ESD SYSTEMS 41290, 41292, 41291 Operation And Maintenance

Surface Resistance Test Kit

Operation and Maintenance

Tech Brief

PS-2111 September 2007 Page 1 of 7

Made in America

Description

The Surface Resistance Test Kit is a

portable, accurate, and versatile

instrument designed to measure

resistance between two points (RTT),

surface to ground (RTG), and surface

resistivity in accordance with ESD

Association Standard S4.1 including:

• Resistance measuring accuracy ± 10%

(E11 and greater ±20%)

• Resistance range <1.0 x 10E3 ohms

to >10E12 ohms

• Open circuit voltages of 10 and 100

volts ± 5%

• Electrification period of 15 seconds

• Electrodes (two) 5 pounds ± 2 oz with

50-70 durometer conductive pads

In addition, the Meter measures ambient

temperature and relative humidity.

The Surface Resistance Test Kit (or its

Meter) is referenced and designed to be

used to make measurements in

accordance with the test methods in:

• Worksurfaces - ANSI/ESD S4.1

Worksurfaces Compliance

Verification - ESD TR53 - Resistance

Measurements

• Floors - ANSI/ESD S7.1- Resistive

Characterization of Materials Floor

Materials

• Footwear - ESD S9.1 - Footwear Resistive Characterization

• Garments - ESD STM2.1 Garments

• Seating - ESD STM12.1- Seating Resistive Measurement

• Floor/Footwear - ESD STM97.1 Floor Materials and FootwearResistance Measurement in

Combination with a Person

• Workstations - ESD-ADV53.1 - ESD

Protective Workstations

Versatility:

Measures RTT, RTG or Resistivity

(requires optional Resistivity

Attachment, item 41292)

• Quick Checks - Surface resistance

exponent number illuminates

immediately i.e. 8 = 10E8 ohms or

100,000,000 ohms

• Periodic Checks of Installed

Products - Surface resistance

exponent number illuminates

immediately and displays

Temperature and Relative Humidity

during 15 second electrification

period making numerous measurements and calculations to then display

mantissa i.e. if LED displays 8 and

LCD displaying 7.14 as mantissa =

7.14 x 10E8 ohms or 714,000,000

ohms

• Test Lab Evaluation of Product -

Display same as Periodic Check

above

The Surface Resistance Test Kit is NIST

calibrated and items available are:

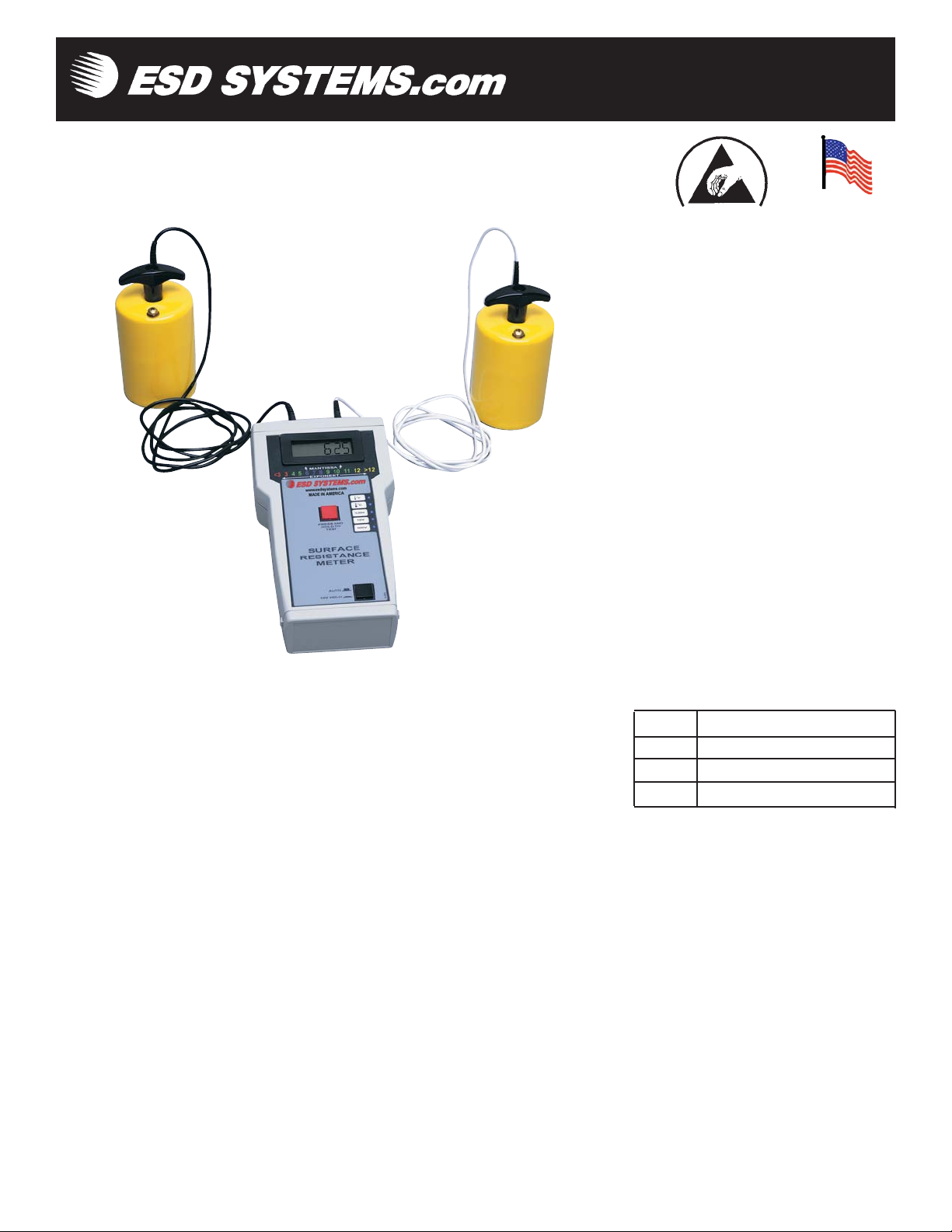

Inspection

Remove the meter from the carton and

inspect for damage. Each Surface

Resistance Test Kit should include the

following:

1 Protective carrying case

1 Meter

2 Test leads

2 5-pound electrodes

2 AA alkaline batteries

Properly store the Meter and component

assemblies when not in use.

Figure 1. Item 41290 Surface Resistance Test Kit

© 2007 DESCO INDUSTRIES INC.

Employee Owned

Model Description

41290 Surface Resistance Test Kit

41291 Meter & Attachment

41292 Resistivity Attachment

PS-2111 Page 2 of 7

ESD protective products

should be tested:

A. Prior to installation to qualify for

listing in user's ESD control plan

approved ESD protective materials

B. During initial installation

C. For periodic checks of installed

products as part of ESD control plan

compliance verification plan

“A Compliance Verification Plan shall

be established to ensure the

Organization’s fulfillment of the

technical requirements of the ESD

Control Program Plan. Process

monitoring (measurements) shall be

conducted in accordance with a

Compliance Verification Plan that

identifies the technical requirements to

be verified, the measurement limits and

the frequency at which those

verifications shall occur. The

Compliance Verification Plan shall

document the test methods and

equipment used for process monitoring

and measurements. If the test methods

used by the Organization differ from

any of the standards referenced in this

document, then there must be a tailoring

statement that is documented as part of

the ESD Control Program Plan.

Compliance verification records shall be

established and maintained to provide

evidence of conformity to the technical

requirements.

The test equipment selected shall be

capable of making the measurements

defined in the Compliance Verification

Plan.” (ANSI/ESD S20.20-2007 section

7.3)

Electrification Period

The Surface Resistance Test Kit

provides the proper electrification

period of 15 seconds per ESD S4.1,

after numerous readings and

calculations are executed, then displays

surface resistance mantissa

measurement (Note: most analog type

meters display measurements

instantaneously).

When the Test Button is depressed, the

liquid crystal display (LCD) will

indicate:

• Temperature in degrees Fahrenheit

(tolerance ±5°F, typical)

• Temperature in degrees Celsius

(tolerance ±3°C, typical)

• Humidity as percentage (from 5% 95% tolerance, ±10 typical)

• Surface resistance mantissa (with

exponent displayed via LED,

measurement in ohms)

Measurement being displayed is

identified by the illuminated function

LED. The surface resistance exponent

(or power of number) is immediately

illuminated and remains illuminated

measuring the range the surface

resistance in ohms.

Reference Literature

In addition to those noted above:

ANSI/ESD S20.20 - Development of

ESD Control Program

ESD ADV1.0 - Glossary of Terms

ANSI/ESD S6.1 Grounding

These documents can be obtained

directly from the ESD Association, 7902

Turin Rd., Suite 4, Rome, NY 134402069, (315) 339-6937 or www.esda.org.

Other standards are available from the

agencies who produce them. MILHDBK 263A, EIA-IS-5-A,

ASTM-F-150, EN 100015, and EIA-

625. If you need help in obtaining these

documents, please contact our customer

service department.

Features

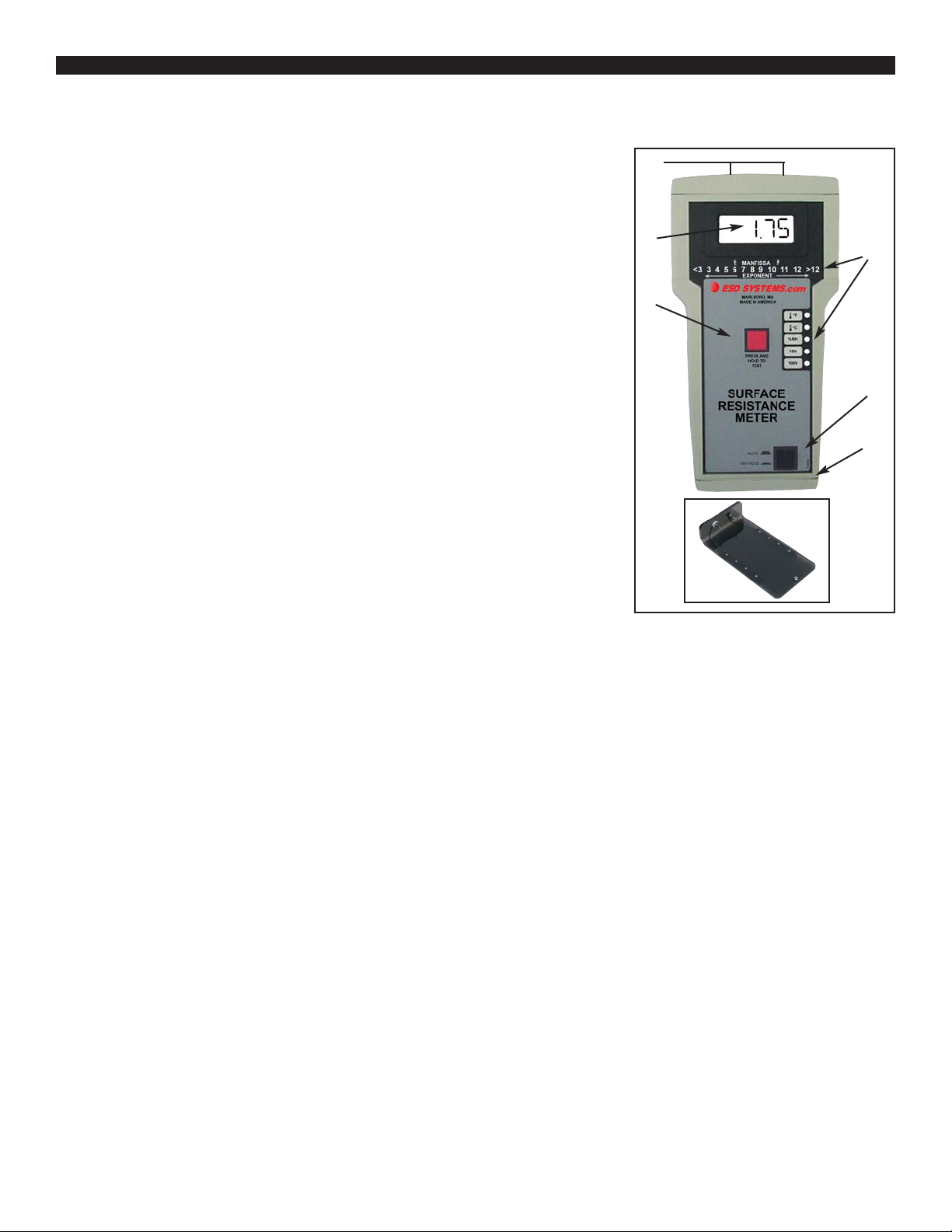

A. LED Displays: Surface resistance

exponent is displayed via light emitting

diodes illuminating 1/8" high number.

There are 12 LEDs displaying surface

resistance exponent measurement. They

are color coded for quick checks:

Exponent Color

<3, 3 Red

4, 5 Green

6, 7, 8 Blue

9, 10, 11 Green

12, >12 Yellow

Five Function LED’s identify the

measurement being displayed (see B

below).

• When battery voltage drops to

approximately 2 volts, one of the

Function LED's to the right of the red

pushbutton switch will begin to flash,

indicating the need to replace

batteries.

A

B

C

D

E

F

G

© 2007 DESCO INDUSTRIES INC.

Employee Owned

B. Liquid Crystal Display (LCD):

Mantissa is displayed via 9/16" high

liquid crystal display and provides easy

to read resistance (or resistivity)

measurements.

When the Test Button is depressed, the

LCD will indicate:

• Temperature in degrees Fahrenheit

• Temperature in degrees Celsius

• Humidity as percentage

• Surface resistance mantissa (with

exponent displayed via LED,

measurement in ohms)

Surface resistance ohm values are

expressed with a mantissa and exponent

or power of the number. For example, if

"8" is illuminated by its LED and the

LCD displays a mantissa of "7.14", the

measurement is 7.14 x 10E8 ohms or

714,000,000 ohms

If surface is over 10E13 ohms, the

following will appear:

• "1____" on the LCD display indicate

Overrange or that the reading exceeds

the display capabilities

Figure 2. Features of the Surface

Resistance Meter

PS-2111 Page 3 of 7

C. Test Button: This red button

activates electrical power to the Meter.

The exponent or power of the number is

displayed immediately with LED

illuminating number. If "8" is

illuminated, the measurement is in the

10

8

or 10E8 ohm range. To make a

measurement in accordance with ESD

S4.1, the button is to be depressed for

10-20 seconds for the unit to make

numerous readings and calculations.

(Testing in accordance with ESD S4.11997 requires 15 seconds of

electrification; in contrast, most analog

type meters display measurements

instantaneously.) The LCD will display

temperature (F), then temperature (C),

then relative humidity, and then the

surface resistance mantissa. For

example, if the LCD displays a mantissa

of "7.14", and "8" is illuminates by its

LED, the measurement is 7.14 x 10E8

ohms or 714,000,000 ohms.

During the entire period, surface

resistance exponent will be displayed by

LED illuminating number.

D. Override Test Range Voltage

Button: When in the “up” position,

during resistance portion of test, Meter

will automatically switch to the correct

voltage for the resistance range. LED

will illuminate noting selected voltage.

Conductive material 10E5 ohms or less

should be measured at 10 volts.

Dissipative material 10E6 or greater

ohms should be tested at 100 volts. The

button is a switch, which if depressed

will override automatic voltage

selection and test will be performed at

10 volts regardless of resistance level.

E. Jacks: One end of Test Leads has

3.5mm plug (fits Meter left jack). The

3.5mm plug is shielded (identified by

insulated tip and barrel black lead) - see

RTG test procedure: Per ESD S4.1 "The

sensing lead of the resistance meter

shall be connected to groundable point."

One end of Test Lead has standard

banana plug (fits 5# Electrode jack).

F. AA Battery Compartment.

G. Resistivity Parallel Attachment

with Electrodes. (optional Item number

41292)

Cleaning

Per ANSI/ESD S4.1 "Clean the

electrodes with a minimum 70%

isopropanol-water solution." Make sure

conductive pads are dry prior to use.

See specific product test standard for

test lab specimen cleaning instructions.

Per ANSI/ESD S4.1 Worksurfaces "The

test specimens and electrodes shall be

cleaned twice with a minimum 70%

isopropanol-water solution using a

clean, low-linting cloth each time."

(Note: then conditioned for 72 hours,

minimum.)

For installed product periodic testing, do

not clean surfaces. However, if any

measurements lie outside acceptable

range, then clean the surface and re-test.

(Note: for worksurfaces, use ESD

Systems.com Reztore™ Antistatic

Surface and Mat Cleaner (item 10630)

or other ESD cleaner not containing

silicone. Be sure the surface is dry

before testing.

Periodic maintenance - The area

surrounding the cable jacks at the top

end of the meter should be wiped with a

clean cloth moistened with alcohol to

remove skin oils that will accumulate

and affect the accuracy at high

resistances. The frequency of cleaning

will depend on usage; once a month

would be a good starting point. Other

items that should also be cleaned in this

fashion are the cable jackets and the

resistivity attachment, if included.

Power Requirements

The Meter is powered by two

replaceable alkaline AAbatteries.

Battery Replacement

Depress buttons on both sides of bottom

end cap of meter housing. Remove cap,

press on right edge of protruding battery

door, unlatching it, and swing door

open. Carefully replace batteries with

alkaline Type AA. Polarity must be

correct or damage may occur. Close

battery door and re-install bottom end

cap on meter housing.

Test Procedure

General Guidelines:

• Use both 5# Electrodes for RTT

• Use one 5# Electrode and one lead to

groundable point for RTG (note:

groundable points are usually snaps

installed on the material or

workstation)

• Use optional Resistivity Attachment

(removing leads & electrodes) for

Resistivity measurements

• Ensure that item being measured is

electrically isolated (i.e. placed on an

insulative surface) as Meter will

measure lowest resistance path

• Ensure that test leads are separated or

Meter may measure lower resistance

path

• When using 5# Electrodes:

• Place no closer than 2" from edge

of surface being measured

• Place no closer than 3" to any

groundable point

• Place 5# Electrodes 10" apart for

RTT

• Preferred placements include: most

commonly used surface portion,

most worn, center, and furthest

from groundable point.

• For RTG, connect the sensing lead

with shielded plug to groundable

point

• If surface has sections (like floor tiles

or garment panels), for RTT place a 5

pound electrodes on different sections

• Clean surface for Test Lab, but do not

initially clean surface for installed

products (if fails, clean and retest).

Test Lab Test Procedure

Guideline

For test lab use of ESD Worksurfaces,

Floor Materials, Footwear, Garments, or

Seating, best advice is to follow

procedures in applicable ESD

Association standards (see above) which

include details regarding:

• Cleaning (For example per S4.1 "The

test specimens and electrodes shall be

cleaned twice with a minimum 70%

isopropanol-water solution using a

clean, low-linting cloth each time).

Allow to dry.

• Environmental chamber (For example

per S4.1 control relative humidity to

© 2007 DESCO INDUSTRIES INC.

Employee Owned

Loading...

Loading...