Escea DX1500, DX1000 User Manual

Installation / Service Guide

DX1000 / DX1500

For the latest documentation, visit www.escea.com

Gas Fireplaces

630228_18

Important:

The appliance shall be installed in accordance with;

• This installation instruction booklet

• Local gas tting regulations

• Municipal building codes

• Electrical wiring regulations

• Any other relevant statutory regulations.

• AS/NZS 5601.1 Gas Installations

This appliance is not intended for use by young children or inrm persons unless they

have been adequately supervised by a responsible person to ensure that they can use the

appliance safely.

Young children should be supervised to ensure that they do not play with the appliance.

Manufactured by: Escea Ltd, PO Box 5277 Dunedin NZ, Ph: +64 3 478 8220

For contact details of your local Escea distributor or dealer please visit:

www.escea.com info@escea.com

WARNING:

Failure to follow these instructions could cause a malfunction of this appliance, which

could result in death, serious bodily injury, and/or property damage. Failure to follow

these instructions may also void your re insurance and/or warranty.

This appliance must not be modied.

THIS APPLIANCE MUST BE FITTED WITH AN ESCEA REMOTE ROOM AIR FAN

AND SUITABLE RETURN AIR VENTILATION

THIS APPLIANCE MUST BE FITTED WITH AN ESCEA REMOTE FLUE FAN

THE TERMINAL MUST ALWAYS VENT DIRECTLY OUTDOORS

Who can install this product:

Installation must be carried out by a qualied and registered installer who, on completion

of the installation, must issue a:

AUS: Certicate of Compliance

NZ: Energy Work Certicate

in accordance with national and/or local codes. If these are not issued then the Escea warranty may be void.

Warranty Repair and Annual Servicing:

Warranty repair work must be carried out by a recognised Escea gas replace technician.

It is recommended that recognised Escea Gas Fireplace Technicians are also used to carry

out annual servicing requirements (particularly during the warranty period). For contact

details of authorised Escea Gas Fireplace Technicians in your area, please contact the

retailer from whom the appliance was purchased.

General installation information:

This appliance must be installed according to these instructions and in compliance with

all relevant building, gas tting, electrical and other statutory regulations (eg. AS/NZS

5601.1). Any shortcomings in the appliance and ue installation will be the responsibility

of the installer, and Escea will not be accountable for any such failings or their consequences.

Once this appliance is installed it cannot be removed without disturbing the wall lining.

This DX Series replaces has been dispatched from the factory set as a single sided version. This can be converted into a double sided appliance by using the Double Sided

Conversion Kit available from your Escea distributor. Conversion details are shown in

Section E.

An electrician is required to install a 3pin power socket – Section C

A Installation Process and Product Description 6

A1 Recommended Installation Process: 6

A2 Product Description 6

A3 Product Dimensions 7

B Creating the Cavity 8

B1 Cavity Shape 8

B2 Designing the Cavity 8

B3 Flue Conguration (For less than 4m length) 9

B4 Flue Conguration (For more than 4m length) 10

B5 Framing Dimensions 11

B6 Cavity Base 11

B7 Hearth 11

B8 Wall Linings 11

B9 Fascia 12

B10 Mantle Clearance 12

B11 Television Clearances 12

B12 Ducting 13

B13 Duct Fan mounting 14

C Installing the Electricity and Gas to the Appliance 15

C1 Power Supply 15

C2 Network Cable 15

C3 Gas Pipe Sizing 16

C4 Gas Pipe Position 16

C5 Gas Isolating Valve 16

D Installing the Flue 17

D1 Installing the Horizontal Powerue Wall Terminal option 17

D2 Installing the Internal Vertical Powerue (Duravent) 18

D3 Installing the Universal Vertical Powerue (Internal Install) 19

D4 Installing an External Vertical Powerue (EVP or UVP) 21

D5 Removing the restrictor plate (EVP, UVP External/Internal) 22

D6 Installing in Accordance with Relevant Codes 23

D7 Creating the Hole in the Outside Wall 24

D8 How to ash the Horizontal Powerue 25

D9 How to ash the Vertical Powerue 25

D10 Running the Flue 26

D11 Running the Powerue Electrical Cable 26

E Installing the Appliance 27

E1 Double Sided conversion 27

E2 Installing the Appliance 28

E3 Connecting the Flue 28

E4 Connecting the Network Cable 28

E5 Removing (and replacing) the Glass 29

E6 Remove the Fuelbed Tray & Burners 29

E7 Gas Type Conversion 30

E8 Checking the Gas Operating Pressure 32

E9 Operating the Appliance 34

E10 Auxillary On/O button 35

E11 Home Automation Setup 35

E12 Reinserting fuel bed and ceramic glass 36

F Finishing the Installation 37

F1 Crystalite, Coal, or Driftwood Fuel Bed Installation 37

F2 Log and cone Fuel Bed (Woodland Selection) 37

F3 Wall lining 38

F4 Fitting the Fascia Panels 39

F5 Locating Wall Mount Cradle for Wireless Control 40

F6 Operating the Appliance 40

F7 Normal Operating Sounds and Smells 42

G Installation Checklist 43

S Service Manual 44

S1 Annual service procedure 44

S2 Error Codes 45

S3 Cleaning the Fuel bed and Glass 47

S4 Checking Operating Pressure 48

S5 Replacing a Remote Control 49

S6 Replacing the burners 50

S7 Accessing the control tray 51

S8 Removing the Circuit Board 51

S9 Servicing the Horizontal / Vertical Powerue 53

S10 Wiring Diagram 54

A

Installation Process and Product Description

A C D E F G SERVICE

A1 Recommended Installation Process:

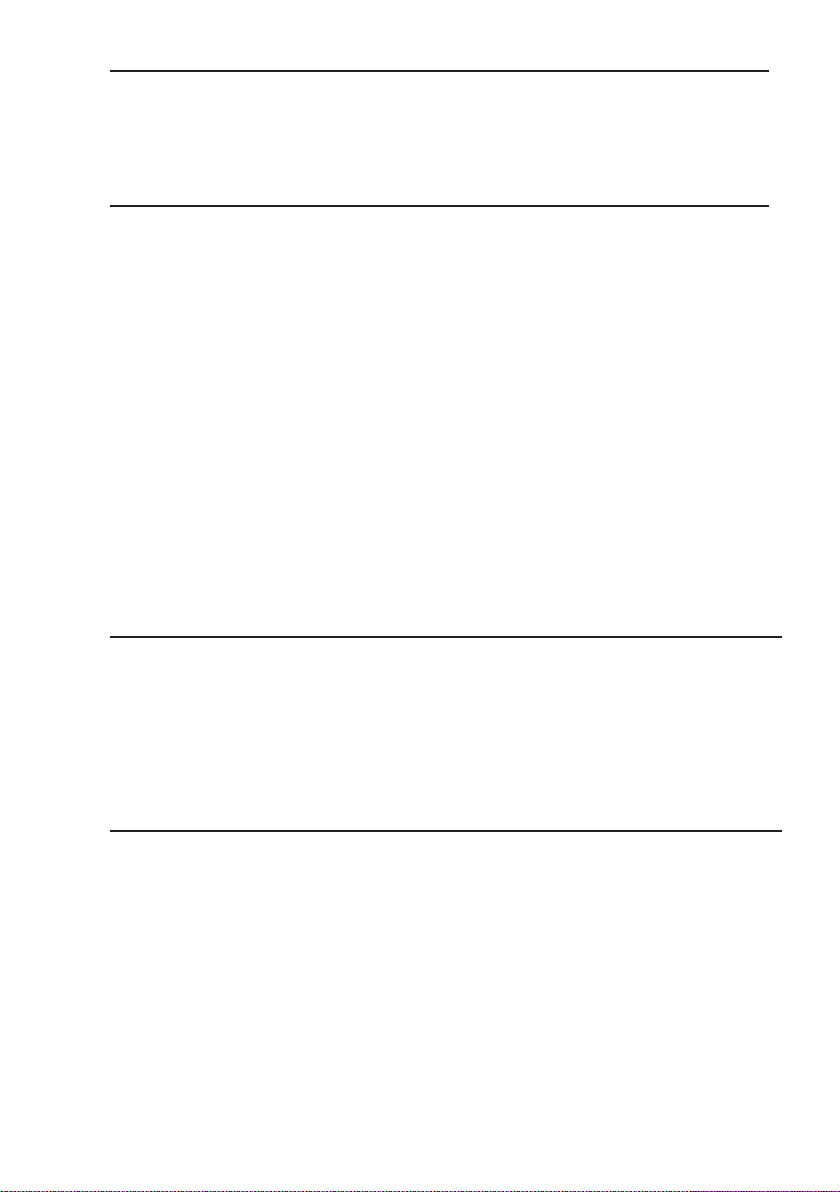

The following diagram illustrates the steps required to install your gas re, and the trades

required at each stage.

The sequence in which you choose to do these tasks will vary depending on your indi-

B

vidual installation. Please read these instructions carefully before proceeding with the

installation. Leave the installation of the optional fascia panels until the very end of the

installation and commissioning to avoid damage to the fascia panels.

Create the Cavity Install electrical / gas

connections, ue system, and

replace

Section B Section C, D Section F

Finish installation and t

fascia

A2 Product Description

The Escea DX1500 / DX1000 gas re is a direct vent (fan draught balanced ue), room

sealed gas appliance designed to be built into a cavity. This appliance is ued using a colinear exible aluminium ue connected to a powerue terminal.

The hot air from the gas re is transferred to the room via 250mm ID / 300 mm OD

ducting.

The user will control their re with the Radio Frequency (RF) remote that will normally be

left in its wall mount cradle. In addition to the RF remote it has a single auxiliary On/O

button on the unit. When not in operation it is in a standby mode unless it is physically

isolated from the mains supply.

To access the product Dataplate, rst remove the replace glass, any fuelbed media, the

burners and the rebox base. An access panel is located to the side of the bottom of the

rebox, the dataplate is located underneath this access panel.

6

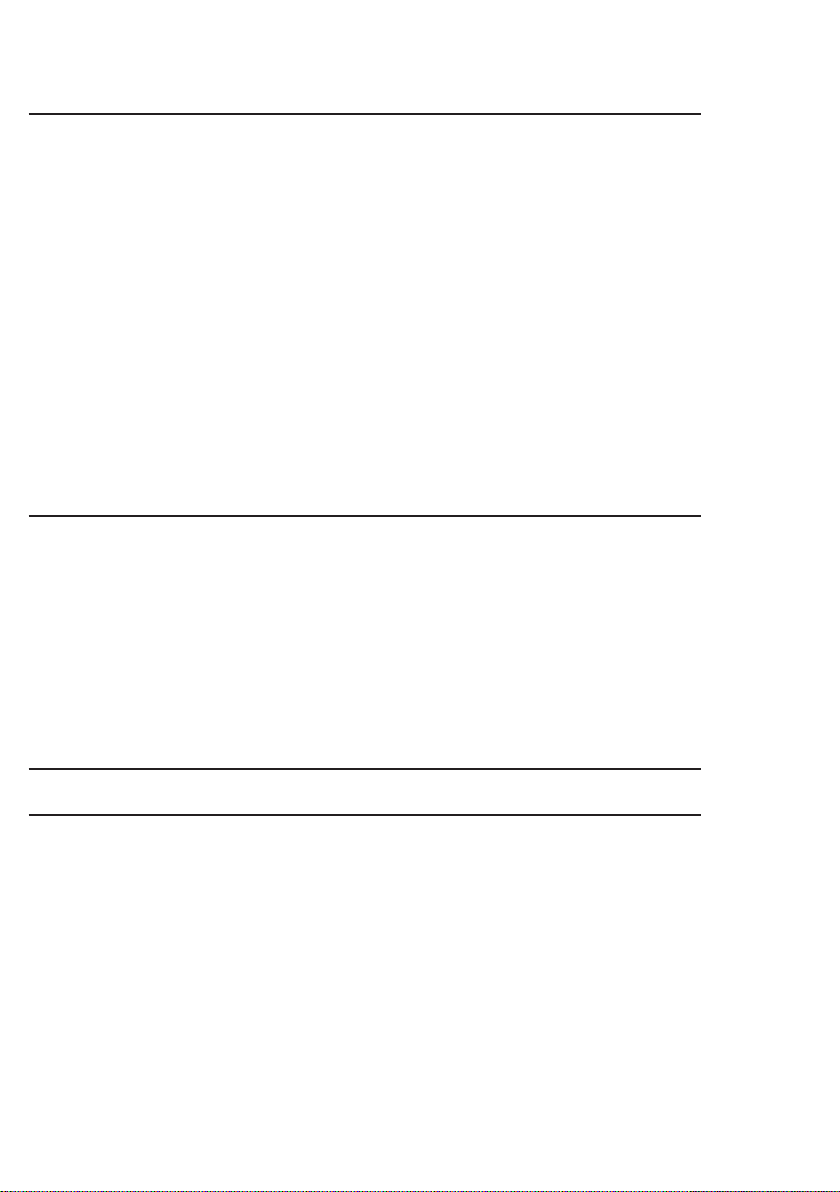

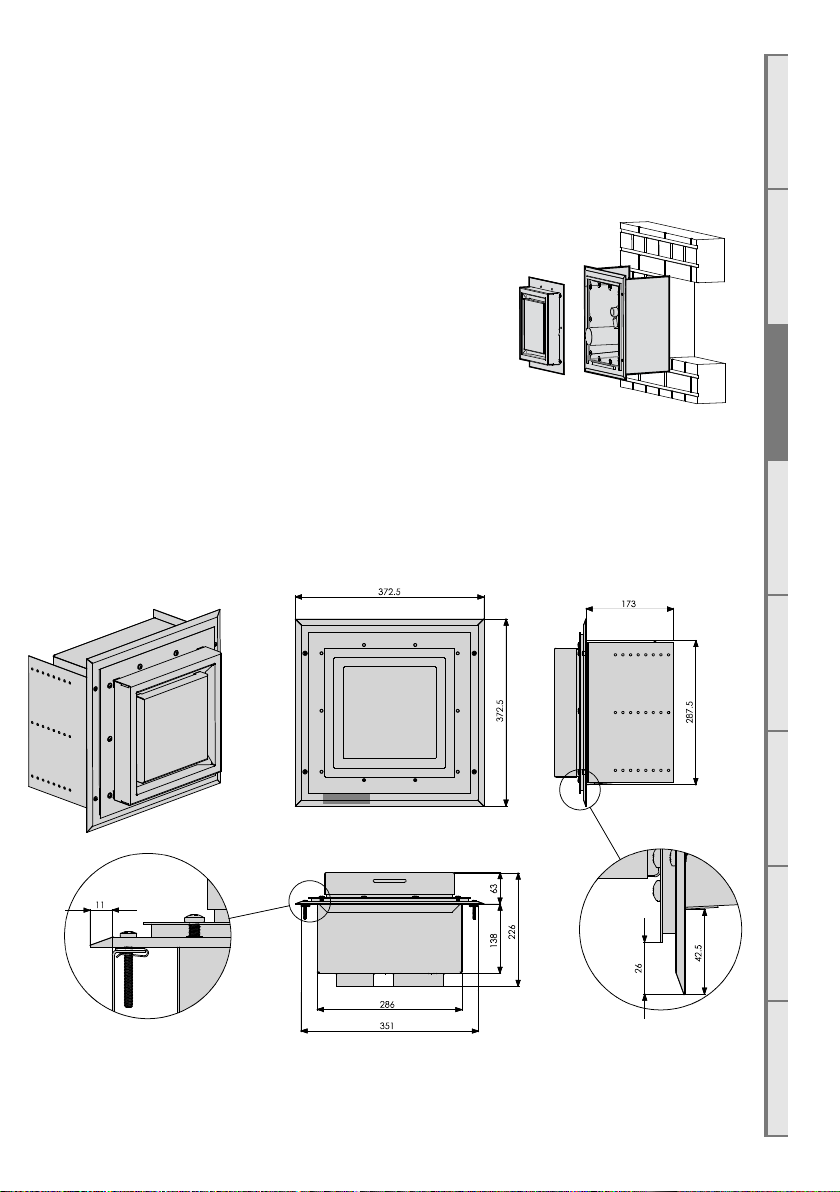

A3 Product Dimensions

183

NOT TO BE MISTAKEN FOR CAVITY DIMENSIONS

All dimensions are in mm

A

744

B

382

Ø250

70 Ø100

ACDEFGSERVICE

61

B

372

Gas, Power, Internet

Connections

Ø75

For more detail, view architectural drawings at www.escea.com

DX1000 DX1500

A 664mm 914mm

B 1328mm 1828mm

7

B

Creating the Cavity

A C D E F G SERVICE

B1 Cavity Shape

The DX1500 / DX1000 is suitable for timber framed cavities.

Most existing masonry cavities will not be suitable.

The cavity design & shape will be dependent on a number of things:

B2 Designing the Cavity

B

The following aspects must be considered when designing this installation:

• Appliance physical size

• Single sided or Double sided

• Wall nishing and interaction with appliance

• Positioning of appliance in regards to wall lining (depth into wall)

• Is a Fascia to be used? one side or two sides?

• Exhaust cowl aspect – horizontal / vertical and ue conguration

• Flue exhaust fan noise

• Exhaust cowl access for maintenance

• Duct layout and cavity spaces to run ducting

• Duct fan position

• Access to duct fan for maintenance

• Gas pipe layout

• Gas isolation valve / pressure test point position

• Electrical isolation switch

• Home automation network connections - Ethernet cable layout

□

This DX1500 / DX1000 re is to be installed prior to any wall lining.

The wall lining is the very last task to be completed in this installation.

The cavity and wall linings may be constructed from standard timber framing materials

and do not need to be non-combustible.

Do not line the top of the cavity.

It is not necessary to line the sides, or back of the cavity.

8

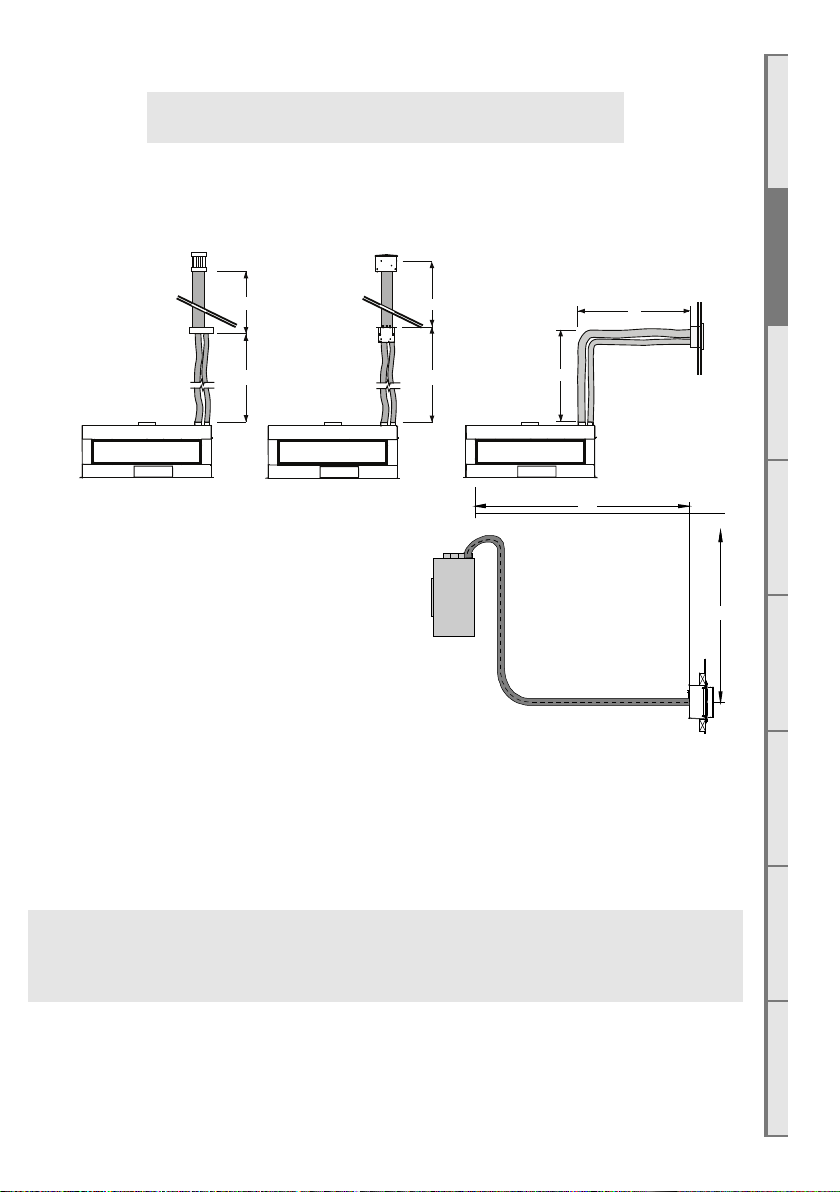

B3 Flue Conguration (For less than 4m length)

X

Y

X + Y = 4m MAX

= 0.6m MIN

4m MAX

1.2m Co-axial Flue

Vertical PowerFlue

Cowl (Duravent)

4m MAX

1.2m F-F Liner

UVP-Internal Cowl

ONLY USE ESCEA APPROVED FLUE COMPONENTS

If your ue system is less than 4m long (as shown in the diagrams below), then a simple

exible ue is required. if you wish to install a longer ue run, up to 12m, see section B4.

X

Note: You must provide sucient access to the

powerue to enable it to be serviced in the

future.

This means that the fan unit must have sufcient

access to allow it to be replaced if necessary.

Y Maximum = 1.5m

Y Minimum = 0m

X Maximum = 4m

X Minimum = 0m

X + Y Maximum = 4m

X + Y Minimum = 0.6m

The ue must be securely xed and adequately supported by brackets fastened to the

building structure at suitable points to ensure

the stability of the ue system.

Any joints within the ue system must be sealed adequately, with a sealing agent used

if necessary. The ue system for the DX1500 / DX1000 is zero rated, so no spaces are

required between the ue and any timber framing.

ACDEFGSERVICE

B

Y

Horizontal Flue option

Minimum: 600mm ue length

Maximum: Total ue length 4m

Note: All sections of horizontal ue if exible must be sloped back toward the re at

□

a rate of no less than 20mm per metre, to allow any condensation to run back into

the appliance.

Vertical Flue option

Minimum: 600mm ue length

Maximum: Total ue length 5.2m

For ue installation, see section D

9

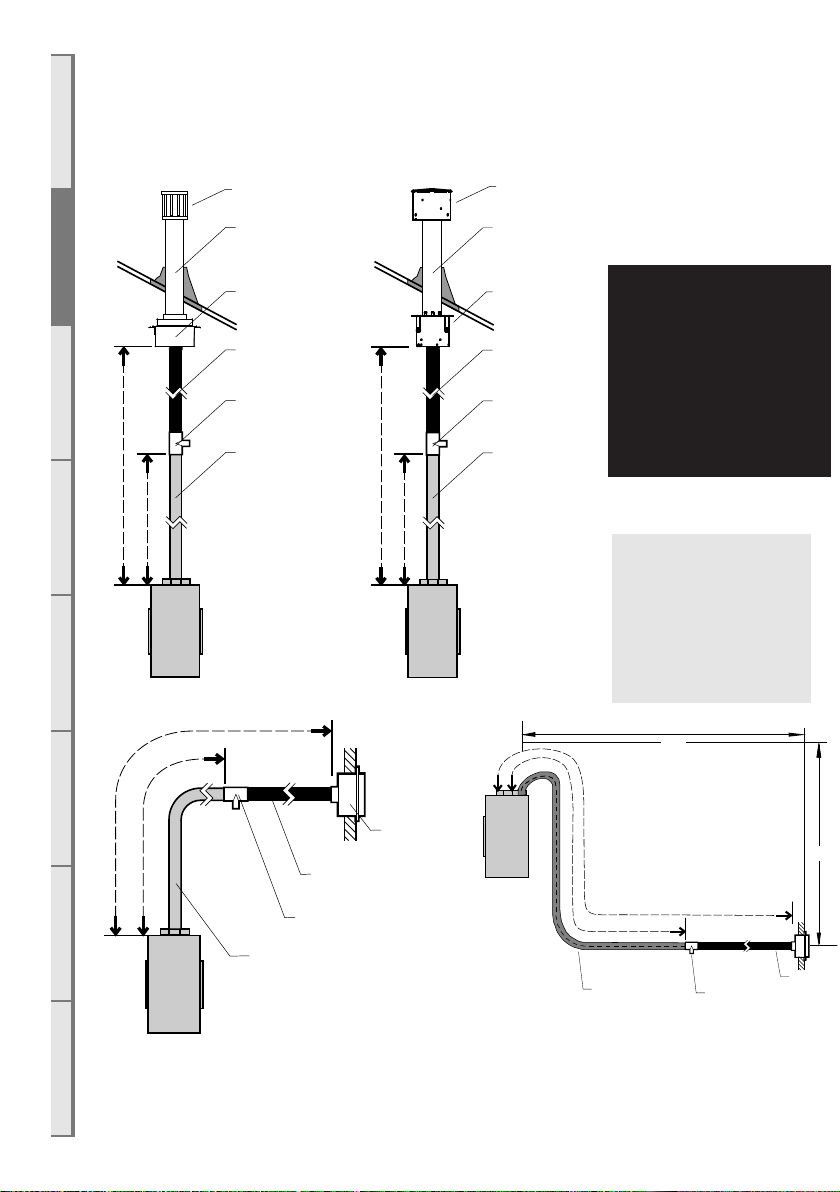

B4 Flue Conguration (For more than 4m length)

X

Condensate Trap

A C D E F G SERVICE

B

If your ue system is greater than 4m long (as shown in diagrams below), then a exible

ue with condensate trap and rigid PolyPro tube ue lengths is required. (For less than

4m ue runs, see section B3)

Vertical PowerFlue

Cowl (Duravent)

1.2m Co-axial Flue

(Duravent)

Vertical Powerue

Enclosure

Ø80mm / Ø100mm

PP Tube

Ø100mm

12m MAX

4m

Condensate Trap

Ø80mm / Ø100mm

Flexible Flue

12m MAX

4m

UVP Cowl

1.2m F-F Liner

UVP Fan Unit

Ø80mm / Ø100mm

PP Tube

Ø100mm

Condensate Trap

Ø80mm / Ø100mm

Flexible Flue

FOR MORE INFORMATION ON

INSTALLATION OF THE POLYPRO FLUE,

SEE ‘POLY PRO FLUE INSTALLATION

INSTRUCTIONS’ AVAILABLE ON:

WWW.ESCEA.COM

OR SUPPLIED WITH THE FLUE.

FOR POLY PRO COMPONENT GUIDES,

THESE ARE AVAILABLE ON:

WWW.ESCEA.COM

HORIZONTAL FLUE COMPONENT GUIDE

VERTICAL FLUE COMPONENT GUIDE

TITLED:

&

Note: All sections of

horizontal ue, if exible,

must be sloped back

toward the re at a rate

of no less than 20mm

per metre, to allow any

condensation to run back

into the appliance.

12m MAX

4m

Y Maximum = 1.5m

Y Minimum = 0m

X Maximum = 12m

ESCEA WALL

TERMINAL

Ø80mm / Ø100mm

Ø80mm / Ø100mm

Flexible Flue

10

PP Tube

Ø100mm

Condensate Trap

Ø80mm / Ø100mm

Flexible Flue

X Minimum = 0m

X + Y Maximum = 12m

X + Y Minimum = 0.6m

4m

12m MAX

Ø100mm

Y

Ø80mm /

Ø100mm

PP Tube

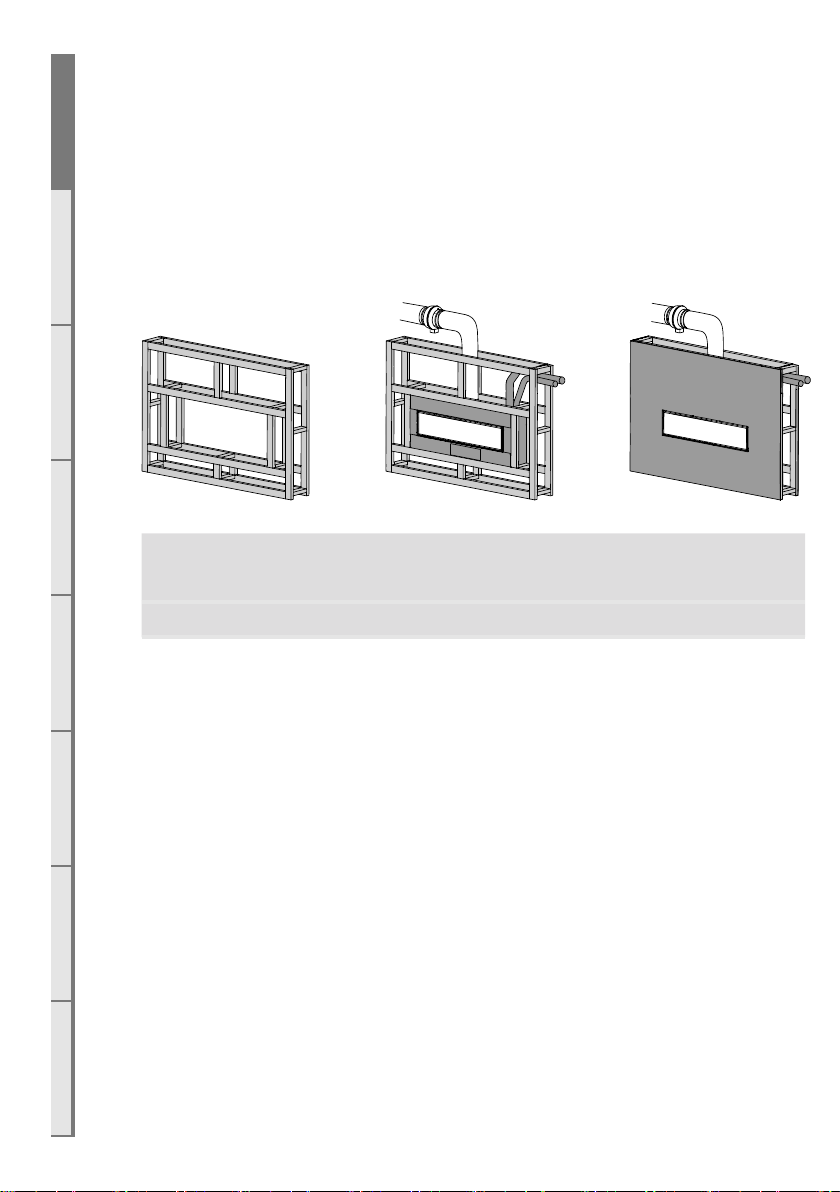

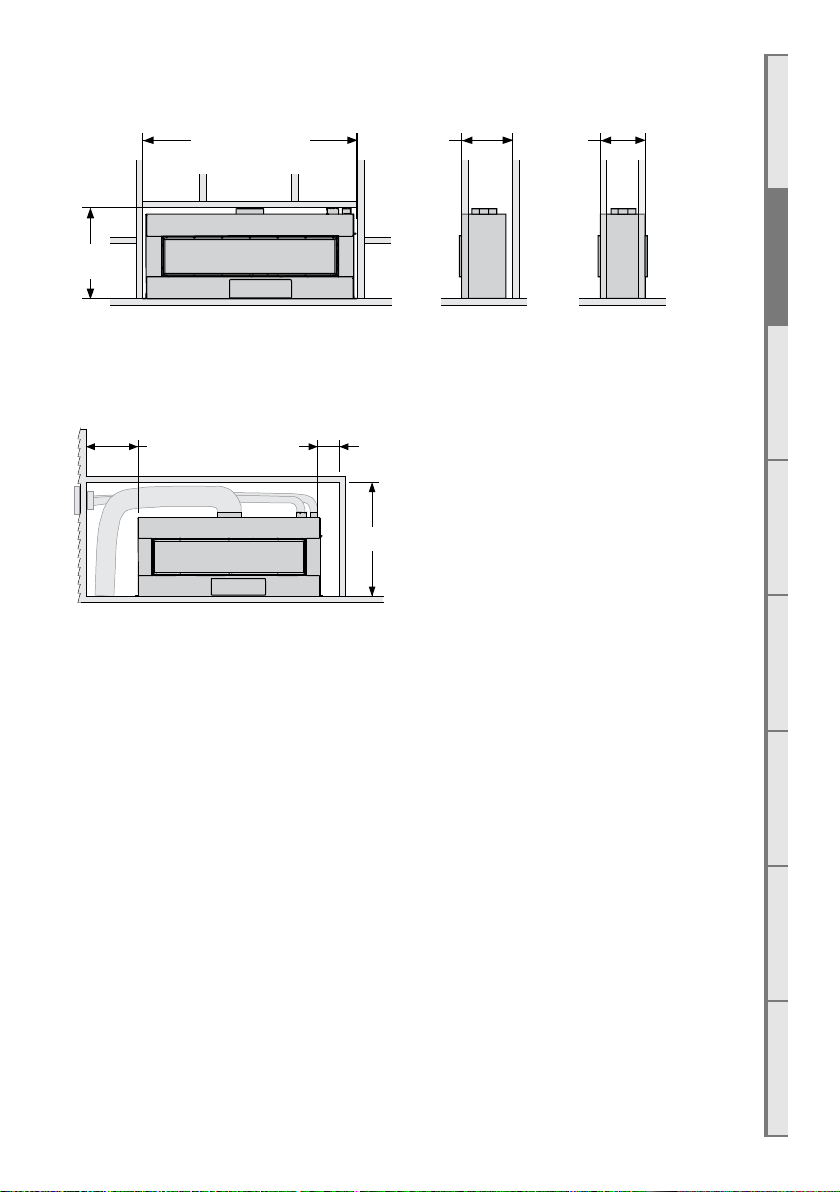

B5 Framing Dimensions

800

1400

1150

MIN

400

MIN

Adequate space to provide

gas inlet connection.

DX1000: MIN

DX1500: MIN

1900

450

MIN

381

ACDEFGSERVICE

MIN

Front Side

Single Sided

Side

Double Sided

Guidelines for Framing Dimensions - Bench top / Hutch style

B6 Cavity Base

This appliance MUST be fully supported on its base, over the entire area of the underside

of the appliance. The base must also be level and strong enough to support the total

product weight, which is approximately 100kg (DX1000) or 120kg (DX1500).

B7 Hearth

No hearth is required

B8 Wall Linings

The appliance must be installed prior to and behind the nished wall surface. Take into

account any plaster board, tiles or any other nishing surface that may be intended for

the nished wall surface. Wall nishing materials must not encroach upon the minimum

cavity clearances given in previous sections. The wall board that lines the outside of the

opening can be normal plaster board and does not need to be non-combustible.

B

Note: The nal wall lining must not encroach within the specied dimensions in this section or section B8. These dimensions indicate the opening required in any wall lining.

These dimensions are for DX1500 / DX1000 without fascia, if using a fascia then please

check the following section of this manual for separate wall lining dimensions.

If not using a fascia, ensure the edge of the wall lining is nished in a tidy manner.

11

A C D E F G SERVICE

362

SideFront

362

192

DX1000:

MIN

1062

DX1500:

MIN

1562

1100

800

MIN

B

B9 Fascia

The Plasterboard is to protrude beyond framework as shown in the following diagram.

WALL OPENING

(WITHOUT FASCIA)

Note: The wall lining directly above the appliance will get warm and hence may discolour

paint nishes that are susceptible to temperature damage or distort vinyl wall coverings.

For durability of nishes and surfaces you should contact the relevant manufacturer for

their specication and avoid materials with temperature ratings less than 80deg C.

Note that a 20mm or less wall lining must be used when installing a DX-series replace without a velo fascia. For wall linings of a total thickness of 10mm or larger, a “Linear Trim” may

be purchased to cover any exposed wall lining. A 9mm wall lining is recommended for ease of

installation.

Velo Fascia

If using a (velo) fascia, the cutout required in the nished plaster board dimensions are:

DX1000: MIN

DX1500: MIN

1600

15

Max

WALL OPENING

(WITH FASCIA)

Note that a 15mm or less wall lining must be used when installing a DX-series replace with a

velo fascia, as this is the maximum distance the velo fascia can sit o the front face of the re

as shown. For wall linings of a total thickness of 10mm or larger, a “Linear Trim for velo fascia”

may be purchased to cover any exposed wall lining.

410

FASCIA

Linear Trim

For 10mm-20mm wall linings, an optional “Linear Trim” can be used to cover any

unwanted exposed wall lining and/or act as a slimline fascia.

B10 Mantle Clearance

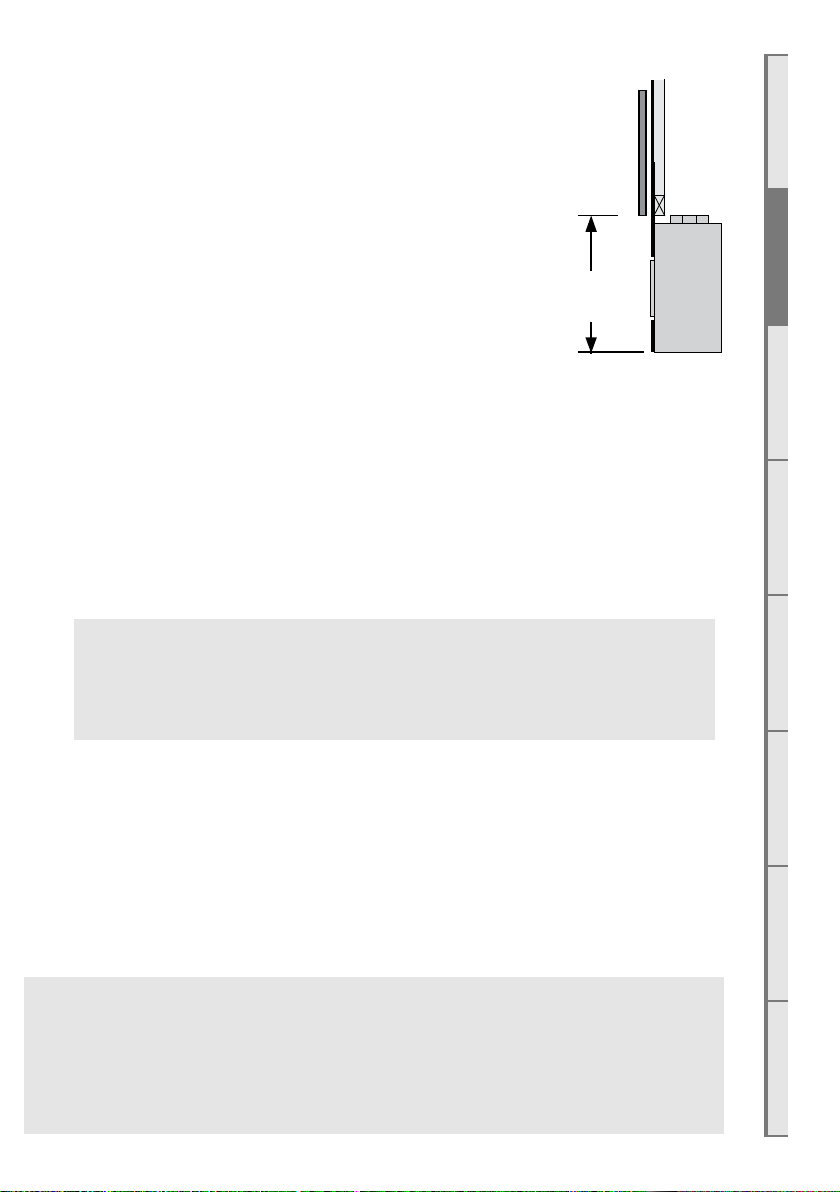

Please refer to the diagram. Mantles or protruding ledges above the

heater must not be installed lower than the dimension shown.

Note: dimension from base of appliance.

12

B11 Television Clearances

800

MIN

The following are the recommended minimum clearances for the

location of any electrical equipment (such as a Plasma TV, LCD TV

or home theatre system) above an Escea DX Series gas re.

Note: The above television clearance recommendations are to

be treated as a suggestion of a suitable installation only. It is the

responsibility of the end user to check the installation instructions of their electrical appliances to ensure that the location in

relation to the gas re is suitable. Escea in no way guarantees or

takes responsibility that the above installation suggestion will be

suitable for all electrical or home entertainment appliances.

Note: Dimension from base of appliance.

For installations with a recessed TV above, allow at least 300mm

above the top of the appliance to allow for Duct and ue routing.

B12 Ducting

Note: The duct fan must be installed in a location accessible for service or replacement, a service hatch (to allow for access) may be required.

This gas re requires a small network of ducting situated in either the ceiling or under the

oor to distribute heat generated by the appliance.

A centrifugal fan (separate purchase) is connected to the duct system and this draws air

through the appliance where it is heated, and then distributes it via the ducting network.

The centrifugal fan is powered by the appliance. When placing outlets in rooms other

than the room the appliance is installed, it is important to allow for return air to

equalise pressure between the rooms.

Caution: Provision must always be made for return air from heated rooms

e.g. undercut doors or natural leakage.

ACDEFGSERVICE

B

WARNING: OVERHEATED ROOMS ARE NOT SAFE FOR INFANTS

DX res require a minimum of three outlets in the ducting system to be fully open at all

times. At least two of those outlets must be present in the same room that the re resides

in. There can be a maximum of 5 outlets for the DX1000 and 8 outlets for the DX1500. A

standard duct kit (separate purchase) has provision for the three minimum outlets - You

can use your own ductwork and outlets, but you must ensure they are rated to temperatures of at least 90 degrees Celsius and have an appropriate R-value.

Ductwork must be adequately sized to avoid excess backpressures. Inadequate duct sizes

will cause unnecessary fan noise and premature fan failure.

We recommend removing the close aps from at least three of the duct outlets to prevent unnecessary back pressure and fan noise.

Ductwork must not be crushed or exposed to excessive heat sources.

Note: If duct backpressure is too great, the appliance can shut down due to overheating.

□

This ducting fan will generate mechanical noise. Ideally it must be installed in a position

where noise will not interfere with daily activities. All air ducts will make noise no matter

how well the system is designed. Increasing the number of outlets is a simple strategy to

reduce this noise.

13

For installations with the duct fan installed in the appliance cavity we recommend:

A C D E F G SERVICE

B

- Contact Escea’s free Architectural Advice Service at aa@escea.com and forward them

a copy of the intended design for comment.

- The cavity to be clad with sound gib.

- The fan to be wrapped in a sound absorbing material.

- The system be tested for sound related issues before it is enclosed. Please contact

Escea for more information at this stage if advice is needed.

- The duct fan must be hung on the provided hanger.

- The ducting must always have a “C” shape or an “S” shape to break up the sound

waves on both sides of the duct fan.

-The duct fan must be installed in a location accessible for service or

replacement, a service hatch (to allow for access) may be required.

-Never place the fan in such a way to result in a straight run to the top of the re,

as the sound of the fan will echo out the front of the re.

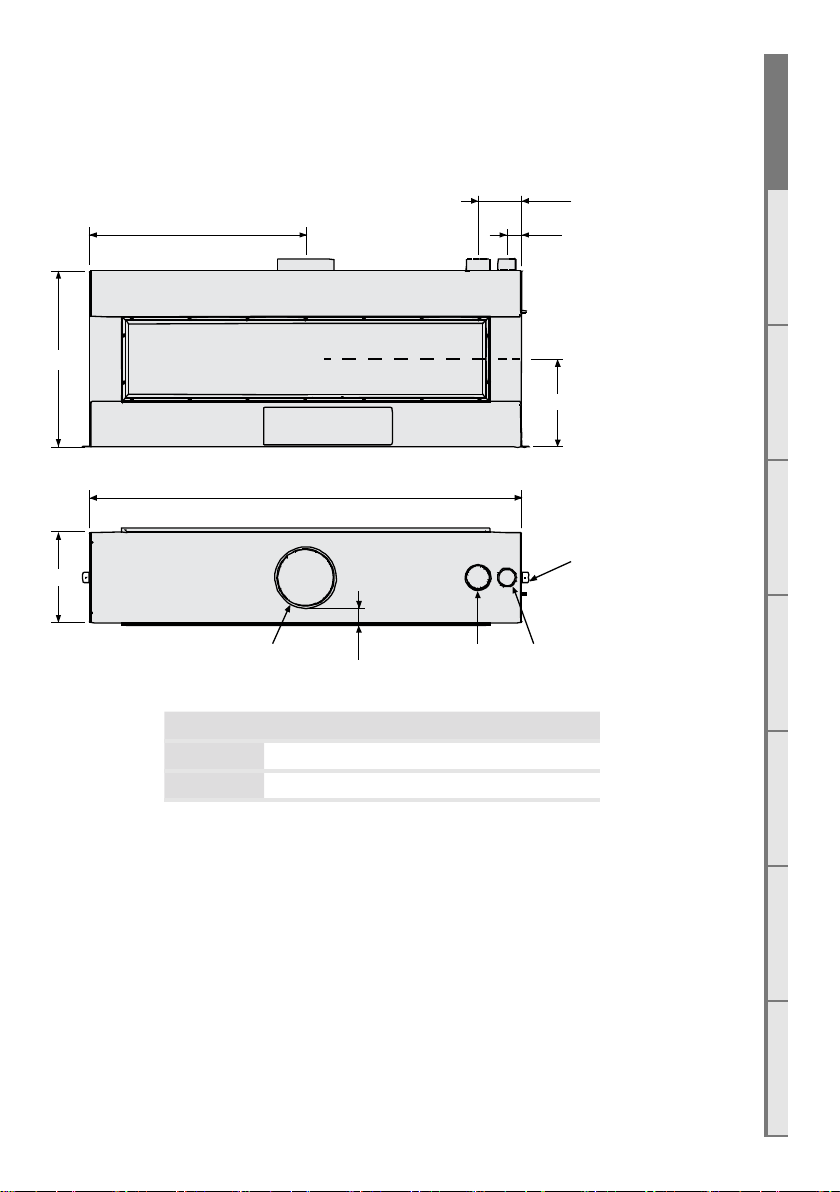

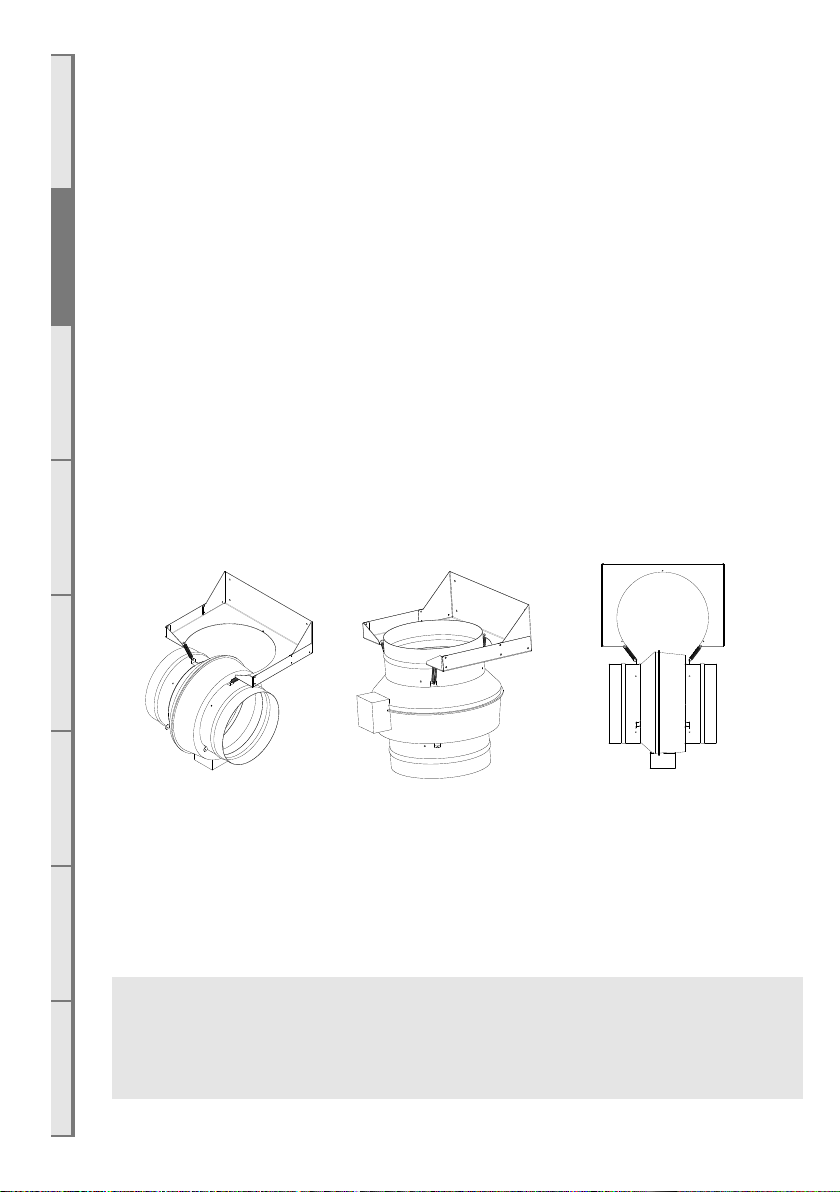

B13 Duct Fan mounting

Using the 3x spring mounts supplied, the duct fan should be installed in one of the

following positions as shown below. You must use the spring mounts as this will help

decrease noise by not transferring vibration into the walls.

Note: The duct fan must be installed in a location accessible for service or replacement, a service hatch (to allow for access) may be required.

Run the electrical cable from the duct fan to the cavity where the appliance will be installed. Ensure the cable is not draped over or in contact with the outer shell of the appliance or either of the exi ue tubes and kept clear from any other possible heat sources.

Fix it appropriately and allow enough cable loop to prevent tension on the cable plugs.

The duct fan unit length is approx 350mm and diameter is approx 340mm.

The duct fan must not be exposed to the outdoors.

END OF SECTION B

By the end of this section, you should have:

□ A framed, but un-lined, cavity sized to suit your fascia and ue conguration

□ Provision for sucient access to the powerue for future servicing

14

C

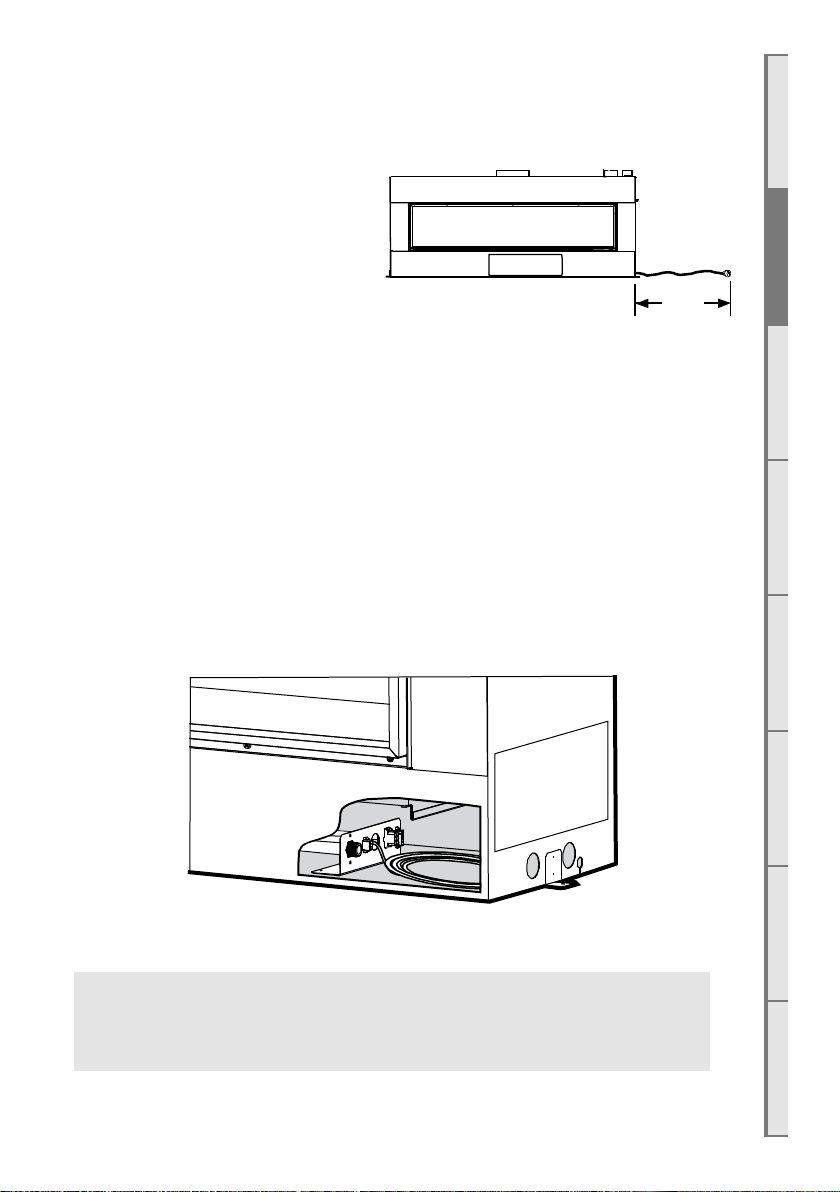

1m

Installing the Electricity and Gas to the Appliance

C1 Power Supply

While the cavity is being created

consideration should be given to

appropriate location of a standard 3 pin,

EARTHED 230/240V power outlet. This

must be within 1.0m of the bottom right

of the appliance.

IMPORTANT: Locating the power outlet within the cavity makes the installation very neat

but provision MUST be made to be able to switch the power supply o and on (electrical isolation switch) and MUST be accessible after the heater has been installed. This is

normally done by means of a separate switch located outside of the cavity and wired to

the plug. This will allow technicians to isolate the power supply before servicing the appliance.

This appliance must not be located immediately below a socket outlet.

This appliance will draw a maximum of 2 Amps from a 230/240V supply.

No additional power supply is required for the power ue.

C2 Network Cable

A 5 meter length of network (Ethernet) cable has been supplied and is coiled inside the

lower right of the replace. Access this via the removable access panel, and connect it to

the buildings modem.

ACDEFGSERVICE

B

If you do not wish to connect the replace to the modem, the Network /

Ethernet cable should be run to somewhere accessible by a service

technician, such as a cupboard.

15

C3 Gas Pipe Sizing

Gas pipe should be sized as per the requirements of AS/NZS 5601.1. The pipe sizing must

A C D E F G SERVICE

B

be sucient to deliver the following volume of gas to the heater with all other gas appliances in the home running at the same time:

C4 Gas Pipe Position

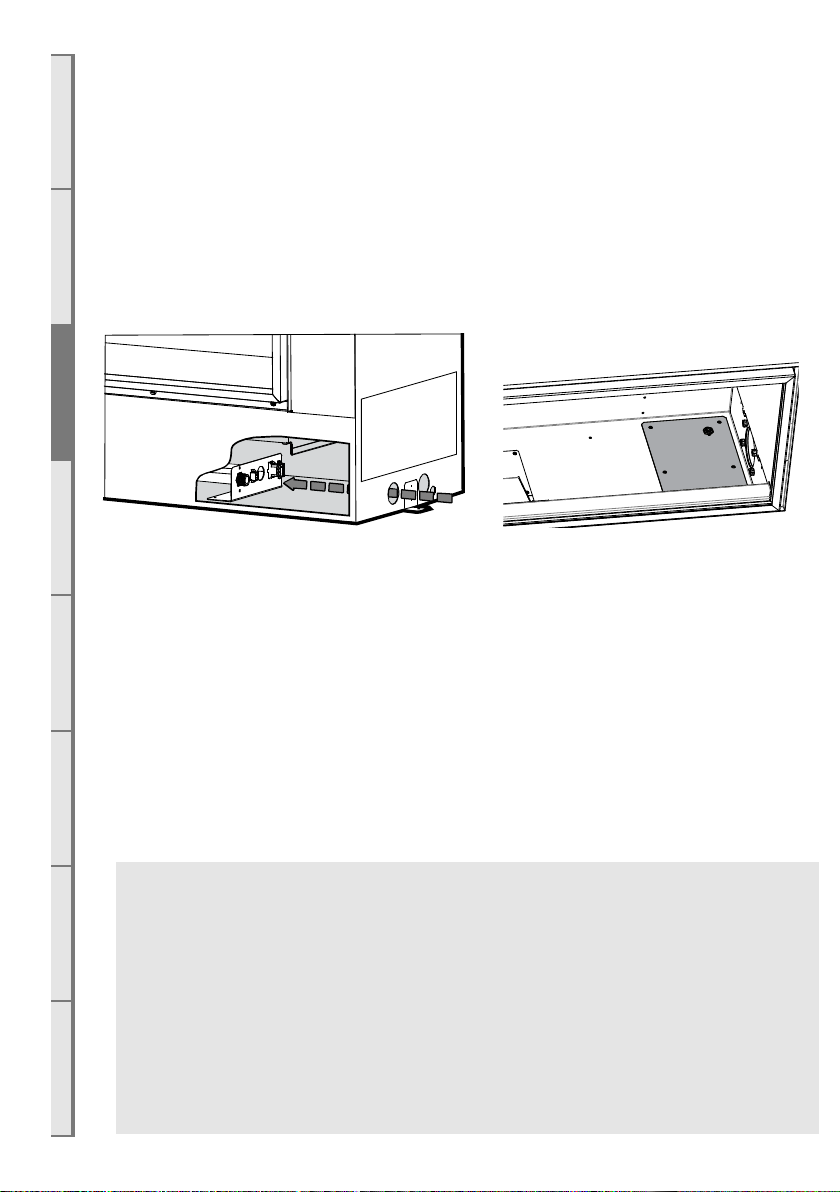

The gas connection is inside the appliance and is ½” male BSP on the lower right of the

appliance as shown. Access is through the bottom of the rebox via a hatch (shaded grey

in the right diagram).

C5 Gas Isolating Valve

A gas isolating valve must be installed in the gas line as close to the appliance as possible.

Fix it in a convenient position to allow it to be closed o quickly and easily during normal

operation. Take into consideration access to this valve once the wall linings are on. This

will also allow for easier servicing in the future.

DX1500 Gas Consumption = 42MJ/hr

DX1000 Gas Consumption = 33MJ/hr

END OF SECTION C

By the end of this section, you should have:

□ An unlined cavity with 230/240V AC supply that the appliance can be plugged into

□ An electrical isolating switch that is accessible once the appliance is installed

□ A suitably sized gas supply to the right hand side of the appliance with a pressure

test point, ready to be connected once installed

□ Network cable installed, ready for plugging into appliance, regardless of being

connected to internet router/network or not

16

D

Installing the Flue

Note: The appliance is designed to operate using the approved exible ue supplied by

Escea. Using other brands of ue may aect the appliance warranty.

D1 Installing the Horizontal Powerue Wall Terminal option

The Horizontal Powerue Wall Terminal must be installed in

the correct orientation. This allows for the correct operation

of the ue system and prevents the ingress of water.

The Horizontal Powerue Wall Terminal must be weathertight when installation is complete to prevent damage to

the dwelling. It must be installed by a suitably qualied

person.

Fit the Horizontal Powerue Wall Terminal into the hole and x in place, making sure the

installation is sealed appropriately to prevent the ingress of water from outside the wall

cladding. Take notice of the label on the termination which shows the correct orientation

that the terminal should be tted.

NOTE: It is the responsibility of the installer to ensure the Horizontal Powerue Wall Terminal is installed to all relevant building codes to ensure weather tightness.

ACDEFGSERVICE

B

17

Loading...

Loading...