TIG 400i

INVERTER TIG

Welding Power Source

Instruction manual

Ver:3.0 3220

TIG 400i

INVERTER WELDING POWER SOURCE

Instruction manual

For

Installation, Operation & General maintenance

1

CONTENTS

Item Page No.

SAFETY

RATING AND INSTALLATION 5-7

CAUTIONS FOR INSTALLATION 7-8

WELDING OPERATIONS 9-11

WIRING DIAGRAM 12

GENERAL MAINTENANCE 13

PARTS LIST AND EXPLODED VIEW

3-4

14-17

ESAB INDIA CONTACT DETAIL 18

2

SAFETY

Users of ESAB welding equipment have the ultimate responsibility for ensuring that

anyone who works on or near the equipment observes all the relevant safety

precautions. Safety precautions must meet the requirements that apply to this type of

welding equipment. The following recommendations should be observed in addition to

the standard regulations that apply to the workplace.

Trained personnel well acquainted with the operation of the welding equipment must

carry out all the work. Incorrect operation of the equipment may lead to hazardous

situations, which can result in injury to the operator and damage to the equipment.

1. Anyone who uses the welding equipment must be familiar with:

• its operation

• location of emergency stops

• its function

• relevant safety precautions

• welding

2. The operator must ensure that:

• no unauthorized person is stationed within the working area of the equipment

when it is started up.

• no one is unprotected when the arc is struck

3. The workplace must:

• be suitable for the purpose

• be free from drafts

4. Personal safety equipment

• Always wear recommended personal safety equipment, such as safety glasses,

flameproof clothing, and safety gloves.

• Do not wear loose—fitting items, such as scarves, bracelets, rings, etc., which

could become trapped or cause burns.

5. General precautions

• Make sure the return cable is connected securely.

• Only a qualified electrician may carry out work on high voltage equipment.

• Appropriate fire extinguishing equipment must be clearly marked and close at

hand.

• Lubrication and maintenance must not be carried out on the equipment during

operation.

Read and understand the instruction manual before installing or operating.

3

ESAB can provide you with all necessary welding protection and accessories.

• Ensure your working stance is safe.

PROTECT YOURSELF AND OTHERS!

WARNING

Arc welding and cutting can be injurious to yourself and others. Take

precautions when welding.

Ask for your employer’s safety practices which should be based on manufacturers’

hazard data.

ELECTRIC SHOCK – Can kill

• Install and earth the welding unit in accordance with applicable

standards.

• Do not touch live electrical parts or electrodes with bare skin, wet

gloves or wet clothing.

• Insulate yourself from earth and the workpiece.

FUMES AND GASES – Can be dangerous to health

• Keep your head out of the fumes.

• Use ventilation, extraction at the arc, or both, to take fumes and gases

away from your breathing zone and the general area.

ARC RAYS – Can injure eyes and burn skin.

• Protect your eyes and body. Use the correct welding screen and filter

lens and wear protective clothing.

• Protect bystanders with suitable screens or curtains.

FIRE HAZARD

• Sparks (spatter) can cause fire. Make sure therefore that there are no

inflammable materials nearby.

NOISE – Excessive noise can damage hearing

• Protect your ears. Use earmuffs or other hearing protection.

• Warn bystanders of the risk.

MALFUNCTION – Call for expert assistance in the event of malfunction.

This product is solely intended for arc welding

Do not dispose of electrical equipment together with normal waste!

In accordance with national law, electrical equipment that has

reached the end of its life must be collected separately and returned

to an environmentally compatible recycling facility. As the owner of

the equipment, you should get information on approved collection

systems from the local representative. By applying this Directive you

will improve the environment and human health

CAUTION!

4

RATING

manual welding

argon arc welding

MMA: 400

range

MMA

:10-400

(Ar

gon arc welding)

(Manual welding)

characteristic

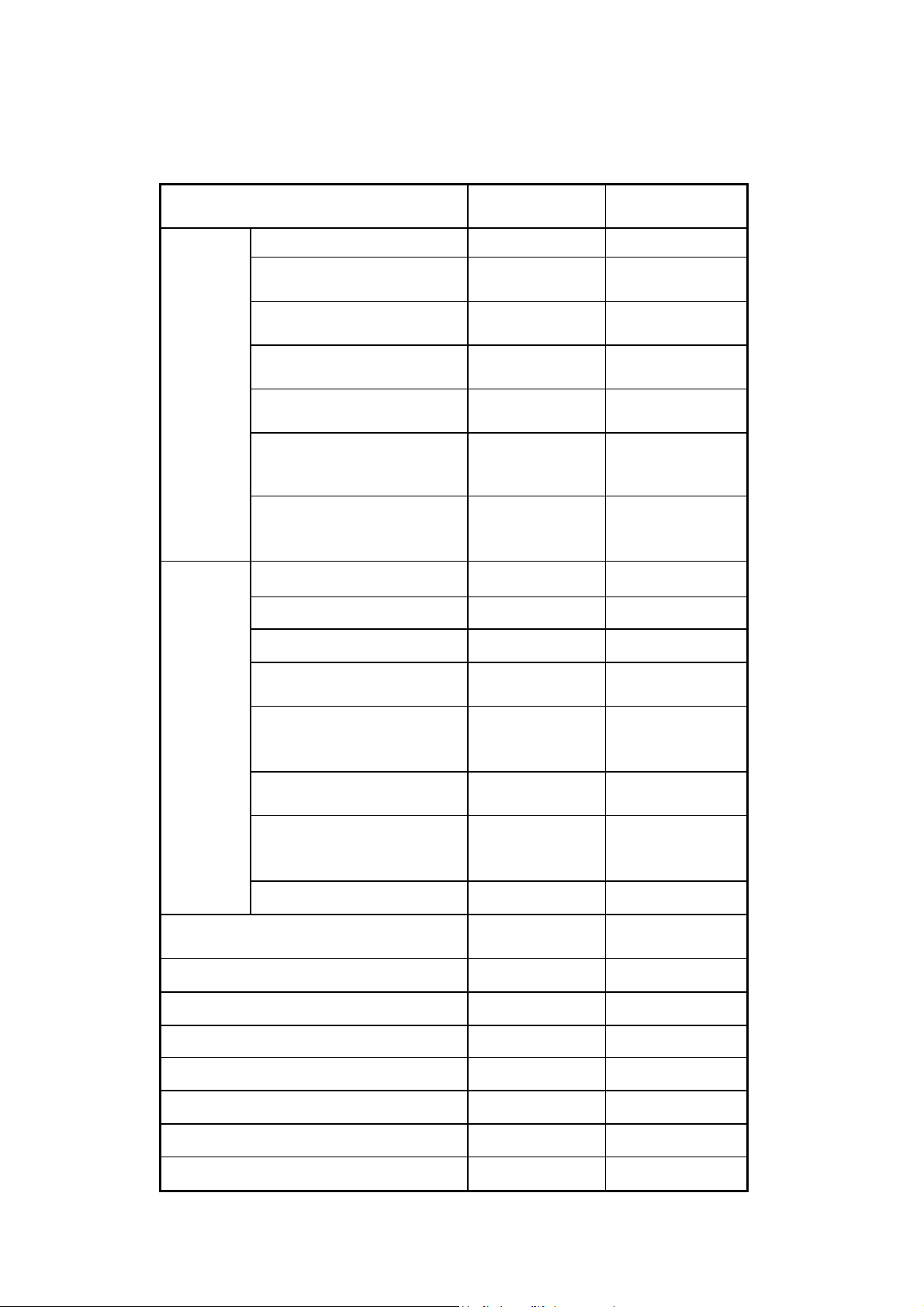

RATING OF TIG 400i INVERTER WELDING POWER SOURCE

Contents of parameters Unit TIG 400i

No-load voltage V 76

The working voltage of

V 20.4-36.0

Output

Input

The working voltage of

Rated welding current A

Current adjustment

Rated load duty cycle

(Argon arc welding)

Rated load duty cycle

(Manual welding)

Number of phases Phase 3

Frequency HZ 50/60

Supply voltage V 415V ±15%

Rated input current

Maximum effective

input current

(Argon arc welding)

Rated input current

V 10.4-26.0

TIG: 400

A

A 18

A 14

A 24

TIG:10-400

400A @ 60%

310A @100%

305A @ 60%

240A @ 100%

Maximum effective

input current

(Manual welding)

Rated input capacity KVA 17

Static external characteristic

Lifting device Handle

Efficiency η ≥85%

Power Factor 0.9

Insulation grade H

Enclosure protection grade IP21S

Weight Kg 35

Boundary dimensions (L* W* H) mm 510×275×420

5

A 14

Down slope

INSTALLATION

Input wiring

o Ensure that the voltage, number of phases, frequency and capacity of the input

power are consistent with the calibration values on the nameplate of the welding

machine.

o Wiring shall be performed by professional electrician.

o The input cable and air inlet are located on the back panel of the welding machine.

Please refer to the structure diagram of welding machine for detailed location.

o Connect the input cable to the power to ensure the reliable connection.

o The casing must be grounded, and the grounding bolt is located at the lower right

corner of the back panel of the welding machine and marked with a grounding

mark.

o Confirm the air inlet is connected smoothly with the argon cylinder during the weld

of argon arc welding.

o The recommended specifications of ground wire, fuse protector or breaker are as

follows:

Specifications for input cables, ground wires and input fuse protectors or breakers at three-phase /50Hz

rated load duty cycle

Welding

machine

model

TIG 400i 60% 415V 24A 14A ≥4 mm2 ≥4 mm2 60 A

Load duty

cycle

Input

voltage

Input

current

Maximum

effective

input

current

60℃ cable specification

Three-phase

input cable

Ground

wire

Fuse

protector

or

breaker

Output connection

o The positive pole of the output end, the negative pole of the output end and the

control connector (welding torch switch) are all located on the lower side of the

front panel, please refer to the structure diagram of welding machine for details.

(1) Manual arc welding connection method

o Connect one end of the negative output cable to the negative quick coupling,

and the other end to the job.

o Connect the negative quick coupling to the negative pole of the output end and

6

tighten it clockwise.

o Connect one end of the positive output cable to the positive quick coupling, and

the other end to the electrode holder.

o Connect the positive quick coupling to the positive pole of the output end and

tighten it clockwise.

(2) Argon arc welding connection method

o Connect one end of the positive output cable to the positive quick coupling, and

the other end to the job.

o Connect the positive quick coupling to the positive pole of the output end and

tighten it clockwise.

o Connect the two-core control plug in the argon arc welding torch cable to the

control connector (welding torch switch) and tighten it, and connect the cable

connector in the argon arc welding torch cable to the negative quick coupling.

o Connect the negative quick coupling to the negative pole of the output end and

tighten it clockwise.

o Connect the air pipe of the argon cylinder to the input of the gas inlet. Please

refer to the structure diagram of back panel for the location of the input gas

connection.

o Connect the air pipe of argon arc welding torch to air outlet nozzle of the air

outlet. Please refer to the front panel structure diagram for the position of the air

outlet nozzle.

o Note: confirm that the air inlet is reliably connected with the argon cylinder.

CAUTIONS FOR INSTALLATION

Provide a Switch Box for every Welding Power Source, and use designated

fuse

Tolerance of Power Voltage Variation is 10% of rated input voltage.

a) Installation place

Install in the place where less moisture and dust exist. Avoid direct sunlight and

rain, and maintain ambient temperature within –10o to +45

o C

as much as

possible.

Keep the welding power source at least 20 cm. away from the wall (if any).

In case of installation of more two units side by side, a distance of more than 20

cm is recommended between the two power sources.

Use a shield to protect the welding arc in case of excessive air draft.

7

b) Ventilation

Adequate ventilation is recommended at the place of installation. For

example the following guideline should be followed:

a) In case of the area being more than 300 square meters (per unit), no

ventilation is required, provided the room is not completely airtight.

b) In case of the area being less than 300 square meters and the welding

is continuously performed, adequate ventilation is recommended with

the help of vent fan or exhaust duct.

c) While performing the grounding work, it is recommended that a skilled

electrician does the work.

8

WELDING OPERATIONS

time

Front Panel

o Select the parameters to be adjusted by adjusting the LEFT or RIGHT shift keys

on the front panel, and preset the parameters to be welded through the panel

ADJUSTMENT knob.

o Each welding parameter on the front panel can be independently adjusted, and

the ranges are as follows:

Pre flow Gas Initial current Up slope time Welding current

0.1-10s 10-welding current 0-15s 10-400A

Down slope

0-25s

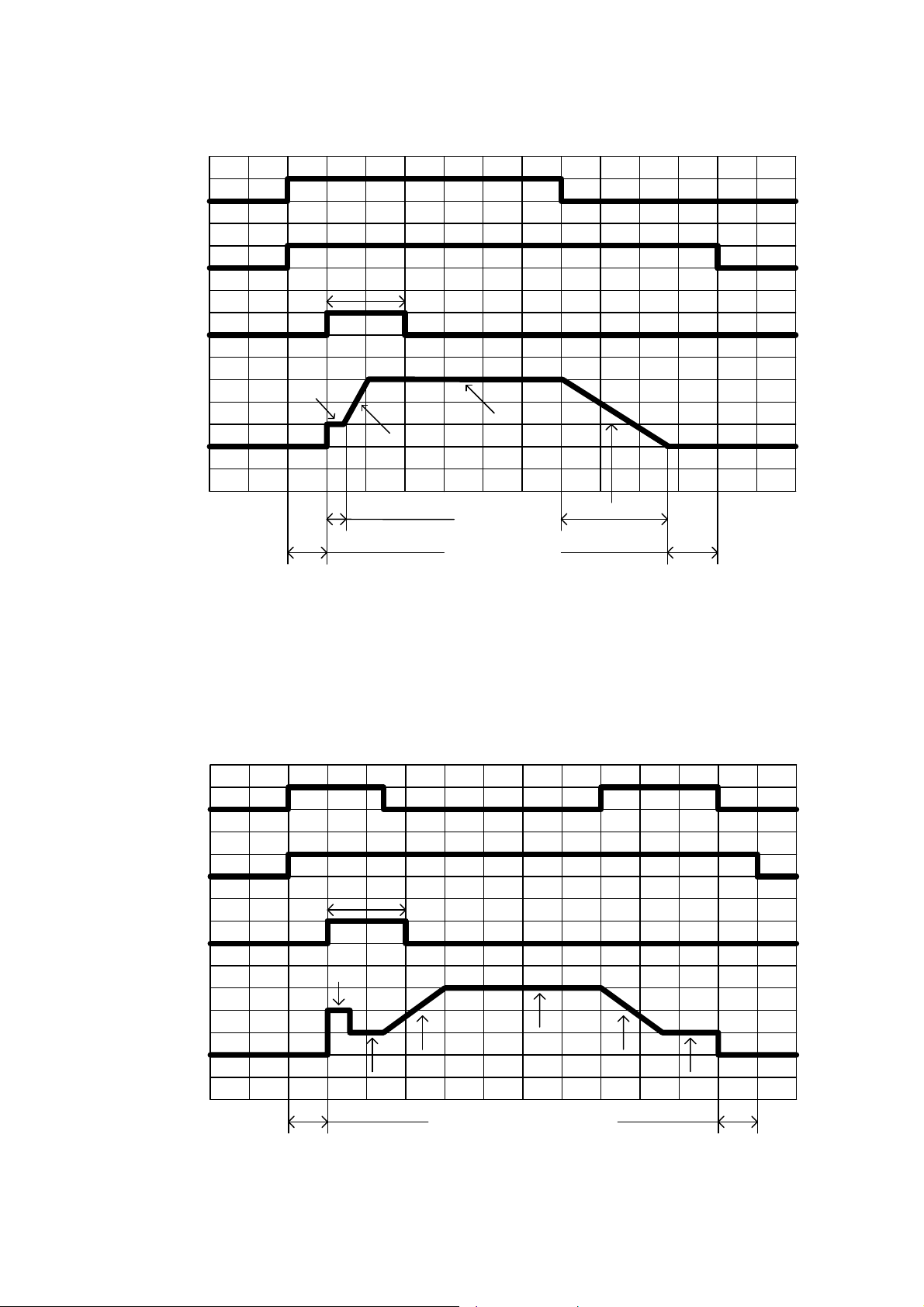

TIG welding has three modes of operation, which are 2-step, 4-step and repeat mode.

The schematic diagram of the operational modes are as follows:

Crater current Post Flow Gas Arc Force

10-welding current 0.5-30s 0-100%

9

2- Step Mode

Welding

gun switch

Solenoid

value

High-frequency

discharge

Welding

current

ON

OFF

ON

OFF

Arc starting current

OFF

OFF

Discharging time 0.5s, stopped until there is current

Welding current

Up slope

4-Step Mode

Welding

gun switch

Solenoid

value

High-frequency

discharge

OFF

OFF

Arc starting current 0.3s

Pre-flow time

ON

OFF

ON

Arc starting current

Down slope

Post flow time

Diagram of 2-step welding mode

ON

Discharging time 0.5s, stopped until there is current

OFF

OFF

Welding

current

Up slope

Initial current

Pre-flow time

Welding current

Down slope

Diagram of 4-step welding mode

10

Crater current

Post flow time

Repeat

Press torch within 1 second

after releasing, arc die out

Welding

gun switch

Solenoid

value

High-frequency

discharge

Welding

current

OFF

OFF

ON

ON

Arc starting current

Up slope

Initial current

Pre-flow time

ON

OFF

Discharging time 0.5s, stopped until there is current

Up slope

Welding current

Down slope

Crater current

Post flow time

Diagram of Repeat welding mode

ON

OFF

OFF

OFF

11

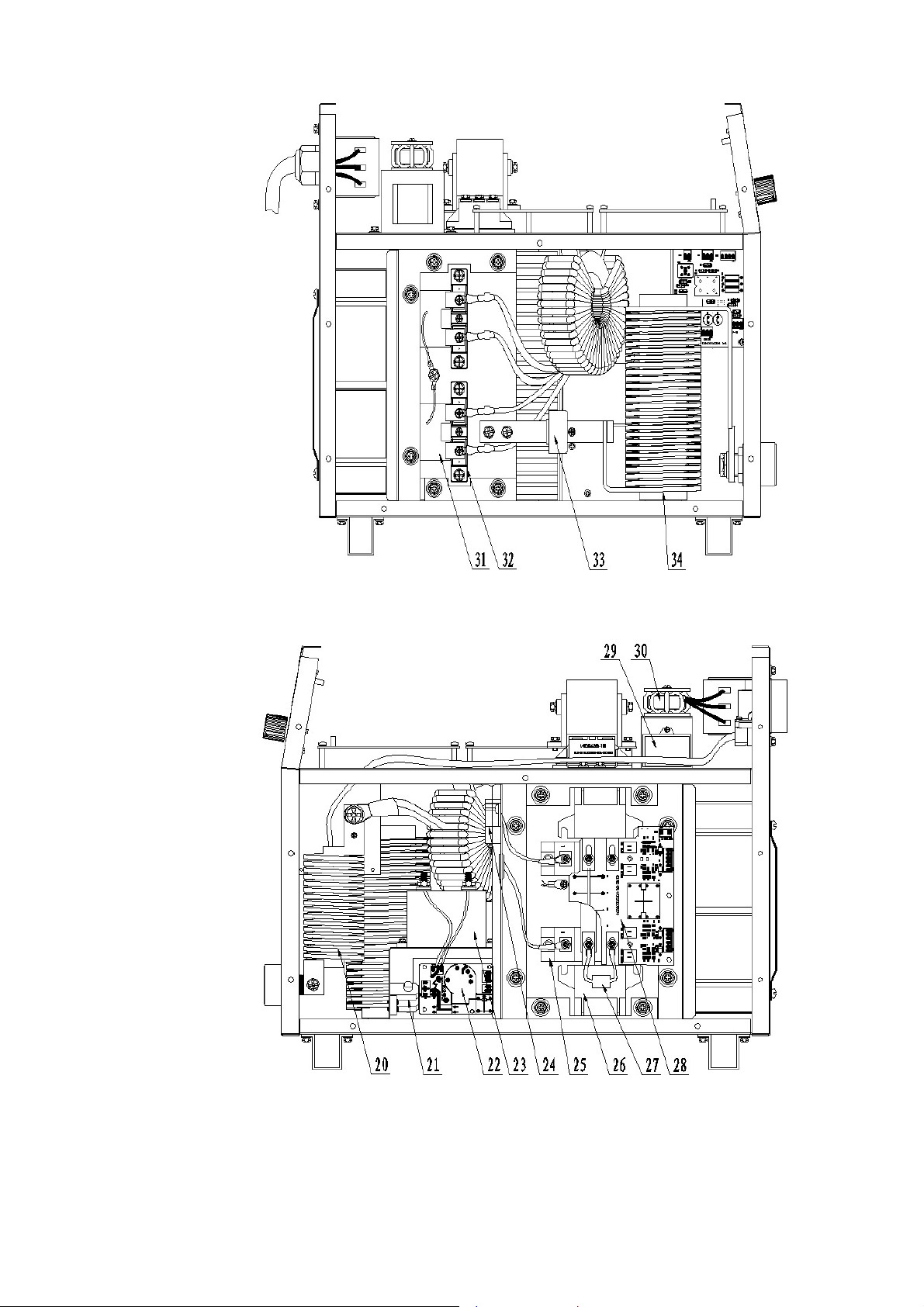

WIRING DIAGRAM

12

General maintenance

No additional maintenance for fan is required as all parts of the fan are sealed.

If the welding machine is used where there is a lot of dust, the dust may block the

air duct of the welding machine and cause the welding machine to heat up.

Therefore, it is necessary to use dry compressed air to remove the dust inside the

welding machine at set intervals.

Overload protection

The temperature monitoring device in the welding machine, which uses the

thermistor (temperature sensor) to prevent overload or insufficient cooling, can

provide effective protection for the important power devices of the welding

machine. When continuous overload occurs or power device IGBT and fast

recovery diode cannot get adequate heat dissipation, the overheating indicator

light will be on, and the normal output of the welding machine will be stopped.

After these power devices cool down, the overheating indicator light will die out

and the output of the welding machine will automatically return to normal.

The control circuit power supply of the welding machine is designed with latest

integrated power supply chip to ensure that the normal power supply of the

welding machine will not be affected when the network voltage is too low or too

high, and the function of the welding machine will not be affected by the network

voltage. However, excessive power grid input voltage will cause damage to main

circuit capacitors, IGBT, rectifier bridges, fans and other devices.

13

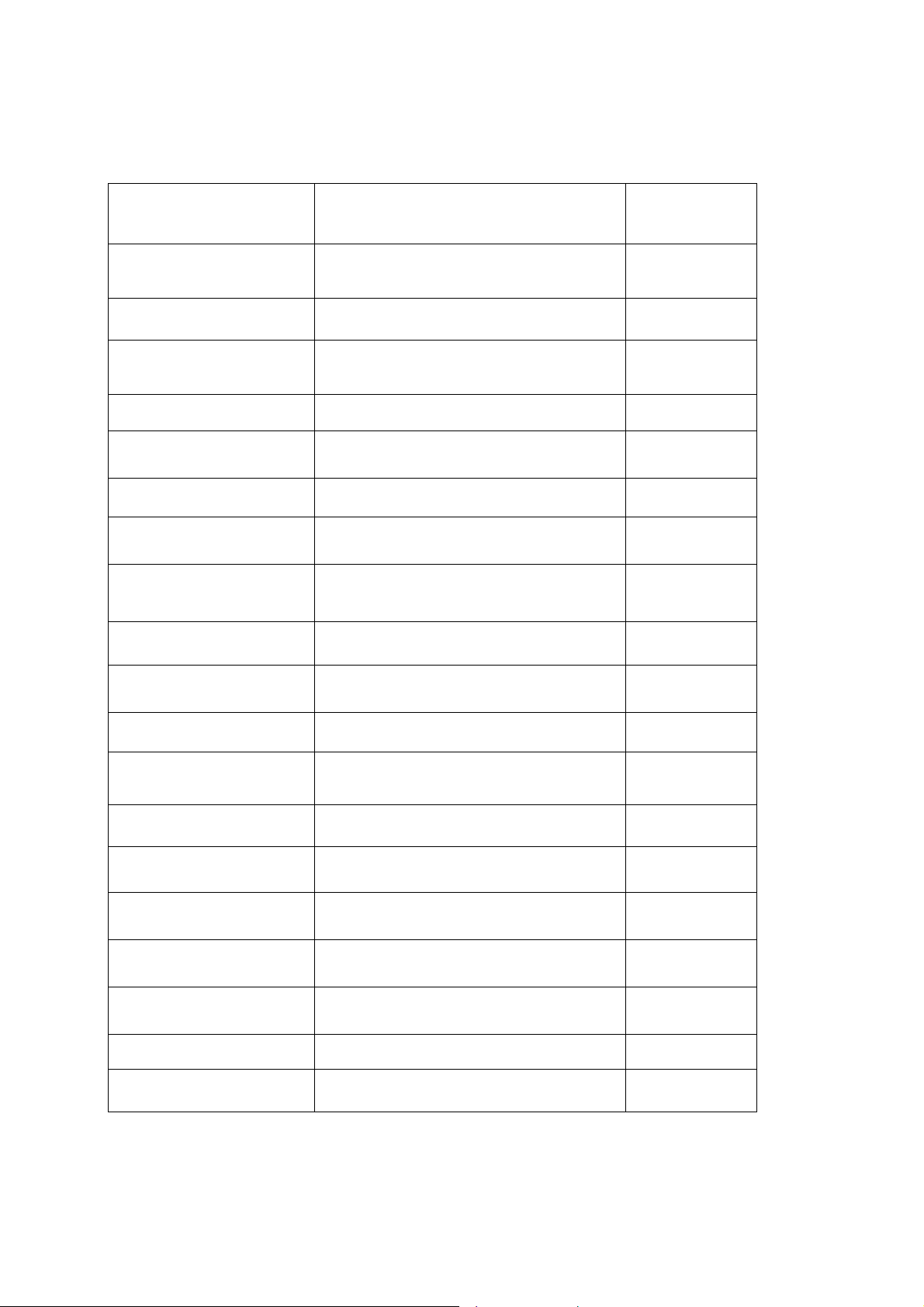

Parts List and Exploded view

No Part Name

1

2 Air outlet nozzle 0061301356

3 Aviation socket (2-core) 0012001047

4 Aviation socket 0012001045

5

6 Display board TIG 400i 0030101983

7 Potentiometer knob (large) 0010603056

8

9 Miniature circuit breaker 0011501003

Welding cable coupling device:

Socket (plate-type)

Welding cable coupling device

Socket

Two-position two-way solenoid

valve

Part

Number

0050804030

0050804024

0011001003

10 Input cables 0030501596

11 Axial flow fan 0011702012

12 Main transformer 0030801632

13 Absorption board 0030101744

14 Filter capacitor 0010222002

15 Three-phase rectifier module 0012103001

16 Power supply detection board 0030101618

17 Control panel 0030101842

18 Power panel 0030101748

19 Control transformer 0060101206

14

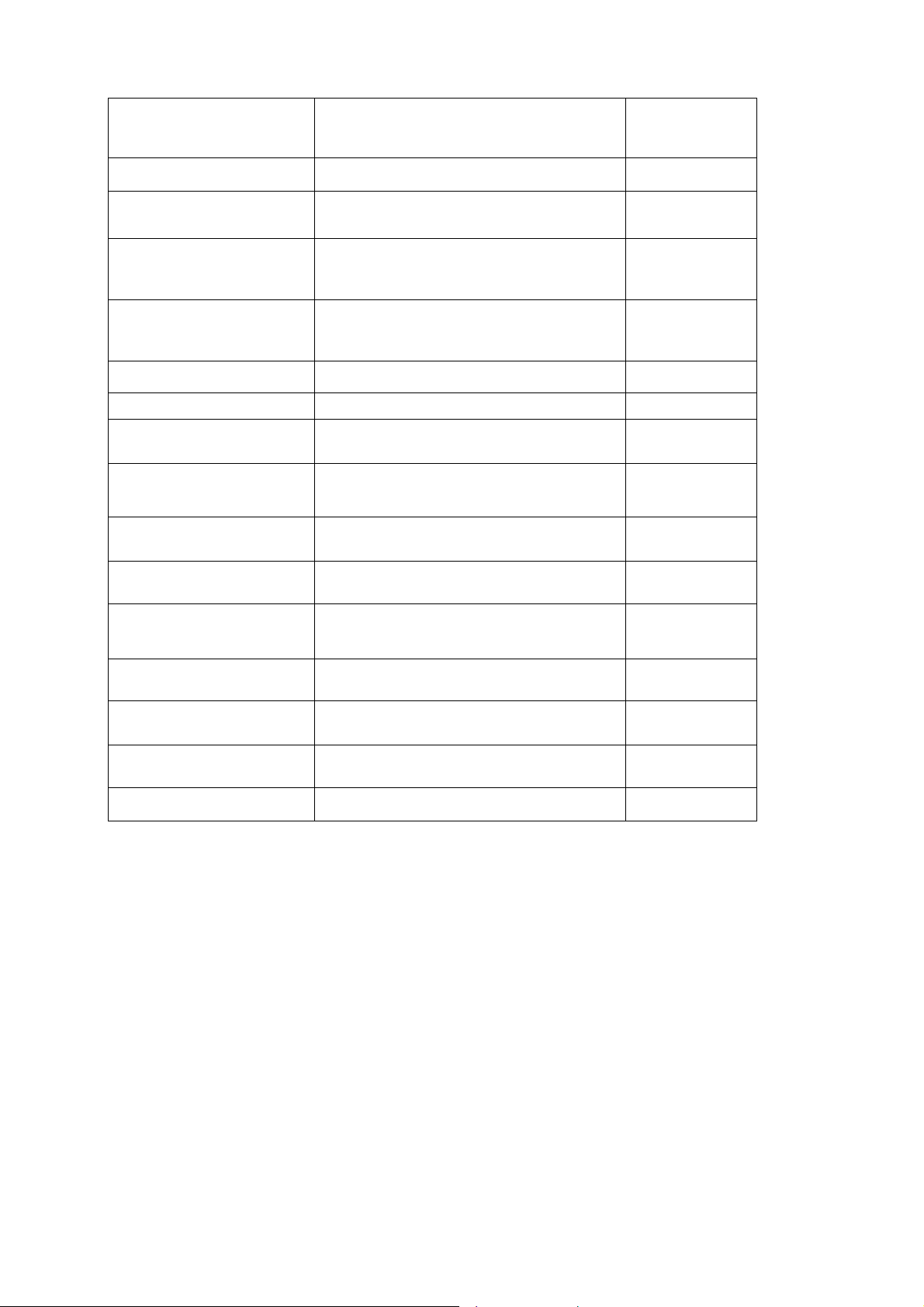

No Part Name

20 Coupler 0030801612

21 Arc striking device (spark plug) 0012301292

22 High-frequency arc striking board 0030101746

Part

Number

23

24 Current transformer 0011303019

25 IGBT module 0012101060

26 Filter capacitor 0010222014

27 Discharge resistor component 0030502252

28 Drive board 0030101747

29 Capacitor 0010227001

30 Three-phase input inductance 0031001147

31 Diode absorption board 0030101565

32 Fast recovery diode module 0012102033

33 Hall current sensor 0011301023

High-frequency and high-voltage

capacitor

0010227003

34 Reactor 0030901172

15

16

17

ESAB INDIA LIMITED

Registered and Head Office

13, Industrial Estate, III Main Road

Ambattur, Chennai - 600058

Telephone: + 91 44 42281100

Fax: + 91 44 4228 1107

Email: info@esab.co.in

Web: www.esabindia.com

18

Loading...

Loading...