Escalade Sports 2L-6540-00 User Manual

OWNER'S

MANUAL

MODEL NO.

P9900

527.25203

BALL RETURN KIT

Thank you for buying our product. We try hard to ensure that our products

are of high quality and free of problems, such as manufacturing defects or

missing parts. However, if you have any problems with your new product,

please

Escalade Sports at:

Please provide model number, serial number, and/or part number of the

product and/or part when you call or write. These numbers can be found on

the product, packaging, and/or in this Owner’s Manual.

If you are doing a new installation refer to the following

instructions. Use the hardware identifier that came in your

table. For replacement parts for your table see the Parts

List that came in your table. For replacement parts for

your ball return see the following.

DO NOT RETURN IT TO THE STORE! Call

TOLL FREE 1-800-426-1421

(THIS IS A CONSUMER ONLY NUMBER)

FAX: 812-467-1399

Or write us at:

CUSTOMER SERVICE DEPARTMENT

P.O. Box 889, Evansville, IN 47706

READ THESE

INSTRUCTIONS

CAREFULLY!

If you are doing a retrofit on an already assembled Lexington

Pool Table.

1 . Remove side aprons.

2 . Remove drop pockets.

3 . Determine which end of the beams are predrilled for ball return tray. See Figure 22.

4 . Perform steps 47 through 49 in this manual.

5 . Perform steps 53 through 61 in this manual.

6 . Perform steps 65 through 67 in this manual.

# PART# DESCRIPTION QTY.

21 2B-6016-00 1/4-20 LOCKNUT 2

22 801-9B 1/4-20 WASHER 2

25 801-54B 3/4 x 16 GA NAIL 30

37 801-4 #8 x 5/8 WASH HD SCREW 8

100 7P-6033-00 DOUBLE BACK TAPE 1

101 710-54 U-CLIP 2

102 701-166 1/4-20 x 3 HH BOLT 2

103 8S-6205-01 SUPPORT TUBE 1

104 3M-6139-00 BALL TRAY 1

105 3M-6140-00 BALL SCOOP 2

106 823-105L HD LFT CORNER POCKET 1

107 823-105R HD Right Corner Pocket 1

108 823-114L Side Left Pocket 1

109 823-114R Side Right Pocket 1

110 823-106 FT Corner Left Pocket 1

111 823-107 FT Corner Right Pocket 1

112 826-50U Ball Return Tube 4

2L-6540-00

IMPORTANT! READ THIS MANUAL ALL

THE WAY THROUGH BEFORE BEGINNING

TO PUT YOUR POOL TABLE TOGETHER!

THEN READ EACH STEP BEFORE

STARTING THAT STEP.

Tools Needed:

! Hammer (Claw Type) ! Putty Knife ! 3/8" Open End Wrench

! Needle Nose Pliers ! Tape Measure ! Hammer (Small Ball Peen Type)

! 7/16" Open End Wrench ! Sanding Block ! Carpenter's level or 36'' Straight Edge

! Standard Screwdriver ! Awl or 8d Nail ! ½" Open End Wrench

! Phillips Screwdriver ! Scissors or Sharp Knife ! Hairdryer

! Power Screwdriver (optional but very helpful)

! In addition to the assembly tools listed above, it would be useful to

have a rachet with 3/8, 7/16 and ½ socket.

NOTE: Rails are made with cushion rubber at a height that requires standard 2 ¼" diameter balls. Your dealer has

a complete line of Billiard Accessories.

NOTE: This table adds weight to any floor. Be sure floor can withstand this kind of weight. If floor sags, table will

be impossible to level.

THE SPRAY ADHESIVE USED FOR APPLYING PLAYFIELD CLOTH IS

EXTREMELY FLAMMABLE AND UNDER PRESSURE! CAREFULLY READ

CAUTIONS ON SPRAY ADHESIVE CONTAINER! KEEP OUT OF REACH OF

CHILDREN! DO NOT USE OR STORE NEAR HEAT SOURCE, FLAMES, SPARKS

OR WHEN SMOKING! WORK AREA MUST BE WELL VENTILATED. OPEN

DOORS AND WINDOWS WHEN USING SPRAY ADHESIVE.

2

30

21

1/8''

22

33

3

1

1

33

This set of holes grouped close

together goes toward the top.

Figure 1

1. Open hardware kits and sort

hardware into "like" groups using

hardware identifier provided in

your table manual. CAUTION:

Some steel parts may have

sharp edges.

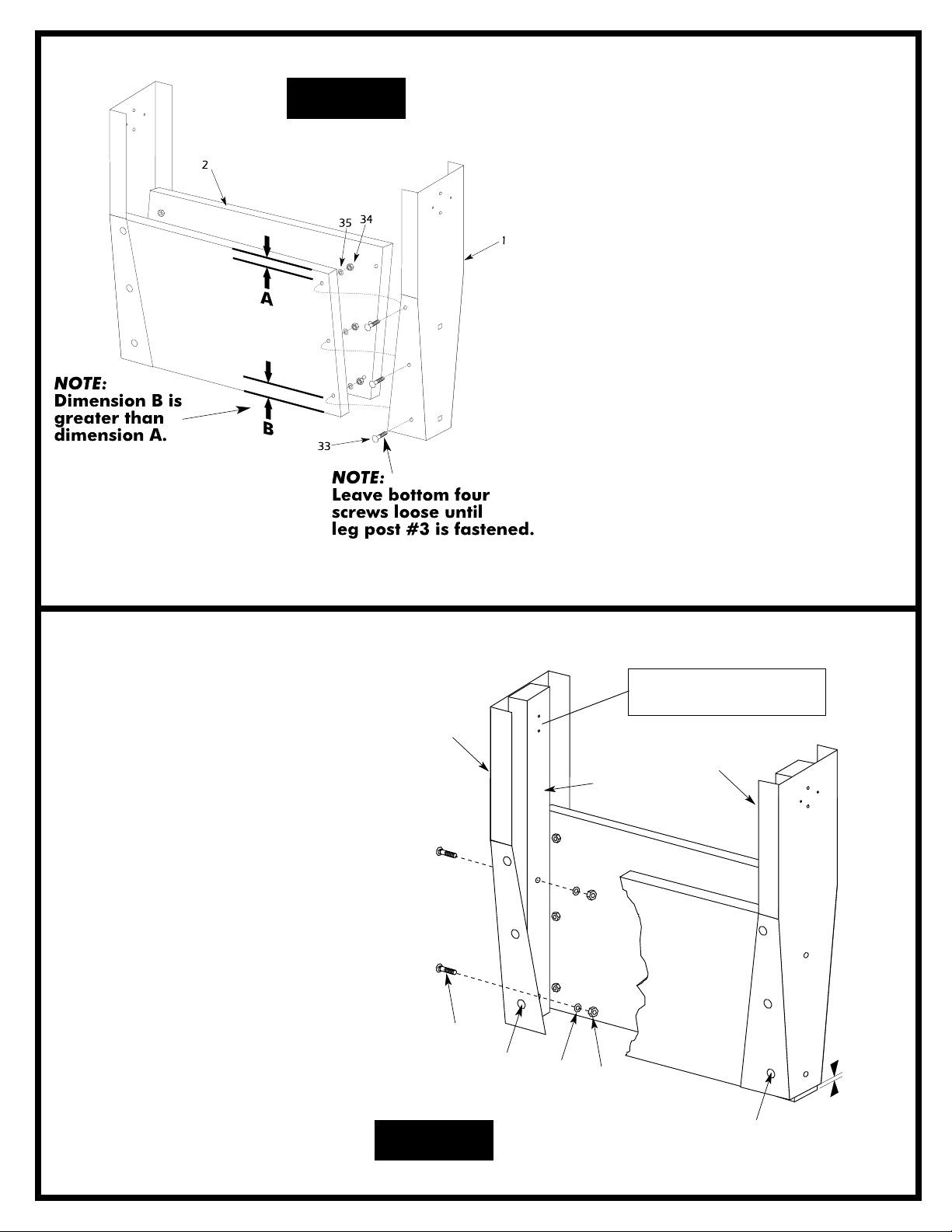

2. Attach two wooden leg panels #2

(be sure wood grain faces out) to

the inside of two leg facades #1

using six screws #33, six washers

#35 and six locknuts #34 per leg

panel. Make sure that dimension

B is at the bottom of the leg panel.

(See Figure 1)

NOTE: Leave all four bottom

screws #33 loose until the leg

post #3 is installed. Leg post

#3 CANNOT be attached if

the four bottom screws #33 are

tight. Tighten finger tight only.

3. Repeat step 2 to put together other

leg assembly.

4a.Attach leg posts #3 to the inside face of

metal leg facades #1 on both leg assemblies (from steps 1 & 2). Use two

carriage bolts #30, two washers #22

and two locknuts #21 per leg post.

NOTE: There is a set of holes at one

end of the leg posts that are grouped

close together. Make sure that these

holes go to the top of the wooden

posts. About 1/8 inch of leg posts #3

will extend below the metal facade #1.

(Figure 2)

4b.Once the leg post is securely fastened,

tighten the four bottom screws #33 on

the leg panels.

Figure 2

3

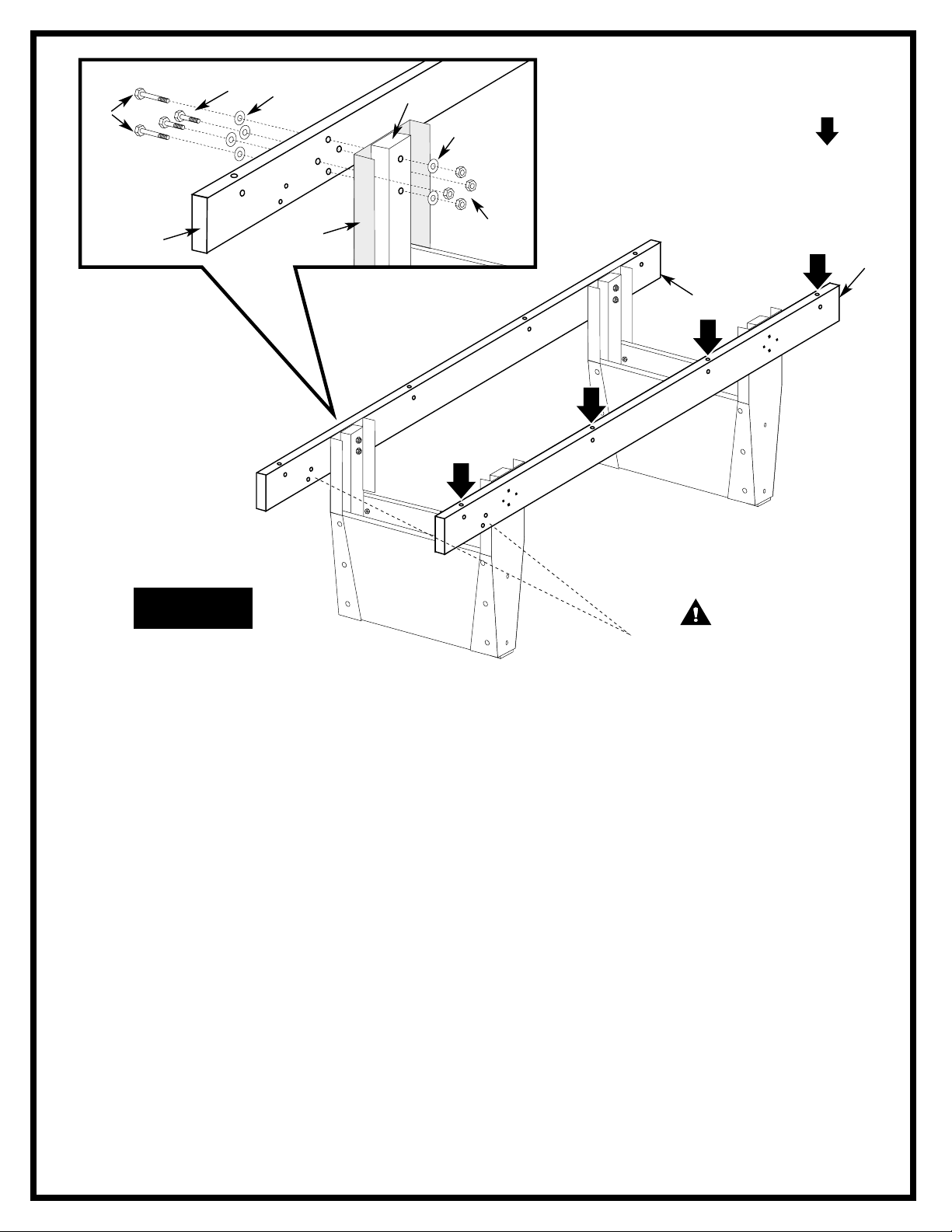

These holes are for ball return

attachment. Be sure both

beams #4 have these holes

at same end of table

27

WARNING:

MUST TOP

Holes marked by arrows

be on the when

attached to the legs!

40

All Washers

#23

3

#23

WARNING:

Holes marked by arrows

MUST TOP

be on the when

attached to the legs!

4

Figure 3

1

All locknuts

#26

4

4

CAUTION:

These holes are for ball return

attachment. Be sure both

beams #4 have these holes

at same end of table

5. Before starting this part of the assembly, orient

beam #4 with ball return attachment holes at the

same end of the table and the holes marked by

arrows in figure 3 facing up.

6. Attach wooden beams #4 to the leg assemblies (that

you just put together). Use two long bolts #27, two

short bolts #40, six washers #23 and four locknuts

#26 as shown.

NOTE: The two longer bolts #27 go through top

and bottom mounting holes in beam #4, metal

facade #1 and leg post #3. These bolts require a

washer between the bolt and beam #4 as well as

between leg post #3 and the locknut.

NOTE: The two shorter bolts #40 go through the

other two mounting holes in beam #4 and metal

facade #1. They only require a washer between the

bolt and beam #4.

4

Figure 4

Countersink

goes up.

4

5

24

6

24

6

24

5

4

39

39

NOTE: Screwheads must

be flush or below the top of

the slats #5 and #6.

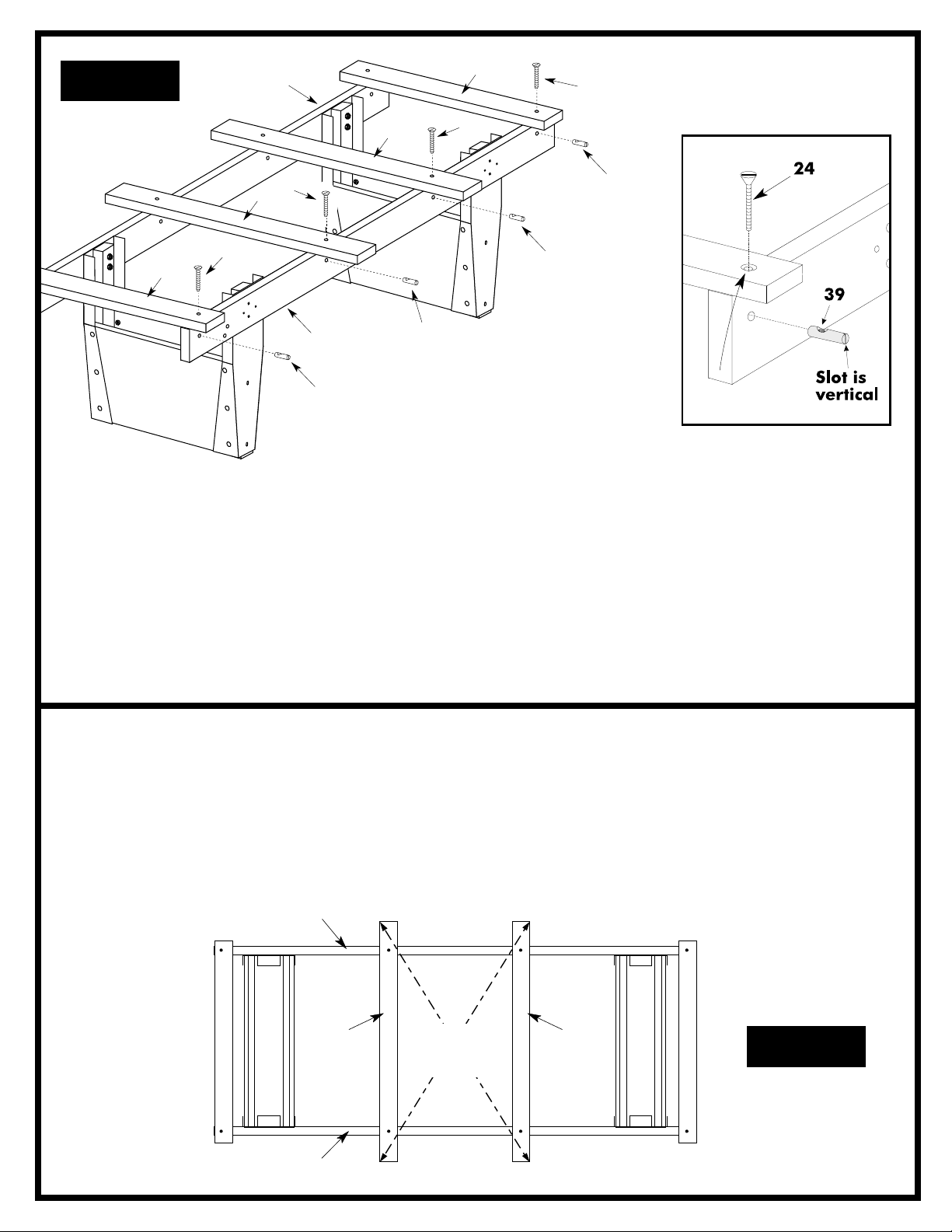

7. Place slats #5 and #6 across beams #4 as shown in

figure 4. Make sure the two shorter slats #5 go on the

ends of the beams and that the two longer slats #6 go

in the center as shown. The side of the slats with the

countersink around each hole faces up. (See detail A).

24

39

39

Detail A

Countersink

goes up.

8. Insert four dowel connectors #39 into the holes in

side of beams #4 just below the slats. Note that the

slot in the end of dowel connectors should be vertical.

(See Figure 4 and Detail A). Start screws #24 the

dowel connectors by hand until you are sure threads

are engaged properly. Do not force them with power

tools. Do not tighten screws completely yet.

9. Square up long slats #6 by measuring diagonally as

shown in figure 5. Diagonals should be the same

length within 1/8". Check to make sure the table is

square. If frame is not square, the adjustment can be

made by moving table beams #4 in opposite directions. Usually only a slight adjustment if any should

be required.

4

6

4

10. Once frame is square, tighten screws #24 holding

SAME

DIMENSION

(within 1/8")

slats to beams. Be sure the heads of screws #24

are flush with or below the top of the slats.

6

Figure 5

5

Loading...

Loading...