Esco Medicon Gas Manifold Maintenance manual

Document Number: Issue Status: Date:

Z03G010 I

24/Oct/07

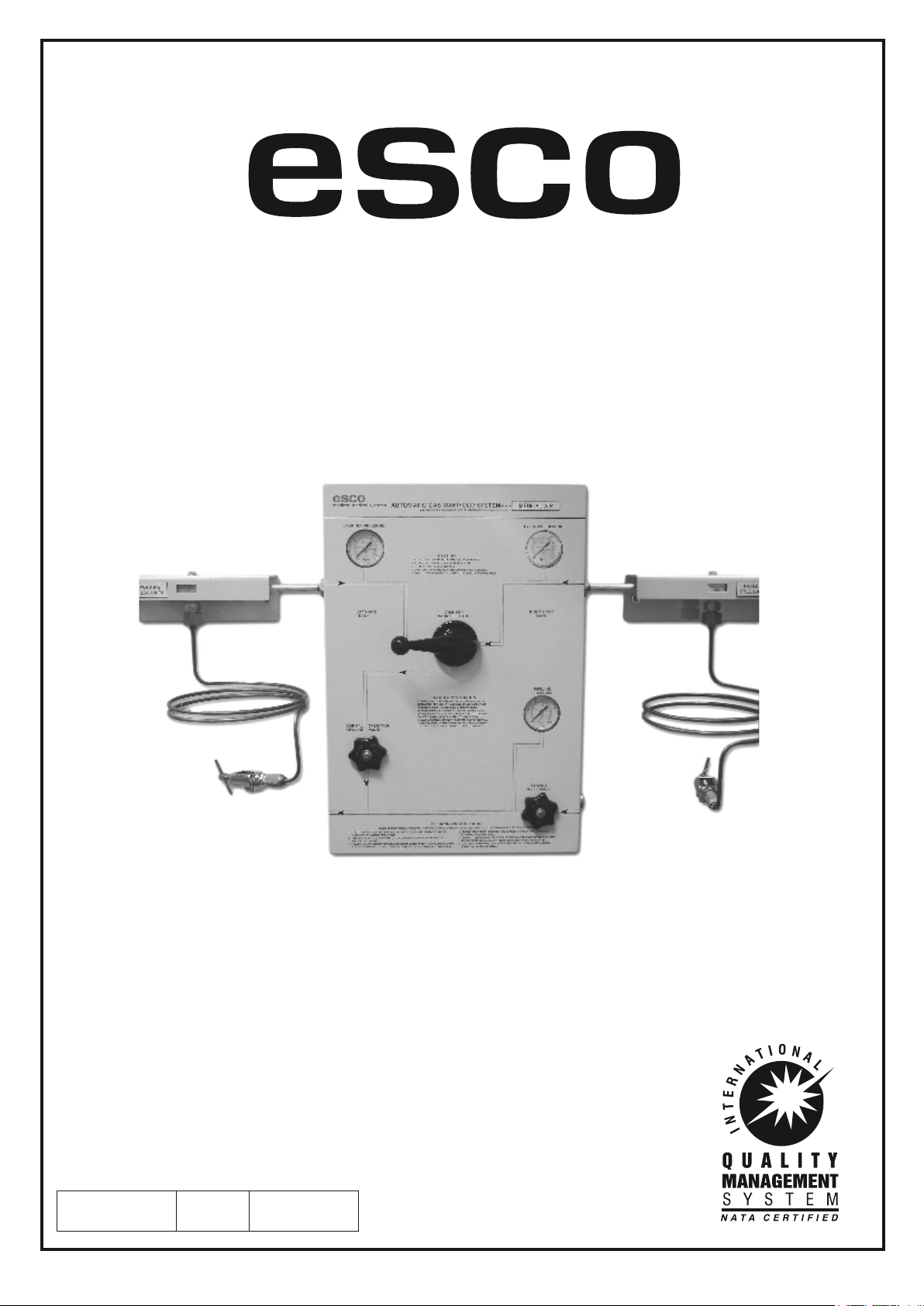

AUTOMATIC GAS MANIFOLDS

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

ALL ESCO AUTOMATIC GAS MANIFOLDS COMPLY WITH THE

OPERATIONAL & SAFETY REQUIREMENTS OF AUSTRALIAN

STANDARD AS2896-1998

m e d i c o n

INDEX

1.

2.

3.

4.

5.

6.

7.

INTRODUCTION 3

Page

Page 2 of 20

SPECIFICATIONS 3

INSTALLATION 4

OPERATION 5

SERVICE 6

SPARE PARTS 9

SETTING INSTRUCTIONS 10

AUTOMATIC GAS MANIFOLDS

m e d i c o n m e d i c o n m e d i c o n m e d i c o n

1. Introduction

2. Specifications

MAXIMUM INLET (Cylinder) PRESSURE

OUTLET (Line) PRESSURES

OUTLET CONNECTION

EMERGENCY INLET CONNECTION

HEADER BLOCK CONNECTIONS

Esco Automatic Gas Manifold (AGM) systems are designed to

supply hospital facilities with Oxygen, Nitrous Oxide, Medical Air and

Surgical Tool Air, meeting the requirements of AS2896.

The concept consists of a central control panel with regulators,

changeover mechanism, pressure switches, gauges, shut off valves and

service inlet facility, all mounted and piped on one easily installed base

plate. A screen printed cover illustrating the operation is fitted over the

assembly.

After factory assembly, the regulators, pressure switches and

relief valves are set and tested prior to despatch as per setting

instructions in this manual. No adjustments should be necessary after

installation, however, if for some reason the AGM is not performing as

per specification, please contact ESCO Industries on (02) 8799 3700.

(a)

(b) Surgical Tool Air 750 & 1,450KPa

Male 5/8” SAE Flare

Sleeve Index,

Nitrous Oxide M16 x 1.5

Oxygen M18 x 1.5

Air M20 x 1.5

Surgical Tool Air M20 x 1.5

Gas specific as per AS2896 Terminal Units

Oxygen, Medical Air & Nitrous Oxide 450KPa

23,000KPa

Page 3 of 20

AUTOMATIC GAS MANIFOLDS

3-Installation

1.

2.

3.

1.

The cylinder size chosen will determine the mounting height of the

manifold control panel. “G” size cylinders are normally used,

however, we suggest you check before commencing installation.

If “G” size cylinders are to be used, mark the wall at 1800mm

above the finished floor level. Temporarily connect a cylinder lead

and header block assembly together. Position the header block

with bracket fixing holes over the 1800mm mark and confirm

cylinder connection height (1460mm) is correct to drawing

32267. Cylinder Lead assemblies are designed to flex vertically

approximately 50mm, accounting for slight variations in cylinders.

If correct, remove screen printed cover from the central control

panel by removing:

Pipeline Connection:

Then proceed and fix the base plate to wall (M6 Dynabolts) to

drawing 32267, spot drilling through slots & holes.

Header Blocks and brackets are supplied assembled, however, you

must attach these to the central control panel high pressure

blocks (right and left hand) using two header block connection

tube assemblies (Z02J008) - refer to drawing 32289. This will

position the header block brackets correctly on either side of the

central control panel. Lastly, position and fix cylinder racks as per

drawing 32267.

The pipeline is connected to the central control panel at the

bottom left hand corner via the 5/8” SAE flare tee fitting. The

5/8” Dia. Copper pipeline may exit the unit either horizontally (as

supplied) or vertically, simply by rotating the tee fitting through

900 clockwise. A 5/8” SAE flare to 3/4” diameter outlet bend

assembly (Item 59 Dwg 32503) is supplied allowing initial pipework

connection with 3/4” copper tube.

a)

b)

c)

Black selector lever.

Two black valve hand wheels.

Two M5 button head screws at bottom.

Page 4 of 20

AUTOMATIC GAS MANIFOLDS

4. Operation

High pressure gas (up to 230 bar) is supplied from both banks of

cylinders into the manifold as indicated by the two pressure gauges in

the top right and left hand corners of the panel.

The “Cylinder Bank Selector” in the centre of the panel determines

which bank of cylinders, left or right hand, is the primary bank and which

is the secondary. The primary bank will always be the one feeding the

system until such time as the pressure in these cylinders drops below;

700KPa (4 Bar) - Oxygen, Air & Nitrous Oxide, or

1200KPa (7 Bar) - Surgical Tool Air, or

1600KPa (14 Bar) - Surgical Tool Air,

at which time the secondary bank will automatically take over and

continue to feed the system. (At this point the pressure switch in the

top left hand corner will open, signalling any remote monitor that empty

cylinders require changing).

In the normal course of operation, the “Primary Bank” designation

will alternate back and forth between left and right banks, if the

operating instructions printed on the front panel are followed.

Safety Precautions:

A shuttle valve is built into the tee just before the low pressure

regulator, to ensure back pressure does not affect the high pressure

regulators during operation. As one regulator is in use, the valve

shuts off the opposite regulator from the feed back.

In addition, two pressure relief valves, in parallel, monitor the line

pressure to ensure a regulator malfunction does not over-pressure the

hospital pipeline system. These relief valves can be removed (cover

removal necessary) one at a time for testing, if required. A self sealing

valve will prevent loss of gas during removal.

Low Pressure Alarm:

The pressure switch on the top right hand side of the central

control panel is set to operate at a pressure approx. 25% lower than the

set pipeline pressure and in turn will signal any remotely connected

alarm panel.

Page 5 of 20

AUTOMATIC GAS MANIFOLDS

5. Service

1. 2.Every six (6) months the manifold system should be inspected /

tested for leaks and malfunctions as follows:

For high usage manifolds, we suggest that all three (3) regulators

be serviced on a twelve (12) monthly basis. Other manifold service

intervals can be extended to suit use. As diaphragm and seat

replacement require special tools and test equipment, it is

recommended that for service, the entire three regulator unit be

removed as a whole and replaced with a changeover unit available

from ESCO Industries. (You are invoiced for the exchange unit and

credited upon receipt of your used unit).

The part numbers for exchange regulator sets are as follows:

As a guide, usage rates can be qualified as follows:

a) AGM3RS-O-A-NO Automatic Gas Manifold Three Regulator Set - Oxygen, Air or Nitrous Oxide (4 Bar)

b) AGM3RS-ST Automatic Gas Manifold Three Regulator Set - Surgical Tool Air (14 Bar)

Up to 4 “G” size cylinders per week.

From 4 to 20 “G” size cylinders per week.

More than 20 “G” size cylinders per week.

a) Low Usage:

b) Medium Usage:

c) High Usage:

Please phone Esco Industries for other outlet pressures and for

current changeover prices on (02) 8799 3700.

a)

b)

c)

d)

e)

Test regulators for external leaks and correct pressure

reduction.

Test all pipe connections for leaks.

Test the system failure pressure switch (right hand switch)

for correct setting and operation.

Test non return valves in header block nipples for proper

closure. Note: these valves do not seal completely.

Inspect cylinder extension leads for flexibility, metal fatigue

and thread damage at cylinder connections. Note: any

damaged leads should be replaced immediately.

Page 6 of 20

AUTOMATIC GAS MANIFOLDS

m e d i c o n m e d i c o n m e d i c o n m e d i c o n m e d i c o n

Loading...

Loading...