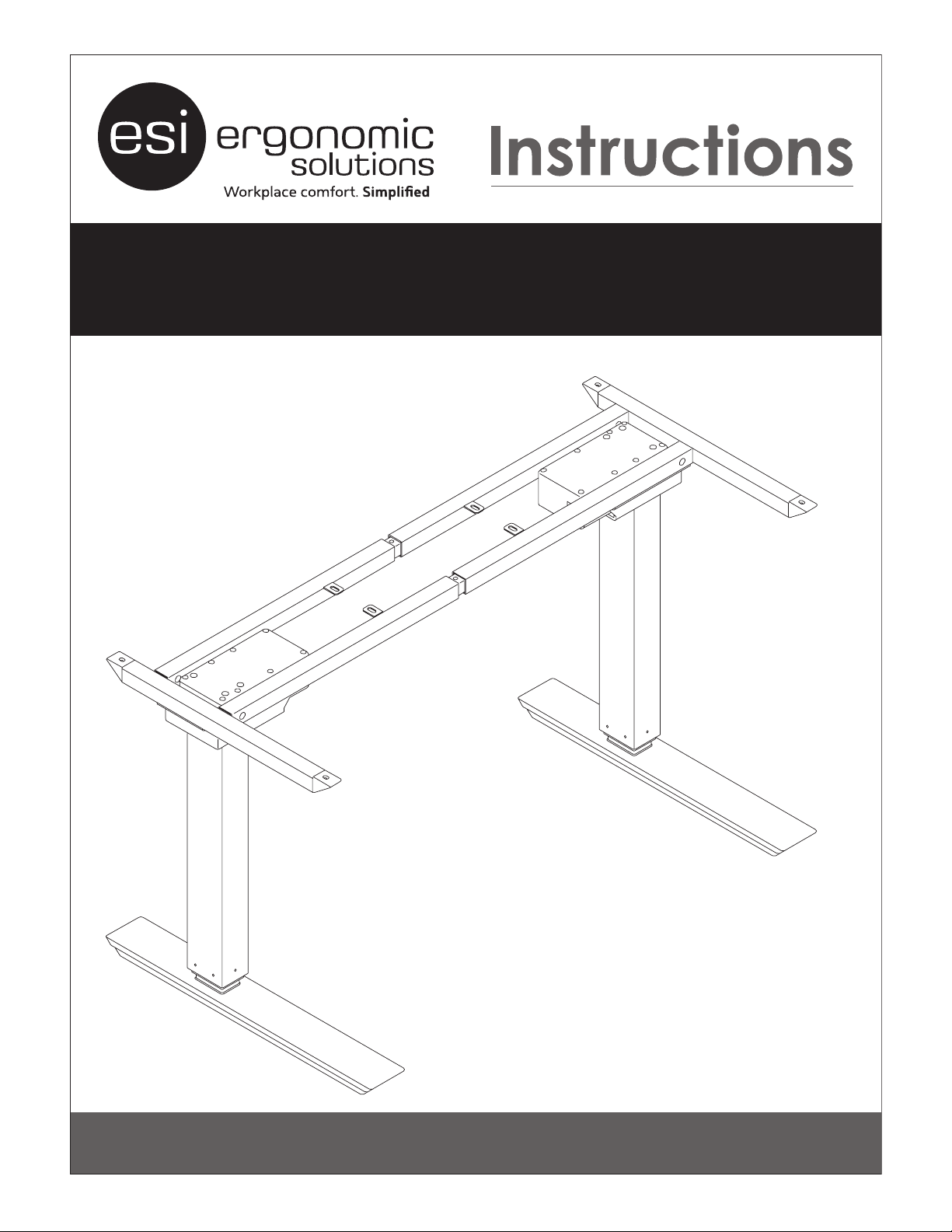

ESi Ergo VICTORY 2VT-C36-30 Series, VICTORY 2VT-C48-24 Series, VICTORY 2VT-C48-30 Series, VICTORY 2VT-C36-24 Series Instructions Manual

ASSEMBLY AND OPERATION

VICTORY

2 LEG ELECTRIC TABLE BASE

Model 2VT-C36-24-___

Model 2VT-C36-30-___

Model 2VT-C48-24-___

Model 2VT-C48-30-___

2VT Rev A 1/17

___ = SLV, BLK or WHT

VICTORY 2 LEG ELECTRIC TABLE BASE PARTS AND TOOLS

PARTS PROVIDED

Work

Surface

PLEASE REVIEW these instructions before beginning the assembly procedures. Check that all the parts shown

below were provided with your order. Contact your supplier if any materials are missing. Do not discard the

packaging until satised that the product operates to your satisfaction.

Cross Channels (2)Legs with Motor (2)

Feet (2)

Digital Keypad (1)Control Unit (1) Power Cable (1)Motor Cables (2)

Top Supports (2)

Foot Plates (2)

Cable Clamps and Ties Fasteners

(6)

(6)(3)

M8x12 (12)

CAUTION: Hand-tighten screws only. Do not use

ADDITIONAL TOOLS REQUIRED

power tools.

• 5mm Allen key

• Phillips screwdriver

CAUTION: Always check that screws

used to attach components to the

work surface are not too long for the

thickness of the surface.

M6x35 (8)

ST 4.8x19 (19) ST 2.9x19 (2)

2

ASSEMBLY VICTORY 2 LEG ELECTRIC TABLE BASE

Rear

Front

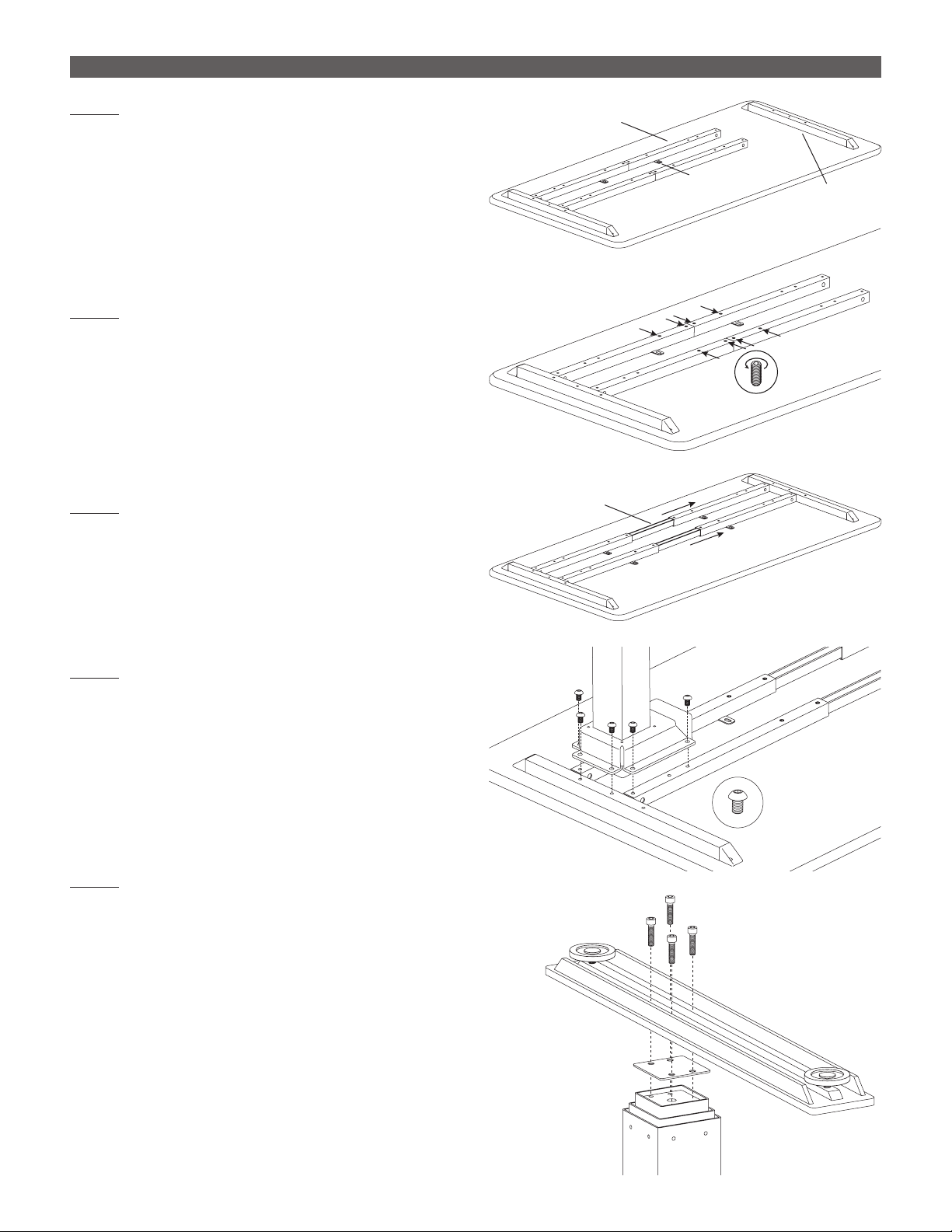

STEP 1

With the table top facing down on a soft, clean

surface, arrange the cross channels and top

supports as shown.

• Positioning does not need to be exact at this time.

• Mounting tabs on the cross channels face inward,

toward each other.

• Holes on the top supports are offset to the rear.

STEP 2

Use an 5mm Allen key to loosen the M10 set screws

on the cross channels (two on each side of center).

STEP 3

Adjust the cross channels to their approximate nal

lengths, as shown.

• Center the inner piece in each cross channel.

Cross Channel

Mounting Tab

Top

Support

Loosen

Set Screws

Center

Inner Piece

STEP 4

Attach the side legs to the cross channels and top

supports with six M8x12 screws per leg.

• Use a 5mm Allen key.

• Two screws attach to each cross channel and

two screws attach to the top supports.

STEP 5

Attach a foot plate and foot to each of the side

legs with the M6x35 screws.

• First, place the foot plate onto the leg with the

smooth side up.

• Position the foot over the foot plate, as shown.

The short side of each foot should face the rear.

• Screw the foot securely in position using a 5mm

Allen key.

M8x12

M6x35

Foot Plate

Side

Legs

3

VICTORY 2 LEG ELECTRIC TABLE BASE ASSEMBLY

Align Rear of Feet with Rear of Table

1"

1"

STEP 6

Adjust the position of the frame before screwing it

to the table.

• The top supports on each side should be

approximately 1" (25mm) from the ends of the

table.

• The rear of the feet should align with the rear

of the table.

STEP 7

Once in their nal position, attach the top supports

and cross channels to the table.

• Use ST4.8x19 screws (8 total required).

• Attach the screws through the mounting tabs on

the cross channels and through the holes at the

ends of the two top supports.

ST4.8x19

Tighten

Set Screws

STEP8

Tighten the M10 set screws in the cross channels

(8 total). Use the 5mm Allen key to hand tighten.

STEP 9

Attach the digital keypad using the two ST2.9x19

screws.

• Position the digital keypad on the left or right side

of the table, according to user preference.

• Align the top of the keypad with the edge of the

table so that the controls will be easily accessible.

STEP 10

Attach the control unit using two ST4.8x19 screws.

• Position the control unit near the back of the

table, on the same side as the digital keypad.

• Be sure the cable from the keypad can reach

the control unit, and the motor cables can

extend from the control unit to both motors.

ST2.9x19

Digital Keypad

Control

Unit

Aligned with

Edge of Table

ST4.8x19

4

ASSEMBLY VICTORY 2 LEG ELECTRIC TABLE BASE

STEP 11

Make connections to the control unit and motors.

• Connect the cable from the digital keypad.

• Connect the motor cables to the control unit and

to each of the motors on the table legs.

Keypad

Cable

• Connect the power cord to the control unit.

• Plug the power cord into an AC outlet.

CAUTION: Do not operate the table until after “zero

Motor

Cables

Power

Cable

setting” the system. See following step.

STEP 12

“Zero set” the system before testing operation.

• Press DOWN t to lower the legs to their lowest

position. (Note that with the table upside-down,

the DOWN arrow faces up).

• Press DOWN t again for about ve seconds.

The legs will move further down slightly to their

absolute lowest position. Release the DOWN t

button.

• Press the UP s and DOWN t buttons to test

operation. End your test with the legs lowered

and unplug the power cord.

• If there are problems with operation, check that

all cable and cord connections are secure. If

problems continue, call ESI Customer Service.

DOWN ▼ Button

STEP 13

Use the cable clamps and ties to secure the cables

in position.

• Cables must not interfere with table operation.

• Cables must not interfere with the user.

STEP 14

With the assistance of a helper, turn the table

upright and place it in its nal position.

IMPORTANT: There must be 1" (25mm) of clearance

on all sides of the work surface (and other moving

parts) to ensure free, unobstructed movement.

• Adjust the leveling glides on the feet to level the

work surface, if necessary.

• Plug the power cord into an AC outlet.

• See the following pages for operating

procedures.

Cable Management

5

VICTORY 2 LEG ELECTRIC TABLE BASE OPERATION

Setting

Memory

Table

DOWN

UP

Button

Buttons

Height

Button

Button

CAUTION: The “zero setting” procedure

must be completed before operating the

table. See Step 12 on page 5.

GENERAL OPERATION

Move the table up or down by pressing UP s or DOWN t until

the work surface reaches the desired height.

The table will continue to move up or down until you release the

button or until the maximum or minimum height is reached.

MINIMUM AND MAXIMUM STOP POSITION

This feature can be used to limit the range of table travel to

prevent the work surface from hitting items below or above it.

• The minimum stop position must be in the lower half of the

movement range, and the maximum stop position must be in

the upper half.

• Minimum and maximum stop positions must be set separately.

Table movement stops when you

release the UP s or DOWN t button.

You can set a minimum stop, a

maximum stop, or both a minimum

and maximum stop.

To set a stop position:

• Move the work surface to the desired minimum or maximum

height.

• Press and hold both the UP s and DOWN t buttons for 10 to 15

seconds. The control unit will click twice when the stop position

has been stored.

To erase a stop position:

• Move the work surface to the stop position to be erased.

• Press and hold both the UP s and DOWN t buttons for 10 to 15

seconds. The control unit will click once when the stop position

has been erased.

SAVING A TABLE POSITION

The three memory buttons can be used to save specic positions

of the work surface. To set a specic position:

• Adjust the work surface to the position you want to save. (The

display on the control pad shows the work surface height.)

• Press the Setting button S. The display will read S––.

• Press the desired Memory button, 1, 2 or 3. Let’s say you

pressed 1. The display will read S1.

Minimum and maximum stops can

serve the same function as memory

stops. For example, minimum stop

could be the user’s standard sitting

position and maximum stop could

be the user’s standard standing

position.

Default stop position for the three

memory buttons is the lowest height

of the work surface.

• The work surface position is now saved. The control unit will

click twice after about two seconds and the display will show

the work surface height.

6

OPERATION VICTORY 2 LEG ELECTRIC TABLE BASE

MOVING THE WORK SURFACE TO A SAVED POSITION

Use this function to move the work surface to one of the saved

positions.

• Press and hold the desired memory button, 1, 2 or 3. The work

surface will move to the saved position and then stop.

• Release the memory button. The work surface will move to

the saved position and then stop. The display shows the work

surface height.

CHANGING THE HEIGHT DISPLAY UNITS

This function allows you to change the display units from

centimeters to inches or the other way around.

• Press and hold memory buttons 1 and 2 and the UP s button.

• Release the three buttons after about ve seconds. The display

will show S and a number — for example, S5.

• Press UP s until the display reads S5.

• Then press the Setting button S. If the display was set to

centimeters, it will now be set to inches; or vice-versa.

RESET THE CONTROL UNIT TO FACTORY SETTINGS

To reset the control unit to factory settings:

• Press and hold memory buttons 1 and 2 and the UP s button.

• Release the three buttons after about ve seconds. The display

will show S and a number — for example, S5.

If you release the memory button

before the saved position is reached,

table movement will stop.

If one or more motors are changed

in a system, the control unit must

be reset to factory settings and

the system must be “zero set” as

described earlier.

• Press UP s until the display reads S0.

• Then press the Setting button S. The control unit is now reset to

factory settings.

CAUTION: After resetting the control unit, the “zero setting”

procedure must once again be completed before operating the

table. See Step 12 on page 5.

7

800.833.3746 esiergo.com

© 2017 ESI Ergonomic Solutions. All rights reserved. 2VT Rev A 1/17

Loading...

Loading...