Escalade Sports 2L-6437-03 User Manual

OWNER'SOWNER'S

OWNER'S

OWNER'SOWNER'S

MANUMANU

MANU

MANUMANU

ALAL

AL

ALAL

WARNING

FAILURE TO FOLLOW THESE

WARNINGS MAY RESULT IN

SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

Owner must ensure that all

players know and follow these

rules for safe operation of the

unit.

! Do not dunk on this unit

! Do not hang from any part of the unit,

including the backboard, rim, or net.

! Do not slide, climb, or play on pole.

! Keep organic material away from

pole base. Grass, litter, etc. could

cause corrosion and /or deterioration.

! Check pole system twice a year for

signs of corrosion (rust, pitting,

chipping). Remove rust and/or loose

paint completely and repaint with

exterior enamel paint. If rust has

penetrated through the steel

anywhere, replace pole immediately.

! Check unit before each use for loose

hardware, excessive wear, and signs

of corrosion and repair before using.

! During play, use extreme caution to

keep players face away from the

backboard, rim, and net.

! Wear a mouthguard when playing to

avoid dental injuries.

! When adjusting height, keep hands

and fingers away from moving parts.

! During play, do not wear jewelry

(rings, watches, necklaces, etc.).

Objects may entangle in net.

ADJUSTADJUST

ADJUST

ADJUSTADJUST

ABLE BASKETBALL POLEABLE BASKETBALL POLE

ABLE BASKETBALL POLE

ABLE BASKETBALL POLEABLE BASKETBALL POLE

WITHWITH

WITH

WITHWITH

PROPRO

“

PRO

PROPRO

STYLESTYLE

STYLE”

STYLESTYLE

BREAKAWAY

MODEL NUMBERS

B9771 & B9772

Thank you for buying our basketball pole. We try hard to ensure that our products are of high quality and

free of manufacturing defects and of missing parts. However, if you have any problems with your

basketball pole, such as a manufacturing defect or a missing part, please DO NOT RETURN IT TO THE

STORE. Call us at:

TOLL FREE 1-800-426-1421

(THIS IS A CONSUMER ONLY NUMBER)

FAX: (812) 467-1399

Or write us at:

CUSTOMER SERVICE DEPT., P.O. Box 889, Evansville, IN 47706

Please provide model number, serial number, and/or part number of the product and/or part when you call or

write. These numbers can be found on the product, packaging, or in this owner's manual.

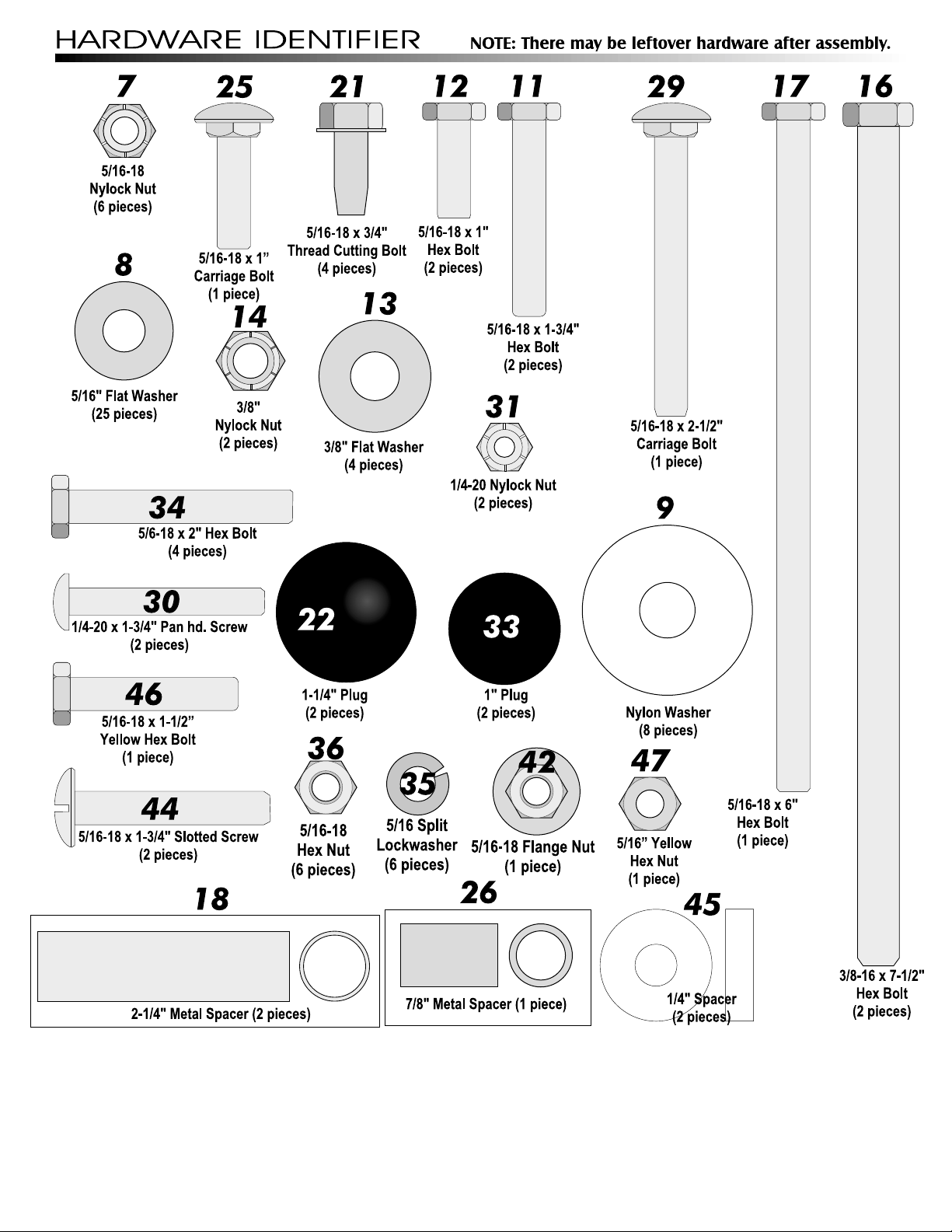

To make assembly of your basketball pole

easier, use the Hardware Identifier on page

2 to identify and sort all fasteners.

Do not tighten hardware until instructed to do so. If

hardware is tightened too soon, mounting holes may not

align and parts may not fit together. Leave locknuts

slightly loose until you are instructed to tighten them.

Read this manual all the way through before

starting to put up your pole. Then read each

step completely before beginning that step.

Some smaller parts may be

shipped inside larger tubes.

Check inside tubes before

assembling or ordering parts.

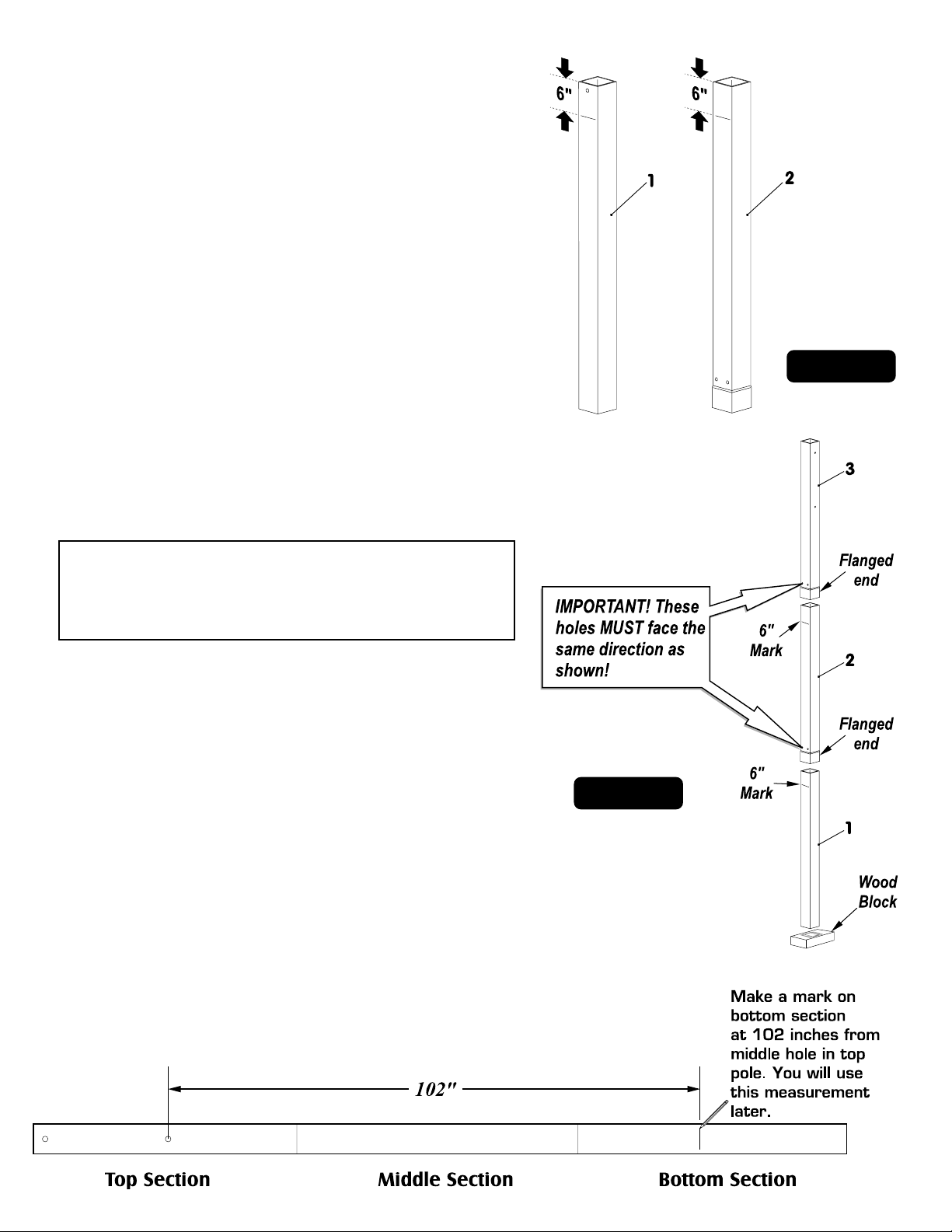

IMPORTANT! The three pole sections are different.

Use the illustration below to identify correct

sections (note the hole locations). Once sections

are seated together, you will NOT be able to

pull them apart!

2L-6437-03

To put up your pole, you will need the following tools:

" Post Hole Digger " Shovel " Level " Ladder " Tape Measure " Phillips and Flat Blade Screwdrivers

" Hammer " Gravel " Two adjustable wrenches OR two 1/2" Wrenches and One 9/16" Wrench

" Besides these tools, you will need approximately 1.6 cubic feet (three 80 lb. bags) of concrete to set your pole in the ground.

2

ASSEMBLY INSTRUCTIONS:

1. Before putting any of the pole tubes together, mark

bottom pole (#1) and middle pole (#2) 6 inches from their

top end. (On the bottom pole, the top end is the end with

the single hole in it). See Figure 1.

2. Align the upper pole (#3) with the middle pole (#2) making

sure the two holes near the flange of each pole face the

same direction as shown in figure 2, and slide them

together. Hit tubes on a piece of wood until there is no

more movement or until the bottom of the upper pole

reaches the 6" mark on the middle pole. Then align the

bottom pole (#1) with the middle pole (#2) (make sure the

weld seams in the poles line up) with your 6" mark on the

bottom pole toward the flange of the middle pole (#2) as

shown, and slide the sections together .

Figure 1

IMPORTANT! Make sure the pole sections are

aligned EXACTLY as shown in Figure 2 before

tapping them together! Once sections are seated

together, you will NOT be able to pull them apart!

3. Now lift tubes and pound them on a piece of wood to

secure. Hit the tubes until there is no more movement or

until the bottom end of the upper and middle tubes reaches

the 6 inch mark on the middle and lower tubes respectively.

Hit tubes a minimum of seven times. This is a friction-locking

joint and requires no hardware. NOTE: You may have to

turn poles upside down and pound top to completly

seat.

4. NOW MEASURE DOWN FROM MIDDLE HOLE IN TOP POLE

102 INCHES, AND MAKE A MARK ON BOTTOM POLE. YOU

WILL USE THIS MEASUREMENT IN STEP 20. SEE

ILLUSTRATION BELOW.

Figure 2

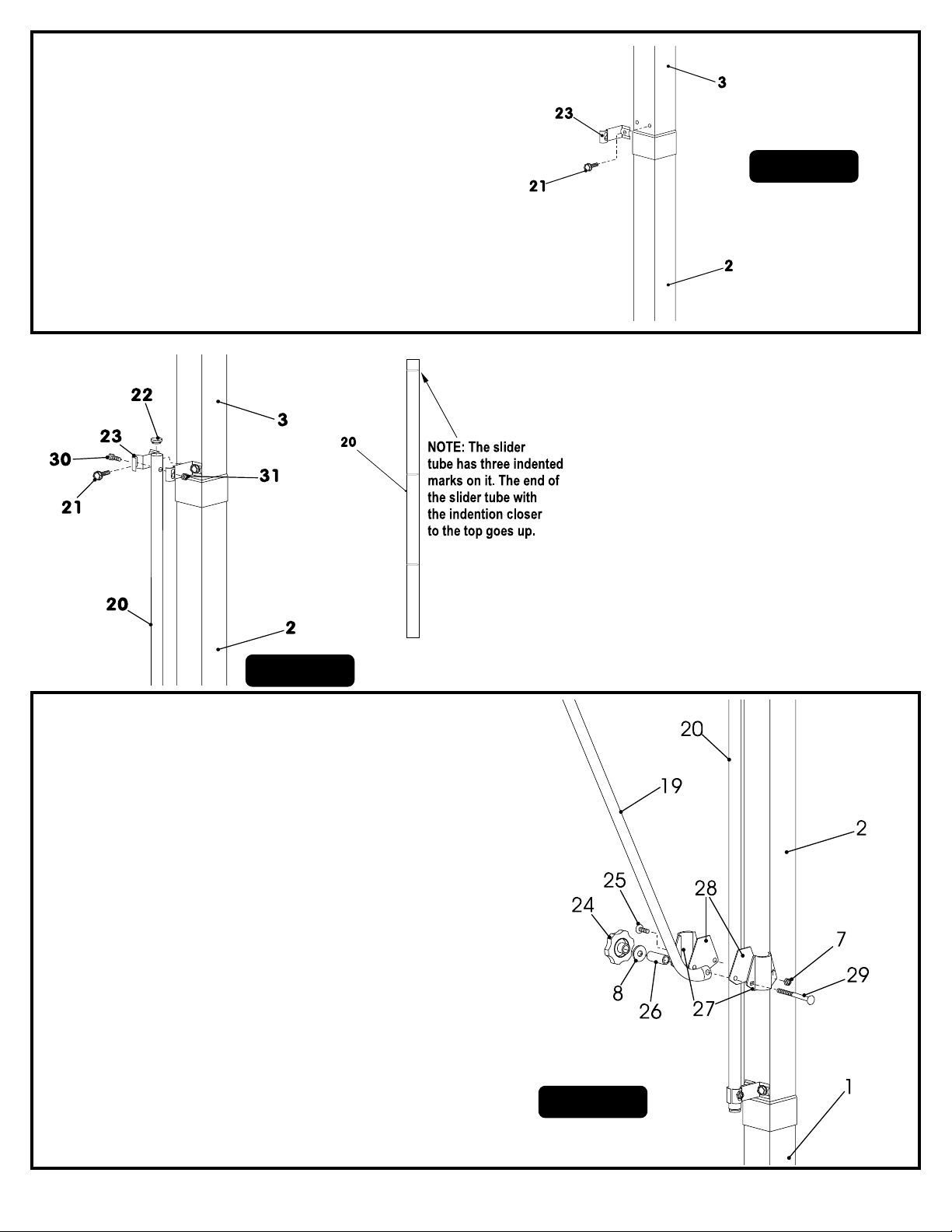

5. It may be helpful to lay the pole assembly at a diagonal

by placing one end on a bench or sawhorse with the

four holes in one side facing up (if necessary, lay the

pole on a piece of cardboard to prevent scratching).

Attach one Stand-off Bracket (#23) to the right-hand hole

near the flange of upper pole (#3) as shown using a ¾"

thread-cutting bolt (#21). Attach another stand-off

bracket (#23) to the middle pole (#2) in the same manner.

See Figure 3.

Figure 3

6. Tap a plug (#22) into each end of the Slider

Tube (#20), and LOOSELY attach it to the

upper stand-off bracket by clamping it with

another stand-off bracket (#23) and

securing with a hex bolt (#30) and hex nut

(#31). NOTE: The tube has three

indentions on it. The end with the

indention closest to the top goes up.

Repeat this process at the lower stand-off

bracket. DO NOT TIGHTEN these screws

completely yet. Refer to Figure 4.

Figure 4

8. Assemble Slider Clamps (#27) to Slider Tube (#20). Be

sure the arrows on the Slider Clamp point up the tube.

Use carriage bolt (#25), two Slider Films (#28), and nylock

nut (#7) through inside holes. Tighten only until end of

bolt contacts plastic in nut. See Figure 5.

9. Assemble bent end of Pull Tube (#19) to Slider Clamp (#27)

with carriage bolt (#29), metal spacer (#26), flat washer

(#8), and knob (#24). Make sure the Pull Tube is between

Slider Films and the longest flat portion of the tube is

facing toward the slider tube as shown in Figure 5. Tighten

slider clamp securely. See Figure 5.

7. Fasten the remaining two stand-off

brackets to the upper and middle poles

with two ¾" thread-cutting bolts, tightened

securely. At this point, go back and tighten

all nuts securely. See Figure 4.

Figure 5

4

Loading...

Loading...