Escorts FarmTrac 45 DT Operator's Manual

OPERATOR ’ S

M A N U A L

OPERATOR ’ S

M A N U A L

45 DT

2

CONTENTS

Page

Limited Warranty ii

Federal Emission Warranty iii-iv

Introduction v

Safety Precautions vi-viii

Universal Symbols ix

Road Speed Decal ix

Safety Decals x

CONTROLS, INSTRUMENTS AND OPERATION

Operator’s Seat, Seat Belt, Safety Frame or Roll Bar 2

Instruments and Controls 2

Starting the Engine 4

Stopping the Engine 5

Parking Brake 5

Foot Controls 6

Transmission 7

Power-Take-Off 7

Hydraulic System 9

Three Point Linkage 14

Track Adjustment 17

Tractor Weighing 20

Tire Inflation 22

LUBRICATION AND MAINTENANCE

Lubrication and Maintenance Chart B/2

Routine Servicing B/4

General Maintenance B/21

SPECIFICATIONS

INDEX

SECTION A

SECTION B

SECTION C

SECTION D

LIMITED WARRANTY

FARMTRAC AGRICULTURAL TRACTORS

ESCORTS LIMITED warrants to its overseas Authorized Dealers that each new Farmtrac Agricultural tractor sold

by it to the Authorized Dealer will be free, under normal usage and service, from defects in materials and workmanship

for a period of one (1) year or one thousand (1000) hours of operation, whichever is earlier, from the date of sale to

the first original retail purchaser. Escorts Limited’s obligation under this warranty is limited to repairing or replacing

at its own, sole and absolute option in an Authorized Dealer’s place of business any part or parts that, within the

warranty period, are returned to its Authorized Dealers with transportation charges prepaid. Escorts Limited’s inspection

must show that the returned part or parts were defective at the time of manufacture. Parts replaced pursuant to this

warranty shall be warranted only for the remainder of the warranty period applicable to the tractor.

This warranty is expressly limited to the repair or replacement of the defective parts as set forth herein and is the

only warranty given by Escorts Limited and is in lieu of any and every warranty of every kind either expressed or

implied, and this warranty cannot be changed, modified or added to except in writing by a duty elected officer of

Escorts Limited and no dealer, distributor, agent, salesman or representative has any right or authority to change,

modify or enlarge this warranty or to make any promise, stipulation and/or agreement inconsistent or in conflict

therewith.

This warranty does not apply if the tractor or any part thereof has been subjected to misuse or negligence on the

part of the owner or operator, or accident. This warranty does not extend to expendable and consumable items

including such items as brake discs, clutch discs, air filters, engine and hydraulic oil, oil filters, fan belts and light

bulbs. This warranty does not cover normal maintenance services such as engine tune-up, cleaning or minor

adjustments. This warranty also does not apply to tractors which have been fitted with any part or parts which have

not been made or supplied by Escorts Limited.

IMPORTANT

No other warranty whether or merchantability, fitness or otherwise, expressed or implied, in fact

or by law, is given by Escorts Limited with respect to any new tractor or part and no other or

further obligation or liability shall be incurred by Escorts Limited by reason of the manufacture or

sale of any new tractor or part whether for breach of any warranty, negligence of manufacture or

otherwise.

The obligations of Escorts Limited set forth in the first paragraph hereinabove shall be the exclusive remedy for any

breach of warranty hereunder. In no event shall Escorts Limited be liable for any general, consequential or incidental

damages including, without limitations, any damages for loss of use or loss of profits.

Farmtrac tractors sold through other than Authorized Dealers are not subject to standard warranty and service

policies of Escorts Limited.

Escorts Limited has a Company policy of continuous improvement and development. Escorts Limited reserves the

right to make changes or improvements at any time without incurring any obligations whatsoever to make such

changes on products sold previously.

This warranty becomes effective upon receipt of a properly completed Pre-Delivery Inspection Report by its Overseas

Authorized Dealers or Distributors.

Escorts Limited makes no warranty with respect to proprietary articles such as tires, tubes batteries etc. which

may be fitted in an overseas territory since such products are warranted separately by the respective manufacturers.

This warranty shall not apply to any tractor or part there of that has been repaired or altered outside of Escorts

Limited’s factor or an Authorized Dealer’s Shop.

SAFETY INSTRUCTIONS

ii

SAFETY INSTRUCTIONS

FEDERAL EMISSIONS WARRANTY

(Applicable only to Tractors sold in United States of America)

Escorts Limited warrants that each new 2002 and later non-road diesel engine fitted on your Farmtrac Agricultural

tractor was designed, built and equippped to confirm to applicable U.S. Environment Protection Agency regulations

for a period of five years of three thousand (3,000) hours of operation, whichever is earlier, from the date of sale to

the first original retail purchaser.

The new model year, class of diesel engine and emission application determination for your engine are identified on

the emission control information label affixed to the top of your engine’s rocker arm cover (see on the next page).

This warranty is expressly limited to repair or replacement of any emission control system parts, which are proven

defective during normal use during the warranty period. The warranty repairs and service will be performed by any

Authorized Dealer of Escorts Limited at the Dealer’s place of business. Parts replaced pursuant to this warranty

shall be warranted only for the remainder of the warranty period applicable to the tractor. This emission control

system warranty applies to the following emission control parts:

Fuel Injection Pump Intake Manifold

Fuel Injectors Exhaust Manifold.

High Pressure Pipes

As a tractor owne, your are responjsible for performing all the required engine maintenance listed in your Owner’s

Manual. Escorts Limited will not deny an emission warranty claim solely for lack of maintenance records with you.

However, a claim may be denied if your failure to perform maintenance resulted in the failure of a warranted part.

Receipts covering regular maintenance should be retained in the event of any clarifications required and these

receipts should be passed to each subsequent owner of the tractor.

To maintain the quality and performance originally designed into your emission certified engine, it is recommended

that only replacement parts supplied by Escorts Limited be used for maintenance or repairs. The use of parts not

supplied by Escort Limited does not invalidate the warranty on other components unless the use of such parts

causes damage to warranted parts. If you beliueve you have not received the service entitled to under this warranty,

you should contact us for assistance at the following address:

Export Department

Agri. Machinery Marketing Division,

Escort Limited,

18/4 Mathura Road,

Faridabad - 121 007, INDIA.

Phone - (91) (0129) 5283071

Fax - (91) (0129) 5284839

Please note that the Emission Warranty does not cover:

1. Systems and Parts that were not first installed on your tractor or engine as original equipment by Escorts

Limited.

2. Part malfunctions caused by abuse, misuse, improper adjustment, modification, alteration, tampering,

disconnection, improper, or inadequate maintenance, or use of non-recommended fuels and lubricating oils.

3. Accident caused damage, acts of nature, or other events beyond Escorts Limited’s control.

4. Replacement of expendable items made in connetion with scheduled maintenance.

5. Parts requiring replacement, inspection or adjustment at regular maintenance intervals for reasons other than

being defective.

iii

6. Parts which are not Escorts Limited’s Service Parts.

7. Loss of time, inconvenience, loss of use of equipment/engine or commercial loss.

8. Equipment with altered or disconnected hourmeter where the hours cannot be determined.

9. Equipment not sold by Escorts Limited in United States or normally operated outside the United States.

10. Non defective parts replaced by other that Escorts Limited’s Dealers.

This warranty becomes effective upon receipt of a properly completed Pre-Delivery Inspection Report by the

Authorized Dealers of Distributors of Escorts Limited.

SAFETY INSTRUCTIONS

EMISSION CONTROL INFORMATION LABELS

NOTE : The Model year shown on the Emission Control Information Lable changes as applicable.

IMPORTANT ENGINE INFORMATION

EPA ENGINE FAMILY : XAELL 2.86 FTD TAPPET CLEARANCE-IN (COLD) : 0.014-0.018 inch

ENGINE MODEL : F3.287 TAPPET CLEARANCE-EX (COLD) : 0.017-0.021 inch

DISPLACEMENT : 2.86 Lts. INJECTION TIMING (STATIC) : 120 BTDC

ADVERTISED POWER : 29KW NET (ISO 2288) HIGH IDLING SPEED : 2300-2400 RPM

RATED SPEED : 2000 RPM LOW IDLING SPEED : 600-700 RPM

• ·THIS ENGINE CONFORMS TO 1999 U.S. EPA REGULATION FOR LARGE NON-ROAD COMPRESSION

IGNITION ENGINES.

• THIS ENGINE IS CERTIFIED TO OPERATE ON COMMERCIALLY AVAILABLE DIESEL FUEL

IMPORTANT ENGINE INFORMATION

EPA ENGINE FAMILY : XAELL 3.14 FTD TAPPET CLEARANCE-IN (COLD) : 0.014-0.018 inch

ENGINE MODEL : F3.315 TAPPET CLEARANCE-EX (COLD) : 0.017-0.021 inch

DISPLACEMENT : 2.86 Lts. INJECTION TIMING (STATIC) : 120 BTDC

ADVERTISED POWER: 34.9KW NET (ISO 2288) HIGH IDLING SPEED : 2300-2400 RPM

RATED SPEED : 2000 RPM LOW IDLING SPEED : 600-700 RPM

• THIS ENGINE CONFORMS TO 1999 U.S. EPA REGULATION FOR LARGE NON-ROAD COMPRESSION-

IGNITION ENGINES.

• THIS ENGINE IS CERTIFIED TO OPERATE ON COMMERCIALLY AVAILABLE DIESEL FUEL

(a) FARMTRAC 45

(a) FARMTRAC 60

iv

INTRODUCTION

Thankyou for purchasing your new Farmtrac tractor.

This Manual has been prepared to assist you in the correct procedure for running-in, driving and operating your new

tractor and to assist you in the correct method of maintenance to keep it in peak condition.

Your tractor has been designed and built to give maximum performance, economy and ease of operation under a

wide variety of operating conditions. Prior to delivery, the tractor was carefully inspected, both at the factory and

by your Authorized Dealer to ensure that it reaches you in optimum condition. To maintain this condition and ensure

trouble-free operation, it is important that the routine services, as specified in this manual, are carried out at the

recommended intervals.

Pages vi to viii inclusive, list the precautions to be observed to ensure your safety and the safety of others. Read

the safety precautions and follow the advice offered before operating the tractor.

A vehicle identification plate is located under the tractor bonnet. The vehicle reference serial number are also

recorded on the pre-delivery inspection sheet that was provided to you by your Authorized Dealer and should be quoted

to the Dealer should the tractor require service.

Read this Manual carefully and keep it at a convenient place for future reference. This manual must be considered

as an integral part of your tractor. If at any time you require service or advice concerning your tractor, do not

hesitate to contact your Authorized Dealer. He has trained personnel, genuine parts and the necessary equipment to

carry out all your service requirements.

Following these introductory pages, this manual is split into four sections. Section A describes the controls and

instruments and advises the correct method of operating your new tractor. Section B details lubrication and maintenance procedures and includes a comprehensive service chart. Section C outlines the specifications of your tractor.

A comprehensive index is provided at the back of the Manual in Section D.

Escorts Limited has a Company policy of continuous improvement and development. Designs, materials and/or

specifications are subject to change without notice and without any liability whatsoever.

All data given in this book is subject to production variations. Dimensions and weights are approximate only and the

illustrations do not necessarily show tractor in standard condition. Some of the equipment /accessories described

in the text may also not be fitted on your tractor. For exact information about any particular tractor, please consult

your Authorized Dealer.

SAFETY INSTRUCTIONS

v

SAFETY INSTRUCTIONS

SAFETY PRECAUTIONS

vi

THE TRACTOR

1. Read this Manual carefully and familiarize yourself

with all the controls before attempting to operate the

tractor. Working with unfamiliar equipment or lack of

operating knowledge may lead to accident.

2. Do not permit anyone to ride on the tractor with the

operator.

3. Use the foot steps and assist handles when getting

on or off the tractor. It is recommended that you face

the tractor when mounting or dismounting. Keep steps

and platform clear of mud and debris.

4. Replace any warning sign on the tractor that

becomes damaged or is painted over. Replace all

missing, illegible or damaged safety decals.

OPERATING THE TRACTOR

1. Never start the engine while standing beside the tractor.

Always sit in the tractor seat, fasten seat belt and ensure

that the Roll Over Protective Structure (ROPS)/Cab is

in place before starting the engine.

2. Apply the parking brake, place the P.T.O. lever in the

“OFF” position, set the control levers in the down

position, the remote control valve levers in the neutral

position and the transmission in neutral before

starting the tractor.

3. Do not bypass the safety starter switch. Consult your

Authorized Dealer if your safety starter controls are

not operating correctly.

4. Stop the engine, disconnect P.T.O. and apply the

parking brake before dismounting.

5. Do not engage the parking brake while the tractor is

in motion.

6. Never get off the tractor while it is in motion.

7. Never park the tractor on a steep incline.

8. To provide maximum lateral stability, add liquid ballast

to tires, use cast iron wheel weights and set front

and rear wheels to maximum tread width

commensurate with the operation being performed.

9. Do not tie ropes, chains, or cables to the axle or

other parts of the chassis. Always hitch the load to

the tractor’s drawbar in the lowest possible position,

except when pulling implements specifically designed

for and properly attached to the three point hitch.

10. Do not operate the tractor with a light front end. If the

front tends to rise with heavy implements at the rear,

install front end or front wheel weights.

11. Ensure that an implement coupled to the three-point

linkage does not contact any part of the cab, if cab

is provided.

12. Never leave equipment in the raised position.

13. If the engine or power steering ceases operating,

stop the tractor immediately.

14. Always engage ‘Position Control’ when attaching

equipment, transporting equipment and when no

equipment is attached. Be sure hydraulic couplers

are properly mounted and will disconnect safely in

case of accidental detachment of the implement.

15. Ensure any attached equipment or accessories are

correctly installed, are approved for use with the

tractor, do not overload the tractor and are operated

and maintained in accordance with the instructions

issued by the equipment or accessory manufacturer.

16. Remember that your tractor, if abused or incorrectly

used, can be dangerous and become a hazard both

to the operator and to bystanders. Do not overload

or operate with attached equipment which is unsafe,

not designed for a particular task or is poorly

maintained.

WARNING : Hearing protection must be worn

when operating this tractor if a safety cab is not

fitted.

CAUTION : Your Farmtrac tractor is not equipped

with a Spark Arrestor. Where there is a risk of fire

to the crop or environs or local legislation so requires, a

suitable Spark Arrestor must be installed.

DRIVING THE TRACTOR

1. Always drive the tractor with care and at speeds

compatible with safety, especially when operating

over rough ground, crossing ditches or slopes or when

turning to avoid overturning the tractor.

2. Never allow the tractor to over-run when going

downhill, particularly with trailed equipment attached.

Keep the tractor in the same gear when going downhill

as used when going uphill. Do not coast or free-wheel

down hills. Use extreme caution while operating on

steep slopes and use a low gear to maintain control

with minimum braking.

3. Lock the foot brakes pedals together when travelling

A careful operator is the best operator. Most accidents can be avoided by observing certain precautions to

prevent the possibility of injury or damage. The following precautions should be taken to help prevent accidents.

Read them carefully before operating your new Farmtrac tractor.

SAFETY INSTRUCTIONS

vii

on the highway.

4. When operating in the field unlock the brake pedals.

5. Reduce speed before turning or applying the brakes.

Brake both the wheels simultaneously when making

an emergency stop.

6. Do not engage the differential lock when turning

the tractor. When engaged, the lock will prevent

the tractor taking the turn and may result in

overturning of the tractor.

7. If the tractor drive wheels are stuck, shift to reverse

gear and back out, to prevent from lifting the front

wheels off the round and possibly rolling the tractor

over backwards.

8. Slow moving vehicles on highways are dangerous.

Use a slow moving (SMV) sign in conjunction with

red lights, tail lights, and flashing warning lights.

9. Use extreme caution and avoid hard application of

the tractor brakes when towing heavy loads. Any

towed vehicle whose total weight exceeds that of

the tractor must be equipped with brakes for safe

operation.

10. Watch where you are going especially at row ends,

on roads, around trees and any low hanging

obstacle.

11. Dip the tractor lights when meeting a vehicle at

night. Ensure the lights are adjusted to avoid

blinding the driver of an on coming vehicle

(applicable only twin beam Head lamps are fitted.

12. Always check overhead clearance, especially when

working in confined spaces.

13. Engage the clutch slowly when driving out of a

ditch, gully or up a steep hillside. Disengage the

clutch promptly if the front wheels rise off the

ground.

OPERATING THE P.T.O.

1. Ensure the P.T.O. guard is always installed and

replace the P.T.O. shaft cap when the P.T.O. is not

being used.

2. Shut off the engine and wait for the P.T.O. shaft to

stop turning before getting off the tractor to connect

or disconnect P.T.O. driven equipment.

3. Apply the parking brake and block the rear wheels,

front and rear, when operating stationary P.T.O.

driven equipment.

4. To avoid injury never clean, unclog, adjust or service

P.T.O. driven equipment while the tractor engine is

running.

5. Never wear loose clothing when operating the P.T.O.

or when near equipment that is rotating.

6. Before operating implements, study the implement

manufacturer’s handbook. Certain implements

require special operating techniques.

SERVICING THE TRACTOR

1. Keep the tractor and equipment, particularly brakes

and steering, maintained in a reliable and

satisfactory condition to ensure your safety and

comply with legal requirements.

2. Stop the engine and disconnect battery terminals

before performing any service on the tractor.

3. To prevent fire or explosion, keep open flames away

from the battery. To prevent sparks which could

cause explosion, use jumper cables according to

instructions.

4. The fuel oil in the injection system and fluid in the

hydraulic system are under high pressure and can

penetrate the skin. Unqualified and unauthorized

persons should not remove or attempt to adjust a

pump, injector, nozzle or any other part of the fuel

injection system. This also may be unlawful under

certain circumstances. Failure to follow these

instructions can result in serious injury.

5. DO NOT

l Use your hand to check for leaks. Use a piece

of cardboard or paper to search for leaks.

l Stop the engine and relieve pressure before

connecting or disconnecting hydraulic or fuel

lines.

l Tighten all connections before starting the

engine or pressurising lines.

l If fluid is injected into the skin obtain medical

attention immediately or gangrene may result.

6. The cooling system operates under pressure which

is controlled by the radiator cap. It is dangerous to

remove the cap while the system is hot. Allow the

engine to cool, then turn the cap slowly to the first

stop and allow the pressure to escape before

removing the cap entirely.

7. Continuous long term contact with used engine oil

may cause skin cancer. Avoid prolonged contact

with used engine oil. Wash skin promptly with soap

and water.

8. Some components on your tractor, such as

gaskets and friction surfaces (brake linings, clutch

linings, etc.), may contain asbestos. Breathing

asbestos dust is dangerous to your health. You

are, therefore, advised to have any maintenance

or repair operations on such components carried

out by an Authorised Dealer. If, however, service

operations are to be undertaken on parts that

contain asbestos, the following essential

precautions must be observed:

ATTENTION ! BECOME ALERT ! YOUR SAFETY IS INVOLVED !

l Work out of doors or in a well ventilated area.

l Dust found on the tractor or produced during

work on the tractor should be removed by

extraction and not by blowing.

l Dust waste should be dampened, placed in a

sealed container and marked to ensure safe

disposal.

l If any cutting, drilling etc., is attempted on

materials containing asbestos, the item should

be dampened and only hand tools or low speed

power tools used.

9. Do not run the tractor engine in a closed building

without adequate ventilation as exhaust fumes

may suffocate you.

10. Do not modify or alter or permit anyone else to

modify or alter the tractor or any of its components

or any tractor function without first consulting your

Authorised Dealer.

11. Tractor wheels are heavy. Handle them with care

and ensure that, when stored, they cannot topple

and cause injury.

DIESEL FUEL

1. Under no circumstances should gasoline, alcohol

or blended fuels be added to diesel fuel. These

combinations can create an increased fire or

explosive hazard. In a closed container, such as

a fuel tank, these blends are more explosive than

pure gasoline. Do not use them blends.

2. Never remove the fuel cap or refuel with the engine

running or hot.

3. Do not smoke or allow an open flame near the fuel

tank or while refuelling the tractor. Wait for the

engine to cool before refuelling.

4. Maintain control on the fuel filler pipe nozzle when

filling the tank.

5. Do not fill the fuel tank to capacity. Allow room for

expansion.

6. Wipe up spilled fuel immediately.

7. Always tighten the fuel tank cap securely.

8. If the original fuel tank cap is lost, replace it with

an approved cap. A non-approved cap may not be

safe.

9. Keep equipment clean and properly maintained.

10. Do not drive equipment near open fire.

11. Never use fuel for cleaning purpose.

12. Use diesel fuel with a minimum cetane rating of

40 (Diesel fuel no. 2) at ambient temperatures

above –700C (200F) or Diesel fuel no. 1 below this

temperature. At very low ambient temperatures

and/or at high attitude, a fuel with a higher cetane

rating is required.

13. Diesel fuel with a sulphur content above 1.3% is

not recommended.

14. Precaution should be taken to ensure that stored

fuel is kept free of dirt, water, etc.

15. Fuel should be stored in black iron tanks, not

galvanised tanks, as the galvanised coating will

react with the fuel and form compounds that will

contaminate the injection pump and injectors.

16. Bulk storage tanks should be installed away from

direct sunlight and angled slightly so that the outlet

pipe is at the higher end. In this way sediment in

the tank will settle away from the outlet pipe.

17. To facilitate moisture and sediment removal, a

drain plug should be provided at the lowest point

(at the opposite end to the outlet pipe). If there is

no filter on the outlet pipe, then a funnel with a

fine mesh screen should be used when filling the

tractor fuel tank.

18. Fuel purchases should be arranged so that summer

grade fuels are not held over and used in winter

and vice-versa.

19. Refill the fuel tank via filler tube which is on the

rear left-hand side of the hood.

CAUTION : The fuel oil in the injection system

is pressurized and can penetrate human skin

with fatal results. Adjustment of fuel injection equipment

should not be carried out by unqualified person.

SAFETY FRAME OR ROLL BAR (where fitted)

Your tractor may be equipped with a safety frame or roll

bar which must be maintained in a serviceable condition.

Be careful when driving through doorways or working in

confined spaces with low headroom.

Under no circumstances:

i) modify, drill, weld or alter the safety frame or roll

bar in any way. Doing so could render you liable to

legal prosecution in some countries.

ii) attempt to straighten or weld any part of the safety

frame, roll bar or retaining brackets which have

suffered damage. By doing so you may weaken

the structure and endanger your safety.

iii) secure any parts on the safety frame or roll bar or

attach if with other than the special high tensile

bolts and nuts specified.

iv) attach chains or ropes to the safety frame or roll

bar for pulling purpose.

v) take unnecessary risks even though your safety

frame or roll bar affords you the maximum

protection possible.

CAUTION : If there is a risk from falling objects

at your work environment, a Falling Objects

Protective Structure (FOPS) must be installed on your

tractor.

SAFETY INSTRUCTIONS

Whenever you see the symbol it means:

viii

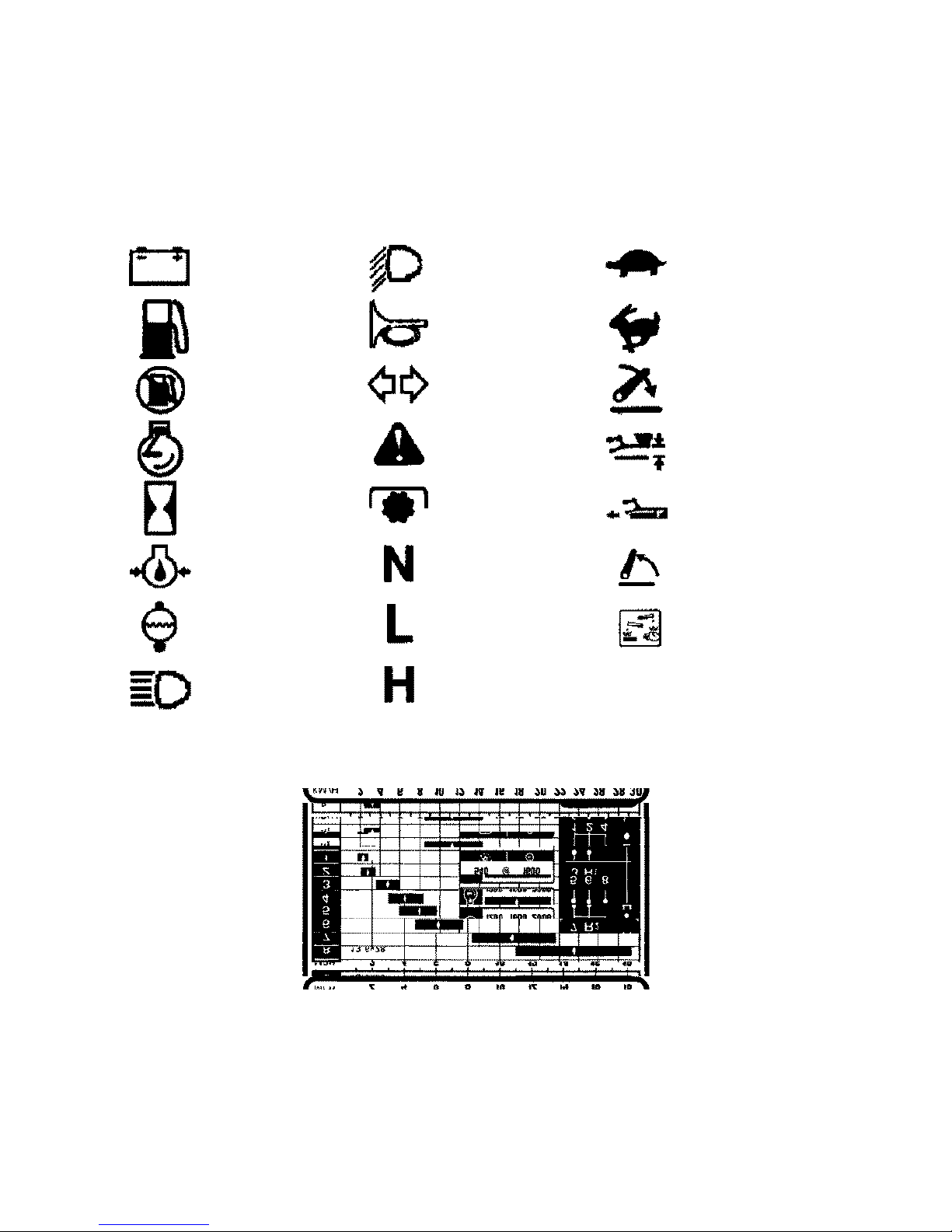

UNIVERSAL SYMBOLS

As a guide to the operation of your tractor, various universal symbols have been utilized on the instruments,

controls, switches and fuse box. The symbols are shown below with an indication of their meaning.

Alternator/Dynamo

Charge

Fuel level

Fuel shut-off

Engine speed

(rev/min × 100)

Hours recorded

Engine oil pressure

Engine coolant

temperature

Headlight

main beam

Headlight dipped

beam

Horn

Turn Signals

Warning!

P.T.O.

Transmission in

neutral

Low transmission

range

High transmission

range

Slow or low setting

Fast or high setting

Linkage lower

Position Control

Draft Control

Linkage raise

Warning! Corrosive

substance

The decal shown above is similar to that fitted next to the instrument panel of your tractor and graphically illustrates

the approximate tractor road speed at three alternative engine speeds. The decal also shows the engine speed at

which P.T.O. speed of 540 RPM is obtained. Accurate road speed charts are provided at the end of Section C.

ix

SAFETY SYMBOLS

x

CAUTION

DO NOT OPERATE

UNTILL YOU READ THE OWNERS MANUAL

IF YOU DID NOT RECEIVE A COPY ONE MAY BE OBTAINED FROM

YOUR AUTHORISED DEALER

l

Pull only from drawbar. Pulling

from other points can cause rear

overturn.

l

Do not operate with unshielded PTO.

l

Disangage PTO and stop engine before

servicing tractor or implements or

attaching and detaching implements.

l

Position drawbar at 14" from end of

PTO shaft to drawbar hole for 540 RPM.

l

When towing equipment use a safety

chain.

FAILURE TO FOLLOW ANY OF THE INSTRUCTIONS

ABOVE CAN CAUSE SERIOUS INJURY TO THE

OPERATOR OR OTHER PERSONS.

WARNING

WARNING

AVOID POSSIBLE INJURY

OR DEATH FROM A

MACHINE RUNAWAY

1. Do not start engine by shorting

across starter terminals.

Machine will statrt in gear and

move if normal starting circuitry is bypassed.

2. Start engine only from operators seat with transmission in

neutral or park.

NEVER start enigine while

standing on the ground.

CAUTION

AFTER FIRST HOUR OF OPERATION FRONT

AND REAR WHEEL LUG NUTS AND BOLTS

SHOULD BE CHECKED FOR PROPER

TORQUE - THERE AFTER CHECK DAILY.

82835415

WARNING

THE DIFFERENTIAL LOCK IS PROVIDED FOR USE ON SLIPPERY SURFACES, IT MUST NOT BE USED ON

THE ROAD.

WARNING

TO AVOID INJURY, KEEP

THIS GUARD IN PLACE

SAFETY INSTRUCTIONS

E2NN-94000R86-AA

82835419

11 78500 AA

CONTROLS,

INSTRUMENTS

and OPERATION

The following pages in this section detail the location and function of the various instruments, switches and controls

on your tractor. Even if you operate other tractors, you should read through this section of the Manual and ensure

that you are thoroughly familiar with the location and function of all the features of your new tractor. Do not start the

engine or attempt to drive or operate the tractor until you are fully accustomed to all the controls. It is too late to

learn once the tractor is moving. If in doubt about any aspect of operation of the tractor, consult your Authorized

Dealer. Reference to tractor models or equipment not available in your territory or to options or accessories not fitted

on your tractor should be ignored.

Particular attention should be paid to the recommendations for running-in to ensure that your tractor will give the

long and dependable service for which it was designed.

See Section B for the routine lubrication and maintenance requirements. The specification of your tractor will be

found in Section C.

SECTION A

1

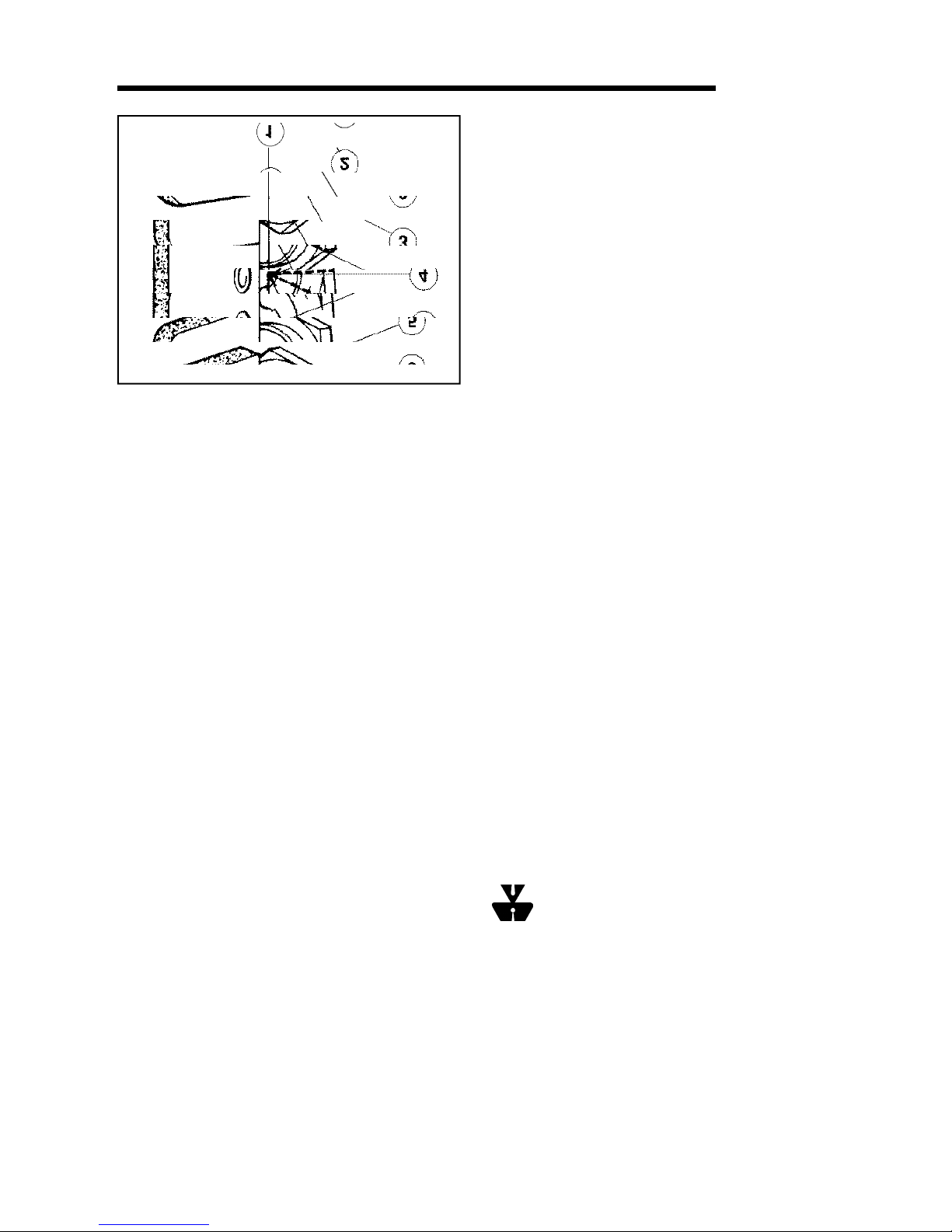

OPERATOR’S SEAT

Before operating the tractor, it is important to adjust

the seat to the most comfortable position. See Figure 1

for details.

To achieve the optimum suspension setting, sit in the

seat and turn the suspension adjuster knob until the

weight indicators on the seat frame align.

Press down the horizontal travel adjustment lever and

move the seat forward or backward, as required. Further

seat travel is possible after loosening the two seat

mounting bolts that secure the seat base to the tractor.

Seat height is adjusted after loosening the two knobs

on both sides of the seat frame.

NOTE: Do not use solvents to clean the seat. Use

warm water with a little detergent added.

SEAT BELT, SAFETY FRAME OR ROLL BAR

(where fitted)

WARNING : Tractors equipped with a safety

frame or roll bar also have a seat belt fitted.

Always use the seat belt with a safety frame or roll-bar

installed. Do not use a seat belt if the tractor is not

equipped with a safety frame or roll bar.

To lengthen the belt, tip the buckle away from the belt

and pull on the buckle. With the belt fastened around

you, pull the free end of the belt until it is a snug fit.

The belt may be sponged with clean, soapy water. Do

1. Seat

1. Suspension adjuster knob

2. Weight indicators

3. Horizontal travel adjustment lever

4. Seat mounting bolts

5. Height adjustment knob

not use solvents, bleach or dye on the belt as a these

chemicals will weaken the webbing. Replace the belt

when it shows signs of fraying, damage or general wear.

If your tractor is fitted with a safety frame or roll bar, it

must be maintained in a serviceable condition.

If your tractor is fitted with a front end loader, it is

recommended that a canopy be fitted to protect the

operator from objects that may fall from the loader

bucket.

WARNING: Do not attach chains or ropes to

the safety frame or roll bar for pulling purpose since

the tractor may tip back-wards. Always pull from the tractor

drawbar. Be careful when driving through door openings

or under low overhead objects. Make sure that there is

sufficient overhead clearance for the roll bar.

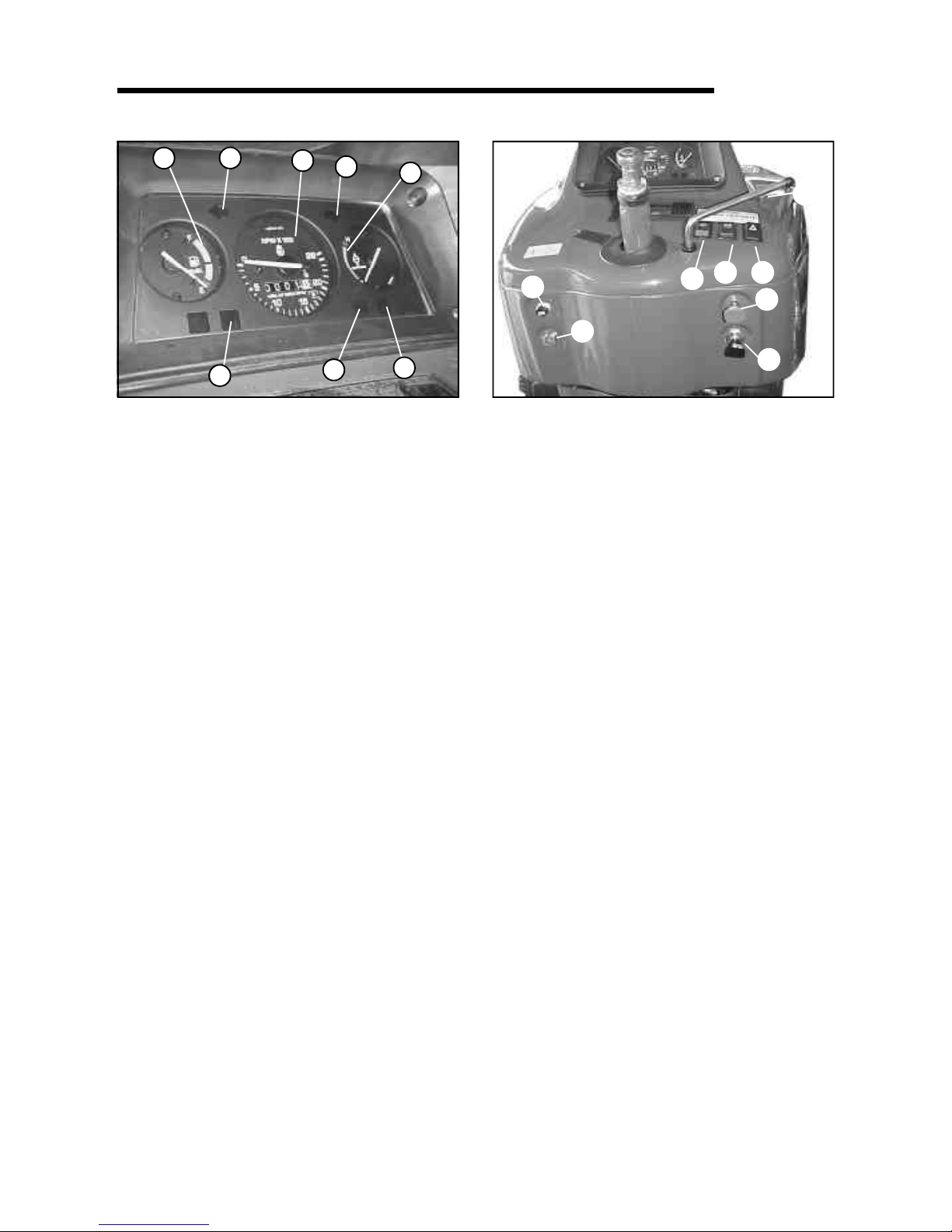

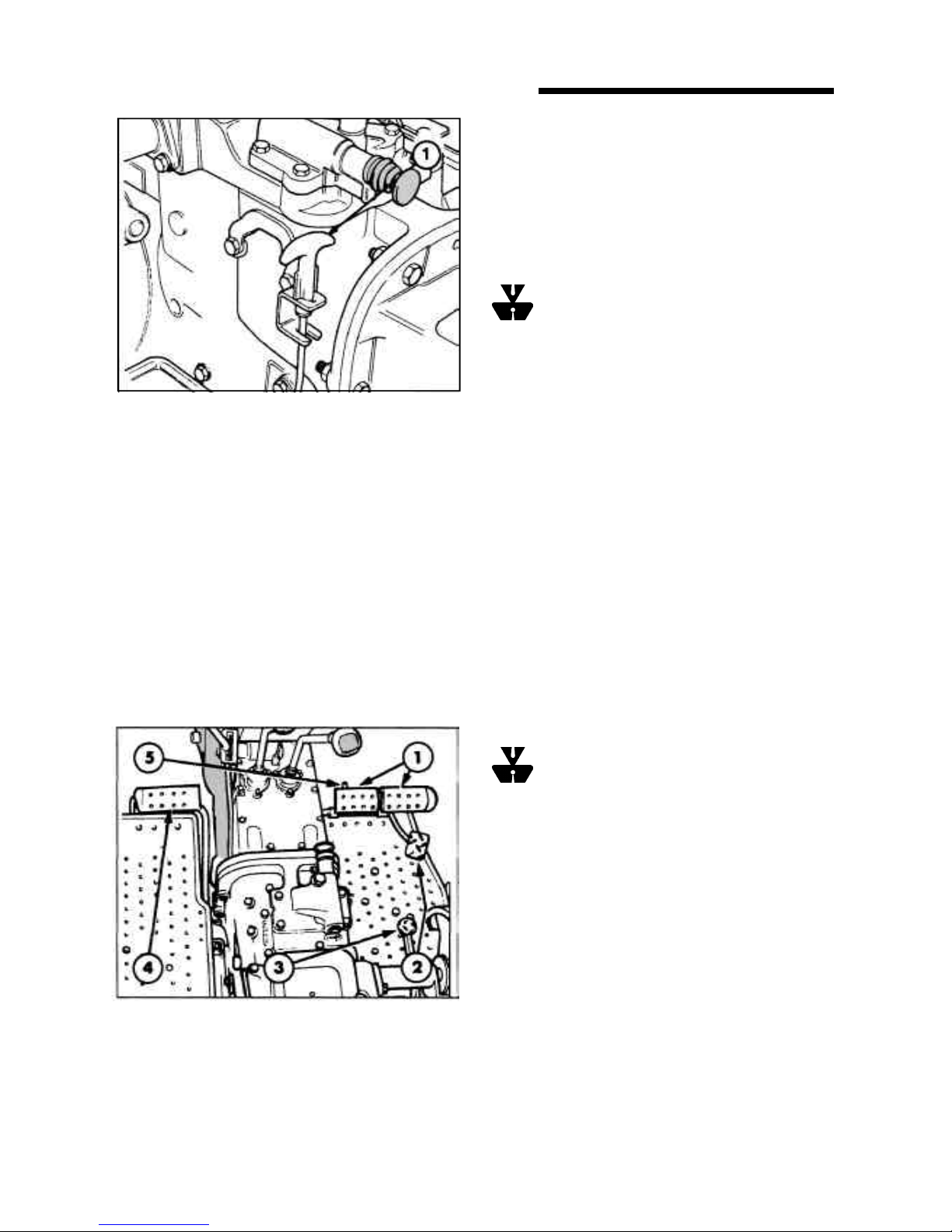

INSTRUMENTS AND CONTROLS

The following text describes the various gauges,

switches and warning lights installed on your tractor,

See Figure 2A and 2B.

Tachometer

The tachometer indicates engine revolutions per minute.

Each division on the scale represents 100 rev/min.-eg.

with the needle indicating ‘20’ the engine is running at

2000 rev/min.

The yellow mark on the tachometer scale indicates the

engine speed at which the standard P.T.O. speed of

540 rev/min is obtained.

The tachometer also records the total number of hours

that the tractor has operated, based on an average

engine speed of 1600 rev/min. If the engine is run at a

speed lower than 1600 rev/min then the tachometer will

accumulate hours at a rate slower than real time. Higher

engine speeds will cause the tachometer to accumulate

hours at a rate faster than real time.

The hours recorded should be used as a guide to

determine hours servicing intervals. (see Section B of

this Manual).

Engine Coolant Temperature Gauge

The gauge indicates the temperature of the engine

coolant. If the needle enters the red area of the gauge

while the engine is running, stop the engine and

investigate the cause.

NOTE : When the key-start switch is turned off, the

gauge needle will assume a random position.

CONTROL, INSTRUMENTS AND OPERATION

2

2A. Single Instrument Cluster

1. Tachometer

2. Engine coolant temperature gauge

3. Engine Oil Pressure Warning Light

4. Fuel Gauge

5. LH Turn Signal Indicator

6. RH Turn Signal Indicator

7. Battery Charging Indicator

8. Hazard Warning Light Switch

9. Air Restriction Warning Light

10. Engine Stop Control

11. Tractor Light Switch

12. Key Start Switch

13. Horn Switch

14. Hand Throttle

15. Turn Signal Indicator Switch

16. Plough Lamp Switch

Engine Oil Pressure Warning Light

The red warning light on the instrument panel indicates

low engine oil pressure and should extinguish immediately

after the engine is started, and is only operative with the

key start switch in the ‘ON’ position.

NOTE : If the light comes on while engine is running,

stop the engine immediately and investigate the cause.

The light indicates low oil pressure and is not an indication

of oil level. The engine oil level must still be checked

daily by means of the dipstick.

Hand Throttle

With the engine running, pull the throttle lever rearwards

to progressively increase engine speed. Push the throttle

lever forward to decrease the engine speed.

Hazard Warning Light Switch

Press the switch to operate both turn signals

simultaneously. The switch, which is internally

illuminated, will flash in unison with the turn signals

and the turn signal indicator lights on the instrument

panel.

Indicator Ligthss

The upper indicator light of the pair will illuminate when

headlamp main beam is selected. When either of the turn

signal is operated, the lower indicator light will flash in

unison with the turn signals.

In some territories, where only single beam (dipped

beam) headlamps are fitted, the upper indicator light

will flash in unison with the turn signals when either of

the turn signal is operated. If, however, the tractor is

also equipped with a 7 pin rear trailer socket, the lower

indicator light will flash in unison with the turn signals

of the trailer when either of the turn signal is operated.

The turn signal indicator lights will also flash in unison

with the turn signals whenever the hazard switch is

operated.

NOTE : Please check with your Authorized Dealer on

which system is fitted on your Tractor.

Tractor Lights Switch

The lights switch is of the push-pull type and has three

positions:

Fully in : lights OFF

Midway : side, rear and instrument lights ‘ON’

Fully out : side, rear, instrument and headlights ‘ON’

Engine Stop Control

Pull the stop control knob fully out and hold it in that

position to cut off the fuel supply to the injectors and

stop the engine. The knob must be pushed fully in before

restarting the engine.

SECTION A

3

2B. Instrument Panel

(Steering wheel removed)

4

7

5

3

9

2

6

1

10

11

12

13

14

15

16

8

4

Key-Start Switch

The key operated switch actuates the starting motor.

See ‘Starting The Engine’ for the correct operating

procedure.

Road Speed Decal

The decal which is also illustrated on Page IX, shows the

approximate tractor speed in all gear ratios. Accurate road

speed charts are provided at the end of section C.

Charging Indicator

The red warning light on the instrument cluster indicates

that the alternator is not charging the battery and should

extinguish when the engine speed is increased above

idle.

Fuel Gauge

The gauge indicates the level of fuel in the tank and is

only operative with the key-start switch in the ‘ON’

position.

NOTE : When the key-start switch is turned off the

gauge needle may assume a random position and may

indicates a fuel level greater than the true level. Always

check the fuel level with the key-start switch on.

Air Restriction Warning Light (where fitted)

When this lamp lights up, clean or replace the outer

element of dryair cleaner. If light comes on during tractor

operation when replacement of element is not

immediately possible, just clean the element and reduce

the engine speed so on to prevent the lamp from lighting.

Seven-Terminal Trailer Socket (where fitted)

This socket allows lights, turn signals and other electrical

equipment on a trailer or impliment to be connected.

This is fitted at the rear of driver’s seat.

Always use additional lighting on the mounted implement

if this conceals the turn signals and other lights at the

rear of the tractor.

CONTROL, INSTRUMENTS AND OPERATION

STARTING THE ENGINE

A five-position key-start switch is installed on all the

tractors. For starting in temperatures down to –180C

(00F) the thermostart option may also be installed,

Basically the thermostart consists of an electrically

heated element in the air in taken manifold which, when

operated, ignites a measure of diesel fuel and

introduces it into the combustion chamber. With the

thermostart installed, all the five positions of the

keystart switch are connected as shown in Figure 3.

However, if the automatic thermostart is not installed,

the starting motor operates at position (4) while as

position (5) is left unconnected (see Figure 3).

IMPORTANT : Never push or tow the tractor to start

the engine. Doing so may overstress the drive train.

NOTE: A safety start switch prevents operation of the

starting motor unless the transmission range lever is in

the neutral (N) position.

Before starting the engine, always carry out the following

procedure:

l Sit in the driver’s seat and ensure that the parking brake

latch is firmly applied.

l Push the stop control knob fully in.

l Ensure that both gearshift levers are in neutral and

that the P.T.O. lever is in the disengaged position.

l Move both hydraulic lift control levers fully forward.

l Place the remote control valve levers in neutral.

WARNING : Start the tractor only from the driver’s

seat. If the key-start switch is bypassed, the

engine may start inadvertently with a gear selected and

cause sudden and unexpected movement of the tractor

or a tractor runaway. Wear eye protection when starting

the tractor with jump leads or when charging the battery.

For standard tractors (without automatic

thermostart)

l Open the hand throttle halfway, depress the clutch

to ease the load on the starter motor and turn the

key-start switch fully clockwise to position (4) to

operate the starting motor. Crank the engine until it

starts but do not operate the starting motor for more

than 40 seconds and then allow the key to return to

position (3).

l Return the throttle to the idle position and check that

all warning lights extinguish and gauge readings are

normal.

Connection Wire Colour

1. Ground Brown

2. Parking RH Grey-Red

3. Turn singal LH Black-White

4. Brake light Red-White

5. Turn signal RH Black-Green

6. Parking LH Grey-Red

3. Key-start Switch

1. Electrical equipment ‘OFF’

2. Accessories ‘ON’

3. Warning lights and instruments ‘ON’

4. Thermostart heater ‘ON’ (where fitted), or

Starting motor operates (where thermostart is

not fitted).

5. Starting motor operates (where thermostart is

fitted), or

Unconnected (where thermostart is not fitted).

For tractors fitted with automatic

thermostart:

l In warm weather, or when the engine is hot, depress

the clutch and turn the keystart switch fully clockwise

to position (5). Operate the starting motor until the

engine starts or for a maximum of 40 seconds and

then allow the key to return to position (3).

l In cold weather with the engine cold, depress the

clutch and turn the key-start switch to position (4),

hold for 20-30 seconds and then turn fully clockwise

to position (5). Operate the starter until the engine

starts or for a maximum of 30 seconds.

l Return the throttle to the idle position and check

that all warning lights extinguish and gauge readings

are normal.

NOTE : If the engine fails to start, repeat the procedure,

after waiting for 1-2 minutes. If the thermo-start is fitted,

the key should be held at position (4) only for 7-10 seconds

when attempting to restart the tractor.

STARTING THE TRACTOR WITH JUMP LEADS

If it is necessary to use jump leads (booster cables) to

start the tractor, proceed as follows:

l Connect one end of the red jump lead to the tractor

battery positive (+) terminal and the other end to

the auxiliary battery positive (+) terminal.

l Connect one end of the black jump lead to the

auxiliary battery negative (-) terminal and the other

end to a suitable projection on the tractor engine

block. Follow the starting procedure previously

described.

l When the engine starts allow it to run at idle speed,

turn on all electrical equipment (Lights etc.) then,

disconnect the jump leads in the reverse order to

the connecting procedure. This will help protect the

alternator from possible damage due to extreme load

changes.

NOTE : When using an auxiliary battery to start the

engine, ensure that the polarity of the jump leads is correct

- positive to positive, negative to negative otherwise

the alternator may be damaged.

STOPPING THE ENGINE

To stop the engine, carry out the following procedure:

l Sit in the driver’s seat and close the throttle.

l Ensure that the parking brake latch is firmly applied.

l Ensure that both gearshift levers are in neutral and

that the P.T.O. lever is in the disengaged position.

l Pull the stop control knob fully out and turn the key-

start switch off.

l Move the hydraulic lift control levers fully forward to

lower all hydraulic equipment to the ground.

l Move the remote control valve levers fully forward

and then fully rearward before placing them in neutral

position.

WARNING : Check the area beneath the

equipment to ensure that no injury or damage will

be caused when equipment is lowered.

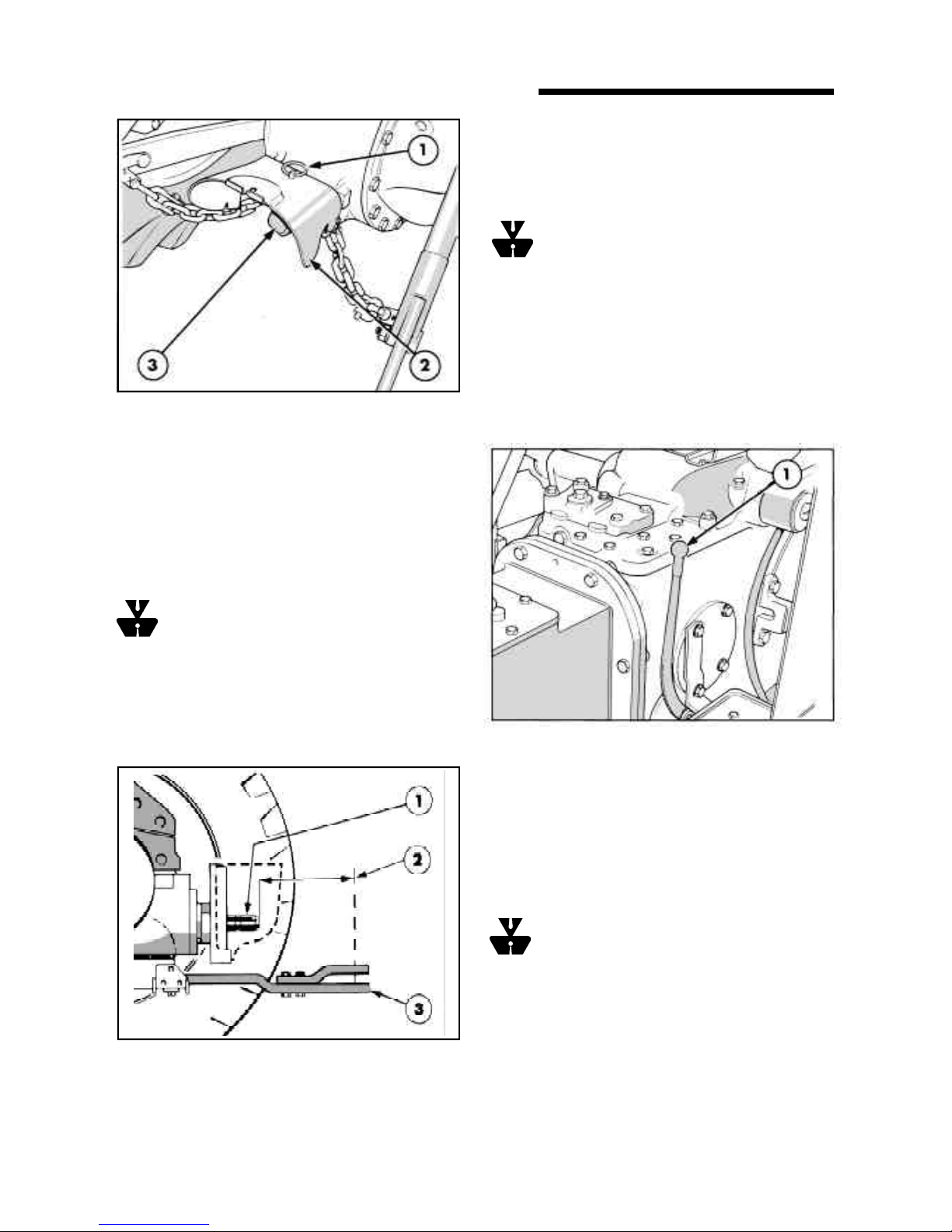

PARKING BRAKE

To parking brake consists of a latch that is used to secure

the foot brakes in the applied position. (See Figure 4).

SECTION A

5

4. Parking Brake

1. T-handle

To operate the parking brake, lock the brakes together

(see the following text titled ‘Foot-brakes’). Apply the

foot brakes, pull up the T-handle and rotate one quarter

turn. To free the parking brake, rotate the T-handle one

quarter turn and release. Momentarily depress the foot

brakes to disengage the ratched. In Figure 4, the parking

brake is shown in the applied position.

IMPORTANT : Ensure that the parking brake is fully

released before driving off.

FOOT CONTROLS

For details of foot operated controls, refer to Figure 5

and the following text.

Foot Brakes

The foot brake pedals, Figure 5, activate the rear wheel

brakes and may be operated independently, to aid

turning in confined spaces or together for normal

stopping. When operating in the field, the brake pedals

may be unlocked. However, due to the close proximity

of the pedals to one another, it is still possible to apply

both brakes together, when required.

WARNING : For your safety, always lock the

brake pedals together when travelling at

transport speeds, or on a highway or if a trailer is

attached. To lock the pedals together, slide the latch (5)

across to engage in the hole in the underside of the

right-hand pedal, as shown.

Foot Accelerator

The foot accelerator, Figure 5, may be used

independently of the hand throttle to control the speed

of the tractor. It is recommended that you use the foot

accelerator when driving on the highway.

NOTE : When it is required to use the foot accelerator,

set the hand throttle to the idle position (fully forward).

Differential Lock

In field conditions including wheel slip, hold down the

differential lock pedal, Figure 5, until the lock is felt to

engage. The lock will automatically disengage when

traction at the rear wheels equalizes.

If conditions cause a rear wheel to spin at speed, reduce

the engine speed to idle before engaging the differential

lock.

WARNING : Never engage the differential lock

at speeds above 5 mph (8 kmph) or when turning

the tractor. When engaged, the lock will prevent the

tractor from turning.

Clutch

When the clutch pedal, Figure 5, is depressed the drive

between the engine and transmission will be disengaged.

Use the clutch pedal to transfer engine power smoothly

to the driving wheels when moving off from a standstill.

Always depress the clutch pedal to engage or disengage

a gear ratio or when operating transmission P.T.O. or

live P.T.O. (see Power Take Off in this section of the

Manual)

NOTE : Avoid resting your foot on the clutch pedal

when operating the tractor. Such action will lead to early

clutch failure.

5. Foot Controls

1. Brake pedals

2. Foot accelerator

3. Differential lock pedal

4. Clutch pedal

5. Locking latch

6

CONTROL, INSTRUMENTS AND OPERATION

TRANSMISSION

The transmission is of the constant mesh type and has

eight forward and two reverse speed ratios.

WARNING : To prevent inadvertent tractor

movement, avoid accidental contact with the

gearshift levers. Always stop the engine, firmly apply

the parking brake and place both gearshift levers in

neutral before dismounting from the tractor. A safety

switch prevent operation of the starting motor unless

the right-hand lever is in the neutral (N) position.

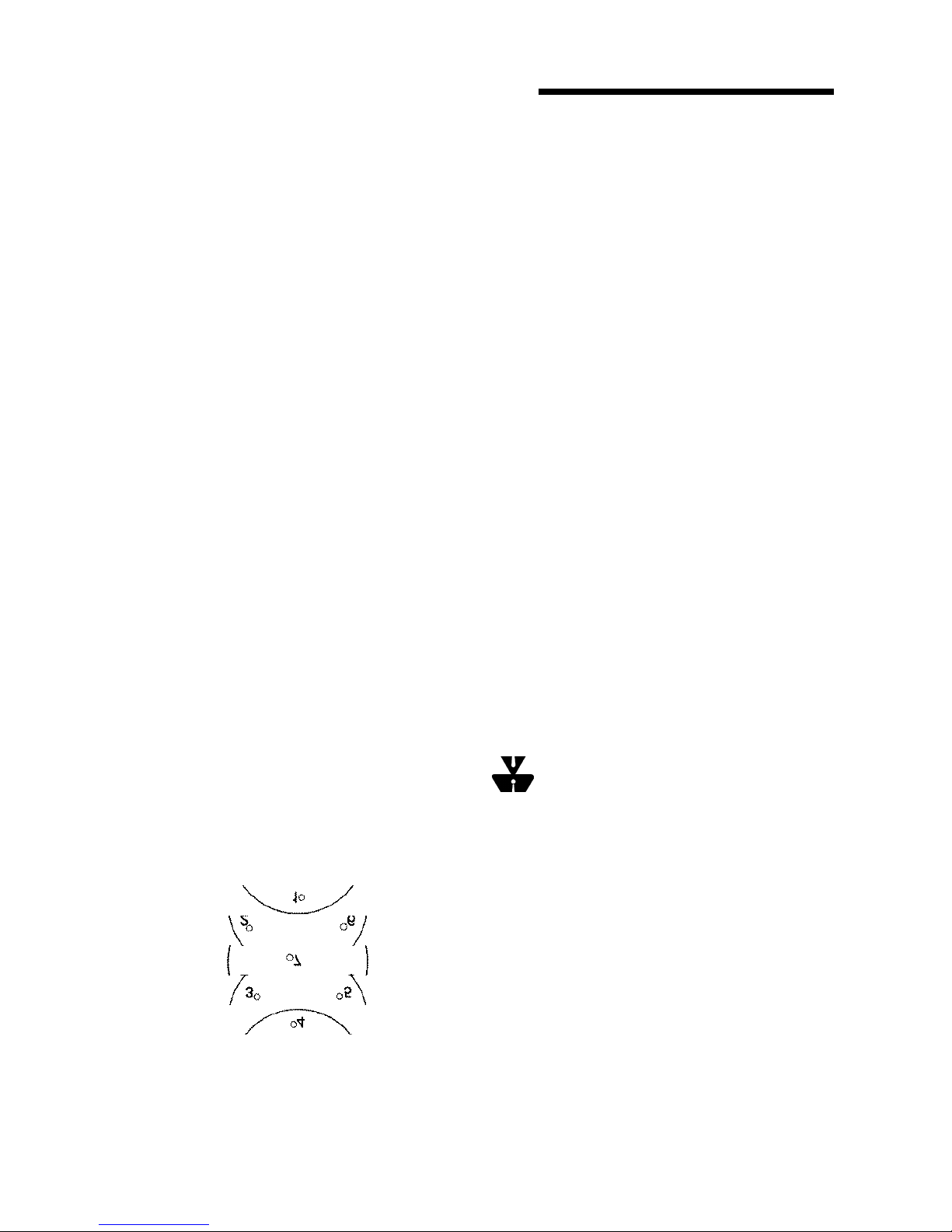

The gearshift levers protrude from the center of the

transmission, beneath the steering wheel.

The left-hand gearshift lever (main) is used to select

any one of four forward or one reverse gear ratio. The

right-hand lever (range) is used to select the high (H) or

low (L) range which has the effect of doubling the number

of available gear ratios. Stop the tractor and fully

depress the clutch before moving either of the gear

levers. See Figure 6 for the gear shift positions.

IMPORTANT : When towing the tractor, it is essential

that the transmission main (right-hand) lever is kept in

the neutral (N) position. Non compliance may result in

damage to transmission components.

Avoid overloading the engine. Operating in too high a

gear under heavy load may cause excessive engine

overloading. Overloading occurs when the engine will

not respond to a throttle increase.

Use the lower gear ratios when pulling heavy loads and

avoid continuous operation at constant engine speeds.

Operating the tractor in too low a gear with a light load

and high engine speed will waste fuel. You will save fuel

and minimize engine wear by selecting the correct gear

ratio for each particular operation.

Check the instruments frequently and keep the radiator

and various oil reservoirs filled to the recommended

levels.

POWER TAKE-OFF (P.T.O.)

The power take-off (P.T.O.) on your tractor transfers

engine power directly to mounted or trailed equipment

via a splined shaft at the rear of the tractor.

The P.T.O. shaft is a 6-spline, 1.375 in (34.9 mm)

diameter shaft designed for 540 rev/min operation, the

speed at which most P.T.O. actuated equipment are

designed to run.

To obtain 540 rev/min at the P.T.O., set the tractor engine

speed to 1600 rev/min if your tractor is equipped with

transmission P.T.O., or 1800 rev/min for live PTO models.

For most P.T.O. operations the ground speed of the tractor

is controlled by selection of the appropriate gear ratio

while maintaining the correct P.T.O. speed by using the

throttle.

Attaching P.T.O. Driven Equipment

WARNING : Before attaching, detaching or

working on P.T.O. driven equipment, the following

precautions must be taken :* Firmly apply the parking brake.

* Ensure that both gearshift levers are in neutral and

that the P.T.O. lever is in the disengaged position.

* Stop the engine.

* Ensure that the P.T.O. shaft has stopped turning.

6. Gear Shift Lever Positions

H = High Range

L = Low Range

N = Neutral

R = Reverse

SECTION A

Range lever Main gear shift lever

RUNNING-IN-PROCEDURE

Your new tractor will provide long and dependable service

if given proper care during the first 50 hours running-inperiod and if serviced at the recommended intervals.

Avoid prolonged operation at either high or low engine

speeds without a load on the engine.

7

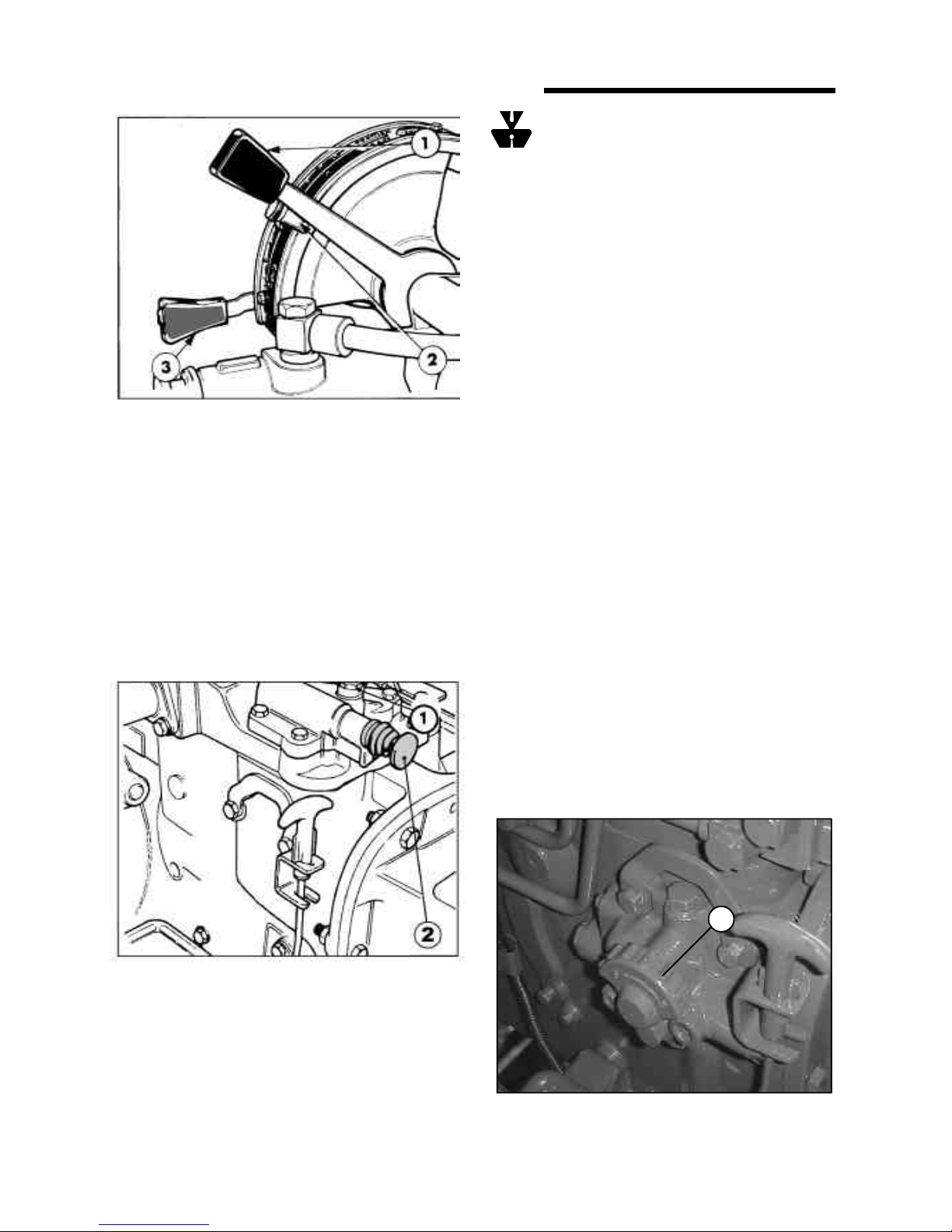

To connect P.T.O. driven equipment to the P.T.O. shaft,

remove the guard (where fitted) which is secured to the

rear axle center housing by a linch pin, as shown in

Figure 7. Unscrew and remove the P.T.O. cap and store

in the toolbox. Attach the implement to the P.T.O. shaft

and reinstall the guard.

WARNING : The guard serves as a support

for drive line shields used with Pull-type P.T.O.

driven equipment and also provides you safety.

If P.T.O. driven equipment is attached to the drawbar

then the drawbar should be set to the extended position

so that the horizontal distance between the end of the

P.T.O. shaft and the pin hole in the end of the drawbar is

at least 14.9 in (378 mm.) See figure 8.

IMPORTANT : After attaching mounted equipment

carefully raise and lower them using Position Control

Lever and check clearances and P.T.O. shaft slide range

/ articulation. When attaching trailed equipment, ensure

the drawbar is correctly set.

WARNING : Do not approach or work on the

P.T.O. shaft or equipment with the P.T.O. in

motion. Block all four wheels when carrying out

stationary P.T.O. work.

OPERATING THE P.T.O.

Transmission P.T.O. (where fitted)

To operate transmission P.T.O., start the engine, fully

depress the clutch pedal and pull the P.T.O. selector

lever, Figure 9, rearwards. Set the engine speed to 1600

rev/min. then release the clutch pedal.

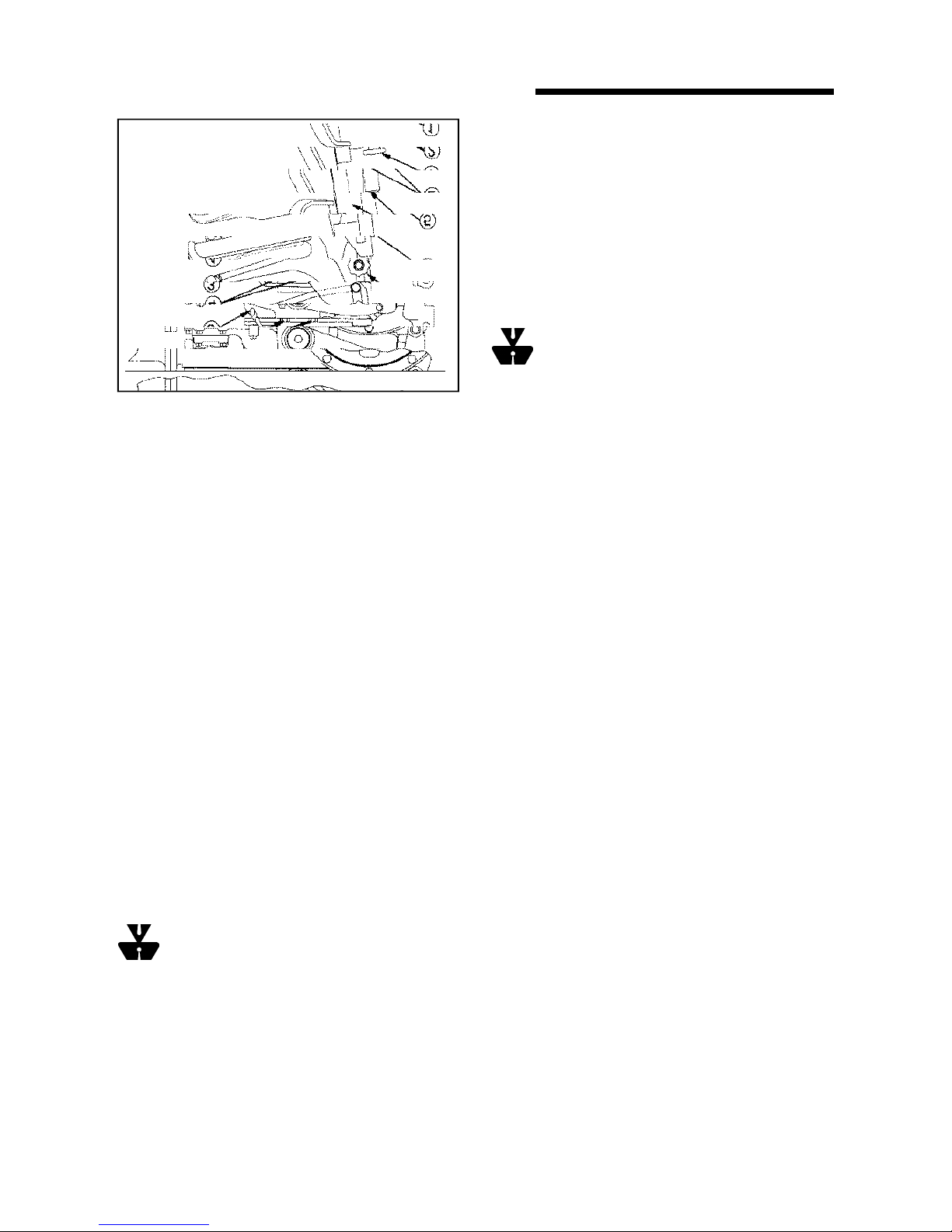

7. Power Take-Off

1. Linch pin

2. Guard

3. P.T.O. cap

8. Drawbar setting

1. P.T.O. output shaft

2. Horizontal distance - shaft to hitch pin

3. Drawbar

9. P.T.O. Selector

1. P.T.O. selector lever

Transmission P.T.O. may be engaged or disengaged

whether the tractor is moving or stationary. When

stopping the tractor, the action of depressing the clutch

pedal will stop rotation of the P.T.O. output shaft.

IMPORTANT : Always depress the clutch pedal before

engaging or dis-engaging the P.T.O. to prevent damage

to P.T.O. components.

WARNING : To avoid inadvertent movement

of the implement, disengage the P.T.O. after each

use.

Live PTO (where fitted)

Live P.T.O. operates in a similar manner to Transmission

P.T.O. except that a two stage clutch permits the tractor

to be stopped while allowing the P.T.O. shaft to continue

turning. With the clutch pedal fully depressed neither

the tractor nor the P.T.O. shaft is operable.

8

CONTROL, INSTRUMENTS AND OPERATION

To operate Live P.T.O., start the engine, fully depress

the clutch and pull the P.T.O. selector lever, Figure 9,

rearwards to engage the P.T.O.

Set the engine speed at 1800 rev/min and release the

clutch pedal to the halfway position to actuate the P.T.O.

output shaft.

With a gear selected, fully release the clutch pedal to

run the tractor.

To stop the tractor, depress the clutch pedal to the midposition and to stop the P.T.O. output shaft depress the

pedal fully.

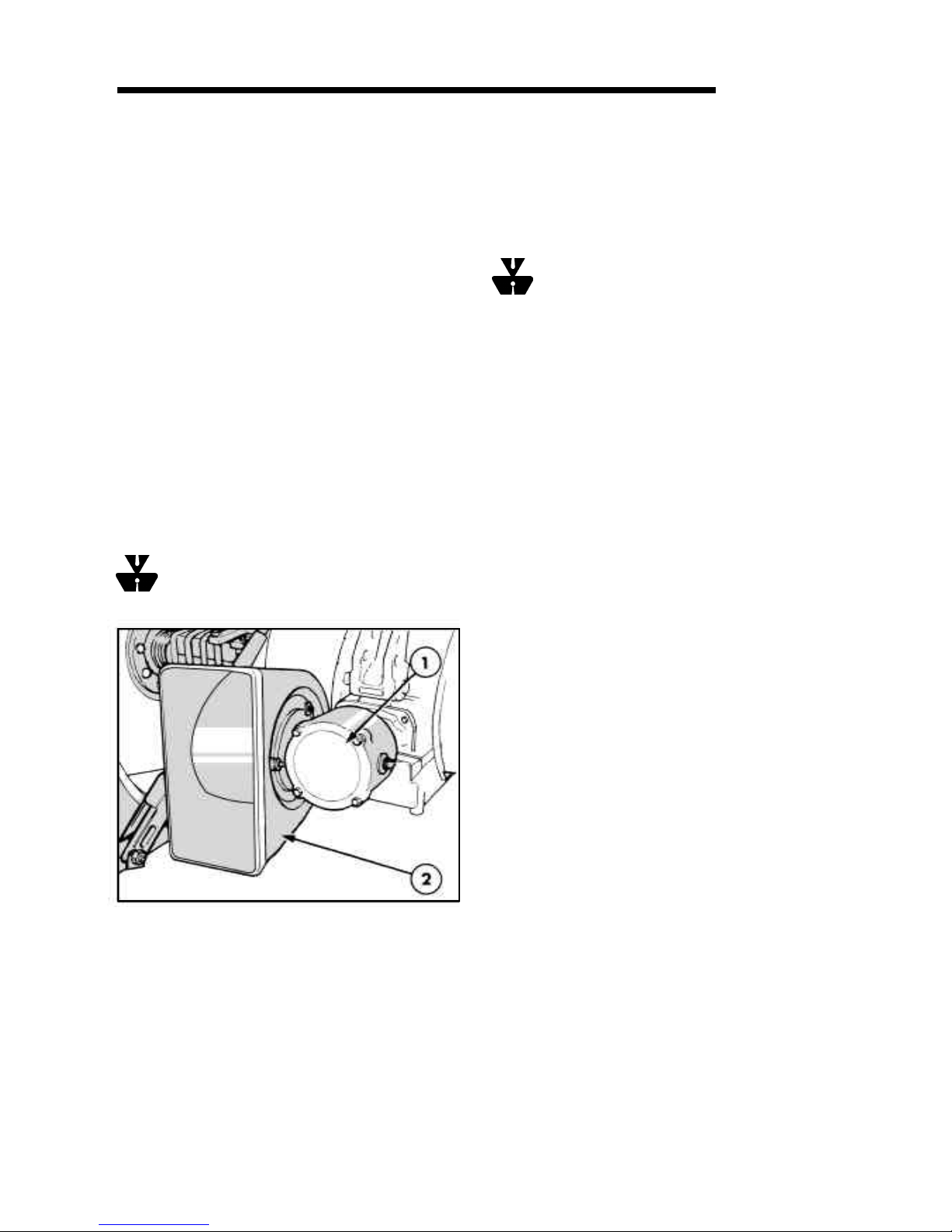

BELT PULLEY (where provided)

The belt pulley, which is driven by the P.T.O . output

shaft, should be installed as shown in Figure 10.

Prior to installation, remove the drawbar and drawbar

hanger to provide the maximum clearance for the drive

belt.

To install the belt pulley, remove the P.T.O. safety cap

and guard and the four bolts securing the check chain

brackets to the rear axle center housing. Install the belt

pulley on the P.T.O. shaft using the four bolts provided.

WARNING : To avoid injury, always use a belt

guard whenever using the belt pulley.

l Hang a chain or lean an iron bar against the tractor

to earth static electricity.

l Start the engine and engage the P.T.O. The

recommended belt speed is 3000-3200 ft/min

(15.3-16.3 m/sec). To obtain this speed set the

engine speed at 2000 rev/min.

WARNING: Never attempt to re-fit or adjust a

belt in motion. Never approach a moving belt

when wearing loose clothing. Apply the parking brake,

place both gearshift levers in neutral and block all four

wheels before operating the belt pulley.

HYDRAULIC SYSTEM

Your tractor is equipped with a hydraulic system

providing accurate and sensitive control over a wide

range of operating conditions.

Two distinct systems are incorporated

1. Upper Link Draft Control.

2. Position Control.

The type of control selected will depend on the type of

implement in use and the operating conditions.

Draft Control is most suitable for mounted

implements operating in the ground. Changes in the

working depth or soil resistance cause the draft loading

on the implement to increase or decrease. This change

in draft loading is sensed through the top link of the

three-point linkage and the hydraulic system responds

by raising or lowering the implement to restore the draft

loading. In this way a uniform draft load is maintained

on the implement. The system responds to both upper

link compression and tension loads and is, thus,

described as a double-acting system.

Position Control provides accurate and sensitive

control of implements such as sprayers, rakes, mowers,

etc., that operate above the ground. Position Control

would not normally be used with ground engaging

equipment unless it is essential to maintain a constant

depth regardless of the draft load.

The tractor has a dual lever system, i.e., separate levers

for Draft and Position Control functions. See Figure 11.

The Draft and Position Control levers are used to raise

or lower the three-point linkage (and implement) to the

required height or working depth.

To Operate the Belt Pulley

l Fully raise and secure the lower links.

l Align the tractor with the equipment to obtain full width

contact on both pulleys without the belt contacting any

other part of the tractor or equipment.

l Apply the parking brake and block all wheels to prevent

tractor movement due to vibration.

SECTION A

10. Belt Pulley

1. Belt pulley

2. Belt guard

9

WARNING: Do not transport or attach

equipment when the hydraulic system is in Draft

Control Use position Control for these operations.

Always lower hydraulic equipment to the ground before

stopping the tractor.

Draft Control Operation

Move the Draft Control Lever in the quadrant to find the

point near the center where the lift links neither raise

nor lower. This is the neutral point.

Lower the implement into work using the Draft control

Lever. Push the Lever forward to increase the draft

loading. Pull rearwards to reduce the draft loading. In

most circumstances, forward movement of the Draft

Control Lever will increase implement depth and

rearward movement will reduce the depth.

Once set, the tractor hydraulic system will automatically

adjust the implement depth to maintain an even pull on

the tractor and so reduce wheel slip to a minimum.

When lowering the implement into work push the Draft

Control Lever down to the bottom of the quadrant to

ensure positive engagement of the implement in the

ground then immediately raise the Draft Control Lever

until the required implement depth is achieved.

When the required implement working depth has been

established, set the adjustable stop adjacent to the Draft

Control Lever to locate the position for repeated use.

The Draft Control Lever may be eased sideways to

bypass the adjustable stop, if required.

A pressure sensitive feathering valve, installing within

the hydraulic system, automatically regulates the

hydraulic oil flow to give smoother response to draft

signals when using soil engaging implements. In

addition, some models have a manually operated flow

control valve fitted to regulate the rate of correction of

the hydraulic system.

CONTROL, INSTRUMENTS AND OPERATION

In order to operate the hydraulic three-point linkage the

auxiliary services control valve knob (if fitted) must be

correctly set. The auxiliary services control valve (A.S.C.

valve) directs oil to the three-point linkage, to external

cylinders or both together, as may be required.

To operate the three-point alone push the A.S.C. valve

knob fully in (rearward). See figure 12.

Pull the A.S.C. valve knob fully out (forward) to operate

external services only.

11. Hydraulic Control

1. Draft Control lever

2. Adjustable stop

3. Position Control lever

The midway position is selected to operate the three point

linkage and external cylinders simultaneously. See

OPERATING REMOTE CYLINDERS WITH THE A.S.C.

VALVE in this section of the manual.

10

12. A.S.C. Valve (where fitted)

1. A.S.C. tapping

2. A.S.C. valve knob

13. Flow Control Valve

1. Flow control valve rocker

1

Tilt the Flow Control Valve Rocker, Figure 13, rearward

for the maximum rate of correction and forward for the

minimum correction rate. The rate of oil flow (correction)

of the hydraulic system is infinitely variable between

these two points.

Pull the Draft Control Lever to the top of the quadrant to

override the Flow Control Valve and raise the implement

quickly.

NOTE: When operating in Draft Control, the Position

Control Lever, Figure 11, should normally be at the

bottom of the quadrant. However, the Position Control

Lever may be used in conjunction with Draft Control to

limit the maximum depth of correction to achieve a more

even depth of cultivation in fields with widely varying

soil conditions.

When grading and backfilling with light equipment, such

as a rear blade, it may be desirable to prevent the blade

from “diving”. This is accomplished by using the Position

Control Lever in conjunction with the Draft Control Lever.

See “Draft Control Operation with Position Control” on

this page.

Position Control Operation

Set the required implement height/depth using the

Position Control Lever, Figure 11. Pull the Lever Back

to raise the implement height/depth using the Position

Control Lever. Pull the lever back to raise the implement,

push forward to lower. Implement height/depth is relative

to the position of the Lever in the quadrant.

When the required implement working height/depth has

been established, set the adjustable stop adjacent to

the Position Control Lever to locate the position for

repeated use. The Lever may be eased sideways when

it is required to by pass the adjustable stop.

The adjustable stop is reversible after loosening the

central clamp screw so that it may also be used when

operating in Draft Control.

When operating in Position Control it is of no advantage

to restrict the oil flow in the hydraulic system. However,

the manual flow control valve (where fitted) may be used

to reduce the rate of lift of the three-point linkage, if

required. To reduce the rate of lift, tilt the Flow Control

Valve Rocker, Figure 13, forward. Tilt the Rocker rearward

to increase the rate of lift.

IMPORTANT : When transporting equipment on the

three-point linkage set the adjustable stop to maintain

the Position Control Lever in the raised position. This

will prevent accidental movement of the lever which

could result in attached equipment lowering and

becoming damaged or damaging the road surface.

Draft Control operation with Position Control

Position Control may be used together with the Draft

Control as follows:

Set the Position Control Lever at the maximum desired

implement depth. The hydraulic system will not lower

the implement below this depth. This will also prevent

“diving” which may be encountered will light equipment,

such as a rear blade, when grading or backfilling.

Adjust the Draft Control Lever for the maximum required

draft load (pull).

The hydraulic lift system will now provide normal draft

response within the range set by the Position Control.

This adjustment provides a more uniform depth while

maintaining an even pull in widely varying soil

conditions.

AUXILIARY SERVICES

Accessory Cover (Where fitted)

The live tapping on top of the accessory cover (where

fitted), Figure 14, is connected directly into the tractor

hydraulic circuit. A remote cylinder connected to the

live tapping may be extended or retracted, in conjunction

with the three-point linkage, by moving the Draft Control

Lever.

SECTION A

11

Operating Remote Cylinders with the A.S.C.

Valve (where fitted)

The optional Auxiliary Services Control (A.S.C.) Valve

is installed in place of the accessory cover or remote

control valves and may be supplied with pipe work

leading to a convenient coupling at the rear of the tractor.

Alternatively, remote cylinders may be connected

directly into the tapping on top of the A.S.C. valve. See

Figure 15.

14. Accessory Cover

1. Live tapping

Loading...

Loading...