Esco Aeris Series, Aeris-BG384, Aeris-BG086, Aeris-BG4830, Aeris-BG4076 Service Manual

Thank you for purchasing the Esco Aeris Thermal Cycler.

Please read this manual thoroughly to familiarize yourself with

the many unique features and exciting innovations we have

built into cycler. You can view this manual online at

www.escoglobal.com, where you can find many other

resources to help you enjoy many years of productive and

safe use of your Esco equipment.

Service Manual

Thermal Cycler

Version 1.0 Publication Time August, 2009Copyright © 2013 Esco Micro Pte.Ltd. All rights reserved.

Aeris

Chapter 1. Introduction

1.1 Products covered

This manual is applicable and specific to the following ESCO products:-

Aeris Thermal Cycler Aeris-MB with following blocks

Rated voltage (V) 96 wells

100-240V, AC,

50/60Hz

1.2 Basic product information

1.2.1 QUICK VIEW

gradient

block

AERISBG096

30 x 0.5ml +

48 x 0.2ml

mix block

AERISB4830

384 wells

gradient

block

AERISBG384

48 x 0.2ml x2

dual block

AERISBD048

4 In Situ

Slides

AERISB4076

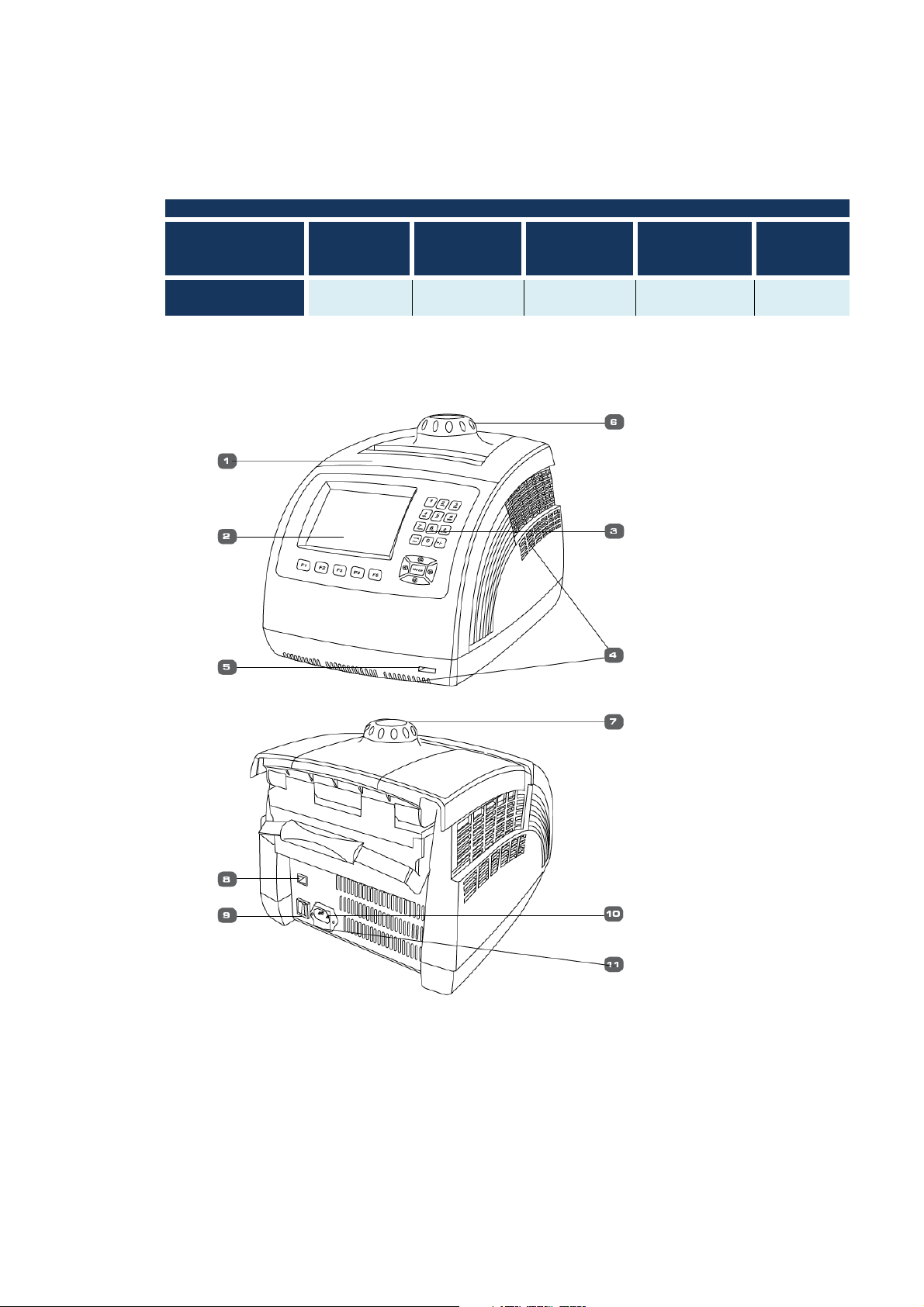

No. Name Description Note

1 Block

2 LCD Screen

3 Keyboard For setting and controlling.

4 Ventilation vent

5 USB interface

6 Hot lid knob Adjust the height of the Knob

7 Unlocking Device Loose the hot lid knob

8 RJ45 interface For PC control and software - Up to 30 Aeris thermal

With hot lid, heat sink and heating&

cooling system.

Display protocol, conditions and

other information during setting and

running.

Blow heat air out through

ventilation vent.

Data transfer between USB and

equipment through USB interface

Five interchangeable blocks

are available for different

requirements.

6.5'' Color LCD Touch Screen

-Don’t block off ventilation

vent

-

Turn the knob counterclockwise before closing the

lid. Note that the knob can be

tightened by turning it

clockwise, and can be

loosened by turning counterclockwise.

If hear click sound at the

beginning of turning the knob

clockwise and counter

clockwise, press the

unlocking device and turn the

knob counter-clockwise for

two rounds to loose the knob

4

upgrades cyclers can be connected and

9 Power Switch Turn the equipment ON/OFF. 10 Power Socket Connect power supply. -

11 Fuse Socket

Install fuse in the socket to protect

equipment from over-current.

1.2.2 Installing your instrument

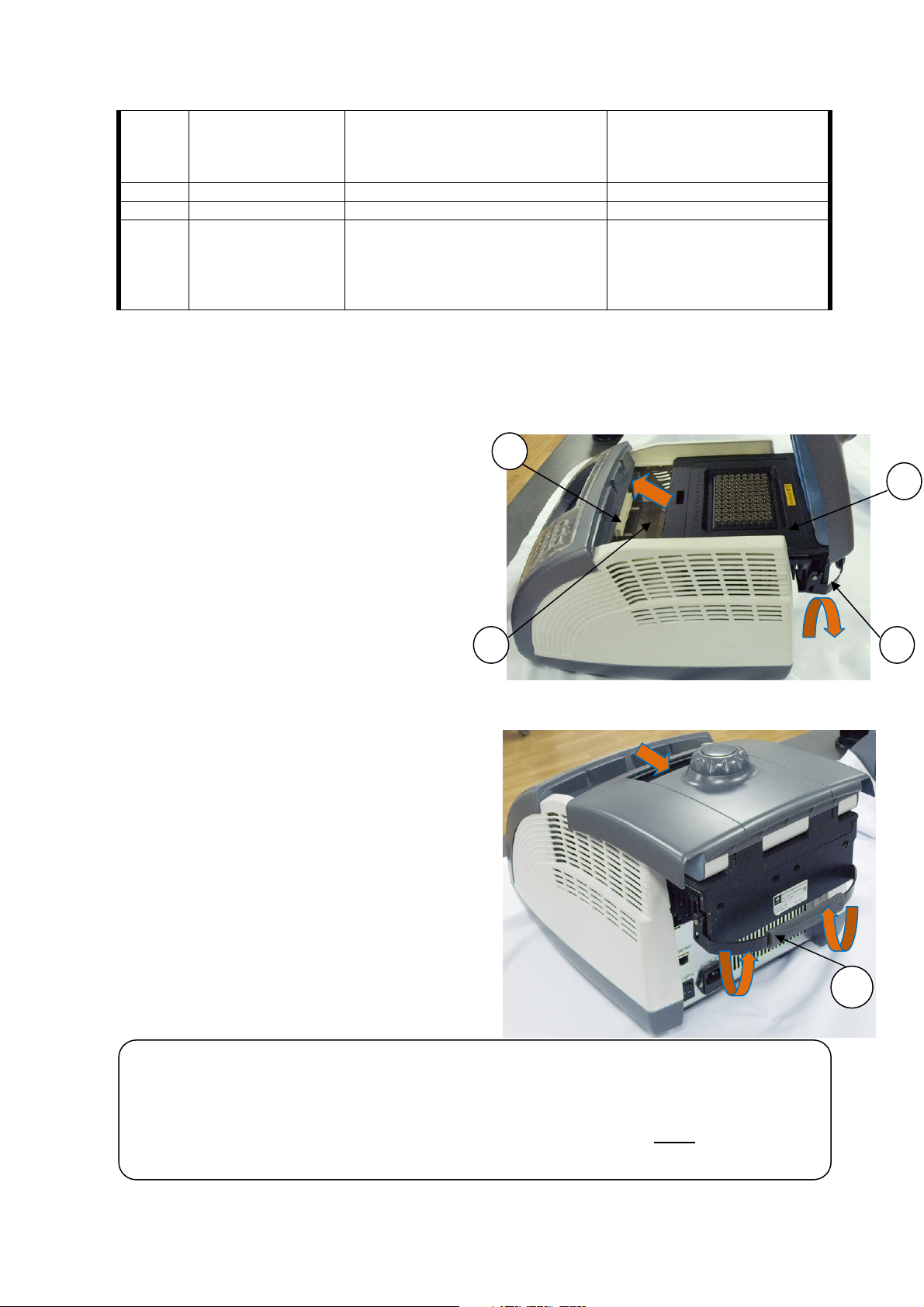

Install and Remove the block as follows:

1.2.2.1 Installation:

• Place the block (1) into the housing well (2) and

push it slowly forwards until a connection between

the block socket and the main unit’s connection

plug (3) is achieved.

• Press the locking handle (4) downwards, the block

will move forward automatically until you hear the

click sound, which means the block is installed

successfully.

• Do not force!

1.2.2.2 Removing the Block

• Turn off the power supply.

• Uplift the locking handle (4), the block will move

backward a bit.

• Pull the locking handle to move block gently

towards the rear of the main body.

• Remove the block from the main body.

Note: • Turn off the power supply before installing block.

• When installing the block, pay close attention to pushing the block slowly and gently ; or the

main unit’s connecting plug may be damaged.

• When uninstalling the block, please pull the block from the block bath gently. Do not tilt the

block or the connection plug may break.

controlled by normal

computer through RJ45

interface.

The fuse specifications are as

follows: 250V 8A, 5×20. Fuse

should be replaced by one

that complies with these

specifications.

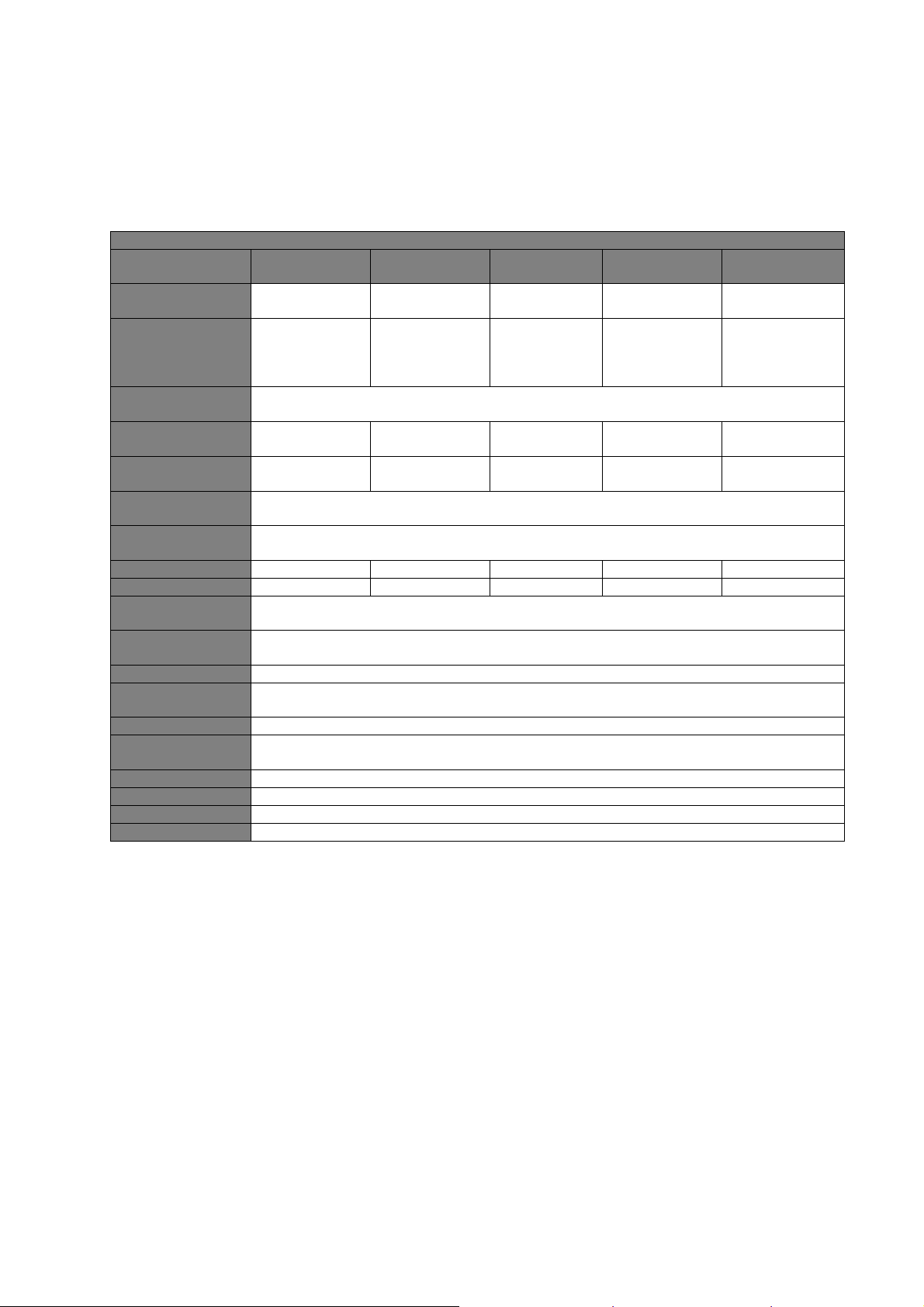

General Specifications, Aeris Thermal Cycler

Block Code

AERIS

-

BG086

AERIS

-

B4830

AERIS

-

AERIS

-

BG384

AERIS

-

B4076

Sample Capacity

Temperature

Max. Heating

Max. Cooling

Temperature

Temperature

Max. Gradient

Min. Gradient

Hot Lid Temp.

Temp. Control

Display

Instrument

PC Interface

Dimensions

Weight (kg)

Power Supply

Fuse

Warranty

1.2.3 Technical specification summary table

48 × 0.2ml + 30

0.2 ml tubes

0.5 ml tubes

4 x 12 strips

Applied

Consumables

Range

96 × 0.2ml

0.2ml tubes

96 micro plate

12 x 8 strips

8 x 12 strips

× 0.5ml

BG384

384 wells

384 micro

plate

4ºC ~ 105ºC

48 × 0.2ml + 48

× 0.2ml

0.2ml tubes

6 x 8 strips

4 slides

4 slides in situ

plate

Uniformity

Accuracy

range

Mode

Memory

(W x D x H)

Rate

Rate

4.0ºC / sec 2.8ºC / sec 2.8ºC / sec 4.0ºC / sec 1.8ºC / sec

4.0ºC / sec 2.8ºC / sec 2.8ºC / sec 4.0ºC / sec 1.8ºC / sec

≤0.2ºC

≤0.1ºC below 50 ºC

30ºC - 30ºC - -

1ºC - 1ºC - -

30ºC ~ 110ºC

Block mode or Tube mode

6.5” Color LCD Touch Screen

Up to 250 programs, unlimited with USB flash drive

RJ45 & USB port

306mm x 386mm x 295mm (WxLxH)

10

100-240 V / 50-60 Hz 600W

250V 8A ø5 × 20

3 years on main body, 2 years on blocks

1.3 Security Notes

i. Turn the power OFF and unplug the power cord before performing any procedure.

ii. Please read all the instructions thoroughly before maintenance. Always follow this

service manual. Keep this service manual well for future reference and review it as

necessary.

iii. Engineers must inspect and ensure operation of the equipment is completely back to

normal after maintenance.

1.4 Guidance

Pay attention on the following before hand.

i. Investigate :-

Situation of the equipment as operating

Previous maintenance record

Symptom of the failure

Hardware environment

Structure of the equipment

Years of the equipment be used

ii. Check power supply.

iii. Check installation of the equipment.

iv. Clean internal of the equipment to eliminate failures caused by dust, dirt, redundant

solder, welding oil.

v. Read all the instructions thoroughly before maintenance to ensure full understanding.

1.5 Maintenance tools

• Wire-stripping pliers, wire stripper

• Torque screwdriver Φ3

• Word screwdriver Φ2

• Cross screwdriver Φ3

• Sharp nose pliers, diagonal cutting nippers

• Pen knife

• Tweezers

• Multimeter

Besides, a multi-channel temperature acquisition device is needed for temperature uniformity and

accuracy testing.

Chapter 2 Service Procedures

2.1 Assemble and disassemble the main body

2.1.1 Assemble procedure

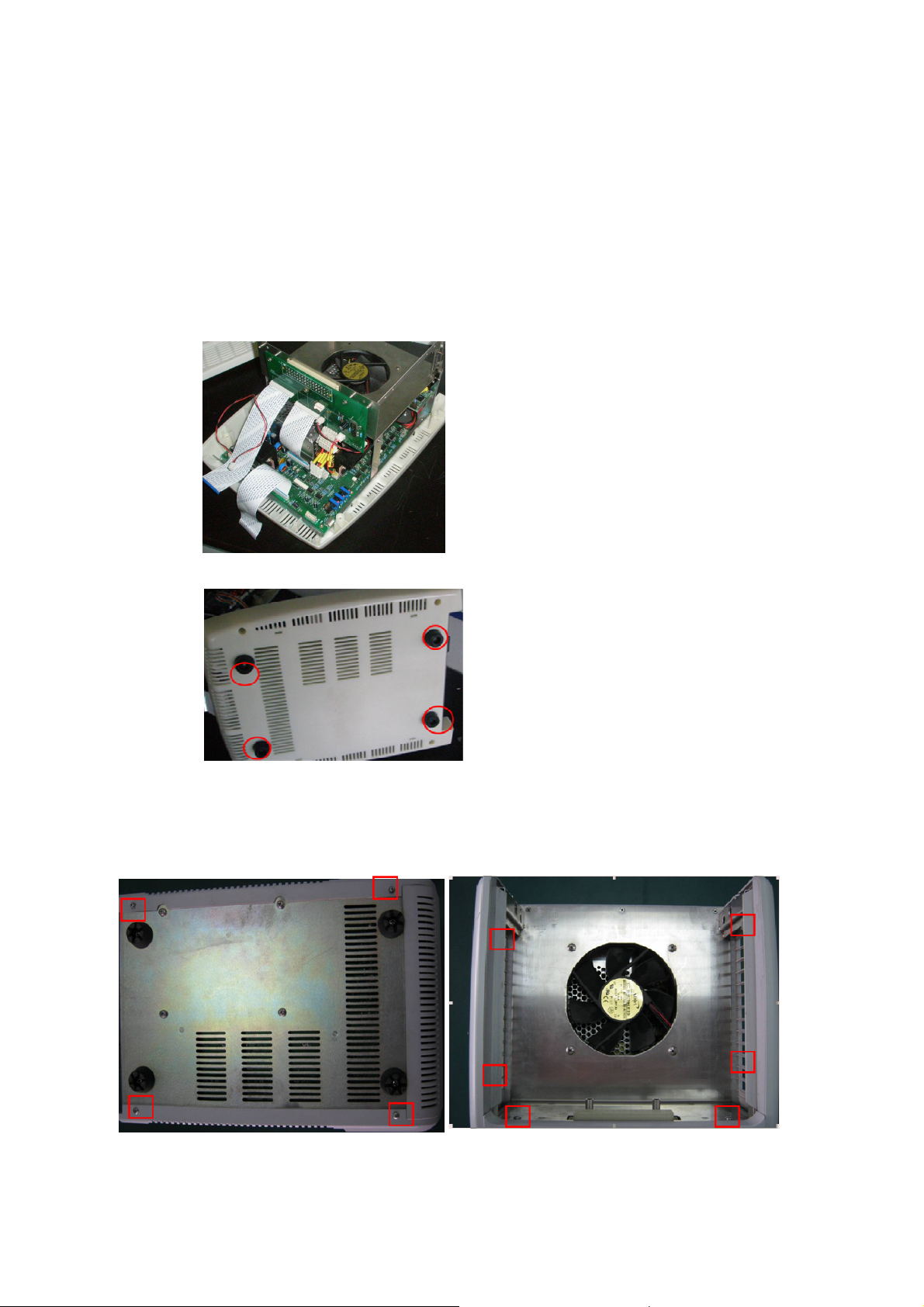

• Assemble the PCB board, power supply and fan with the stainless steel stand.

Put the whole part in the bottom casing and make sure the part is fastened by the

buckle of the bottom casing. Refer to Fig. 1

• Tighten the four screws to fix the rubber feet with bottom casing. Refer to Fig. 2

2.1.2 Disassemble procedure

• Remove the screws as showed in the red square. Take down the left and right

board. Refer to Fig 3, and then you can see the whole main body structure

without the cover(Fig 4)

Fig. 1

Fig 2

Fig 3

Fig 4

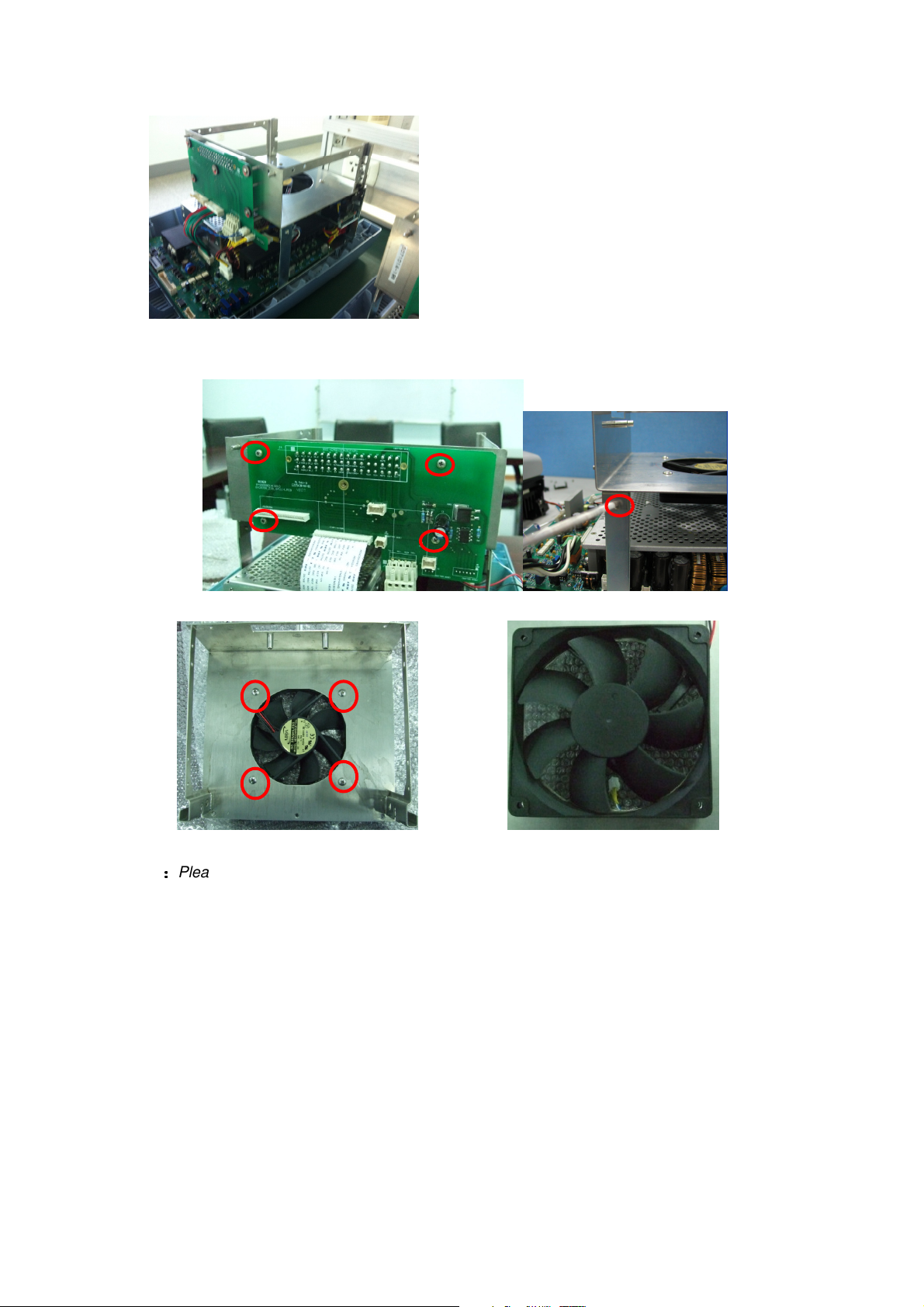

• Unplug all the connectors. Remove the screws in the interface (connector) board.

As Fig.4 and 5

• Remove the screws as Fig 5, and take out the old fan and replace a new fan

Fig 5 Fig 6

Notes

::::

Please note the air flow direction of the fan and the polarity of the connection wire when

replacing the fans. Please mark them to avoid forgetting the correct sequence and make sure the

connection is secure.

2.2 LCD Replacement

Remove the front cover and see the CPU control board as Fig.7

LCD contrast

adjustable screw

Fig.7

Note: A small brass screw on the resistor. Rotating the knob clockwise will brighten the display.

Rotating the knob anti-clockwise will darken the display.

Remove the screws as Fig.8, and then remove the CPU control board.

Fig.8

Remove the screws and get the LCD and LCD control board which are combined into

one part. As Fig.9 and Fig.10

Fig.9 Fig. 10

2.3 Key Pad replacement

Remove the screws as Fig.8 above, and then remove all screws as Fig. 11.

Loading...

Loading...