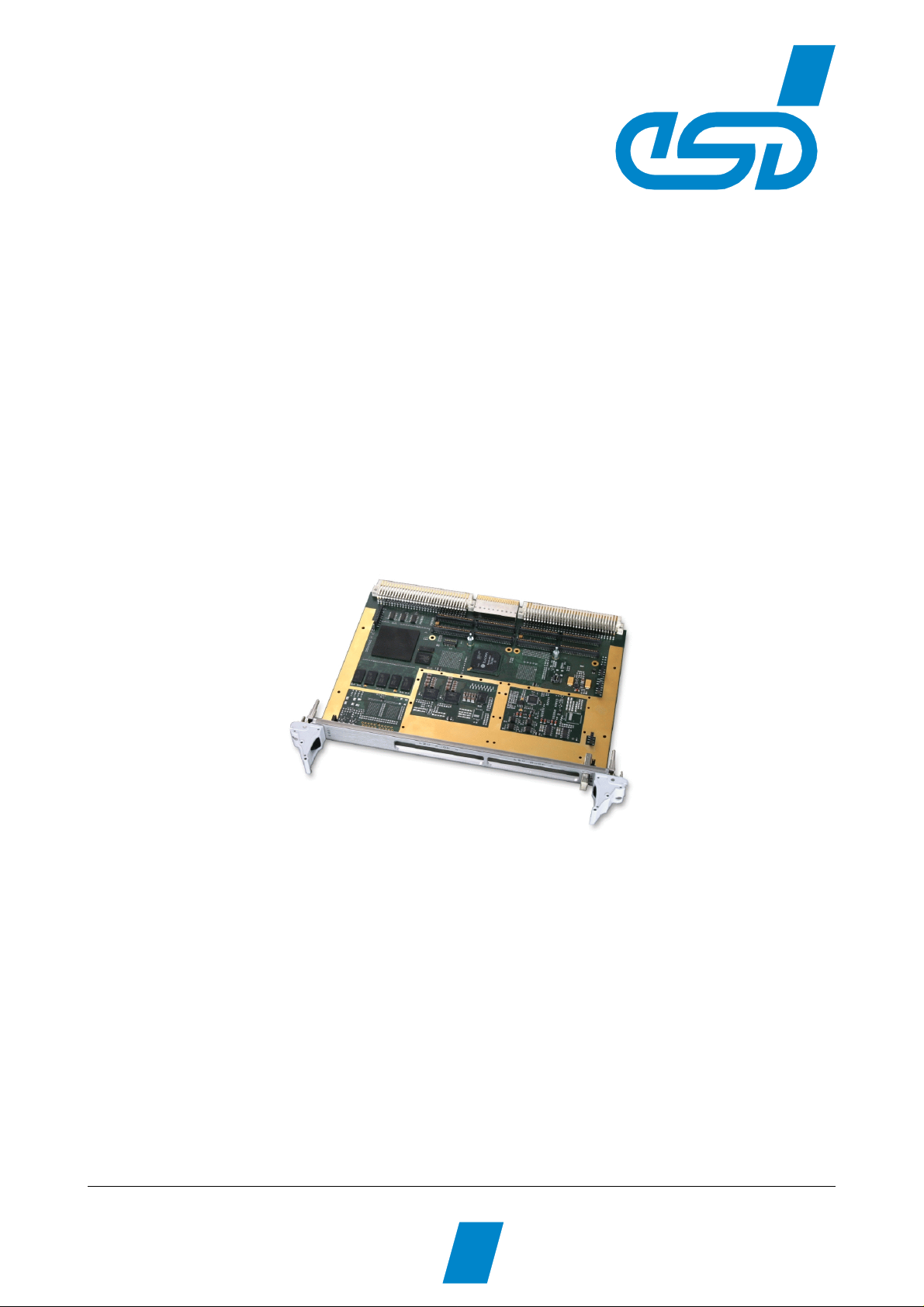

ESD VME-PMC-CADDY/2 Hardware Manual

VME-PMC-CADDY/2

VME-Carrier Board

for PMC Modules

Hardware Manual

to Product:

V.1915.xx ,

V.1916.xx

VME-PMC-CADDY/2

esd electronic system design gmbh

Vahrenwalder Str. 207 • 30165 Hannover • Germany

http://www.esd.eu

Phone: +49 (0) 511 3 72 98-0 • Fax: +49 (0) 511 3 72 98-68

Hardware-Manual • Doc.-No.: V.1915.21 / Rev. 1.0

Page 1 of 43

N O T E

The information in this document has been carefully checked and is believed to be entirely reliable. esd

makes no warranty of any kind with regard to the material in this document, and assumes no

responsibility for any errors that may appear in this document. esd reserves the right to make changes

without notice to this, or any of its products, to improve reliability, performance or design.

esd assumes no responsibility for the use of any circuitry other than circuitry which is part of a product

of esd gmbh.

esd does not convey to the purchaser of the product described herein any license under the patent rights

of esd gmbh nor the rights of others.

esd electronic system design gmbh

Vahrenwalder Str. 207

30165 Hannover

Germany

Phone: +49-511-372 98-0

Fax: +49-511-372 98-68

E-mail: info@esd.eu

Internet: www.esd.eu

USA / Canada:

esd electronics Inc.

525 Bernardston Road

Suite 1

Greenfield, MA 01301

USA

Phone: +1-800-732-8006

Fax: +1-800-732-8093

E-mail: us-sales@esd-electronics.com

Internet: www.esd-electronics.us

Trademark Notices

CiA® and CANopen® are registered community trademarks of CAN in Automation e.V.

All other trademarks, product names, company names or company logos used in this manual are reserved by their respective

owners.

Page 2 of 43

Hardware Manual • Doc. No.: V.1915.21 / Rev. 1.0

VME-PMC-CADDY/2

DocumentFile:

I:\Texte\Doku\MANUALS\VME\PMC-CADDY2\Englisch\VME-PMC-CADDY2_Manual_en_10.wpd

Date of print:

PCB version:

2012-02-01

VME-PMC-CADDY/2 Rev. 2.1

Changes in the chapters

The changes in the document listed below affect changes in the hardware and firmware as well as

changes in the description of facts only.

Chapter Changes versus previous version

1.0 First English version

Technical details are subject to change without further notice.

VME-PMC-CADDY/2

Hardware-Manual • Doc.-No.: V.1915.21 / Rev. 1.0

Page 3 of 43

Safety Instructions

!

When working with VME-PMC-CADDY/2 modules follow the instructions below and read the

manual carefully to protect yourself and the VME-PMC-CADDY/2 module from damage.

!

Protect the VME-PMC-CADDY/2 module from dust, moisture and steam.

!

Protect the VME-PMC-CADDY/2 module from shocks and vibrations.

!

The VME-PMC-CADDY/2 module may become warm during normal use. Always allow adequate

ventilation around the VME-PMC-CADDY/2 module and use care when handling.

!

Do not operate the VME-PMC-CADDY/2 module adjacent to heat sources and do not expose it to

unnecessary thermal radiation. Ensure an ambient temperature as specified in the technical data.

!

Do not use damaged or defective cables to connect the VME-PMC-CADDY/2 module.

Qualified Personal

This documentation is directed exclusively towards qualified personal in control and automation engineering.

The installation and commissioning of the product may only be carried out by qualified personal, which is

authorized to put devices, systems and electric circuits into operation according to the applicable national

standards of safety engineering.

Intended Use

The intended use of the VME-PMC-CADDY/2 module is the operation as a carrier board in a VME-system.

The esd guarantee does not cover damages which result from improper use, usage not in accordance with

regulations or disregard of safety instructions and warnings.

!

The VME-PMC-CADDY/2 module is intended for installation in a VME-system only.

!

The operation of the VME-PMC-CADDY/2 module in hazardous areas, or areas exposed to

potentially explosive materials is not permitted.

!

The operation of the VME-PMC-CADDY/2 module for medical purposes is prohibited.

Service Note

The VME-PMC-CADDY/2 module does not contain any parts that require maintenance by the user. The VMEPMC-CADDY/2 module does not require any manual configuration of the hardware. Unauthorized intervention

in the device voids warranty claims. Remove all cables before cleaning. Clean the device with a slightly moist,

lint-free cloth. Cleaning agents or solvents are not suitable.

Disposal

Devices which have become defective in the long run have to be disposed in an appropriate way or have to be

returned to the manufacturer for proper disposal. Please, make a contribution to environmental protection.

Page 4 of 43

Hardware Manual • Doc. No.: V.1915.21 / Rev. 1.0

VME-PMC-CADDY/2

Contents

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Block Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Characteristics of the Available Hardware Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.1 Option “-32P2”: Changed I/O-Pin Routing on P2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.2 Option “-T”: Extended Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.3 Option: “-CC”: Conduction Cooled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.1 General Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.2 Serial Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.3 PMC-Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4.4 XMC Slot (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.5 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2. Front Panel and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

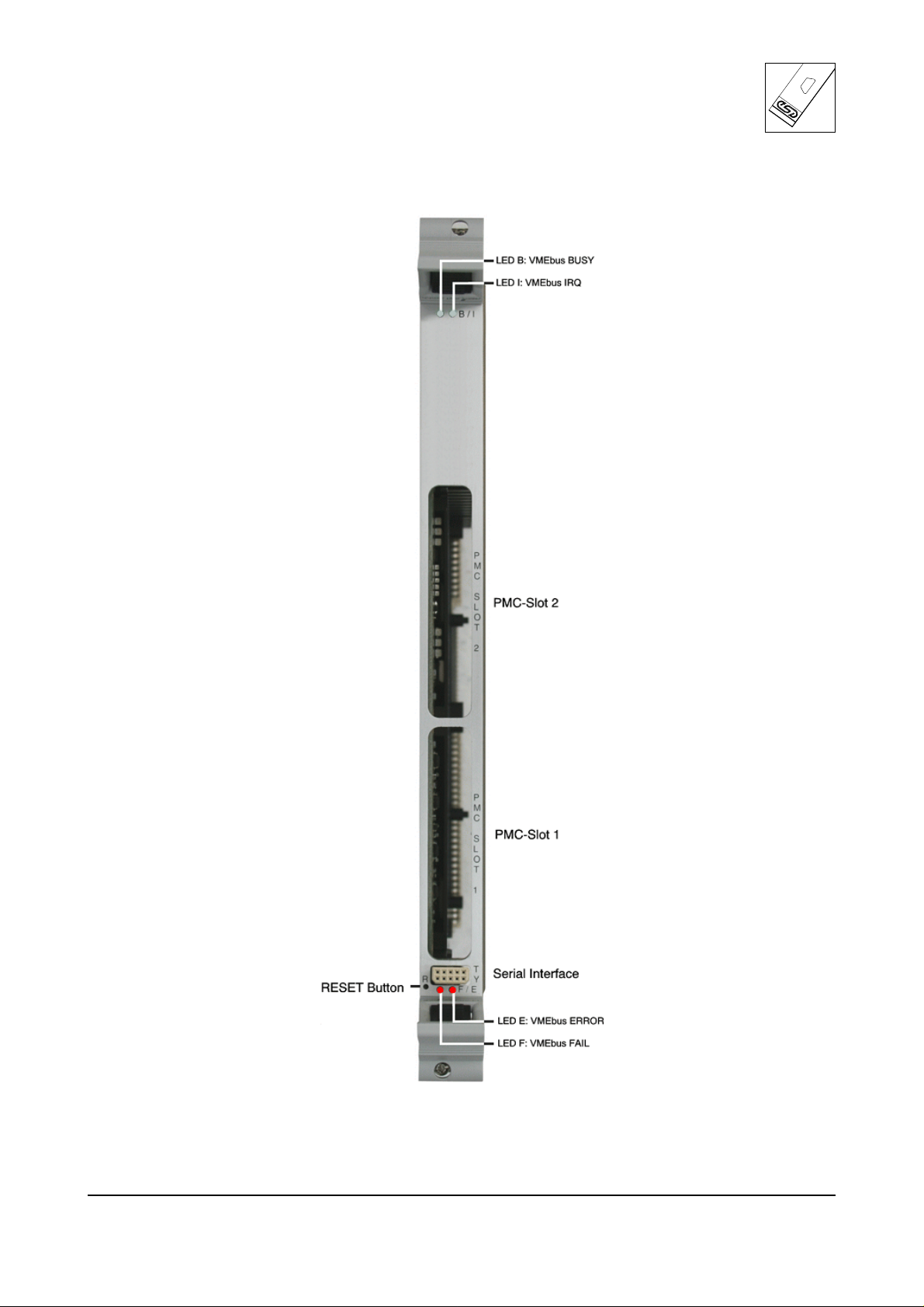

2.1 LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. PCB View with Coding Switches and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Default Setting of the Coding Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 VMEbus Configuration (SW600) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.2 VMEbus System Controller Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.3 VMEbus Power-Up-Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 PMC Slot Configuration (SW800) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Address Assignment of VME-PMC-CADDY/2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5. Connector Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Serial Interfaces RS232 (X1940) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Adapter Cable “VME-PMC-CPU/Cable” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Adapter Cable “VME-PMC-CPU/Cable-Y” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 VMEbus P1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5 Standard Assignment of I/O-Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.1 Standard Assignment VMEbus P2 (According to VITA 35, P4 V2-64ac) . . . . . . . . . 27

5.5.2 Standard Assignment of Transfer Module with P2 Row a and c Signals . . . . . . . . . . 28

5.5.3 Standard Assignment VMEbus P0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5.4 Standard Assignment of the I/O Connector J14 at PMC Slot 1 . . . . . . . . . . . . . . . . . 30

5.5.5 Standard Assignment of the I/O Connector J24 at PMC Slot 2 . . . . . . . . . . . . . . . . . 31

5.6 Assignment of the I/O-Signals using the‘-32P2’ Option . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.6.1 Assignment VMEbus P2 using ‘-32P2’ Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.6.2 Assignment of a Transfer Module at ‘-32P2’ Option . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.6.3 Assignment VMEbus P0 at ‘-32P2’ Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.6.4 Assignment of the PMC Connector J14 at ‘-32P2’ Option . . . . . . . . . . . . . . . . . . . . . 35

5.6.5 Assignment of the PMC Connector J24 at ‘-32P2’ Option . . . . . . . . . . . . . . . . . . . . . 36

5.7 Special Assembly: J24-I/O-Signals to d+z of P2 (acc. VITA 35, P4 V2-46dz) . . . . . . . . . . 37

5.7.1 Assignment of P2 at Special Assembly with RC800, RC801, ...RC811 . . . . . . . . . . . 37

5.7.2 Assignment I/O Connector J24 at Assembly with RC800, RC801, ...RC811 . . . . . . . 38

5.8 XMC Socket J15 (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6. References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7. Order Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

VME-PMC-CADDY/2

Hardware-Manual • Doc.-No.: V.1915.21 / Rev. 1.0

Page 5 of 43

Overview

1. Overview

1.1 Block Circuit Diagram

XMC-

Option

2eSST

s

u

b

E

M

V

1

P

s

u

b

E

M

V

2

P

VME

Address

Driver

VME

Control Logic

VME

Data

Driver

VME

Address

Driver

VME

Control Logic

VME

Data

Driver

VME PCI

Bridge

Tundra

Tsi148

64 bit at 66 MHz PCI bus

Flash

DDR2

PEX

PCI

Freescale

MPC 8349

PMC Add On

Connectors

J11 J12

J13

J21 J22

J23

2x Serial

Interface

RS-232

PMC Module

J15

Slot 1

XMC

J14

PMC Module

Slot 2

J24

Only at VME-PMC-CADDY/2 versions (order no. V.1915.xx)

P2 I/O Signals to

PMC Module 1 / J14

(Standard Routing:

P4V2-64ac acc. to

ANSI/VITA 35)

O

/

I

2

P

P0 I/O Signals to

PMC Module 2 / J24

(Standard Routing:

P4V0-64 acc. to

O

ANSI/VITA 35)

/

I

0

P

2x RS-232 Interface

HARLINK10

Figure 1: Block circuit diagram of VME-PMC-CADDY/2

1.2 General

The VMEbus unit VME-PMC-CADDY/2 is a VME64-base board which can carry up to two PMC

modules of normal size. For the VMEbus connection the VME-PCI bridge Tsi148 by Tundra is used.

The Tsi148 is designed in a way that the board can either operate as slave or as master on the VMEbus.

If the board operates as master, it supports a 4-level arbiter.

The VMEbus interrupt can be applied to any of the seven interrupt-request lines. The VME-PMCCADDY/2 is connected to the VMEbus by two 160-pin VG-connectors (complementary to DIN41612)

for VME64 systems.

An active VMEbus-interrupt request is indicated by a red LED and a VMEbus access onto the board

is indicated by a yellow LEDs in the front panel (not in Conduction Cooled version)

Both PMC slots are designed according to the standard IEEE Std 1386-2001 (except the standard I/O

pin routing). It is possible therefore to insert all PMC modules, that use 3.3 V signalling only.

In addition to the connectors for the PMC-address/data and control signals, every slot of the

VME-PMC-CADDY/2 has an I/O-connector which applies the I/O-signals of the PMC modules to

VMEbus connector P2.

Two different P2 pin assignments are available: In the standard configuration each P2-pin is only

connected to one I/O-pin of the PMC-modules acc. to VITA 35 (P4V2-64ac, P4V0-64).

In the option ‘-32P' the pin assignment is designed acc. to IEEE Std 1386-2001, Table 8. This pin

Page 6 of 43

Hardware Manual • Doc. No.: V.1915.21 / Rev. 1.0

VME-PMC-CADDY/2

Overview

assignment offers the connection of the two PMC-modules via P2, because several PMC-I/O-signals

are shorted at P2.

The front panel of the VME-PMC-CADDY/2 has two cutouts for the front panels of the PMC modules.

A blank cover for unused slots is included in the price.

Example libraries for the initialization of the board in C source code for VxWorks is available for a fee

on a disk (MS-DOS format). Drivers for other operating systems are available on request. Please state

your operating system with the version number when you order.

1.3 Characteristics of the Available Hardware Options

Note: All options given below have to be specified when ordering. They can not be installed later. For

an overview of the possible combinations of the options see page 42.

1.3.1 Option “-32P2”: Changed I/O-Pin Routing on P2

The VME-PMC-CADDY/2 is currently available with two different I/O-pin assignments:

- In the Standard configuration each of the I/O-pins of the PMC slot 1 (J14) is connected to exactly

one pin of the VMEbus connector P2 (according to VITA 35 (P4V2-64ac)) and each of the I/O-pins

of the PMC slot 2 (J24) is connected with exactly one I/O-pin of the VMEbus connector P0

(according to VITA 35 (P4V0-64)) .

- In the VME-PMC-CADDY/2 with the option “-32P”the pins are assigned according to IEEE

Std.1386-2001, Table 8. In this option the I/O-signals of both PMC-slots are connected with the pin

rows a+c of the VME-connector P2:

The pins 33...64 of the PMC-connector J24 are connected in parallel to this also to the rows

a and c of the P2 connector. This leads to a double assignment of the pins a1..a16 and c1...c16

on P2. Furthermore by this both PMC slots are connected with each other via 32 of their I/Opins.

Advantage: Access via a Standard-VMEbus-P2-I/O-adapter to each the half of the I/O-signals

of both PMC slots.

Disadvantage: You have to pay attention that your choice of inserted PMC modules does not

lead to undesired interactions between the modules, due to the I/O-signal

connection between the slots!

VME-PMC-CADDY/2

Hardware-Manual • Doc.-No.: V.1915.21 / Rev. 1.0

Page 7 of 43

Overview

1.3.2 Option “-T”: Extended Temperature Range

The VME-PMC-CADDY/2 with this option is designed for the operation in the extended temperature

range of -40 /C ...+85 /C.

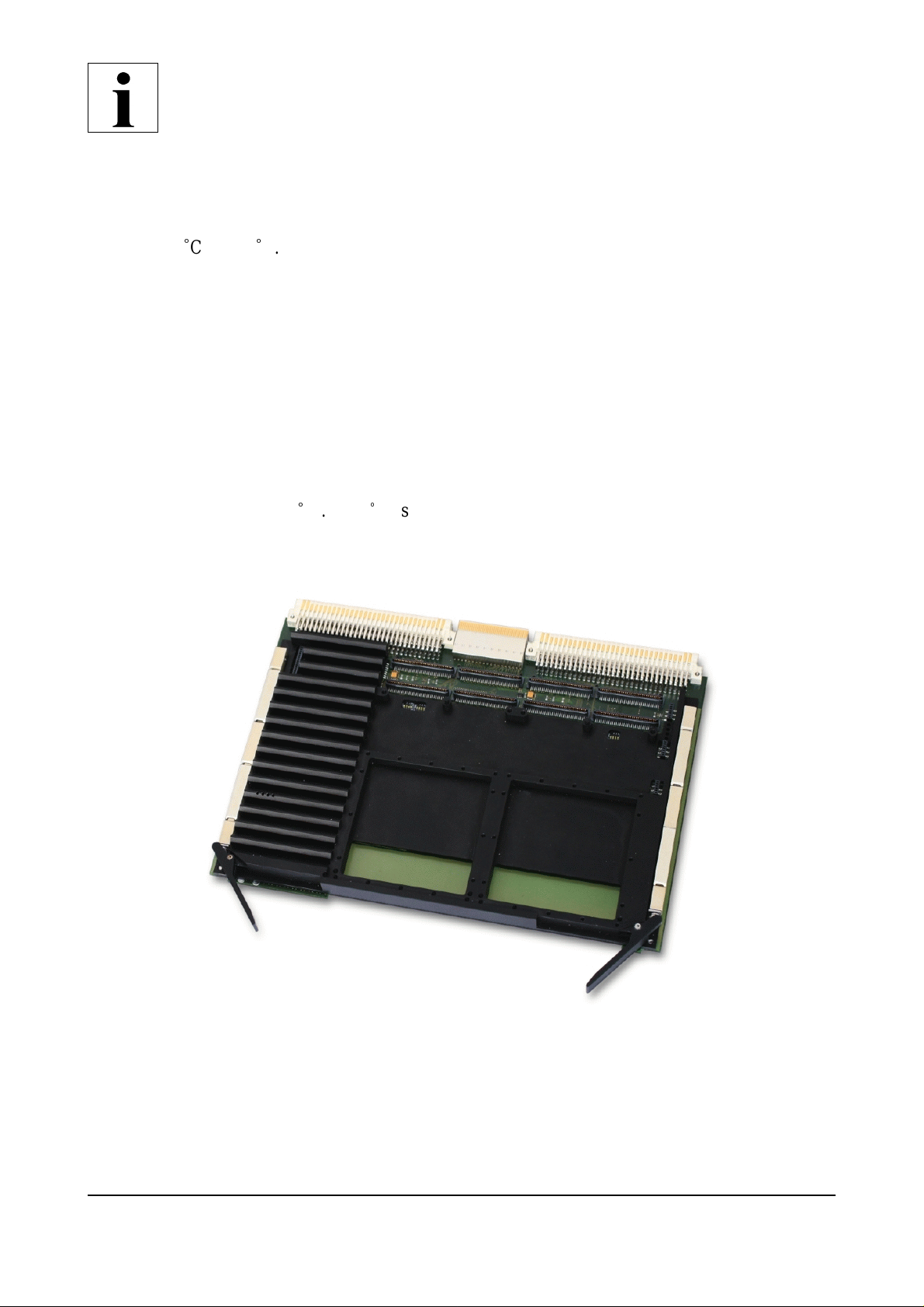

1.3.3 Option: “-CC”: Conduction Cooled

The VME-PMC-CADDY/2-CC is designed with covering heat sinks for heat dissipation in conduction

cooled systems. The slots of the PMC modules are conduction cooled PMC modules.

As a result of the heat sinks the front panel and with it the 10-pin har-link®-connector with the serial

interfaces are not equipped. Furthermore the front panel LEDs are not equipped.

The conduction cooled version VME-PMC-CADDY/2-CC is designed for operation in the extended

temperature range from -40 /C ...+85 /C as the VME-PMC-CADDY/2-T version.

Page 8 of 43

Figure 2: Conduction cooled version VME-PMC-CADDY/2-CC

Hardware Manual • Doc. No.: V.1915.21 / Rev. 1.0

VME-PMC-CADDY/2

1.4 Technical Data

1.4.1 General Technical Data

Overview

VMEbus-Interface

Base address geographical addressing

Address modifier

VMEbus access

VMEbus back plane compatible to VME32, VME64 and VME64x back planes

Ambient temperature

range

Humidity max. 90%, non-condensing

IEEE 1014 / Rev. D

Master or Slave functionality

standard supervisory and non-privileged data access,

extended supervisory and non-privileged data access,

short supervisory and non-privileged access

- Legacy-protocols supporting the preservation of existing VMEsystems

- VME64 extensions

- 2eVME- and 2eSST protocols

Standard: 0...50 /C (order no.: V.1915.02/.11)

Extended

temperature range: -40...+85 /C (order no.: V.1915.03 /.13)

Conduction cooled: -40...+85 /C (order no.: V.1916.02 /.11)

P1, P2 - 160-pin VG-connector according to DIN 41612

in compliance with VME64 extension

P0 - 95-pin I/O-connector according to

IEC 1076-4-101

J11 to J24 - 64-pin PMC-socket connector:

J11, J12, J21, J22 - PMC-address/data signals

J13, J23 - PCI 64 signals

J14, J24 - PMC I/O-signals

Connectors

Dimensions 160 mm x 233 mm

Slot format 6 U high / 4 HP wide

VME-PMC-CADDY/2

J15 - 114-pin XMC socket (optional)

X1940 - 10-pin har-link socket: 2x serial (RS232)

Service- and diagnostic connector:

X1800 - Socket connector 1x16: Debug CPU

X1801 - Socket connector 1x7: JTAG-TSI148

X2120 - Socket connector 1x7: JTAG-PCI

X2310 - Socket connector 1x6: ISP-ADU848

Hardware-Manual • Doc.-No.: V.1915.21 / Rev. 1.0

(not at VME-PMC-CADDY/2-CC)

Page 9 of 43

Overview

Weight

VME-PMC-CADDY/2 (order no.: V.1915.xx): 350 g

VME-PMC-CADDY/2-CC (order no.: V.1916.xx): 650 g

VMEbus P1, P2: 5 V ±5% / ca. 1,0 A

Power supply voltage

(without PMC modules)

Table 1: General technical data

1.4.2 Serial Interfaces

Number 2

Control UART im MPC8349

Signals

to X1940: RxD, TxD, RTS, CTS (for each port)

to VMEbus P0: RxD, TxD (for each port)

Bit rate 300 bit/s ... 115.200 bit/s

3.3 V ±5% / ca. 400 mA

+12V ±5% (only to PMC slots)

-12V ±5% (only to PMC slots)

Physical interface RS232

Connector

X1940 (10-pin har-link) and VMEbus P0,

Adapter cable 10-pol har-link to 9-pin DSUB available

Table 2: Serial interfaces

Page 10 of 43

Hardware Manual • Doc. No.: V.1915.21 / Rev. 1.0

VME-PMC-CADDY/2

1.4.3 PMC-Slots

PMC-Standard IEEE Std 1386-2001, IEEE Std 1386.1-2001

Equipment two single-size modules

VME-PCI-Bridge Tundra Tsi148

Standard: according to VITA 35 (P4V2-64ac, P4V0-46), i.e.

PMC slot 1 (J14) completely to P2 row a and c,

PMC slot 2 (J24) completely to VMEbus connector

P0

I/O-Signals

to VMEbus P2 and P0

Option ‘-32P2’:

PMC slot 1 (J14): as above but additionally on P2

parallel assignment with J24 pins 33...64,

PMC slot 2 (J24): as above but additionally on P0

parallel assignment with J14-pins 1...32

Overview

Signal voltage level 3.3 V

In the standard placement all PMC-power supply voltages are

directly suppled via the VMEbus connectors.

3.3 V: max. 1.5 A current consumption per PMC slot

3.3 V AUX: for both PMC slots together

Power supply voltage

+12V: max. 1.0 A current consumption per PMC slot

-12V: max. 1.0 A current consumption per PMC slot

Note:

The maximum permissible sum of the power consumption of a

PMC module corresponds to the value of 15 W for double-sided

modules defined in the IEEE Std. 1386-2001.

3.3 V power supply voltage of the PMC modules generated from

Option for power

supply voltage

+5V-power supply voltage of the VMEbus (Necessary, if

VMEbus-back plane connector J1 is not of 160-pin design or no

3.3 V voltage is supplied via the VMEbus.)

Please contact our support before you order this version.

max. 250 mA current consumption

VME-PMC-CADDY/2

Table 3: PMC slots

Hardware-Manual • Doc.-No.: V.1915.21 / Rev. 1.0

Page 11 of 43

Overview

1.4.4 XMC Slot (Option)*

VITA 42.3,

XMC standard

Link-definition according to table 4-1: Single width, 4-Lane, only

connector P15 is used

Bus system PCI-Express

Connector Connector assignment according to VITA 42.3, table 4-2

U

= 5V ±5 % (max. 1.0 A current consumption)

VPWR

(alternatively, adjustable via solder bridges U

U

= 3.3 V ±0,3V (max. 1.0 A current consumption)

3.3V

Power supply voltage

U

U

U

= 3.3 V ±0,3V (max. 1.0 A current consumption)

3.3VAUX

= +12 V ±5 % (max. 1.0 A current consumption)

+12V

= -12 V ±5 % (max. 1.0 A current consumption)

-12V

= 12V ±5%)

VPWR

Note:

The maximum permissible sum of the power consumption of the

XMC-module corresponds to the value of 15 W for double-sided

PMC-modules defined in IEEE Std. 1386-2001

* At the moment for this assembly variant there is no order option. If you need this hardware variant, please contact our

sales team (sales@esd.eu) before ordering.

1.4.5 Software

Example libraries for the initialisation of the VME-PMC-CADDY/2 in C-code for VxWorks are

available for a fee. Ask our support for drivers for other operating systems.

Please specify your operating system with release number when ordering.

Page 12 of 43

Hardware Manual • Doc. No.: V.1915.21 / Rev. 1.0

VME-PMC-CADDY/2

2. Front Panel and LEDs

Front Panel and LEDs

VME-PMC-CADDY/2

Figure 3: Front of the VME-PMC-CADDY/2

Hardware-Manual • Doc.-No.: V.1915.21 / Rev. 1.0

Page 13 of 43

Loading...

Loading...