Escalade sports P3269A User Manual

OWNER’S MANUAL

QUEEN ANNE 8FT. LEATHER DROP POCKET POOL TABLE

MODEL NO. P3269A

1. READ THIS MANUAL CAREFULLY BEFORE STARTING ASSEMBLY.

Read each step completely before beginning each step.

2. SOME SMALLER PARTS MAY BE SHIPPED INSIDE LARGER PARTS. CHECK INSIDE ALL PARTS

AND CARTONS BEFORE ASSEMBLING OR ORDERING PARTS.

3. USE THE HARDWARE IDENTIFIER TO IDENTIFY AND SORT ALL FASTENERS. CHECK ALL CARTONS

FOR KITS. ALL HARDWARE IS NOT LOCATED IN ONE KIT.

THIS TABLE IS CONTAINED IN THREE SEPARATE CONTAINERS:

PLEASE DO NOT RETURN PRODUCT TO THE STORE!

Contact Escalade® Sports customer service department at:

Phone: 1-866-556-2757 Toll Free !

Fax: 1-866-873-3532Toll Free !

E-mail: pooltables@escaladesports.com

Mailing Address: Escalade® Sports, PO Box 889, Evansville, IN 47706

Please visit our World Wide Web site at:

www.escaladesports.com

On-Line Trouble Shooting Frequently Asked Questions

Technical Assistance On-Line Parts Requests

Additional Escalade® Sports Product Information

2L-6859-00

Escalade® Sports products may be manufactured and/or licensed under the following patents.

D446275

Additional patents may be pending. One or more of the listed patents and/or pending patents may cover specific product.

CAUTION

THE SPRAY ADHESIVE USED FOR APPLYING PLAYFIELD CLOTH IS EXTREMELY FLAMMABLE AND UNDER

PRESSURE

CHILDREN

AREA

To ensure safety, do not attempt to assemble system without following instructions carefully. Proper and complete assembly, use, and supervision is essential for

proper operation and to reduce the risk of accident or injury. A high probability of serious injury exists if this system is not installed, maintained, and

operate properly.

! CAREFULLY READ CAUTIONS ON SPRAY ADHESIVE CONTAINER! KEEP OUT OF THE REACH OF

! DO NOT USE OR STORE NEAR HEAT SOURCE, FLAMES, SPARKS OR WHEN SMOKING! WORK

MUST BE WELL VENTILATED. OPEN DOORS AND WINDOWS WHEN USING SPRAY ADHESIVE.

Tools Needed: (Not Included)

• Standard Screwdriver

• Phillips Screwdriver

• Drill with 1/8" Drill Bit

• Putty Knife

NOTE: Rails are made with cushion rubber at a height that requires standard 2 1/4” diameter balls.

Your dealer has a complete line Billiard Accessories.

NOTE: This table adds weight to any floor. Be sure floor can withstand this kind of weight. If floor sags,

table will be impossible to level.

• Tape Measure

• Sanding Block

• Scissors or Sharp Knife

• Sandpaper (80 grit)

• 7/16” Open End Wrench

• 1/2” Open End Wrench

• 9/16” Open End Wrench

• Hammer (Small Ball Peen Type)

• Carpenters Level or 36” Straight Edge

• Rachet with 7/16” and 1/2” sockets

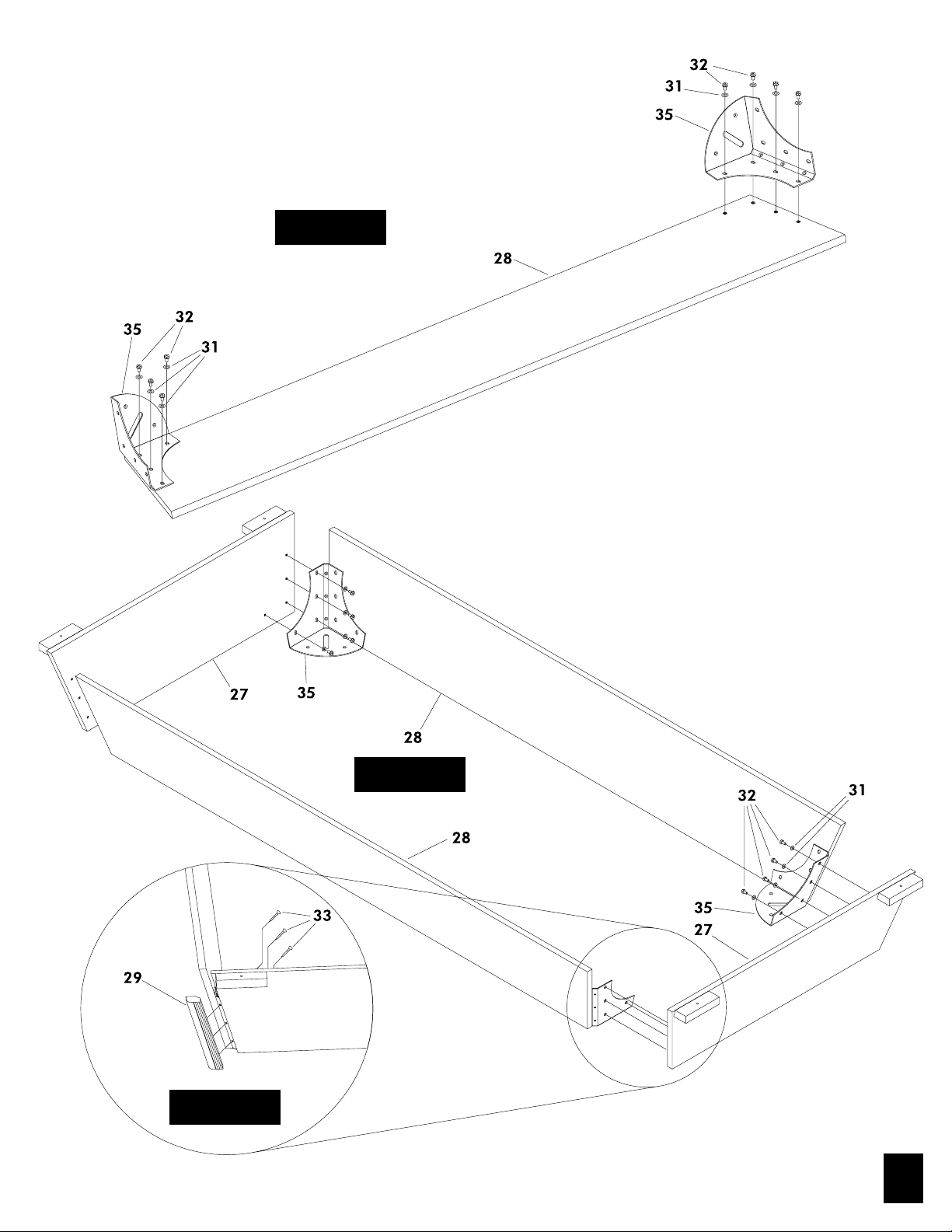

1. Begin by opening hardware kits and sort hardware. Attach leg

bracket #35 to side cabinet panel #28 using four bolts #32 and

four washers #31 for each leg bracket. Do not tighten bolts at this

time. (See Figure 1) Repeat for other side cabinet panel #28.

Figure 1

2. Attach end cabinet panels #27 to leg brackets #35, as shown in

Figure 2, using four bolts #32 and four washers #31 for each leg

bracket. Do not tighten bolts at this time.

Figure 2

3. Attach a corner posts #29 to each leg bracket #35 using three

screws #33 and pilot holes in corner post. See Figure 3. Go back

and tighten bolts #32 from previous step.

Figure 3

Page

3

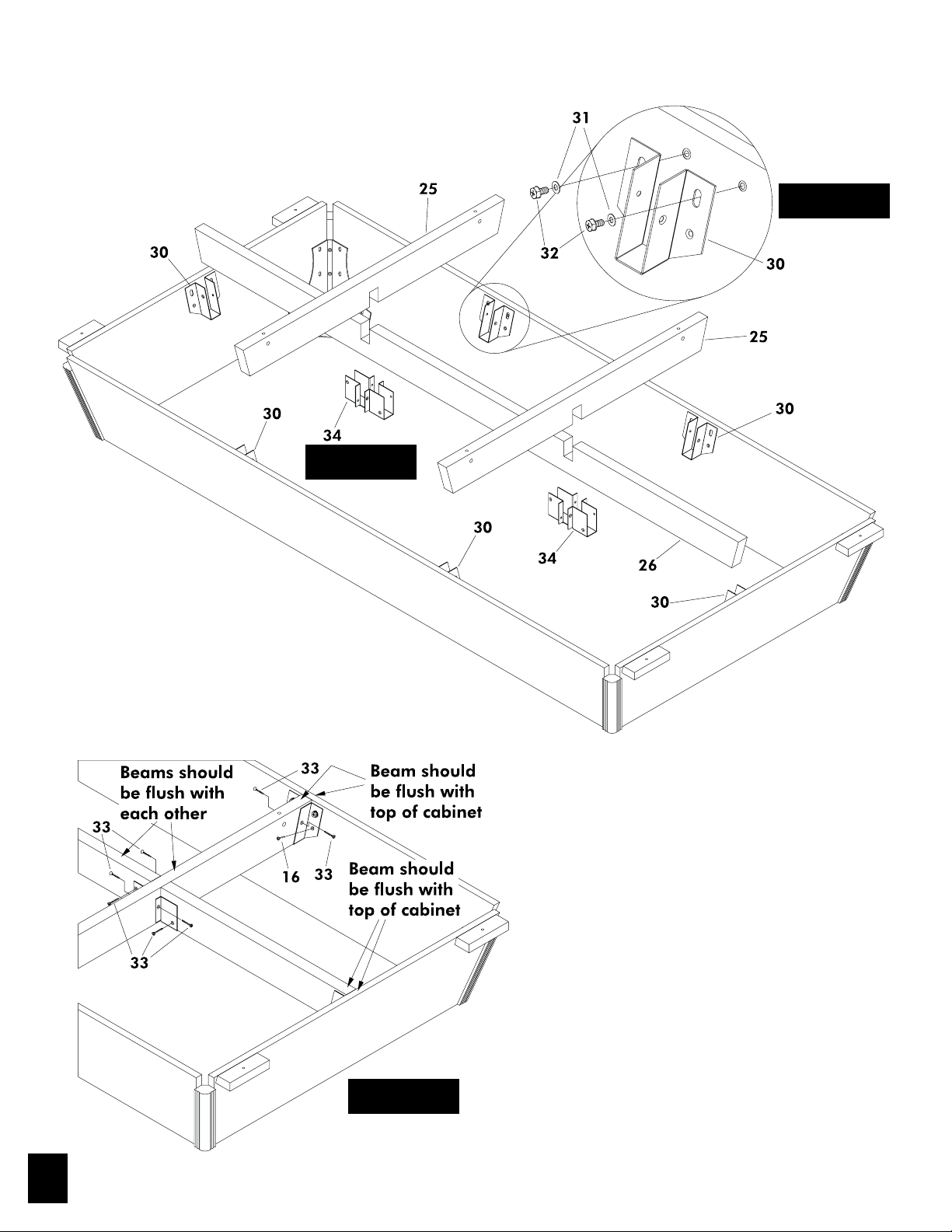

4. Install six hanger brackets #30 to inserts on inside of cabinet using

two hex bolts #32 and two washers #31 for each hanger bracket.

Do not tighten hex bolts #32 at this time. See Figure 4.

5. Slide center beam #26 and cross beams #25 into hanger brackets

as shown in Figure 5. Beams should rest on the bottoms of the hanger

brackets.

Figure 5

Figure 4

6. Slide two cross brackets #34 up from

the bottom onto center beam #26 and cross

beams #25.

7. Slide each hanger bracket #30 up until beams are flush

with top of cabinet and tighten hex bolts #32.

IMPORTANT! The shortest screws #16 must be

used to attach hanger brackets #30 to cabinet. The

longer screws will break through the cabinet.

8. Secure hanger brackets #30 to cabinet using two

SHORT screws #16 for each hanger bracket. See

Figure 6.

9. Secure hanger brackets #30 to cross and center

braces using two screws #33 for each hanger bracket.

See Figure 6.

Page

4

Figure 6

10. Secure cross brackets #34 to cross and center braces

using two screws #33 for each cross bracket. See

Figure 6.

11. Attach legs #39 to leg brackets #35 using one stud #36, one

washer #37 and one locknut #38 for each leg, do not

tighten them at this point. See Figure 7.

12.Square leg up with corner of cabinet and secure in place with

two screws #33. Tighten locknuts #38 form previous step.

Figure 7

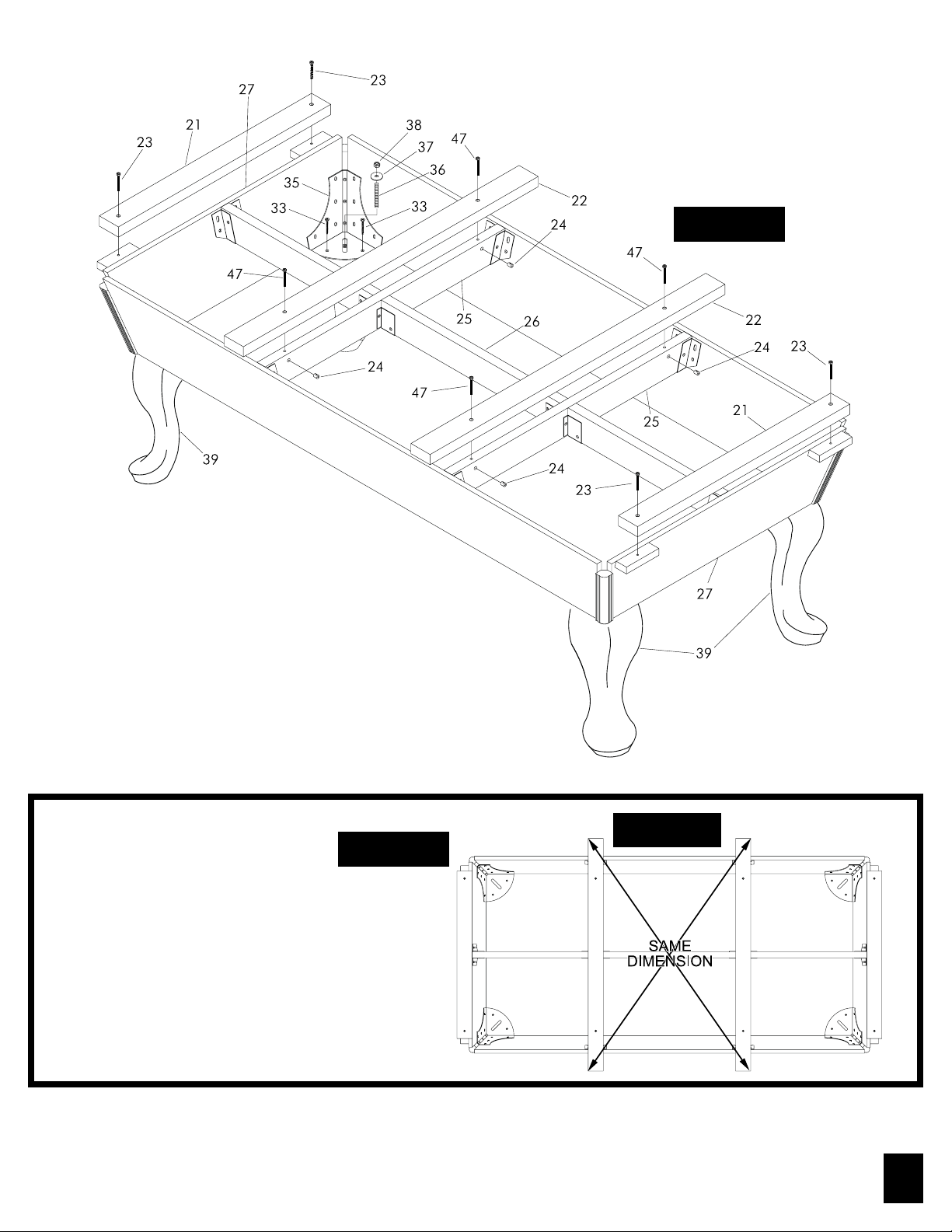

13. Place long slats #22 (50 inches long) and

short slats #21 (36 inches long) across table

as shown in Figure 7. Make sure to use the two shorter

slats #21 on the ends and the two longer slats #22 in the

center as shown.

14. Insert two dowel connectors #24 into the holes in the side of each of the

cross beams #25. Attach the long slats #22 to the cross beams #25 by

placing bolts #47 through the slats and into the dowel connectors #24,

do not tighten them at this point. See Figure 7.

15. Attach the short slats #21 to the end cabinet panel #27 using bolts #23,

do not tighten them at this point. See Figure 7.

Figure 8Figure 8

Figure 8

Figure 8Figure 8

16. Square up the long slats #22 by measuring

diagonally (See Figure 8) After squaring up

slats, tighten all the screws holding slats #21

and #22 to the beams.

Top ViewTop View

Top View

Top ViewTop View

LEVELING BASE FRAME

17. Using a carpenter's level, level table as well as possible. It is easier to do it now rather than after the slatron is on frame. Determine

the highest corner of the frame. Raise other three corners to the level of the highest corner by shimming underneath legs using

playing card stock or grey chipboard stock (#44) shipped with this table. Cut this chipboard and place under legs (#39).

Page

5

Loading...

Loading...