Escalade sports T8233 User Manual

OWNER’S MANUAL

Table Tennis Table

See separate sheet for product part numbers. Be sure to

write your model number and serial number here for future

reference. You can find these numbers printed on the bottom

of the table.

MODEL # T8233

Patent Pending

SERIAL #

READ ASSEMBLY, OPERATING AND SAFETY INSTRUC-

CAUTION:

Thank you for buying our product. We try hard to insure that our products are of high quality and free of problems

such as manufacturing defects or missing parts. However, if you have any problems with your new product, please

call us at:

Please have this Assembly Instruction Sheet with you when you call.

TIONS CAREFULLY! AT LEAST TWO ADULTS ARE NEEDED

TO PUT THIS TABLE TOGETHER!

TOLL FREE 1-800-426-1421

(THIS IS A CONSUMER ONLY NUMBER)

Or write us at: CUSTOMER SERVICE DEPT., P.O. Box 889, Evansville, IN 47706

Fax Number (812) 467-1399

Please provide model number and/or part number (not just the key number) of the product and/or part when you call

or write. These numbers can be found on the product, packaging and/or on this instruction sheet.

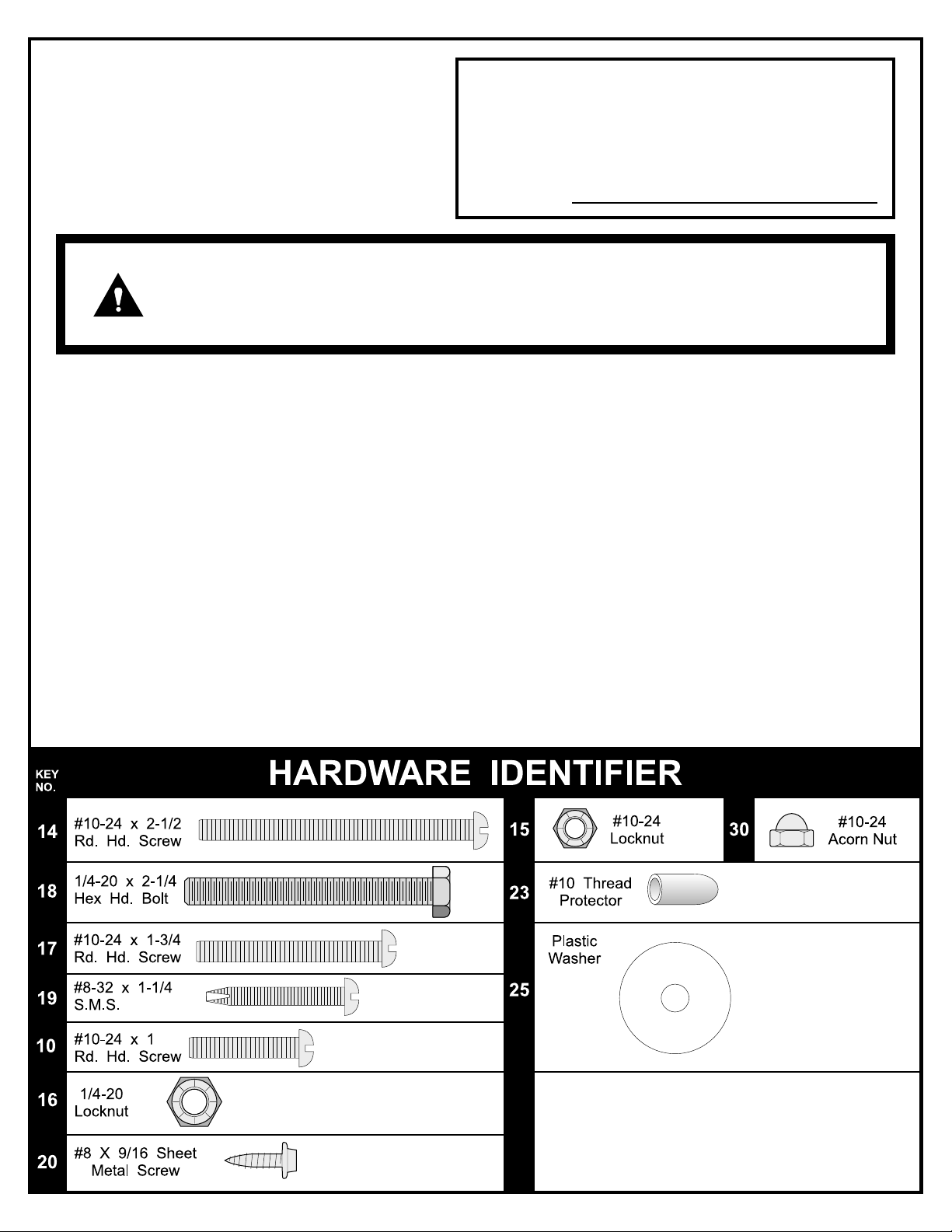

TOOLS NEEDED:

Phillips Screwdriver, Standard (Flat Blade) Screwdriver, Two 7/16 Wrenches, One 3/8 Wrench (an adjustable

wrench may be substituted for the wrenches), Scissors, Tape Measure

2L-6551-00

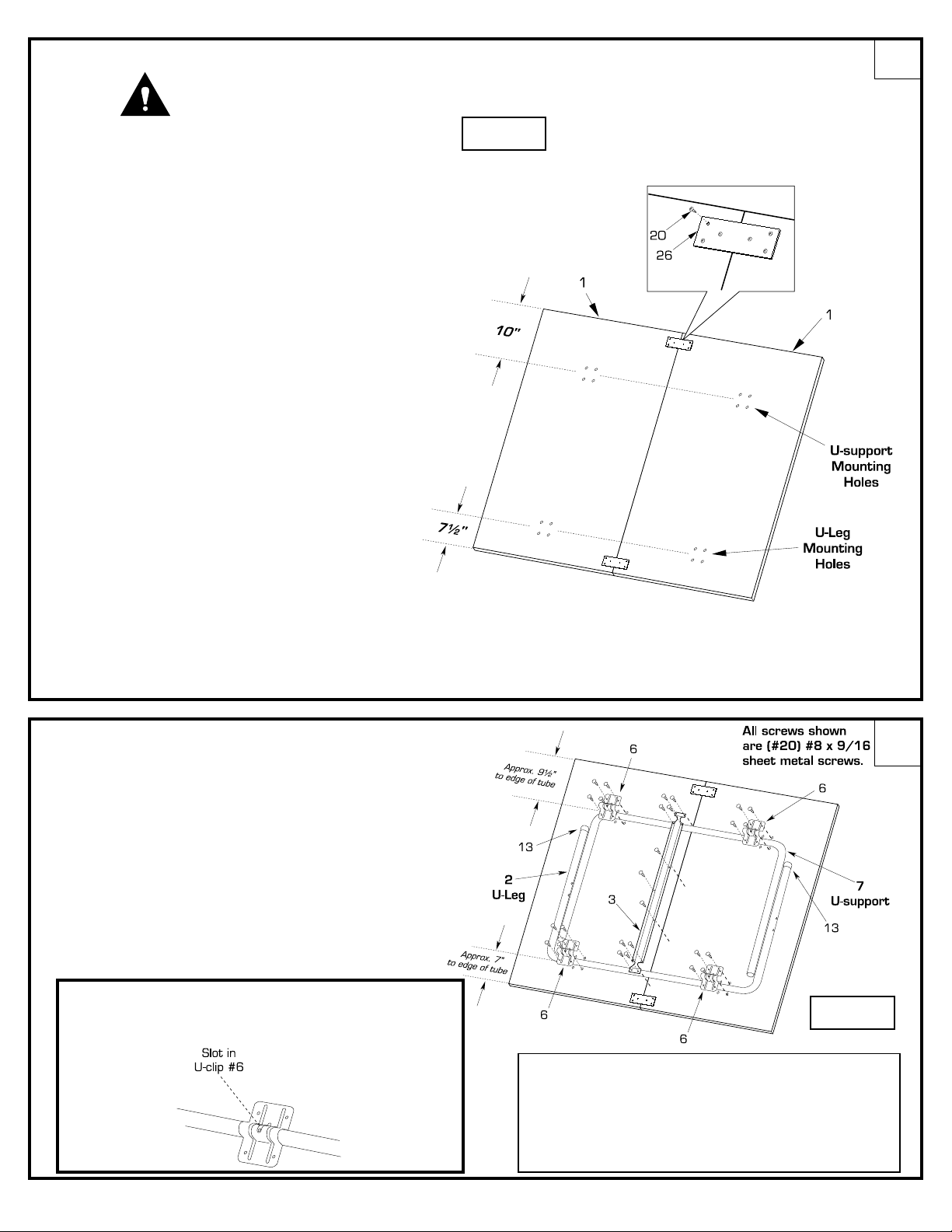

CAUTION:

DO NOT MOVE TABLE TOP HALF SECTIONS

UNTIL AFTER THE U-LEGS AND U-SUPPORTS

ARE INSTALLED! MOVING TABLE TOP

SECTIONS WITH ONLY CONNECTING PLATES

INSTALLED WILL CAUSE SEVERE DAMAGE!

1. Lay two table top sections #1 (painted side down,

U-leg and U-support mounting holes aligned) on

a smooth, flat surface. Use the shipping container to protect the painted surface of the table

top sections. NOTE: It is very important that the

surface you are working on is flat. If it isn't, the

table top sections may not line up properly.

DO NOT PUT YOUR ENTIRE WEIGHT ON

TABLE TOP BOARDS WHEN ASSEMBLING

TOP. YOU COULD DAMAGE BOARDS.

A

Figure 1

2. Align holes in connecting plates #26 with pilot

holes in boards #1 and attach with six screws

#20 each. Do not overtighten screws causing

them to strip out pilot holes.

3. Put plastic caps #13 on the end of U-leg #2.

4. Lay one U-leg #2 and one U-support #7 on the first table top

assembly as shown. (U-leg is wider than U-support. The distance between the edge of the U-leg and the end of the

table top assembly measures approximately 7 inches. The

distance between the edge of the U-support and the end of

the table top assembly measures approximately 9½ inches.)

5. Align the holes in the long stiffener #3 and the U-clips

#6 with pilot holes in table top assembly and secure

with eleven screws #20 as shown.

B

IMPORTANT:

Be sure the slot in the four U-clips #6 all face the same

direction (toward the end of the table with the U-support)

as shown.

Figure 2

IMPORTANT: U-Leg is wider than U-support.

Make sure they are assembled exactly as

shown. If not, there will be a large gap

between table halves and table will not

operate properly!

2

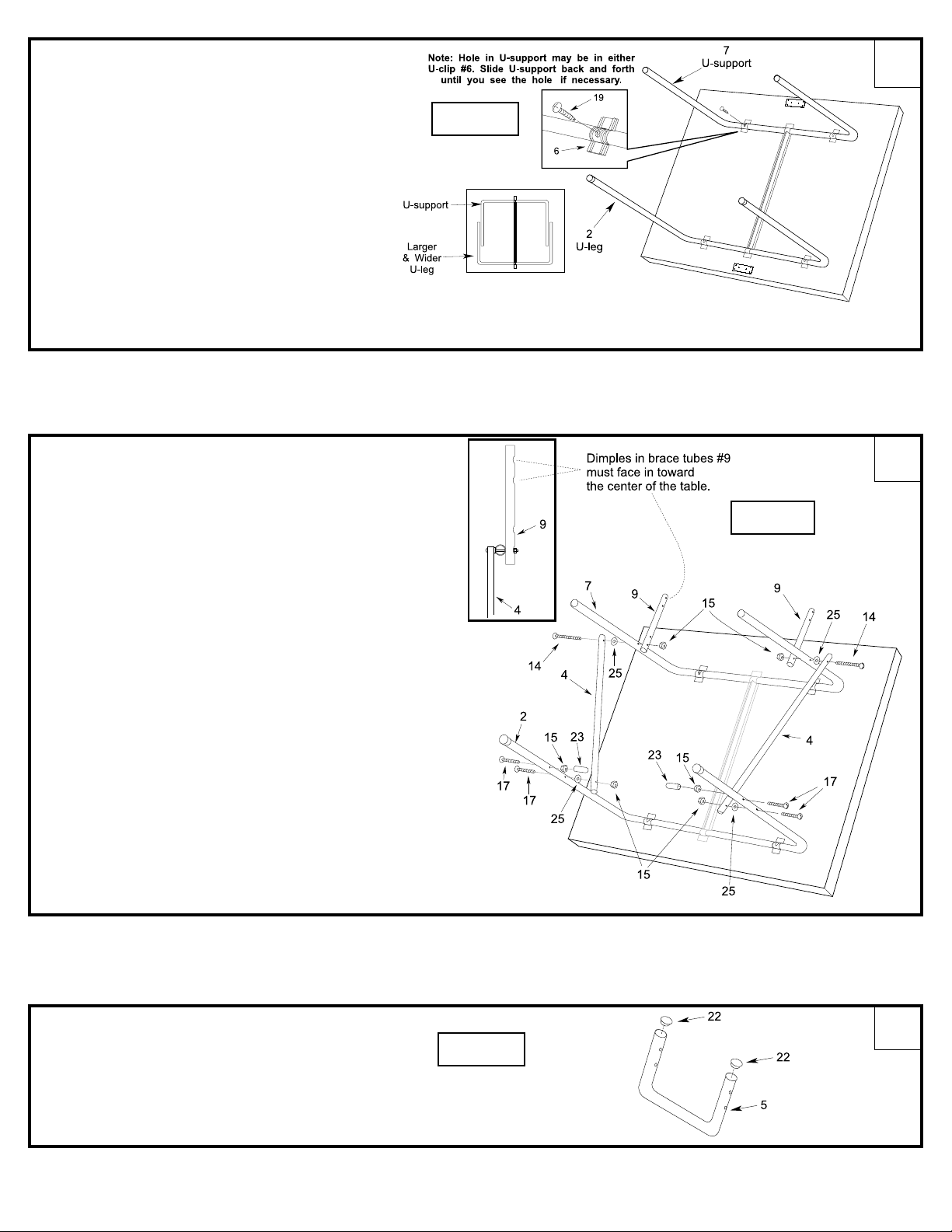

6. Rotate U-support #7 until you see the screw hole

in the slot of U-clip # 6. Slide U-support #7 side

to side if necessary. NOTE: Screw hole may be

in either U-clip. If you don't see hole in slot of

one U-clip, look for it in the other U-clip.

7. Insert screw #19 through slot in U-clip #6 and

into U-support #7. Thread it all the way into Usupport #7 until it touches the back of the tube.

There should be about 3/8 inch of screw #19

left sticking out.

C

Figure 3

8. Attach linkages #4 to INSIDE of U-leg #2 in the hole

shown in Figure 5 (the hole closest to the table top).

Secure with screws #17, locknuts #15 and plastic washers #25. Tighten hardware snug enough to keep table

stable but do not overtighten. Tubes must pivot. NOTE:

Plastic washers go between linkages #4 and U-leg #2.

9. Attach leg stop screws #17 to U-leg #2 in the hole

shown in Figure 4 (the hole closest to the end of tube

#2). NOTE: THESE SCREWS ARE LEG STOP SCREWS.

NOTHING IS ATTACHED TO THEM. Secure with locknuts #15 and thread protectors #23.

10. Attach other end of linkages #4 to OUTSIDE of U-sup-

port #7 with screws #14 and plastic washers #25.

Then slide braces #9 onto the same screws #14 on

INSIDE of U-support #7.

NOTE: Dimples in brace tubes #9 must face in toward the center of the table as shown in Figure 4.

Secure with locknuts #15. Tighten hardware until snug

but do not overtighten. Tubes must pivot freely.

D

Figure 4

11. Put tube plugs #22 into both U-braces #5.

E

Figure 5

3

Loading...

Loading...