Esco 10439 Operating Instructions & Parts Manual

Air Actuated

Hydraulic Jacks

Operating Instructions & Parts Manual

Model 10439

Capacity 44 Ton

Save these instructions. For your safety and the safety of others around you, read carefully before attempting

to assemble, service or use your jack. Observe all safety and warning information. Always wear safety glasses

when operating this product. Failure to comply with the information contained within could result in severe, even

fatal injury and/or property damage.

PRODUCT DESCRIPTION

ESCO Air Actuated Hydraulic Bottle Jack is designed for lifting, but not sustaining, load ranging up to 44 tons

(10434). It can be used vertically or angled to 5 degrees from vertical position. After lifting, loads must be

immediately supported by appropriate means. This model(10434) is equipped with a 3-position handle lock to

aid in proper saddle/lift point alignment. To further aid positioning, 10434 is equipped with large rubber, pivot

wheels. This jack is not recommended for use in lifting or positioning houses and/or other building structures.

This jack comply with applicable ASME / ANSI Standards. Ensure that your air source can dedicate 7.8 CFM @

120 - 200 PSI to each jack operated. To ensure dependable, troublefree operation an air dryer and oiler is

recommended.

SPECIFICATIONS

Model

10439 44 Ton 23" x 14 1/2" 9 ¼” 16 ¼”

Capacity Jack Size( L x W) Min. Height Max. Height

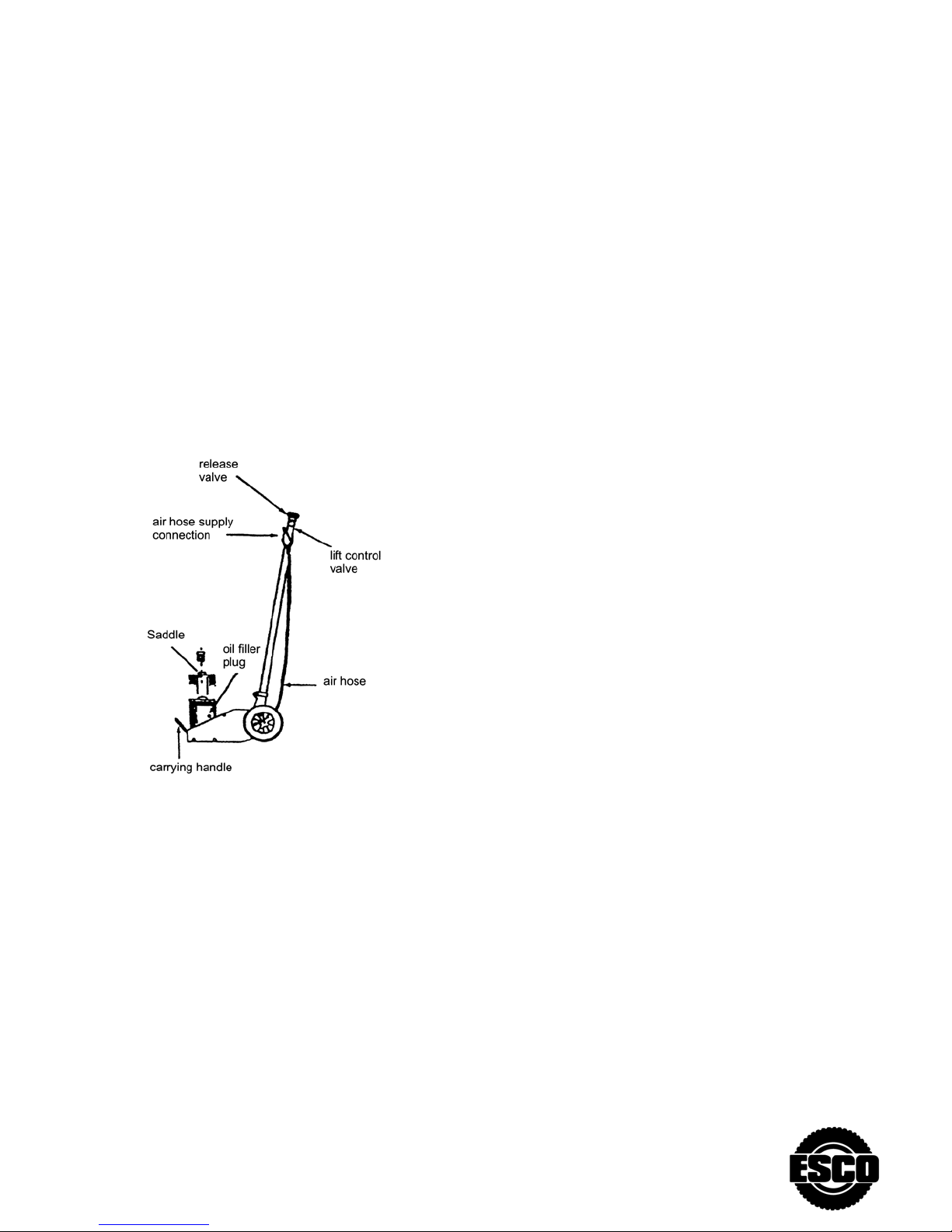

Figure 1 - Model 10439 Nomenclature

BEFORE USE

1.Verffy that the product and the application are

compatible, if in doubt call ~ESCO Technical

Service (800) 352-9852, (352) 754-1117.

2.Before using this product, read the ~owner's

manual completely and familiarize yourself

thoroughly with the product and the hazards

associated with it's improper use.

3.Open the release valve. (counter-clockwise

no more than 2 full turns)

4.With ram fully retracted, locate and remove

the oil filler plug. This will help release any

pressurized air which may be trapped within the

reservoir. Ensure the oil level is just below the

oil filler plug hole. Reinstall the oil filler plug.

5. Inspect before use. Do not use if broken

cracked or damaged parts are noted.

6. Pour a teaspoon of good quality, air tool

lubricant into the air supply inlet of the lift

control valve. (See Illustration) Connect to air

supply and operate for 3 seconds to evenly

distribute

7. Check to ensure that jack rolls freely (if so equipped) and that the air pump operates smoothly before putting

into service. Replace worn or damaged parts and assemblies with ESCO Authorized Replacement Parts only.

8. This product is fitted to accept the popular ¼” NPT air nipple. When installing 1/4" NPT nipple of your

choice, ensure that thread tape or compound is used when servicing connections.

OPERATION

Lifting

1. Assemble handle, use OIPM illustration as

guide, connect to adequate air source.

2. Secure the load to prevent inadvertent shifting

and movement.

3. Position the jack near desired lift point.

4. Close the release valve by turning the handle

mounted knob, clockwise firmly.

CAUTION: DO NOT USE A SADDLE

EXTENDER WHEN USING THIS PRODUCT, LIFT

ONLY ON THE MANUFACTURER'S

RECOMMENDED LIFT POINTS AND IN

ACCORDANCE WITH THE PUBLISHED

GUIDELINES IN YOUR VEHICLE OWNERS

MANUAL. ALWAYS USE JACK STANDS TO

SUPPORT THE LOAD IMMEDIATELY AFTER

LIFTING.

5. Squeeze the lift control valve until saddle

contacts load. Check to ensure proper

saddle/lift point alignment. To end cycle, simply

release the grip on the lift control valve.

NEVER WIRE, CLAMP OR OTHERWISE DISABLE

THE LIFT CONTROL VALVE TO WORK BY ANY

MEANS OTHER THAN BY USING THE

OPERATORS HAND.

6. Raise load to desired height, then immediately

transfer the load to appropriately rated support

devices such as jack stands.

WARNING

THIS IS A LIFTING DEVICE ONLY. IT IS

DESIGNED TO LIFT PART OF THE TOTAL

VEHICLE (ONE WHEEL OR AXLE). ALWAYS

WEAR SAFETY GLASSES WHEN USING THIS

EQUIPMENT. CENTER LOAD ON SADDLE

BEFORE LIFTING. NEVER WORK ON, UNDER OR

AROUND LOAD UNTIL IT IS PROPERLY

SUPPORTED. TRANSFER THE LOAD

IMMEDIATELY TO APPROPRIATELY RATED

JACK STANDS. DO NOT USE THIS PRODUCT

FOR ANY PURPOSE OTHER THAN THAT FOR

WHICH IT WAS INTENDED. IT IS OWNER'S

RESPONSIBILITY TO KEEP LABELS AND

INSTRUCTIONAL MATERIAL LEGIBLE AND

AVAILABLE. REPLACEMENT LABELS AND

MANUALS ARE AVAILABLE FROM THE

MANUFACTURER. FAILURE TO HEED THESE

AND ALL OTHER WARNINGS PERTAINING TO

THIS PRODUCT CAN RESULTIN SUDDEN LOSS

OF LIFTED LOAD RESULTING IN DEATH,

PERSONAL INJURY OR PROPERTY DAMAGE.

Lowering

1. Raise load enough to carefully remove jack

stands,

2. Slowly turn handle mounted release valve

knob, counter-clockwise, no more than 1/2 turn.

If load fails to lower, carefully transfer the load

to another lifting device and stands. Carefully

remove affected ~jack(s) and stands. Carefully

remove jack, again turning the release valve,

slowly, no more than 1/2 full turn.

WARNING

BE SURE ALL TOOLS AND PERSONNEL ARE

CLEAR BEFORE LOWERING LOAD.

DANGEROUS DYNAMIC SHOCK LOADS ARE

CREATED BY QUICKLY OPENING AND CLOSING

THE RELEASE VALVE AS THE LOAD IS BEING

LOWERED. THE RESULTING OVERLOAD MAY

CAUSE HYDRAULIC SYSTEM FAILURE WHICH

COULD CAUSE SEVERE PERSONAL INJURY

AND/OR PROPRTY DAMAGE.

3. After removing jack from under the load,

ensure ram is fully lowered to reduce

exposure to rust and contamination.

Loading...

Loading...