.

WARNING!

Only perform troubleshooting as authorized by the product documentation, or as directed by

a service and support team. Repairs not authorized by warranty may void the warranty and

damage the system.

WARNING!

Always make sure to disconnect the system from the AC electrical source. Powering down the

system DOES NOT ensure there is no electrical activity in the system.

WARNING!

Server components and circuit boards are easily damaged by discharges of static electricity.

Working on servers that are connected to a power supply can be extremely dangerous. Follow

the guidelines below to avoid personal injury or damage to the server.

WARNING!

Always disconnect the server from the power outlet whenever you are working inside the

server case.

WARNING!

Wear a grounded wrist strap. If none are available, discharge any personal static electricity by

touching the bare metal chassis of the server case, or the bare metal body of any other

grounded device.

WARNING!

Humid environments tend to have less static electricity than dry environments. A grounding

strap is warranted whenever danger of static electricity exists.

WARNING!

Do not touch the components on the unless it is necessary to do so. Do not flex or stress circuit

boards.

WARNING!

Leave all replacement components inside their static-proof packaging until you are ready to

use them.

HARD DISK D

RIVE

2.2 Hard Disk Drive Assembly

The system supports up to twelve 3.5" HDD or twenty-four 2.5" HDD configuration.

Removing the HDD Assembly

1. Press the HDD tray release button to unlock the tray assembly.

2. Pull the HDD tray handle open.

3. Pull the HDD tray assembly out of the system.

ASSEMBLY

Figure 2-1. Removing the HDD tray assembly

2-2

INSTALLING THE HDD ASSEMBLY

Installing the HDD Assembly

1. Insert the HDD tray assembly into the chassis.

2. Push the HDD tray assembly handle to close.

2-3

Figure 2-2. Installing the HDD tray assembly

INSTALLING HARDWARE SOLID-STATE DISK

2.3 Solid-State Disk

The solid-state disk is on rear panel. See

CAUTION!

E

NSURE

!

ALL

WARNING!

!

Repairs should be perfomed by a certified service technician. Damage to the system or components due to unauthorized servicing is not covered by the warranty agreement.

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

Removing the SSD Module

1. Press the SSD tray release button to unlock the tray assembly.

2. Push in the SSD tray release.

System Rear View

on page 1-9.

3. While holding the tray release, pull the SSD tray assembly out of the system.

Figure 2-3. Removing the SSD Component

4. Remove the screws to release the SSD.

2-4

INSTALLING THE SSD MODULE INSTALLING HARDWARE

5. Remove the SSD from the bracket.

Figure 2-4. Removing the SSD module

Installing the SSD Module

1. Align the SSD in the bracket, make sure the connector is facing the rear of the

bracket.

2. Secure the SSD in the bracket with the provided screws.

Figure 2-5. Installing the SSD module

2-5

INSTALLING HARDWARE INSTALLING THE SSD MODULE

3. Align the SSD assembly with the SSD bay.

4. Insert the SSD in the bay and slide in place until it is seated correctly, the tray release

clicks in place.

Figure 2-6. Installing the SSD tray assembly

2-6

POWER SUPPLY UNIT INSTALLING HARDWARE

2.4 Power Supply Unit

Removing a Power Supply Unit

CAUTION!

!

1. Lift the PSU handle up.

DISCONNECT THE POWER SUPPLY UNIT FROM THE POWER SOURCE BEFORE REMOVING PSU. FAILURE TO DO SO

COULD RESULT IN DAMAGE TO THE EQUIPMENT OR PERSONAL INJURY.

Figure 2-7. Opening the PSU Handle.

2. Press the release latch and pull the PSU out of the chassis.

Figure 2-8. Removing PSU

2-7

INSTALLING HARDWARE INSTALLING A POWER SUPPLY UNIT

Installing a Power Supply Unit

1. Align the PSU in the chassis and make sure the release lever is positioned on the

right side.

2. Slide the PSU into the chassis until the release latch is secure and the component is

locked in place.

.

Figure 2-9. Inserting the PSU

3. Push the PSU handle down.

Figure 2-10. Closing the PSU Handle

2-8

TOP COVER INSTALLING HARDWARE

2.5 Top Cover

Removing the Top Cover

The following procedure illustrates the 2.5” and 3.5” systems. Both top covers are outlined

in the section.

CAUTION!

E

NSURE

!

1. Remove screw(s) from the top cover (A).

2. Press the top cover release button (B) and slide the top cover away from the HDDs

(C).

ALL

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

C

B

A

B

Figure 2-11. Removing the Top Cover (2.5” System)

C

B

A

B

2-9

Figure 2-12. Removing the Top Cover (3.5” System)

Note:

Only the 2.5” system is designed with a middle top and top cover.

INSTALLING HARDWARE INSTALLING THE TOP COVER

Installing the Top Cover

1. Place the top cover on the chassis.

2. Slide the cover toward the front of the chassis.

3. Secure the cover to the chassis with the supplied screw(s).

.

A

B

Figure 2-13. Installing the Top Cover (2.5” System)

.

A

B

Figure 2-14. Installing the Top Cover (3.5” System)

2-10

R

EMOVING THE MIDDLE TOP COVER INSTALLING HARDWARE

Removing the Middle Top Cover

The mid-top cover is only available in the 2.5” model. Removal is required for servicing the

several components.

CAUTION!

E

NSURE

!

1. Remove the top cover. See

2. Remove screw(s) from the top cover (A).

3. Slide the mid-top cover toward the rear of the system (B).

4. Remove the mid-top cover.

ALL

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

Removing the Top Cover

on page 2-9.

2-11

A

B

Figure 2-15. Removing the Middle Top Cover

INSTALLING HARDWARE INSTALLING THE MIDDLE TOP COVER

Installing the Middle Top Cover

The mid-top cover is only available in the 2.5” model.

1. Align the mid-top cover on the chassis.

2. Slide the cover toward the front of the chassis.

3. Secure the cover to the chassis with the supplied screw(s).

B

A

Figure 2-16. Installing the Middle Top Cover

2-12

Table 1: Fan Cable Connection

FAN MODULE INSTALLING HARDWARE

MAINBOARD CONNECTOR

FAN MODULE

C

ABLE

COLOR CODE

FAN_SYS0_0

Fan module 0

White cable connector

FAN_SYS0_1

Fan module 0

Blue cable connector

FAN_SYS1_0

Fan module 1

White cable connector

FAN_SYS1_1

Fan module 1

Blue cable connector

FAN_SYS2_0

Fan module 2

White cable connector

FAN_SYS2_1

Fan module 2

Blue cable connector

FAN_SYS3_0

Fan module 3

White cable connector

FAN_SYS3_1

Fan module 3

Blue cable connector

2.6 Fan Module

CAUTION!

E

NSURE

!

ALL

The system fan cage includes four (4) fan modules. The modules can be removed and

installed.

Removing the Fan Module

The fan cabling is color coded for easier servicing. Use the following table to correctly con-

nect the fan cabling to the mainboard.

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

To remove the fan module:

1. Remove the top cover. See

Removing the Top Cover

on page 2-9.

2. Disconnect the fan module cabling from the connectors on the mainboard.

2-13

INSTALLING HARDWARE INSTALLING THE FAN MODULE

3. Remove the cabling from the routing on the fan cage.

Figure 2-17. Disconnecting the fan cables

4. Pull the fan module up to remove from the chassis.

Installing the Fan Module

CAUTION!

!

The fan cabling is color coded for easier servicing. Use the following table to correctly con-

nect the fan cabling to the mainboard.

Table 2: Fan Cable Connection

MAINBOARD CONNECTOR FAN C

FAN_SYS0_0 Fan module 0 White cable connector

FAN_SYS0_1 Fan module 0 Blue cable connector

FAN_SYS1_0 Fan module 1 White cable connector

FAN_SYS1_1 Fan module 1 Blue cable connector

FAN_SYS2_0 Fan module 2 White cable connector

POSITION THE FAN MODULE CORRECTLY, TO AVOID

SEVERE

SYSTEM OVERHEATING.

ABLE

C

ABLE

COLOR CODE

FAN_SYS2_1 Fan module 2 Blue cable connector

FAN_SYS3_0 Fan module 3 White cable connector

FAN_SYS3_1 Fan module 3 Blue cable connector

2-14

INSTALLING THE FAN MODULE INSTALLING HARDWARE

To install the fan module:

1. Align the fan modules with the fan cage. Make sure the positioning arrows are facing the mainboard.

2. Install the fan module in the cage.

3. Route the cabling as shown in the following image.

4. Connect the cabling on the mainboard. See connector location in

page 5-1.

.

FAN_SYS3_1

FAN_SYS3_0

FAN_SYS2_1

FAN_SYS2_0

FAN_SYS1_1

FAN_SYS1_0

FAN_SYS0_1

FAN_SYS0_0

Figure 2-18. Installing the fan assembly

Mainboard

on

5. Install the top cover. See

Installing the Top Cover

on page 2-10.

2-15

INSTALLING HARDWARE SUPERCAP

2.7 SuperCap

CAUTION!

E

NSURE

!

ALL

Replacing the SuperCap Power Module (RAID Backup Unit)

To remove the supercap:

1. Remove the system out of the front rack to disconnect it from the power.

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

2. Remove the top cover. See

Removing the Top Cover

on page 2-9.

3. Disconnect the cabling from the existing SuperCap module.

4. Remove the screws securing the supercap assembly to the air duct.

front of air duct

Figure 2-19. Removing screws

5. Slide the SuperCap free of the clips on the bracket.

cabling

Figure 2-20. Removing a Supercap

2-16

INSTALLING A SUPERCAP INSTALLING HARDWARE

Installing a SuperCap

To install the supercap:

1. Slide the new SuperCap module into the clips on the bracket.

Figure 2-21. Installing a SuperCap

2. Secure the supercap assembly to the air duct with the provided screws.

front of air duct

air flow markings

Figure 2-22. Installing screws

cabling

3. Connec the cabling from the RAID controller to the new SuperCap.

4. Install the top cover. See

Installing the Top Cover

on page 2-10.

5. Replace the system in the rack to connect to power.

2-17

INSTALLING HARDWARE

E

XPANSION CARDS

2.8 Expansion Cards

CAUTION!

E

NSURE

!

ALL

Note:

Locate the expansion assembly and the PCIe slot from rear view and check the PCIe card spec

before installing.

The following guidelines apply to both slot 1 and 2. For instructional purposes the mezza-

nine assembly is removed from the images. It is not necessary to remove the mezzanine

assembly prior to servicing or installing a PCIe card.

Removing a PCIe Card

To remove the PCIe riser card:

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

1. Remove the system from the rail to disconnect from the power.

2. Remove the top cover. See

Removing the Top Cover

on page 2-9.

3. Select the card to service and remove the securing screw.

4. Slide the PCIe card out to remove it from the riser board.

Figure 2-23. Removing screws

5. Place the PCIe card in an anti-static bag.

2-18

INSTALLING A PCIE CARD INSTALLING HARDWARE

Installing a PCIe Card

To install the PCIe riser card:

1. If a dust cover is present remove the securing screw and slide the dust cover off.

2. Align the new PCIe card with the connector on the riser board and the chassis.

3. Insert the PCIe card and gently press it in place to seat properly.

4. Secure the PCIe card with the provided screw.

Figure 2-24. Remove the PCIe card from board

5. Install the top cover. See

Installing the Top Cover

6. Replace the system in the rack to connect to power.

2-19

on page 2-10.

INSTALLING HARDWARE

E

XPANSION ASSEMBLY

2.9 Expansion Assembly

CAUTION!

E

NSURE

!

ALL

The 2U expansion assembly is designed to support either of these configurations:

One PCIe riser card on slot 1 and two PCIe riser cards on slot 2

Slot 4 supports either PCIe or Mezzanine expansion card

Removing the Expansion Assembly

To remove the expansion assembly:

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

1. Remove the top cover. See

Removing the Top Cover

on page 2-9.

2. Remove the screws securing the expansion assembly to the node.

3. Locate the handle based on the illustration below.

4. Pull out the handle upwards.

Figure 2-25. Expansion the Assembly Handle

5. Unsecure the thumb screws.

2-20

INSTALLING THE

E

XPANSION ASSEMBLY INSTALLING HARDWARE

6. Lift the expansion assembly to remove it from the node.

Figure 2-26. Removing the Expansion Assembly

Installing the Expansion Assembly

To instsall the expansion assembly:

1. Grab the expansion assembly using the handle.

2. Align the expansion assembly to slot 1 and 2.

3. Push the assembly firmly into the expansion slot.

4. Ensure that the screw holes / insertion points are aligned.

2-21

INSTALLING HARDWARE INSTALLING THE

5. Secure the thumb screws.

Figure 2-27. Replacing the Expansion Assembly

E

XPANSION ASSEMBLY

6. Replace the screws that were removed.

7. Replace the handle by pushing it downwards.

Figure 2-28. Replacing the Assembly Handle

2-22

PCI

E

R

ISER BOARD INSTALLING HARDWARE

2.10 PCIe Riser Board

CAUTION!

E

NSURE

!

ALL

The system supports only either a PCIe riser board or a mezzanine board on slot 2. If a

mezzanine board is installed in slot 2, remove the mezzanine board first before installing

the PCIe riser board on slot 2. Refer to

on how to remove the mezzanine board.

Removing the PCIe Riser Board

To remove the PCIe riser board:

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

Removing a Mezzanine Board

on page 2-29 for steps

1. Remove the Expansion Riser Assembly. See

Removing the Expansion Assembly

page 2-20.

Figure 2-29. Remove the Expansion Riser Assembly from the Mainboard

on

2. Remove the screws that attach the PCIe riser board to the riser assembly.

2-23

INSTALLING HARDWARE INSTALLING THE PCI

3. Slide the PCIe board downward to detach it from the 2 securing buttons.

Figure 2-30. Remove the PCIe Riser Board from the Riser Assembly

E

R

ISER BOARD

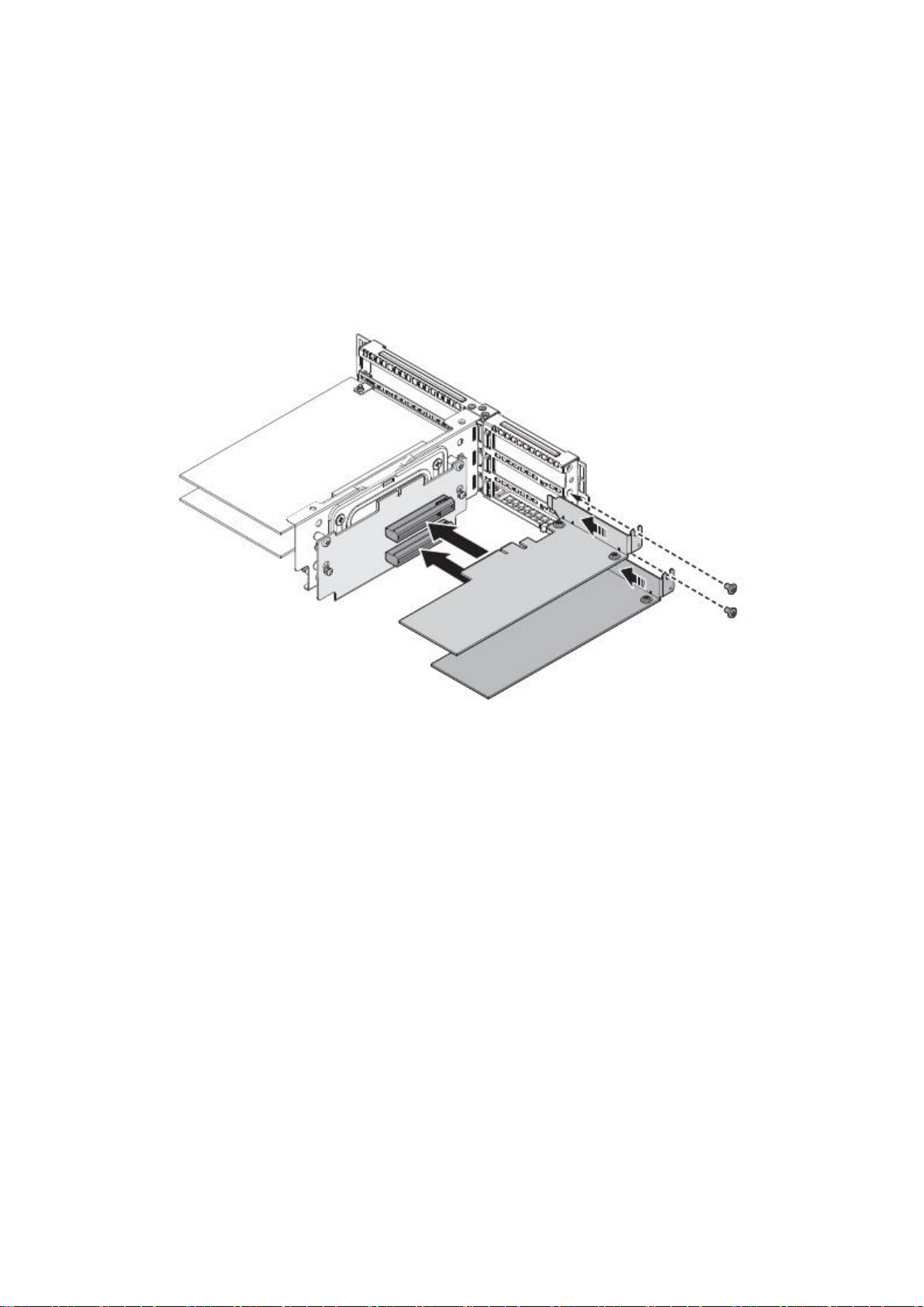

Installing the PCIe Riser Board

To install the PCIe riser board:

1. Place the PCIe riser board onto the riser assembly, aligning the screws of the board

with the screw holes on the riser assembly.

2. Secure the lock buttons by moving the board upward.

Figure 2-31. Install the PCIe Riser Board to the Riser Assembly

2-24

INSTALLING THE PCI

E

R

ISER BOARD INSTALLING HARDWARE

3. Replace the PCIe board unto the main board.

Figure 2-32. Replace the Expansion Riser Assembly

2-25

INSTALLING HARDWARE MEZZANINE

2.11 Mezzanine

CAUTION!

E

NSURE

!

ALL

The system supports the following mezzanine solutions:

10G LAN mezzanine card

1G LAN mezzanine card

SAS2 6Gbps mezzanine card

Removing a Mezzanine Assembly

1. Remove the system from the rail to disconnect from the power.

POWER IS DISCONNECTED FROM THE SYSTEM BEFORE PROCEEDING.

2. Remove the top cover. See

Removing the Top Cover

on page 2-9.

3. Remove the screw securing the mezzanine assembly to the riser bracket.

4. Lift the cover to remove.

Figure 2-33. Removing the Mezzanine Assembly