Page 1

INSTRUCTION MANUAL for the

ESAB SmartFlow

PLASMA CUTTING SYSTEM

F14-129

August, 1997

411 South Ebenezer Road

Florence, SC 29501-0545

Page 2

The equipment described in this manual is

potentially hazardous. Use caution in installing,

operating, and maintaining this equipment.

The purchaser is solely responsible for the

safe operation and use of all products

purchased, including compliance with OSHA

and other government standards. ESAB

Cutting Systems has no liability for personal

injury or other damage arising out of the use

of any product manufactured or sold by ESAB.

See standard ESAB terms and conditions of

sale for a specific statement of ESAB’s

responsibilities and limitations on its liability.

ESAB Cutting Systems is not responsible for

any errors that may appear in this document.

The information in this document is subject to

change without notice.

This manual is ESAB Part Number F14129.

This manual is for the convenience and use of the

cutting machine purchaser. It is not a contract or

other obligation on the part of ESAB Cutting

Systems.

ESAB Cutting Systems, 1997

Printed In USA

Page 3

This manual is not a safety guide for the use of the

equipment. The purchaser, through its own

judgment and safety procedures, is solely

responsible for safe operation. However, in

presenting the information in this manual, a system

of advisory notes has been provided to point out

specific information that will be helpful in the safe

and proper operation of the equipment.

The method used to identify these notes and the

purpose for each are as follows:

An operational procedure or background

information that aids the operator in efficient use

of the system and in performing maintenance, or

information that requires additional emphasis.

An operational procedure which, if not

properly followed, may cause damage to the

system.

An operational procedure that, if not

properly followed, may cause injury to the

operator or others in the operating area.

Page 4

Page 5

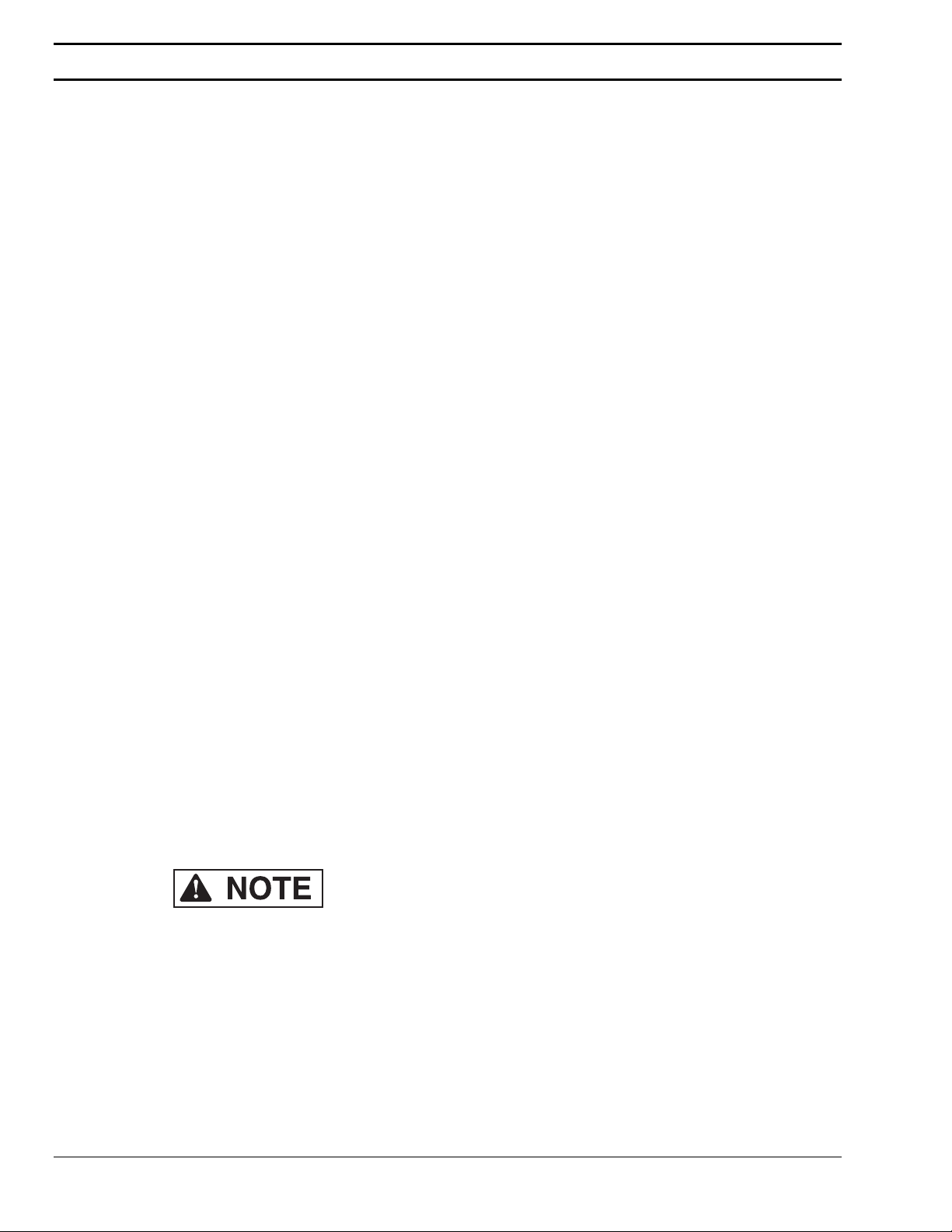

SmartFlow Plasma System

Preface

This manual applies only to the ESAB SmartFlow

Plasma Cutting System using the Vision CNC and

ASIOB I/O Structure. For plasma systems with

alternate hardware, refer to the appropriate

manual.

The ESAB SmartFlow Plasma Cutting System is

an advanced, numerically controlled plasma

cutting package manufactured by ESAB Cutting

Systems of Florence, South Carolina. This

system is designed to be installed on an ESAB

Gantry Shape Cutting Machine. It is designed to

provide years of dependable, accurate, repeatable

part cutting, with a high degr ee of reliability, ease

of service and ease of operation.

There are various optional configurations possible

with the SmartFlow system. For completeness, all

of these options are described in this manual.

However, not all options or capabilit ies described

in this manual are present on all machines. In

addition, more capabilities and features may be

added in the future, which are not covered in this

manual. ESAB Cutting Systems reserves the

right to change or add features and capabilities

without notice.

Before operating the system, one should become

familiar with this manual in its entirety, wit h special

attention to the SAFETY section.

Page 6

Contents

1 Safety...................................................................................................1

2 Introduction...........................................................................................5

3 Installation ............................................................................................ 9

1.1 Introduction...............................................................................1

1.2 General Safety Information.......................................................2

1.3 Plasma Marking Precautions.....................................................3

1.3.1 Electrical Shock Prevention...........................................3

1.3.2 Eye Safety..................................................................... 3

1.4 Skin Safety................................................................................ 4

1.5 Electrical Grounding.................................................................. 4

2.1 Overview................................................................................... 5

2.2 System Description...................................................................5

2.2.1 Component Description.................................................5

2.2.2 SmartFlow System with PT-15XL Torch........................6

2.2.3 SmartFlow System with PT-19XL Torch........................7

3.1 Requirements............................................................................9

3.1.1 Gas Supply Requirements.............................................9

3.1.2 Water Supply Requirements.......................................... 9

3.1.3 Deionized Water Requirements (PT-15XL).................... 9

3.1.4 Electrical Input Requirements........................................ 9

3.2 Connections............................................................................ 10

3.2.1 Hose and Cable Connections......................................10

3.2.2 Pilot Arc Cable Connections........................................10

3.3 Supply Setup........................................................................... 11

3.3.1 Gas Supply Pressures................................................. 11

3.3.2 Cut Water Supply Pressure.........................................12

3.3.3 Cut Water Pump Setup................................................ 12

4 Setup..................................................................................................13

4.1 Introduction.............................................................................13

4.2 Prerequisites........................................................................... 13

4.3 Gas Regulator Setup .............................................................. 14

4.3.1 Gas Regulator Panel Setup......................................... 14

4.3.2 Shield Air Regulator..................................................... 15

4.4 CNC Setup.............................................................................. 16

Page 7

SmartFlow Plasma System

5 Process Data ......................................................................................19

6 Maintenance .......................................................................................25

6.1 Routine Maintenance...............................................................25

6.2 Technical Description..............................................................26

6.2.1 Gas Control..................................................................26

6.2.2 Cut Water Control........................................................28

6.2.3 Secondary Shield Gas Control.....................................30

6.2.4 Cooling Water Circuit...................................................32

6.3 Maintenance Procedures.........................................................34

6.3.1 Introduction..................................................................34

6.3.2 Gas Pressure Switch ...................................................34

6.3.3 Water Pressure Switch ................................................36

6.3.4 Gas Regulator..............................................................37

6.3.5 Interlock Switch............................................................38

6.3.6 Cut Water Pressure .....................................................40

6.3.7 Gas Filters ...................................................................41

6.3.8 Gas Proportional Valve................................................41

6.3.9 Water Proportional Valve.............................................42

6.3.10 Cooling Water Flow Switch ........................................42

6.4 Schematics..............................................................................43

6.5 Troubleshooting.......................................................................47

7 Replacement Parts..............................................................................49

7.1 General Information.................................................................49

7.2 Ordering Information ...............................................................50

7.3 SmartFlow Plasma Flow Control..............................................51

7.3.1 Arc Starter Box Assembly............................................57

7.3.2 Flow Tube Box Assembly.............................................59

Page 8

Page 9

1 Safety

1.1 Introduction

SmartFlow Plasma System

ESAB plasma cutting products are designed to

provide both safety and efficiency in operation.

However, sensible attention to operating

procedures, precautions, and safe practices is

necessary to achieve a full measure of safety.

Whether an individual is involved with operation,

servicing, or as an observer, compliance with

established precautions and safe practices must be

accomplished. Failure to observe certain

precautions could result in serious injury to

personnel or severe damage to the equipment.

The following precautions are specific guidelines

applicable to the plasma cutting process. More

general precautions are presented in the instruction

literature pertaining to the cutting machine.

Safety Page 1

Page 10

Section 1

1.2 General Safety Information

All personnel, materials, and equipment not

involved in the production process must be

kept clear of the entire system area. Only

qualified personnel should be allowed to

operate or service the equipment.

Read entirely through a procedure to become

familiar with the task before operating or

performing maintenance on any part of the

system. Special attention must be given to all

WARNINGS, CAUTIONS, and NOTES which

provide essential information regarding

personnel safety and/or possible damage to

equipment.

All safety precautions relevant to electrical

equipment and the process operations must

be strictly observed by all who have

responsibility or access to the system. DO

NOT touch the plasma marking torch during

operation. Do not operate any part of the

system with any of the protective covers

removed or electrical component boxes open.

Refer to all safety publicati ons made available

by your company.

Fence off the entire work cell to prevent

personnel from passing through the area or

standing within the working envelope of the

equipment. Post appropriate CAUTION signs

at every entrance to the work cell area.

Page 2 Safety

Page 11

1.3 Plasma Cutting Precautions

1.3.1 Electrical Shock Prevention

SmartFlow Plasma System

The plasma arc cutting process employs high

voltages. High voltage can kill. Do NOT touch the

marking torch, cutting table or cable connections

during the plasma cutting process.

Electrical Shock Can Kill You!

• Always turn off power to the plasma power

supplies before touching or servicing a plasma

marking torch.

• Always turn off power to the plasma power

supplies before opening or servicing the plasma

power supply or interface box.

1.3.2 Eye Safety

• Do not touch live electrical parts.

• Keep all panels and covers in place when the

machine is connected to a power source.

• Insulate yourself from the workpiece and

electrical ground: wear insulating gloves, shoes

and clothing.

• Keep gloves, shoes, clothing, work area, and

this equipment dry.

Arc rays can injure eyes and burn skin.

To protect your eyes from burns caused by high

intensity ultraviolet light, sparks and hot metal :

• Do not look at the arc.

• Wear correct eye protection. Wear dark safety

glasses or goggles with side shields.

• Replace glasses/goggles when the lenses

become pitted or broken

• Warn other people in the area not to look

directly at the arc unless they wear appropriate

Safety Page 3

Page 12

Section 1

1.4 Skin Safety

safety glasses.

• Prepare the cutting area in a manner that

reduces the reflection and transmission of

ultraviolet light:

• Paint walls and other surfaces with dark colors

to reduce reflections.

• Install protective screens or curtains to reduce

ultraviolet transmission.

To protect skin against burns caused by high

intensity ultraviolet light, sparks and hot metal:

• Wear protective clothing:

1.5 Electrical Grounding

• Wear gauntlet gloves.

• Wear flame-retardant clothing which covers all

exposed areas.

• Wear cuffless trousers to prevent entry of

sparks and slag.

• Do not touch the torch when it is about to sta rt

or while marking. After marking, allow time for

the front of the torch to cool.

Electrical grounding is imperative for proper

machine operation as well as for SAFETY.

All ESAB Shape Cutting Machines must have a

good electrical connection to earth ground.

Page 4 Safety

Page 13

2 Introduction

2.1 Overview

2.2 System Description

SmartFlow Plasma System

The SmartFlow Plasma Cutting System is a

streamlined, high performance plasma cutting

package designed for use exclusively with the

ESAB Vision CNC. ESAB’s exclusive SmartFlow

technology integrates gas and water control into

the cutting machine CNC.

Using a system of proportional valves driven by

CNC outputs, this system dramatically reduces the

amount of plumbing hardware necessary to c ontrol

the plasma torch. Operation is simplified by putting

control of gas and water flow rates on scre en at the

Vision CNC.

2.2.1 Component Description

The SmartFlow system components include a

plumbing box, a flow tube box, and a regulator

panel. The plumbing box contains the p roportional

valves and plumbing necessary to control gas and

water flows. The flow tube box contains three flow

indicator tubes, which provide visual feedback to

the machine operator of the actual gas and water

flow rates. The regulator panel provides pressure

regulation for the incoming gas and water supplies.

When the PT-15XL water injection torch is used,

the complete SmartFlow cutting system also

includes a plasma power supply, a recirculating

water cooler, a cut water pump, an air curtain

control, and the Vision CNC. If the PT-19XL dry

torch is used, then the cut water supply system and

air curtain control are omitted.

The following pages show the complete system

overviews.

Introduction Page 5

Page 14

Section 2

2.2.2 SmartFlow System with PT-15XL Torch

The illustration below shows the SmartFlow system

when a PT-15XL water injection torch is used.

Page 6 Introduction

Page 15

2.2.3 SmartFlow System with PT-19XL Torch

SmartFlow Plasma System

The illustration below shows the SmartFlow system

when the PT-19XL dry torch is used. In this system

the cut water supply equipment is omitted, a

secondary shield is used instead of an air curtain,

and shield gas is controlled through the SmartFlow

plumbing Box.

Introduction Page 7

Page 16

Section 2

Page 8 Introduction

Page 17

3 Installation

3.1 Requirements

3.1.1 Gas Supply Requirements

SmartFlow Plasma System

Nitrogen 125 PSI (1/2 NPT)

99.999% Pure

Oxygen 125 PSI (1/2 NPT)

99.999% Pure

Compressed Air (PT-19XL

with Secondary Shield only)

3.1.2 Water Supply Requirements

Cooling Water 120 PSI

3.1.3 Deionized Water Requirements (PT-15XL)

Deionized Water 35 PSI (1/2 NPT)

3.1.4 Electrical Input Requirements

Voltage Supply +24 VDC for proportional valves,

100 PSI (1/2 NPT)

Clean, Dry, Filtered to 5 micron.

1.5 GPM

> 200,000 Ω

.5 GPM for up to 600 Amp cutting

1.5 GPM for 1000 Amp cutting

flow and pressure switches.

+15 VDC for pressure switch.

Voltage Signals 120 VAC input to start gas

solenoid valve.

120 VAC input to cut gas solenoid

valve.

120 VAC input to Arc Starter.

0 - 10 Volt DC inputs to

proportional valves.

Installation Page 9

Page 18

Section 3

3.2 Connections

3.2.1 Hose and Cable Connections

The SmartFlow Plasma Cutting package is

designed to be interfaced with the ESAB Vision

CNC and any ESP Plasma Power Supply.

Connections to the plumbing box are illustrated

here. A color code is used on the hose

connections between the flow tube box and the

plumbing box:

Green = Oxygen

Yellow = Nitrogen

White = Cooling Water

Blue = Cut Water

The Control Cable Entrance plate can be removed,

allowing the control cables to be installed or

removed without any re-wiring at the plug terminals.

3.2.2 Pilot Arc Cable Connections

The Options Cover is replaced by an additional

hose adaptor when the PT-19XL is used with a

Secondary Shield kit, allowing the plumbing box to

control shield gas flow. The Options Cover also

allows space for a third power cable connector for

PT-15XL installations cutting at 1000 Amps.

The Pilot Arc Cables must be connected properly

to the insulated high voltage terminals at the Arc

Starter Box, as shown here.

The Pilot Arc Ground Cable (from the plasma power

supply) is connected to TB1, toward the open side

of the plumbing box.

The Pilot Arc Torch Cable (from the torch leads) is

connected to TB3, toward the back of the

plumbing box.

TB2 is connected to the Busbar, internal to the

plumbing box.

Page 10 Installation

Page 19

3.3 Supply Setup

3.3.1 Gas Supply Pressures

SmartFlow Plasma System

The Oxygen and Nitrogen gases may be supplied

from bottles or bulk tanks. The supplies to the

cutting machine must be controlled with the proper

type of regulator. Adjust these pressures as

follows:

Oxygen

Set the Oxygen pressure to 140 PSI while the gas

is flowing.

Nitrogen

Set the Nitrogen pressure to 140 PSI while the gas

is flowing.

Installation Page 11

Page 20

Section 3

3.3.2 Cut Water Supply Pressure

Installations using the PT-15XL water injection torch

require a supply of deionized water. This water

must be regulated to a minimum of 30 PSI to

prevent the cut water pump from cavitating.

The cut water regulator is located on the Plasma

Regulator Panel. Set the Cut Water pressure to 30

PSI while the water is flowing.

3.3.3 Cut Water Pump Setup

Installations using the PT-15XL water injection torch

require a cut water pump. The cut water pump

supplies high pressure water to the plumbing box,

where the flow is regulated. The cut water pump

must be adjusted to 120 PSI. Refer to Section

6.3.6 for the adjustment procedure.

Page 12 Installation

Page 21

4 Setup

4.1 Introduction

4.2 Prerequisites

SmartFlow Plasma System

The information in this section is intended for use by

the operator during daily setup prior to starting the

cutting process.

The following setup procedures can only be

completed after all of the requirements,

connections, and suppliy setups have been

properly completed, as detailed in Section 3.

Setup Page 13

Page 22

Section 4

4.3 Gas Regulator Setup

4.3.1 Gas Regulator Panel Setup

The plasma system requires regulated gas and

water supplies for proper operation. The plasma

regulator panel, shown here, is mounted on the

cutting machine gantry near the operator’s control

console.

When the PT-15XL torch is used, all three

regulators must be set properly. When the PT19XL torch is used, only the oxygen and nitrogen

regulators are used.

Adjust the pressure settings while the gas is

flowing, since there will be a slight drop in indicated

pressure when the gas is flowing.

Oxygen

Set the Oxygen pressure to 120 PSI while the gas

is flowing.

Nitrogen

Set the Nitrogen pressure to 120 PSI while the gas

is flowing.

Page 14 Setup

Page 23

4.3.2 Shield Air Regulator

SmartFlow Plasma System

When the secondary shield is used with the PT19XL torch, an air regulator is located at the

Plumbing Box. This regulator sets the air supply

pressure for the secondary shield air.

Set the regulator pressure to 60 PSI. Air flow is

then controlled throught he Vision CNC’s parameter

screen.

Setup Page 15

Page 24

Section 4

4.4 CNC Setup

The SmartFlow Plasma System may is interfaced to

the ESAB Vision CNC. The following parameters

are adjusted through the CNC. Prior to plasma

cutting, check these parameters at the Vision CNC:

Standoff

Initial Height

Start Gas Flow

Cut Gas Flow

Start Water

Flow

This parameter adjusts the actual cutting height

that the torch will maintain, after the arc has

started.

Set the distance to raise the torch after sensing the

plate. When VHC is turned on, the torch will lower

to the plate, then retract this distance before

starting the arc.

This parameter adjusts the flow of gas prior to and

during arc starting. Start Gas, which is Nitrogen, is

flowed at this rate during preflow and postflow.

This parameter adjusts the flow of plasma gas

during plasma cutting. When the arc starts, the

gas supplied to the torch switches from the Start

Gas Flow rate to the Cut Gas Flow rate. Cut Gas

may be Oxygen or Nitrogen.

Systems equipped with a water injection torch use

Cut Water. It can be flowed at a reduced rate prior

to and during arc starting. This param eter sets the

water flow during preflow, arc starting, and

postflow.

Cut Water

Flow

Start Shield

Gas

Shield Gas

Remote

Current

Pre Switch Cut

Gas

Page 16 Setup

This parameter sets the water flow rate after arc

starting, during the cutting process.

Systems equipped with a secondary shield instead

of a cut water system use the SmartFlow plumbing

box to control Shield Gas flow. This parameter

sets the Shield Gas flow rate during preflow, arc

starting, and postflow.

This parameter sets the Shield Gas flow rate after

the arc starts, during the cutting process.

Set the cutting Amperage for the plasma power

supply.

This timer sets the length of time prior to starting

the arc that the system will switch from start gas to

cut gas. This allows the system to be used equally

well with any length of torch leads. When set

Page 25

SmartFlow Plasma System

properly, the cut gas will reach the torch

momentarily after the arc starts.

Plasma Rise

On Pierce

Plasma Pierce

Time

Plasma Travel

Delay

Master Up

Set this timer according to the length of time you

want the plasma torch to raise, starting at the

moment the arc strikes. This can be used to raise

the torch while piercing to avoid blow-back and

spatter. See the chart following this list.

This timer starts when the Plasma Rise On Pierce

time ends. The lift motor is de-energized, AHC is

turned OFF, and machine motion is held. This

timer can be set longer for thicker material, to allow

more time to pierce through the material, while the

torch is held at a set height. See the chart below.

This timer starts when the Plasma Pierce Time

ends. AHC is turned ON, but Travel is delayed.

This can be set longer for thicker materials to allow

time to pierce through the material. It also allows

the torch to reach the cutting height before travel

starts. See the chart following this list.

This timer sets the length of time the torch will be

raised at the end of each cut.

Refer to Section 5 of this manual for the appropriate

values for each of these parameters.

Refer to the machine manual for detailed

instructions on how to change process parameter

settings.

Setup Page 17

Page 26

Section 5

Page 18 Setup

Page 27

5 Process Data

SmartFlow Plasma System

The SmartFlow Plasma System can produce high

quality cuts on a wide range of plate thicknesses

and cutting amperages. It is designed to support

both the PT-15XL and the PT-19XL plasma cutting

torches. The following pages provide process data

for various material thicknesses. Each page shows

the setup parameters for one material thickness.

These cutting parameters were developed under

laboratory conditions. Actual cutting conditions will

vary, and cutting parameters must be adjusted as

necessary.

Process Data Page 19

Page 28

Section 5

Torch Amperage Material Thickness

PT-19XL 250 Amp Cutting Carbon Steel 1/4 inch

Conditions:

ELECTRODE:

PLASMA GAS:

START GAS:

SHIELD GAS:

Setup Screen:

FEED RATE:

KERF WIDTH:

Parameter Screen:

STANDOFF:

INITIAL HEIGHT:

START GAS FLOW:

NOZZLE:

SHIELD:

PN: 21822

100-200 Amp, PN: 21945

PN: 34557

Oxygen @ 125 PSI

Nitrogen @ 125 PSI

AIR @ 80 PSI

200 ipm

.125 inch

122

76

28.6

(4.4 flow)

CUT GAS FLOW:

START SHIELD GAS:

SHIELD GAS:

REMOTE CURRENT:

PLASMA RISE ON PIERCE:

PLASMA PIERCE TIME:

PLASMA TRAVEL DELAY:

Page 20 Process Data

60.0

(5.1 flow/50 PSI cutting)

45

(7.5 PSI while cutting)

45

(7.5 PSI while cutting)

250

0

0

0

Page 29

SmartFlow Plasma System

Torch Amperage Material Thickness

PT-19XL 250 Amp Cutting Carbon Steel 3/8 inch

Conditions:

ELECTRODE:

PLASMA GAS:

START GAS:

SHIELD GAS:

Setup Screen:

FEED RATE:

KERF WIDTH:

Parameter Screen:

STANDOFF:

INITIAL HEIGHT:

START GAS FLOW:

NOZZLE:

SHIELD:

PN: 21822

100-200 Amp, PN: 21945

PN: 34557

Oxygen @ 125 PSI

Nitrogen @ 125 PSI

AIR @ 80 PSI

135 ipm

.125 inch

135

76

28.6

(4.4 flow)

CUT GAS FLOW:

START SHIELD GAS:

SHIELD GAS:

REMOTE CURRENT:

PLASMA RISE ON PIERCE:

PLASMA PIERCE TIME:

PLASMA TRAVEL DELAY:

Process Data Page 21

60.0

(5.1 flow/50 PSI cutting)

45

(7.5 PSI while cutting)

45

(7.5 PSI while cutting)

250

0

0

.1

Page 30

Section 5

Torch Amperage Material Thickness

PT-19XL 250 Amp Cutting Carbon Steel 1/2 inch

Conditions:

ELECTRODE:

PLASMA GAS:

START GAS:

SHIELD GAS:

Setup Screen:

FEED RATE:

KERF WIDTH:

Parameter Screen:

STANDOFF:

INITIAL HEIGHT:

START GAS FLOW:

NOZZLE:

SHIELD:

PN: 21822

100-200 Amp, PN: 21945

PN: 34557

Oxygen @ 125 PSI

Nitrogen @ 125 PSI

AIR @ 80 PSI

115 ipm

.185 inch

140

76

28.6

(4.4 flow)

CUT GAS FLOW:

START SHIELD GAS:

SHIELD GAS:

REMOTE CURRENT:

PLASMA RISE ON PIERCE:

PLASMA PIERCE TIME:

PLASMA TRAVEL DELAY:

Page 22 Process Data

60.0

(5.1 flow/50 PSI cutting)

45

(7.5 PSI while cutting)

45

(7.5 PSI while cutting)

250

0

.2

0

Page 31

SmartFlow Plasma System

Torch Amperage Material Thickness

PT-19XL 250 Amp Cutting Carbon Steel 3/4 inch

Conditions:

ELECTRODE:

PLASMA GAS:

START GAS:

SHIELD GAS:

Setup Screen:

FEED RATE:

KERF WIDTH:

Parameter Screen:

STANDOFF:

INITIAL HEIGHT:

START GAS FLOW:

NOZZLE:

SHIELD:

PN: 21822

100-200 Amp, PN: 21945

PN: 34557

Oxygen @ 125 PSI

Nitrogen @ 125 PSI

AIR @ 80 PSI

74 ipm

.185 inch

145

76

28.6

(4.4 flow)

CUT GAS FLOW:

START SHIELD GAS:

SHIELD GAS:

REMOTE CURRENT:

PLASMA RISE ON PIERCE:

PLASMA PIERCE TIME:

PLASMA TRAVEL DELAY:

Process Data Page 23

60.0

(5.1 flow/50 PSI cutting)

45

(7.5 PSI while cutting)

45

(7.5 PSI while cutting)

250

.3

.2

.1

Page 32

Section 5

Torch Amperage Material Thickness

PT-19XL 250 Amp Cutting Carbon Steel 1 inch

Conditions:

ELECTRODE:

PLASMA GAS:

START GAS:

SHIELD GAS:

Setup Screen:

FEED RATE:

KERF WIDTH:

Parameter Screen:

STANDOFF:

INITIAL HEIGHT:

START GAS FLOW:

NOZZLE:

SHIELD:

PN: 21822

100-200 Amp, PN: 21945

PN: 34557

Oxygen @ 125 PSI

Nitrogen @ 125 PSI

AIR @ 80 PSI

50 ipm

.185 inch

150

76

28.6

(4.4 flow)

CUT GAS FLOW:

START SHIELD GAS:

SHIELD GAS:

REMOTE CURRENT:

PLASMA RISE ON PIERCE:

PLASMA PIERCE TIME:

PLASMA TRAVEL DELAY:

Page 24 Process Data

60.0

(5.1 flow/50 PSI cutting)

45

(7.5 PSI while cutting)

45

(7.5 PSI while cutting)

250

.3

.4

.1

Page 33

6 Maintenance

6.1 Routine Maintenance

SmartFlow Plasma System

The SmartFlow System consists of a plasma powe r

supply, a recirculating water cooler, a cut water

pump (for the PT-15XL), a regulator panel, an

optional flow tube box, the SmartFlow Plumbing

Box, and the plasma torch.

For maintenance information on the plasma power

supply, water cooler, cut water pump, or plasma

torch, refer to the appropriate instruction manual.

The following routine maintenance should be

performed on the plasma marker system.

• Inspect the supply hoses, torch leads, ground

cable, and interface cables for damage or wear

at least weekly.

• Inspect and clean the PCM-500i at least

monthly. The unit can be blown out using a

clean, dry gas source, such as compressed air

or nitrogen.

Maintenance Page 25

Page 34

Section 6

6.2 Technical Description

6.2.1 Gas Control

Control of cut gas and start gas is accomplished

with two solenoid valves, a fixed pressure regulator,

and a proportional valve.

Start gas (Nitrogen) and cut gas (Oxygen) are both

supplied to the plumbing box, where they are

applied to the inlets of the solenoid valves. Only

one of these two valves will be open at a time. The

outlet of the two valves are manifolded together

then fed into the fixed pressure regulator. This

regulator sets the incoming line pressure to the

proportional valve at a value within the range of the

valve. The proportional valve is controlled by a

voltage signal from the CNC, and sets the flow rate

of gas based on the status of the plasma cutting

cycle. A pressure switch monitors line pressure

into the fixed pressure regulator, and provides an

input into the CNC. The CNC can then shut down

the process if gas pressure drops below a preset

threshold. A pressure gauge displays actual gas

pressure supplied to the torch by tapping off of the

output manifold. This important indication provides

visual feedback to the operator, and can be helpful

in spotting torch problems.

Page 26 Maintenance

Page 35

SmartFlow Plasma System

The illustration below shows the location of gas

control components in the plumbing box, and

indicates the gas flow path through those

components.

Gas Control

Components

The diagram below shows a schematic of the gas

control system.

Gas

Control

Diagram

Maintenance Page 27

Page 36

Section 6

6.2.2 Cut Water Control

Control of cut water is accomplished with a

solenoid valve and a proportional valve.

Deionized cut water is supplied to the plumbing box

and applied to the inlet of the solenoid valve. The

outlet of the valve is fed into the proportional valve,

and is also monitored by a pressure switch. The

proportional valve is controlled by a voltage signal

from the CNC, and sets the flow rate of water

based on the status of the plasma cutting cycle.

The pressure switch monitors line pressure into the

proportional valve, and provides an input into the

CNC. The CNC can then shut down the process if

water pressure drops below a preset threshold.

Page 28 Maintenance

Page 37

SmartFlow Plasma System

The illustration below shows the location of water

control components in the plumbing box, and

indicates the water flow path through those

components.

Water Control

Components

The diagram below shows a schematic of the water

control system.

Water Control Diagram

Maintenance Page 29

Page 38

Section 6

6.2.3 Secondary Shield Gas Control

The SmartFlow Plumbing Box is designed to

support both the PT-15XL and PT-19XL torches.

Since the PT-19XL is a dry torch, meaning it does

not use cut water, the cut water control

components can be used to control the secondary

shield gas. An additional hose connection is

installed on the rear of the plumbing box in place of

the options cover, to connect the controlled shield

gas to the secondary shield.

Control of secondary shield gas is accomplished

with a solenoid valve and a proportional valve.

Shield gas is supplied to the plumbing box through

a pressure regulator, then applied to the inlet of the

solenoid valve. The outlet of the valve is fed into

the proportional valve, and is also monitored by a

pressure switch. The proportional valve is

controlled by a voltage signal from the CNC, and

sets the flow rate of shield gas based on the sta tus

of the plasma cutting cycle. The pressure switch

monitors line pressure into the proportional valve,

and provides an input into the CNC. The CNC can

then shut down the process if gas pressure drops

below a preset threshold.

Page 30 Maintenance

Page 39

SmartFlow Plasma System

The illustration below shows the location of

secondary shield gas control components in the

plumbing box, and indicates the gas flow path

through those components.

Secondary Shield

Gas Control

Components

The diagram below shows a schematic of the

secondary shield gas control system.

Secondary Shield

Gas Control Diagram

Maintenance Page 31

Page 40

Section 6

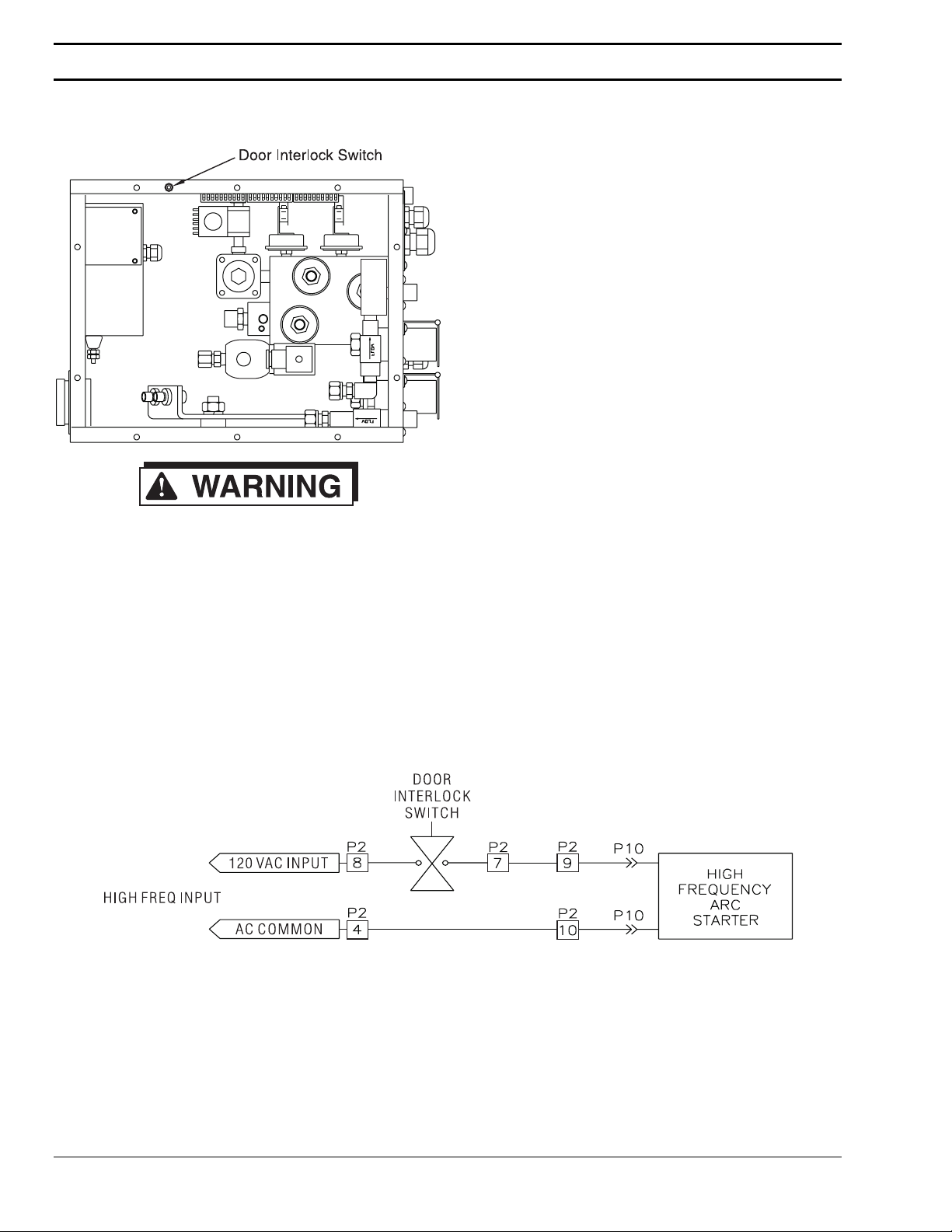

6.2.4 Cooling Water Circuit

The cooling water circuit consists of two reverse

flow check valves and a flow switch.

The cooling water circuit is a closed loop

recirculating system which cools the electrode and

torch body of the PT-15XL, or cools the electrode,

nozzle, nozzle retaining cup, and torch body of the

PT-19XL. The primary concern of the cooling water

system is the flow rate. Insufficient cooling water

flow results in insufficient cooling of the electrode

and/or nozzle. The result can be catastrophic

damage to the consumables and torch body. The

reverse flow check valves prevent the cooling water

system from draining when the consumables are

removed, and prevent the system from functioning

if the cooling water hoses are connected improperly

The flow switch is calibrated to close at or above a

flow rate of 1.0 gallons per minute, and is located in

the cooling water return line so that it indicates

actual flow through the torch. The switch is wired

as an input to the CNC so that the system can be

shut down if cooling water flow falls below this

threshold.

Page 32 Maintenance

Page 41

SmartFlow Plasma System

The illustration below shows the location of the

cooling water circuit components in the plumbing

box, and indicates the cooling water flow path

through those components.

Cooling Water Circuit

Components

The diagram below shows a schematic of the

cooling water circuit.

Cooling Water Circuit Diagram

Maintenance Page 33

Page 42

Section 6

6.3 Maintenance Procedures

6.3.1 Introduction

6.3.2 Gas Pressure Switch

The following section contains maintenance

procedures for many of the systems and devices

used in the SmartFlow Plumbing Box. These

procedures are for use by qualified maintenance

personnel. These procedures are intended to give

sufficient detail to allow maintenance personnel to

maintain the system.

Electrical Shock Can Kill You! Always turn

off power to the plasma power supplies

before opening or servicing the plasma

plumbing box.

The gas pressure switch monitors the pressure of

plasma gas supply to the plumbing box. The

switch is wired as an input to the numerical control.

Logic codes in the control look for a change of

state of the input signal, therefore the switch can

not be jumpered out of the circuit. The gas

pressure switch should be set to close at 50 PSI.

Page 34 Maintenance

Page 43

SmartFlow Plasma System

To adjust the gas pressure switch:

1. Switch OFF all power to the Plasma Power

Supply.

Electrical Shock Can Kill You! Always turn

off power to the plasma power supplies

before opening or servicing the plasma

plumbing box.

2. Set a voltmeter to read 24 Volts DC. Install the

volt meter across the terminals of the gas

pressure switch, or across P3 plug, term inals 7

and 10. Refer to the schematics in this section.

The voltmeter should read 24 Volts DC when

the switch is open, 0 Volts when the switch is

closed.

3. Turn ON the Plasma Test Mode. The start gas

solenoid valve will open allowing start gas to

preflow through the torch.

4. Observe the pressure at the nitrogen supply

regulator on the plasma regulator panel.

5. Adjust the nitrogen pressure regulator until the

gauge reads 40 PSI. The pressure switch

should be open.

6. Slowly turn in the nitrogen pressure regulator

until the gauge reads 50 PSI. The switch

should close at 50 PSI.

7. Adjust the thumbwheel on the pressure switch

as necessary to make the switch close at 50

PSI.

8. Turn OFF the Plasma Test Mode.

9. Remove the volt meter from the plumbing box.

10.Readjust the nitrogen pressure regula tor to 100

PSI.

Maintenance Page 35

Page 44

Section 6

6.3.3 Water Pressure Switch

The water pressure switch monitors the pressure of

the plasma cut water supply to the plumbing box.

The switch is wired as an input to the numerical

control. Logic codes in the control look for a

change of state of the input signal, therefore the

switch can not be jumpered out of the circuit. The

water pressure switch should be set to cl ose at 50

PSI.

To adjust the gas pressure switch:

1. Switch OFF all power to the Plasma Power

Supply.

Electrical Shock Can Kill You! Always turn

off power to the plasma power supplies

before opening or servicing the plasma

plumbing box.

2. Set a voltmeter to read 24 Volts DC. Install the

volt meter across the terminals of the gas

pressure switch, or across P3 plug, term inals 8

and 10. Refer to the schematics in this section.

The voltmeter should read 24 Volts DC when

the switch is open, 0 Volts when the switch is

closed.

3. Turn ON the Plasma Test Mode. The cut water

solenoid valve will open allowing cut water to

preflow through the torch.

Page 36 Maintenance

Page 45

6.3.4 Gas Regulator

SmartFlow Plasma System

4. Adjust the cut water pump pressure down to 40

PSI. The pressure switch should be closed.

5. Slowly increase the cut water pump pressure to

50 PSI. The switch should close at 50 PSI.

6. Adjust the thumbwheel on the pressure switch

as necessary to make the switch close at 50

PSI.

7. Turn OFF the Plasma Test Mode.

8. Remove the volt meter from the plumbing box.

9. Readjust the cut water pump pressure regulator

to 120 PSI.

The gas regulator is mounted to the output of the

manifold assembly. It regulates the gas pressure

input to the gas proportional valve. This ensures

accurate gas delivery since the proportional valve

always receives the same input pressure. The

proportional valve is rated for inputs up to 90 PSI.

Therefore, the gas regulator is adjusted to deliver

80 PSI. This regulator is factory preset and should

not be adjusted in the field, unless the regulator

must be replaced.

To set the gas regulator pressure, the plum bing box

gas output must be restricted. Use the torch

nozzle with the smallest available orifice size.

Partially plug the orifice if necessary so that only a

small amount of gas will leak. Turn out the

pressure adjusting screw on the regulator. Turn on

the cut gas and slowly turn in the pressure

adjusting screw on the regulator. Adjust the

regulator until a pressure of 80 PSI is achieved on

the plumbing box pressure gauge. Replace the

torch nozzle.

Maintenance Page 37

Page 46

Section 6

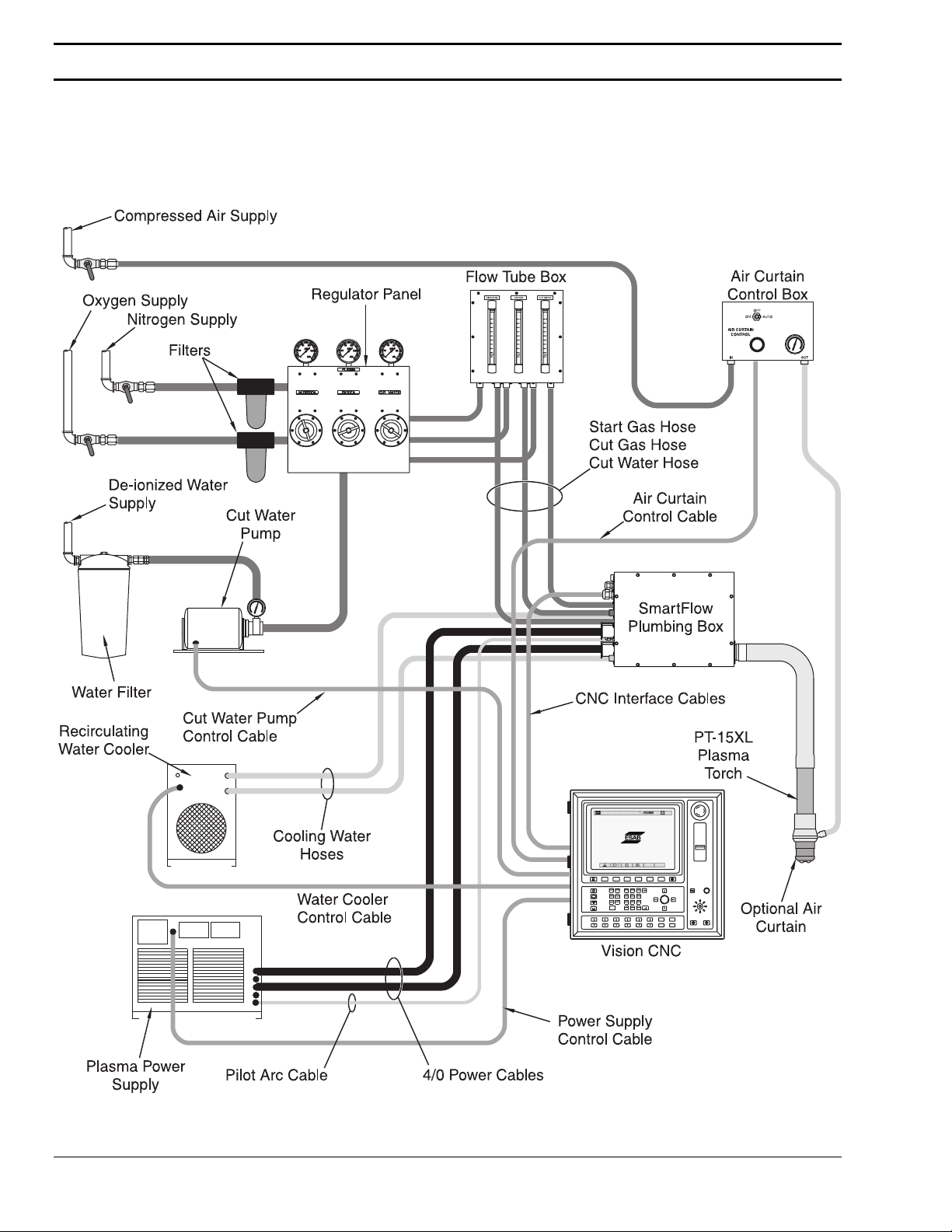

6.3.5 Interlock Switch

The Door Interlock Switch is mounted to the top of

the plumbing box, and is positioned to actuate

when the cover is installed. This switch has three

positions: open, closed, and defeated. When the

plumbing box cover is installed, it depresses the

switch plunger, closing the switch. When the

plumbing box cover is removed, the plunger is

released, and the switch returns to the open

position. The plunger may also be manually pulled

out, where it locks in the defeated position. In this

position the switch contacts are closed. The

defeated position should only be used during

service by qualified technicians.

Electrical Shock Can Kill You! The Door

Interlock Switch should only be defeated

by a qualified service technician. High

Voltage, High Frequency .electricity can be

generated when the Door Interlock Switch

is defeated.

The Door Interlock Switch is wired in series with the

High Frequency Arc Starter, as shown below.

When the switch is open, the 120 VAC input to the

arc starter is disconnected. When the switch is

either closed or defeated, the arc starter will

generate high frequency when the 120 VAC input is

supplied.

Page 38 Maintenance

Page 47

Spark Gap

SmartFlow Plasma System

The SmartFlow plumbing box uses a high

frequency arc starter to initiate the plasma arc

within the cutting torch. The arc starter box is

mounted in the upper left hand corner of the

plumbing box, and contains an adjustable spark

gap.

The spark gap forms one component of an L-C

tank circuit. A capacitor discharges across the

spark gap to create a high frequency signal which is

then coupled to the torch nozzle through the pilot

arc cable.

The spark gap setting is a compromise between

reliable firing and high frequency electrical noise.

As the spark gap setting is increased, more energy

is coupled to the torch, which results in more

reliable firing, and creates more high frequency

noise. As the spark gap setting is decreased, less

electrical noise is generated, but a point may be

reached where the torch will not fire reliably. The

spark gap in the SmartFlow plumbing box should

be adjusted to .060 inches.

Adjustment Procedure

Electrical Shock Can Kill You! Always turn

off power to the plasma power supplies

before opening or servicing the plasma

plumbing box.

1. Remove the cover from the plumbing box.

2. Remove the cover from the arc starter box.

3. Use a feeler gauge to measure the spark gap

setting.

4. If adjustment is required, loosen the locknut on

one of the spark gap electrodes.

5. Turn the hex head on the electrode as

necessary to increase or decrease the spark

gap, then lock in place with the lock nut.

Maintenance Page 39

Page 48

Section 6

6.3.6 Cut Water Pressure

The cut water system uses a carbonator pump with

bypass type pressure regulation to supply high

pressure water to the plumbing box. This pump

requires at least 25 PSI input to prevent cavitating,

and should be adjusted to deliver 120 PSI output.

Output pressure is adjusted by turning the pressure

adjusting screw on the pump body, which is

located beneath an acorn nut.

Adjustment Procedure

1. Remove the acorn nut with an adjustable

wrench.

2. Turn ON the Plasma Test Mode. The cut water

pump will energize, and the cut water solenoid

will open, allowing cut water to preflow through

the torch.

3. Using a screwdriver, turn the pressure adjusting

screw until the pressure gauge reads 120 PSI.

4. Reinstall the acorn nut, then recheck the

pressure setting.

5. Turn OFF the Plasma Test Mode.

Page 40 Maintenance

Page 49

6.3.7 Gas Filters

SmartFlow Plasma System

The nitrogen and oxygen gas supplies must be

filtered before entering the plumbing box. When

using a PT-19XL with secondary shield, the air

supply must also be filtered. Check these filters

regularly and replace the filter element when

necessary. Unfiltered gas supplied to the plumbing

box will result in clogging of the proportional valves

or other plumbing box components.

The gas filters should be installed in the gas supply

lines prior to the Gas Regulator Panel, as shown

below. Use a 5 micron filter.

6.3.8 Gas Proportional Valve

The gas proportional valve controls the flow of gas

to the plasma torch. The same valve is used to

regulate both start gas and cut gas. The Vision

CNC outputs an analog DC voltage signal between

0 and 10 volts representing the desired gas flow

rate. The proportional valve is fully open for a signal

of 10 volts, fully closed at 0 volts.

The gas proportional valve contains no user

servicable parts. In case of failure, the valve should

be replaced or returned to ESAB for repair.

Maintenance Page 41

Page 50

Section 6

6.3.9 Water Proportional Valve

6.3.10 Cooling Water Flow Switch

When the SmartFlow plumbing box is used with a

PT-15XL torch, the water proportional valve

controls the flow of cut water. When the

SmartFlow plumbing box is used in conjunction

with a PT-19XL torch, the water proportional valve

may be used ton control shield air. The Vision CNC

outputs an analog DC voltage signal between 0 and

10 volts representing the desired water flow rate.

The proportional valve is fully open for a signal of 10

volts, fully closed at 0 volts.

The water proportional valve contains no user

servicable parts. In case of failure, the valve should

be replaced or returned to ESAB for repair.

The cooling water circuit uses a 1.0 gallon per

minute flow switch to monitor cooling water flow.

This flow switch is located in the cooling water

return line, so that it indicates actual flow through

the torch. The flow switch is wired as an input to

the numerical, which looks for a change of state of

the input signal when the plasma station is turned

on. Therefore the switch input cannot be jumpered

out of the circuit.

Cooling water flow problems may fall into one of the

following categories:

1. Insufficient flow due to a restriction in the

cooling water circuit.

If a cooling water flow restriction is traced to the

flow switch, the switch may be disassembled

and cleaned, or it may be replaced.

2. Sufficient flow but no flow switch closure.

If measurement of the actual cooling water flow

rate indicates more than 1.0 gallons per minute,

but the flow switch does not close, then the

switch may be damaged or clogged. If

disassembly and cleaning does not remedy the

situation, then the switch must be replaced.

Page 42 Maintenance

Page 51

6.4 Schematics

SmartFlow Plasma System

The schematic below shows the electrical

connections internal to the flow control box. The

schematics are based on the three plug in

connectors, located in the top of the box. All of the

electrical components are wired to those

connectors, where they connect to interface cables

from the CNC.

Maintenance Page 43

Page 52

Section 6

P1 Wiring

Page 44 Maintenance

Page 53

SmartFlow Plasma System

P2 Wiring

Maintenance Page 45

Page 54

Section 6

P3 Wiring

Page 46 Maintenance

Page 55

6.5 Troubleshooting

SmartFlow Plasma System

The following error messages are associated with

the SmartFlow Plasma System, and will appear on

screen at the Vision CNC.

PLASMA STATION n CUT WATER PRESSURE

PLASMA STATION n CUT GAS PRESSURE

This error is generated if the Cut Water Pressure

switch input is in the wrong state. When controlling

a PT-19XL torch’s secondary shield, the Cut Water

Pressure switch monitors shield air pressure.

The CNC watches this input for a change of state,

from the off condition to the on condition when the

cut water solenoid valve is energized. An error is

generated if the input is on when it should be off, or

if the input is off when it should be on.

If this error message appears, check the following:

1. Check the cut water pump, it should be

adjusted to deliver 120 PSI when pumping.

2. Check the appropriate BITI at the Vision CNC.

It should turn on and off with the cut water.

This error is generated if the Cut Gas Pressure

switch input is in the wrong state. This pressure

switch is actuated by start gas during the start ga s

sequence, then by cut gas during cutting.

The CNC watches this input for a change of state,

from the off condition to the on condition when one

of the gas solenoid valves is energized. An error is

generated if the input is on when it should be off, or

if the input is off when it should be on.

If this error message appears, check the following:

1. Check the Nitrogen and Oxygen supply

pressures at the regulator panel. They should

be adjusted to deliver 120 PSI to the plumbing

box.

2. Check the appropriate EPEP at the Vision CNC.

It should turn on and off with the gas flow.

Maintenance Page 47

Page 56

Section 6

PLASMA STATION n COOLING WATER FLOW

PLASMA STATION n DID NOT FIRE

This error is generated when the Cooling Water

Flow Switch input is in the wrong state. The

Cooling Water Flow Switch is in the return line of

the cooling water circuit, and is calibrated to close

at or above 1.0 gallons per minute of flow.

The CNC watches this input for a change of state

from the off condition to the on condition when the

plasma station is turned on. An error is generated if

the input is on when it should be off, or if the input

is off when it should be on.

If this error message appears, check the following:

1. Make sure the Water Cooler is turned on.

2. Check the cooling water recirculator pump. It

should be adjusted to deliver 150 PSI.

3. Check the plasma consumables.

This error is generated all inputs from the plumbing

box are correct, but the torch still does not fire.

The CNC monitors the Arc On input from the

plasma power supply to determine if the arc has

transferred. If the CNC completes a firing

sequence, including energizing the high freq. arc

starter, but does not receive an Arc On input, then

this message is generated.

If this error message appears, check the following:

1. Check the torch consumables for wear or

damage.

2. Open the spark gap cover on the High Freq.

Arc Starter and observe the spark gap while

firing the torch. Verify that a spark is being

generated in the spark gap. Make sure that the

interlock switch in the plumbing box is pulled

out, in the bypass position.

Page 48 Maintenance

Page 57

7 Replacement Parts

7.1 General Information

SmartFlow Plasma System

This section provides replacement parts information

and will assist the service/repair person when

performing maintenance on the system.

The four column parts list for each figure is

arranged to show the assembly relationship of parts

and subassemblies. Information given in each of

these columns is as follows:

Column 1, ITEM: Lists each index number found

on the illustration. When no index number is given

for a part or assembly, it is not illustrated separately

in the illustration, but its name and description

provide identification.

Column 2, PART #: Gives the ESAB part number

of the part or assembly to which the index number

has been assigned. Common hardware items or

other parts readily available for commercial sources

have not been included. Parts purchased by ESAB

from vendors are listed by ESAB part numbers.

Hardware is specified as items in our parts lists but

it normally carries no ESAB part number.

Column 3, QUANTITY: Indicates the quantity of

that part used in that assembly. This quantity

number is not to be used as a recommended

quantity of spare parts. The customer must

determined how many parts are to be purchased

as spare parts.

Column 4, DESCRIPTION: Gives the nam e of the

part or assembly, as well as other information which

will be helpful in identifying it.

Replacement Parts Page 49

Page 58

Section 7

7.2 Ordering Information

When ordering replacement parts, order by part

number and complete description of the part as

given in the description column of the list. In

addition, give the model number of the machine

and the machine serial number. Address all

inquiries to your local ESAB Distributor or to ESAB

Cutting Systems, P.O. Box 100545, Florence,

South Carolina, 29501.

This manual may contain illustrations of parts not

applicable to your specific system. Be sure to

positively identify the correct assembly before

ordering replacement parts to avoid unnecessary

delays.

Page 50 Replacement Parts

Page 59

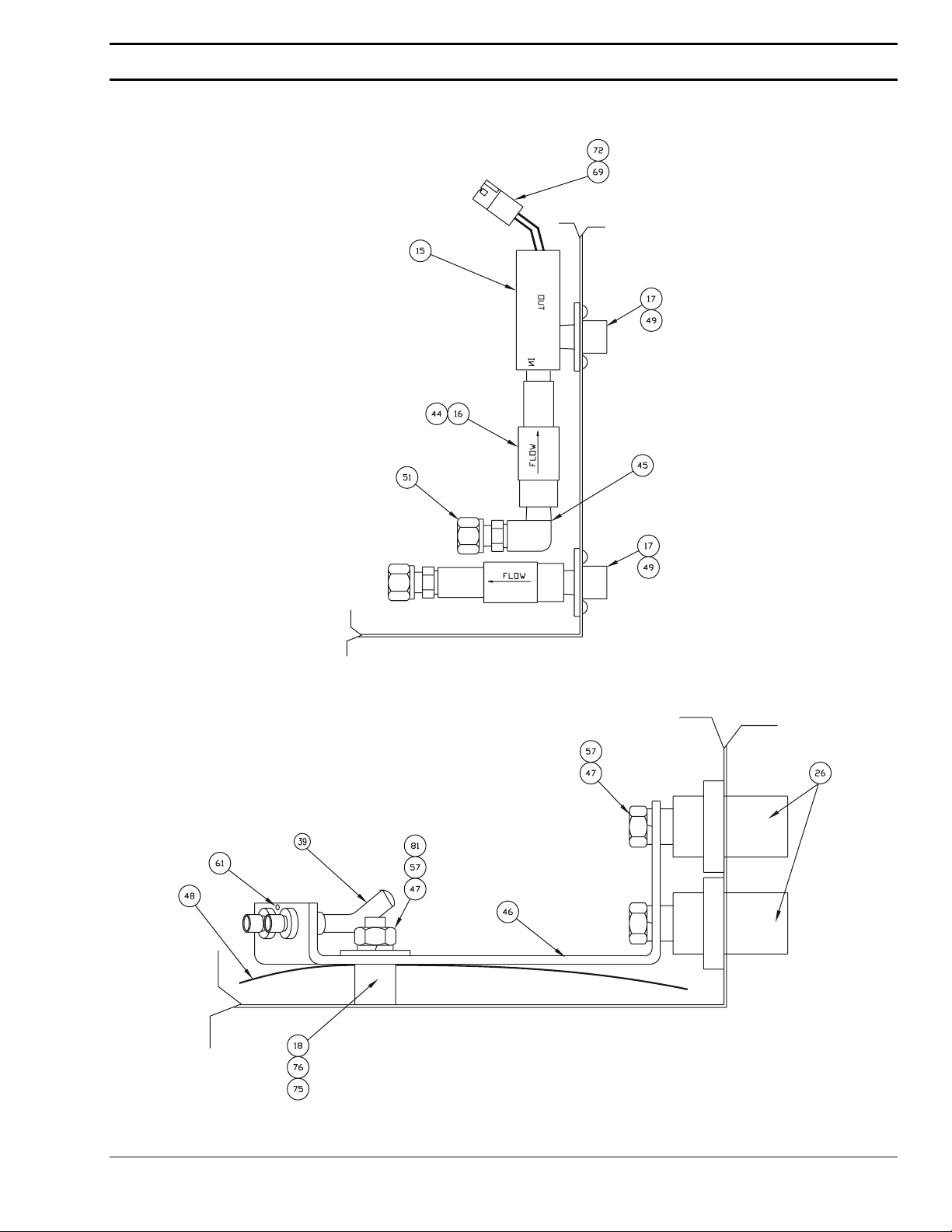

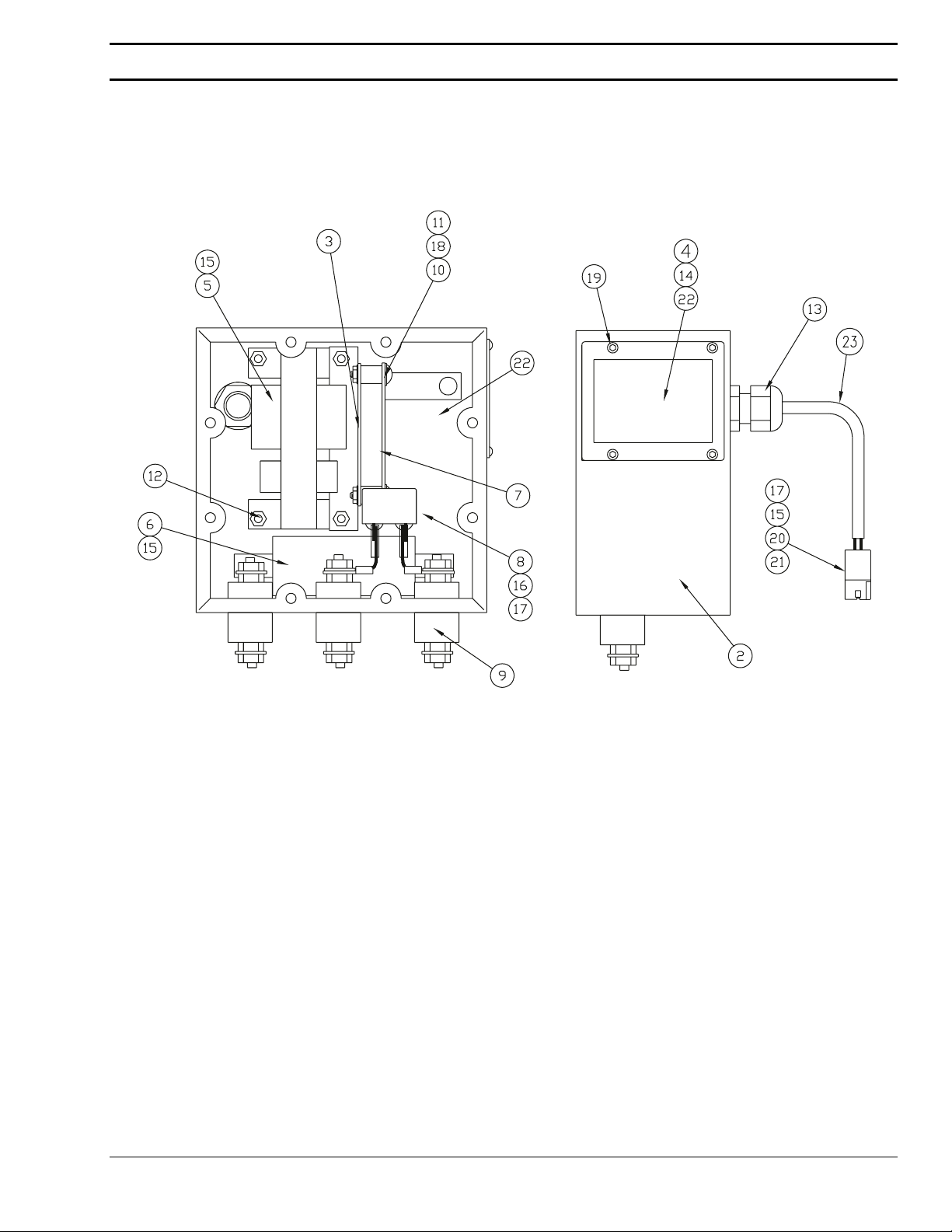

7.3 SmartFlow Plasma Flow Control

SmartFlow Plasma System

Replacement Parts Page 51

Page 60

Section 7

Valve and Pressure Switch Assembly

Connector Assembly

Page 52 Replacement Parts

Page 61

Cooling Water Connections

SmartFlow Plasma System

Buss Bar Connections

Replacement Parts Page 53

Page 62

Section 7

Front Panel Assembly

Item Part # Qty Description

1 Flow Control Assembly

2 56997191 1 Enclosure

3 56997190 1 Cover

4 56998131 1 Pressure Gauge, 0-100 PSI, 2” Dia

5 56998130 1 Regulator, 0-160 PSI, 1/8 NPT

6 33053 1 Torch Connector

7 56998134 3 Solenoid Valve

8 11NZ04 1 Fitting, 1/4 x 1/4 NPTM

9 56997206 1 Exhaust Muffler, 1/8 NPT

10 2078865 1 Door Interlock Switch

11 56997189 1 Manifold Block

12 951982 2 Pressure Switch, 150 PSI

13 56997044 1 Proportional Valve, Cut Water/Shield gas

14 56995748 1 Proportional Valve, Gas

Page 54 Replacement Parts

Page 63

SmartFlow Plasma System

15 636383 1 Cooling Water Flow Switch

16 21124 2 Check Valve

17 58V75 2 Bulkhead Fitting

18 674156 1 Bussbar Standoff

19 98W18 1 O-ring

20 44151300 1 Coupling, 1/8 NPT

21 2062311 2 Safety Cap

22 2 Screw, 6-32x3/16, button hd

23 2234268 1 DIN Rail

24 2234266 3 Connector Socket, 10 Position

25 2234267 3 Connector Plug, 10 Position

26 2062309 2 Male CamLok Receptacle

27 8 Screw, M5-.8x20 Button hd

28 12 Hex Nut, M5-.8 self lock

29 12 Screw, M4-.7x10mm button hd

30 56997186 1 Gas Manifold

31 2 Screw, M6-1x30mm socket hd

32 4 Screw, M6-1x16mm button hd

33 56997187 1 Service Entrance Plate

34 2 Strain Relief

35 2 Strain Relief

36 56997185 1 Blanking Cover

37 2234503 A/R Gasket, EPDM PSA, 3/4 x .90

38 20 Screw, M5-.8x10mm button hd

39 34116 2 Cooling Water Hose Assembly

40 2 Close Nipple, 1/8 NPT Brass

41 2 Elbow, 1/8 NPTM x 1/8 Tube

42 2 Hex Plug, 1/8 NPT

44 1 Nipple, 1/4 NPT x 1-1/2 Brass

45 1 Street Elbow, 1/4 NPTM x 1/4 NPTF Brass

46 56997188 1 Bussbar Assembly

47 3 Hex Nut, 1/2-13

48 33039 1 Nomex Insulator

49 2 Screw, M4-.7 x8mm button hd

50 2 Hex Nut, M4-.7, self locking

51 10Z30 3 Cooling Water Fitting

52 1 Brass Fitting, 1/4 NPTM x 3/8 Tube

53 1 Brass Fitting, 1/8 NPTM x 3/8 Tube, 90

54 1 Fitting, 1/8 NPTM x 1/8 Tube, prestolock

55 A/R Nylon Tubing, 1/8 O.D., Natural

Replacement Parts Page 55

Page 64

Section 7

56 01457226 A/R Copper Tubing, 3/8 O.D. x .308 I.D.

57 3 Split Washer, 1/2

58 84600513 A/R Nomex Sheet, 8.75W x 6.5L x 10 mil

59 1 Set Screw, 1/4-20 hex socket hd

60 2 End Bracket

61 1 Screw, 8-32x3/8 pan hd phillips

62 12 Washer, M4, internal tooth

63 56997180 1 Arc Starter Assembly

64 74S76 2 Start Gas Inlet Fitting

65 3389 1 Oxygen Inlet Fitting

66 11N16 1 Cut Water Inlet Fitting

67 2210514 3 R-C Network (Snubber)

68 4 Ring Terminal, #8 Stud 16AWG

69 4 Connector, 2 Position Plug

70 5 Connector, 2 Position Receptacle

71 10 Terminal Crimp Female, .093

72 8 Terminal Crimp Male, .093

73 2 Terminal Full Ins. Female, .25 18AWG

74 2 Terminal Full Ins. Female, .25 16AWG

75 2 Screw, 6-32 x 5/8 Pan Hd Phillips

76 2 Flat Washer

77 2 Crimp On Terminal /187 Female

79 A/R Wire, #18AWG, 600V, 105 Deg C

80 71200732 A/R DOW 732 RTV Clear Silicon

81 1 Flat Washer, 1/2

82 1 Adaptor Nipple, 1/4 NPT x 1/8 NPT

83 1 Fitting, 1/8 NPTF x 1/8 Tube Prestolok

84 38039 1 Voltage Divider Circuit Board

85 951570 4 Nylon Standoff, 6-32

86 2134208 4 Nylon Hex Nut, 6-32

87 75480012 1 Pressure Plug, 1/16 NPTM Brass

Page 56 Replacement Parts

Page 65

7.3.1 Arc Starter Box Assembly

Assembly 56997180

SmartFlow Plasma System

Replacement Parts Page 57

Page 66

Section 7

Item Part # Qty Description

1 56997180 High Frequency Arc Starter Assembly

2 56997179 1 Enclosure

3 56997178 1 PC Board Mounting Bracket

4 56997177 1 Access Cover

5 951179 1 Transformer

6 56997157 1 Choke

7 31490 1 High Frequency Circuit Board

8 2239157 1 Capacitor

9 3 High Voltage Feed Through

10 4 Unthreaded Spacer

11 4 Screw, 6-32x.75 pan hd

12 4 Hex Nut/Star Washer, 8-32

13 1 Strain Relief

14 A/R EDPM Gasket, 3/4 x .090

15 10 Full Insulated Terminal, .25 Female

16 2 Terminal, 1/4 ring, #18-14 AWG

17 A/R Wire, #18AWG 600V, black, 105º C.

18 5 Hex Nut/Star Washer, 6-32

19 4 Screw, M4-.7x8mm Button Hd

20 1 Connector Receptacle, 2 Position

21 2 Terminal Crimp .093 Fem #14-20AWG

22 1 Nomex Insulator, .10 Thick

23 90862534 A/R Fiberglass Tubing, .204 ID

Page 58 Replacement Parts

Page 67

7.3.2 Flow Tube Box Assembly

SmartFlow Plasma System

Replacement Parts Page 59

Page 68

Section 7

Item Part # Qty Description

1 56997181 1 Enclosure

2 56997182 1 Cover

3 12 Fitting, 1/4 NPTM x 3/8 Tube Gyrolock

4 58V58 2 Nitrogen Gas Bulkhead Fitting

5 679064 2 Oxygen Gas Bulkhead Fitting

6 58V75 2 Cut Water Bulkhead Fitting

7 821124 3 Check Valve

8 01457226 A/R Copper Tubing, .38 OD x .308 ID

9 21898 3 Flowmeter Body

10 996854 1 Cut Water Float Ball

11 3 Brass Fitting, 1/4 NPTM

12 A/R Teflon Tape

13 30 Screw, M4-.7x8mm Button Hd

14 6 Hex Nut, M4-.7, Nylon Self Lock

15 2132818 4 Hole Plug, .312, Nylon, Black

Page 60 Replacement Parts

Page 69

SmartFlow Plasma System

Replacement Parts Page 61

Page 70

F 14 - 129 8/97 Printed in USA

Loading...

Loading...