Escalade sports T8408C User Manual

MODEL NOS.

T8408C,T8408C,

T8408C, 527.73544

T8408C,T8408C,

PING PONG G2

TABLE TENNIS TABLE

OWNER'S MANUAL

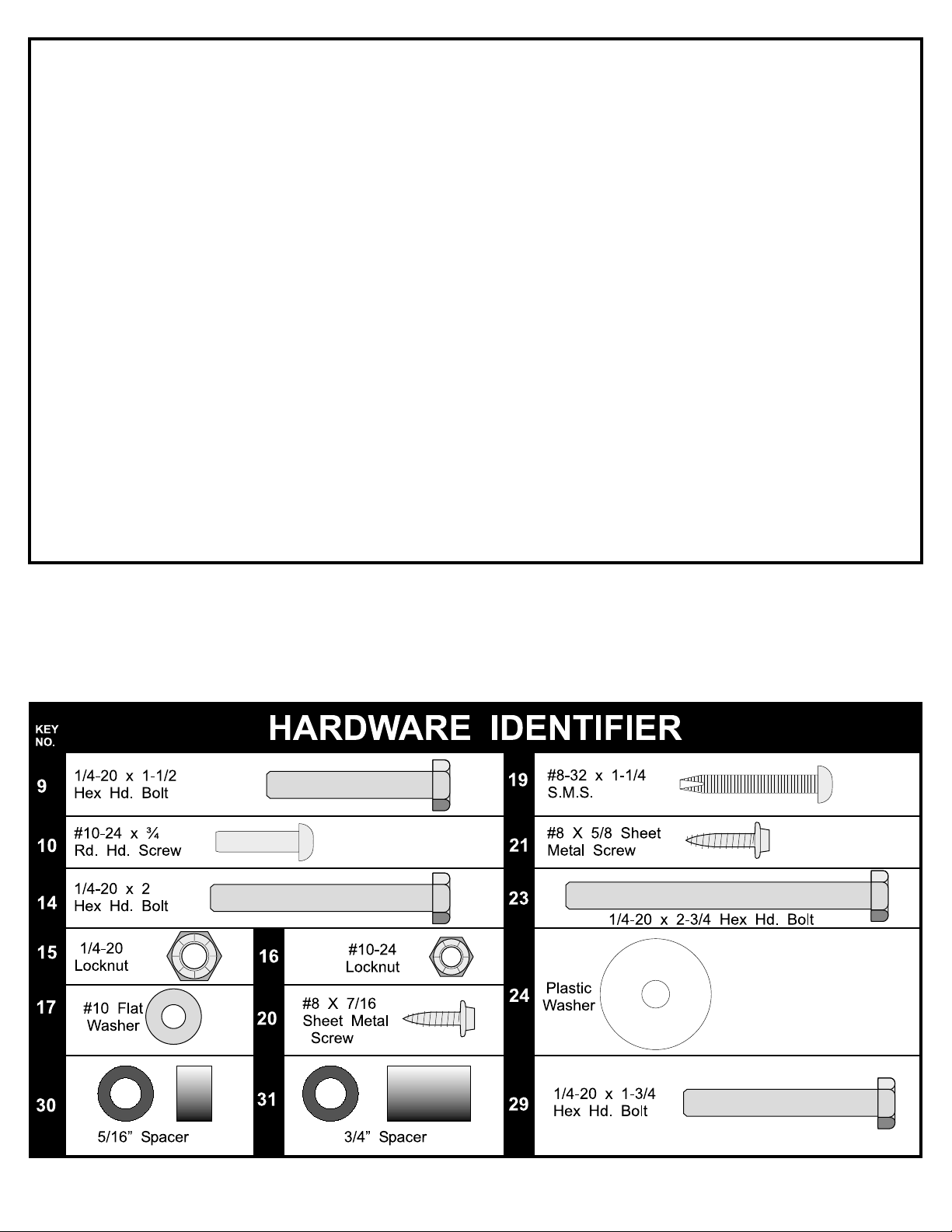

1. Read this manual carefully before starting assembly. Read each step completely before beginning

each step.

2. Some smaller parts may be shipped inside larger parts. Check inside all parts and cartons

before assembling or ordering parts.

3. To make assembly easier, use the Hardware Identifier on page 9 to identify and sort all

fasteners. Check all cartons for kits. All hardware may not be located in one kit.

4. Do not tighten hardware until instructed to do so. If hardware is tightened too soon, mounting holes

may not align and parts may not easily fit together. Leave locknuts slightly loose until you are instructed to

tighten them.

5. Tools required for assembly: Phillips Screwdriver, Two 7/16 Wrenches, One 3/8 Wrench (an adjustable

wrench may be substituted for the wrenches).

Please Do Not Return This Product To The Store!

Contact Escalade® Sports customer service department at:

Phone: 1-866-873-3528 Toll – Free!

Fax: 1-866-873-3533 Toll – Free!

E-mail: tabletennis@escaladesports.com

Mailing Address (correspondence only):

Escalade Sports

PO Box 889

Evansville, IN 47706

Please visit our World Wide Web site at: www.escaladesports.com

ON-LINE TROUBLE SHOOTING TECHNICAL ASSISTANCE

ON-LINE PARTS REQUESTS FREQUENTLY ASKED QUESTIONS

®

ADDITIONAL ESCALADE

SPORTS PRODUCT INFORMATION

2L-6848-01

Escalade® Sports products may be manufactured and/or licensed under the following patents:

6120397, 5816957, 5769744, 5119741, 4911085, 4717157, D460140, D420563

Additional patents may be pending. One or more of the listed patents and/or pending patents may cover specific product.

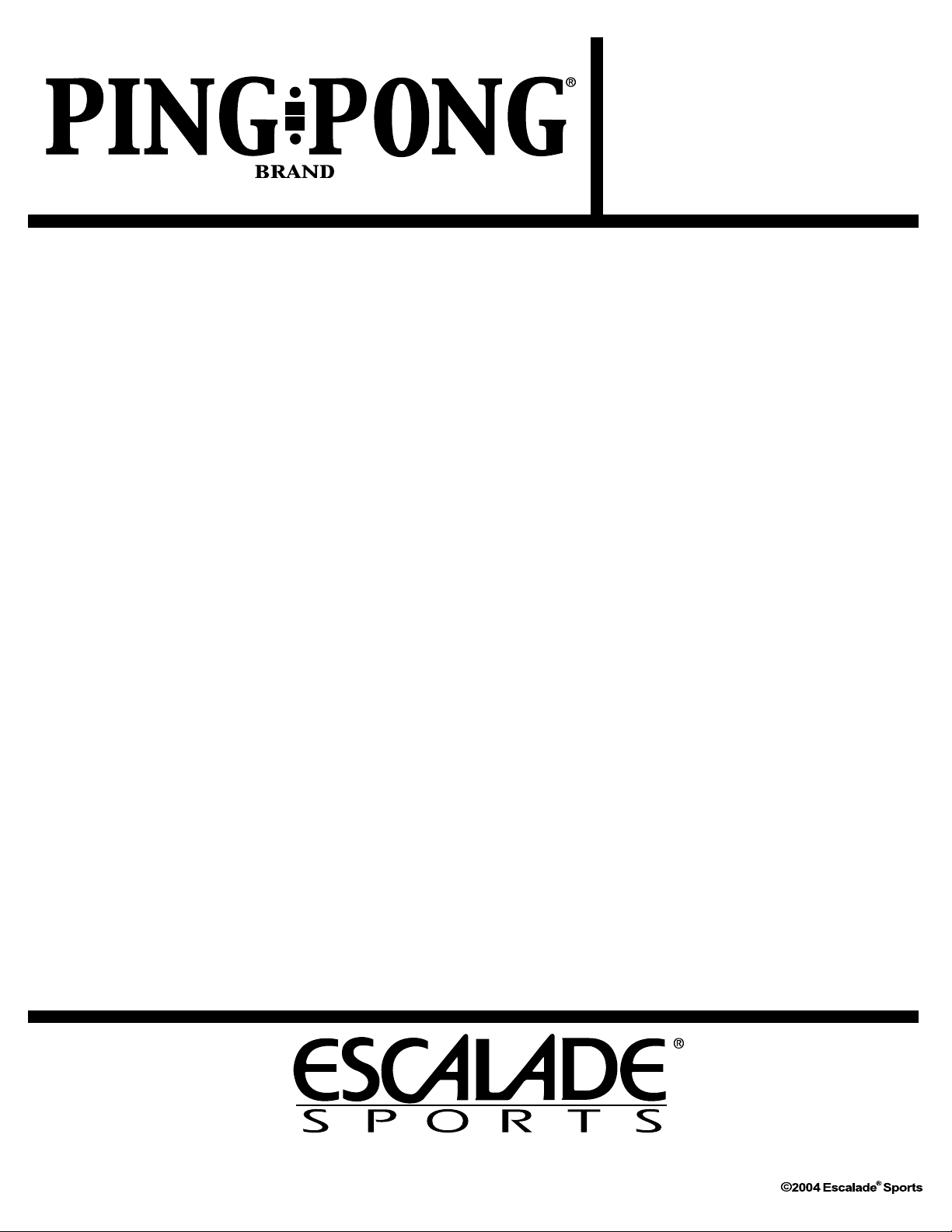

1. Lay table top #1 painted side down, on a smooth, flat

surface. Use the shipping container to protect the

painted surface of the table top.

2. Assemble the two “L” tubes and the center tubes that

make up the “U” Support and the “U” Leg. Align on

Table Top as shown in Figure 1. Note: “U” Leg is

larger and wider than the U Support. The Uleg should be installed on the end of the table

half with the end rail mounting holes.

3. Put plastic caps #13 on the end of U-leg #2.

Figure 1

4. Align the holes in the U-clips #3 with pilot holes in table top

assembly and secure with twenty four screws #20 as shown.

IMPORTANT:

Be sure the slot in the six U-clips #3 all face the same

direction (toward the end of the table with the Usupport) as shown.

Figure 2

IMPORTANT: U-Leg is wider than U-support.

Make sure they are assembled exactly as

shown. If not, there will be a large gap between

table halves and table will not operate properly!

2

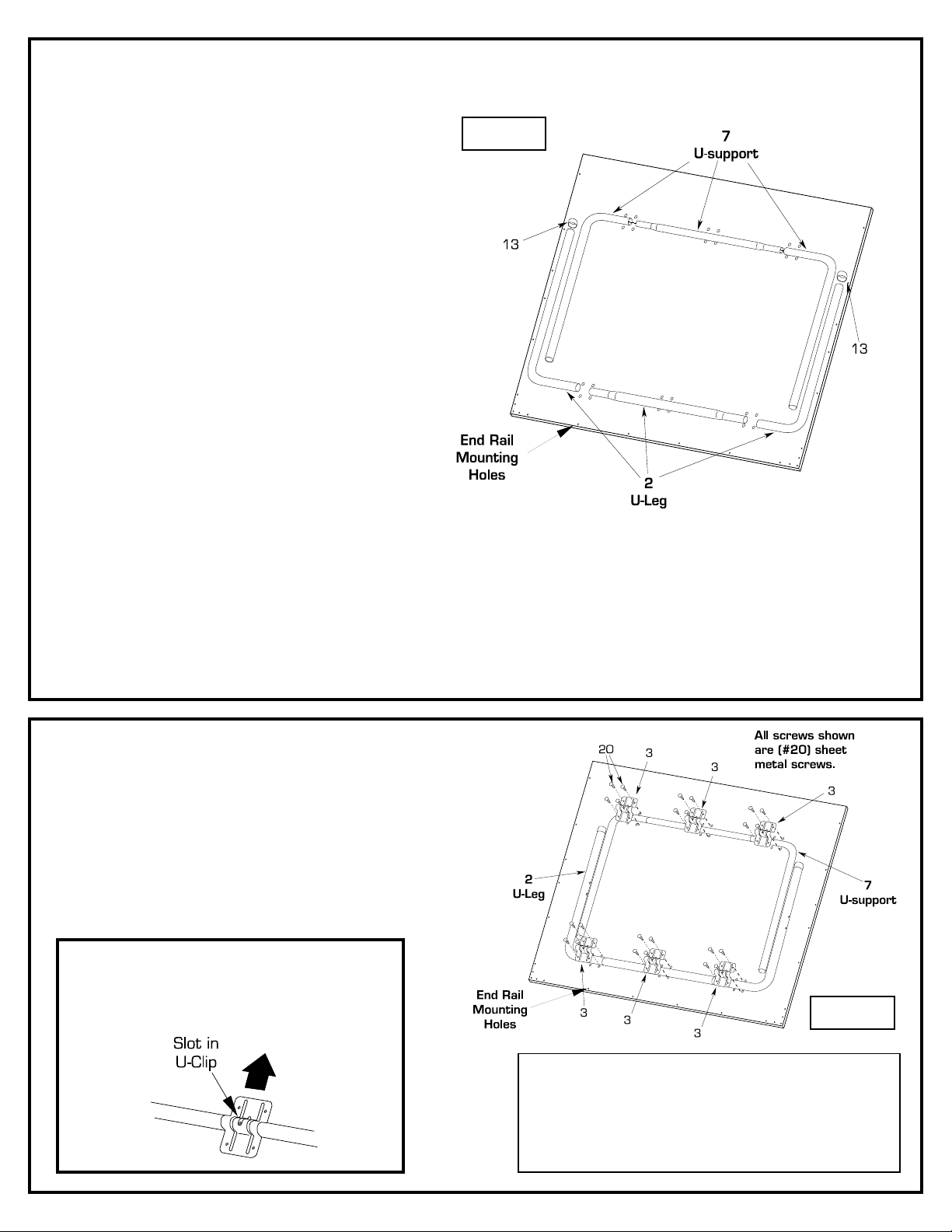

5. Lay out rails #25 and 26, as shown in Figure 3, around edges

of table top.

6. Line up holes in rails with pilot holes in top and secure using

eighteen screws #20. See Figure 3.

Figure 3

7. Lay Corner Caps #22 on table as shown in Figure 4. If Corner

Cap sticks above table top surface of table, flip over so shorter

distance is against edge. Secure to bottom of table with three

screws #21.

8. Rotate U-support #7 until you see the screw hole in

the slot of U-clip # 3. Slide U-support #7 side to side

if necessary.

9. Insert screw #19 through slot in U-clip #3 and into

U-support #7. Thread it all the way into U-support

#7 until it touches the back of the tube. There should

be about 3/8 inch of screw #19 left sticking out. Repeat for U Leg #2.

Figure 4

Figure 5

3

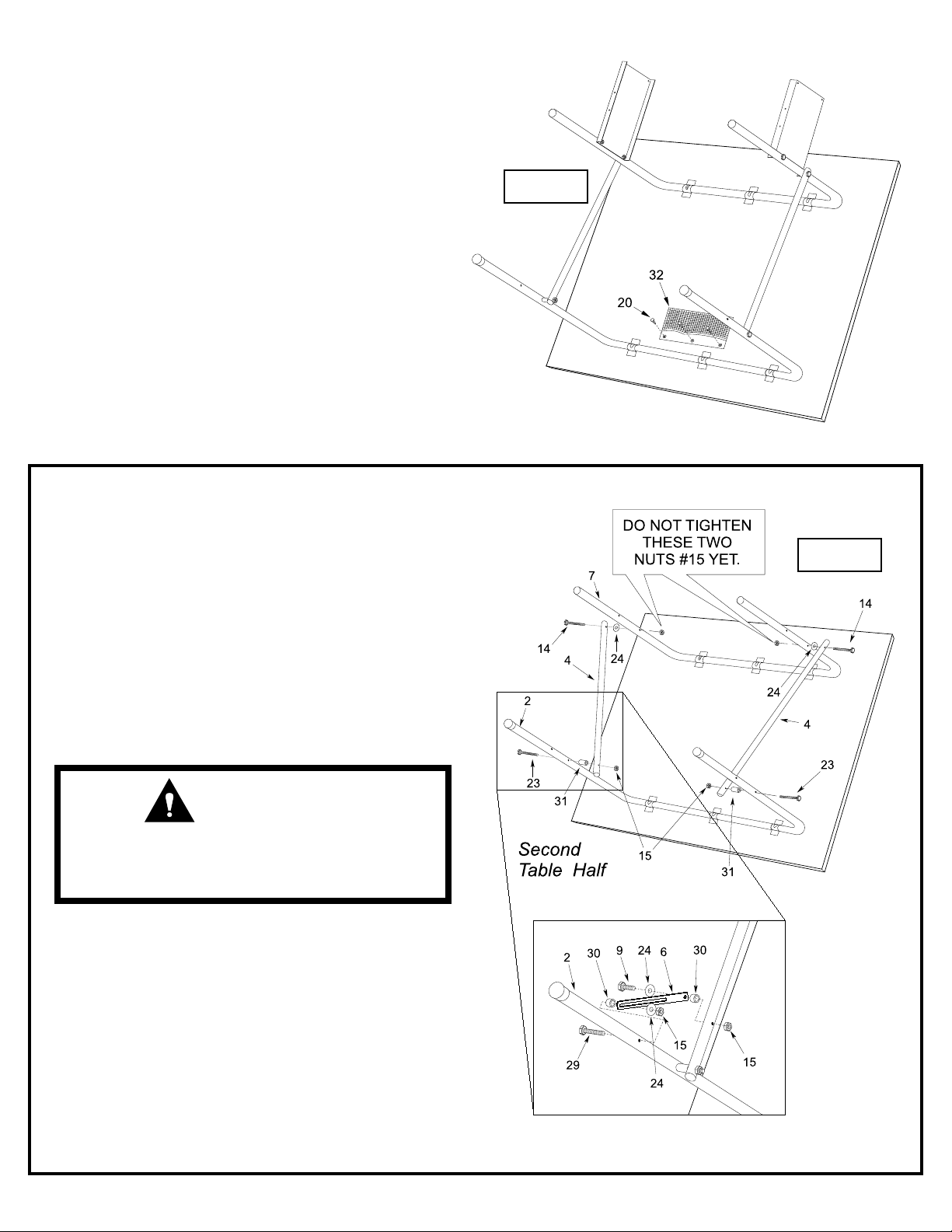

10. Attach end of linkages #4 with two holes to INSIDE of U-leg

#2 as shown in Figure 6. Secure through end hole with screws

#23, locknuts #15 and plastic spacers #31. Tighten hardware

snug enough to keep table stable but do not overtighten. Tubes

must pivot freely.

11. On one side of the table attach slotted end of safety strap #6 to

INSIDE of U-Leg #2 using one bolt #29, one spacer #30,

one washer #24, and one hex nut #15. Tighten hardware until

snug but do not overtighten. Tubes must pivot freely. See Figure

7.

12. Attach other end of safety strap #6 to OUTSIDE of linkage #4

using one bolt #9, one washer #24, one spacer #30, and one

hex nut #15.

Important! Do NOT put other safety strap #6 on this table half.

It will be installed on other table half later.

13. Attach other end of linkages #4 to OUTSIDE of U-support #7

with screws #14 and plastic washers #24. Then slide name

panel #5 onto the same screws #14 on INSIDE of U-support

#7. Secure with locknuts #15. Tighten hardware until snug but

do not overtighten. Tubes must pivot freely.

Figure 6

Figure 7

14. Attach bottom of name panel #5 to U-supports #7. Secure with

hex bolts #9 and locknuts #15. Tighten nuts but be careful not

to crush tubes. See Figure 6.

15. Gently tap caster sockets #12 into U-support #7 until flange

on sockets touches the edge of the tube. DO NOT HIT CASTER

SOCKET DIRECTLY WITH A HAMMER! SET A PIECE OF

WOOD ON CASTER SOCKET AND HIT PIECE OF

WOOD TO DRIVE CASTER SOCKET INTO U-SUPPORT.

16. Insert casters #11 into caster sockets #12.

CAUTION:

AT LEAST TWO ADULTS ARE NEEDED

TO MOVE TABLE HALF!

17. Prepare an area for the assembly of the second table top half. If

necessary, move the first table top half aside with the aid of a

helper. Be sure to place it in a location where it won't be disturbed or damaged. If setting on its side, be sure to place the

bottom edge no less than 12 inches away form the wall. Also

be sure to place carpet or pieces of the shipping carton down

to protect table top edges. If floor is not carpeted, brace table

top half with a heavy object to keep it from sliding.

Figure 8

4

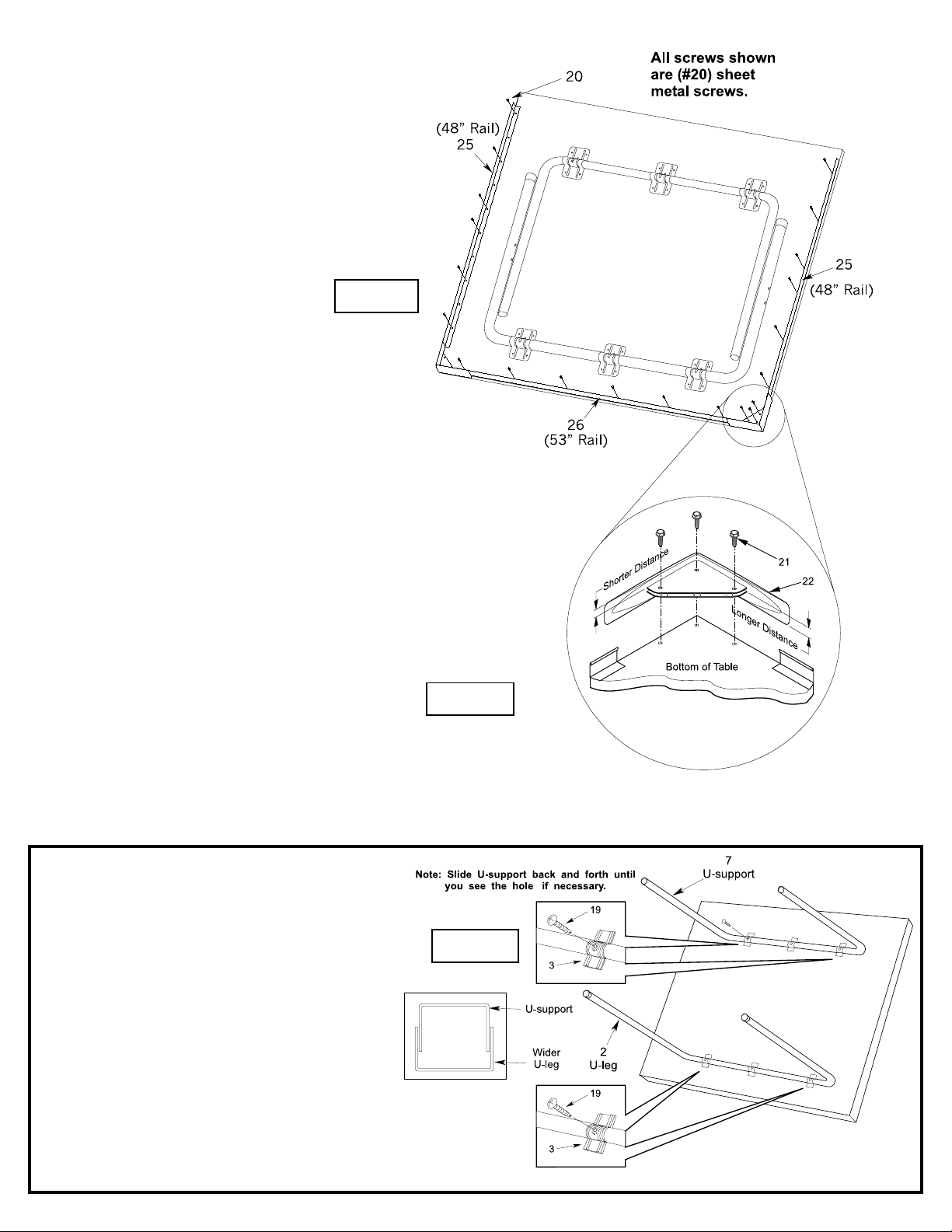

18. Attach paddle pouch #32 to bottom of table, as shown in Figure 9,

using three screws #20.

19. Repeat steps 1 through 12 on second table half.

20. Gently tap caster sockets #12 into U-support #7 on second table

half until flange on sockets touches the edge of the tube. DO NOT

HIT CASTER SOCKETS TOO HARD WITH A HAMMER. Casters could break if hit too hard.

21. Insert casters #11 into caster sockets #12 on second table half.

Figure 9

Figure 10

22. Attach linkages #4 to the OUTSIDE of U-support #7 on second

table half. Use screws #14, plastic washers #24 and hex nuts #15.

NOTE: Tighten locknuts #15 finger tight only. They will be

removed when the two table top halves are connected.

CAUTION:

AT LEAST TWO ADULTS ARE NEEDED TO

COMPLETE THE REMAINDER OF THE

ASSEMBLY!

5

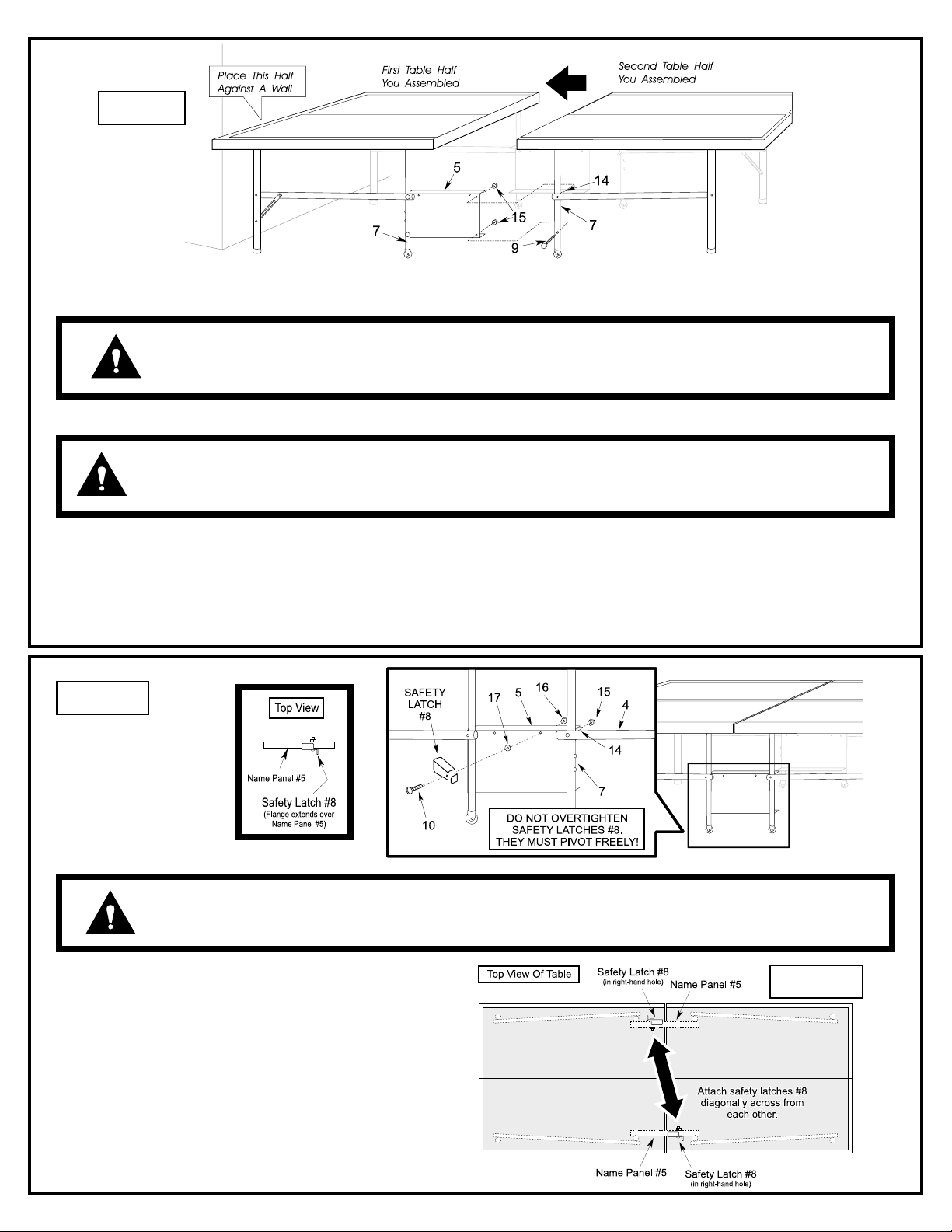

Figure 11

23. Make sure the legs on the first table top half (the half with the name panel #5) are open. With one person on each side of the table, lift and set

table half on its legs. Place table against a wall as shown above to help stabilize table top half while second half is being attached. Be sure there

is enough room to connect second half.

BE SURE THE FIRST TABLE HALF YOU ASSEMBLED (WITH NAME PANELS #5

CAUTION:

24. Place a hex bolt #9 and a locknuts #15 on floor next to caster wheels (on both sides of the table half) so they will be handy for the next step.

CAUTION:

25. With a person on both sides of the second table half, slide the second table half against the first table half. Remove locknuts #15 from screws

#14 on second table half where U-support #7 and linkages #4 join. Align holes in name panels #5 (on first table half) with holes in Usupports (on second table half). Secure second table half to top hole in name panel #5 using hex bolt #14 installed earlier and locknuts just

removed. Secure second table half to bottom hole in name panel #5 with the two hex bolts #9 and locknuts #15 you placed on the floor

earlier. Tighten locknuts snug but do not overtighten. These joints must pivot. At this point go back and tighten hex bolts #9.

ATTACHED) IS STABLE AND AGAINST A WALL. DO NOT LEAVE TABLE HALF

STANDING UNATTENDED.

UNTIL THE TABLE HALVES ARE CONNECTED THEY WILL NOT STAND ON THEIR

OWN. IT IS RECOMMENDED TO HAVE THREE PEOPLE TO CONNECT TABLE

HALVES. TWO TO STABILIZE TABLE AND ONE TO BOLT TABLE TOGETHER.

Figure 12

INSTALL SAFETY LATCHES #8 AS SHOWN ABOVE FOR PROPER USE OF

CAUTION:

26. Choose a name panel #5 on either side of the table and install

one safety latch #8 into the right-hand hole on that name panel

as shown in Figures 12 & 13. Use one screw #10 one washer

#17 and one hex nut #16. NOTE: Flange on safety latch

must extend over top of name panel as shown in Figure

12. Safety latch must pivot freely.

27. Go to the other side of the table and install the second safety latch

into the right-hand hole on the other name panel #5.

Safety latches must be attached diagonally across

from each other. (See Figure 13)

TABLE! DO NOT SKIP THIS STEP! DO NOT OPERATE TABLE UNTIL SAFETY

LATCHES ARE INSTALLED AND ASSEMBLY IS COMPLETE!

NOTE:

Figure 13

6

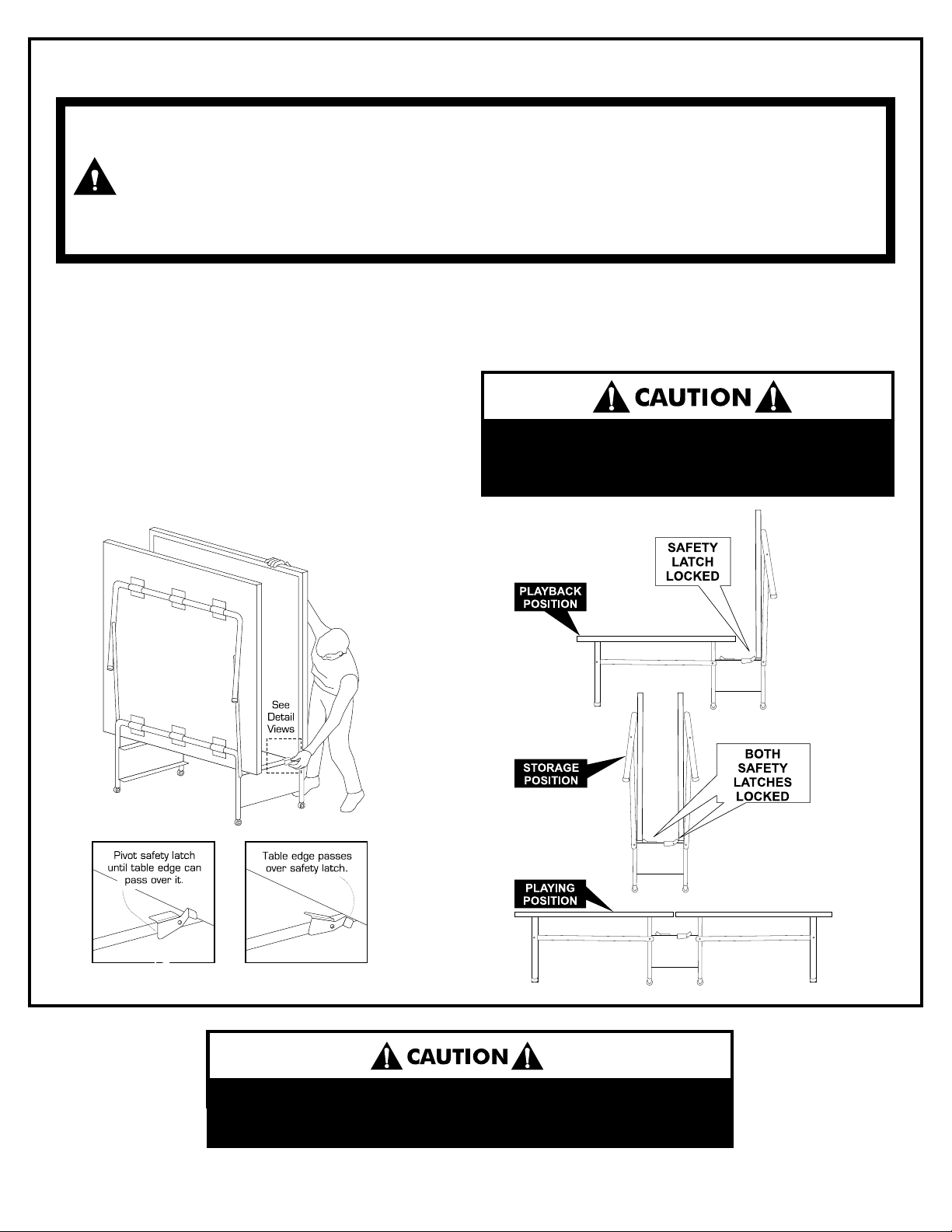

OPENING AND CLOSING INSTRUCTIONS

READ OPERATING INSTRUCTIONS CAREFULLY BEFORE OPERATING TABLE! DO

NOT ALLOW CHILDREN TO OPEN TABLE! DO NOT CLIMB, STAND OR JUMP ON

CAUTION:

TABLE! SERIOUS OR FATAL INJURY MAY RESULT! THIS IS NOT A TOY! TABLE IS

TO BE OPENED OR CLOSED BY ADULTS ONLY! FAILURE TO COMPLY WITH

OPENING AND CLOSING INSTRUCTIONS COULD RESULT IN PERSONAL INJURY

OR PROPERTY DAMAGE.

TO OPEN:

IMPORTANT! Be sure legs are not pushed flat against table

top before opening.

1. Pull both legs away from table slightly.

2. Stand behind the table near the safety latch.

3. Hold table half with one hand and pivot safety latch enough to

allow the edge of the table half to pass over it.

4. While keeping an eye on the safety latch, pivot table half until it

moves past the safety latch. Once edge of table has passed over

safety latch, stop pivoting table half.

5. With both hands on the table half, center yourself along the table

half and lower the table half to the floor.

6. Repeat for the other table half.

TO CLOSE:

1. Lift table half upward and inward to vertical position.

2. Check to be sure that table half is locked in the safety latch.

3. Do NOT push legs flat against table top.

4. Repeat for the other table half.

When closing table to storage position make sure

table top is past latch and latch is in locked position.

Do NOT leave table unattended until latch is locked

as shown.

THIS IS A GAME TABLE. DO NOT SIT, STAND, LEAN, WALK OR JUMP

ON TABLE! FAILURE TO COMPLY WITH THIS CAUTION COULD

RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

7

90 DAY LIMITED WARRANTY

This consumer warranty extends to the original consumer purchase of any ESCALADE® SPORTS Product

(hereinafter referred as the "Product").

WARRANTY DURATION:

ninety (90) days from the original purchase.

WARRANTY COVERAGE: ESCALADE SPORTS warrants to the original Consumer Purchaser that any

Product of its manufacture is free from defects in material and workmanship when used for the intended

purpose under normal use and conditions. THIS WARRANTY IS VOID IF THE PRODUCT HAS BEEN DAMAGED BY ACCIDENT, UNREASONABLE USE, NEGLIGENCE, IMPROPER SERVICE, FAILURE TO FOLLOW

INSTRUCTIONS PROVIDED WITH THE PRODUCT OR OTHER CAUSES NOT ARISING OUT OF

DEFECTS IN MATERIAL AND WORKMANSHIP.

WARRANTY PERFORMANCE:

shall repair or replace with a comparable model, and Product, or component thereof, which may prove

defective under normal use and proper care, and which our examination shall disclose to our satisfaction

to be thus defective, please contact our Warranty Dept.

Escalade® Sports, Inc. - P.O. Box 889, Evansville, IN 47706 - Attn: Warranty Dept.

This Product is warranted to the original consumer purchase of a period of

During the above ninety (90) day warranty period, ESCALADE SPORTS

1-800-426-1421 / Warranty Dept.

Or Write us at:

Or E-mail us at:

customerservice@escaladesports.com

Other than shipping requirements no charge will be made for such repair or replacement of in-warranty

Products. ESCALADE® SPORTS strongly recommends that the Product is insured for value prior to mailing.

WARRANTY DISCLAIMERS: ANY IMPLIED WARRANTIES ARISING OUT OF THIS SALE, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PAR-

TICULAR PURPOSE, ARE LIMITED IN DURATION TO THE ABOVE NINETY (90) DAY WARRANTY PERIOD. ESCALADE® SPORTS SHALL NOT BE LIABLE FOR LOSS OF USE OF THE PRODUCT OR OTHER

CONSEQUENTIAL OR INCIDENTAL COSTS, EXPENSES OR DAMAGES INCURRED BY THE CONSUMER OF ANY OTHER USE.

Some states do not allow the exclusion or limitation of implied warranties or consequential or incidental

damages, so the above limitations or exclusions may not apply to you.

LEGAL REMEDIES: This warranty gives you specific legal rights and you may also have other rights

which may vary from state to state.

8

CARE AND MAINTENANCE

You have purchased a quality product that will give you years of enjoyment. By following these simple maintenance steps, you will add to the life of

your new table.

THE TABLE TOP

The top (playing surface) of your table is made of particle board. Like all products made of wood, it can be affected by atmospheric changes in both

temperature and humidity. This may cause a slight sag or distortion as the top expands or contracts. This is normal and should not cause concern

as it does not detract from the play or utility value of the table. After assembly of the table, you can minimize the effects of temperature and humidity

changes by storing the table in the folded up position in a dry area when table is not in use.

STORAGE OF YOUR TABLE

This table must be stored indoors to prevent damage to the playing surface. Dampness and extreme temperature changes can cause the wood to

warp, swell, crack or blister. When your table is not in use, it should be folded up in a dry area. Due to the nature of particle board, table top may

bow. Damp and humid conditions will amplify this. This is normal and will not affect playability of table.

CLEANING YOUR TABLE

To clean your table use a soft, damp (NOT WET) cloth only. To prevent damage to your table's playing surface, DO NOT USE ANY CHEMICALS,

ABRASIVE OR CLEANING PRODUCTS on your table's playing surface.

MAINTENANCE OF YOUR TABLE

Be sure to oil all moving parts of your table including the pivot points. This will insure the safety and ease of use of your table.

This table must be kept indoors to prevent damage to the playing surface. Dampness and extreme temperature changes which occur on patios or

similar areas can cause wood to warp, swell, crack or blister.

UNLEVEL FLOORS

If table does not seem level, it is probably due to uneven or unlevel floors. Set the table in its PLAYING POSITION and move table several inches in

different directions to find the best location for the table. If the floor is extremely unlevel, table may not play or operate properly. If table is high in

the center, shim up under the outer U-legs.

9

Loading...

Loading...