PL160T/R,

PL260T/T and

PL460T/R

Installation Guide

ESCALA

REFERENCE

86 A1 55EW 01

ESCALA

PL160T/R, PL260T/T and

PL460T/R

Installation Guide

Hardware

July 2008

BULL CEDOC

357 AVENUE PATTON

B.P.20845

49008 ANGERS CEDEX 01

FRANCE

REFERENCE

86 A1 55EW 01

The following copyright notice protects this book under Copyright laws which prohibit such actions as, but not limited

to, copying, distributing, modifying, and making derivative works.

Copyright IBM, 2007-2008

Copyright © Bull SAS 2007-2008

Printed in France

Trademarks and Acknowledgements

We acknowledge the rights of the proprietors of the trademarks mentioned in this manual.

All brand names and software and hardware product names are subject to trademark and/or patent protection.

Quoting of brand and product names is for information purposes only and does not represent trademark misuse.

The information in this document is subject to change without notice. Bull will not be liable for errors

contained herein, or for incidental or consequential damages in connection with the use of this material.

Contents

Safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

About this publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

How to send your comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Installing the model 03E/4A . . . . . . . . . . . . . . . . . . . . . . . . . .1

Chapter 1. Prerequisite tasks for the 03E/4A installation . . . . . . . . . . . . . . .3

Chapter 2. Installing your system in a rack . . . . . . . . . . . . . . . . . . . . .5

Installing the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Rack safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Determining the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Marking location by using the rack-mounting template . . . . . . . . . . . . . . . . . . .8

Marking the location without a rack-mounting template . . . . . . . . . . . . . . . . . .10

Installing the 14T/00, 14T/42 racks . . . . . . . . . . . . . . . . . . . . . . . . . .11

Completing a parts inventory . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Positioning the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Leveling the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Attaching the stabilizer brackets . . . . . . . . . . . . . . . . . . . . . . . . . .13

Attaching the rack to a concrete floor . . . . . . . . . . . . . . . . . . . . . . . . .14

Attaching the rack doors . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Connecting multiple racks with rack-to-rack attachment kit . . . . . . . . . . . . . . . .21

Attaching the rack to the concrete floor beneath a raised floor . . . . . . . . . . . . . . . .23

Connecting the power distribution system . . . . . . . . . . . . . . . . . . . . . . .27

Power distribution unit plus (PDU+) . . . . . . . . . . . . . . . . . . . . . . . . .27

Checking the ac outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Attaching the front or back ac electrical outlet . . . . . . . . . . . . . . . . . . . . . .28

Installing the ac outlet-mounting plates with ac outlets . . . . . . . . . . . . . . . . . .28

Installing the ac outlet-mounting plate without ac outlets . . . . . . . . . . . . . . . . .30

Connecting a dc power source . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Installing the rack security kit . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Installing the model in a rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Attaching the mounting hardware to the rack . . . . . . . . . . . . . . . . . . . . . . .40

Installing the cable-management arm . . . . . . . . . . . . . . . . . . . . . . . . . .43

Chapter 3. Installing an 03E/4A with logical partitions . . . . . . . . . . . . . . .45

Checklist: Installing an 03E/4A with logical partitions . . . . . . . . . . . . . . . . . . . . .45

Cabling your server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Cabling the server and the Hardware Management Console (HMC) . . . . . . . . . . . . . . .46

Cabling the server to access the Integrated Virtualization Manager . . . . . . . . . . . . . . . .49

Cabling the server to access the Operations Console . . . . . . . . . . . . . . . . . . . . .53

Setting up your console or interface and create logical partitions . . . . . . . . . . . . . . . . .58

Setting up the HMC and create logical partitions . . . . . . . . . . . . . . . . . . . . . .58

Setting up Virtual I/O Server, IVM, and logical partitions . . . . . . . . . . . . . . . . . . .59

Setting up the Operations Console, twinaxial console, or 5250 console and creating logical partitions . . . .59

Setting up your server to connect to service and support . . . . . . . . . . . . . . . . . . . .60

Installing operating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Obtaining updates and upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Chapter 4. Installing a model 03E/4A without logical partitions . . . . . . . . . . . .61

Checklist: Installing an 03E/4A without logical partitions . . . . . . . . . . . . . . . . . . . .61

Cabling your server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Cabling the server and the Hardware Management Console (HMC) . . . . . . . . . . . . . . .62

iii

Cabling the server to access the Advanced System Management Interface (ASMI) . . . . . . . . . . .65

Cabling the server to access the Operations Console . . . . . . . . . . . . . . . . . . . . .69

Setting up your console, terminal, or interface to manage your system . . . . . . . . . . . . . . .74

Setting up the HMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Connecting to ASMI or SMS menus . . . . . . . . . . . . . . . . . . . . . . . . . .75

Setting up the Operations Console or 5250 console . . . . . . . . . . . . . . . . . . . . .75

Setting up your server to connect to service and support . . . . . . . . . . . . . . . . . . . .75

Installing operating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Obtaining updates and upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Chapter 5. Common procedures (installing operating systems and obtaining updates)

for the model 03E/4A . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Installing AIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Installing Linux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Configuring Electronic Service Agent on standalone AIX systems . . . . . . . . . . . . . . . . .77

Obtaining HMC machine code updates and upgrades . . . . . . . . . . . . . . . . . . . . .79

Obtaining firmware updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Updating the Virtual I/O Server’s firmware and device microcode through the Integrated Virtualization

Manager with an Internet connection . . . . . . . . . . . . . . . . . . . . . . . . . .79

Step 1. View the existing firmware level . . . . . . . . . . . . . . . . . . . . . . . .79

Step 2. Apply firmware and device microcode using the IVM . . . . . . . . . . . . . . . . .79

Step 3. Verify that the firmware updated correctly . . . . . . . . . . . . . . . . . . . .80

Updating the Virtual I/O Server’s firmware and device microcode through the Integrated Virtualization

Manager without an Internet connection . . . . . . . . . . . . . . . . . . . . . . . . .80

Step 1. Obtain the hardware microcode and firmware CD . . . . . . . . . . . . . . . . . .80

Step 1. Obtain the firmware update on CD . . . . . . . . . . . . . . . . . . . . . . .81

Step 2. Apply firmware and device microcode using the IVM . . . . . . . . . . . . . . . . .81

Step 3. Verify that the firmware updated correctly . . . . . . . . . . . . . . . . . . . .82

Obtaining operating system fixes . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Obtaining operating system fixes for AIX or Linux . . . . . . . . . . . . . . . . . . . . .82

Place the rack-mounted model 04E/8A, 03E/4A in the service position . . . . . . . . . . . . . . .82

Appendix. Accessibility features . . . . . . . . . . . . . . . . . . . . . . . . .87

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Electronic emission notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Class A Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Terms and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

iv Installation Guide for the 03E/4A, 07M/15, and 08M/25

Safety notices

Safety notices may be printed throughout this guide.

v DANGER notices call attention to a situation that is potentially lethal or extremely hazardous to

people.

v CAUTION notices call attention to a situation that is potentially hazardous to people because of some

existing condition.

v Attention notices call attention to the possibility of damage to a program, device, system, or data.

World Trade safety information

Several countries require the safety information contained in product publications to be presented in their

national languages. If this requirement applies to your country, a safety information booklet is included

in the publications package shipped with the product. The booklet contains the safety information in

your national language with references to the U.S. English source. Before using a U.S. English publication

to install, operate, or service this product, you must first become familiar with the related safety

information in the booklet. You should also refer to the booklet any time you do not clearly understand

any safety information in the U.S. English publications.

Laser safety information

The servers can use I/O cards or features that are fiber-optic based and that utilize lasers or LEDs.

Laser compliance

All lasers are certified in the U.S. to conform to the requirements of DHHS 21 CFR Subchapter J for class

1 laser products. Outside the U.S., they are certified to be in compliance with IEC 60825 as a class 1 laser

product. Consult the label on each part for laser certification numbers and approval information.

CAUTION:

This product might contain one or more of the following devices: CD-ROM drive, DVD-ROM drive,

DVD-RAM drive, or laser module, which are Class 1 laser products. Note the following information:

v Do not remove the covers. Removing the covers of the laser product could result in exposure to

hazardous laser radiation. There are no serviceable parts inside the device.

v Use of the controls or adjustments or performance of procedures other than those specified herein

might result in hazardous radiation exposure.

(C026)

CAUTION:

Data processing environments can contain equipment transmitting on system links with laser modules

that operate at greater than Class 1 power levels. For this reason, never look into the end of an optical

fiber cable or open receptacle. (C027)

CAUTION:

This product contains a Class 1M laser. Do not view directly with optical instruments. (C028)

CAUTION:

Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the following

information: laser radiation when open. Do not stare into the beam, do not view directly with optical

instruments, and avoid direct exposure to the beam. (C030)

v

Power and cabling information for NEBS (Network Equipment-Building System)

GR-1089-CORE

The following comments apply to the servers that have been designated as conforming to NEBS

(Network Equipment-Building System) GR-1089-CORE:

The equipment is suitable for installation in the following:

v Network telecommunications facilities

v Locations where the NEC (National Electrical Code) applies

intrabuilding ports of this equipment are suitable for connection to intrabuilding or unexposed

The

wiring or cabling only. The intrabuilding ports of this equipment must not be metallically connected to the

interfaces that connect to the OSP (outside plant) or its wiring. These interfaces are designed for use as

intrabuilding interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE) and require isolation

from the exposed OSP cabling. The addition of primary protectors is not sufficient protection to connect

these interfaces metallically to OSP wiring.

Note: All Ethernet cables must be shielded and grounded at both ends.

The ac-powered system does not require the use of an external surge protection device (SPD).

The dc-powered system employs an isolated DC return (DC-I) design. The DC battery return terminal

shall not be connected to the chassis or frame ground.

vi Installation Guide for the 03E/4A, 07M/15, and 08M/25

About this publication

This book contains instructions to assist you in setting up your server. It is intended to ensure that the

system is running and is functional before you perform more complex and custom configurations.

For information about the accessibility features of this product, for users who have a physical disability,

see “Accessibility features,” on page 87.

How to send your comments

Your feedback is important in helping to provide the most accurate and highest quality information. If

you have any comments about this publication, send your comments to us. Be sure to include the name

of the book and the specific location of the text you are commenting on (for example, a page number or

table number).

vii

viii Installation Guide for the 03E/4A, 07M/15, and 08M/25

Installing the model 03E/4A

This book contains the tasks and information that is needed to set up your system in order to get it

running and into production.

Chapters 3 and 4 in this book have been broken down into two sections: installing an 03E/4A with

logical partitions and installing an 03E/4A without logical partitions. Each of those sections has a

separate checklist that you can use as a guide to assist you in setting up your system. The tasks listed

within each section and checklist are listed in chronological order. This will help give you an idea of what

tasks need to be completed when. Not all tasks that are listed need to be completed. That will depend on

your particular situation. For example, you might not be installing your system in a rack in which case

those tasks do not have to be completed.

See one of the following sections to continue:

v Chapter 3, “Installing an 03E/4A with logical partitions,” on page 45

v Chapter 4, “Installing a model 03E/4A without logical partitions,” on page 61

1

2 Installation Guide for the 03E/4A, 07M/15, and 08M/25

Chapter 1. Prerequisite tasks for the 03E/4A installation

Prior to setting up and installing your new system, complete the following tasks to ensure that you are

prepared for the installation.

1. If you are using a previously existing Hardware Management Console (HMC), you need to ensure

that your HMC is at the correct code level (7.3.2 or later).

To update your HMC code level, see Chapter 8, ”Updating, upgrading, and migrating your HMC

machine code″ in the Installation and Configuration Guide for the Hardware Management Console.

To view the PDF file of the Installation and Configuration Guide for the Hardware Management Console

(SA76-0084), approximately 3 MB in size, see sa76-0084.pdf

2. The System Planning Tool (SPT) helps you design a managed system that can support a specified set

of workloads. When you are done making changes to the system, you can save your work as a

system plan. You can import this file into your Hardware Management Console (HMC) or the

management partition for the Integrated Virtualization Manager (for systems that have multiple

logical partitions) and deploy the system plan to a managed system. When you deploy the system

plan, the HMC or the Integrated Virtualization Manager creates the logical partitions from the system

plan on the managed system

.

3

4 Installation Guide for the 03E/4A, 07M/15, and 08M/25

Chapter 2. Installing your system in a rack

Complete these tasks to install your system in a rack.

To install your system in a rack, perform the tasks in “Installing the model in a rack” on page 38.

Installing the rack

You might need to install the rack. Use the procedure in this section to perform this task.

Rack safety notices

You will need to read the rack safety notices before installing equipment. Use the procedure in this

section to perform this task.

Before installing a rack, rack features, or a system or expansion unit into a rack, read the following safety

information:

Attention: If you are installing equipment into a rack, the rack must comply with the Electronics

Industries Association (EIA) 310D specifications. If you do not have a rail kit designed for the equipment

in the rack, do not install the equipment into the rack as damage to the equipment or personal injury

could occur.

5

DANGER

Observe

the following precautions when working on or around your IT rack system:

v Heavy equipment–personal injury or equipment damage might result if mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest

devices in the bottom of the rack cabinet. Always install servers and optional devices starting

from the bottom of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top

of rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect all power cords in

the rack cabinet when directed to disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the same rack

cabinet. Do not plug a power cord from a device installed in one rack cabinet into a power

device installed in a different rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

CAUTION

v Do not install a unit in a rack where the internal rack ambient temperatures will exceed the

manufacturer’s recommended ambient temperature for all your rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not

blocked or reduced on any side, front, or back of a unit used for air flow through the unit.

v Consideration should be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection. To

provide the correct power connection to a rack, refer to the rating labels located on the

equipment in the rack to determine the total power requirement of the supply circuit.

v (For sliding drawers.) Do not pull out or install any drawer or feature if the rack stabilizer brackets

are not attached to the rack. Do not pull out more than one drawer at a time. The rack might

become unstable if you pull out more than one drawer at a time.

v (For fixed drawers.) This drawer is a fixed drawer and must not be moved for servicing unless

specified by the manufacturer. Attempting to move the drawer partially or completely out of the

rack might cause the rack to become unstable or cause the drawer to fall out of the rack.

(R001)

Lift precautions:

6 Installation Guide for the 03E/4A, 07M/15, and 08M/25

Determining the location

You might need to determine where to install the system in the rack. This section includes procedures so

that you can perform these tasks.

Before installing the system unit into a rack, complete the following steps:

1. Read the “Rack safety notices” on page 5.

2. Plan where you will place the units. Place the larger and heavier units in the lower part of the rack.

This system unit is four Electronic Industries Alliance (EIA) units high. An EIA unit is 1.75 in (44.45

mm) in height. The rack contains three mounting holes for each EIA unit of height. This system unit

therefore is 7 in high and covers 12 mounting holes in the rack.

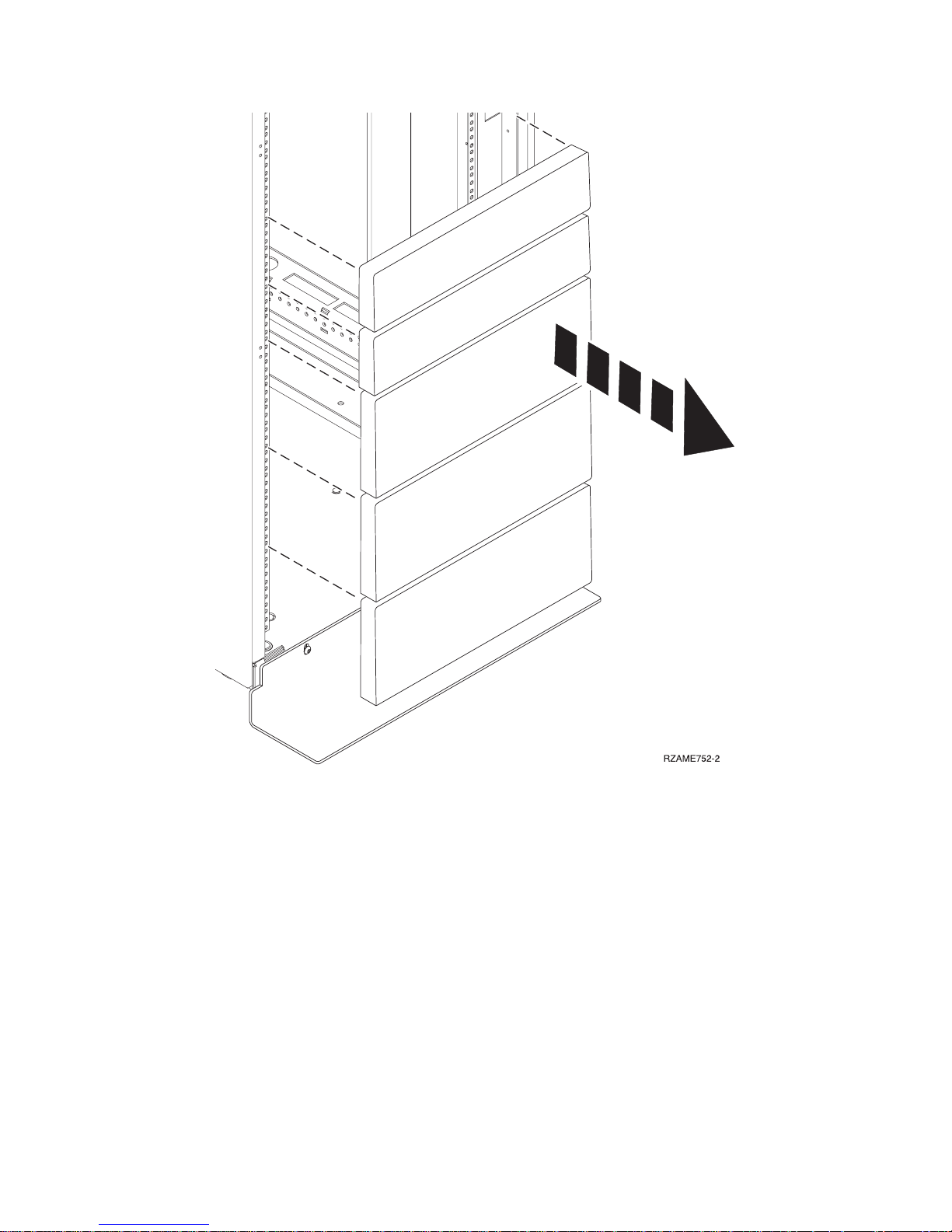

3. If necessary, remove the filler panels to allow access to the inside of the rack enclosure where you

plan to place the unit.

Chapter 2. Installing your system in a rack 7

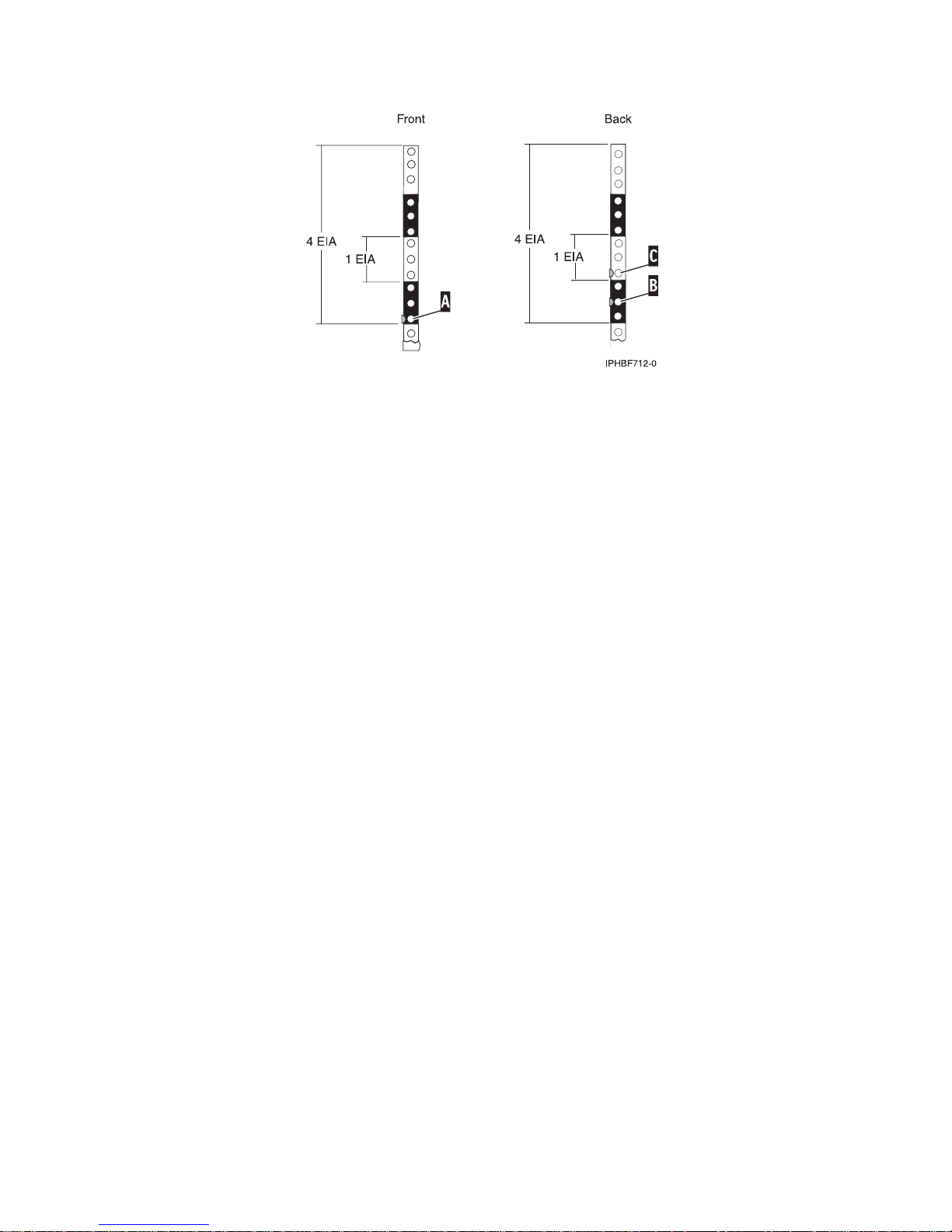

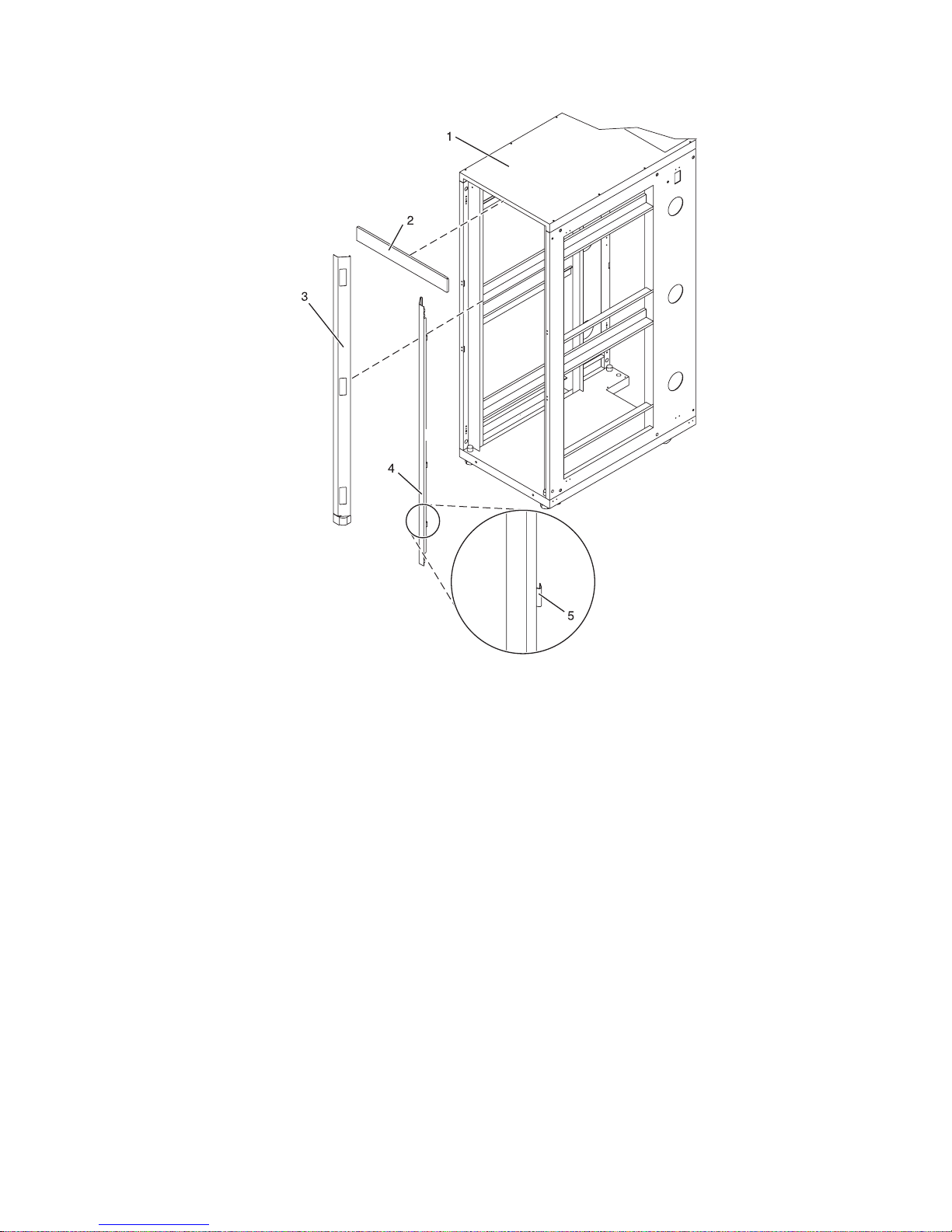

Figure 1. Removing the filler panels.

4. If necessary, remove the front and back rack doors.

5. Use the rack-mounting template to mark the location (see Mark location using the rack-mounting

template). If you do not have a rack-mounting template, following instructions for marking the

location without a template (see Mark the location without rack-mounting template).

Marking location by using the rack-mounting template

You might need to mark the installation location by using a rack-mounting template. Use the procedure

in this section to perform this task.

1. Using the rack-mounting template, determine where in the rack to place the unit. Install units in the

lower part of the rack first. Place larger and heavier units in the lower part of the rack.

8 Installation Guide for the 03E/4A, 07M/15, and 08M/25

Figure 2. Rack-mounting template

Note: The front of the rack-mounting template has printed illustrations designed to help you identify

the mounting holes to be used when you add units to the rack. Do not use the rack-mounting

template without completing the following steps.

2. Note the following when using the rack-mounting template:

v Each black or white unit on the template is equal to one Electronic Industries Alliance (EIA) unit.

v An EIA unit is 1.75 in (44.45 mm) in height.

v The rack contains three mounting holes for each EIA unit of height.

v The EIA units that are illustrated on the template must be aligned with the EIA units located on the

rack.

v It is not necessary to align like-colored EIA units. For example, a black EIA unit on the

rack-mounting template can be aligned with a white EIA unit that are located on the rack.

v The template is two-sided. When using the template, ensure that the appropriate side of the

template is facing out.

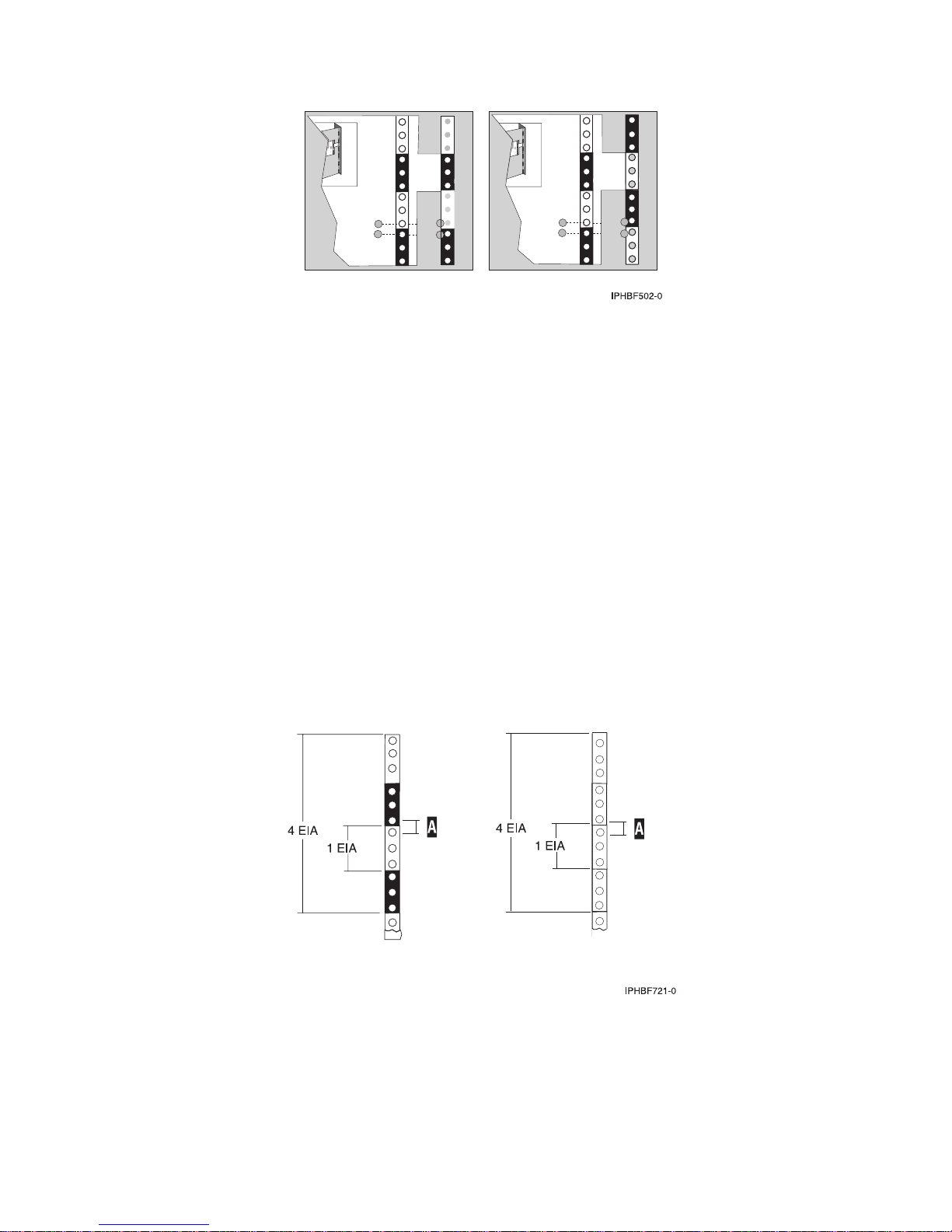

Figure 3 shows one EIA unit and four EIA units. Depending on the rack manufacturer, the EIA units

might be separated either by color or by a line. Notice that the holes along the rail are not evenly

spaced. If your rack has no color or line separation between EIA units, assume that each EIA unit

begins where the hole spacing is closest together as shown by A in Figure 3.

Figure 3. EIA units

To use the rack-mounting template, complete the following steps:

a. Remove the protective coating from each adhesive strip located on the back of the rack-mounting

template. Lightly press the template into position on the rack. Ensure that both the left and right

sides are at the corresponding EIA locations.

Chapter 2. Installing your system in a rack 9

Note: The tabs on each side of the template show a notch to indicate the correct spacing between

the front flanges.

b. Locate the dots that are printed on the left and right side of the template. Place a self-adhesive dot

directly across from the template’s printed dots on or near the rack’s EIA numbering strip. You

will be using these dots to aid in correctly positioning the rail-alignment pins located on the front

of each rail.

c. Remove the rack-mounting template from the front of the rack. The front of your rack should now

contain dots.

d. Mount the rack-mounting template to the rack’s back EIA frame. Place the rack-mounting template

at the same EIA-numbered location that was used on the front of the rack.

e. Wrap a self-adhesive dot directly across from the template’s printed dots. Ensure that a portion of

the self-adhesive dot wraps around the rack frame so that it can be seen from the front of the rack.

f. Remove the rack-mounting template from the back of the rack. The back of your rack should now

contain dots that have been partially wrapped around the frame.

Marking the location without a rack-mounting template

You might need to mark the location without using a template. Use the procedure in this section to

perform this task.

To mark the installation location and install the nut clips into a rack without using the rack-mounting

template, complete the following steps:

1. Determine where in the rack to place the system. Install units in the lower part of the rack first. Place

larger and heavier units in the lower part of the rack. Record the EIA location. The system is four

Electronic Industries Alliance (EIA) units high. An EIA unit is 1.75 in (44.45 mm) in height. The rack

contains three mounting holes for each EIA unit of height. This system therefore is 7 in high and

covers 12 mounting holes in the rack.

2. Facing the front of the rack and working from the right side, place a self-adhesive dot next to the

bottom hole of the bottom EIA unit of the four you will be using for this system unit A in Figure 4 on

page 11.

Note: The self-adhesive dots are used to aid in identifying locations on the rack. If you do not have

the dots, use some other form of marking tool to aid you in identifying hole locations (for example,

tape, or a marker). You will need to identify the marked hole from both the front and back of the

rack.

3. Place another self-adhesive dot next to the bottom hole of the bottom EIA unit on the left side of the

rack.

4. Go to the back of the rack. On the right side, find the EIA unit that corresponds to the bottom EIA

unit marked on the front of the rack.

10 Installation Guide for the 03E/4A, 07M/15, and 08M/25

Figure 4. Marking holes on the front and back of the rack frame.

5. Place a self-adhesive dot at the middle hole of the bottom EIA unit, B in Figure 4.

6. Place a self-adhesive dot at the bottom hole of the next (higher) EIA unit, C in Figure 4.

7. Mark the corresponding holes on the left side of the rack.

Installing the 14T/00, 14T/42 racks

You might need to install the rack. Use the procedure in this section to perform this task.

If you are installing a rack security kit in this rack, see “Installing the rack security kit” on page 35 after

you have installed the rack.

Before installing a rack, read the “Rack safety notices” on page 5.

Completing a parts inventory

You might need to complete a parts inventory. Use the procedure in this section to perform this task.

If you have not done so, complete a parts inventory before installing the unit in the rack:

1. Locate the kitting report in an accessory box.

2. Ensure that you received all of the features that you ordered and all of the parts on the kitting report.

If there are incorrect, missing, or damaged parts, contact:

v Your reseller

Positioning the rack

You might need to position the rack. Use the procedure in this section to perform this task.

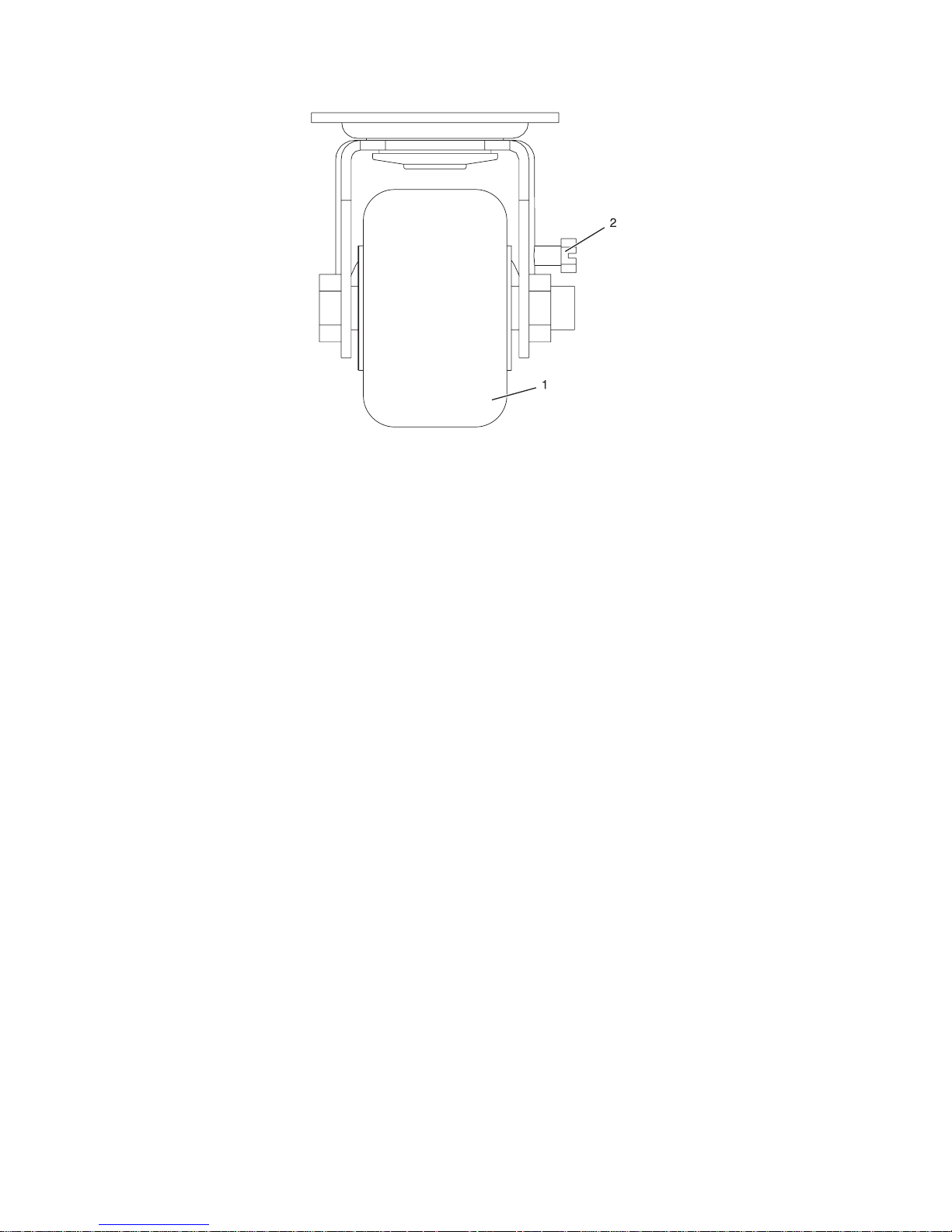

After the rack has been placed into its location on the floor, lock each caster by tightening the locking

screw. See the following illustration for the locking screw location. Remove all of the tape and packing

materials from the rack.

Chapter 2. Installing your system in a rack 11

1 Caster

2 Locking screw

Figure 5. Tightening the locking screw.

Use the following to determine the next step:

v If the rack is being bolted to a concrete floor, go to “Attaching the rack to a concrete floor” on page 14.

v If the rack is being bolted to a concrete floor beneath a raised floor, go to “Attaching the rack to the

concrete floor beneath a raised floor” on page 23.

v If the rack is not being attached to the floor, go to “Leveling the rack.”

Leveling the rack

You might need to level the rack. Use the procedure in this section to perform this task.

To level the rack, complete the following steps:

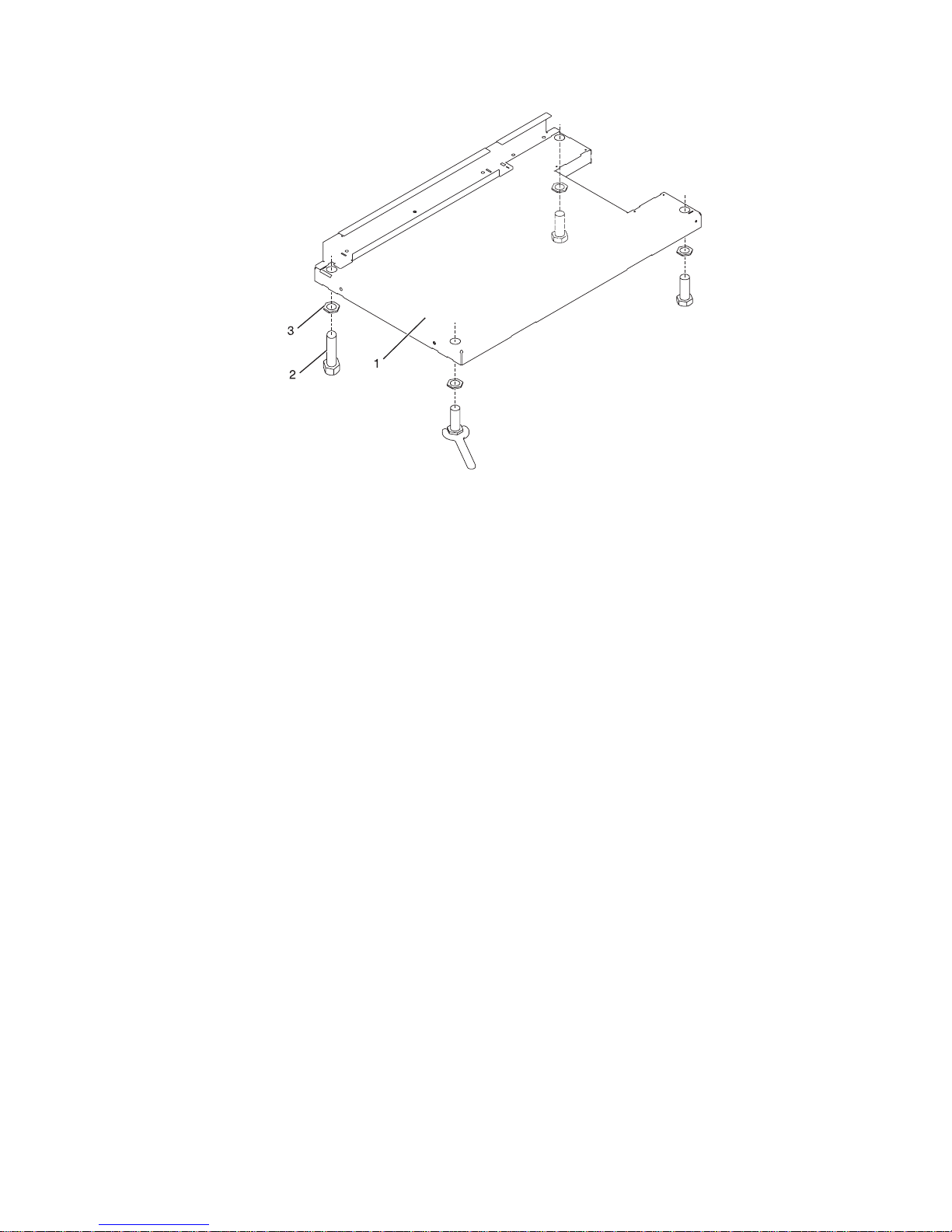

1. Loosen the jam nut on each leveling foot.

2. Rotate each leveling foot downward until it contacts the surface on which the rack is placed.

3. Adjust the leveling feet downward as needed until the rack is level. When the rack is level, tighten

the jam nuts against the base.

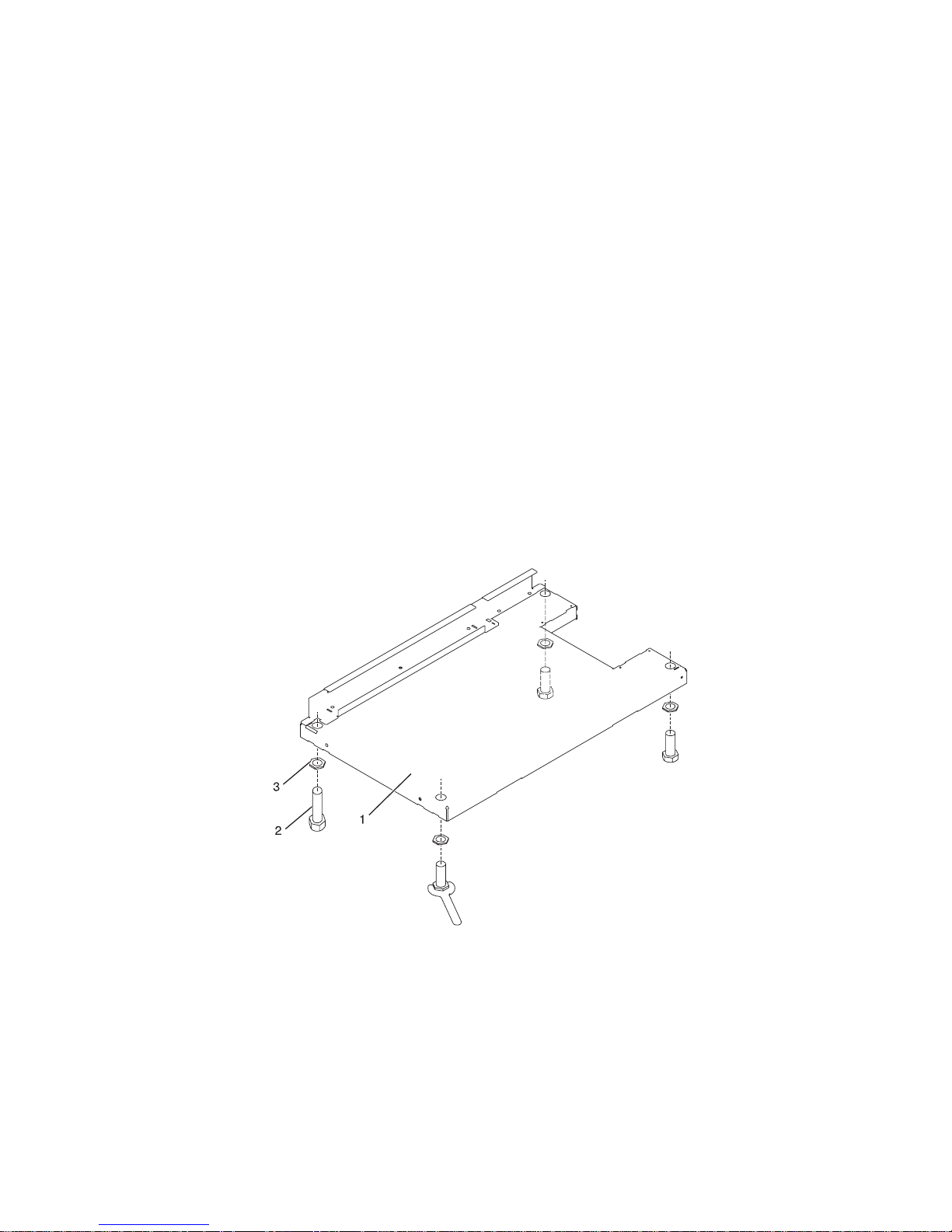

12 Installation Guide for the 03E/4A, 07M/15, and 08M/25

1 Rack Front (base)

2 Leveling Foot (quantity 4)

3 Jam Nut (quantity 4)

Figure 6. Adjusting the leveling feet.

Attaching the stabilizer brackets

You might need to attach the stabilizer brackets to the rack. Use the procedure in this section to perform

this task.

If the front or back ac electrical outlets are going to be installed in the rack, you cannot attach the

stabilizer brackets. The rack must be bolted to the floor. Stabilizer brackets are used only if you will not

be bolting the rack to the floor. If you are going to bolt the rack to the floor, go to “Attaching the rack to

a concrete floor” on page 14.

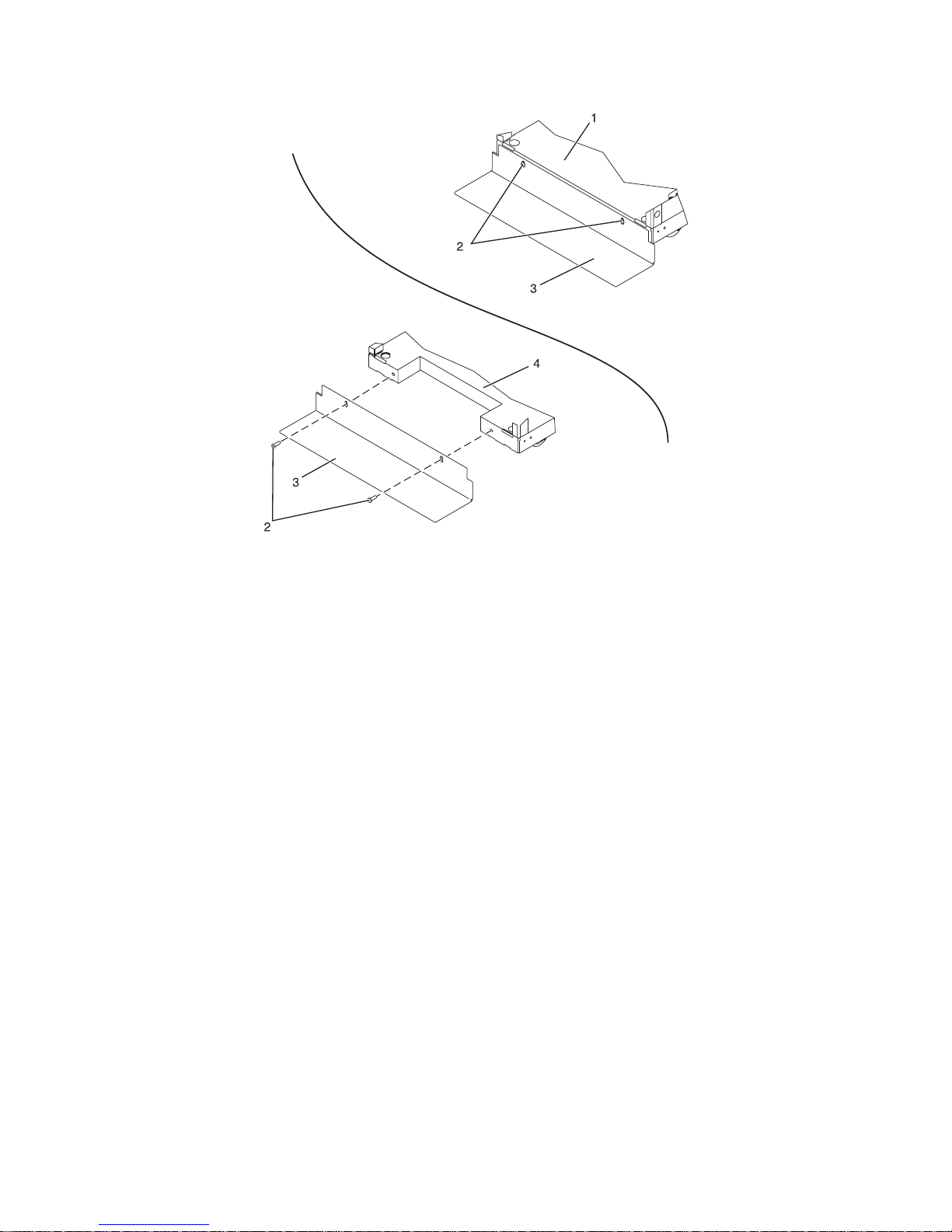

To attach the stabilizer brackets to the bottom of the rack, do the following:

Note: Before installing the stabilizer brackets, see “Attaching the front or back ac electrical outlet” on

page 28 for instruction on installing the ac outlet-mounting plates.

1. Align the slots of one of the stabilizer brackets with the mounting holes at the bottom front of the

rack.

2. Install the two mounting screws.

3. Ensure that the base of the stabilizer bracket rests firmly on the floor. Use the Allen wrench that was

supplied with the rack to tighten the mounting screws alternately until they are tight.

Chapter 2. Installing your system in a rack 13

1 Rack front (base) 3 Stabilizer bracket

2 Stabilizer mounting screws 4 Rack rear (base)

Figure 7. Attaching the stabilizer brackets.

4. To install the second stabilizer bracket on the back of the rack, repeat steps 1 through 3.

Attaching the rack to a concrete floor

You might need to attach the rack to a concrete floor. Use the procedure in this section to perform this

task.

Obtain the services of a mechanical contractor to attach the rack-mounting plates to the concrete floor.

The mechanical contractor must determine that the hardware being used to secure the rack-mounting

plates to the concrete floor is sufficient to meet the requirements for the installation.

To attach the rack to a concrete floor, do the following:

1. Put the rack in its predetermined location, and tighten the locking screws on the casters.

2. If they are installed, remove the top, left, and right trim panels. The trim panels are held in place

with spring clips. See the following illustration.

14 Installation Guide for the 03E/4A, 07M/15, and 08M/25

1 Rack chassis 4 Right-side trim panel

2 Top trim panel 5 Spring clip

3 Left-side trim panel

Figure 8. Removing the trim panels.

3. If they are installed, remove the front and back doors. After the rack doors have been removed, go to

the next substep. To remove a rack door:

a. Unlock and open the door.

b. Grasp the door firmly with both hands and pull it away from the hinges.

4. Locate the hardware mounting kit and the two mounting plates. Refer to the following illustration

when reviewing the contents of the hardware mounting kit. The hardware mounting kit contains the

following:

v 4 Rack-mounting bolts

v 4 Thin washers

v 8 Plastic isolator bushings

v 4 Thick washers

v 4 Spacers

5. If you are installing an ac-powered rack, temporarily install the lower plastic isolator bushings to

help you locate the mounting locations for the stabilizer bracket. After the stabilizer bracket has been

Chapter 2. Installing your system in a rack 15

correctly located, remove the lower plastic isolator bushings.

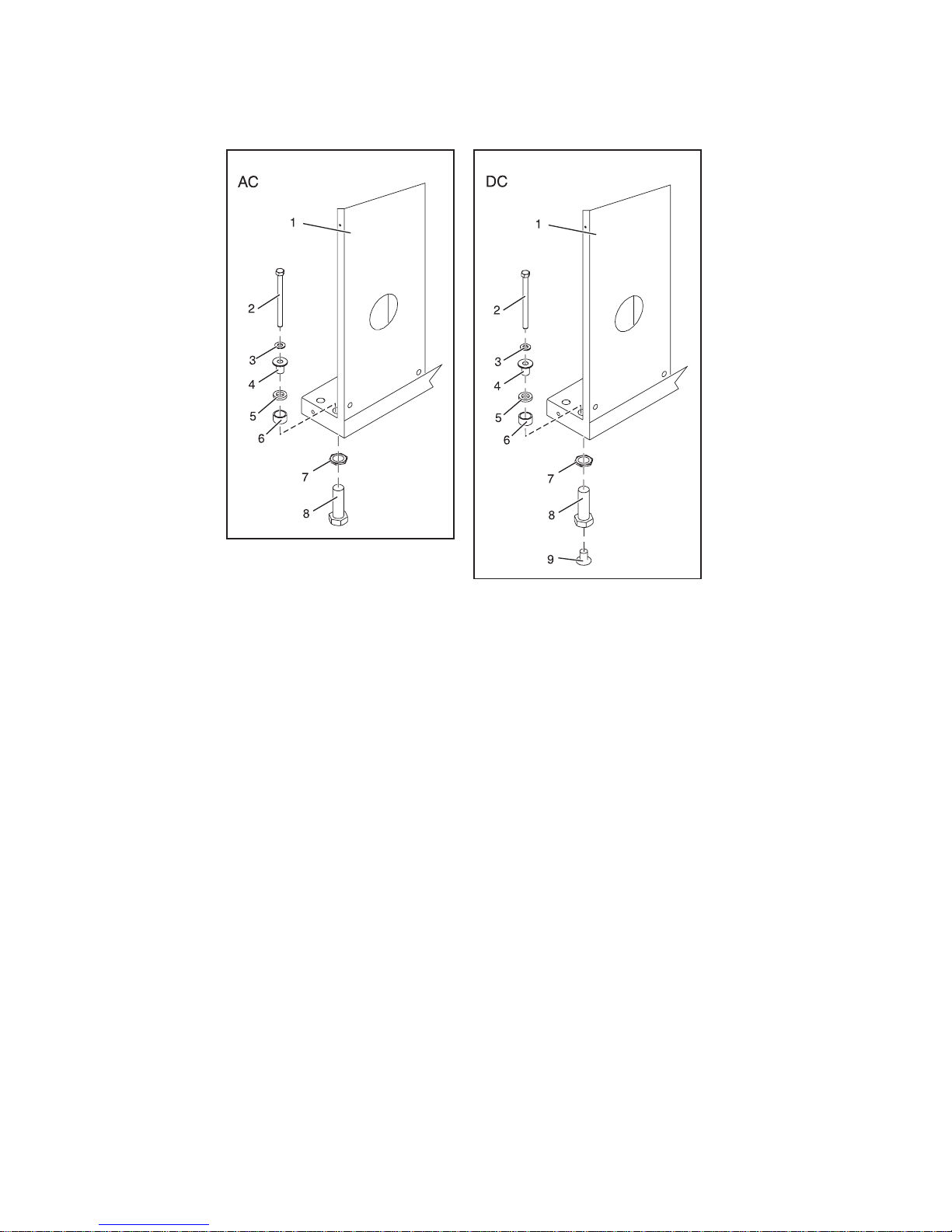

Figure 9. Installing ac-power mounting plates

1 Rack chassis 7 Jam nut

2 Rack-mounting bolt 8 Leveling foot

3 Thin washer 9 Lower plastic isolator bushing (used

only on dc powered systems)

4 Top plastic isolator bushing AC Typical leveling foot installation for

an ac-powered rack

5 Thick washer DC Typical leveling foot installation for

an dc-powered rack

6 Spacer

6. Position the two mounting plates in the approximate mounting location under the rack.

7. Create a rack-mounting bolt assembly by adding the following items, in the order listed, to each

rack-mounting bolt.

a. Thin washer

b. To p plastic isolator bushing

c. Thick flat washer

d. Spacer

8. Insert a rack-mounting bolt assembly through each of the leveling feet.

9. Reposition the rack-mounting plates under the four rack-mounting bolts so that the mounting bolts

are centered directly over the threaded bolt holes.

10. Turn the rack-mounting bolts four complete turns into the mounting plate’s threaded bolt holes.

16 Installation Guide for the 03E/4A, 07M/15, and 08M/25

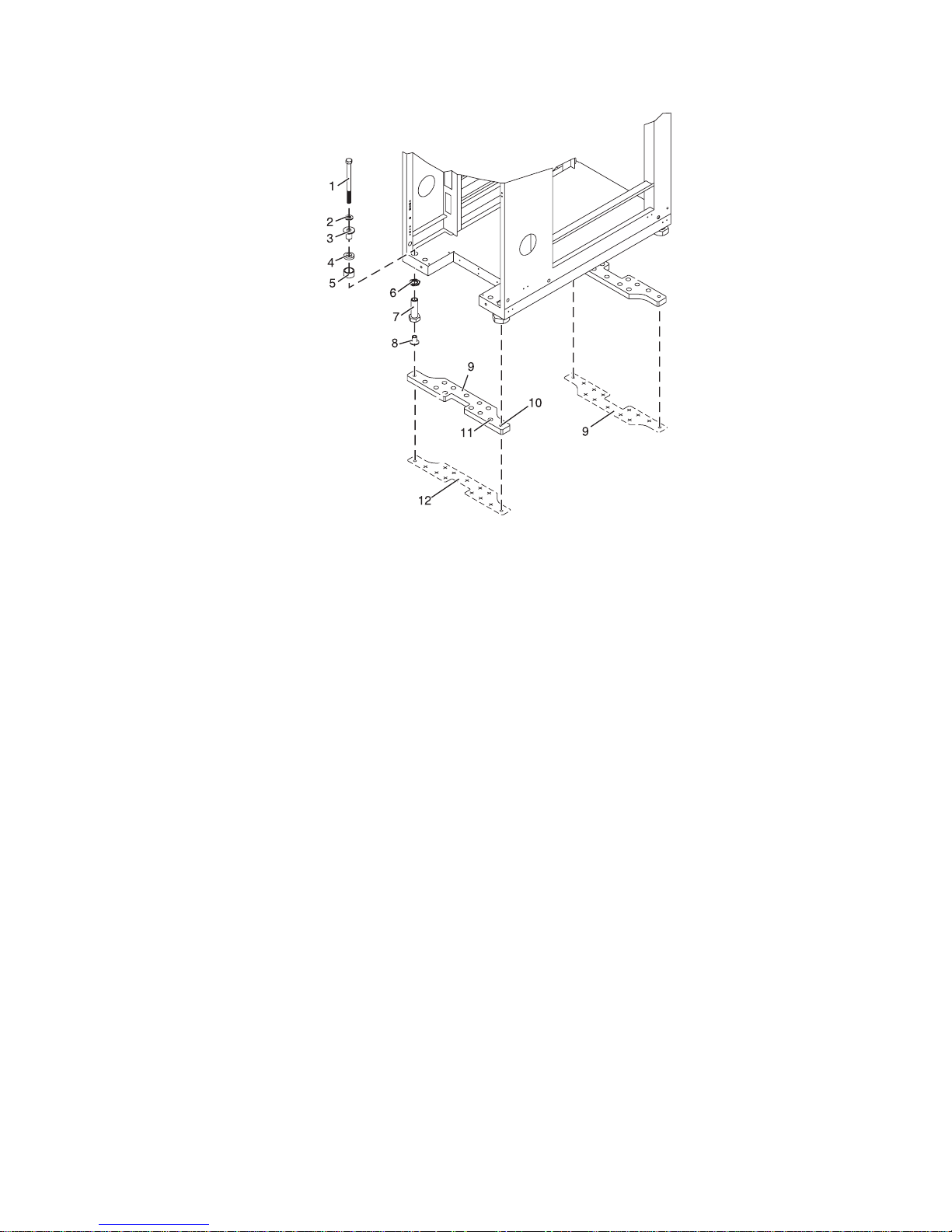

1 Rack-mounting bolt 7 Leveling foot

2 Thin washer 8 Lower plastic isolator bushing (Used

only on dc powered systems)

3 Top plastic isolator bushing 9 Mounting plate

4 Thick washer 10 Threaded hole (Used to secure the

rack to stabilizer bracket.)

5 Spacer 11 Anchor bolt hole

6 Jam nut 12 Traced pattern (Pattern to be traced

onto the floor using the stabilizer

bracket as a template)

Figure 10. Securing the rack to the floor.

11. Mark the floor around the edges of both stabilizer brackets.

12. Mark the plate bolt-down holes that are accessible through the opening in the rear of the rack.

13. Remove the rack-mounting bolt assemblies.

14. If you are installing an ac-powered rack, remove the bottom isolator bushing from each of the

leveling feet.

15. Remove the stabilizer brackets from the marked locations.

16. Loosen each of the locking screws on the casters.

17. Move the rack so that it is clear of both areas that were marked on the floor for the stabilizer bracket

locations.

18. Reposition the stabilizer brackets within the marked areas.

19. Mark the floor at the center of all holes in both stabilizer brackets.

20. Remove the two rack-mounting plates from the marked areas.

21. At the marked location of the threaded rack-mounting bolt holes, drill four clearance holes into the

concrete floor. Each clearance hole should be approximately 1-inch deep. This depth allows the

rack-mounting bolts enough room to protrude past the thickness of the stabilizer brackets.

Chapter 2. Installing your system in a rack 17

Note: You must use a minimum of two anchor bolts for each rack-mounting plate to securely attach

the plate to the concrete floor. Because some of the holes in each rack-mounting plate might align

with concrete reinforcement rods embedded in the concrete, some of the rack-mounting plate holes

might not be usable.

22. Select at least two suitable hole locations for each stabilizer bracket bolt. The selected locations

should be as close to the threaded bolt holes as possible. Be sure that the holes selected at the back

of the rack are accessible. Drill holes at the selected locations into the concrete floor.

23. Position the stabilizer brackets over the concrete anchors.

24. Securely bolt the front stabilizer bracket to the concrete floor.

25. Position the stabilizer bracket over the concrete anchors.

26. Securely bolt the back stabilizer bracket to the concrete floor.

Note: The size of the anchor bolts and concrete anchors must be determined by the mechanical

contractor who will be installing the rack-mounting plate.

27. Position the rack over the stabilizer bracket.

28. Insert each of the stabilizer bracket bolts through a flat washer, a plastic isolator bushing and a thick

washer, and through a leveling foot.

29. Align the four stabilizer brackets bolts with the four tapped holes in the two mounting plates and

turn three to four rotations.

30. Tighten the locking screw on each caster.

31. Adjust the leveling feet downward as needed until the rack is level. When the rack is level, tighten

the jam nuts against the base of the rack.

Figure 11. Adjusting the leveling feet.

32. If you have multiple racks that are connected in a suite (bolted to each other), go to “Connecting

multiple racks with rack-to-rack attachment kit” on page 21. Otherwise, torque the four bolts to

40-50 ft-lbs (54-67 nm).

18 Installation Guide for the 03E/4A, 07M/15, and 08M/25

1 Rack front (base)

2 Leveling foot (quantity 4)

3 Jam nut (quantity 4)

33. If you are not installing doors on your rack, install the top, left, and right trim panel.

34. Connect the power distribution system as described in “Connecting the power distribution system”

on page 27.

35. After all racks are bolted down, go to “Attaching the front or back ac electrical outlet” on page 28.

36. If you are not going to attach a front electrical outlet and you are installing rack doors, go to

“Attaching the rack doors”

Attaching the rack doors:

You might need to attach the rack doors. Use the procedure in this section to perform this task.

Depending on the model of the rack, the front door of a rack might be an optional feature. If your system

already has the front door installed, or does not have a front door to install, skip this step.

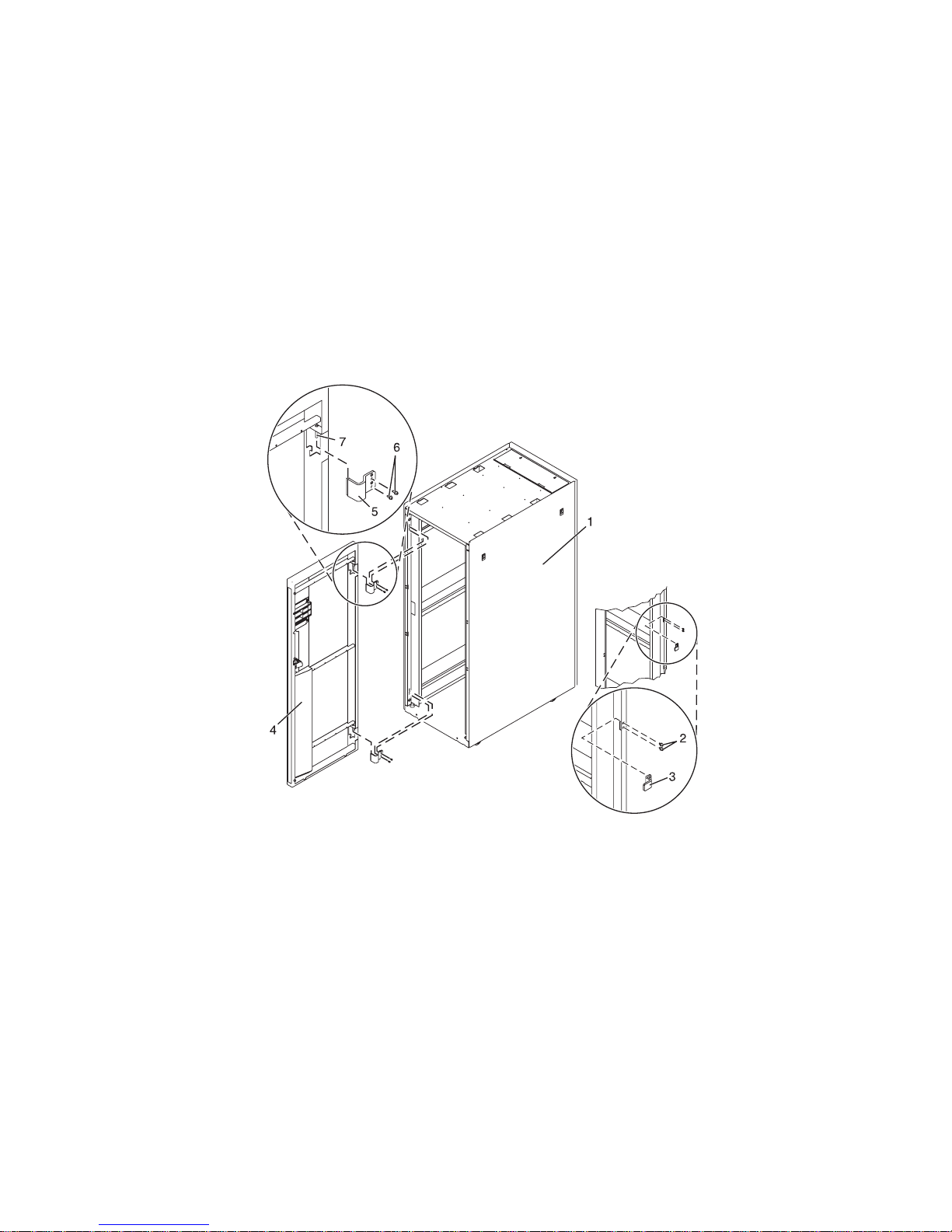

Figure 12. Attaching the rack door

Attaching a rack front door:

You might need to attach a front door to a rack. Use the procedure in this section to perform this task.

To install a rack front door to open from right to left, follow the installation steps described in “Attaching

a high-perforation front door” on page 20.

To install a rack front door to open from left to right, refer to the previous illustration, and perform the

following steps:

1. Read the “Rack safety notices” on page 5.

2. Remove the door latch and cover plate and reinstall them on the opposite side of the door.

3. Remove the door hinges and reinstall them on the opposite side of the door.

4. Install the rack latch on the opposite side of the rack.

5. Align the front door with the hinge pins, and lower the door into position.

Chapter 2. Installing your system in a rack 19

6. Adjust the latch so the door latches securely.

Removing a rack door:

You might need to detach a front door to a rack. Use the procedure in this section to perform this task.

1. Read the “Rack safety notices” on page 5.

2. Raise the front door off the hinge pins.

Attaching

a high-perforation front door:

You might need to attach a front door to the rack. Use the procedure in this section to perform this task.

To install the high-perforation front door, do the following:

1. Read the “Rack safety notices” on page 5.

2. Remove the top, left, and right trim panels.

Figure 13. Removing the trim panels.

20 Installation Guide for the 03E/4A, 07M/15, and 08M/25

1 Rack chassis

2 Top trim panel

3 Left side trim panel

4 Right side trim panel

5 Spring clip

3. Install the door latch on the right and the door hinges on the left.

4. For a high-perforation front door, align the door over the rack hinge, then move up the hinge pin on

the door, and lower the hinge pin into the hinge.

5. Adjust the latch so the door latches securely.

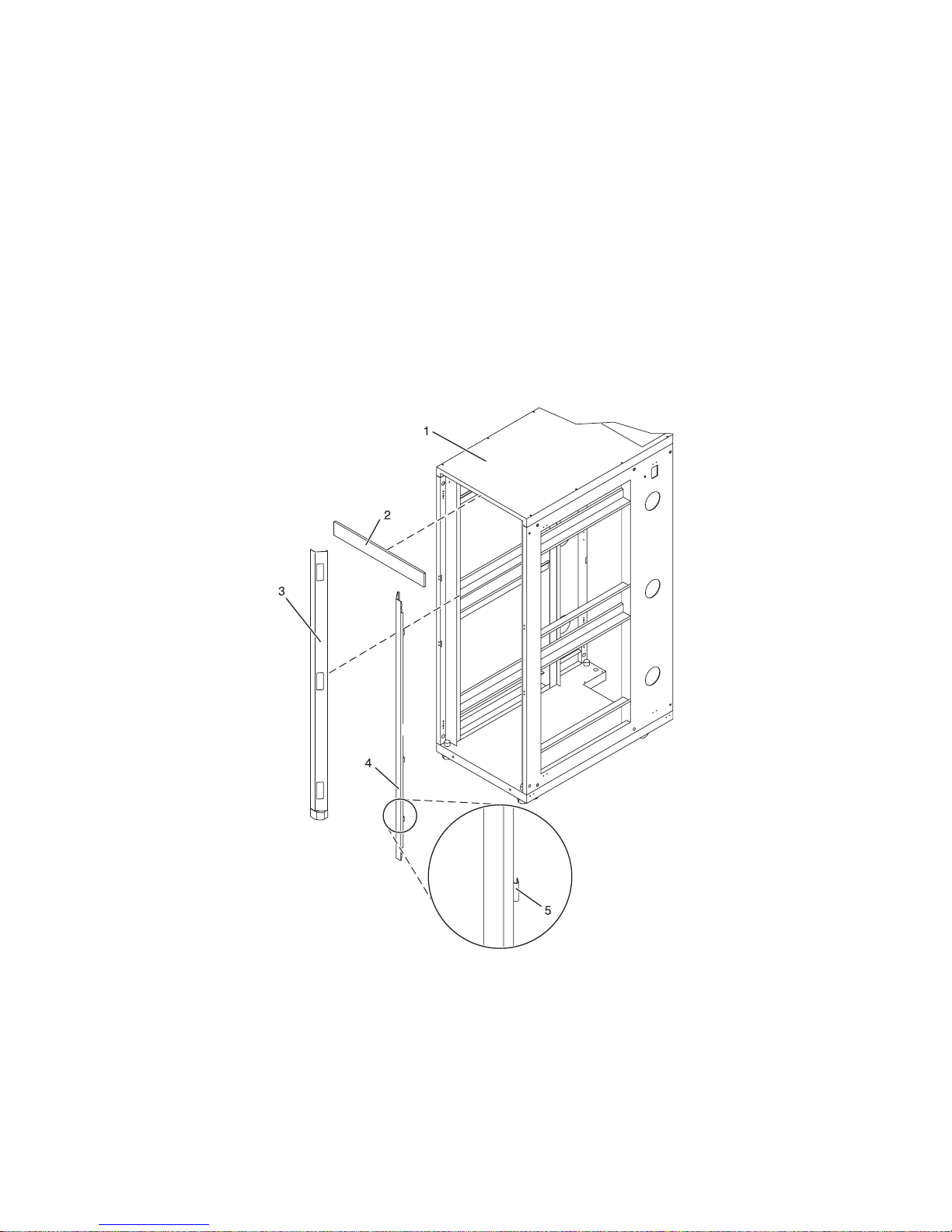

Connecting multiple racks with rack-to-rack attachment kit:

You might need to connect multiple racks together. Use the procedure in this section to perform this task.

This topic describes how to connect multiple racks to each other using a rack-to-rack attachment kit. To

do this, you will need the rack-to-rack attachment kit:

1. Read the “Rack safety notices” on page 5.

2. If they are installed, remove the side panels from each rack. Remove side panels only from the sides

that will be attached to each other. To do this:

a. Lift up the two panel-release tabs.

b. Pull the panel up and away from the rack chassis. This motion will release the panel from the

two lower J brackets.

c. Store the side panels.

3. Remove the two Z brackets and the two J brackets. These brackets are used to hang the side panels.

4. Install the first two standoffs in the upper-left and lower-right corners of the first rack as shown in

Figure 14 on page 22.

5. Install the second two standoffs in the upper-left and lower-right corners of the second rack as

shown in Figure 14 on page 22.

6. Attach the long foam as shown in Figure 14 on page 22. For a model T42 rack, join the short foam to

the end of the long foam, and adhere it to the frame length of the rack.

7. Position the racks together.

8. Align the standoff holes. You might need to adjust the leveling feet to do this.

9. Install a screw and washer into all four positions, but do not tighten.

Chapter 2. Installing your system in a rack 21

Figure 14. Removing the side panels, Z and J brackets, and installing standoffs and long foam to connect multiple

racks.

Figure 15. Location of foam strips (top view).

10. After all racks are bolted together, level the racks.

11. Tighten all four screws.

12. Snap on the trim pieces that go between the front and back racks.

13. Snap on the trim piece that goes on top and between the racks.

14. Install rack filler panels to cover the open areas at the front of the racks. All the gaps in the front of

the rack must also be sealed, including the gaps between equipment. This step ensures that proper

airflow within the rack is maintained.

15. Connect the cables that go between the racks.

22 Installation Guide for the 03E/4A, 07M/15, and 08M/25

16. If you are installing tip plates, go to step 5 in “Installing the rack” on page 5.

Attaching the rack to the concrete floor beneath a raised floor

You might need to attach the rack to the floor. Use the procedure in this section to perform this task.

Obtain the services of a mechanical contractor to attach the rack-mounting plates to the concrete floor.

The mechanical contractor needs to determine that the hardware being used to secure the rack-mounting

plates to the concrete floor is sufficient to meet the requirements for the installation.

To attach the rack to a concrete floor beneath a raised floor, do the following:

1. Put your rack in its predetermined location and tighten the locking screws on the casters.

2. If installed, remove the top, left and right trim panels. The trim panels are held in place with spring

clips. See the following illustration.

1 Rack chassis 4 Right-side trim panel

2 Top trim panel 5 Spring clip

3 Left-side trim panel

Figure 16. Removing the trim panels.

3. If installed, remove the front and rear doors. To remove a rack door, go to “Removing a rack door”

on page 20. After the rack doors have been removed, go to the next substep.

Chapter 2. Installing your system in a rack 23

4. Locate the hardware mounting kit and the two mounting plates. Refer to the following illustration

when reviewing the contents of the hardware mounting kit. The hardware mounting kit contains the

following:

v Four rack-mounting bolts

v Four thin washers

v Eight plastic isolator bushings

v Four thick washers

v Four spacers

5. If you are installing an ac-powered rack, temporarily install the lower plastic isolator bushings to

help you locate the rack-mounting plate. After the mounting plate has been correctly located, remove

the lower plastic isolator bushings.

Figure 17. Installing the ac power-mounting plates.

1 Rack chassis 7 Jam nut

2 Rack-mounting bolt 8 Leveling foot

3 Thin washer 9 Lower plastic isolator bushing (used

4 Top plastic isolator bushing AC Typical leveling foot installation for

5 Thick washer DC Typical leveling foot installation for

6 Spacer

6. Position the two mounting plates in the approximate mounting location under the rack.

7. Create a rack-mounting bolt assembly by adding the following items, in the order listed, to each

rack-mounting bolt.

a. Thin washer

b. To p plastic isolator bushing

24 Installation Guide for the 03E/4A, 07M/15, and 08M/25

only on dc powered systems)

an ac-powered rack

an dc-powered rack

c. Thick flat washer

d. Spacer

8. Insert a rack-mounting bolt assembly through each of the leveling feet.

9. Reposition the rack-mounting plates under the four rack-mounting bolts so that the mounting bolts

are centered directly over the threaded bolt holes.

10. Turn the rack-mounting bolts four complete turns into the mounting plate’s threaded bolt holes.

11. Mark the raised-floor panel around the edges of front and back rack-mounting plates.

12. Mark the plate bolt-down holes that are accessible through the opening in the back of the rack.

13. Remove the rack-mounting bolt assemblies.

14. If you are installing an ac-powered rack, remove the bottom isolator bushing from each of the

leveling feet.

15. Remove the rack-mounting plates from the marked locations.

16. Loosen each of the locking screws on the casters.

17. Move the rack so that it is clear of both areas that were marked on the floor for the rack-mounting

plate locations.

18. Reposition the mounting plates within the marked areas.

19. Mark the raised-floor panel at the center of each hole in the rack-mounting plates (including the

tapped holes).

20. Remove the two rack-mounting plates from the marked locations on the raised floor panel.

21. Drill two clearance holes on each end of each rack-mounting plate. The drilled holes should be

approximately 1-inch deep. This depth will accommodate any rack-mounting bolt extending past the

rack-mounting plate when securing the rack to the rack-mounting plate.

22. For each rack-mounting plate, select at least two suitable hole locations. Select the hole locations as

close to the threaded hole areas as possible. Be sure the hole locations selected at the back of the rack

are accessible.

23. Drill pass-through holes in the raised-floor panel. The pass-through holes allow the anchor bolts to

be inserted into the rack-mounting plate and pass through the raised floor panel to the concrete

floor.

Note: You must use a minimum of two anchor bolts for each rack-mounting plate to securely attach

the rack-mounting plate through the raised-floor panel to the concrete floor. Because some of the

holes in each rack-mounting plate may align with concrete reinforcement rods imbedded in the

concrete, some of the rack-mounting plate holes may not be usable.

24. Transfer the locations of the anchor bolt holes (exclude the clearance holes drilled for the

rack-mounting bolts ) from the raised-floor panel to the concrete floor directly beneath, and mark the

hole locations on the concrete floor.

25. Drill holes in the concrete floor to secure the anchor bolts.

26. Position the raised-floor panel back into position over the anchor bolt holes.

27. Position the front stabilizer bracket within the marked area on the raised-floor panel.

28. Using your anchor bolts, secure the front stabilizer brackets on top of the raised floor and through to

the concrete floor.

29. Position the rear stabilizer brackets within the marked area on the raised-floor panel.

Chapter 2. Installing your system in a rack 25

1 Rack-mounting bolt 7 Leveling foot

2 Thin washer 8 Lower plastic isolator bushing (used

only on dc-powered systems)

3 Top plastic isolator bushing 9 Stabilizer brackets

4 Thick washer 10 Threaded hole (used to secure the

rack to mounting plate.)

5 Spacer 11 Anchor bolt hole

6 Jam nut 12 Traced pattern (pattern to be traced

onto the floor using the mounting

plate as a template)

Figure 18. Securing the rack to the floor.

30. Using your anchor bolts, secure the back stabilizer bracket on top of the raised floor and through to

the concrete floor.

31. Replace all raised-floor panels that may have been removed when aligning and securing the anchor

bolts to the concrete floor.

32. Align the rack over the front and back stabilizer brackets.

33. Insert each of the bolt assemblies through a leveling foot.

34. Align the rack-mounting bolts with the threaded holes in each stabilizer bracket. Turn each bolt three

to four rotations.

35. Tighten the locking screw on each caster.

36. Adjust the leveling feet downward as needed until the rack is level. When the rack is level, tighten

the jam nuts against the base of the rack.

37. If you have multiple racks that are connected as a suite (bolted to each other), go to “Connecting

multiple racks with rack-to-rack attachment kit” on page 21. Otherwise, torque the four bolts to

40-50 ft-lbs (54-67 nm).

38. If you are not installing doors on your rack, install the top, left, and right trim panel.

26 Installation Guide for the 03E/4A, 07M/15, and 08M/25

39. Connect the power distribution system as described in “Connecting the power distribution system.”

40. After the rack is bolted down and you are going to attach a front electrical outlet, go to “Attaching

the front or back ac electrical outlet” on page 28.

41. If you are not going to attach a front electrical outlet and you are installing rack doors, go to

“Attaching the rack doors” on page 19.

Connecting the power distribution system

You might need to connect a power distribution system. Use the procedure in this section to perform this

task.

To connect a Power Distribution Unit, see “Power distribution unit plus (PDU+).”

Power distribution unit plus (PDU+)

The power distribution unit plus (PDU+) can be installed in the 14T/00 and 14T/42 racks, and allows

you to monitor the individual power loads of the devices that are plugged into it.

Checking the ac outlets

You might need to check the ac outlets. Use the procedure in this section to perform this task.

Before you begin, ensure that you have a multimeter to check voltages and an appropriately approved

ground-impedance tester to test the grounding resistances.

Note: Use only an appropriately approved ground-impedance tester to test the grounding resistances. Do

not use a multimeter to measure grounding resistance.

Before plugging the rack into the ac power source, complete the following checks on the ac power source.

1. Turn off the branch circuit breaker for the ac power outlet that the rack will plug into. To the circuit

breaker switch, attach tag S229-0237, which reads ″Do Not Operate.″

Note: All measurements are made with the receptacle faceplate in the usual installed position.

2. Some receptacles are enclosed in metal housings. For this type of receptacle, do the following:

a. Using a multimeter, check for less than 1 volt from the receptacle case to any grounded metal

structure in the building, such as a raised-floor metal structure, water pipe, building steel, or

similar structure.

b. Using a multimeter, check for less than 1 volt from the receptacle ground pin to a grounded point

in the building.

Note: If the receptacle case or faceplate is painted, be sure the probe tip penetrates the paint and

makes good electrical contact with the metal.

c. Using a multimeter, check the resistance from the receptacle ground pin to the receptacle case.

Check resistance from the ground pin to the building ground. The readings should be less than 1.0

ohm, which indicates the presence of a continuous grounding conductor.

If any of the checks made in step 2 are not correct, ask the customer to remove the power from the

3.

branch circuit and make the wiring corrections. Recheck the receptacle after the wiring is corrected.

4. Using a ground-impedance tester, check for infinite resistance between the ground pin of the

receptacle and each of the phase pins. This is a check for a wiring short to ground or a wiring

reversal.

5. Using a ground-impedance tester, check for infinite resistance between the phase pins. This is a check

for a wiring short.

6. Turn on the branch circuit breaker.

7. Using a multimeter, measure for the appropriate voltages between phases. If no voltage is present on

the receptacle case or grounded pin, the receptacle is safe to touch.

Chapter 2. Installing your system in a rack 27

8. Using a multimeter, verify that the voltage at the ac outlet is correct.

Attaching the front or back ac electrical outlet

You might need to attach an ac outlet. Use the procedure in this section to perform this task.

Attention: The front and back ac outlet-mounting plates mount through the same mounting holes in

that secure the stabilizer brackets to the rack chassis. Therefore, if the rack must be bolted to the floor, the

stabilizer brackets must be removed.

Install the ac outlet-mounting plates only after the rack has been bolted to the floor and the stabilizer

brackets have been removed.

The following items are installed at the customer’s site:

v The ac outlet-mounting plates for installing customer-supplied ac electrical outlets on the front or back

of the rack. The ac outlet-mounting place provides the mounting location for an ac electrical outlet.

v The brass ground lug for an electrostatic discharge (ESD) connection.

The customer is responsible for providing both the outlets and the power cables that attach to the

Note:

power source. The customer is also responsible for connecting the ac outlet correctly. These items are not

field-replaceable units (FRUs).

Installing

the ac outlet-mounting plates with ac outlets:

You might need to install ac mounting plates. Use the procedure in this section to perform this task.

If you do not want ac outlets installed on the rack, go to “Installing the ac outlet-mounting plate without

ac outlets” on page 30.

If you want ac outlets installed on the front or back ac outlet-mounting plate, do the following:

1. Determine the number of ac outlets that you are installing.

2. Confirm with your contractor that the number and location of ac outlets to be installed are correct.

3. Remove the blank filler plates from the ac outlet-mounting plates for the number of ac outlets being

installed.

4. Install the ac outlets on the ac outlet-mounting plate.

5. Install the ground lug in the ac outlet-mounting plate using only one nut, as shown in the following

illustration.

6. Securely tighten the one nut on the ground lug.

7. Locate the ″Y″-shaped ground cable supplied with the mounting plate.

Note: The remaining steps can be used to install ac outlets on the front or the back of the rack.

8. Place the star washer onto the ground lug of the front ac outlet-mounting plate.

9. Place the lug on the long end of the ground cable onto the ground lug.

10. Place a ground lug nut onto the ground lug and securely tighten it.

11. Position the front ac outlet-mounting plate onto the rack frame with the ground lug fully inserted

through the mounting holes in the rack.

12. Route the cable under the rack.

13. Place the star washer onto the ground lug of the back ac outlet-mounting plate.

14. Place the lug on the short end of the ground cable onto the ground lug.

15. Place a ground lug nut onto the ground lug and securely tighten it.

28 Installation Guide for the 03E/4A, 07M/15, and 08M/25

1 Ground cable lug 7 Ground lug

2 Star washer 8 Ground connector (short end of

ground cable)

3 Front of rack 9 ″Y″ End of ground cable

4 Power cable from the power source 10 Ground lug nut (quantity 2)

5 Mounting plate 11 Long end of ground cable

6 Long end of ground cable 12 Ground lug nut (quantity 2)

Figure 19. Installing the ground lug.

16. Position the back ac outlet-mounting plate onto the rack frame with the ground lug fully inserted

through the mounting holes in the rack.

17. Install the front ac outlet-mounting plate screws (stabilizer mounting screws) into the mounting plate

and through the mounting holes in the rack. Securely tighten the screws.

1 Front or back of rack (as applicable) 4 Mounting plate

2 Power cable from power source 5 Allen wrench

Chapter 2. Installing your system in a rack 29

3 Button-head screw 6 Long end of ground cable

Figure 20. Installing the front mounting plate.

18. Connect the ″Y″-shaped end of the ground cable to the rack frame, either near the center in the back

of the rack or to the ground bus bar at the back of the rack.

19. Install the back ac outlet-mounting plate screws (stabilizer mounting screws) into the mounting plate

and through the mounting holes in the rack. Securely tighten the screws.

Note: The bus bar might be located at either the top or bottom of the rack.

1 Bus bar mounting plate 3 Hex screws (M5 x 20) (quantity 2)

2 Lock washer (quantity 2) 4 Ground bus bar

21. Installing the back mounting plate.

Figure

Installing the ac outlet-mounting plate without ac outlets:

You might need to install an outlet plate without the outlets. Use the procedure in this section to perform

this task.

30 Installation Guide for the 03E/4A, 07M/15, and 08M/25

If you do not want any ac outlets installed on the front or rear ac outlet-mounting plate, perform only

“Attaching the rack to the concrete floor beneath a raised floor” on page 23 through “Connecting the

power distribution system” on page 27.

For front or rear ac outlet-mounting plates, refer to “Installing the ac outlet-mounting plates with ac

outlets” on page 28.

Connecting a dc power source

You might need to connect a dc power source to the rack. Some rack models (such as the 14T/00) can

support a dc power configuration for servers that require dc power. Use the procedure in this section to

perform this task.

Note: The customer is responsible for providing and connecting the -48 V dc power source and -48 V dc

power return cables from the customer’s source -48 V dc to the bus bars in the power distribution panel.

The customer is also responsible for connecting the ground cable to the rack frame. This procedure

provides information about accessing the power distribution panel.

1. Remove the six mounting screws from the top cover of the dc power distribution panel and remove

the top cover.

2. If they are installed, remove the four screws from the cable channel cover.

3. Remove the cable channel cover.

1 Cable channel cover retaining screw 5 Shield

2 Cable channel cover 6 Power distribution panel

3 Power distribution panel top cover

retaining screws

4 Power distribution panel top cover

Figure 22. Removing the cable channel cover.

4. Remove the -48 V dc bus bar shield from the power distribution panel.

Chapter 2. Installing your system in a rack 31

Attention: The bus bar shield must be correctly reinstalled over the -48 V dc return bus bars to

protect against injury while servicing the power distribution panel.

5. Ensure that the following steps are performed when connecting the dc power source.

a. At -48 V dc power source, turn off any -48 V dc power sources that will be connected to the

power distribution panel.

b. After the -48 V dc power sources are turned off, be sure there is a tag or label over the power

source switches or fuses (lock-out/tag-out) to indicate that the power source is turned off

intentionally.

Note: Ensure that any oxidation on the copper bus bars is removed.

c. If this is a raised-floor installation and you are working at the back of the rack, route the power

cables up the rack’s right side.

d. Ensure that the external -48 V dc power cable is connected correctly to the -48 V dc bus bar.

e. Ensure that the external -48 V dc return cable is routed correctly and installed on the return bus

bar.

Figure 23. Routing the power cables.

1 -48 V dc power cable and return power cable

2 Power distribution panel

3 Front of rack

4 -48 V dc power cable and return power cable

32 Installation Guide for the 03E/4A, 07M/15, and 08M/25

1 Front of power distribution panel 6 (B) Return (-) power cable

2 (A) -48 V dc (-) bus bar 7 (B) -48 V dc (-) power cable

3 (A) -48 V dc (-) power cable 8 (B) Return (-) bus bar

4 (A) Return (-) bus bar 9 (B) -48 V dc (-) bus bar

5 (A) Return (-) power cable

Figure 24. Return bus bar.

f. If you want to install a power status alarm, connect the alarm cable to the terminal board on the

back cover of the dc power distribution panel.

Note: Ensure that you remove the oxidation on the copper bus bars.

g. Ensure that the power-source ground cable is routed correctly and connects the power-source

ground cable to the copper bar at the lower-back or upper-back center of the rack.

h. If the rack is on a raised floor, attach the -48 V dc power source cables to the back of the rack with

cable-restraint straps.

Chapter 2. Installing your system in a rack 33

1 Back view of rack (dc)

2 Power cable, power return cable, and ground

3 Ground cable (Install at either top or bottom of the rack)

Figure 25. Cable locations.

6. Reinstall the -48 V dc bus bar shield.

7. Reinstall the top cover on the dc power distribution panel.

8. Reinstall the cable channel cover.

34 Installation Guide for the 03E/4A, 07M/15, and 08M/25

1 Cable channel cover

2 Terminal block (both sides)

3 Power distribution panel

4 Front of rack

Figure 26. Reinstalling the cable channel cover.

Installing the rack security kit

You might need to install the rack security kit. Use the procedure in this section to perform this task.

To install a rack security kit that consists of the security lock and security slide bars, complete the

following procedure:

1. Read the “Rack safety notices” on page 5.

2. Verify the inventory in the rack security kit.

v

27. Rack security kit inventory.

Figure

1 Two lock hardware kits. Each kit contains:

- Rack lock

- Bracket

- Screw

- Tw o keys

2 Two security slide bars

3 Two locked/unlocked stickers

Chapter 2. Installing your system in a rack 35

3. Remove the existing door latch.

Figure 28. Removing the existing door latch.

a. Open the front rack door.

b. On the inside of the door, remove the screw 4 in Figure 28, that secures the lock to the rack door.

c. Remove the bracket 5.

d. From the outside of the door, remove the door latch 6.

If the rack is equipped with the ruggedized kit, remove the jam nut and hex nut from the

Note:

existing door latch and reinstall both nuts on the new door lock latch.

4. Install the locking latch.

a. Insert the keyed rack lock into the latch slot on the front of the door 6 in Figure 28.

b. Secure the lock by attaching the lock bracket 5 with the screw 4, on the inside of the door.

5. Repeat steps 3 and 4 to install the second lock on the back rack door.

6. Install a security slide bar on the right side of the rack.

36 Installation Guide for the 03E/4A, 07M/15, and 08M/25

Figure 29. Installing a security slide bar.

Note: Each slide bar rail has two long tabs on the bottom of the rail. The slide bar rails are identical

and can be installed on either the right or left side cover panel.

a. Unlatch right-side cover panel and lean the panel back so that you can access the top of the panel.

b. With the flat side of the slide bar rail 7 in Figure 29, facing the inside of the cover panel 8, insert

the two tabs 9, on the slide bar rail into the two vertical support channels 10 on the side cover

panel.

Note: When installed correctly, the slide rail moves from front to back.

c. Reinstall the side panel cover on to the rack.

d. Lock the side panel covers by sliding the bars to the front of the rack.

e. Place a locked/unlocked sticker on the inside of the cover panel so that when the slide bar is in

the locked position, the tab is over the locked symbol, 11, as shown in Figure 30 on page 38 and

over the unlocked symbol, 12, when the slide bar is unlocked.

Chapter 2. Installing your system in a rack 37

Figure 30. Placing the locked/unlocked sticker on the cover panel.

f. Repeat the procedure for the left side of the rack.

Installing the model in a rack

You might need to install the system into a rack. Use the procedure in this section to perform this task.

This topic describes how to install the system in a rack. This is a customer task. You can perform this task

yourself, or contact a service provider to perform the task for you. You might be charged a fee by the

service provider for this service.

Important: To complete this procedure, use two people to attach the rail assembly to the rack, one in

front of the rack and one at the back of the rack. You will need three people to lift the system unit onto

the rack.

This procedure assumes that you are installing the system into an existing rack. If the rack is not

installed, go to the instructions for installing the rack and then return to this procedure for instructions

on installing the system unit in a rack.

Note: This procedure applies only to the models that are designed to be mounted in a rack. Do not

attempt to install a stand-alone model in a rack.

To install model in a rack, complete the following steps:

CAUTION:

Installing the rails in the rack is a complex procedure. To install the rails correctly, you must perform

each task in the following order. Failure to do so might cause rail failure and potential danger to

yourself and the system unit.

1. Read the “Rack safety notices” on page 5.

2. Complete a parts inventory, if you have not done so.

38 Installation Guide for the 03E/4A, 07M/15, and 08M/25

Figure 31. Rack-mounting kit

A Rack-mounting hardware kit

- Four large retaining screws

- Two rack-latch brackets

- Two rack-latch bracket screws

- Two cable restraint brackets

B Left and right rack rails with rack brackets

C Cable-management arm pins

D Cable-management arm bracket

E Cable-management arm

F Two rack latches

If there are incorrect, missing, or damaged parts, contact:

v Your reseller

Locate the rack-mounting hardware kit A, and the rack rails B that were included with your system

3.

unit as shown in Figure 31.

The system rails B are front-to-back and left-to-right side dependent. The rails are labeled left and

right to indicate their placement when you face the front of the rack. There are two large latch

assemblies at the back of each rail. These latch assemblies go in the back of the rack.

4. Determine where you will locate the system unit in the rack. See “Determining the location” on page

7.

Chapter 2. Installing your system in a rack 39

Attaching the mounting hardware to the rack

You might need to attach the mounting hardware to the rack. Use the procedure in this section to

perform this task.

Attention: Installing the rails in the rack is a complex procedure. To install the rails correctly, you must

perform each task in the following order. Failure to do so might cause rail failure and potential danger to

yourself and the system unit.

To install the rack-mounting hardware into the rack, complete the following steps:

1. With the right rail, pull back the latch assembly release tab, A in Figure 32, and then slide tab B back

to the retracted position and lock the latch assembly. The back-alignment pins should be fully

retracted.

2. After the alignment pins are retracted, insert the right side rail’s front-alignment pin as shown in

Figure 32, into the rack front flange hole identified by the self-adhesive placement dot that you

previously installed. Have a second person hold the rail securely in the front hole.

Figure 32. Front slide rail alignment pin, retaining screws, and latch bracket.

3. Align the back-alignment pins of the rail with the holes at the back of the rack identified by the

self-adhesive placement dots on the back of the rack. The back EIA location will be one position

higher than the front rail position. Ensure that the rails are level.

4. Slide the release tab, B, to extend the two back-alignment pins into the back of the rack. Ensure that

the pins have passed through the correct holes in the rack frame.

5. From the back of the rack, insert one of the large rail-retaining screws into the hole that is located

between the two back alignment pins. Partially tighten the screw. Do not tighten completely at this

time.

6. Repeat steps 1 through 5 for the left side rail.

40 Installation Guide for the 03E/4A, 07M/15, and 08M/25

7. Locate the two latch brackets, F in Figure 31 on page 39. Screw the brackets onto the sides of the

system (located near the front) using the two small screws.

8. Extend the inner rails by pulling the rails out. They should be extended from the frame as the rails

shown in Figure 33.

9. Using three people, grasp the two handles located on each side of the system drawer and place the

system onto the inner rail as shown in Figure 33.

Figure 33. Place system onto the rails

10. After the system is firmly in place, simultaneously press the safety latches and push the system unit

into the rack as shown in Figure 34 on page 42.

Chapter 2. Installing your system in a rack 41

Figure 34. Inner rail extended

11. Use the retaining screws to attach the rack latches to the rack as shown in Figure 35.

Figure 35. Secure system to rack through rack latches

42 Installation Guide for the 03E/4A, 07M/15, and 08M/25

12. After both rails have been installed, ensure that none of the rail’s retaining screws are more than

finger-tight. The rails must be level from front to back and from left to right.

Installing the cable-management arm

You might need to install the cable-management arm. Use the procedure in this section to perform this

task.

To install the cable-management arm, complete the following steps:

1. Determine on which side of the rack you want to install the cable-management arm.

2. Place the correct arm bracket (Left or Right) with the cable-management arm.

3. Use pin F to pin the cable-management arm E to the rack frame D as shown in Figure 36.

Figure 36. Attaching the cable-management arm.

Tip: If access to the back of the rack is obscured by a large number of existing cables, it might be

easier to remove the small connecting hinge from the cable-management arm and attach it first. Then,

you can attach the remaining section of the cable-management arm to the connecting hinge.

4. Use the second pin F to pin the other end of the cable-management arm to the flange C that is

attached to the sliding portion of the left system rail assembly B as shown in Figure 36.

Chapter 2. Installing your system in a rack 43

44 Installation Guide for the 03E/4A, 07M/15, and 08M/25

Chapter 3. Installing an 03E/4A with logical partitions

Use these tasks to set up your logical partitioned system.

Checklist: Installing an 03E/4A with logical partitions

The 03E/4A with logical partitions installation checklist comprises a complete, chronological list of all the

tasks associated with setting up your system. This is a comprehensive checklist. Complete only the tasks

that apply to your particular situation.

System installation tasks

__ Chapter 1, “Prerequisite tasks for the 03E/4A installation,” on page 3

__ Chapter 2, “Installing your system in a rack,” on page 5

__ “Cabling your server”

__ “Cabling the server and the Hardware Management Console (HMC)” on page 46

__ “Cabling the server to access the Integrated Virtualization Manager” on page 49

__ “Cabling the server to access the Operations Console” on page 53

__ “Setting up your console or interface and create logical partitions” on page 58

__ “Setting up the HMC and create logical partitions” on page 58

__ “Setting up Virtual I/O Server, IVM, and logical partitions” on page 59

__ “Setting up the Operations Console, twinaxial console, or 5250 console and creating logical partitions” on

page 59

__ “Installing operating systems” on page 60

__ “Installing AIX” on page 77

__ “Installing ” on page 77

__ “Installing Linux” on page 77

__ “Setting up your server to connect to service and support” on page 60

__ “Obtaining updates and upgrades” on page 60

__ “Obtaining HMC machine code updates and upgrades” on page 79

__ “Obtaining firmware updates” on page 79

__ “Obtaining operating system fixes” on page 82

Cabling your server

Learn how to cable your server with a console or interface that is available for your server. This might

include the Advanced System Management Interface (ASMI), Hardware Management Console (HMC), or

Integrated Virtualization Manager.

To learn more about the cabling options that are available for your server, see the following console and

interface descriptions.

Advanced System Management Interface

The Advanced System Management Interface (ASMI) is the interface to the service processor that

allows you to perform general and administrator-level service tasks, such as reading service

processor error logs, reading vital product data, setting up the service processor, and controlling

the system power. The ASMI might also be referred to as the service processor menus. Set up

access to the ASMI if you plan to manage the AIX® or Linux® operating systems without an

HMC. The ASMI can also be used to setup your Virtual I/O Server (VIOS).

Hardware Management Console

The Hardware Management Console (HMC) is a dedicated workstation that runs integrated

system management software. The HMC manages hardware tasks and configures logical

partitions on managed systems. It also acts as a focal point for hardware detection and reporting.

45

Integrated Virtualization Manager

The Integrated Virtualization Manager provides a Web-based system management interface and a

command-line interface that you can use to manage and configure servers that use the Virtual

I/O Server. On the managed system, you can create logical partitions, manage the virtual storage

and virtual Ethernet, and view service information related to the server. The Integrated

Virtualization Manager is packaged with the Virtual I/O Server, but it is enabled only on certain

platforms and where no Hardware Management Console (HMC) is present.

Cabling the server and the Hardware Management Console (HMC)

Learn how to cable the expansion units, connect the external cables, power cords, and HMC cables, attach

devices, and route the cables after you install all of your hardware features or replace parts.

DANGER

working on or around the system, observe the following precautions:

When

Electrical voltage and current from power, telephone, and communication cables are hazardous. To

avoid a shock hazard:

v Connect power to this unit only with the provided power cord. Do not use the provided power

cord for any other product.

v Do not open or service any power supply assembly.