Appendix A

SCHEM.EPP-362,380/400/460V

05580011805-B

SCHEM.EPP-362,380/400/460V

05580011805-B

0558011730-A

0558011730-A

Appendix B

Isolated DC/DC

ISOLATIONISOLATION

CAN Bus #1 Driver

CAN Bus

Port #1 Signals

ISOLATIONISOLATION

Isolated DC/DC

CAN Bus #2 Driver

ISOLATIONISOLATION

CAN Bus

Second Power Supply Signals

ISOLATIONISOLATION

CAN Bus

Port #2 Signals

Relay Drivers

LED Indicators

Note:

Pin1-2: 24Vac

Pin4: +15Vac

Pin5: 15Vac CT

Pin6: -15Vac

Power Supply

++

++

++

Note: Originally, there were 2 3W

resistors, and they were replaced

with 8 1/4W SMT resistors. This

may not be enough.

++

++

++

++

++

++

++

++

Note: The MC7915 should have a

copper pour to help dissipate

heat. There may not be a

partitioned copper plane, but

the opposite side of the board

can be used for additional heat

sink area.

Note: The LM2576 should have a copper pour

to improve heat dissipation. That pour should

be stiched to the ground plane.

++

Note:

This is a switching 24V regulator

for the isolated inputs. Clearances

must be maintained with respect to

the rest of the circuitry.

++

++

++

++++

++

++

Note: All current

transducers are oriented

in the positive direction

to minimize the load on

on the -15V supply.

Analog LDO voltage

regulator. The local

analog and digital

power planes are

seperated here.

Precision

Analog LDO

Current Sensor

Connector

Note:

Pin 5 on the plug

should have a jumper

connecting to pin 3

The cable shields

should be tied to pin 1.

Current Sensor Inputs:

Current Sensor 2000:1

360A/2000 = 180mA

Voltage Conversion

180mA * 6.6 Ohm = 1.188V

OpAmp Transfer Function

Output Margins

Nearly 15% at the bound-

aries leaving a 70% oper-

ating range.

Vout=

-5.6k/(2.7k+180)*Vin -

5.6k/(3.3k+1.2k)*Vref33+

(1+5.6k/(2.7k+180)+

5.6k/(3.3k+1.2k))*Vref165

TransferFunc(1.188V) = 0.4756V

TransferFunc(0.000V) = 2.7898V

The OpAmp biasing will introduce

some error into the signal

Chassis GND

Note:

Remove the B ports

when not feeding

into servo micro

Terminating

Resistor

Terminating

Resistor

Netbridge

Here

Note:

This is an analog supply

preload. It also provides

a 1.65V reference for the

inverting configuration.

Gain = [[0.57143,0.28562][0.28562,0.57143]]

Offset = [[0.468V][0.468V]]

Note:

Remove the B ports

when not feeding

into servo micro

Gain = 2.1277

Terminating Resistor

Gain = 0.5

LABEL PCB LAYOUT

0558954317

5

Appendix C

R118

R81

R81

22.0

22.0

0.25W

0.25W

R159

R159

10.0

10.0

0.25W

0.25W

R149

R149

22.0

22.0

0.25W

0.25W

R89

R89

22.0

22.0

0.25W

0.25W

R203

R203

10.0

10.0

0.25W

0.25W

R96

R96

22.0

22.0

0.25W

0.25W

R211

R211

10.0

10.0

0.25W

0.25W

C76

C76

68.0nF

68.0nF

R144

R144

22.0

22.0

0.25W

0.25W

R190

R190

10.0

10.0

0.25W

0.25W

R88

R88

22.0

22.0

0.25W

0.25W

R168

R168

10.0

10.0

0.25W

0.25W

R150

R150

22.0

22.0

0.25W

0.25W

R174

R174

10.0

10.0

0.25W

0.25W

R155

R155

22.0

22.0

0.25W

0.25W

R182

R182

10.0

10.0

0.25W

0.25W

C61

C61

68.0nF

68.0nF

R118

22.0

22.0

0.25W

0.25W

R160

R160

10.0

10.0

0.25W

0.25W

R126

R126

22.0

22.0

0.25W

0.25W

R198

R198

10.0

10.0

0.25W

0.25W

R128

R128

22.0

22.0

0.25W

0.25W

R204

R204

10.0

10.0

0.25W

0.25W

R135

R135

22.0

22.0

0.25W

0.25W

R212

R212

10.0

10.0

0.25W

0.25W

C53

C53

68.0nF

68.0nF

R117

R117

22.0

22.0

0.25W

0.25W

R125

R125

22.0

22.0

0.25W

0.25W

R127

R127

22.0

22.0

0.25W

0.25W

R136

R136

22.0

22.0

0.25W

0.25W

R99

R99

22.0

22.0

0.25W

0.25W

R106

R106

22.0

22.0

0.25W

0.25W

R107

R107

22.0

22.0

0.25W

0.25W

R114

R114

22.0

22.0

0.25W

0.25W

HVdd_24v0

HGND

1

3

6

U14

U14

VCC

GND

GND

IXDD630YI

IXDD630YI

OUT

EN

HVdd_9v00

HGND

TP19TP19

2

4

IN

5

C14

C14

1.00uF

1.00uF

R13

R13

33.0

33.0

0.1W

0.1W

R82

R82

R156

R186

R186

22.0

22.0

0.25W

0.25W

R157

R157

10.0

10.0

0.25W

0.25W

R87

R87

22.0

22.0

0.25W

0.25W

R166

R166

10.0

10.0

0.25W

0.25W

R200

R200

22.0

22.0

0.25W

0.25W

R172

R172

10.0

10.0

0.25W

0.25W

R213

R213

22.0

22.0

0.25W

0.25W

R180

R180

10.0

10.0

0.25W

0.25W

C63

C63

1.00uF

1.00uF

22.0

22.0

0.25W

0.25W

R158

R158

10.0

10.0

0.25W

0.25W

R169

R169

22.0

22.0

0.25W

0.25W

R196

R196

10.0

10.0

0.25W

0.25W

R90

R90

22.0

22.0

0.25W

0.25W

R202

R202

10.0

10.0

0.25W

0.25W

R95

R95

22.0

22.0

0.25W

0.25W

R210

R210

10.0

10.0

0.25W

0.25W

R156

22.0

22.0

0.25W

0.25W

R189

R189

10.0

10.0

0.25W

0.25W

R105

R105

22.0

22.0

0.25W

0.25W

R167

R167

10.0

10.0

0.25W

0.25W

R170

R170

22.0

22.0

0.25W

0.25W

R173

R173

10.0

10.0

0.25W

0.25W

R183

R183

22.0

22.0

0.25W

0.25W

R181

R181

10.0

10.0

0.25W

0.25W

HVdd_24v0

C65

C65

68.0nF

68.0nF

HGND

R197

R197

10.0

10.0

0.25W

0.25W

R100

R100

22.0

D7

HVdd_9v00

D8

HVdd_9v00

D9

HVdd_9v00

D10

D10

HVdd_9v00

R187

R187

10.0

10.0

0.25W

0.25W

R165

R165

10.0

10.0

0.25W

0.25W

R171

R171

10.0

10.0

0.25W

0.25W

R179

R179

10.0

10.0

0.25W

0.25W

22.0

0.25W

0.25W

TVS_20VD7TVS_20V

R188

R188

10.0

10.0

0.25W

0.25W

R199

R199

22.0

22.0

0.25W

0.25W

TVS_20VD8TVS_20V

R195

R195

10.0

10.0

0.25W

0.25W

R108

R108

22.0

22.0

0.25W

0.25W

TVS_20VD9TVS_20V

R201

R201

10.0

10.0

0.25W

0.25W

R113

R113

22.0

22.0

0.25W

0.25W

TVS_20V

TVS_20V

R209

R209

10.0

10.0

0.25W

0.25W

C73

C73

C55

C55

1.00uF

1.00uF

10uF

10uF

J8

J8

1

A1

2

A2

PHOENIX TERMINAL 2

PHOENIX TERMINAL 2

D D

J9

J9

1

A1

2

A2

PHOENIX TERMINAL 2

PHOENIX TERMINAL 2

J10

J10

1

A1

2

A2

PHOENIX TERMINAL 2

PHOENIX TERMINAL 2

C C

J11

J11

1

A1

2

A2

PHOENIX TERMINAL 2

PHOENIX TERMINAL 2

B B

Note:

Capacitor biasing

circuit, and supply

preloading.

HGND

R74

R74

10.0K

10.0K

0.1W

0.1W

MainPwmChannel

PwmEnable

U6

U6

IN3OUTA

ADJ/GND1OUTB

LM1086CS-ADJ

LM1086CS-ADJ

R12

R12

330

330

0.1W

0.1W

4

Note:

A CMOS isolator was

chosen to reduce

HGND

U15A

U15A

MC74AC14D

MC74AC14D

12

nMainPwmChannel

TP5TP5

TP4TP4

nMainPwmChannel

nRefPwmChannel

nFaultReset

nFault

HVdd_5v00

HGND

propagation delay,

and output jitter.

U1

U1

16

VCC2

14

OUTA

13

OUTB

12

OUTC

11

IND

10

EN2

15

GND2

9

GND2

ADUM2401CRWZ

ADUM2401CRWZ

ISOLATION

ISOLATION

LVdd_3v30

1

VCC1

3

INA

4

INB

5

INC

6

OUTD

7

EN1

2

GND1

8

GND1

LGND ALGND

14 7

HVdd_5v00

HVdd_24v0

R57

R57

10.0K

10.0K

0.1W

0.1W

MH1

TP6TP6

HGND

HVdd_5v00

2

4

+

+

R11

R11

HGND

120

120

0.1W

0.1W

C8

C8

100uF

100uF

HGND

C33

C33

1.00uF

1.00uF

TP16TP16

MH1

1

HOLE_0v330-0v156_PLATED

HOLE_0v330-0v156_PLATED

HGND

3

U7

U7

1

VCC

2

1Y

3

2Y

4

GND

SN65LVDS9637D

SN65LVDS9637D

U8

U8

1

VCC

2

R

3

D

4

GND

SN65LVDS179D

SN65LVDS179D

2

R21

R21

R28

R28

120

120

120

120

0.1W

0.1W

0.1W

8

1A

7

1B

6

2A

5

2B

8

A

7

B

5

Y

6

Z

0.1W

R29

R29

120

120

0.1W

0.1W

R23

R23

120

120

0.1W

0.1W

ALVdd_5v00

L2

47uHL247uH

Netbridge

Here

+

C43

+

C43

100uF

100uF

R320R32

0

ALGND

FASTON 1/4" TERMINAL

FASTON 1/4" TERMINAL

FASTON 1/4" TERMINAL

FASTON 1/4" TERMINAL

FASTON 1/4" TERMINAL

FASTON 1/4" TERMINAL

LVdd_3v30

J2

1

2

nMainPwm1N

nMainPwm1P

nRefPwm1P

nRefPwm1N

nFaultResetN

nFaultResetP

PWM_FAULTP

PWM_FAULTN

nPaIgbtP

nPaIgbtN

nMainPwm2N

nMainPwm2P

nRefPwm2P

nRefPwm2N

VarcP

VarcN

VbusP

VbusN

LGND

VOUT(-)

J4

J4

VWORK(+)

J6

J6

VBUS(-)

J7

J7

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

LGND

ALGND

C11

C11

1.00uF

1.00uF

R53

R53

R61

R61

2

1

2

1

2

1

G=[[4.3310E-4,-2.1648E-4][-2. 1648E-4,4.3310E-4]]

[VworkOut-VbusOut][VworkOut-V ArcOut]] =

G * [[VworkIn-VbusIn][VworkIn -VarcIn]]

100K

100K

0.25W

0.25W

R73

R73

100K

100K

0.25W

0.25W

R98

R98

100K

100K

0.25W

0.25W

100K

100K

0.25W

0.25W

R69

R69

100K

100K

0.25W

0.25W

R79

R79

100K

100K

0.25W

0.25W

ALVdd_5v00

TP9TP9

LVdd_3v30

TP10TP10

C56

C56

100nF

100nF

HVdd_5v00

HGND

R52

R52

100K

100K

0.25W

0.25W

R68

R68

100K

100K

0.25W

0.25W

R78

R78

100K

100K

0.25W

0.25W

LGND

TP11TP11

TP12TP12

ALVdd_5v00

R39

R39

2.70K

2.70K

0.1W

0.1W

R42

R42

2.70K

2.70K

C44

C44

0.1W

100nF

100nF

R34

R34

2.20K

2.20K

0.1W

0.1W

R15

R15

2.20K

2.20K

0.1W

0.1W

R55

R55

2.20K

2.20K

0.1W

0.1W

R43

R43

2.20K

2.20K

0.1W

0.1W

0.1W

8

2

7

1

8

2

7

1

ALVdd_5v00

3

+

VOCM

PD

-

6

ALGND

ALVdd_5v00

3

+

VOCM

PD

-

6

ALGND

U4

O-

VS+

O+

VS-

THS4521IDU4THS4521ID

U11

U11

O-

VS+

O+

VS-

THS4521ID

THS4521ID

R38

R38

10.0K

10.0K

0.1W

0.1W

R14

R14

10.0K

10.0K

0.1W

0.1W

R62

R62

10.0K

10.0K

0.1W

0.1W

R41

R41

10.0K

10.0K

0.1W

0.1W

5

4

5

4

C2

100nFC2100nF

R58

R58

100K

100K

0.25W

0.25W

R71

R71

100K

100K

0.25W

0.25W

R80

R80

100K

100K

0.25W

0.25W

ALVdd_5v00

ALGND

ALGND

R25

R25

2.20K

2.20K

0.1W

0.1W

R19

R19

2.20K

2.20K

0.1W

0.1W

R50

R50

2.20K

2.20K

0.1W

0.1W

R47

R47

2.20K

2.20K

0.1W

0.1W

ALGND

ALGND

ALGND

ALGND

ALGND

C39

C39

10.0nF

10.0nF

C13

C13

10.0nF

10.0nF

C54

C54

10.0nF

10.0nF

C41

C41

10.0nF

10.0nF

C22

C22

C35

C35

100nF

100nF

100nF

100nF

HVdd_5v00

R51

R51

C52

C52

221

221

10.0nF

10.0nF

0.1W

0.1W

TP13TP13

HGND

C59

C59

R67

R67

10.0nF

10.0nF

221

221

0.1W

0.1W

TP14TP14

HGND

HGND

C74

C74

10.0nF

10.0nF

HGND

R77

R77

221

221

0.1W

0.1W

TP15TP15

1

VDD1

2

VIN+

3

VINGND14GND2

ACPL-C784

ACPL-C784

1

VDD1

2

VIN+

3

VINGND14GND2

ACPL-C784

ACPL-C784

TP17TP17

HGND

ALGND

U10

U10

U13

U13

ISOLATION

ISOLATION

ISOLATION

ISOLATION

VDD2

VOUT+

VOUT-

VDD2

VOUT+

VOUT-

LVdd_3v30

LGND

ALVdd_5v00

8

7

6

5

ALVdd_5v00

8

7

6

5

C4

100nFC4100nF

RIBBON_26-PIN_IDC_HT_REFLOWJ2RIBBON_26-PIN_IDC_HT_REFLOW

R60

R60

100K

100K

0.25W

0.25W

R72

R72

100K

100K

0.25W

0.25W

R97

R97

100K

100K

0.25W

0.25W

1

R33

R33

120

120

0.1W

0.1W

R37

R37

VarcP

120

120

0.1W

0.1W

R24

R24

VarcN

120

120

0.1W

0.1W

R18

R18

120

120

0.1W

0.1W

R54

R54

120

120

0.1W

0.1W

R59

R59

VbusP

120

120

0.1W

0.1W

R49

R49

VbusN

120

120

0.1W

0.1W

R46

R46

120

120

0.1W

0.1W

HVdd_9v00

R56

R56

1.00

1.00

0.25W

0.25W

R63

R63

1.00

1.00

0.25W

0.25W

R65

R65

1.00

1.00

0.25W

0.25W

R70

R70

1.00

1.00

0.25W

0.25W

HVdd_9v00

TP7TP7

HVdd_9v00

C5

C5

R45

R45

+

+

220uF

220uF

1.00

1.00

0.25W

0.25W

C6

R40

R40

1.00

1.00

0.25W

0.25W

R36

R36

1.00

1.00

0.25W

0.25W

R27

R27

1.00

1.00

0.25W

0.25W

C6

220uF

220uF

C25

C25

220uF

220uF

C48

C48

220uF

220uF

C62

C62

220uF

220uF

+

+

+

+

+

+

+

+

HVdd_24v0

C64

C64

10uF

10uF

C28

C28

10uF

10uF

D3

C72

C69

C69

1.00uF

1.00uF

C15

C15

100nF

100nF

C46

C46

100nF

100nF

C72

C75

C75

C68

68.0nF

68.0nF

HGND

C49

C49

470nF

470nF

C27

C27

100nF

100nF

ALVdd_5v00

ALGND

C68

68.0nF

68.0nF

C23

C23

470nF

470nF

C32

C32

470nF

470nF

1.00uF

1.00uF

C38

C38

100nF

100nF

C45

C45

100nF

100nF

5

C71

C71

10uF

10uF

A A

C26

C26

100nF

100nF

LVdd_3v30

LGND

C70

C70

68.0nF

68.0nF

C30

C30

10.0uF

10.0uF

C1

470nFC1470nF

C67

C67

68.0nF

68.0nF

C24

C24

10.0uF

10.0uF

J5

J5

A1

A2

A3

PHOENIX HEADER 3

PHOENIX HEADER 3

1

2

3

D3

D_400V_3A_SMC

D_400V_3A_SMC

D2

D2

D_400V_3A_SMC

D_400V_3A_SMC

D5

D5

D_400V_3A_SMC

D_400V_3A_SMC

D6

D6

D_400V_3A_SMC

D_400V_3A_SMC

4

C58

C58

100nF

100nF

C17

C17

100nF

100nF

U12

U12

2

VIN

5

RT/SYNC

7

EN

4

GND

8

GND

LM22670TJ-ADJ

LM22670TJ-ADJ

U2

U2

2

VIN

5

RT/SYNC

7

EN

4

GND

8

GND

LM22670TJ-ADJ

LM22670TJ-ADJ

BOOT

BOOT

R66

C57

C57

10.0nF

10.0nF

MBRS360T3GD4MBRS360T3G

C16

C16

10.0nF

10.0nF

STPS5L60SD1STPS5L60S

R64

R64

1.00K

1.00K

0.1W

0.1W

R16

R16

1.00K

1.00K

0.1W

0.1W

R66

10.0K

10.0K

0.1W

0.1W

L3

33uHL333uH

R20

R20

6.80K

6.80K

0.1W

0.1W

L1

56uHL156uH

3

C66

C66

10.0uF

10.0uF

C34

C34

10.0uF

10.0uF

+

+

+

+

C60

C60

100uF

100uF

C20

C20

100uF

100uF

HVdd_24v0

HVdd_9v00

HGND

TP8TP8

+

C50

+

C50

100uF

100uF

TP18TP18

+

C7

+

C7

100uF

100uF

C51

C51

1.00uF

1.00uF

HVdd_24v0

C47

C47

47.0nF

47.0nF

HGND

1

VIN

GND2-V

U5

U5

+V

0V

ISOLATION

ISOLATION

MEV1D2412SC

MEV1D2412SC

J3

J3

A1

A2

PHOENIX HEADER 2

PHOENIX HEADER 2

7

6

5

R1

R1

4.70K

4.70K

0.25W

0.25W

R2

R2

4.70K

4.70K

0.25W

0.25W

1

2

TP3TP3

2

R4

R4

100

100

0.25W

0.25W

C12

C12

47.0nF

47.0nF

C21

C21

47.0nF

47.0nF

TP2TP2

R5

R5

100

100

0.25W

0.25W

U3

U3

8

VC

7

ANODE

VO1

6

C9

VO2

10.0uFC910.0uF

5

ISOLATION

ISOLATION

VE

ACPL-J313-500E

ACPL-J313-500E

C10

C10

10.0uF

10.0uF

TP1TP1

CATH

LVdd_3v30

LVdd_3v30

U9

U9

1

VCC

2

1Y

3

2Y

4

GND

SN65LVDS9637D

SN65LVDS9637D

1A

1B

2A

2B

Q1

1

NC1

2

2N3904Q12N3904

3

4

NC2

LGND

R8

R8

LGND

150

150

0.1W

0.1W

R22

R22

120

120

0.1W

0.1W

8

7

6

5

nPaIgbtP

nPaIgbtN

nMainPwm2P

nMainPwm2N

R31

R31

120

120

0.1W

0.1W

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

0558038381 A

D

0558038381 A

D

0558038381 A

D

Date: Sheet of

Date: Sheet of

Date: Sheet of

1

LVdd_3v30

LGND

C31

C31

100nF

100nF

1 1Monday, November 26, 2012

1 1Monday, November 26, 2012

1 1Monday, November 26, 2012

6

FB

3

1

SW

D4

6

FB

3

1

SW

D1

Appendix D

C

A

P1

1 TB7-1 BLU

2 J1-J RED

3

4 TB4-2 ORN

5 TS2-1 WHT

1 TB3-13 BLU

2 TB3-14 YEL

3 TB3-15 BRN

4 TB3-4 ORN

5 TB3-5 VIO

6 K5-7 VIO

1 PCB1 P8-3 WHT

2 PCB1 P8-4 BLK

3 PCB1 P8-1 WHT

4 PCB1 P8-2 BLK

P2

1 TB3-9 WHT

2

3 TB3-10 GRY

1 HS1/HS2 SHIELD

2 HS1-1/HS2-1 BLK

3 HS1-3/HS2-3 RED

PCB1 P9-5 RED

4 HS1-2 WHT

5 PCB1 P9-3 RED

6

7

8 HS2-2 ORN

PCB1

P3

P8

PCB1 P16-2

P9

BLK

P6

RIBBON CABLE

TO

RB1 (RELAY TERM BLK)

P12

RIBBON CABLE

TO

PCB2 J2 (DRIVER PCB)

P15

1 J2-1 WHT

2 J2-2 BRN

3 J2-3 GRN

B

B

B

B

B

B

P16

BLK

B

B

B

1 J3-1 RED

2 J3-2 BLK

PCB1 P8-4

3 J3-3 BRN

K4 (FRONT)

K5 (REAR)

B

J3 (FS1 CONNECTION)

RB1

PCB1

(CONTROL)

PCB2 (DRIVER)

RIBBON CABLE TO PCB1 P6

PL1

FL1

C

TB7

JUMPER (11-5 TO 11-6)

TB4

GND-3

D

D

PL1-2 VIO

TB2-7 BLU

K4-4 ORN

D

TB3-9 WHT

D

K2-B WHT

D

K1-B ORN

D

M1-2 BLU

D

FL1-2 RED

J1-D YEL

D

J1-C BLK

K4-8 BLK

J1-G GRY

RB1

1 2 3 4 5 6 7

B

C

8

C

TB7-2 ORN

J1-L ORN

TS1-1 (SP) ORN

PCB1 P1-4 ORN

K5-4 ORN

2

TB4

(11)

1

(14)

J1-K G/Y

GND-3 G/Y

TB3-12 WHT

(12)

GND-3

J1-H WHT

TB4-1 G/Y

D

RB1-2 (11) ORN

TB2-3 BRN

K5-A WHT

J1-E BLU

TB4-2 ORN

PCB1 P1-6 VIO

K4-A WHT

CB1-2 RED

K4

2

1

4

7

AB

3

5

6

8

9

TB3-10 GRY

K2-A VIO

D

K5-B YEL

TB3-6 YEL

RB1-6 (11) BLK

D

K5

2

1

4

7

AB

3

5

6

8

9

K4-B YEL

B

B

B

1

PCB1 P14-1 WHT

2

PCB1 P14-2 BRN

3

PCB1 P14-3 GRN

4

TRIM YEL

5

TRIM GRY

6

TRIM PNK

7

TRIM BLU

8

TRIM RED

PL1

1

2

ORN

TB3-17 VIO

RB1-4 (11) VIO

J2

PCB1 P1-1 BLU

LS1-1 WHT*

12

B

J1

C

B

TB7

TB4-2 ORN

LS1-2 WHT*

J1

TB3-16 ORN

B

J2

5

4

3

6

8

7

2

1

C

C

F

G

H

M

I

N

E

D

C

J

L

K

B

A

A

B

RB1-6 (14) BLK

C

RB1-5 (14) YEL

D

K4-A BLU

E

TB3-8 BRN

F

RB1-5 (11) GRY

G

TB4-1 WHT

H

I

J

PCB1 P1-6 RED

K

TB4-1 G/Y

TB4-2 ORN

L

M

N

C

TB3-1 BLK

TB3-2 RED

D

D

Q1-6 (SPLICE) RED

1

2

3

Q1-7 (SPLICE) WHT

RIBBON CABLE TO PCB1 J12

2

1

2

1

2

1

2

1

2

1

Q5-7 RED

Q5-6 BLK

ELECTRODE BLU

WORK WHT

NEG(-) BUS BRN

A

Q2-7 (SPLICE) WHT

Q2-6 (SPLICE) RED

Q3-6 (SPLICE) RED

Q3-7 (SPLICE) WHT

Q4-6 (SPLICE) RED

WIRING DIA EPP-362, 400-460V

Q4-7 (SPLICE) WHT

1

FL1

RB1-4 (14) RED

2

0558011841

SHEET 1 OF 6

D

F2-1 SPLICE RED X2

C

X4 T2-H5(SPLICE) RED

K5-4 ORN

D9

TS1

TS2-2 (SPLICE) VIO

PCB2 J8-2 (SPLICE) RED

PCB2 J8-1 (SPLICE) WHT

Q1 Q2

1

2

B

TOP VIEW

Q3 Q4

PCB2 J9-1 (SPICE) WHT

PCB2 J9-2 (SPICE) RED

L1-X1 (+)

COLLECTOR BUS

NEG (-) BUS

DIODE PLATE (-)

PCB2 J7 BRN

POS (+) BUS

DIODE PLATE (+)

PCB2 J11-1 (SPICE) WHT

PCB2 J11-2 (SPICE) RED

PCB2 J10-1 (SPICE) WHT

PCB2 J10-2 (SPICE) RED

C

A

A

F3-2 SPLICE BLK X1

L3

(CE UNIT ONLY)

X3 T2-H1 BLK

TB1

GND-1

TB1

(CE UNIT ONLY)

BLK L2-AH1

1

BLK L2-BH1

2

BLK L2-CH1

3

(ALL EXCEPT CE)

BLK K1-L1

1

BLK K1-L2

2

BLK K1-L3

3

*

*

*

TB1

F1

CB1

F2F3

ELECTRODE YEL

Q5-1 RED

WORK (4GA)

HS1

HS2

PCB1 P9-3 RED

PCB1 P9-4 WHT

PCB1 P9-2 BLK

3

2

1

HS1

CB1

TB3-11 BLK

K4-5 RED

1

2

GND-1

C

K2-L1 BLK

F3-2 BLK

T2-H1 (SPLICE) BLK

K2-L2 RED

(460V) T2-H6 (SPLICE) RED

C

(400V CE) L3-X2 (SPLICE) RED

(380V CCC) T2-H4 (SPLICE) RED

REAR WIRING VIEW

F1

BLU K1-L1

21

F2

GRY K1-L2

21

C

T2-H1(SPLICE) BLK (ALL EXCEPT CE)

C

L3-X1(SPLICE) BLK (CE UNIT ONLY)

C

F3

C

F1-1 BLK

M2-1 BRN

21

C

PCB1 P9-3 RED

PCB1 P9-8 ORN

PCB1 P9-2 BLK

3

2

1

HS2

WIRING DIA EPP-362, 400-460V

0558011841

SHEET 2 OF 6

TB3

T2 BRN *

PCB2 J5-3 RED

PCB2 J5-1 BLK

FLOW

T2 BLU *

PCB1 P3-5 VIO

PCB1 P3-4 ORN

J3-1 RED*

J3-2 BLK*

J3-3 BRN*

T2 BLU *

T2 BRN *

FS1

WORK (OUT) BLK

T2 ORN (BOT) *

K4-B YEL

T2 YEL *

1110987654321

J1-F BRN

K4-6 GRY

RB1-1 (11) WHT

PCB1 P2-1 WHT

PCB1 P2-3 GRY

B

TB5-1 WHT*

TB5-2 WHT*

T2 BLK *

T2 YEL *

T2 ORN (TOP) *

T2 RED *

T2 RED *

T2 BLK *

12

PCB1 P3-1 BLU

TB4-1 WHT

CB1-1 BLK

T2 VIO *

T2 RED/YEL *

PCB1 P3-3 BRN

PCB1 P3-2 YEL

FL1-1 ORN

LS1

B

T2 VIO *

181716151413

PL1-2 VIO

LS1

FS1

T2-H3 BLU

F3-1 BRN

GRN/YEL GND-4

C14

T2

K1

L2

K2

FN3

(380V CCC) F2-1 (SPLICE) RED

H4

H3

H2

H1

T2

TOP

VIEW

M2-4 BLU

(460V) F2-1 (SPLICE) RED

C

(400V CE) L3-X4 (SPLICE) RED

H7

H6

H5

F1-1 (SPLICE) BLK

(ALL EXCEPT CE)F3-2 BLK

(CE UNIT ONLY) L3-X3(SPLICE) BLK

RB1-1 (14) WHT

K1-L3 WHT

C

F2-1 RED

C

F1-1 BLK

L3

L2

L1

TOP

BOT

D

B

T3

K2

T2

T1

A

K4-9 VIO

D

TB3-11 BLK *

TB3-12 BLK *

TB3-1 BRN *

TB3-2 BRN *

TB3-8 ORN *

TB3-15 RED *

TB3-14 RED/YEL *

TB3-13 RED *

TB3-6 ORN *

TB3-9 YEL *

TB3-10 YEL *

TB3-5 BLU *

TB3-4 BLU *

TB3-17 VIO *

TB3-16 VIO *

R3-2 WHT

R2-2 RED

R1-2 BLK

PCB3

ELECTRODE (OUT) YEL

ELECTRODE OUT BLK

COLLECTOR BUS BLK

X1

L1

FRONT VIEW

X2

PA STUD

GND2

(ELECTRODE)

D9 ANODE YEL

L3-X2 BLK

PCB2 J4 BLU

R9-2 YEL

PCB3 J1 YEL

M2

TB1-1 *

4

1

TB1-2 *

TB1-3 *

AH1

BH1

CH1

AH2

BH2

CH2

L2

C

(CE UNIT ONLY) L2-AH2 BLK*

(ALL EXCEPT CE) TB1-1 BLK

F1-2 BLU

C

RB1-2(14) ORN

D

B

D

L1 L2 L3

K1

K1-L1 *

K1-L2 *

K1-L3 *

F2-2 GRY

(CE UNIT ONLY) L2-BH2 BLK*

(ALL EXCEPT CE) TB1-2 BLK

A

(CE UNIT ONLY)

K2-L3 WHT

(CE UNIT ONLY) L2-CH2 BLK*

(ALL EXCEPT CE) TB1-3 BLK

TB2-1 BRN

D

BRN*

FN3

RED*

(CE UNITS

BLK*

ONLY)

GRN/YEL*

T1 T2 T3

L1

T1

R1-1 BLK R2-1 RED

T1-CH1 BLK

C

C

T1-BH1 BLK

T1-AH1 BLK

R3-1 WHT

WIRING DIA EPP-362, 400-460V

C

0558011841

SHEET 3 OF 6

PCB2 J3-2 RED

PCB2 J3-1 BLK

67

C14 (+) RED

D7

Q5

3

2

Q5-2 RED

R4-1 RED

R7-2 YEL

POS (+) BUS BLK

D8

POS BUS RED

1

B

C14

Q5

RESISTOR ASSY

1

1

1

R1

R2

R3

2

2

2

K1-T1 BLK

K1-T2 RED

K1-T3 WHT

1

1

1

R1

R2

R3

2

2

2

BLK K2-T1

RED K2-T2

WHT K2-T3

FN2

FN5

D2 BLK SPLICE

D4 BLU SPLICE

D6 BRN SPLICE

D2, D4, D6 COMMON GRN/YEL

D2 BLK SPLICE

D4 BLU SPLICE

D6 BRN SPLICE

GND GRN/YEL

*

*

*

*

*

*

*

FN5

*

(CE UNIT ONLY)

FN2

D2 D1

T1A-X4 SPLICE (380V)

T1A-X2 SPLICE (460V)

D4

T1A-X3 SPLICE (400V)

T1B-X4 SPLICE (380V)

T1B-X2 SPLICE (460V)

T1B-X3 SPLICE (400V)

T1C-X4 SPLICE (380V)

T1C-X2 SPLICE (460V)

T1C-X3 SPLICE (400V)

T1C-X4 SPLICE (380V)

T1C-X2 SPLICE (460V)

T1C-X3 SPLICE (400V)

T1B-X4 SPLICE (380V)

T1B-X2 SPLICE (460V)

T1B-X3 SPLICE (400V)

T1A-X4 SPLICE (380V)

T1A-X2 SPLICE (460V)

T1A-X3 SPLICE (400V)

BLK NEG BUS

D1 BLK SPLICE

D3 BLU SPLICE

D5 BRN SPLICE

D1, D3, D5 COMMON GRN/YEL

*

*

*

FN1

*

D3

FN1

D1 BLK SPLICE

D3 BLU SPLICE

D5D6

FN4

D5 BRN SPLICE

GND GRN/YEL

(CE UNIT ONLY)

*

*

*

*

FN4

R8-2 YEL

WIRING DIA EPP-362, 400-460V

0558011841

SHEET 4 OF 6

M1-1 BLK

K1-A BRN

BLK (460 ONLY)

BLK (400CE ONLY)

BLK (380CCC ONLY)

1 2 3 4 5 6 7 8 9 10 11 12

BLK (460 ONLY)

BLK (400CE ONLY)

BLK (380CCC ONLY)

B

TB2

TB2

T1-AX5

T1-AX6

TB2-1 BLK

RB1-3 (14) BLU

T1-AX7

K4-7 BRN

D

T1-AX8

M1

1

2

T1-AX9

RB1-3(11) BLU

T1-AX10

T1-AX11

M1

TS2

B B

(WORK)

BLK POS(+) BUS

BLK R9-1

BLK PCB3 J2

WHT PCB2 J6

PA STUD

R7-1 BLK

PCB3 J3 WHT

GRN2 for PCB3

(CONNECTION MADE ON REAR OF BOARD)

(CONNECTION MADE ON REAR OF BOARD)

(CONNECTION MADE ON REAR OF BOARD)

PCB1 P1-7 WHT

1

TS2

2

TS3-2 (SPLICE) VIO

C14 (+) RED

YEL NEG (-) DIODE PLATE

YEL ELECTRODE (OUT)

YEL YEL

YEL

C14 (-) YEL

22

2

R4

B

1

RED

21

2

2

R5

R6

R7

PA STUD BLK

1

1

R8

R9

1

BLK

BLK

1

WORK (+) BLK

WIRING DIA EPP-362, 400-460V

SECTION B-B

SCALE 1 : 4

0558011841

SHEET 5 OF 6

CX1

(460 VAC VERSIONS) D4,D3 SPLICE BLK*

(400 VAC VERSIONS) D4,D3 SPLICE BLK*

(380 VAC VERSIONS) D4,D3 SPLICE BLK*

(460 VAC VERSIONS) D1,D6 SPLICE BLK*

(400 VAC VERSIONS) D1,D6 SPLICE BLK*

(380 VAC VERSIONS) D1,D6 SPLICE BLK*

CX2

CX3

CX4

BX1

BX2

BX3

BX4

AX1

AX2

BX3

AX5

AX6

AX7

AX8

AX9

AX10

AX11

AX4

TB2-1 *

TB2-2 *

TB2-4 *

TB2-5 *

TB2-6 *

TB2-8 *

TB2-9 *

D2,D5 SPLICE BLK * (400 VAC VERSIONS)

D2,D5 SPLICE BLK * (380 VAC VERSIONS)

D2,D5 SPLICE BLK * (460 VAC VERSIONS)

T1-BH2 BLK

K1-T1 BLK

T1-AH1 BLK

CH1

CH2

T1-AH2 BLK

K1-T2 BLK

MAIN TRANSFORMER

BH1

T1

BH2

AH1

T1-CH1 BLK

AH2

T1-BH1 BLK

T1-CH2 BLK

K1-T3 BLK

WIRING DIA EPP-362, 400-460V

0558011841

SHEET 6 OF 6

Source

Appendix E

Torch type input from the RAS box.

Ground

Thermal switch connection

PS Enable signal from the RAS box

Isolated Source

Control Transformer TB3-9

Control Transformer TB3-10

Power for Board

Control Transformer TB3-13

Control Transformer TB3-14

Control Transformer TB3-4

Control Transformer TB3-15

Control Transformer TB3-5

Display (used for testing)

Secondary Relay Block

Cut Gas solenoid relay signal

Start gas solenoid relay signal

Shield gas solenoid relay signal

Coolant flow OK signal to CNC

Coolant level OK signal to CNC

Comments

24 HVDC Digital Inputs

Coolant Level Signal from Level Sensor in the coolant tank.

Spare

Primary Relay Block

Power source fault signal to CNC

Main arc established signal to CNC

Main fan operation signal

Main contactor close signal

Fault Light operation signal

Bus Charger contactor close signal

Spare

Spare

00 - EPP 202

01 - EPP 362

Power supply MachineID

High Frequency Input to RAS box

Mark mode signal to RAS box for VDR ratio

Servo Micro Programming Header

Source

Source

Current Sensors

Chasis ground connection

Electrode Current From Hall Sensor 1

Spare

Not Used

Work Current from Hall Sensor 2

Main Micro Programming Header

Electrode Current From Hall Sensor 3 used for 540/720

Remote Mode Operation Input Signal

Test Box Connection (used for testing)

Spare

Spare

Spare

Trigger or Start or Arc ON Input Signal

Test Mode or Load Bank Mode Operation Input Signal

Main Arc Current Potentiometer Reference Input Signal

Display Version Information Input Signal

J1 (Mini Phoenix Connector)

EPP 202/362 CAN Control Board IO Type Main Micro Pin# Servo Micro Pin#

1. Coolant Level Input Digital Input 57 xx

2. Torch Type selection Digital Input 71 xx

3. 24 HVDC Source xx xx

4. HV GND Ground xx xx

5. Thermal Switch Input Digital Input 79 xx

6. PS Enable Signal Digital Input 80 xx

5. 24 VAC COM AC COMMON xx

J4 (Amp Connector)

1. 5 VDC xx xx

2. MTXSRX-RS232 51 xx

3. DGND xx xx

4. DispBUSY1 66 xx

5. MRXSTX-RS232 52 xx

6. DispResetOut 48 xx

J5 (Ribbon Cable Connector)

1. Cut Gas Relay Out Digital Output 98 xx

2. Start Gas Relay Out Digital Output 94 xx

3. Shield Gas Relay Out Digital Output 93 xx

4. Coolant Flow OK Relay Out Digital Output 92 xx

5. Coolant Level OK Relay Out Digital Output 91 xx

6. Main Arc Est. Relay Out Digital Output 56 xx

7. Power Source Fault Relay Out Digital Output 61 xx

8. ExtraRelaySignal3Output Digital Output 60 xx

9. 24 VDC Source xx xx Source

10. DGND Ground xx xx Ground

11. 24 VDC Source xx xx Source

12. DGND Ground xx xx Ground

13. 24 VDC Source xx xx Source

14. DGND Ground xx xx Ground

J6 (Ribbon Cable Connector)

1. Bus Charger Relay Out Digital Output 17 xx

2. Main Contactor Relay Out Digital Output 28 xx

3. Main Fan Relay Out Digital Output 5 xx

4. Fault Light Relay Out Digital Output 4 xx

5. Mark Mode Relay Out Digital Output 100 xx

6. HF Ignite Relay Out Digital Output 3 xx

7. ExtraRelaySignal2Output Digital Output 38 xx

8. ExtraRelaySignal1Output Digital Output 99 xx

9. 24VDC Source xx xx Source

10. DGND Ground xx xx Ground

11. 24VDC Source xx xx Source

12. DGND Ground xx xx Ground

13. 24VDC Source xx xx Source

J2 (Phoenix Connector)

1. 24 VAC Source xx xx

2. NC Not Connected xx xx

3. 24 VAC COM AC COMMON xx xx

J3 (Phoenix Connector)

1. 17 VAC Source xx

2. 17-0-17 VAC COM Center Tap xx

3. 17 VAC Source xx

4. 24 VAC Source xx

14. DGND Ground xx xx Ground

J7 (Amp Connector)

J8 (Mini Phoenix Connector)

1. nMCLR2 Programming xx 18

2. 3.3 VDC Soruce xx xx

3. DGND Ground xx xx

4. PGD2 Programming xx 34

5. PGC2 Programming xx 35

1. 3.3 VDC Source xx xx

2. MachineID_1 Input 68 xx

3. MachineID_2 Input 69 xx 10 - EPP540

4. DGND Ground xx xx 11 - EPP720

J9 (Phoenix Connector)

1. Mounting Hole_Chasis Ground xx xx

2. 15VDC Source xx xx

3. -15VDC Source xx xx

4. Electrode Current 1 Input xx 21

5. CurrentConnectorFlag Input 83 xx

6. Electrode Current 2 Input xx 25

7. I_Extra Input xx 26

8. Work Current Input xx 22

J10 (Amp Connector)

J11 (Ribbon Cable Connector)

1. nMCLR1 Programming 13 xx

2. 3.3 VDC Source xx xx

3. DGND Ground xx xx

4. PGD1 Programming 73 xx

5. PGC1 Programming 74 xx

1. SW_1A Digital Input 6 xx

2. SW_1B Digital Input 7 xx

3. SW_2A Digital Input 8 xx

4. SW_2B Digital Input 9 xx

5. Main Ref Pot Analog Input 35 xx

6. SW_3A Digital Input 42 xx

7. SW_3B Digital Input 43 xx

8. SW_4A Digital Input 49 xx

3. nGATED_MAIN_PWM1N

PWM Outputxx12

Inverted PWM1 Differential signal

4. nGATED_MAIN_PWM1P

PWM Outputxx12

Inverted PWM1 Differential signal

7. nPWM_FLT_RESET1N

Digital Output96xx

PWM Fault Reset Differential Output Signal

8. nPWM_FLT_RESET1P

Digital Output96xx

PWM Fault Reset Differential Output Signal

15. nGATED_MAIN_PWM3N

PWM Outputxx8

Inverted PWM3 Differential Signal

16. nGATED_MAIN_PWM3P

PWM Outputxx8

Inverted PWM3 Differential Signal

Source

Ground

Not Connected

Not Connected

CAN 1 Header

CAN 1 Reciever Signal

CAN 1 Transmit Signal

Display Hex Value Input Signal

Inverted PWM4 Differential Signal

Arc Voltage 2 Differential Input Signal

Arc Voltage 2 Differential Input Signal

Bus Voltage 2 Differential Input Signal

Bus Voltage 2 Differential Input Signal

Inverted PWM4 Differential Reference Signal

Inverted PWM4 Differential Reference Signal

CAN 2 Header

CAN 2 Receiver Signal

CAN 2 Transmit Signal

Isolated Ground not connected to DGND

Isolated ground not connected to DGND

Pilot Arc Current Potentiometer Reference Input Signal

Source

Ground

Flow Sensor Input

CAN 2 Receiver Signal

CAN 2 Transmit Signal

CAN 2 120 Ohm Termination Header

Isolated ground not connected to DGND

Operation)

Flow Sensor frequency signal for respective GPM

24 VDC Digital Inputs (Used for Analog Power Supply

box

Source

Ground

Preflow Input signal from CNC

Pilot Arc High or Low input signal from CNC

Mark Mode operation input signal from CNC

Trigger or Start or Arc ON signal from CNC

Gas flow switch input signal from the plumbing box

Current reference scaling signal 1 from the plumbing box or interface

87 xx

88 xx

90 xx

89 xx

90 xx

89 xx

9. SW_4B Digital Input 50 xx

10. Sec Pot Ref Analog Input 41 xx

11. DGND Ground xx xx Ground

12. DGND Ground xx xx Ground

13. DGND Ground xx xx Ground

14. DGND Ground xx xx Ground

15. 3.3VDC Source xx xx Source

16. DGND Ground xx xx Ground

17. DGND Ground xx xx Ground

18. DGND Ground xx xx Ground

19. DGND Ground xx xx Ground

J16 (Phoenix Connector)

26. NC Not Connected xx xx

J14 (Mini Phoenix Connector)

1. CAN1_H

2. CAN2_L

J12 (Ribbon Cable Connector) Primary Diver Board

20. 3.3VDC Source xx xx Source

1. Vdd_3v30 Source xx xx Source

2. GND Ground xx xx Ground

5. nGATED_REF_PWM1P PWM Ref Output xx 13 Inverted PWM1 Differential Reference Signal

6. nGATED_REF_PWM1N PWM Ref Output xx 13 Inverted PWM1 Differential Reference Signal

9. PWM_FAULT1P Digital Input 67 4 PWM Fault Differential Input Signal

10. PWM_FAULT1N Digital Input 67 4 PWM Fault Differential Input Signal

11. NC Not Connected xx xx Not Connected

12. GND Ground xx xx Ground

13. nGATED_PA_IGBT_1P PWM Output xx 35 Pilot Arc IGBT1 Inverted PWM Differential Signal

14. nGATED_PA_IGBT_1N PWM Output xx 35 Pilot Arc IGBT1 Inverted PWM Differential Signal

17. nGATED_REF_PWM3P PWM Ref Output xx 9 Inverted PWM3 Differential Reference Signal

18. nGATED_REF_PWM3N PWM Ref Output xx 9 Inverted PWM3 Differential Reference Signal

19. VARC1P Analog Input xx 24 Arc Voltage 1 Differential Input Signal

20. VARC1N Analog Input xx 24 Arc Voltage 1 Differential Input Signal

21. VBUS1P Analog Input xx 23 Bus Voltage 1 Differentail Input Signal

22. VBUS1N Analog Input xx 23 Bus Voltage 1 Differentail Input Signal

23. VDD_5v00 Source xx xx Source

24. GND Ground xx xx Ground

25. NC Not Connected xx xx Not Connected

J13 (Ribbon Cable Connector) Secondary Driver Board

26. NC Not Connected xx xx Not Connected

1. 3.3 VDC Source xx xx Source

2. GND Ground xx xx Ground

3. nGATED_MAIN_PWM2N PWM Output xx 10 Inverted PWM2 Differential Signal

4. nGATED_MAIN_PWM2P PWM Output xx 10 Inverted PWM2 Differential Signal

5. nGATED_REF_PWM2P PWM Ref Output xx 11 Inverted PWM2 Differential Reference Signal

6. nGATED_REF_PWM2N PWM Ref Output xx 11 Inverted PWM2 Differential Reference Signal

7. nPWM_FLT_RESET2N Digital Output 97 xx PWM Fault Reset Differentail Output Signal

8. nPWM_FLT_RESET2P Digital Output 97 xx PWM Fault Reset Differentail Output Signal

9. PWM_FAULT2P Digital Input 67 4 PWM Fault Differential Input Signal

10. PWM_FAULT2N Digital Input 67 4 PWM Fault Differential Input Signal

11. NC Not Connected xx xx Not Connected

12. GND Ground xx xx Ground

13. nGATED_PA_IGBT2P PWM Output xx 34 Pilot Arc IGBT2 Inverted PWM Differential Signal

14. nGATED_PA_IGBT2N PWM Output xx 34 Pilot Arc IGBT2 Inverted PWM Differential Signal

15. nGATED_MAIN_PWM4N PWM Output xx 14 Inverted PWM4 Differential Signal

16. nGATED_MAIN_PWM4P PWM Output xx 14

17. nGATED_REF_PWM4P PWM Ref Output xx 15

18. nGATED_REF_PWM4N PWM Ref Output xx 15

19. VARC2P Analog Input xx 33

20. VARC2N Analog Input xx 33

21. VBUS2P Analog Input xx 32

22. VBUS2N Analog Input xx 32

23. 5 VDC Source xx xx

24. GND Ground xx xx

25. NC Not Connected xx xx

3. GND Ground xx xx

J15 (Mini Phoenix Connector)

1. CAN2_H

2. CAN2_L

3. GND Ground xx xx

1. 24VDC Source xx xx

2. GND Ground xx xx

3. Flow Sensor Frequency Input Analog Input xx

J17 (Mini Phoenix Connector)

1. CAN2_H

2. CAN2_L

3. GND Ground xx xx

J18 (Mini Phoenix Connector)

1. Pilot Arc High/Low Input Digital Input 59 xx

2. Plumbing Box Scaling 1 Digital Input 58 xx

3. Mark Mode Input Digital Input 47 xx

4. 24 HVDC Source xx xx

5. HV GND Ground xx xx

6. Flow Switch Input Digital Input 1 xx

7. Main Start Input Digital Input 84 xx

8. Preflow Input Digital Input 70 xx

box

Not Connected

Current reference scaling signal 2 from the plumbing box or interface

Source

Ground

Current Reference Input

Current Reference Input from CNC or Potentiometer

Same as J5-8

Same as J5-7

Same as J5-9

Same as J5-6

Same as J5-9

Same as J5-5

Same as J5-4

Same as J5-3

Same as J5-2

Same as J5-10

Same as J5-10

Same as J19-1

Analog Power Supply Operation Signals

Same as J19-2

Same as J5-1

Same as J5-10

Same as J18-1

Same as J18-5

Same as J18-5

Same as J18-9

Same as J18-5

Same as J18-8

Same as J18-2

Same as J18-7

Same as J18-3

Same as J18-6

Not Connected

9. Plumbing Box Scaling 2 Digital Input 95 xx

10. NC Not Connected xx xx

J19 (Mini Phoenix Connector)

1. 10 VDC Source xx xx

2. VOLT. REF Analog Input 21 xx

3. GND Ground xx xx

J20 (Ribbon Cable Connector)

1. ExtraRelaySignal3Output Digital Output

2. PwrSrcFaultOutputRelay Digital Output

3. 24 VDC Source

4. MainArcEstOutputRelay Digital Output

5. 24 VDC Source

6. CoolantLevelOkRelay Digital Output

7. 24 VDC COM Ground

8. CoolantFlowOkRelay Digital Output

9. 24 VDC COM Ground

10. ShieldGasRelay Digital Output

11. 10 VDC Source

12. StartGasRelay Digital Output

13. VOLT. REF. Analog Input

14. CutGasRelay Digital Output

15.24 VDC COM Ground

16. PilotArcHighLowInputSignal Digital Input

17. HV GND Ground

18. HV GND Ground

19. PlumbingBoxScalingSignal2 Digital Input

20. HV GND Ground

21. PreFlowInputSignal Digital Input

22. PlumbingBoxScalingSignal1 Digital Input

23. MainStartInputSignal Digital Input

24. MarkModeInputSignal Digital Input

25. FlowSwitchInputSignal Digital Input

26. NC Not Connected

Notes:

Green Used in standard 202/362/540/720 Operation

Blue Used for testing and programming

Gold Not used

Brown Used when power supply is used as analog power supply or ESP

J

S

XWV

LWDO,Q

*URXQG

3:0,QSXW

3:0,QSXW

3:0,QSXW

3:0,QSXW

$QDORJ2XW

$QDORJ2XW

$QDORJ2XW

3:05HI,QSXW

3:05HI,QSXW

6RXUFH

$QDORJ2XW

*URXQG

1RW&RQQHFWHG

1RW&RQQHFWHG

3$,*%73:06LJQDO

$UF9ROWDJH,QSXW

6RXUFH

$&&20021

1RW&RQQHFWHG

$&6XSSO\9ROWDJH

:RUN9ROWDJH,QSXW

+9'&'L

-3KRHQL[+HDGHU

-5LEERQ&DEOH+HDGHU

-)DVWRQ%ODGH7HUPLQDO

(33&$1'ULYHU%RDUG 7\SH

-3KRHQL[+HDGHU

-)DVWRQ%ODGH7HUPLQDO

-)DVWRQ%ODGH7HUPLQDO %XV9ROWDJH,QSXW

----3KRHQL[7HUPLQDO 0DLQ,*%73:06LJQDOV

/9GGY 6RXUFH

/*1' *URXQG

Q0DLQ3ZP1 3:0,QSXW

Q0DLQ3ZP3 3:0,QSXW

Q5HI3ZP3 5HI3:0,QSXW

Q5HI3ZP1 5HI3:0,QSXW

Q)DXOW5HVHW1 'LJLWDO,QSXW

Q)DXOW5HVHW3 'LJLWDO,QSXW

3:0B)$8/73 'LJLWDO2XWSXW

3:0B)$8/71 'LJLWDO2XWSXW

/*1'

Q3D,JEW3

1& 1RW&RQQHFWHG

Q3D,JEW1

Q0DLQ3ZP1

Q0DLQ3ZP3

Q5HI3ZP3

Q5HI3ZP1

9DUF3

9DUF1

9EXV3

9EXV1

9GGY

$/*1'

1&

1&

*DWH

(PLWWHU

9$&

1&

9$&&20

*DWH

(PLWWHU

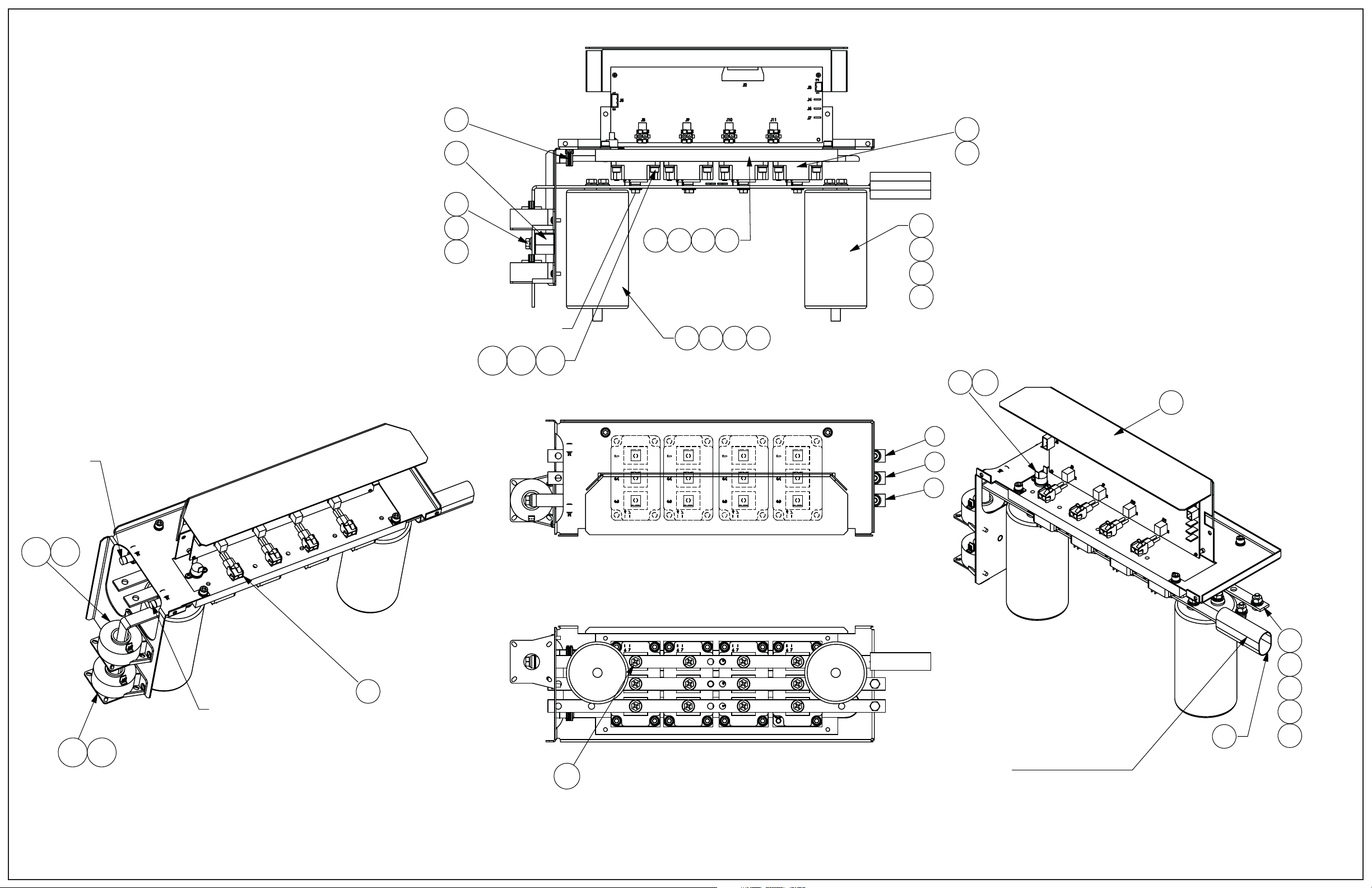

EPP CAN2 Second Station Kit

P/N 0558011641

To enable the EPP power source to accomodate two torch stations, the EPP CAN Second Station Kit must be installed. Do

so as follows.

Before installation:

1. Disconnect input power to machine.

2. Remove covers as shown.

3. Route Braided Connector assembly as shown below.

4. Use supplied clamp to ground the braid to machine cabinet. Install on ground stud opposite existing clamp by

removing and re-install nut.

5. Insert Plug into J17 header on PCB board. Ensure connection is completely inserted into terminal.

6. Slide SW5 position from CLOSE to OPEN position only on station #1 power supply.

7. Insert 8 pin receptacle into access hole in sheetmetal. Use kit at washer inside cabinet, use external tooth lock

washer outside of cabinet, and secure with supplied receptacle nut.

SW5 position

Ensure fully inserted connections

as shown here

Station #1: OPEN

Station #2: CLOSE

Kit plugs into J17 header

(***shown NOT fully inserted***)

J14

not

used

J15

CAN1

station

J17

CAN2

station

Use at washer on inside

of cabinet.

Add supplied clamp to existing clamp,

attach to existing ground stud.

Secure 8 pin recetacle in existing access hole,

use supplied external tooth lock washer on

outside of cabinet .

0558008950 12/2013

575v

c

)

T

g)

g)

)

)

)

(

)

T

T

T

g

g

g

(

)

T

G

V

R

S

R

R

T

A

A

0558011317

0558011316

400v CE

380v

0558011315

0558011314

460v

ITEM

NO

PART NO SYMBOL DESCRIPTION

575v

0558011317

0558011316

400v CE

0558011315

380v

222210558007258 SKID 1111570558000749

111120558010785 BASE 1111580558007484

444430558010786 LEG A-FRAME 111159 35908

222240558007271B BAIL LIFTING 222260 678025

111150558010730 SHELF 111161 951814

111160558011907 SUPPORT SHELF LEFT 111162 951815

111170558011908 SUPPORT SHELF RIGH

2222630558008806

111180558011967 DRIPPAN - 2 - - 64 0558011726

111190558010789 BAFFLE LOWER (Base

1111100558010788 BAFFLE UPPER (Shelf

1111110558010731 COVER ACCESS MAIN XFMR TAPS

Shelf

- 1 - - 65 0558011724

- 1 - - 66 0558011728

1111670558007895

1111120558010787 COMPARTMENT INPUT POWER CONNECTION 111168 950829

1111130558010734 BOX CONTROL 3333690558007710

ITEM

NO

460v

0558011314

PART NO SYMBOL DESCRIPTION

M1

M2

PA

WORK / ETRODE

PL1

FL1

FN1,2

FN4,5

FN3

L3

D7,8

CB1

F1,2,3

MOTOR FAN 1/3 HP 230V

MOTOR COOLANT PUMP 1/2 HP 115/230V

TERMINAL BOARD ASSY - Pilot Ar

TERMINAL OUTPUT ASSY (Bussbar

LAMP WHITE 14V PANEL

LAMP AMBER 12V PANEL

FILTER MODULE (Rin

FILTER MODULE CE (Rin

FILTER MODULE CE (Ferrule

FILTER INDUCTOR CE 1 PHASE

KIT MOV 275VAC 140J

CIRCUIT BREAKER 3A 32VDC 250VAC

FUSE MIDGET SLO-BLO 15A 600V

1111140558010742 COVER HEAT EXCHANGERS 333370 952136 HOLDER FUSE MIDGE

1111150558011843 COVER CONTROL BOX SILK SCREENED 444471 673905

1111160558010741 CAP CORNER LEFT FRON

1111170558010740 CAP CORNER RIGHT FRON

111172 951085

1111730558004782

1111180558010728 PANEL OUTPUT CONNECTION 1 - - 1 74 0558001010

1111190558010738 PANEL CONTROL CONNECTION - 3 3 - 75 0558011850

1111200558010739 PANEL ACCESS FRONT 111176 950487

1111210558010733 PANEL DISPLAY SILK SCREENED 111177 952026

1111220558010729 PANEL REAR SILK SCREENED 222278 952073

1111230558007264B PANEL ACCESS INPUT POWER CONNECTION 11117913730583

F4,5

TS1

TS2

TB1

TB1

TB4

TB3

TB2,3

TB7

FUSE LINK 150A 250V

SWITCH THERMAL N/C 80°C 176°F

SWITCH THERMAL N/C 100°C 212°F

BLOCK TERMINAL 3P (14-2/0)awg

BLOCK TERMINAL FEED-THRU (4-3/0)aw

BLOCK TERMINAL 2-POS x 4 FASTON

BLOCK TERMINAL 7-POS (12-18)aw

BLOCK TERMINAL 12-POS (12-18)aw

BUSHING TERMINAL FAST 1/4" MALE .687MH

2222240558010726 PANEL SIDE LEFT / RIGHT 222280 952155 MARKER PLATE (1-12)

1111250558010725 PANEL TOP 1111810558008087 MARKER PLATE

1111260558007254

- 1 - - 27 0558007863

- 1 1 1 28 0558011800

1 - - - 29 0558011734

1111300558012004

L1

L2

T1

T1

T2

INDUCTOR OUTPU

111182 952937

REACTOR LINE CE 3 PHASE 1111830558011641

TRANSFORMER MAIN 380/400/460V 1111840558011612

TRANSFORMER MAIN 575

KIT TRANSFORMER CONTROL 200-575V w/ FERRULES

1111850558011932

1111860558011703

1111310558011930 BUSBAR POSITIVE 4444870558007808

2222320558011931 BUSBAR NEGATIVE / COLLECTO

1111880558010255

2222330558007275 PLATE DIODE MOUNTING Pos / Neg 1111890558011993

222234 34916 BUSSBAR TAB 1111900560986171

1111350558011909 COLD PLATE POWER IGBT 333391 951005

1111360558008823 HEATSINK PA IGBT 111192 951007

4444370558006183

1111380558007886

3333390558003658

3333400558003657

1111410558038362

1111420558038382

1111430558038391

2222440558007255

111145 952185

1111460558012002

1111470558010711

1111480558010713

2222490558007736

8888500560947008

1111510558010765

2222520558006886

33335317300002

44445417300008

11115517280215

11115617280230

Q1,2,3,4

Q5

D2,4,6

D1,3,5

PCB1

PCB2

PCB3

C1,2

C14

D9

K2

K1

K4,5

RB1-(1-8)

RB1

HS1,2

R1,2,3

R4,5,6,7

R8

R9

KIT IGBT CHOPPER 400A 1200V w/ PLUG 1111930560986173

IGBT 50A 1200V 1111940558008954

DIODE FORWARD 300A 1200V 1111950558007485 PUMP COOLANT 225PSI 125GPH

DIODE REVERSE 300A 1200V 1111960558007501 COUPLING 3-PC - COOLANT PUMP

PC BOARD - CONTROL 1111970558007502 ADAPTOR COOLANT PUMP / MOTO

PC BOARD - DRIVER 2222980558003078 HEAT EXCHANGE

PC BOARD - FILTER 1111990558010757

CAPACITOR ALUM 6000uF 450VDC 11111000558011981 T-STRAINER 100-MESH SCREEN 3/4NPTF

CAPACITOR ALUM 1000uF 400VDC w/ NU

111110113735508 SHROUD FAN POLY 14"

KIT DIODE REVERSE 85A 1200A w/ LEAD 1111102 36173 BLADE FAN 14"

CONTACTOR 3P 40A 24VAC 11111030558011990

CONTACTOR 3P 150A 115VAC 11111040558012052 REGULATOR BACK-PRESSURE R-22-175

RELAY 3PDT 24VAC 10

2222105 21124 CHECK VALVE 1/4NPTF

RELAY ASSY SPDT 24VDC 6A w/ BASE 1111106 58v75 ADAPTOR BULKHEAD LH B/A-W*F 1/4NPTM

ADAPTOR 8 x RELAY ASSY SPDT / RIBBON 14 PIN 1111107 33033 ADAPTOR BULKHEAD RH B/A-W*M 1/4NPTM

TRANSDUCER CURRENT 300

6666108 10Z30 ADAPTOR RH B/A-W*M 1/4NPTM

RESISTOR 2 OHM 300W 2222109 74S76 ADAPTOR RH B/IG*F 1/4NPTM

RESISTOR 8 OHM 300W 222211068100126 BUSHING 1/4NPTF 3/8NPTM

RESISTOR 1.5K OHM 100W 222211168100276 BUSHING HEX 3/4NPTM 1/4NPTF

RESISTOR 3K OHM 100W 222211244261400 ELBOW PIPE 45° 1/4NPT

PCB1-P12 / PCB2-P2

PCB1-P2,16 , PCB2-P5

J1

J2 / PCB1-P15

PCB1-P6 / RB1

PCB1-P20 / DB25

PCB2-P8,9,10,11

PCB1-P8

PCB1-P1

PCB2-P3

PCB1-P3

PCB1-P9

J3

(LS1)

FS1 / P3

RECEPTACLE PNL MT HOUSING FEMALE 14 POS X-Rotation

KIT RCPT PNL MT (M12) 8 SOCKET w/ 3 POS PLU

RIBBON CABLE ASSY 14 SKT 18"

RIBBON CABLE ASSY (DB25 SKT - 26 SKT) 20"

RIBBON CABLE TWISTED PAIR ASSY 26 SKT 20"

LEAD ASSY DRIVER PC BOARD

CONNECTOR MINI-COMBICON 4 PO

CONNECTOR MINI-COMBICON 6 POS

CONNECTOR COMBICON 2 PIN

CONNECTOR COMBICON 3 PIN

CONNECTOR COMBICON 5 PIN

CONNECTOR COMBICON 8 PIN

HOUSING UNIV CAP 3 POS - Wht

KIT TANK COOLANT w/ LEVEL SWITCH

KIT SENSOR FLOW ROTO w/ PLUG 5.0 GPM

13-24

Page 1

575v

T

(

ydex

K

T

T

(

)

(

)

ydex

x

ydex

R

A

A

ARARARA

ARARARA

(

(

)

A

A

A

A

A

0558011317

0558011316

400v CE

380v

0558011315

0558011314

460v

ITEM

NO

PART NO SYMBOL DESCRIPTION

575v

0558011317

0558011316

400v CE

0558011315

380v

ITEM

NO

460v

0558011314

PART NO SYMBOL DESCRIPTION

22221130558006693 ELBOW STREET 45° 1/4NPT 4444169 * SCREW HEX CAP 3/8-16 x 4.00

5555114 182w82 ELBOW STREET 90° 1/4NPT 2222170 * SCREW HEX CAP 1/2-13 x 1.50

111111567100088 NIPPLE 1/4NPT 8"LG 105 105 105 105 171 * SCREW HEX WSH TRI 1/4-20 x .50

22221162226715 NIPPLE HEX 1/4NPT 1-7/16"LG 24 24 24 24 172 * SCREW HEX WSH TRI 1/4-20 x .50 Serrated

11111170558011884 NIPPLE DRIPPAN 3/8 HOSE 6666173 * SCREW SQ PAN TRI #4-40 x .25

11111180558011883 WASHER RUBBER 0.516 ID x 0.781 OD x .063 NBR 10 10 10 10 174 * SCREW SQ PAN TRI #6-32 x .38

22221190558004647 TEE NYLON 3/8" BARBED 8888175 * SCREW SQ PAN TRI #6-32 x .75

2222120 461107 TEE STREET 1/4NP

8888176 * SCREW SQ PAN TRI #8-32 x .50

24421212234485 CLAMP END DIN 35 RAIL 9999177 * SCREW SQ PAN TRI #8-32 x .63

12211220558009578 RAIL MOUNTING 4.5" DIN

11111230558011992 BAFFLE IGBT K

11111240558010743 BRACKET COOLANT TAN

1111125 36043

11111260558010763

11111270558010764

BRACKET FAN GALVANIZED

BRACKET HEAT EXCHANGER LEF

BRACKET HEAT EXCHANGER RIGH

11111280558011968 BRACKET IGBT / CAP / COLD PLATE MODULE 20 20 20 20 184 *

22221290558010784 BRACKET MOUNTING 4x RESISTOR HORIZONTAL

22221300558006596 BRACKET MOUNTING 4x RESISTOR VERTICAL

35/7.5) PERFORATED 20 20 20 20 178 * SCREW SQ PAN TRI #10-24 x .50

8 10 10 8 179 * SCREW SQ PAN TRI #10-24 x .63

4224180 *

26 26 26 26 181 *

SCREW SQ PAN TRI #10-24 x 1.00

SCREW SQ PAN TRI #8-32 x .38

4644182 * SCREW SQ PAN TRI #10-24 x .38

4444183 * SCREW SKT HEX M6-1.0 x 12 Blk

SCREW SKT HEX M6-1.0 x 20 Blk

Base

Shelf

18 18 18 18 185 * WASHER FLAT #8

22 22 22 22 186 * WASHER FLAT #10

444413199512069 BRACKET RESISTOR #12 43 43 43 43 187 * WASHER FLAT 1/4

11111320558007276 INSULATOR DIODE BRIDGE K

- 1 - - 133

680398

INSULATOR LINE REACTOR Nome

1 - - 1 134 0558007288 INSULATOR TERMINAL BLOCK K

11111350558010744 PLATE MOUNTING COOLANT PUMP MOTO

10 10 10 10 188 * WASHER FLAT 5/16

27 27 27 27 189 * WASHER FLAT 3/8

7777190 * WASHER FLAT 1/2

1111191 * WASHER FLAT 5/8

44441368672225 STANDOFF GLASTIC FEMALE 1/4-20 HEX 1.25" LG 6666192 * WASHER FLAT M4

22221370558003292 CLAMP CABLE STEEL .187 DI

1111138 950799 CLAMP CABLE ALUM .750 DI

1111139

0558004079

STRAIN RELIEF 2" STEEL 32 32 32 32 195 * WASHER LOCK 1/4

20 20 20 20 193 * WASHER FLAT M6

1111194 * WASHER FLAT M16

4444140 950823 BUSHING SNAP .56ID .69MH 25 25 25 25 196 * WASHER LOCK #8

8888141 639533 BUSHING SNAP .88ID 1.09MH 23 23 23 23 197 * WASHER LOCK #10

1111142 647345 BUSHING SNAP 1.31ID 1.50MH 7777198 * WASHER LOCK 5/16

1111143 952144 GASKET RUBBER LIFTING EYE 15 15 15 15 199 * WASHER LOCK 3/8

44441440558012007 GROMMET RUBBER 1.00ID 1.38GD .13W 3333200 *

WASHER LOCK 1/2

11111450558004053 GROMMET RUBBER 2.12ID 2.50GD .06W 4444201 * WASHER LOCK EXT #8

4' 4' 4' 4' 146 * STRIP RUBBER FOAM 0.75W 0.063 THK 1111202 * WASHER LOCK EXT 3/8

R 147 * TUBING PVC, 600V 105C, 1" BLACK 1111203 * WASHER LOCK INT 1/2

R 148 * TUBING PVC, 600V 105C, 1.25" BLACK 1111204 * WASHER LOCK EXT 5/8

11111490558010374

JUMPER 2 POS Red

32 32 32 32 205 * WASHER LOCK M6

3333150 81F60 TERM LUG, MECHANICAL 17/32" 2/0-4/0 AWG 18 18 18 18 206 * NUT #8-32

11111512057726 LUG, MECHANICAL

1111152 98W68

GND1

LUG, MECHANICAL (4-3/0)AWG 21 21 21 21 208 * NUT #10-24

4-14)AWG 4444207 * NUT LOCK #8-32

33331530558009294 FERRULE NON-INSULATED 4/0 15 15 15 15 209 * NUT 1/4-20

66661540558011877 FERRULE NON-INSULATED 2 AWG 7777210 * NUT 5/16-18

7777155 46n08 ROD THREADED #8-32 x 9.75" LG 11 11 11 11 211 * NUT 3/8-16

14 14 14 14 156 91w19 WASHER CENTERING 3333212 * NUT 1/2-13

14 14 14 14 157 647182 WASHER INSULATING MICA 3333213 * NUT LOCK NYLON #8-32

13 13 13 13 158 13734871 CLAMP WORM GEAR .250-.625 1111214 * NUT 1/2-20 JAM

12 12 12 12 159 0558006557 SCREW PHL HEX #10-32 x .50 w/ FLW Blk 6666215 * NUT 3/4-16 JAM

22221600558002087 SCREW PHL HEX w/ FLW M5 x 12 9999216 * NUT SST M4-0.7

12 12 12 12 161 0558006737 SCREW PHL HEX w/ FLW M6 x 12 12 12 12 12 217 * NUT M6-1.0

10 10 10 10 162 * SCREW HEX CAP 1/4-20 x .50 1111218 * BOLT CARRIAGE 1/2-13 x 1.75

10 10 10 10 163 * SCREW HEX CAP 1/4-20 x .63 4444219 * RIVET 1/8

8888164 * SCREW HEX CAP 1/4-20 x .75 - - - 1 220 N

4444165 * SCREW HEX CAP 1/4-28 x .50 - - 1 - 221 N

7777166 * SCREW HEX CAP 5/16-18 x 1.00 - 1 - - 222 N

6666167 * SCREW HEX CAP 3/8-16 x .75 1 - - - 223 N

6666168 * SCREW HEX CAP 3/8-16 x 1.00 1111224 N

LABEL RATING EPP-362 460V

LABEL RATING EPP-362 380V CCC

LABEL RATING EPP-362 400V CE

LABEL RATING EPP-362 575V

LABEL NAMEPLATE Stock / Serial No

.126-.187

Page 2

575v

R

Y

E

L

T

A

A

A

E

ARARARA

ARARARA

ARARARA

ARARARA

ARARARA

A

A

T

A

A

T

A

T

K

P

R

R

T

T

Y

T

0558011317

0558011316

400v CE

380v

0558011315

0558011314

460v

ITEM

NO

PART NO SYMBOL DESCRIPTION

575v

0558011317

0558011316

400v CE

0558011315

380v

ITEM

NO

460v

0558011314

PART NO SYMBOL DESCRIPTION

11112252091514 LABEL WARNING GENERAL ARC WELD & CUT

- - 1 - 226 0558954289 LABEL WARNING GENERAL ARC WELD & CUT Chinese 0558010799 Kit IGBT / CAP / HEATSINK MODULE EPP-362

1111227 995110 LABEL WARNING EXPOSED VOLTAGE INSIDE

(Includes) Includes the Following Items:

1111228 954291 LABEL WARNING COOLANT GENERAL 1111310558011930 BUSBAR POSITIVE

111122999512240 LABEL CAUTION LIFTING EYE 2222320558011931 BUSBAR NEGATIVE / COLLECTO

11112300558954172 LABEL CAUTION GROUNDED PNL / REMOVE CAREFULL

11112312091558 LABEL PE GROUND 4444370558006183

1111232 954509 LABEL SYMBOL CAUTION HIGH VOLTAG

1111233 955269 LABEL SYMBOL CAUTION READ MANUA

1111350558011909 COLD PLATE POWER IGBT

1111420558038382

2222440558007255

Q1,2,3,4

PCB2

C1,2

IGBT CHOPPER 400A 1200V w/ PLUG

PC BOARD - DRIVER

CAPACITOR ALUM 6000uF 450VDC w/ NU

111123413732733 LABEL COPPER WIRE ONLY Wht/Clr 46

1111235 954507 LABEL WORK/ PILOT ARC/ ELECTRODE Wht/Clr 111172 951085

TS1

SWITCH THERMAL N/C 176°F

11112360558954244 LABEL COOLANT FILL Blk/Wht 4444870558007808 LEAD ASSY DRIVER PC BOARD

- 1 - - 237 N

- - 1 - 238 N

11112390558954292

LABEL CE - Plain 11111280558011968 BRACKET IGBT / CAP / COLD PLATE MODULE

LABEL CCC 12 12 12 12 161 0558006737 SCREW PHL HEX w/ FLW M6 x 12

LABEL SET EPP-202/362

4444165 * SCREW HEX CAP 1/4-28 x .50

222224013734588 LABEL ESAB DIE CUT 9.0 x 5.1 Blk 4444183 * SCREW SKT HEX M6-1.0 x 12 Blk

1111241 N

LABEL ISO 9001 16 16 16 16 184 * SCREW SKT HEX M6-1.0 x 20 Blk

4444242 951833 PAD THERMAL POWER IGBT MODULE 2222174 * SCREW SQ PAN TRI #6-32 x .38

1111243 951191 PAD THERMAL PA IGBT MODUL

4444187 *

WASHER FLAT 1/4

R 244 * ADHESIVE THREADLOCKER LOCTITE 242 - Blue 4444195 * WASHER LOCK 1/4

R 245 * SEALANT THREAD LOCTITE PST 592 - White 20 20 20 20 205 * WASHER LOCK M6

R 246 * ADHESIVE SILICON RUBBER DOW 732 - Clear 4444242 951833 PAD THERMAL POWER IGBT MODULE

R 247 * COMPOUND ELECTRICAL JOINT ALCOA #2

AR AR AR AR 248 * TYWRAP LG 7.25" 0558010797 KIT COOLANT PUMP

R 249 * TYWRAP MED 5.5"

(Includes) Includes the Following Items:

2522250 * TYWRAP X-LG 14.5" 1111950558007485 PUMP COOLANT 250PSI 125GPH

1111251 * BAG CLOTH 4" x 6" 2222108 10Z30 ADAPTOR RH B/A-W*M 1/4NPTM

1111252 N

1111253 N

1 - 1 1 254 N

1111255 N

WIRE KIT EPP-202/362 222211068100126 BUSHING 1/4NPTF 3/8NPTM

CABLE KIT EPP-362 COMMON 1111120 461107 TEE STREET 1/4NP

CABLE KIT EPP-362 NON-CE 2222114182w82 ELBOW STREET 90° 1/4NPT

HOSE KIT EPP-202/362 1111109 74S76 ADAPTOR RH B/IG*F 1/4NPTM

11112560558954317 LABEL PC BOARD LAYOUT EPP-202/362

99 0558010757 KIT TANK COOLAN

(Includes) Includes the Following Items:

1111301 N

TANK COOLAN

11113020558010759 CAP COOLANT TAN

11113030558011991

LS1

SWITCH COOLANT LEVEL w/ LEADS

22221170558011884 NIPPLE COOLANT TANK 3/8 HOSE

22221180558011883 WASHER RUBBER 0.516 ID x 0.781 OD x .063 NBR

2222190 * WASHER FLAT 1/2

2222214 * NUT 1/2-20 JAM

ADDITIONAL SPARES

1111304 19972 STRAINER - COOLANT PUM

11113050558011982 O-RING 1" 100-MESH T-STRAINE

11113060558011983 SCREEN 100-MESH T-STRAINE

COOLANT HOSE SPARES

1111-0558011599 HOSE 34.00" TANK OUTLET to PUMP INLE

1111-0558011604 HOSE 16.00" PUMP OUTLET to REGULATOR INLE

1111-0558011608 HOSE 31.00" PUMP OUTLET to TORCH SUPPL

1111-0558011600 HOSE 40.00" RADIATOR OUTLET to FILTER INLET

1111-0558011607 HOSE 11.75" REGULATOR OUTLET to FLOW SENSOR OUTLET

1111-0558011599 HOSE 34.00" FLOW SENSOR OUTLET to COLD PLATE INLET

1111-0558011602 HOSE 31.00" TORCH RETURN to RADIATOR INLE

Page 3

T1

38

OR

T1

39

8X

2X

30

64

H

190

4X

X

146

4X

4

4X

63

144

4X

1.5k ohms

3.00kohm

176

4X

4X

185

31

65

8X

2

8 186

12X

177

2X

211

2X

186

221

2X

197

2X

575V only

2202X158

2X

2X

209

DETAIL X

SCALE 2 : 1

(TYP 4 PLCS)

2X

196

159

160

Ref.

63

2X

2X

2X

2X

2X

6X

182

209

220

31

DETAIL H

SCALE 2 : 1

(TYP 2 PLCS)

4X

4X

4X

212

191

204

222

SCALE 1 : 1

A

193

206

224

203

228

DETAIL A

4X

4X

193

171

G

NOTE:

4 Quantity

of Foot should be

supplied with ITEM

NO: 3

224

206

193

193

171

DETAIL G

SCALE 2 : 3

TYP 4 PLCS

0558011844

D

EPP-362-M3 TOP

ASSEMBLY FAMILY

SHEET 4 OF 15

F

V

80

F5

ORIENT BUSBAR VERTICALLY, 3 PLCS,

FOLD 6 INCHES OF TUBING IN HALF

TO CREATE COVER FOR BUSBAR,

SECURE WITH TYWRAP

TYPICAL CONNECTION, 3 PLCS,

COVER CONNECTION WITH 4

INCHES OF TUBINGAND SECURE

WITH TYWRAP

NOTE: APPLY EJC ESAB

P/N 73585980 TO ALL

CONNECTIONS

4X

136 176

2X

43

145

4X

176

36

L1

W

150

2X

174

194

225

207

2X

168

192

205

223

DETAIL U

SCALE 1 : 1

TYPICAL CONNECTION, 6 PLCS,

U

150

260

TS2

82 179

T

260

DETAIL V

SCALE 1 : 1

COVER WITH 4 INCHES OF TUBING,

2X

145

145

SECURE WITH TYWRAP

D2

49 227

NOTE: APPLY EJC ESAB

P/N 73585980 TO ALL

CONNECTIONS

1691922X223

205

D1

50 227

F4,F5

2X

80

2X

169

192

4X

205

2X

2X

223

REMOVE SECTION OF BUSBAR

AND INSTALL F4 AND F5 AS SHOWN

(TYPICAL 2 PLCS)

DETAIL T

SCALE 1 : 1

151

259

DETAIL W

SCALE 1 : 2

172

2X

193

2X

206

224

(TYP 2 PLCS)

(TYP 3 PLCS)

TYPICAL CONNECTION, 2 PLCS, COVER

WITH 4 INCHES OF TUBING AND SECURE

WITH TYWRAP

175

194

207

225

AA

145

DETAIL AA

SCALE 1 : 1

72

FN1

261

D4

49

227

151

259

140

4X

(Input connection of

Transformer

TYPICAL CONNECTION,

3 PLCS, COVER

CONNECTION WITH 4

INCHES OF TUBINGAND

SECURE WITH TYWRAP

167

192

205

(TYP 4 PLCS)

49 227

D6

50 227

D5

D3

50

227

FN2

72

261

EPP-362-M3 TOP

ASSEMBLY FAMILY

0558011844

SHEET 5 OF 15

F

224206172

(TYP 2 PLCS)

Q5

2X

2X

4X

2X

(TYP 3 PLCS)

48 189

221

25346

211

197

2X

76 163

55

179

C3,R10

2X

149

4X

2X

186

2X

197

2X

211

2X

221

DETAIL AB

SCALE 1 : 1

2X

2X

3X

(TYP 3 PLCS)

220

209

196

2X

2X

2X

89

144

(TYP 3 PLCS)

159

160

144

5

2X

32

10176

AB

3X

62

158

(CE UNIT ONLY)

FN4

73

261

257

112

M1

66

196

4X

219

4X

2X

28

177

(CE UNIT ONLY)

FN5

73

261

257

167

205

192

(TYP 4 PLCS)

2X

176

74

FN3

(CE UNIT ONLY)

75

L3

(CE UNIT ONLY)

40

T2

176

3X

87

181

3X

89

TB3

90

86

181

TB3

2X

145

87

181

9

176

145

3X

2X

EPP-362-M3 TOP

ASSEMBLY FAMILY

0558011844

SHEET 6 OF 15

F

2X

161

139

167

205

192

NOTE: FOLLOW TORQUE SPECS LISTED

ON IGBT DRAWING

4X

202

4X

217

TYP 4 PLCS

4X

200

4X

200

4X

4X

45

202

217

54 1702X1922X205

C2

2X

2X

2X

2X

Q1, Q2, Q3, Q4

47

252

C1

54

170

192

205

81

2X

179

TS1

4X

4X

29

TO TANK INLET

HS1

2X

6161182

HS2

182

2X

FROM FLOW SENSOR TEE

4X

96

PCB2-P8,11

USE EJC (ITEM ) ON ALL BUS BAR BOLTED CONNECTIONS

164

258

NOTE: FOLLOW TORQUE SPECS LISTED

ON IGBT DRAWING

6X

42

42

41

TYP CONNECTION,

3 PLCS,

COVER EACH

W/4 INCHES OF

VINYL TUBE

3X

150

Ref.

42

192

205

223

168

(TYP 3 PLCS)

EPP-362-M3 TOP

ASSEMBLY FAMILY

0558011844

SHEET 7 OF 15

F

NOTE: ORIENTATION OF

CHECK VALVES

TO RADIATOR INLET TEE

16

PCB3

53

2X

178

44 1731932X206224

(TYPICAL 2 PLCS)

FROM PUMP OUTLET

118

119

2X

122

2X

126

2X

115

2X

123

2X

2X

183

209

209

183

2X

2X

116

117

68

PA

184

2X

221

4X

69

187

4X

2X

153

166

2X

191

204

222

(TYPICAL 2 PLCS)

REF

116

117

REF

244

154

EPP-362-M3 TOP

ASSEMBLY FAMILY

0558011844

SHEET 8 OF 15

F

192

2X

205

2X

167

2X

176

25

5

4X

Ref.

Ref.

128

118

120

114

130

33

TO PUMP OUTLET

128 129 131 113 131 129 125 121 110 121 124 118

118

TO COLD PLATE INLET

NOTE ORIENTATION

OF PUMP

TO RADIATOR OUTLET TEE

NOTE ORIENTATION OF FILTER

TO Back Pressure

REGULATOR INLET

106

118

GROUND TETHER POINT FOR

SIDE AND TOP PANEL

TO TANK OUTLET

3X

176

182

2X

186

186

11

5X

120

105107119

308

175

207

194

4X

4X

4X

25

67

M2

173

206

193

(TYP 4 PLCS)

169

205

192

6

TO TORCH OUTLET

3X

3X

3X

2X

177

3X

176

8X

176

4X

176

7

EPP-362-M3 TOP

ASSEMBLY FAMILY

0558011844

SHEET 9 OF 15

F

NOTE:

ORIENT FLAT SURFACE OF STEM FACING UPWARD.

SUPPLIED WASHER LOCATED INSIDE TANK.

302

301

Ref.

305304 307306

10826

2X

161

303

4X

211

4X

221

(TO PUMP INLET)

(FROM IGBT OUTLET)

2X

2X

161

127

(TO FILTER INLET)

(TO TORCH INLET)

27

4X

221

4X

211

2X 2X 2X 2X

2X

108

161

176

2X

34

12

221

2X

Ref.

211

2X

EPP-362-M3 TOP

ASSEMBLY FAMILY

0558011844

SHEET 10 OF 15

F

INSTALL FERRULES ON CABLE

AND TIGHTER SET SCREWS ON

CONTACTOR

6X

157

K1

57

4X

188

4X

211

4X

197

2X

460V

&

575V

ONLY

138

83

189

TB1

2X

134

132

84

187

TB1

400V (CE)

&

380V(CCC)

ONLY

3X

2X

182