Esco 10405 User Manual

User’s Guide

For

Air Hydraulic Jack

Model 10405 (25-2)

User's Guide for Air-hydraulic Jack

Model 10405 (25-2)

WARNINGS – SAFE USAGE INSTRUCTION

1. This is a lifting device only.

Do not move or dolly the load while on the jack. The load must be supported immediately by other appropriate means.

2. Do not over load. Over loading can cause damage to or failure of the jack.

3 Lift only areas as specified by the manufacturer.

4 Do not use more than 2 standard extensions in sequence.

5. This jack is designed for use only on hard level surfaces capable of sustaining the load. Use on other than hard level surfaces can

result in jack instability and possible loss of load.

6. It is recommended that the wheels of a vehicle be chocked.

7 No person should remain in. on, or get bodily under a load that is being jacked or is supported only by a jack.

8 The safety valve being adjusted and sealed by the manufacturer shall not be additionally adjusted.

9. Max mum permissible V mature 17D PSI 12 had

10. Failure to heed these warnings may result in loss of load damage to jack, and/or failure resulting personal injury or property damage

Assembly

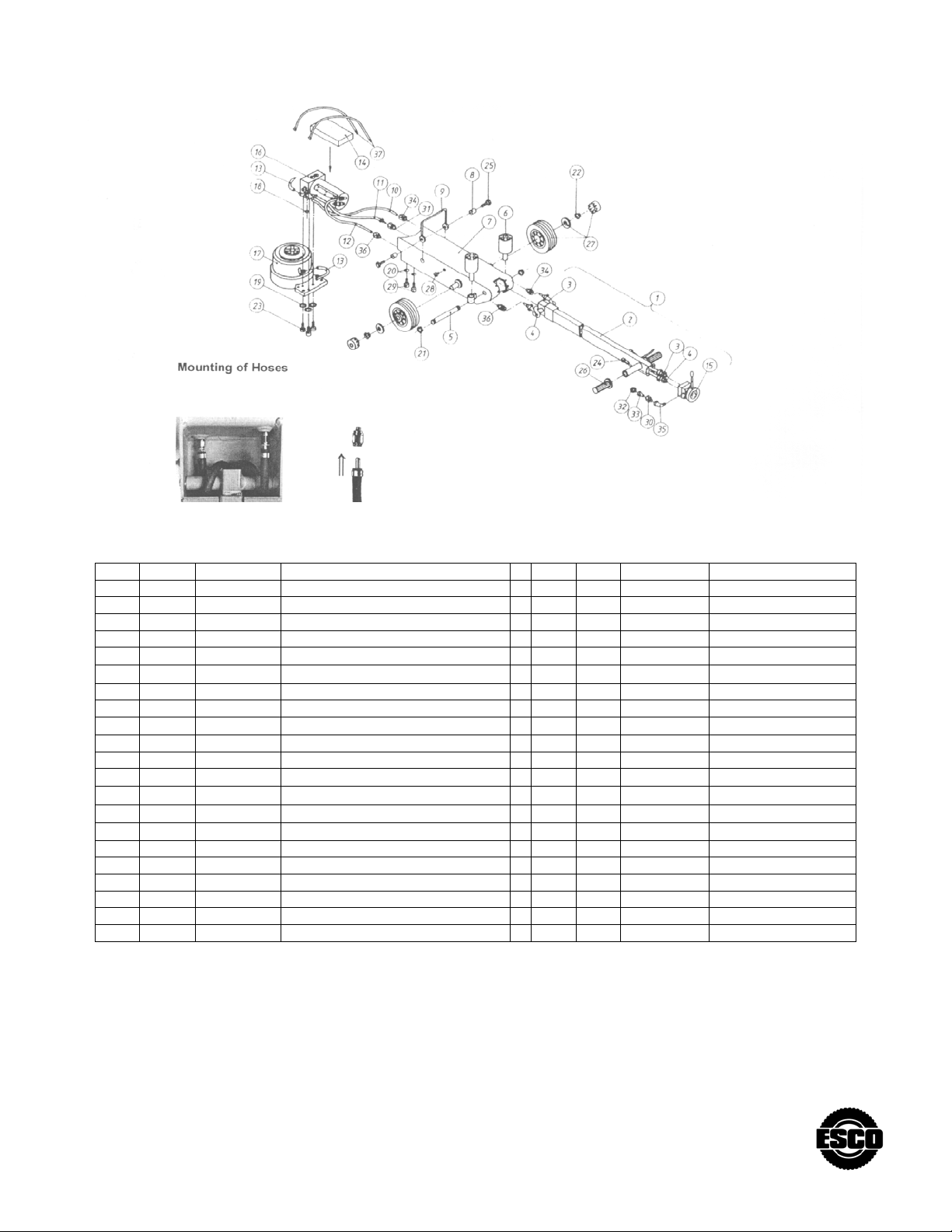

When mounting the handle (1) turn the hoses round the bearing tubes of the handle as shown on the detail drawing – Ø6 connection (3) for Ø6 quick

fitting (34) and Ø8 connection (4) for Ø8 quick fitting (36). When the jack has been turned over or upside-down a little oil will come into the hoses and

come out with the pump exhaust.

Oil the mechanical parts before starting up – and regularly thereafter.

Use of the Jack

Lifting: Turn the control valve clockwise until the pump starts. Max capacity at 9,0 bar.

Lowering: Turn the control valve counter clockwise.

The handle can be placed in 3 different positions by pulling the spring loaded release grip handle and tipping the handle into the required position.

Lower the jack after use to protect the lifting cylinder.

Maintenance

Like other pneumatic tools, the air pump of the jack needs oil for lubricating the moving parts. It is recommended to use a built-in air lubricator and water

3

separator on the compressor. If not, inject, with about every 25 lifts, approx. 1 cm

Lubricate at the same time the mechanical moving parts with a few drop of oil. Refill of oil: Screw off the filing plug (28) at the side of the jack to refill.

Correct oil level is to lower edge of the hole for the filling plug with the jack in horizontal position, and the cylinder in lowest position. Quantity of oil: 3,01.

Any good hydraulic oil of viscosity 10° - 32° cST/40° C can be used.

NEVER USE BRAKE FLUID!

Possible faults and how to overcome them

1. The jack cannot lift to maximum height, and the pump runs continuously: Refill the oil tank.

2. The air engine goes slowly: the air filter (33-no 22 of the handle) of the control valve has been blocked and needs cleaning or change.

3. The control valve cannot be turned or goes very slowly, even with pressure on the system. The air supply is very watery and the lubricating

film in the valve has been washed out. Mount a water separator with lubricator on your compressor. Loosen the elbow (35) from the valve, fill

the valve with oil, and use the valve many times without air connection. Oil the jack more frequently.

4. In frosty weather: The jack will not pump: There is too much water in the air supply, which has frozen. Mount a water separator with lubricator

on the compressor. Change the oil in the jack, if water in it.

Apart from the above, faults may arise after intensive use due to worn seals, which must then be replaced by new seals.

Max. PERMISSIBLE PRESSURE: 12 bar – 170 PSI.

Destruction:

When the jack after several years is worn and must be dismantled, the oil must be drained off and legally disposed of.

oil into the air connection, and operate the pump to spread the oil.

MODEL 10405 (25-2)

Pos. Pcs. No. Description Pos. Pcs. No. Description

44.400.00 25-2, air-hydraulic jack, complete 20 4 02.103.00 Spring washer

1 1 44.001.00 Handle, complete 21 2 02.204.00 Circlip

2 1 44.002.00 Handle 22 2 02.222.00 Circlip

3 1 44.003.00

4 1 44.004.00

5 1 44.005.00 Axle for handle 25 2 02.520.00 Screw

6 2 44.006.00 Extension 26 2 02.390.00 Handle

7 1 44.007.00 Frame 27 2 02.518.00

8 2 44.008.00 Bushing 28 1 02.470.00 Filling plug

9 1 44.009.00 Carrying handle 29 4 02.485.00 Screw

10 1 44-010.00

11 1 44-211.00

12 1 44.012.00

13 1 44-013.00

14 1 44.015.00 Sound absorbing material' 34 2 02-512.00 Quick fitting

15 1 42.000.00 Control valve 35 1 02-515-00 Elbow

16 1 90.725.00 Pump, complete 36 2 02.516.00 Quick fitting

17 1 90.745.00 Cylinder, complete 37 2 02.517.00 Cable ties

18 1 01.000.00 0-ring

19 3 02.102.00 Spring washer

Hose compl. w. ∅ 6 connection

Hose compl. w ∅ 8 connection

Hose, ∅ 6

Oil tube ∅14 complete

Hose ∅8

Hose ∅6 for cylinder

23 3 02.306.00 Screw

24 2 02.324.00 Screw

Wheel ∅l5O

30 1 02-494.00 Gland

31 1 02.498.00 Gland

32 1 02.506.00 Gland

33 1 02-511.00 Filter

Loading...

Loading...