Escalade sports T8104 User Manual

MODEL NOS.

T8104T8104

T8104

T8104T8104

SUPREME

TABLE TENNIS TABLE

OWNER'S MANUAL

1. Read this manual carefully before starting assembly. Read each step completely before beginning

each step.

2. Some smaller parts may be shipped inside larger parts. Check inside all parts and cartons

before assembling or ordering parts.

3. To make assembly easier, use the Hardware Identifier on page 7 to identify and sort all

fasteners. Check all cartons for kits. All hardware may not be located in one kit.

4. Do not tighten hardware until instructed to do so. If hardware is tightened too soon, mounting holes

may not align and parts may not easily fit together. Leave locknuts slightly loose until you are instructed to

tighten them.

5. Tools required for assembly: Phillips Screwdriver, two 9/16 Wrenchs, 3/8 Wrench, and Two 7/16

Wrenches (adjustable wrenches may be substituted for the wrenches).

Please Do Not Return This Product To The Store!

Contact Escalade® Sports customer service department at:

Phone: 1-866-873-3528 Toll – Free !

Fax: 1-866-873-3533 Toll – Free !

E-mail: tabletennis@escaladesports.com

Mailing Address (correspondence only):

Escalade Sports

PO Box 889

Evansville, IN 47706

Please visit our World Wide Web site at: www.escaladesports.com

ON-LINE TROUBLE SHOOTING TECHNICAL ASSISTANCE

ON-LINE PARTS REQUESTS FREQUENTLY ASKED QUESTIONS

®

ADDITIONAL ESCALADE

SPORTS PRODUCT INFORMATION

2L-6809-00

Escalade® Sports products may be manufactured and/or licensed under the following patents.

6120397, 5816957, 5769744, 5119741, 4911085, 4717157, D460140, D420563

Additional patents may be pending. One or more of the listed patents and/or pending patents may cover specific product.

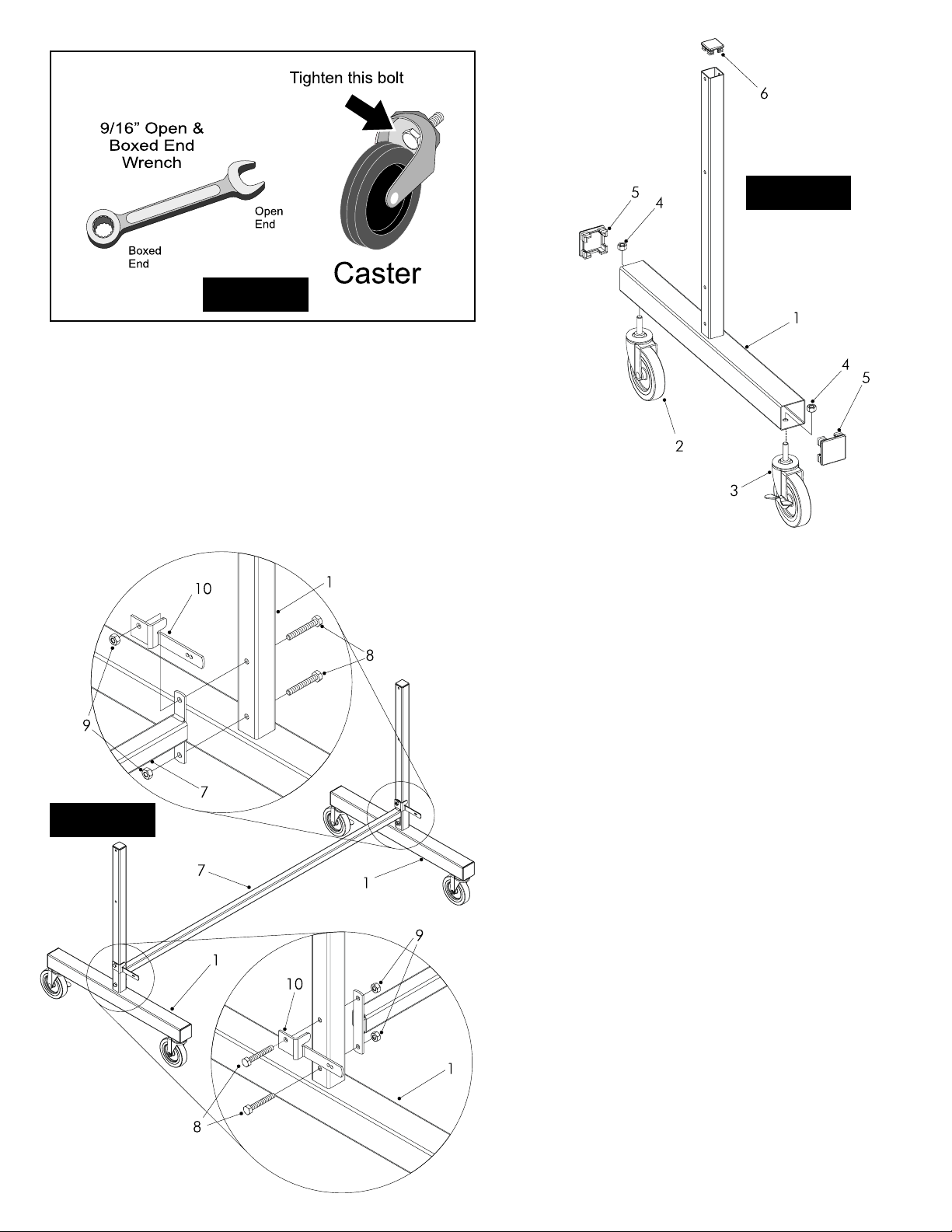

DETAIL A

1. Attach one non-locking caster (#2) and one locking

caster (#3) to each upright assembly (#1) using

one locknut (#4) on inside of tube, as shown in

Figure 1 and Detail A.

2. Place a tube plug (#5) in each end of each upright

assembly (#1) and a tube plug (#6) in the top of

each upright assembly (#1).

FIGURE 1

FIGURE 2

3. Attach cross tube (#7) between two upright assembly

(#1) using two bolts (#8) and two locknuts (#9) in

the lower holes in cross tube and upright assembly.

Note: Do NOT tighten nuts at this time.

4. Attach a latch mounting brackets (#10) to each side

of upright assembly (#1) using two bolts (#8) and

two locknuts (#9) in the upper holes in cross tube.

Note: One latch mounting bracket (#10) will

be mounted on the outside of the upright

assembly (#1) and the other will be mounted

on the inside.

5. Tighten all bolts tight.

2

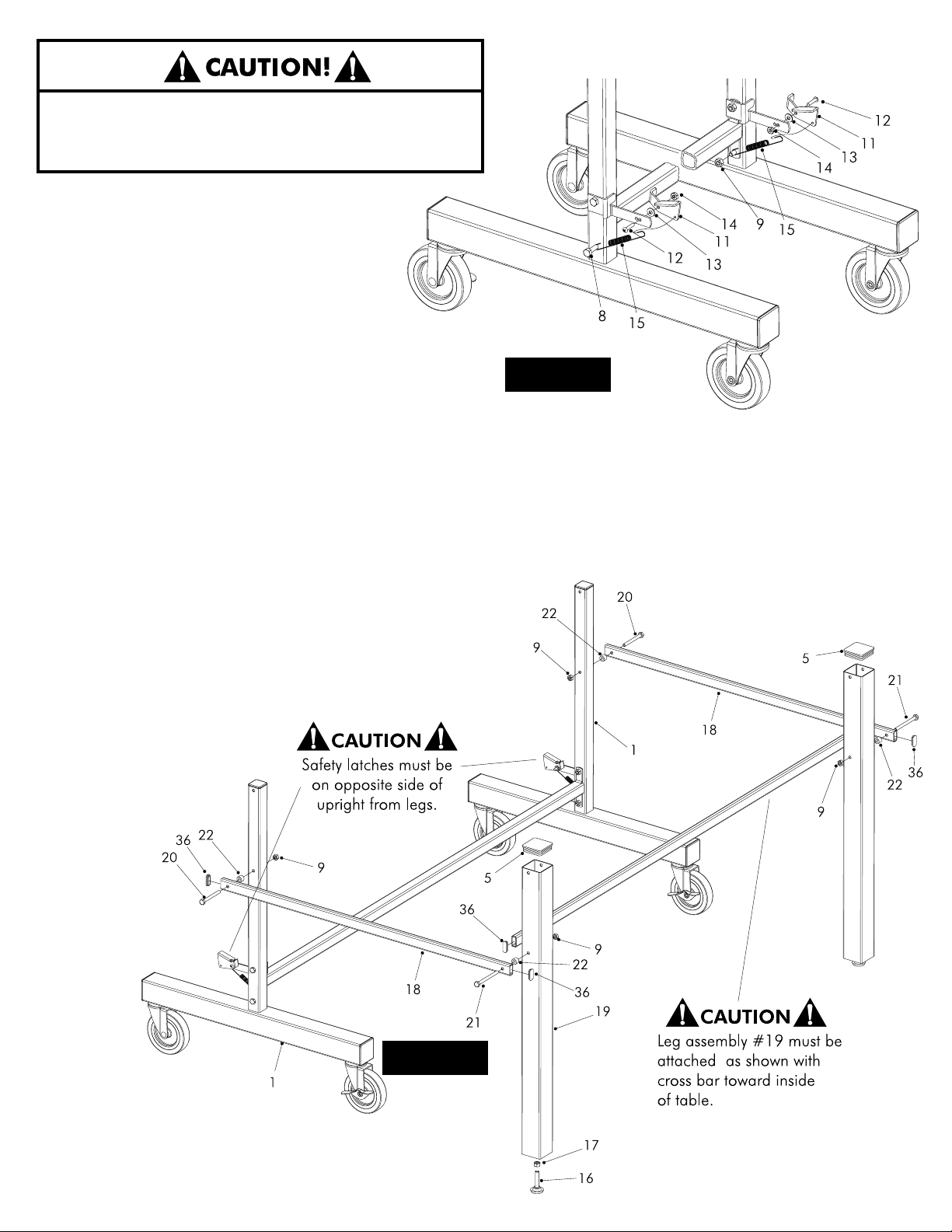

SAFETY LATCHES MUST BE INSTALLED EXACTLY

AS SHOWN. FAILURE TO DO SO COULD RESULT

IN PERSONAL INJURY OR PROPERTY DAMAGE.

6. Attach a safety latch (#11) to each latch mounting

bracket (#10) using one screw (#12), one washer

(#13), and one nut (#14). See Figure 3.

7. Loosen lower bolt (#8) and locknut (#9) and

loop one end of spring (#15) around bolt. Loop

other end of spring through hole in end of safety

latch (#11). Re-tighten bolt (#8) and locknut (#9). See

Figure 3. Repeat for other safety latch.

FIGURE 3

8. Repeat steps 3-7 for other cross tube and upright

9. Install a jam nut (#17) onto each leg leveler (#16) and install leg leveler into ends of legs (#19). See Figure 4.

10. Insert leg cap #5 into tops of legs #19. See Figure 4.

11. Insert tube plug #36 into both ends of linkages #18 and in both ends of cross bar on leg assemblies #19. See Figure 4.

12. Attach linkages #18 to the outside of the upright assembly #1 using one bolt #20, one spacer #22, and one locknut #9

for each linkage. (See figure 4) Do not over tighten these

locknuts, joints must be free to pivot.

13. Attach other end of linkages #18 to the outside of the leg

assembly #19 using bolt #21, spacer #22, and locknut

#9. (See figure 4) Do not over tighten these locknuts,

joints must be free to pivot.

14. Repeat steps 12-13 for

other leg and upright

assemblies.

FIGURE 4

3

Loading...

Loading...