Page 1

INSTRUCTIONS for

F-12-747-F

March, 1995

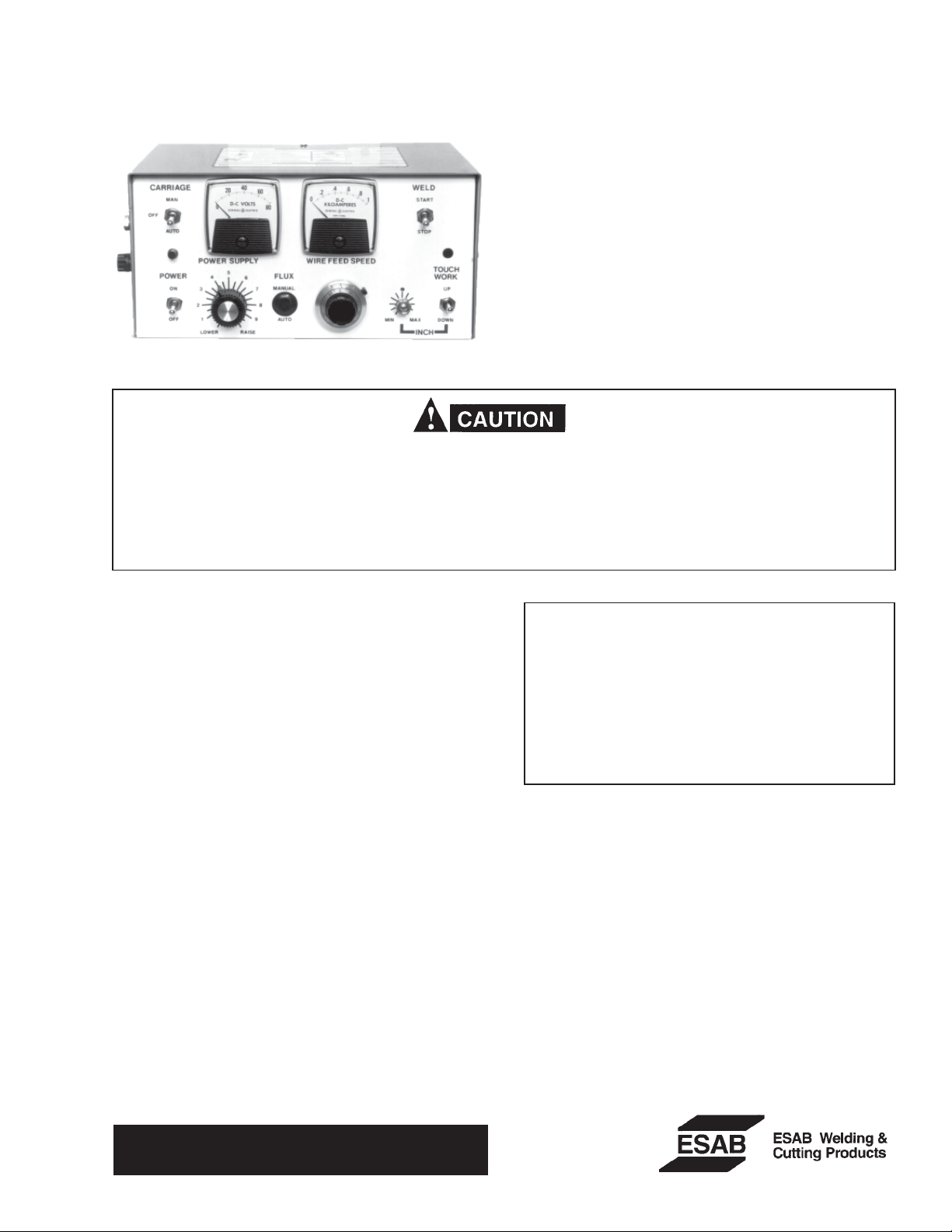

UEC-8

UNIONMELT® ELECTRONIC

WELDING CONTROL

Part No. 677190

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation and safe

practices for electrical welding equipment, we urge you to read our booklet, "Precautions and Safe Practices for Arc Welding,

Cutting and Gouging", Form 52-529. Do NOT permit untrained persons to install, operate, or maintain this equipment. Do NOT

attempt to install or operate this equipment until you have read and fully understand these instructions. If you do not fully

understand these instructions, contact your supplier for further information. Be sure to read the Safety Precautions on page 2

before installing or operating this equipment.

Before applying electrical power, refer to Section IV for an important checklist on the proper interconnection of the UEC-8 Control.

FEA TURES/BENEFITS

Solid State Control ... To assure economical weld-

ing, precise control of welding conditions and arc stability is maintained with UEC-8 solid state accuracy.

Compact Size ... For easy installation and capability

to fit into simple fixtures, OM-48 carriages, or the most

complex automated production lines.

Low Maintenance ... Two basic solid state plug-in

printed circuit boards simplify troubleshooting and

minimize maintenance time.

Operating Versatility ... The UEC-8 is adapted to a

wide range of Sub Arc operations.

Rugged Construction ... Minimize downtime and

maintenance costs, and provides for worry-free operation.

Variable INCH/STRIKE Wire Feed S peed ... Smooth

starts can be obtained even under the most demanding conditions with the UEC-8's front panel variable

INCH/STRIKE wire feed speed adjustment.

Positive Starts ... Result from the UEC-8 voltage/

current detection circuit. This circuit will only allow

transfers from INCH/STRIKE to Welding Wire Feed

speed after an "ARC" has been established. Most

competitive controls do not offer this feature.

Adjustable Anti-Stick ... This feature allows adjust-

Dimensions and weight of the UEC-8 are as follows:

Height ...................................................... (152 mm) 6-in.

Width ..................................................... (305 mm) 12-in.

Depth ...................................................... (209 mm) 8-1/3

Input requirements: 120 Volt 50/60 Hz. 1 phase power @

5 amps A.C.

ment of the wire retract time to prevent the electrode

from sticking in the puddle after completion of a weld.

OM-48 Compatibility.... The UEC-8 has a plug-in

connection for direct interface with the J Governor/

OM-48 Carriage.

UEC-8 and EH-10 or EH-11 Motor .... With large 2-

in. diameter feed rolls offers the reserve power

needed to assure consistent wire feeding under the

most demanding conditions.

Optional Digital Meters .... Provide excellent means

of observing and controlling welding voltage, wire feed

speed - I.P.M., and amperage.

SPECIFICATIONS

Be sure this information reaches the operator.

You can get extra copies through your supplier.

Page 2

SAFETY PRECAUTIONS

WARNING: These Safety Precautions are for

your protection. They summarize precautionary information from the references listed in

Additional Safety Information section. Before

performing any installation or operating procedures, be

sure to read and follow the safety precautions listed below

as well as all other manuals, material safety data sheets,

labels, etc. Failure to observe Safety Precautions can result

in injury or death.

PROTECT YOURSELF AND OTHERS

Some welding, cutting, and gouging

processes are noisy and require ear

protection. The arc, like the sun, emits

ultraviolet (UV) and other radiation and

can injure skin and eyes. Hot metal can cause burns.

Training in the proper use of the processes and equipment is essential to prevent accidents. Therefore:

1. Always wear safety glasses with side shields in any work

area, even if welding helmets, face shields, and goggles

are also required.

2. Use a face shield fitted with the correct filter and cover

plates to protect your eyes, face, neck, and ears from

sparks and rays of the arc when operating or observing

operations. Warn bystanders not to watch the arc and

not to expose themselves to the rays of the electric-arc

or hot metal.

3. Wear flameproof gauntlet type gloves, heavy long-sleeve

shirt, cuffless trousers, high-topped shoes, and a welding helmet or cap for hair protection, to protect against

arc rays and hot sparks or hot metal. A flameproof apron

may also be desirable as protection against radiated

heat and sparks.

4. Hot sparks or metal can lodge in rolled up sleeves,

trouser cuffs, or pockets. Sleeves and collars should be

kept buttoned, and open pockets eliminated from the

front of clothing

5. Protect other personnel from arc rays and hot sparks

with a suitable non-flammable partition or curtains.

6. Use goggles over safety glasses when chipping slag or

grinding. Chipped slag may be hot and can fly far.

Bystanders should also wear goggles over safety glasses.

FIRES AND EXPLOSIONS -- Heat from

flames and arcs can start fires. Hot slag

or sparks can also cause fires and explosions. Therefore:

1. Remove all combustible materials well away from the

work area or cover the materials with a protective nonflammable covering. Combustible materials include wood,

cloth, sawdust, liquid and gas fuels, solvents, paints and

coatings, paper, etc.

2. Hot sparks or hot metal can fall through cracks or

crevices in floors or wall openings and cause a hidden

smoldering fire or fires on the floor below. Make certain

that such openings are protected from hot sparks and

metal.“

3. Do not weld, cut or perform other hot work until the

workpiece has been completely cleaned so that there

are no substances on the workpiece which might produce flammable or toxic vapors. Do not do hot work on

closed containers. They may explode.

4. Have fire extinguishing equipment handy for instant use,

such as a garden hose, water pail, sand bucket, or

portable fire extinguisher. Be sure you are trained in its

use.

5. Do not use equipment beyond its ratings. For example,

overloaded welding cable can overheat and create a fire

hazard.

6. After completing operations, inspect the work area to

make certain there are no hot sparks or hot metal which

could cause a later fire. Use fire watchers when necessary.

7. For additional information, refer to NFPA Standard 51B,

"Fire Prevention in Use of Cutting and Welding Pro-

--

2

cesses", available from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL SHOCK -- Contact with live

electrical parts and ground can cause

severe injury or death. DO NOT use AC

welding current in damp areas, if movement is confined, or if there is danger of

falling.

1. Be sure the power source frame (chassis) is connected

to the ground system of the input power.

2. Connect the workpiece to a good electrical ground.

3. Connect the work cable to the workpiece. A poor or

missing connection can expose you or others to a fatal

shock.

4. Use well-maintained equipment. Replace worn or damaged cables.

5. Keep everything dry, including clothing, work area, cables,

torch/electrode holder, and power source.

6. Make sure that all parts of your body are insulated from

work and from ground.

7. Do not stand directly on metal or the earth while working

in tight quarters or a damp area; stand on dry boards or

an insulating platform and wear rubber-soled shoes.

8. Put on dry, hole-free gloves before turning on the power.

9. Turn off the power before removing your gloves.

10. Refer to ANSI/ASC Standard Z49.1 (listed on next page)

for specific grounding recommendations. Do not mistake

the work lead for a ground cable.

ELECTRIC AND MAGNETIC FIELDS —

May be dangerous. Electric current flowing through any conductor causes localized Electric and Magnetic Fields

(EMF). Welding and cutting current creates EMF around welding cables and

welding machines. Therefore:

1. Welders having pacemakers should consult their physician before welding. EMF may interfere with some pacemakers.

2. Exposure to EMF may have other health effects which are

unknown.

3. Welders should use the following procedures to minimize

exposure to EMF:

A. Route the electrode and work cables together. Secure

them with tape when possible.

B. Never coil the torch or work cable around your body.

C. Do not place your body between the torch and work

cables. Route cables on the same side of your body.

D. Connect the work cable to the workpiece as close as

possible to the area being welded.

E. Keep welding power source and cables as far away

from your body as possible.

11/95

Page 3

FUMES AND GASES -- Fumes and

gases, can cause discomfort or harm,

particularly in confined spaces. Do

not breathe fumes and gases. Shielding gases can cause asphyxiation.

Therefore:

1. Always provide adequate ventilation in the work area by

natural or mechanical means. Do not weld, cut, or gouge

on materials such as galvanized steel, stainless steel,

copper, zinc, lead, beryllium, or cadmium unless positive

mechanical ventilation is provided. Do not breathe fumes

from these materials.

2. Do not operate near degreasing and spraying operations. The heat or arc rays can react with chlorinated

hydrocarbon vapors to form phosgene, a highly toxic

gas, and other irritant gases.

3. If you develop momentary eye, nose, or throat irritation

while operating, this is an indication that ventilation is not

adequate. Stop work and take necessary steps to improve ventilation in the work area. Do not continue to

operate if physical discomfort persists.

4. Refer to ANSI/ASC Standard Z49.1 (see listing below)

for specific ventilation recommendations.

CYLINDER HANDLING -- Cylinders, if

mishandled, can rupture and violently

release gas. Sudden rupture of cylinder, valve, or relief device can injure or

kill. Therefore:

1. Use the proper gas for the process and use the proper

pressure reducing regulator designed to operate from

the compressed gas cylinder. Do not use adaptors.

Maintain hoses and fittings in good condition. Follow

manufacturer's operating instructions for mounting regulator to a compressed gas cylinder.

2. Always secure cylinders in an upright position by chain

or strap to suitable hand trucks, undercarriages, benches,

walls, post, or racks. Never secure cylinders to work

tables or fixtures where they may become part of an

electrical circuit.

3. When not in use, keep cylinder valves closed. Have

valve protection cap in place if regulator is not connected. Secure and move cylinders by using suitable

hand trucks. Avoid rough handling of cylinders.

4. Locate cylinders away from heat, sparks, and flames.

Never strike an arc on a cylinder.

5. For additional information, refer to CGA Standard P-1,

"Precautions for Safe Handling of Compressed Gases in

Cylinders", which is available from Compressed Gas

Association, 1235 Jefferson Davis Highway, Arlington,

VA 22202.

EQUIPMENT MAINTENANCE -- Faulty or improperly maintained equipment can cause

injury or death. Therefore:

perform any electrical work unless you are qualified to

perform such work.

2. Before performing any maintenance work inside a power

source, disconnect the power source from the incoming

electrical power.

3. Maintain cables, grounding wire, connections, power cord,

and power supply in safe working order. Do not operate

any equipment in faulty condition.

4. Do not abuse any equipment or accessories. Keep

equipment away from heat sources such as furnaces, wet

conditions such as water puddles, oil or grease, corrosive

atmospheres and inclement weather.

5. Keep all safety devices and cabinet covers in position and

in good repair.

6. Use equipment only for its intended purpose. Do not

modify it in any manner.

ADDITIONAL SAFETY INFORMATION -- For

more information on safe practices for electric arc welding and cutting equipment, ask

your supplier for a copy of "Precautions and

Safe Practices for Arc Welding, Cutting and

Gouging", Form 52-529.

The following publications, which are available from the

American Welding Society, 550 N.W. LeJuene Road, Miami,

FL 33126, are recommended to you:

1. ANSI/ASC Z49.1 - "Safety in Welding and Cutting"

2. AWS C5.1 - "Recommended Practices for Plasma Arc

Welding"

3. AWS C5.2 - "Recommended Practices for Plasma Arc

Cutting"

4. AWS C5.3 - "Recommended Practices for Air Carbon Arc

Gouging and Cutting"

5. AWS C5.5 - "Recommended Practices for Gas Tungsten

Arc Welding“

6. AWS C5.6 - "Recommended Practices for Gas Metal Arc

Welding"“

7. AWS SP - "Safe Practices" - Reprint, Welding Handbook.

8. ANSI/AWS F4.1, "Recommended Safe Practices for Welding and Cutting of Containers That Have Held Hazardous

Substances."

This symbol appearing throughout this manual

means Attention! Be Alert! Your safety is

involved.

The following definitions apply to DANGER, WARNING,

CAUTION found throughout this manual:

Used to call attention to immediate hazards which, if not avoided, will result in

immediate, serious personal injury or loss

of life.

Used to call attention to potential hazards which could result in personal injury

or loss of life.

1. Always have qualified personnel perform the installation, troubleshooting, and maintenance work. Do not

Used to call attention to hazards which

could result in minor personal injury.

3

Page 4

I. INTRODUCTION

1. The UEC-8 electronic welding control P/N 677190 is

designed for a wide range of Subarc† welding applications, and can be used with either a constant-voltage or a constant-current power supply as follows:

650 cvcc, 60 hz.*....................................P/N36006

653 cvcc, 60 hz.*....................................P/N36234

* If higher welding currents are desired, a kit is avail-

able from ESAB that allows you to parallel two 650

cvcc units to provide up to 1300 amperes output.

† If the UEC-8 is to be used with power sources no

longer manufactured (or recommended), please contact your ESAB Welding Supplier or the Factory and

request a copy of edition F-12-747-"E". The "E" edition contains historical information and requirements

previously provided for low-range Subarc and Mig

welding applications.

The UEC-8 is recommended for use with the following

welding heads: EH-11 (for either constant-voltage or

constant-current operation) or the EH-10 or 10A (for constant-voltage operation only). The control utilizes two

solid-state printed circuit boards (described in Sec. II-C)

to obtain excellent wire feed speed regulation. The control is designed to be used for "Touch Work" (with optional D.C. touch work kit) and "scratch" starts (for AC

or DC). In scratch starting the carriage is moving before

the wire has contacted the work; in touch-work starting,

the wire inches down to the work and the carriage does

not move until the welding arc has been initiated.

II. DESCRIPTION

A. FRONT PANEL CONTROLS

1. Main Line Switch -- double pole single throw; breaks

both sides of 120 VAC power to control. Pilot light

built in 5 ampere Slo-Blo fuse in hot side of AC lines.

2. Voltage Control Potentiometer--allows remote ad-

justment of output voltage.

3. Wire Feed Speed Potentiometer -- controls rate of

wire feed speed during welding. This potentiometer

dial contains a 10 turn vernier calibrated from 0 to

100, and a computer which indicates the number of

turns (0 to 9) giving a total of 1000 increment settings

for accurate repeatable wire speed conditions.

4. Inch Speed Potentiometer -- screwdriver adjustment

controls rate of wire feed speed during inching.

5. Inch Up-Down Switch--spring loaded to center off

position - provides signal to allow motor to inch wire

up or down.

6. Carriage Auto-Manual-Off Switch---when a compat-

ible carriage governor is connected to the UEC-8,

allows automatic starting and stopping of carriage in

"Auto" position. In "Manual" position, carriage drive

is energized continuously. In center "Off" position,

there is no carriage operation.

7. Weld Start-Stop Switch--double pole double throw,

no center off position - in. "Start" position is initiates

welding action. In "Stop" position, weld sequence is

terminated.

8. T ouch Work Light -- included in optional Touch Work

Kit-lights when wire touches work prior to arc initiation.

9. Anti-Stick Potentiometer -- located on the left side

panel of the UEC-8. control. The potentiometer controls the length of time the wire is retracted at the end

of the weld cycle, thus allowing the welding wire to

retract a controlled amount. With a clockwise adjustment, the anti-stick time will increase, with a counterclockwise adjustment, the anti- stick time will increase,

with a counter-clock wise adjustment, the anti-stick

time will decrease.

B. INTERNAL CONTROLS

1. Sensitivity Potentiometer (See Figure 3) -- an arc

voltage sensitivity potentiometer is located on the inside back panel of the UEC-8 control. The adjustment of this "pot" controls the amount of arc voltage

signal with respect to motor back e.m.f. (electro-motive force) used; thus controlling motor response to

arc voltage changes.

2. Weld Power Selector Switch (See Figure 5) -- lo-

cated on the Reversible Governor PC Board - allows

the control to be used with either a constant-current

or a constant-potential power supply. Switch must

be placed in the proper position with respect to

the type of power supply selected.

C. PRINTED CIRCUIT BOARDS (See Figures 5 and

6)

1. Logical Board (P/N 675330) -- provides basic se-

quencing of wire feed motor, weld contactor and antistick. A 1/2- amp standard fuse to protect the current

detector circuit is located on the right side of the board.

Also the PC board contains two LED* indicator lights.

These lights help in troubleshooting the unit by indicating the state of the voltage and current detector at

all times.

2. Reversible Governor Board (P/N 675332) -- solid

state motor speed control. Automatic reversing feature for retract starts. During welding, if wire stubs to

the plate or the arc is lost the wire will retract (at inch

speed ) and inch down automatically until the arc is

reestablished. A weld power selector switch (see IIB-2 above) is located on the right side of the PC board.

Also the board contains an LED indicator light to check

proper electrical installation of the wire feed motor.

* Light emitting diode

4

Page 5

III. INSTALLATION

A. EQUIPMENT REQUIRED

1. A 25-ft., 12-conductor cable with 14-pin (@ UEC-8)

extension cables with 19-pin (@ power source)

amphenols at each end to connect the UEC-8 to the

650 cvcc power source, P/N 34135.

D. INST ALLA TION OF METERS

Before performing any installation inside the control, disconnect the electrical power cable at the receptacle (P6) on the control.

Also available are extension cables with 19-pin

amphenols at each as follows:

30-ft., 19-conductor cable ...................... P/N 34378

60-ft., 19-conductor cable ...................... P/N 34377

2. Two-single conductor voltage pickup cables; 6-ft. long,

P/N 996806; or 25-ft. long, P/N 996805.

3. D. C. Analog meters as follows: Voltmeter, 0-80 volts,

P/N 2062416; Ammeter, 0-800 amps, P/N 2062422,

and Trimpot assembly P/N 997507. The trimpot adjusts the ammeter to match the power source ammeter for precise current readings.

4. Flux Manual/Auto Switch Kit, P/N 996369. This

switch can be used to operate an (optional) automatic

flux gate P/N 01E62 (ordered separately).

To install the switch, refer to the schematic and wiring

diagrams in this booklet, and to instructions packed

with the kit.

B. OPTIONAL ACCESSORIES

1. Motor Extension Cable P/N 996808. Provides an extra 25-ft. of cable between the welding head and the

UEC-8.

2. Touch Work Kit, P/N 997868: (Recommended for

sub-arc welding; for use only in D.C. applications.)

The touch work kit senses contact between the welding wire and workpiece, automatically stopping the

wire when contact is established and lighting the touch

work light. For installation, refer to Figs. 7 and 8 and

the instruction literature packed with the kit.

3. Voltage Raise/Lower Switch Kit, P/N 953559: (For use

only with power supplies with motorized control. The

remote voltage control consists of a switch and

silkscreened mounting plate. The switch is installed

in the UEC-8 to control the voltage when the power

supply is not located near the control. For installation, refer to instructions packed with kit.

C. MOUNTING THE CONTROL

Since the operating controls are in the control front panel

the box should be mounted so that the meters and controls are within easy reach and view of the operator. The

control can be mounted on a sidebeam carriage or other

vertical surface by means of the two holes provided on

back of the control.

1. With the UEC-8 cover removed, install the two analog

meters using screws supplied with the meters. (Voltmeter on left, ammeter at right, as viewed from the

front.) Connect meter leads in UEC-8 control as follows:

Ammeter leads: Violet (-) to in-line connector P10

Blue (+) to in-line connector P11

Voltmeter leads: Positive (+) terminal to Yellow lead

from TB1-5, Negative (-) terminal to

Violet lead from TB1-6

Be careful when making the following adjustment

so as not to touch other components. T ouching other

components could result in damage to the unit or

personal injury .

2. The trimpot calibrates the ammeter for applications

where the control is more than 25-ft. from the power

supply. On the rear of the ammeter, mount trimpot

assembly so that the adjusting screw is at the top of

the meter, as you are looking at the chassis. Connect

trimpot leads to terminal points for ammeter as shown

in D-1 above. Under actual welding conditions, remove the UEC-8 cover and adjust the trimpot adjusting screw to bring the control ammeter reading in line

with the power supply ammeter reading.

E. CONNECTIONS FOR SINGLE WIRE OPERATION

Make the required cable connections in accordance with

the interconnection diagram, Fig. 1, and the following:

1. Connect the 14-pin Amphenol of the 12-conductor

cable to the receptacle (P6) on the side of the control. Connect the 19-pin Amphenol to the power supply as shown in Fig. 1.

NOTE: When using DC power and making ammeter

connections from power supply to two leads

of 12-cond. cable connected to control via the

14-pin receptacle, the polarity MUST be proper

or the weld current detector will not operate

and the control will not properly sequence.

2. Connect the motor cable to receptacle (P7) on the side

of the control. See Note 1 on Fig. 1.

3. Connect the plug end of the voltage pick-up cable to

5

Page 6

19-PIN

650 cvcc POWER SOURCE

4/0 CABLES TO WORKPIECE

4/0 CABLE TO NOZZLE BUSBAR

12 COND. CABLE

(OPTONAL EXT. CABLE, see III-A-1

25-FT. 34135

3 COND. CABLE

SUPPLIED WITH WIRE

FEED MOTOR, see

Note 1 or 2.

STRAIN LEFT

UEC-8 CONTROL

DC AMMETER

W/TRMPOT

TB1-8

BLU

P11

BLU

TB1-7

RED

P6

P10

VIO

P7

P8

P9

4 COND. GOV CABLE

2 FT. - 997965

2 - SINGLE COND. CABLES

6-FT. ASSY. - 996806

(also see III-A-2)

TB1-6

VIO

DC VOLTMETER

'J' GOV.

TB1-5

YEL

2 COND. CARRIAGE

CABLE, 10-IN. - 948226

OM-48 CARRIAGE

EH-9 MOTOR

CHART 1

WIRE COLOR PIN

FIELD (-), BLK A

FIELD (+), RED B

ARM (-), GRN C

ARM (+), WHT D

CHART 2

WIRE COLOR PIN

ARM (-), GRN C

ARM (+), WHT D

GND, GRN E

WIRE FEED MOTOR

BUSBAR

4/0 CABLES TO TERMINAL

ON POWER SUPPLY

NOZZLE

See Note 3

4/0 CABLES TO TERMINAL

ON POWER SUPPLY

NOTES

1. If shunt wound motor does NOT have mating plug for UEC-8 motor

receptacle (P7) use connector plug 996513 & cable clamp 525564

and wire per chart-1.

2. If permanent magnet motor does NOT have mating plug for UEC-8

motor receptacle (P7) use above plug and cable clamp and wire per

chart-2.

3. The work voltage pick-up lead must be corrected as shown from the

workpiece. This function is also provided from the power supply thru

P6-1 to TB1-6 in the UEC-8 (via a faston connection). This connection

must be disconnected and taped.

Fig. 1 - Interconnection Diagram

6

Page 7

receptacle (P8) on the side of the control. Connect

the lead tagged No. 1 to busbar and lead No. 2 to the

workpiece or fixture (see Note 3 on Fig. 1).

4. Connect the plug end of the carriage governor cable to

receptacle (P9) on the control.

NOTE: When using "J" Gov. P/N 953534 cable

997965 is required (see Section III-B-5). Insert the lugged end through the strain relief

on the back of the "J" Governor and connect

to TB1 in governor as follows: Red to TB1-8;

White to TB1-9; Black to TB1-10; Green to

ground stud.

F. CONNECTIONS FOR DUAL WIRE OPERATION

1. DC/AC Connection (see Fig. 1). With the numerous

power supplies available for use with the UEC-8, it is

suggested in dual-wire applications that the operator

use a DC unit as the lead power supply source to

provide weld penetration. An AC unit should be used

as the trail power supply to give the weld a cosmetic

finish.

G.IMPORTANT WIRING/OPERATING MODIFICA-

TION USING EH-10A MOTOR

As noted in this booklet, one of the welding heads the

UEC-8 is recommended for use with is the new EH-10A

motor that can accommodate wire speeds from 0-1000

ipm. As a result, the Wire Feed Speed potentiometer

may not have the fine adjustment (or resolution) range

settings that you may prefer, and would normally be afforded the other motors with lower wire speed (ipm)

ranges.

If finer resolution in the "speed" potentiometer is desired,

and you do not plan to operate the control at wire feed

speeds above 500 ipm, you can modify the circuitry to

spread the operating range of this "speed control". To

do this, add a resistor (100K ohm, 1/4 watt) to the Wire

Speed potentiometer as shown in the schematic dia-

gram. Remember, if this modification is made, that

the effective operating range of the potentiometer

will be changed from 0-1000 ipm to 0-500 ipm.

IV. IMPORTANT CHECKLIST

To confirm that the various components (control, head,

carriage, and power supply) have been properly interconnected, it is imperative that the following tests be

performed BEFORE operation starts.

Note: Failure to perform these tests may result in dam-

age to the printed circuit boards in the control.

A. PREP ARA TORY INSTRUCTIONS

Precautionary measures should be taken to provide

maximum protection against electrical shock. Be

sure that all power is off by opening the line (wall)

disconnect switch. To be doubly safe, check your

input leads with a voltmeter to make sure that all

power is OFF.

1. Remove the cover (5 screws) from the UEC-8 Control.

2. Remove the two printed circuit boards (P/N's 677330

& 675332) from inside the UEC-8.

3. The following readings should be taken after all equipment has been installed and interconnected, BEFORE

POWER IS APPLIED to the system, and WITH

PRINTED CIRCUIT BOARDS REMOVED.

B. TEST FOR INPUT POWER CONNECTION

1. Place "MLS" switch in the ON position.

2. Place ohmmeter to the highest resistance scale.

3. Check for continuity between TB1-3 and ground stud;

then check for continuity between TB1-1 and ground

stud. There should be a small deflection when the

meter leads are first connected to these points; then

both readings should be infinity.

C. TEST FOR CONTACTOR, CARRIAGE AND FLUX

GATE CONNECTION

1. Place carriage travel and flux gate switches in the

"OFF" position, ("MLS" switch ON).

2. Place ohmmeter on Rx-1 scale. Check for continuity

between TB1-3 and the center terminal of CTS switch.

Reading should be approx. 1000 ohms (for "J" Gov.).

3. Check for continuity between TB1-3 and the red wire

on WSSS switch. Reading should be approx. 40

ohms. If flux gate is used, check for continuity between TB 1-3 and the center terminal of the Flux

switch. Readings should be approx. 40 ohms.

D. TEST FOR VOLTMETER AND AMMETER CON-

NECTIONS

1. If hookup is made to a DC power supply:

a. Place the positive meter lead on TB1-5 and nega-

tive meter lead on TB1-6. Reading should be

approx. 500 ohms, but this reading will vary con-

7

siderably from power supply to power supply.

Page 8

b. Reverse meter leads and reading should be 50 ohms

or less. To test for ammeter harnessing, place meter

across terminals TB1-7 and TB1-8, reading should

be approx. 1 ohm.

E. TEST FOR MOTOR CONNECTION

1. For permanent-magnet motors such as EH-10, EH11, check for continuity between TB1-13 and TB1-14.

Reading should be approx. 5 ohms.

2. For shunt-wound motors such as EH-2, EH-3, check

for continuity between P7-A and P7-B. Reading

should be approx. 500 ohms.

3. Check for shorts between TB1-13 and ground stud;

check for continuity between P7-B and ground stud.

Both readings should be infinity.

F. RESULTS

If any of the readings do NOT correspond with the readings above, DO NOT APPLY POWER. Instead, check

all connections between components until the problem

is found and corrected.

If all readings correspond with the readings above, place

"MLS" switch in the OFF position and re-install the printed

circuit boards inside the control. UEC-8 is now ready

for operation.

G. LED INDICATOR LIGHTS

There are three LED indicator lights mounted on the PC

boards that will help in setting up the equipment and in

troubleshooting. Two of the lights are located on the

Logic Board (675330) and one on the Reversible Governor Board (675332).

In setting up the equipment, the indicating light (REVLED) on the Reversible Gov. Board (675332) is of main

concern. (Refer to Fig. 5)

1. The control and wire feeder should be set up such

that when the inch switch is depressed in the down

position the motor should be feeding forward. If the

motor feeds in the reverse direction, reverse the yellow and gray armature leads at TB1-13 and TB1-14.

2. To double check motor setup, perform this final test:

Depress inch up switch and see if indicating light on

the Reversible Gov. Board is dimly lit. The unit should

not be operated if the indicating light is not on.

The other two lights are located on the logic board (Fig.

6) and marked C-DET and V-DET. These lights will be

illuminated only when welding currents and welding voltages are detected.

Page 9

V. OPERATION

In each of the starting methods to be considered, it will

be assumed that the unit has been properly installed,

wire placed on reel and fed through sub-arc nozzle, and

checked to insure proper operation and that fuses are

of the proper values. In no case should fuses of larger

capacity be substituted. If sub-arc welding, fill the hopper with welding composition.

The following is a description of the procedures to be

followed in making starts.

IMPORTANT NOTE: When using any of the procedures,

make sure that the Weld Start-Stop

Switch is in the "Stop" position before the Main Line Switch is moved

to "ON" position to energize the

control.

A. SUB-ARC SCRATCH STARTING SEQUENCE

1. Provide flux cover of weld zone.

2. Place Carriage Auto-Manual switch in "Manual", Carriage will move in direction of weld.

3. Place Weld Start-Stop switch in "Start" position.

Welding wire will begin slow inch down through flux

burden; when the wire touches the plate and an arc

is established, wire speed is transferred to the main

control potentiometer and the weld is in progress.

4. Place Carriage Auto-Manual switch in "Auto" position if automatic stoppage of the carriage is required.

5. To stop weld, place Weld Start-Stop switch into the

"Stop" position.

4. Place Weld Start-Stop switch in "Start" position. Power

supply contactor is automatically energized and weld

commences.

5. With start of welding current, carriage starts, and wire

retracts at inch speed creating an arc.

6. After arc is established, the wire is fed in the forward

direction at weld speed required to properly maintain

the selected arc voltage.

7. To end the weld, the Weld Start-Stop switch is placed

in the "Stop" position. Wire feed will cease, and the

contractor and carriage travel will continue for the desired anti-stick time. (To adjust the length of time for

the anti-stick, refer to Section II-A-9).

D. SUB-ARC RETRACT ST ART - C. C. MODE

In this mode the wire is in contact with the workpiece

before the Start key is operational. After the wire is energized, and the current detector detects short circuit

current, the motor will reserve and the wire will retract at

inch speed. As soon as the wire separates from the

workpiece, and arc voltage and current and detected,

the motor will change direction to forward and feed wire

at preset weld speed.

B. POSITIONED STARTING SEQUENCE

(without touch-work kit installed)

1. Wedge a tightly rolled ball of steel wool about 3/8-in.

in diameter between the welding wire and the

workpiece, and cover the weld zone with flux. Place

the Carriage Auto-Manual switch in "Auto" position.

2. Place Weld Start-Stop switch in "Start" position. The

power supply contactor comes in immediately, initiating the welding action and carriage travel.

3. To stop the welding action, place Weld Start-Stop

switch in "Stop" position.

C. TOUCH WORK STARTING SEQUENCE (optional

accessory)

1. Place Carriage Auto-Manual in "Auto" Carriage will

start and stop with welding action.

2. Place Inch Up-Down in "Down" position. Wire will

inch toward work and automatically stop when contact is made, at which time the touch work light will be

energized.

3. Place flux over weld zone, leaving Weld Start-Stop

switch in "Stop" position.

Page 10

VI. TROUBLESHOOTING INFORMATION

If this equipment does not operate properly, stop

work immediately and investigate the cause of the

malfunction. Troubleshooting and maintenance

work must be performed by an experienced person,

and electrical work by a trained electrician. Do not

permit untrained persons to inspect, clean or repair

this equipment. Use only recommended replacement parts.

Precautionary measures should be taken to provide

maximum protection against electrical shock. Be

sure that all power is off by operating the line (wall)

disconnect switch, before attempting any work inside the control.

A. SYMPTOM: F1 fuse blows whenever main line

switch is turned "ON".

1. Check wiring for shorts.

2. If no short, replace governor PC board.

B. SYMPTOM: F1 fuses blows when Inch Switch is

operated.

1. Check for jammed or defective wire feed motor/

drive unit.

2. Replace governor PC board.

F. SYMPTOM: No control over motor speed at wire

feed potentiometer.

1. Check wire speed potentiometer with ohmmeter.

Resistance should range from 0 through 100 K

ohms. Resistance should range from 0 through

100 K ohms. Replace if defective.

2. Replace governor PC board.

3. Replace logic PC board.

G. SYMPTOM: Contactor in power supply does not

energize. Motor operates.

1. Check power supply control cable.

2. Check fuse (power supply).

3. Replace logic PC board.

H. SYMPTOM: Erratic or pulsing wire feed rate.

1. Replace logic PC board.

C. SYMPTOM: Motor inoperative.

1. Check setting of Inch Speed pot.

2. Check main line fuse F1.

3. Check motor plug.

4. Check motor brushes.

5. Replace logic PC board.

6. Replace Governor PC board.

D. SYMPTOM: Wire feed motor operates by inching

but does not operate for welding.

1. Check setting of WFSP.

2. Check touch work indicator light for operation when

wire torches work.

3. Observe that both LED lights on logic PC board

are lit after arc initiating.

4. Replace logic PC board.

E. SYMPTOM: If wire feed motor continues to run

when wire touches plate and work light not on.

1. Check fuse (1/2 amp) located on logic board.

2. Check for fused flux at tip of welding wire.

3. Check power supply ground cable for connection to workpiece.

4. Replace logic PC board.

Page 11

VII. REPLACEMENT P ART DATA

1. All replacement parts are keyed on the illustrations which follow. Order replacement parts by part number and part

name, as shown on illustrations. DO NOT ORDER BY PART NUMBER ONLY.

2. Many of the parts on the illustrations, particularly electronic parts, are 'vendor items.' This means that they are

standard commercial parts made by and purchased from other manufacturers. If you order from these outside

sources, use the manufacturer's part number or designated as shown in the Electrical Parts List.

3. Always state the series or serial number of the machine on which the parts are used. The serial number is stamped

on the unit nameplate.

.

VOLTMETER

(Accy, Refer to Sec. III-A)

CTS, SWITCH 672831

SIDE PANEL - 6787866

(OLD PANEL - 2075186)

CABINET - 30782

POWER PILOT LIGHT 598227

MLS, SWITCH - 97W64

VCP, POTENTIOMETER - 639541

KNOB - 996501

WSP, 10-TURN POTENTIOMETER - 181W85

KNOW - 181W87

* WARNING LABEL - 995204

WARNING

ELECTRICAL SHOCK HAZARD

DO NOT OPERATE WITH COVER REMOVED

NETWORK - 996918

FN, FILTER

RI, RESISTOR

17240005

Fig. 2 - UEC-8 Control, P/N 677190

SENSITIVITY POTENTIOMETER - 92W64

KNOB - 994305

AMMETER/INCHES-PER MINUTE METER

(Accy, Refer to Sec. III-A)

COVER - 677867

(OLD COVER - 2075227)

WSSS, SWITCH 634518

ISP,

POTENTIOMETER 995301

IS, SWITCH 599692

NOTE: Two cap screws 5/16" — 18

X 1/2" lg. (provided in cloth bag) for

attaching control to OM-48 Side

Beam Carriage.

LOGIC BOARD - 675330

INCLUDES:

FUSE - 996523 (1/2 A. STD)

REVERSIBLE GOV.

BOARD - 675332

TB1, TERMINAL BLOCK 635568

TI, CONTROL

TRANSFORMER

995284

* Replace label if it becomes excessively worn or lost.

TOUCH WORK KIT

997868 (OPTIONAL)

INCLUDES:

FUSE - 82W43 (IA. SLO-BLO)

Fig. 3 - UEC-8 Control (Inside View)

Page 12

WARNING LABEL - 995164

WARNING

Disconnect power cord before

performing any maintenance

RECEPTACLE - 6271128

ASP,

POTENTIOMETER

995301

RECEPTACLE - 636694

RECEPTACLE - 996514

Replace label if it becomes

excessively worn or lost. Be

sure to order decal if replacing sheet metal.

REV. LED, See

Sect. IV-G

MOV-2

WELD POWER

SEL. SW.

F-1, FUSE - 97W06

FUSE HOLDER 182W15

RECEPTACLE - 523543

Fig. 4 - UEC-8 Control (Left Side View)

The new Rev. Gov. Bd. P/N 675332 (which replaced

old P/N 997250) is designed for use with permanent

magnet motors only (such as EH-10 or EH-11) and can-

not be used with field-wound motors (such as EH-2 or

EH-5). If your set-up uses a field-wound motor, consult

with the factory.

Fig. 5 - Reversible Governor PC Board, P/N 675332

FUSE 1/2 AMP.

VOLTAGE

DETECTOR

LED

CURRENT

DETECTOR

LED

Fig. 6 - Logic P .C. Board, P/N 9971 15 (Earlier Unit s - obso-

lete)

Logic P.C. Board, P/N 675330 (Later Units - after

March 1984)

Page 13

Fig. 7 - Schematic Diagram, UEC-8 Control

Page 14

Fig. 8 - Wiring Diagram, UEC-8 Control

Page 15

Page 16

ESAB Welding & Cutting Products, Florence, SC Welding Equipment

COMMUNICATION GUIDE - CUSTOMER SERVICES

A. CUSTOMER SERVICE QUESTIONS:

Telephone: (800)362-7080 / Fax: (800) 634-7548 Hours: 8:00 AM to 7:00 PM EST

Order Entry Product Availability Pricing Order Information Returns

B. ENGINEERING SERVICE:

Telephone: (843) 664-4416 / Fax : (800) 446-5693 Hours: 7:30 AM to 5:00 PM EST

Warranty Returns Authorized Repair Stations Welding Equipment Troubleshooting

C. TECHNICAL SERVICE:

Telephone: (800) ESAB-123/ Fax: (843) 664-4452 Hours: 8:00 AM to 5:00 PM EST

Part Numbers Technical Applications Specifications Equipment Recommendations

D. LITERATURE REQUESTS:

Telephone: (843) 664-5562 / Fax: (843) 664-5548 Hours: 7:30 AM to 4:00 PM EST

E. WELDING EQUIPMENT REPAIRS:

Telephone: (843) 664-4487 / Fax: (843) 664-5557 Hours: 7:30 AM to 3:30 PM EST

Repair Estimates Repair Status

F. WELDING EQUIPMENT TRAINING

Telephone: (843)664-4428 / Fax: (843) 679-5864 Hours: 7:30 AM to 4:00 PM EST

Training School Information and Registrations

G. WELDING PROCESS ASSISTANCE:

Telephone: (800) ESAB-123 Hours: 7:30 AM to 4:00 PM EST

H. TECHNICAL ASST. CONSUMABLES:

Telephone : (800) 933-7070 Hours: 7:30 AM to 5:00 PM EST

IF YOU DO NOT KNOW WHOM TO CALL

Telephone: (800) ESAB-123

Fax: (843) 664-4462

Hours: 7:30 AM to 5:00 PM EST

or

visit us on the web at http://www.esabna.com

The ESAB web site offers

Comprehensive Product Information

Material Safety Data Sheets

Warranty Registration

Instruction Literature Download Library

Distributor Locator

Global Company Information

Press Releases

Customer Feedback & Support

F-12-747-F 3/95 1M Printed in U.S.A.

Loading...

Loading...