Esco ES-30 User Manual

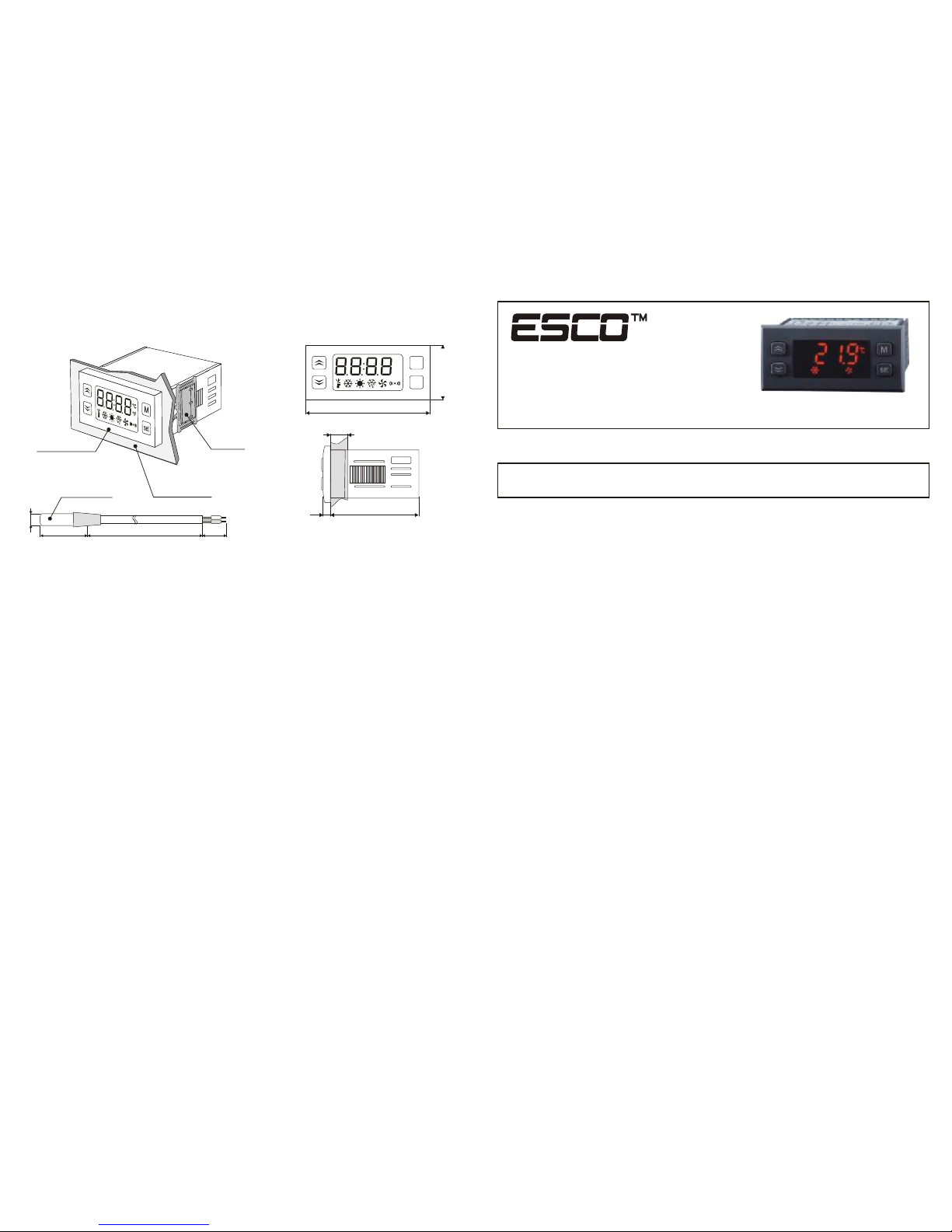

8. MOUNTING.

Controller should be placed in the panel in hole sized 71x29mm and fasten with mounting

terminals.

Mounting

terminals

Ip65

protection class

Panel surface

(maximum thickness

20mm)

9. INSTALLATION.

Controller meets the requirements for immunity to electromagnetic interference in an

industrial environment according to the following standards:

Electromagnetic compatibility (EMC):

–EN-61000 part 6-4 – requirements for emissivity in an industrial environment

–EN-61000 part 6-2 – requirements for immunity in an industrial environment

It also meets the safety requirements according to standard:

°C

°F

72

max 20

4,5

76

35

M

set

Controller meets the requirements for immunity to electromagnetic interference in an

industrial environment according to the following standards:

Electromagnetic compatibility (EMC):

–EN-61000 part 6-4 – requirements for emissivity in an industrial environment

–EN-61000 part 6-2 – requirements for immunity in an industrial environment

It also meets the safety requirements according to standard:

–EN-61000 part 1 – safety requirements for eletrical devices

Controller meets the requirements of EU directives No. 72/23/EEC; 93/68/EEC; 89/336EEC.

10. ADMISSIONS.

Ip67 protection

class

6

2000 2050

ES-30

COOLING CONTROLLER

Version 2.0

USER MANUAL / WARRANTY

1. SPECIFICATIONS

Input:

Sampling period:

330 ms

230V~ ±15% or 12V=/~, max 3VA

Operation conditions: -5...60°C; 0...85%RH (non-condensing)

Storage conditions: -40...85°C; 0...85%RH (non-condensing)

Power supply:

2 temperature sensors: NTC 5k by 25°C

bistate input (normally opened or normally closed)

Measuring accuracy: ±0,5%

Resolution: 0,1°C in whole range

Control form:

ON-OFF with hysteresis

Display:

LED, 4 digits, 11mm height with graphic icons

Degree and protection class:

IP65 / II

Measuring range: -50...+150°C

Attention! The total current charged by the device can not exceed 12A.

2. OUTPUTS CARRYING CAPACITY

3. FRONT PANEL.

°C

°F

M

set

Temperature setting signalling

Compressor operation signalling. LIGHTS: compressor operates; BLINKS: waits for start-up (see F21)

Heating output signalling. LIGHTS: output active; BLINKS: waits for start-up (see F21)

Defrosting signalling. LIGHTS: automatic defrosting mode ; BLINKS: manual defrosting

Fans operation signalling. LIGHTS: fans operate

Emergency states signalling. BLINKS: alarm active

Temperature/time display

Temperature unit indicator

Entry to the parameters menu

Temperature setting button

by pressing you can displat current time

Value increasing button

pressinf fro more than 5 sec. Forces heating/cooling

Value decreasing button

holding it you can display evaporator temperature

pressing for more than 5 sec. forces defrosting cycle

5.5. REAL TIME CLOCK (RTC).

Controller has a built-in real time clock due to defrosting function can be carried out at specified

hours during the day (maximally 6 cycles per day). The clock can be set in F60 parameter or in

normal operation mode.

Press button

Display indicates

Current time.

Using:

or

button set the hour and

Confirm with

set

set

set

set

°C

M

set

Zatwierdź nastawę

przyciskiem

set

Press button for 3 sec

to enter the time setting

mode.

Hours block starts to

flash.

Using:

or

Set the minute and

confirm with

Minutes block starts to

Flash.

M

M

set

set

M

set

M

Remarks:

Press button in any time to cancel the setting.

Clock setting in case of controller power failure can be maintained for minimum 3 days.

6. ALARM MESSAGES.

6

When alarm activates the indicator starts blinking and the sound signaller (beep) will be

activated (when F83=1). According to the occurence controller turns on/off output and the front

panel displays one of the following alarm messages:

Statement Occurence

A11 bistate input activation.

A21 chamber sensor error:

OPE - open circuit

SHr - short circuit

A22 Evaporator sensor error

A99 Timer setting ime elapsed

Outputs signalling

All outputs inactive

Compressor output operates in accordance

with F22 and F23 parameters, other outputs

inactive

All outputs inactive

All outputs inactive

ES-30

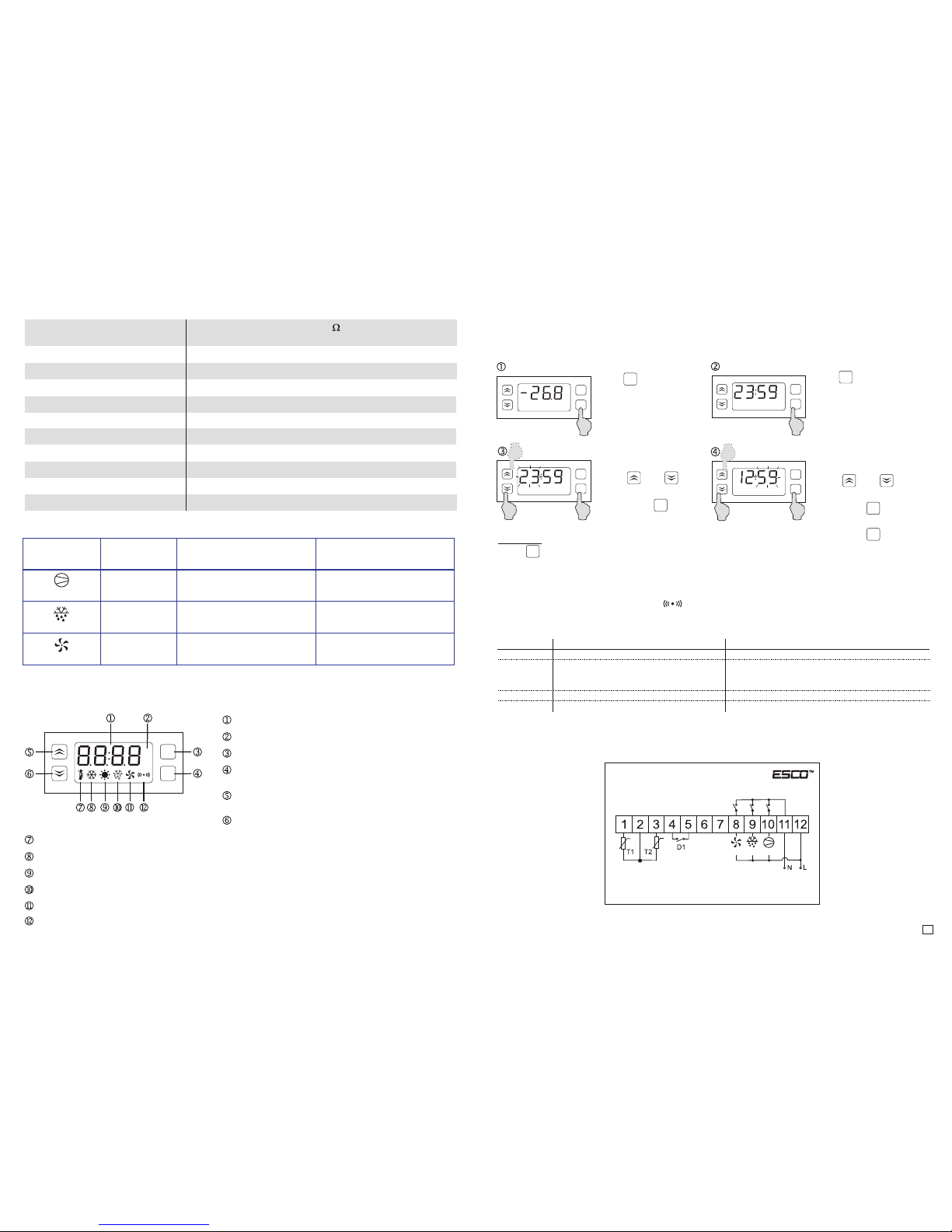

7. WIRING DIAGRAM.

T1 - chamber sensor

T2 - evaporator sensor

D1 - bistate input

Power supply

230V~

8(2)A

8A 250V~

5

10 cycles

Input: Relay:

Maximum resistive charge

(e.g. Heater):

Maximum inductive

charge (e.g. Engine):

Compressor

Defrosting

Fan

8A 250V~

5

10 cycles

8A 250V~

5

10 cycles

8A, 1500W

8A, 1500W

8A, 1500W

2A, 400W, 0.5HP(0.5KM)

2A, 400W, 0.5HP(0.5KM)

2A, 400W, 0.5HP(0.5KM)

Fan

Defrost.

Compressor

Loading...

Loading...