ESD SYSTEMS 42755 Operation And Maintenance

Portable Ionization Test Kit

Operation and Maintenance

PS-2062 6/05 Page 1 of 4

Tech Brief

Made in America

© 2005 DESCO INDUSTRIES INC.

Employee Owned

Description

Our Portable Ionization Test Kit is a

portable and cost effective means of

verifying the performance of a wide

variety of ionization equipment. The

Test Kit includes a 42721 Digital

Fieldmeter, an Isolated Plate

Assembly, and a Charger. The

Charger is used to place a 1000V

charge on the isolated adapter plate

assembly, making it possible to also

measure the neutralization

performance of air ionization

equipment.

NOTE: Our 42721 Digital

Fieldmeter is designed to operate

with our 42755 Portable Ionization

Test Kit. It is not compatible with

other brands.

Currently there are no established

standards describing a periodic

verification device or procedure for

air ionizers. The ESD Systems.com

Portable Ionization Test Kit has been

designed to make measurements that

correspond to those made by using a

charged plate analyzer and ESD

Association's Standard 3.1. While

the Ionization Test Kit provides

convenience and portability, it does

not meet all of the requirements of

the ESD Association Standard. ESD

Systems.com recommends our

model 42630 Charged Plate

Analyzer if precise measurements

are required.

The Portable Ionization Test Kit

includes a slide-on isolated plate

assembly, a ±1000 volt charging unit

and a durable thermoplastic carrying

case with custom cut-outs for all of

the above components along with

the model 42721 fieldmeter. The

42721 Digital Fieldmeter can be

purchased separately.

Inspection

Remove the kit from the carton and

inspect for damage. Each kit

includes:

1 Digital Fieldmeter (Item 42721)

1 Isolated Plate Assembly

1 ± 1000 Volt Charger

1 9 Volt alkaline battery (installed)

1 Carrying case

Taking Balance

Measurements

The Portable Ionization Test Kit has

been designed to match the compact

size and hand held convenience of

the 42721 Digital Fieldmeter. Use

the following procedure to verify the

balance of air ionization equipment.

This quick and easy procedure will

indicate if the piece of ionization

equipment is working within the

manufacturer's specifications or user

requirements. It is extremely

important that ionizers be checked

regularly for balance. An ionizer

operating in an out-of-balance state

can damage sensitive electronic

components or assemblies.

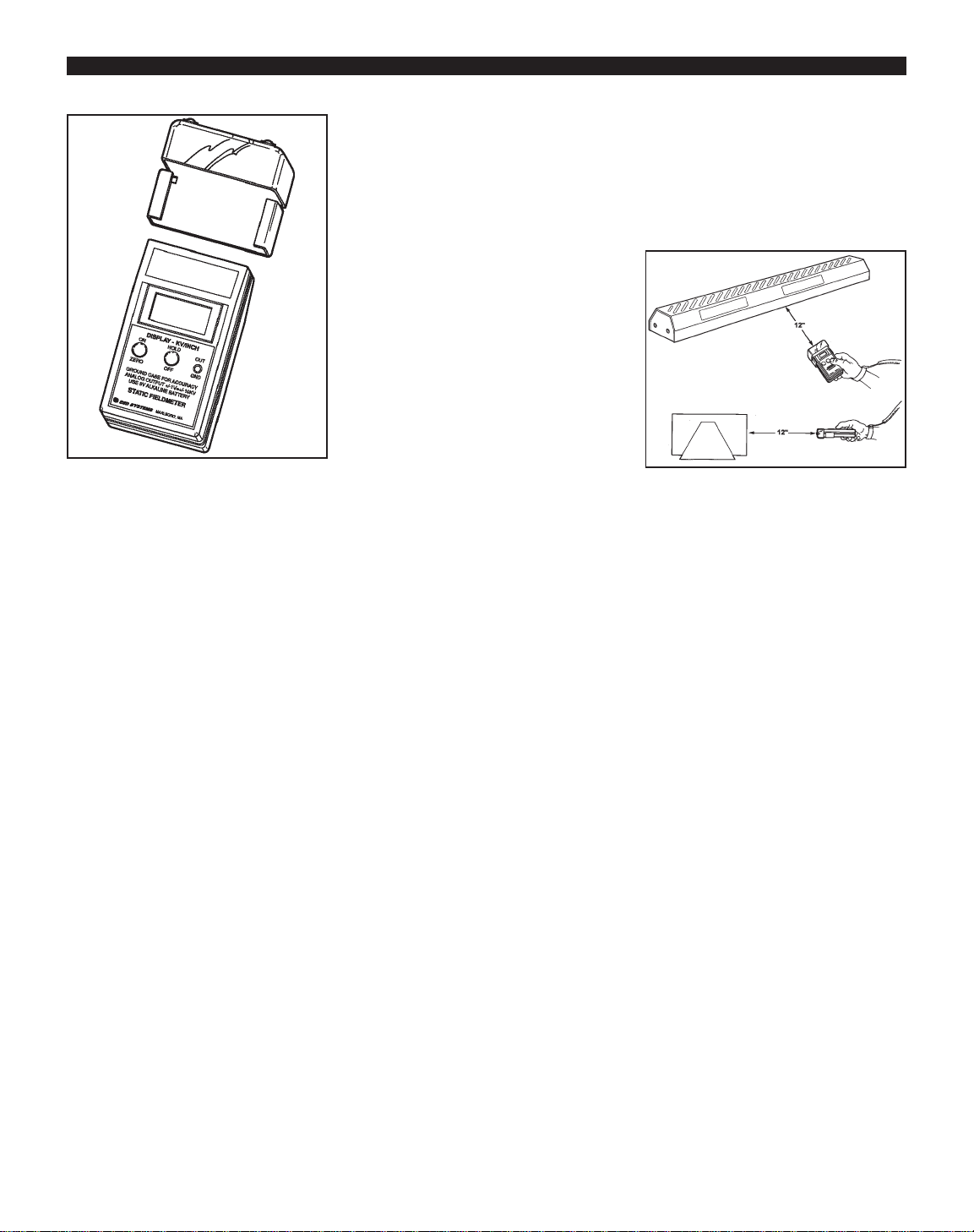

1. INSTALLING THE ISOLATED

PLA TE ASSEMBLY- The case of

the Model 42721 Fieldmeter has two

slots along its slides. The top slot is

closest to the front of the instrument.

Slide the tabs of the Isolated Plate

Assembly into the top slot of the

meter case as far as they go.

Figure 1. 42755 Portable Ionization Test Kit

PS-2062 Page 2 of 4

© 2005 DESCO INDUSTRIES INC.

Employee Owned

2. ZERO THE INSTRUMENT -

Make connection between the

Adapter Plate Assembly and the

Digital Fieldmeter case either

through your finger or a test lead.

Face the Fieldmeter away from

charged objects and press the

ON/ZERO button. Hold until the

display reads zero. The instrument

may also be zeroed by pointing it

toward a known grounded surface

(such as the palm of the opposite

hand) and depressing the ON/ZERO

button. Although you must be

careful not to contact the recessed

sensor plate, the amount of spacing

between the instrument and the

target is not critical when zeroing the

instrument.

NOTE: The 42721 has a conductive

case that provides a ground

reference for the measuring circuit.

For accurate measurements it is

necessary that the person holding

the meter be properly grounded.

3. TAKE A MEASUREMENT -

Locate the meter in an ionized

environment at the appropriate

distance from the device under test

(typically 12"). The static field

displayed is the actual balance of the

ionizer or voltage offset. NOTE:

When testing pulsed ionizer systems,

the voltage displayed is constantly

changing. This pulse rate may be

faster than the display update rate of

the fieldmeter, therefore the

displayed voltage is an average of

the actual voltage. This average

reading is more accurate than

analog style meters which only

display positive or negative values.

AUTO SHUTDOWN TIMER

During normaloperation (not during

ZERO) a blinking decimal point

indicates the AUTO SHUTDOWN

TIMER is enabled. If the AUTO

SHUTDOWN TIMER is disabled

the decimal point will be on

continuously.

Holding down the ZERO button,

while unit is ON, for less than 3

seconds resets the AUTO

SHUTDOWN TIMER (if enabled).

The AUTO SHUTDOWN TIMER is

enabled or disabled by turning on the

unit and keeping the ON/ZERO

button pressed then toggling the

HOLD/OFF button. Enable/disable

of the AUTO SHUTDOWN TIMER

is indicated by the decimal point:

DP on

= timer on, DP off = timer off.

AUTO SHUTDOWN TIMER state

is maintained during power off.

AUTO SHUTDOWN TIMER can be

continually toggled as long as the

ON/ZERO button remains pressed,

up to 20 seconds, after which the

unit will turn off. A blinking decimal

point indicates the AUTO

SHUTDOWN TIMER is active.

During the last minute before power

off ALL annunicators will blink at a

fast rate. Pressing any button will

reset the timer. Timeout is nominally

15 minutes.

Taking Discharge Measurements

In order to verify that an ionizer is

operating properly it is also

important that its ability to neutralize

or discharge static electricity is

measured. The following procedure

will measure an ionizer's discharge

time.

1. OPERATING THE

CHARGING UNIT - The Charger

has a momentary push-button that

turns on the power to the unit.

Holding the button down supplies

power to the output terminals.

2. OUTPUT CONTACTS - Two

output contacts are provided on the

Charger. They are connected to an

internal power source. When one

contact is connected to ground the

other contact will provide a charge

of the indicated polarity. The

Charger is designed so that an

operator can press the power button

and touch an output contact,

simultaneously with the fingers of

the same hand.

Figure 2. Installing the Isolated Plate

Assembly on the 42721 Digital

Fieldmeter

Figure 4. Taking a balance

measurement.

Loading...

Loading...