GB

Tradescool 220

Instruction manual and

spare parts list

AH 0836

Valid for serial no. 827--xxx--xxxx0460 762 074 081013

1 DIRECTIVE 3........................................................

2SAFETY 3...........................................................

3 INTRODUCTION 4...................................................

3.1 Equipment 4................................................................

4 TECHNICAL DATA 5.................................................

5 INSTALLATION 5....................................................

5.1 Location 5..................................................................

5.2 Mains power supply 5........................................................

5.3 Installing welding equipment 6................................................

6 OPERATION 6.......................................................

6.1 Connections 6..............................................................

6.2 Water connection 6..........................................................

7 MAINTENANCE 7....................................................

7.1 Inspection and cleaning 7....................................................

7.2 Filling the coolant 7..........................................................

8 FAULT--TRACING 8..................................................

9 ORDERING SPARE PARTS 8..........................................

10 DISMANTLING AND SCRAPPING 8...................................

ASSEMBLY INSTRUCTIONS 9...........................................

DIAGRAM 10............................................................

PUMP DATA 12..........................................................

SPARE PARTS LIST 13...................................................

ACCESSORIES 18.......................................................

Rights reserved to alter specifications without notice.

TOCe

-- 2 --

GB

1DIRECTIVE

Murex Welding Products Ltd, EN8 7TFF England, gives its unreserved quarantee that cooling unit

Tradescool 220 from serial number 827 (2008 w. 27) is constructed and tested in compliance with the

standard EN 60974--2 and EN 60974--10 (Class A) in accordance with the requirements of directive

(2006/95EC) and (2004/108/EEC).

DECLARATION OF CONFORMITY

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Laxå 2008--10--10

Kent Eimbrodt

Global Director

Equipment and Automation

Manufactured by ESAB AB, Welding Equipment

SE--695 81 Laxå Sweden

2SAFETY

Users of ESAB welding equipment have the ultimate responsibility for ensuring that anyone who

works on or near the equipment observes all the relevant safety precautions. Safety precautions

must meet the requirements that apply to this type of welding equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace.

All work must be carried out by trained personnel well--acquainted with the operation of the welding

equipment. Incorrect operation of the equipment may lead to hazardous situations which can result

in injury to the operator and damage to the equipment.

1. Anyone who uses the welding equipment must be familiar with:

S its operation

S location of emergency stops

S its function

S relevant safety precautions

S welding

2. The operator must ensure that:

S no unauthorized person is stationed within the working area of the equipment when it is

started up.

S no--one is unprotected when the arc is struck

3. The workplace must:

S be suitable for the purpose

S be free from drafts

4. Personal safety equipment

S Always wear recommended personal safety equipment, such as safety glasses, flame--proof

clothing, safety gloves.

S Do not wear loose--fitting items, such as scarves, bracelets, rings, etc., which could become

trapped or cause burns.

5. General precautions

S Make sure the return cable is connected securely.

S Work on high voltage equipment may only be carried out by a qualified electrician.

S Appropriate fire extinquishing equipment must be clearly marked and close at hand.

S Lubrication and maintenance must not be carried out on the equipment during operation.

CAUTION!

Read and understand the instruction manual before

installing or operating.

bk09d1me

-- 3 --

GB

WARNING

Arc welding and cutting can be injurious to yourself and others. Take precausions when welding.

Ask for your employer’s safety practices which should be based on manufacturers’ hazard data.

ELECTRIC SHOCK - Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES - Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to take fumes and gases away from your breathing zone

and the general area.

ARC RAYS - Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE - Excessive noise can damage hearing

S Protect your ears. Use earmuffs or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION - Call for expert assistance in the event of malfunction.

Read and understand the instruction manual before installing or operating.

PROTECT YOURSELF AND OTHERS!

Murex can provide you with all necessary welding protection and accessories.

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and returned to an

environmentally compatible recycling facility. As the owner of the equipment, you should

get information on approved collection systems from our local representative.

By applying this European Directive you will improve the environment and human

health!

CAUTION!

Class A equipment is not intended for use in residential locations where

the electrical power is provided by the public low--voltage supply

system. There may be potential difficulties in ensuring electromagnic

compatibility of class A equipment in those locations, due to conducted

as well as radiated disturbances.

3 INTRODUCTION

Cooling unit Tradescool 220 is intended for cooling TIG torches.

Accessories for the product can be found on page 18.

3.1 Equipment

The cooling unit is supplied with instruction manual, assembly instructions and

4 x screws for mounting the cooling unit on a power source.

bk09d1me

-- 4 --

GB

4 TECHNICAL DATA

Tradescool 220

Mains voltage 230 V, ¦10%, 1μ 50/60 Hz

Primary current

I

50 Hz

max

I

60 Hz

max

Cooling power

at 230 V, 50 Hz

at 230 V, 60 Hz

Continual sound pressure in

open--circuit

Type of cooling 50% water / 50% mono--ethylene glycol (ready mixed)

Coolant quantity 2.2 l

Maximum water flow 2.0 l/min

Fuse (delayed --action) 2x1.6A

Max pressure lift for welding gun

Q

max

Operating temperature -- 1 0 t o + 6 0 ˚C

Transportation temperature -- 2 0 t o + 5 5 ˚C

Dimensions lxwxh 407 x 188 x 151 mm

Maximum water pressure

at 50 Hz

at 60 Hz

Weight

water--filled

empty

Enclosure class IP23 C

0.5 A

0.7 A

780W at 40˚C temperature difference and flow 1 l/min

780W at 40˚C temperature difference and flow 1 l/min

<70dB(A)

7m

0.23 MPa (2.3 bar)

0.23 MPa (2.3 bar)

6.2 kg

4.5 kg

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water. Equipment marked IP23 is designed for indoor and outdoor use.

5 INSTALLATION

The installation must be execu ted by a professional.

5.1 Location

Position the cooling unit such that its cooling air inlets and outlets are not obstructed.

5.2 Mains power supply

The cooling unit is connected to the power source’s mains and control cables, see

page 9.

bk09d1me

-- 5 --

GB

5.3 Installing welding equipment

The installation must be execu ted by a professional.

See installation instructions on page 9.

AH 0838

6 OPERATION

General safety regulations for the handling of the equipment can be found on

page 3. Read through before you start using the equipment!

6.1 Connections

1 Connection for mains cable from

power source

2 Connection for control cable from

power source

3 Filling the coolant

4 Connection BLUE, with ELP* for

coolant from cooling unit

5 Connection RED for coolant to

cooling unit

*ELP = ESAB Logic Pump, see point 6.2.

6.2 Water connection

The cooling unit is equipped with a detection system ELP (ESAB Logic Pump) which

checks that the water hoses are connected. When connecting a water--cooled TIG

torchcoolingstarts.

Detection only works with power sources that are equipped with the ELP function.

Note! Flow guard cannot be installed in Tradescool.

bk09d1me

-- 6 --

GB

7 MAINTENANCE

Regular maintenance is important for safe, reliable operation.

Only those persons who have appropriate electrical knowledge (authorized

personnel) may remove the safety plates.

WARNING!

The mains supply must be disconnected before cleaning!

CAUTION!

All guarantee undertakings from the supplier cease to apply if the customer himself

attempts any work in the product during the guarantee period in order to rectify any faults.

7.1 Inspection and cleaning

IMPORTANT! T h e mains supply must be disconnected before cleaning!

The air stream through the cooling unit carries particles that become trapped in the

cooling element, particularly in dirty working environments. This results in reduced

cooling capacity. For this reason, blow clean using compressed air at regular

intervals.

Dismantle the right side panel and blow the filter clean with compressed air.

Change the coolant approximately once a year.

7.2 Filling the coolant

Coolant recommended for use, see accessories on page 18.

CAUTION!

The coolant must be handled as chemical waste.

S Fill with coolant.

(The fluid level must not exceed the upper

marking but neither must it be below the

lower marking)

S Disconnect the coolant hose for outgoing

water (TIG torch blue connection) in order

for any trapped air to disappear.

S Connect the coolant hose again.

NOTE! When adjusting the water level by

topping up, the coolant hose does not need to be

disconnected.

bk09d1me

-- 7 --

GB

Coolant must be topped up if connecting a welding torch or connection cables that are

5 meters in length or longer.

The temperature of the coolant must not exceed 70˚C.

8 FAULT--TRACING

Try these recommended checks and inspections before sending for an authorised

service technician.

Fault Corrective action

Poor cooling effect S Clean the cooling element using compressed air.

S Check the coolant level.

9 ORDERING SPARE PARTS

Repair and electrical work should be performed by an authorized serviceman.

Use only original spare and wear parts.

Tradescool 220 is designed and tested in accordance with the international and European standards IEC/EN 60974--2 and EN 60974--10. It is the obligation of the service

unit which has carried out the service or repair work to make sure that the product still

conforms to the said standard.

Spare parts may be ordered through your nearest dealer.

10 DISMANTLING AND SCRAPPING

Weldingequipment primarily consists of steel, plastic and non --ferrous metals, and must

be handled according to local environmental regulations.

Coolant must also be handled according to local environmental regulations.

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and returned to an

environmentally compatible recycling facility. As the owner of the equipment, you should

get information on approved collection systems from our local representative.

By applying this European Directive you will improve the environment and human

health!

bk09d1me

-- 8 --

Assembly instructions

9

Tradescool 220 + Tradestig AC 220 / Tradestig AC 220a

bk09m11a

-- 9 --

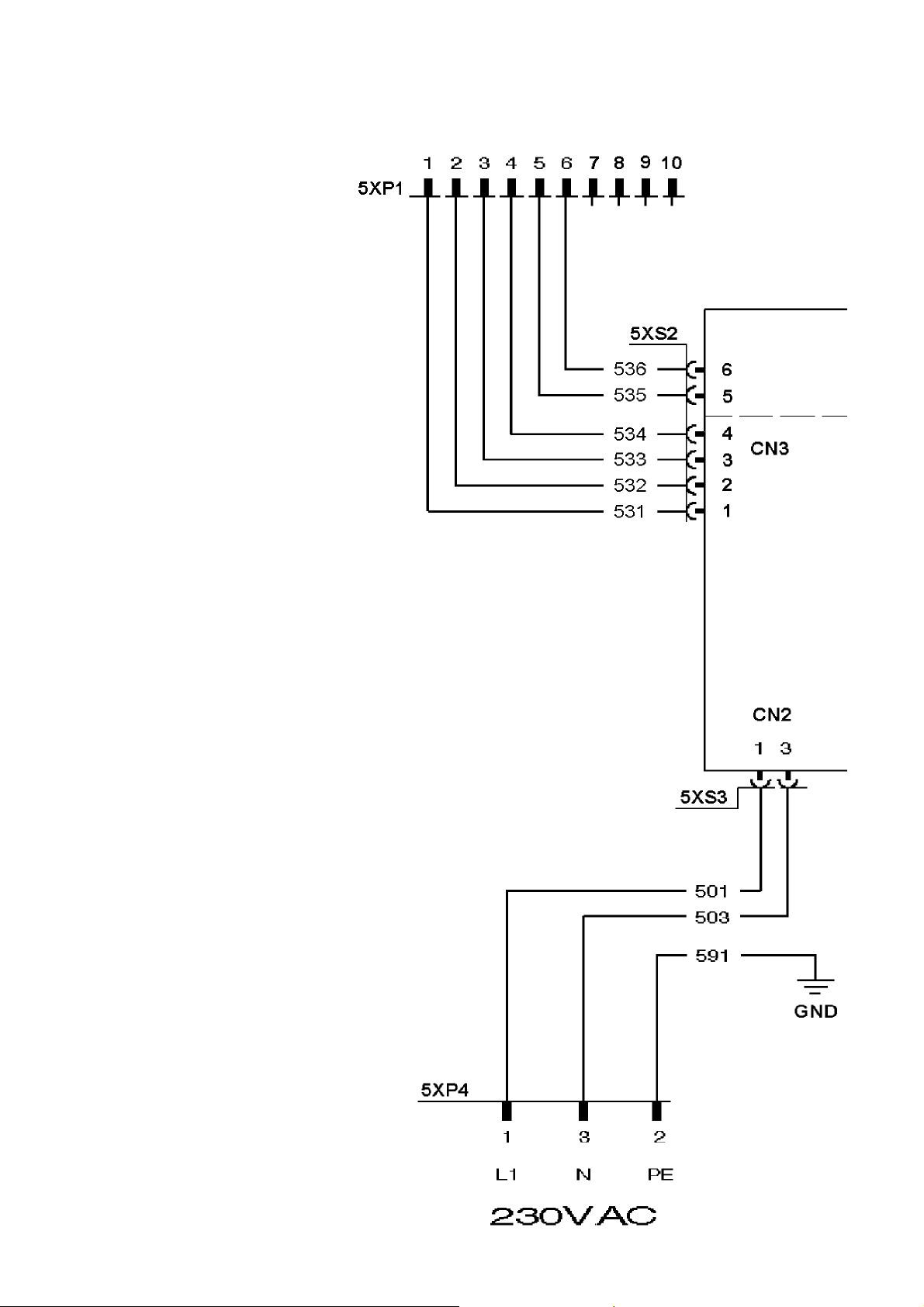

Diagram

bk09e

-- 1 0 -Edition 081013

bk09e

-- 1 1 -Edition 081013

Pump data

p = Pump pressure

Q =Flowrate

bk09k

-- 1 2 --

Tradescool 220

Spare parts list

AH 0836

Valid for serial no. 827--xxx--xxxx

Ordering number

0460 144 881 Cooling unit Tradescool 220

Spare parts are to be ordered through the nearest MUREX agency. Kindly indicate type of unit, serial

number, denominations and ordering numbers according to the spare parts list.

Maintenance and repair work should be performed by an experienced person, and electrical work only

by a trained electrician. Use only recommended spare parts.

bk09mo

-- 1 3 --

Edition 081013

Tradescool 220

C = component designation in the circuit diagram

Item Qty Ordering no. Denomination Notes C

AA1 1 0194 069 003 Rubber inlet Ø 37mm hole

AA2 1 0460 195 880 Tank with connections

AA3 1 0460 229 880 Pump with connections

AA4 1 0460 208 880 Cable set pump, fan

AA5 1 0365 539 001 Fan without cables

AA6 1 0460 120 001 Cooling radiator

AA7 1 0460 139 001 Rear panel cooling / AC

AA8 4 0194 153 329 Screw Remform Torx 5x16

AA9 4 0192 790 102 Spacer 6.3mm, LCBS 4R

AA10 1 0487 540 880 PC--board

AA11 1 0460 206 880 Cable set power source

AA12 2 0192 526 004 Sealing strip

AA13 -- 0194 230 001 Anti--freezing mixture 6704

AA14 1 0460 199 881 Front complete

bk09saa1

-- 1 4 --

Tradescool 220

bk09saa1

-- 1 5 --

Tradescool 220

Item

Qty Ordering no. Denomination Notes

AB1 1 0190 735 314 Nut M5

AB2 1 0193 104 002 Washer D16/5x1

AB3 1 0458 365 001 Spring

AB4 1 0458 366 001 Water lock cam

AB5 1 0365 803 015 Quick connector Female, blue

AB6 1 0458 368 001 Water lock outlet

AB7 1 0192 238 337 Screw M5x35

AB8 1 0365 803 014 Quick connector Female, red

AB9 1 0194 245 001 Micro switch

AB10 1 Nut M3

AB11 1 0460 370 880 Damper hose

AB12 1 0460 370 880 Damper hose

AB13 1 0456 496 001 Hose Ø 9/5 PVC, red, to be ordered per metre

AB14 1 0460 198 001 Hose

SPARE PARTS SET

Item Qty Ordering no. Denomination Notes

AB50 1 0458 370 900 Water connection spare kit Contains items AB1, AB2, AB3, AB4, AB6 and AB7

H

bk09sab1

-- 1 6 --

R0460 762 074/E081013/PNO TAG

Tradescool 220

bk09sab1

-- 1 7 --

R0460 762 074/E081013/PNO TAG

Tradescool 220

Accessories

Coolant 50% water and 50% ready mixed

mono--ethyleneglycol(10l) ..............

0007 810 012

bk09a

-- 1 8 --

Edition 081013

NOTES

notes

-- 1 9 --

Please ensure that this

Operating Manual is

available to the user of

the equipment.

Murex Welding Products Ltd

Hanover House

Queensgate

Britannia Road

Waltham Cross

Hertfordshire EN8 7TF

England

Loading...

Loading...