RT Robo Welding Torch System

RTKS-2, RTFL-2, KSC-2, FLC-2, RT42, RT52,

RT62, RT72, RT82, RT42-NG, RT82WNG

Návod na použitie

0463 373 101 SK 20181227

OBSAH

1

BEZPEČNOSŤ............................................................................................. 5

1.1 Význam symbolov .................................................................................. 5

1.2 Bezpečnostné opatrenia ........................................................................ 5

2

ZÁRUKA ...................................................................................................... 8

2.1 Podmienky určeného použitia............................................................... 8

3

ÚVOD ........................................................................................................... 9

3.1 Prehľad systémov zváracích horákov.................................................. 10

4

TECHNICKÉ ÚDAJE ................................................................................... 12

4.1 Hrdlo zváracieho horáka........................................................................ 12

4.2 Menovité napätie .................................................................................... 13

4.2.1 Obmedzenia chladiacich okruhov ........................................................ 14

4.3 Držiak horáka.......................................................................................... 14

4.3.1 Držiaky horáka pre štandardný systém RT .......................................... 14

4.3.1.1 Bezpečnostný vypínací mechanizmus RTKS-2................................ 15

4.3.1.2 Priechodová obruba RTFL-2 ............................................................ 15

4.3.2 Držiaky horáka pre systém sdutým zápästím...................................... 16

4.3.2.1 Držiak horáka RTKSC-2 G/W sbezpečnostným vypínacím

mechanizmom ...................................................................................

4.3.2.2 Pevný držiak horáka RTFLC-2 G/W................................................. 18

4.4 Adaptérové obruby................................................................................. 19

4.5 Káblové zväzky....................................................................................... 19

4.5.1 Káblové zväzky pre štandardný systém RT ......................................... 19

4.5.2 Káblové zväzky pre systémy spriechodným zápästím ........................ 20

5

INSTALLATION............................................................................................ 22

5.1 RTKS-2 standard arm installation........................................................ 22

5.1.1 RTKS-2 safety-off mechanism............................................................. 22

5.1.1.1 Torch installation with adjustable mount............................................ 23

5.1.2 Standard arm cable assembly for KS-2 and FL-2 ................................ 25

5.1.3 RTKS-2 wire feeder connection........................................................... 26

5.1.4 RTKS-2 electrical connections ............................................................ 27

5.1.4.1 RTKS-2 safety-off mechanism connection ....................................... 27

5.1.5 RTKS-2 Torch installation .................................................................... 28

5.2 RTFL-2 standard arm installation ........................................................ 29

17

5.2.1 RTFL-2 rigid mount.............................................................................. 29

5.2.2 RTFL-2 torch installation ..................................................................... 31

5.3 RTKSC-2 hollow wrist system installation.......................................... 31

5.3.1 RTKSC-2 mount with safety off mechanism........................................ 31

5.3.2 Mounting the cable assembly............................................................... 32

5.3.2.1 RTKSC-2 feeder cabinet connections .............................................. 33

5.3.3 RTKSC-2 cable assembly ................................................................... 35

5.3.3.1 RTKSC-2 cable assembly installation .............................................. 35

0463 373 101 © ESAB AB 2018

OBSAH

5.3.3.2 RTKSC-2 electrical connections....................................................... 38

5.3.4 RTKSC-2 torch installation .................................................................. 39

5.4 RTFLC-2 installation.............................................................................. 40

5.4.1 RTFLC-2 mount................................................................................... 40

5.4.2 RTFLC-2 wire feeder connection......................................................... 40

5.4.2.1 Feeding through the robot arm.......................................................... 40

5.4.2.2 RTFLC-2 feeder cabinet connections............................................... 41

5.4.3 RTFLC-2 cable assembly .................................................................... 43

5.4.3.1 RTFLC-2 cable assembly installation ............................................... 43

5.4.4 RTFLC-2 electrical connections .......................................................... 46

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly........... 46

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly................. 47

5.5 Torch installation.................................................................................... 47

5.5.1 Torch neck equipment .......................................................................... 47

5.5.2 Aristo RT torch neck installation........................................................... 48

5.6 Installing the wire guide for standard and hollow Wrist arm ............. 49

5.6.1 Installing the neck liner......................................................................... 49

5.6.2 Installing a split wire guide in the cable assembly ................................ 50

5.6.3 Installing a continuous wire guide in the cable assembly ..................... 52

5.7 Adjust the narrow gap contact tip ........................................................ 53

6

OPERATION ................................................................................................ 56

6.1 Important information for programming (hollow wrist system only) 56

7

SERVIS A ÚDRŽBA..................................................................................... 58

7.1 Povinné kontroly aopatrenia ................................................................ 58

8

RIEŠENIE PROBLÉMOV ............................................................................ 60

9

OBJEDNÁVANIE NÁHRADNÝCH DIELOV ................................................ 62

Práva na zmenu technických údajov bez upozornenia vyhradené.

0463 373 101 © ESAB AB 2018

1 BEZPEČNOSŤ

1 BEZPEČNOSŤ

1.1 Význam symbolov

Ako sa používajú v tomto manuáli: Buďte opatrní! Dávajte pozor!

NEBEZPEČENSTVO!

Znamená bezprostredné ohrozenie, ktoré, pokiaľ mu nepredídete, môže

spôsobiť bezprostredný vážny úraz alebo ohrozenie života.

VÝSTRAHA!

Znamená potenciálne riziko, ktoré môže spôsobiť poranenie alebo

ohrozenie života.

UPOZORNENIE!

Znamená riziko, ktoré môže spôsobiť ľahký úraz.

VÝSTRAHA!

Pred použitím si prečítajte aosvojte návod na obsluhu

asledujte všetky štítky, bezpečnostné predpisy

zamestnávateľa akarty bezpečnostných údajov (SDS).

1.2 Bezpečnostné opatrenia

Používatelia zariadení ESAB nesú konečnú zodpovednosť za to, že zaistia, aby každý, kto

pracuje s takýmto zariadením alebo v jeho blízkosti, dodržiaval všetky príslušné

bezpečnostné opatrenia. Bezpečnostné opatrenia musia spĺňať požiadavky vzťahujúce sa na

tento typ zariadení. Odporúčame dodržiavať okrem predpisov a noriem platných pre dané

pracovisko aj ďalej uvedené odporúčania.

Všetky práce musí vykonávať školený personál, ktorý je dobre oboznámení sobsluhou

zariadenia. Nesprávna obsluha zariadenia môže viesť ku vzniku nebezpečných situácií,

následkom ktorých môže dôjsť k úrazu obsluhy alebo k poškodeniu zariadenia.

1. Každý, kto používa toto zariadenie, musí byť dobre oboznámený s:

○ s jeho prevádzkou

○ umiestnením núdzových vypínačov

○ princípom jeho činnosti

○ platnými bezpečnostnými opatreniami

○ zváraním a rezaním alebo iným príslušným použitím vybavenia

2. Obsluha musí zabezpečiť, aby:

○ pri spustení zariadenia nebola v jeho pracovnom priestore žiadna neoprávnená

osoba

○ nikto nebol nechránený pri zapálení oblúka alebo začatí práce so zariadením

3. Pracovisko musí byť:

○ vhodné na daný účel

○ bez prievanov

0463 373 101

- 5 -

© ESAB AB 2018

1 BEZPEČNOSŤ

4. Osobné ochranné prostriedky:

○ Vždy používajte osobné ochranné prostriedky, ako sú ochranné okuliare, odev

odolný proti ohňu a ochranné rukavice

○ Nenoste voľné doplnky či ozdoby, ako sú šály, náramky, prstene atď., ktoré by sa

mohli zachytiť alebo spôsobiť popáleniny

5. Všeobecné bezpečnostné opatrenia:

○ Presvedčte sa, či je spätný vodič bezpečne pripojený

○ Prácu na vysokonapäťovom zariadení smie vykonávať len kvalifikovaný

elektrikár

○ K dispozícii musí byť vhodný ajasne označený hasiaci prístroj

○ Mazanie a údržba zariadení sa nesmie vykonávať pri prevádzke.

VÝSTRAHA!

Zváranie a rezanie oblúkom môže byť nebezpečné pre vás aj pre iné osoby. Pri

zváraní alebo rezaní dodržujte bezpečnostné opatrenia.

ZÁSAH ELEKTRICKÝM PRÚDOM – Dokáže usmrtiť.

• Vykonajte montáž auzemnenie zariadenia vsúlade snávodom na

použitie.

• Nedotýkajte sa častí alebo elektród pod napätím holou kožou, vlhkými

rukavicami alebo vlhkým odevom.

• Izolujte sa od pracovných auzemňovacích vodičov.

• Pri práci dbajte na bezpečný pracovný postoj.

ELEKTROMAGNETICKÉ POLIA – Môžu byť zdraviu škodlivé.

• Zvárači, ktorí používajú kardiostimulátor, by sa mali pred zváraním poradiť

so svojím lekárom. Elektromagnetické polia môžu mať na niektoré

kardiostimulátory rušivý vplyv.

• Vystavenie účinkom elektromagnetického poľa môže mať aj ďalšie účinky

na zdravie, ktoré sú zatiaľ neznáme.

• Zvárači by mali dodržiavať tieto postupy, aby čo najviac obmedzili

vystavenie účinkom elektromagnetických polí:

○ Vodiče kelektróde apracovné káble veďte spolu na rovnakej strane

tela. Ak je to možné, prichyťte ich páskou. Nestojte medzi horákom

apracovnými káblami. Nikdy si neovíjajte horák ani pracovné káble

okolo tela. Zvárací zdroj akáble držte čo najďalej od tela.

○ Pracovný kábel pripojte kzvarencu čo najbližšie kzváranej ploche.

DYM A PLYNY – Môžu byť zdraviu škodlivé.

• Nevystavujte tvár i hlavu pôsobeniu dymu.

• Používajte vetranie, odsávanie pri oblúku, alebo oboje, aby sa výpary a

plyny nedostali do vašej oblasti dýchania a okolitého priestoru.

OBLÚKOVÉ ŽIARENIE – Môže poraniť oči a spáliť kožu.

• Chráňte si oči aj telo. Používajte správny ochranný štít, okuliare s

filtračnými sklami a ochranný odev.

• Okoloidúcich chráňte vhodnými štítmi alebo závesmi.

0463 373 101

HLUK – Nadmerný hluk môže poškodiť sluch.

Chráňte si uši. Noste chrániče uší alebo iné prostriedky na ochranu sluchu.

- 6 -

© ESAB AB 2018

1 BEZPEČNOSŤ

POHYBLIVÉ ČASTI – Môžu spôsobiť zranenia.

• Dbajte na to, aby boli všetky dvierka, panely akryty zatvorené azaistené

proti pohybu. Vprípade potreby na účely údržby aodstraňovania porúch

môžu kryty odmontovať len kvalifikované osoby. Po skončení údržby ešte

pred naštartovaním motora namontujte späť panely alebo kryty azatvorte

dvierka.

• Pred montážou alebo pripojením jednotky vypnite motor.

• Dbajte na to, aby sa vaše ruky, vlasy, voľné oblečenie anástroje nedostali

do kontaktu spohyblivými časťami.

NEBEZPEČENSTVO POŽIARU

• Iskry (odstrekujúci kov) môžu spôsobiť požiar. Uistite sa, či sa v blízkosti

nenachádzajú žiadne horľavé materiály.

• Nepoužívajte na zatvorené nádoby.

FUNKČNÁ PORUCHA – Pri funkčnej poruche požiadajte o odbornú pomoc.

CHRÁŇTE SEBA AJ OSTATNÝCH!

UPOZORNENIE!

Tento výrobok je určený výhradne na zváranie oblúkom.

VÝSTRAHA!

Nepoužívajte tento zdroj energie na rozmrazovanie zamrznutého potrubia.

UPOZORNENIE!

Zariadenie triedy A nie je určené na používanie v

obytných oblastiach, v ktorých je elektrické napájanie

zaisťované verejnou, nízkonapäťovou rozvodnou

sieťou. Kvôli rušeniu šírenému vedením a vyžarovaním

sa môžu v takýchto oblastiach objaviť prípadné ťažkosti

so zaručením elektromagnetickej kompatibility pri

zariadení triedy A.

POZOR!

Elektronické zariadenie likvidujte v recyklačnom

zariadení!

V súlade s európskou smernicou 2012/19/ES o likvidácii

elektrických a elektronických zariadení a jej

implementácií podľa národných zákonov sa musí

elektrické zariadenie, ktoré dosiahlo koniec životnosti,

zlikvidovať v recyklačnom zariadení.

Ako osoba zodpovedná za zariadenie máte povinnosť

informovať sa o schválených zberných miestach.

Ak chcete ďalšie informácie, obráťte sa na najbližšieho

predajcu spoločnosti ESAB.

Spoločnosť ESAB ponúka na predaj sortiment zváracieho príslušenstva aosobných

ochranných prostriedkov. Pre informácie oobjednávaní kontaktuje miestneho

predajcu spoločnosti ESAB alebo navštívte našu webovú lokalitu.

0463 373 101

- 7 -

© ESAB AB 2018

2 ZÁRUKA

2 ZÁRUKA

Pred dodaním sú naše výrobky dôkladne skontrolované. Spoločnosť ESAB kontroluje každý

výrobok, či je včase dodávky bez chýb materiálu aspracovania ači funguje podľa určeného

použitia.

Spoločnosť ESAB poskytuje záruku na chyby materiálu a spracovania podľa požiadaviek

právnych predpisov. Na spotrebný materiál sa táto záruka nevzťahuje.

Záruka sa nevzťahuje na žiadne škody ani funkčné vady vyplývajúce z nasledujúcich

dôvodov:

• preťaženie, zneužitie alebo nedodržanie zamýšľaného použitia výrobku,

• kolízie a nehody,

• nedodržiavanie pokynov uvedených vtomto návode na obsluhu,

• nesprávna inštalácia alebo montáž,

• nedostatočná údržba,

• úprava produktu oproti pôvodnému stavu,

• chemické vplyvy,

• bežné opotrebovanie.

Spoločnosť ESAB nenesie žiadnu inú zodpovednosť okrem náhrady alebo opravy chybných

dielov.

2.1 Podmienky určeného použitia

1. Výrobok je určený na priemyselné akomerčné použitie asmie ho používať iba

vyškolený personál. Výrobca nezodpovedá za žiadne škody ani nehody spôsobené

nesprávnym použitím.

2. Robotický zvárací systém Aristo® RT je navrhnutý avyrobený vsúlade snajnovším

stavom techniky aje bezpečný aspoľahlivý počas prevádzky, ak sním manipuluje,

inštaluje ho aúdržbu vykonáva vyškolený personál. Musia sa dodržiavať pokyny na

inštaláciu, prevádzku aúdržbu uvedené vtomto dokumente.

3. Robotický zvárací systém Aristo® RT smie inštalovať, obsluhovať aúdržbu

zabezpečovať iba vyškolený personál. Dodržiavajte predpisy na inštaláciu, prevádzku

aúdržbu uvedené vtejto príručke.

4. Robotický zvárací systém Aristo® RT sa môže používať výlučne na účel, ktorý určil

výrobca vtechnických údajoch, as automatizovanými manipulačnými systémami. Typ

horáka sa musí vybrať tak, aby vyhovoval úlohe zvárania.

5. Robotický zvárací systém Aristo® RT bol navrhnutý na používanie ako kompletný

systém. Začlenenie komponentov od iných výrobcov do systému nie je povolené.

6. RTKS-2 aRTKSC-2 sa používajú iba ako mechanizmy núdzového zastavenia

vrámci svojich technických špecifikácií avkombinácii skáblovými zväzkami

štandardného ramena RT (KS-2), Infiniturn alebo Helix (KSC-2), adaptérovou obrubou

ESAB vrátane držiakov horákov RT (KS-2) azváracích horákov Aristo RT.

7. Do vyfukovacieho plynu sa nesmie pridávať žiaden olej ani tekutina proti

rozstrekovaniu. Spoločnosť ESAB nezaručuje chemickú odolnosť voči týmto látkam.

Spoločnosť ESAB odporúča používať striekaciu jednotku ESAB na nanášanie

minimálneho množstva kvapaliny proti rozstrekovaniu na horák, atak chrániť životné

prostredie.

8. Pri preprave, skladovaní apoužívaní musí byť výrobok udržiavaný vsuchu achránený

pred vlhkosťou.

9. Systém je navrhnutý pre teploty prostredia vrozmedzí od 5°C do 40°C (41°F až

104°F). Ak sa tieto hranice prekročia, sú potrebné osobitné opatrenia. Vprípade

nebezpečenstva mrazu použite vhodné chladivo.

0463 373 101

- 8 -

© ESAB AB 2018

3 ÚVOD

3 ÚVOD

Systémy zváracích horákov RT sú vyvinuté pre úplne automatické zváranie MIG/MAG

pomocou robotov. Systémy pozostávajú zrôznych hrdiel horákov Aristo RT určených na

robotické použitie, držiakov horákov, káblových zväzkov optimalizovaných na robotické

použitie abezpečnostných vypínacích prvkov, ktoré zabraňujú poškodeniu systému

vprípade kolízie.

Štandardný zvárací systém RT poskytuje ochranu pred kolíziou pomocou systému RTKS-2,

čo je mechanická pružinová bezpečnostná vypínacia funkcia. Môže byť prípadne nahradená

systémom RTFL-2, aby sa využila funkcia detekcie kolízie riadiaceho systému robota.

Štandardný zvárací systém RT je možné použiť srôznymi typmi káblových zväzkov.

Držiaky horákov RTKSC-2 aRTFLC-2 skáblovými zväzkami Infiniturn alebo Helix sú

určené na použitie vrobotických zváracích systémoch sdutým zápästím určených pre

aplikácie pokročilého zvárania. Bezpečnostný vypínací mechanizmus vdržiaku horáka

RTKSC-2 umožňuje veľké pružné odklonenie horáka vprípade kolízie. Káblové zväzky

Infiniturn aHelix sa jednoducho inštalujú aposkytujú vysoko spoľahlivý systém spresnými

manévrovacími schopnosťami.

Vkombinácii sosvedčenými robotickými zváracími horákmi Aristo RT tieto komponenty

vytvárajú vysoko spoľahlivý atrvanlivý systém, ktorý vyžaduje len minimálnu údržbu.

Návod na použitie je súčasťou dodávky horákov akáblových zväzkov.

Objednávacie čísla spoločnosti ESAB, dostupné príslušenstvo, náhradné diely

asúčasti podliehajúce opotrebovaniu nájdete vzozname Náhradné diely.

0463 373 101

- 9 -

© ESAB AB 2018

3 ÚVOD

3.1 Prehľad systémov zváracích horákov

Štandardný systém RT

Podrobný opis nájdete vpríslušnej časti

kapitoly TECHNICKÉ ÚDAJE:

1. Hrdlo horáka

Pozrite si časť „Zvárací horák“.

2. Káblový zväzok

Pozrite si časť „Káblové zväzky pre

štandardný systém RT“.

3. Držiak horáka

Pozrite si časť „Držiaky horáka pre

štandardný systém RT“.

4. Bezpečnostný vypínací

mechanizmus RTKS-2

Pozrite si časť „Bezpečnostný

vypínací mechanizmus RTKS-2“.

5. Priechodová obruba RTFL-2

Pozrite si časť „Priechodová obruba

RTFL-2“.

6. Adaptérová obruba (ak je

potrebná)

Pozrite si časť „Adaptérová obruba“.

0463 373 101

- 10 -

© ESAB AB 2018

3 ÚVOD

Systém sdutým zápästím

Podrobný opis nájdete vpríslušnej časti

kapitoly TECHNICKÉ ÚDAJE:

1. Hrdlo horáka

Pozrite si časť „Zvárací horák“.

2. Držiak horáka RTKSC-2

Pozrite si časť „Držiak horáka

RTKSC-2 sbezpečnostným

vypínacím mechanizmom“.

3. Držiak horáka RTFLC-2

Pozrite si časť „Pevný držiak horáka

RTFLC-2“.

4. Adaptérová obruba

Pozrite si časť „Adaptérová obruba“.

5. Káblový zväzok Helix alebo

Infiniturn

Pozrite si časť „Káblové zväzky pre

systémy sdutým zápästím“.

0463 373 101

- 11 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

4 TECHNICKÉ ÚDAJE

4.1 Hrdlo zváracieho horáka

Vyberte model horáka podľa zváracej aplikácie. Musí sa zvážiť požadovaný pracovný cyklus

akapacita, metóda chladenia apriemer drôtu. Prípadné zvýšené požiadavky spôsobené

napríklad predhriatymi obrobkami alebo vysokým odrazom tepla vrohoch zohľadnite

výberom zváracieho horáka sprimeranou rezervou výkonu.

Zváracie horáky RT sú určené na použitie so zváracími zdrojmi soznačením ozhode CE pre

procesy zvárania vochrannej atmosfére inertného plynu (MIG), zváranie taviacou sa

elektródou vaktívnom plyne (MAG) aspájkovania MIG skomerčnými okrúhlymi drôtmi.

Horák nepoužívajte viných procesoch.

Na impulzné oblúkové zváranie ocele alebo hliníka sa musí použiť vodou chladený horák

RT82W.

Dostupné modely horákov nájdete nižšie.

Model horáka Spôsob chladenia Ochranný plyn Menovité hodnoty

RT42G Chladenie plynom CO

Chladenie plynom 300A/100%

Chladenie plynom Zmes 350A/60%

Chladenie plynom 250A/100%

RT42W Chladenie vodou CO

Chladenie vodou 420A/100%

Chladenie vodou Zmes 350A/60%

Chladenie vodou 350A/100%

RT52G Chladenie plynom CO

Chladenie plynom 300A/100%

Chladenie plynom Zmes 350A/60%

Chladenie plynom 250A/100%

RT52W Chladenie vodou CO

Chladenie vodou 470A/100%

Chladenie vodou Zmes 400A/60%

Chladenie vodou 400A/100%

RT62G Chladenie plynom CO

Chladenie plynom 340A/100%

2

2

2

2

2

420A/60%

420A/60%

420A/60%

470A/60%

500A/60%

Chladenie plynom Zmes 420A/60%

Chladenie plynom 290A/100%

RT62W Chladenie vodou CO

Chladenie vodou 530A/100%

Chladenie vodou Zmes 450A/60%

Chladenie vodou 450A/100%

0463 373 101

- 12 -

2

530A/60%

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

Model horáka Spôsob chladenia Ochranný plyn Menovité hodnoty

RT72G Chladenie plynom CO

2

480A/60%

Chladenie plynom 320A/100%

Chladenie plynom Zmes 400A/60%

Chladenie plynom 270A/100%

RT72W Chladenie vodou CO

2

480A/60%

Chladenie vodou 430A/100%

Chladenie vodou Zmes 480A/60%

Chladenie vodou 430A/100%

RT82W Chladenie vodou CO

2

600A/60%

Chladenie vodou 600A/100%

Chladenie vodou Zmes 550A/60%

Chladenie vodou 550A/100%

Menovité hodnoty horáka aprevádzkového cyklu platia pre 10minútové cykly.

Technické údaje platia pre štandardizované aplikácie využívajúce štandardné spotrebné

anáhradné diely. Menovité hodnoty horáka sa znižujú, keď sa používa režim impulzového

oblúkového prenosu kovu.

Rozsah teplôt Uskladnenie: -15 – 50°C (5 – 122°F)

Prevádzka: 5 – 40°C (41 – 104°F)

Vyfukovací plyn Max. 10bar, samostatná plynová dýza

Celková hmotnosť (hrdlo horáka,

Približne 5kg

bezpečnostný vypínací mechanizmus, držiak

horáka a1m káblový zväzok)

4.2 Menovité napätie

Max. povolené napätie/prúd

Kompletný systém zváracieho horáka 141V(maximálna hodnota pre zváranie)

Regulačný obvod bezpečnostného

vypínacieho mechanizmu RTKS-2

Tlačidlo RTKS-2

Regulačný obvod bezpečnostného

vypínacieho mechanizmu RTKSC-2

Používanie funkcie snímača dýzy so

štandardným káblovým zväzkom

Používanie funkcie snímača dýzy

skáblovými zväzkami Helix alebo Infiniturn

24V/1A

48V/0,1A

48 V

50V/5A

(Povolené zaťaženie max. 1minúta pri

menovitom prúde)

50V/5A

(Povolené zaťaženie max. 1minúta pri

menovitom prúde)

Uvedené menovité hodnoty sa vzťahujú na štandardné používanie.

Menovité hodnoty káblových zväzkov nájdete včasti „Káblové zväzky“.

0463 373 101

- 13 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

4.2.1 Obmedzenia chladiacich okruhov

Len verzie chladené vodou.

Min. prietok vody: 1,0l/min (1,1kvartu/min)

Min. tlak vody: 2,5bar (36,3psi)

Max. tlak vody: 3,5bar (50,8psi)

Teplota prívodu: Max. 40°C (104°F)

Teplota spätného toku: Max. 60°C (140°F)

Kapacita chladenia: Min. 1000W, vzávislosti od aplikácie

UPOZORNENIE!

Teplota spätného toku nad 60°C (140°F) môže spôsobiť poškodenie alebo zničenie

káblového zväzku.

4.3 Držiak horáka

Požadovaný typ držiaka horáka závisí od konštrukcie systému zváracieho horáka RT aod

výberu bezpečnostných vypínacích zariadení, pozrite si časť „Prehľad systémov zváracích

horákov“.

Komponent Približná hmotnosť

Držiak horáka (pre štandardný systém) 0,43 kg

Bezpečnostný vypínací mechanizmus

0,85 kg

RTKS-2 (pre štandardný systém)

Priechodová obruba RTFL-2 (pre štandardný

0,35 kg

systém)

Držiak horáka RTKSC-2 (pre systém

1,90 kg

sdutým zápästím)

Pevný držiak horáka RTFLC-2 (pre systém

1,22 kg

sdutým zápästím)

Robotický zvárací horák 0,66 kg

4.3.1 Držiaky horáka pre štandardný systém RT

Vštandardných systémoch RT je držiak horáka nainštalovaný na bezpečnostnom vypínacom

mechanizme RTKS-2 (alternatívne na priechodovej obrube RTFL-2), ktorý upína káblový

zväzok apripojené hrdlo horáka.

Vyberte držiak horáka podľa typu ageometrie horáka. Môžu sa použiť rôzne typy držiakov.

Zoznam dostupných horákov pre štandardný systém RT nájdete vzozname náhradných

dielov.

0463 373 101

- 14 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

Držiak horáka pre štandardné robotické ramená

4.3.1.1 Bezpečnostný vypínací mechanizmus RTKS-2

Bezpečnostný mechanizmus RTKS-2 je pružinové zariadenie, ktoré chráni robota asystém

horáka vprípade kolízie.

POZOR!

Nerozoberajte RTKS-2.

4.3.1.2 Priechodová obruba RTFL-2

Namiesto mechanizmu RTKS-2 sa môže použiť pevná priechodová obruba RTFL-2, ak má

robot elektronický systém na detekciu kolízií.

0463 373 101

- 15 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

4.3.2 Držiaky horáka pre systém sdutým zápästím

Vsystéme sdutým zápästím sú hrdlá zváracích horákov Aristo RT spojené sdržiakom

horáka KSC-2 alebo FLC-2.

Držiak horáka RTKSC-2 umožňuje pružné odklonenie horáka vprípade kolízie. Súčasne sa

otvorí elektrický kontakt, ktorý signalizuje zastavenie riadeniu robota. Po resetovaní chyby sa

pôvodná geometria astredový bod nástroja (TCP) horáka dosiahnu svysokou presnosťou.

Tento pružinový systém funguje čisto mechanicky.

Držiak horáka RTFLC-2 nemá zabudovanú funkciu bezpečnostného vypnutia.

Odporúča sa pre systémy sdutým zápästím RTKSC-2 G/W (alternatívne RTFLC-2 G/W).

Tento držiak horáka sa dá použiť splynom aj vodou chladenými horákmi série Aristo RT.

RTKSC-2 G/W RTFLC-2 G/W

Funkčný princíp

Mechanický Nepoužiteľné (pevný držiak)

bezpečnostného vypínacieho

mechanizmu

Axiálna uvoľňovacia sila (Fz) 650 N Nepoužiteľné (pevný držiak)

Uvoľňovací moment na

24Nm Nepoužiteľné (pevný držiak)

priečnej osi (Mx)

Resetovanie po uvoľnení Automatická Nepoužiteľné (pevný držiak)

Opakovateľnosť Laterálne ±0,1mm vTCP

Nepoužiteľné (pevný držiak)

štandardného horáka Aristo

RT

Max. odklonenie Približne ±8° Nepoužiteľné (pevný držiak)

Bezpečnostný spínač Normálne zatvorený

Nepoužiteľné (pevný držiak)

Elektrické zaťaženie max.

48V/1A

0463 373 101

- 16 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

Elektrický regulačný obvod

pre funkciu snímača dýzy

Menovité hodnoty:

• Pre káblové zväzky

Helix: max.

50VDC/5A, max.

1minúta

Po zistení kontaktu sa

rýchlo odpojí napätie

snímania.

• Pre káblové zväzky

Infiniturn je funkcia

snímača dýzy

Menovité hodnoty:

• Pre káblové zväzky

Helix: max.

50VDC/5A, max.

1minúta

• Pre káblové zväzky

Infiniturn: max.

50VDC/1A, max.

1minúta

Po zistení kontaktu sa rýchlo

odpojí napätie snímania.

obmedzená. Ak chcete

získať podrobné

informácie omožných

riešeniach vo vašej

aplikácii, kontaktujte

spoločnosť ESAB.

Menovité napätie Maximálne povolené napätie

pre bezpečnostný vypínací

regulačný obvod: 48V.

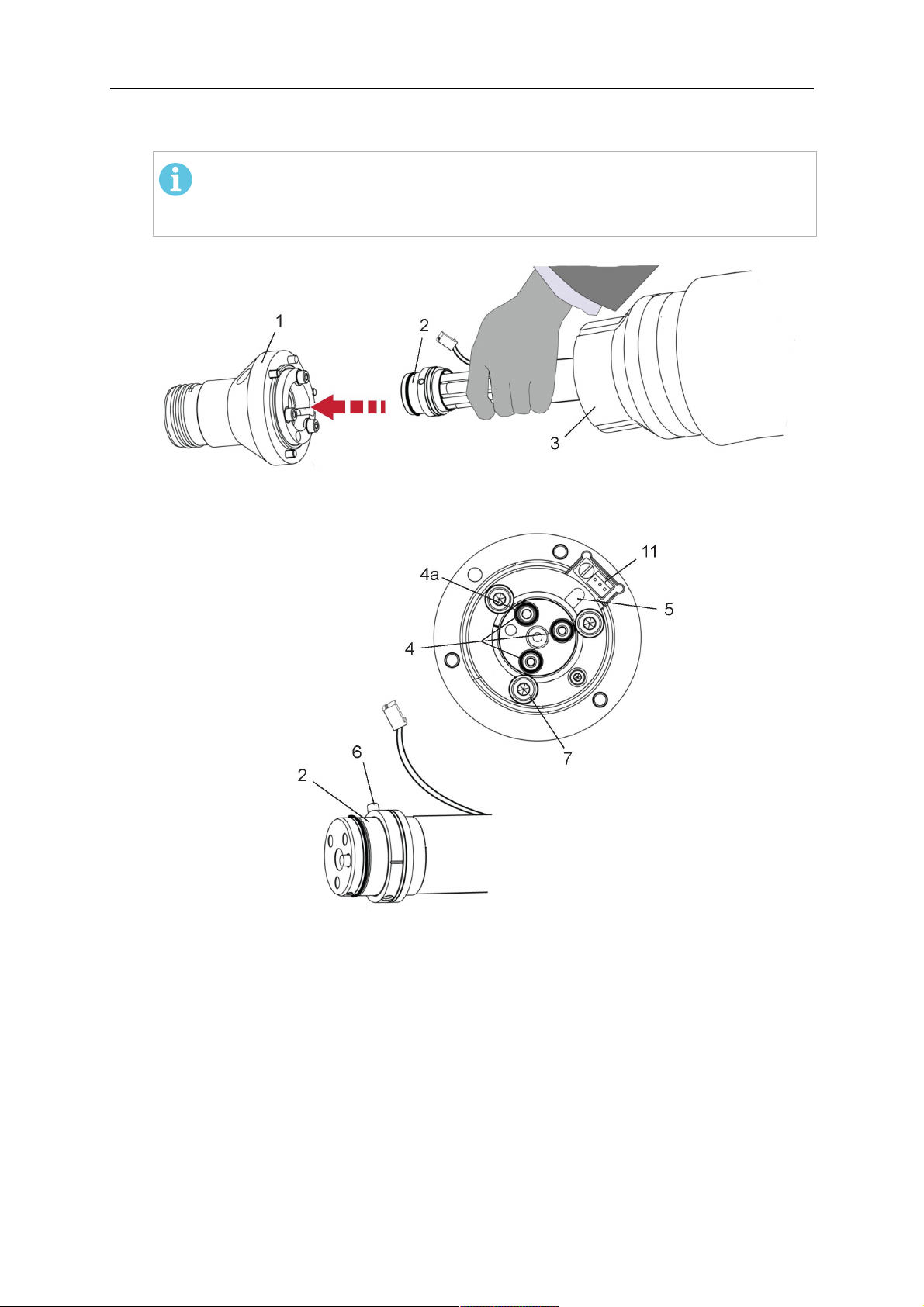

4.3.2.1 Držiak horáka RTKSC-2 G/W sbezpečnostným vypínacím mechanizmom

Polo

Popis Funkcia

žka

1 Podpera hrdla horáka Priechodka horáka Aristo RT

2 Kryt RTKSC-2 Zostava skáblom ahorákovými priechodkami

0463 373 101

- 17 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

Polo

Popis Funkcia

žka

3 Gumový chránič Ochrana bezpečnostného vypínacieho mechanizmu

4 Hlavné teleso RTKSC-2 Umožňuje mechanické odklonenie pri kolízii

5 Adaptérová obruba Oddeľovacia priechodka robotického zápästia (musí

byť vhodná pre konkrétneho robota)

6 Západkový kolík Na presné zarovnanie do adaptérovej obruby

7 Konektor pre kábel regulácie Elektrické pripojenie pre kolízny signál afunkciu

snímača dýzy

8 Mikrospínač Snímač detekcie kolízie

4.3.2.2 Pevný držiak horáka RTFLC-2 G/W

Polo

Popis Funkcia

žka

1 Podpera hrdla horáka Priechodka horáka Aristo RT

2 Kryt RTFLC-2 Zostava skáblom ahorákovými priechodkami

3 Hlavné teleso RTFLC-2 Umožňuje mechanické odklonenie pri kolízii

4 Západkový kolík Na presné zarovnanie do adaptérovej obruby

5 Adaptérová obruba Oddeľovacia priechodka robotického zápästia (musí

byť vhodná pre konkrétneho robota)

6 Konektor pre kábel regulácie

(3-pólový)

0463 373 101

Elektrické pripojenie funkcie snímača dýzy (v

prípade potreby)

- 18 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

4.4 Adaptérové obruby

Vyberte adaptérovú obrubu potrebnú pre inštaláciu na rameno robota vzávislosti od typu

robota. Kdispozícii sú adaptérové obruby pre všetky vhodné štandardné systémy asystémy

sdutým zápästím, pozrite si zoznam náhradných dielov.

4.5 Káblové zväzky

Pripojenie na podávač drôtu je ovplyvnené káblovým zväzkom, dostupnými verziami hlavne

vzávislosti od konštrukcie systému achladiacich médií (plyn alebo voda), pozrite si zoznam

náhradných dielov.

Menovité hodnoty platia pre dĺžky káblov od 1 do 5 m.

Štandardný káblový

Infiniturn Helix

zväzok

Menovité hodnoty

(10min. cyklus)

Chladenie plynom

(zmes plynov)

Menovité hodnoty

(10min. cyklus)

500A/60%

zaťažovací cyklus

350A/100%

zaťažovací cyklus

600A/100%

zaťažovací cyklus

400A/60%

zaťažovací cyklus

320A/100%

zaťažovací cyklus

550A/100%

zaťažovací cyklus

Chladenie vodou

Rozsah otáčania Obmedzená

otáčavosť

Hmotnosť

Chladenie plynom

Hmotnosť

Chladenie vodou

Dĺžka 1,2m:

2,35 kg

Dĺžka 1,2m:

2,35 kg

Neobmedzená

otáčavosť

Dĺžka 1,0m:

2,0 kg

Dĺžka 1,0m:

2,0 kg

4.5.1 Káblové zväzky pre štandardný systém RT

400A/60%

zaťažovací cyklus

320A/100%

zaťažovací cyklus

550A/100%

zaťažovací cyklus

±270° zneutrálne

polohy

Dĺžka 1,0m:

2,0 kg

Dĺžka 1,0m:

2,0 kg

0463 373 101

- 19 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

Kolíky konektora Burndy

A. Plynová dýza sdotykovým

snímačom

C. Kolízny snímač

F. 0V

G. + napätie motora

H. - napätie motora

D. Kolízny snímač

E. Posúvanie

Polo

Popis Funkcia

žka

1 Podperná obruba hrdla Priechodka horáka

2 Ochranný kryt Chráni káblový zväzok pred poškodením

3 Konektor Burndy, 12-pólový Elektrické prepojenie medzi bezpečnostným

vypínaním apodávačom drôtu

4 Kábel regulácie Pre KS-2 (bezpečnostné vypínanie atlačidlo)

5 Konektor EURO Pripojenie podávača drôtu

6 Vyfukovacia hadica (čierny

uzáver)

7 Prívod vody (modrý uzáver)

8 Spätný tok vody (červený

Na čistenie horáka stlačeným vzduchom po cykle

čistenia

Prívod vody na chladenie horáka

Spätný tok zohriatej vody od horáka

1

1

uzáver)

9 Zásuvka kábla regulácie

mechanizmu bezpečnostného

Elektrické prepojenie sRTKS-2 pre signál

bezpečnostného vypnutia afunkciu snímača dýzy

vypnutia

1

Len vodou chladené systémy horákov

4.5.2 Káblové zväzky pre systémy spriechodným zápästím

Káblový zväzok Infiniturn umožňuje otáčanie horáka voboch smeroch. Súčasne sa prenáša

chladiaca tekutina, ochranný plyn, vyfukovací vzduch, zvárací výkon asignál

bezpečnostného vypínacieho mechanizmu.

Káblový zväzok Helix je navrhnutý pre rozsah otáčania ±270° zneutrálnej polohy. Môže sa

používať na zváranie, ktoré nevyžaduje neobmedzené otáčanie.

Káblové zväzky Infiniturn sa dodávajú vo verziách schladením plynom achladením vodou.

Káblové zväzky Helix sa môžu univerzálne používať pre aplikácie schladením plynom alebo

chladením vodou.

POZOR!

Káblový zväzok Helix používaný pre hrdlo horáka schladením plynom nepripájajte

kvodnému chladiacemu systému.

0463 373 101

- 20 -

© ESAB AB 2018

4 TECHNICKÉ ÚDAJE

Polo

Popis Funkcia

žka

1 Obruba Držiak horáka RTKSC-2/priechodka RTFLC-2

2 Západkový kolík Zabezpečenie správnej orientácie pri spojení

3 Zásuvka kábla regulácie Elektrické prepojenie sRTKSC-2 pre signál

bezpečnostného vypnutia afunkciu snímača dýzy (v

prípade potreby)

4 Konektor EURO Pripojenie podávača drôtu

5 Kábel regulácie Elektrické prepojenie pre signál bezpečnostného

vypnutia (z RTKSC-2) afunkciu snímača dýzy

(snímač dýzy je štandardné vybavenie pre zväzky

Helix, nie pre zväzky Infiniturn)

6 Spätný tok vody (červený

Spätný tok zohriatej vody od horáka

uzáver)

7 Prívod vody (modrý uzáver) Prívod vody na chladenie horáka

8 Vyfukovacia hadica (čierny

Na čistenie horáka stlačeným vzduchom po zváraní

uzáver)

9 Spojka médií Neobmedzene otáčavá spojka na prenos médií

10 Ochranný kryt Chráni káblový zväzok pred poškodením

0463 373 101

- 21 -

© ESAB AB 2018

5 INSTALLATION

5 INSTALLATION

VÝSTRAHA!

For your own safety, make sure that the robot is either in standby or power-less

state before doing maintenance work in the moving radius of the robot.

Follow the assembly instructions exactly. Pay attention during assembly that the cables are

not damaged. Damaged cables can lead to a short circuit, which may damage the electronics

of the robot or the welding torch.

Use only original ESAB components that have been specially developed for this purpose.

Only then the correct functioning of the whole welding torch system can be guaranteed.

5.1 RTKS-2 standard arm installation

5.1.1 RTKS-2 safety-off mechanism

1. Dismount the insulation flange (10) from the RTKS-2 (11) by removing the screws

(12).

2. Position the insulation flange (10) with the index pin on the robot arm and fix it with the

screws (20) included.

The insulation flange (10) is directly compatible with robots with tool flange according

to DIN ISO 9409-1-A40 (diameter 40mm, 4×M6). If the insulation flange (10) does

not fit, use an adapter flange (21).

POZOR!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

3. Mount the RTKS-2 the back on the insulation flange (10).

0463 373 101

- 22 -

© ESAB AB 2018

5 INSTALLATION

4. Position the mount on the RTKS-2 and carefully insert the cylindrical pins (14) into the

holes provided. Take the position of the torch into account. Two mounting positions

may be potentially possible.

5. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (12).

POZOR!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

12 - Cylinder screw with hexagon socket

M6DIN912 (length of the screw depending

on the torch mount)

14 - Cylindrical pins Ø4×20

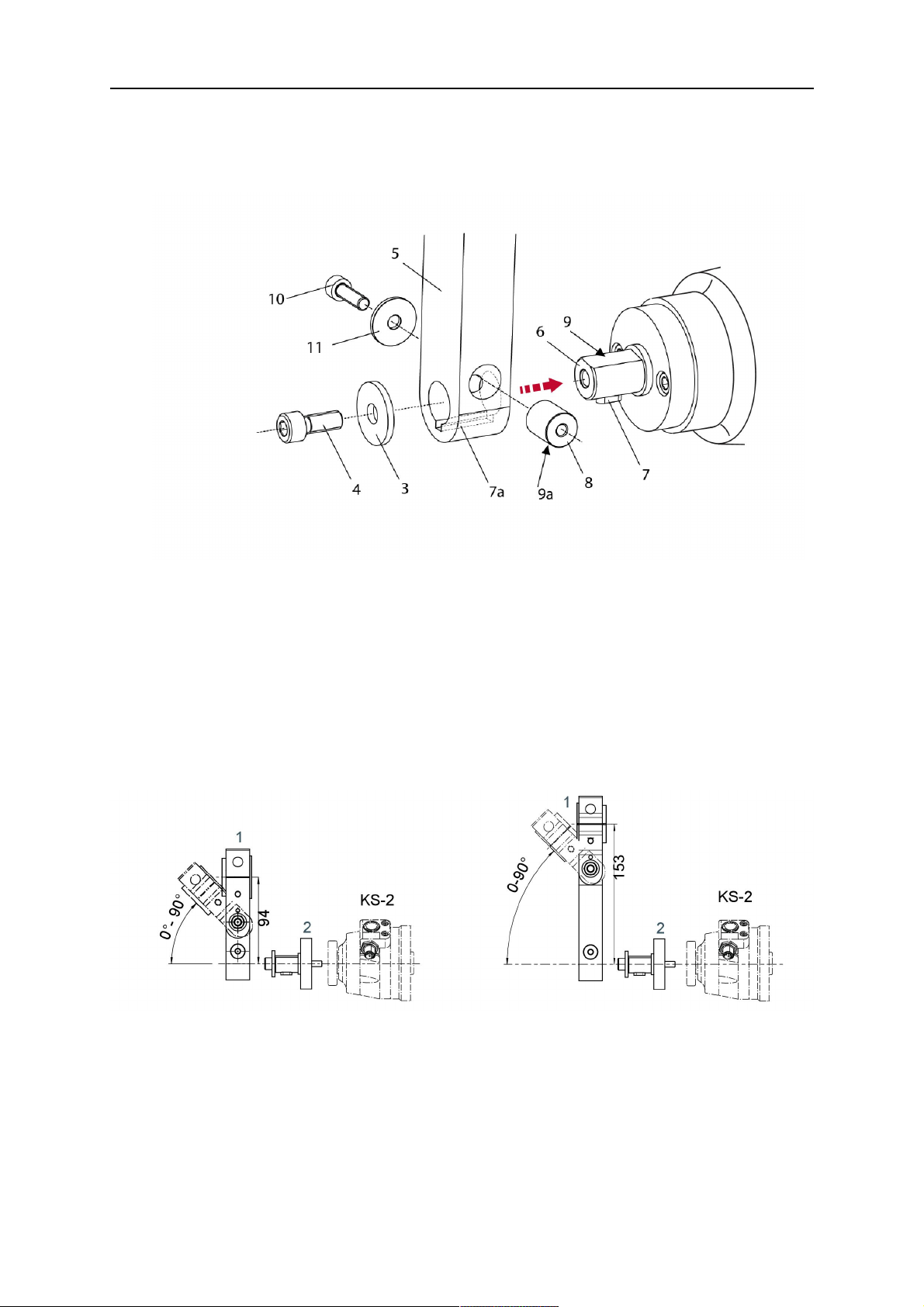

5.1.1.1 Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. The pins should protrude by approximately 5 mm (0.2 in.).

2. Position the mount on the safety-off mechanism RTKS-2 and carefully insert the

cylindrical pins (1) into the holes provided. In doing so, take the later position of the

torch into account. Two mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

POZOR!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

0463 373 101

- 23 -

© ESAB AB 2018

5 INSTALLATION

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

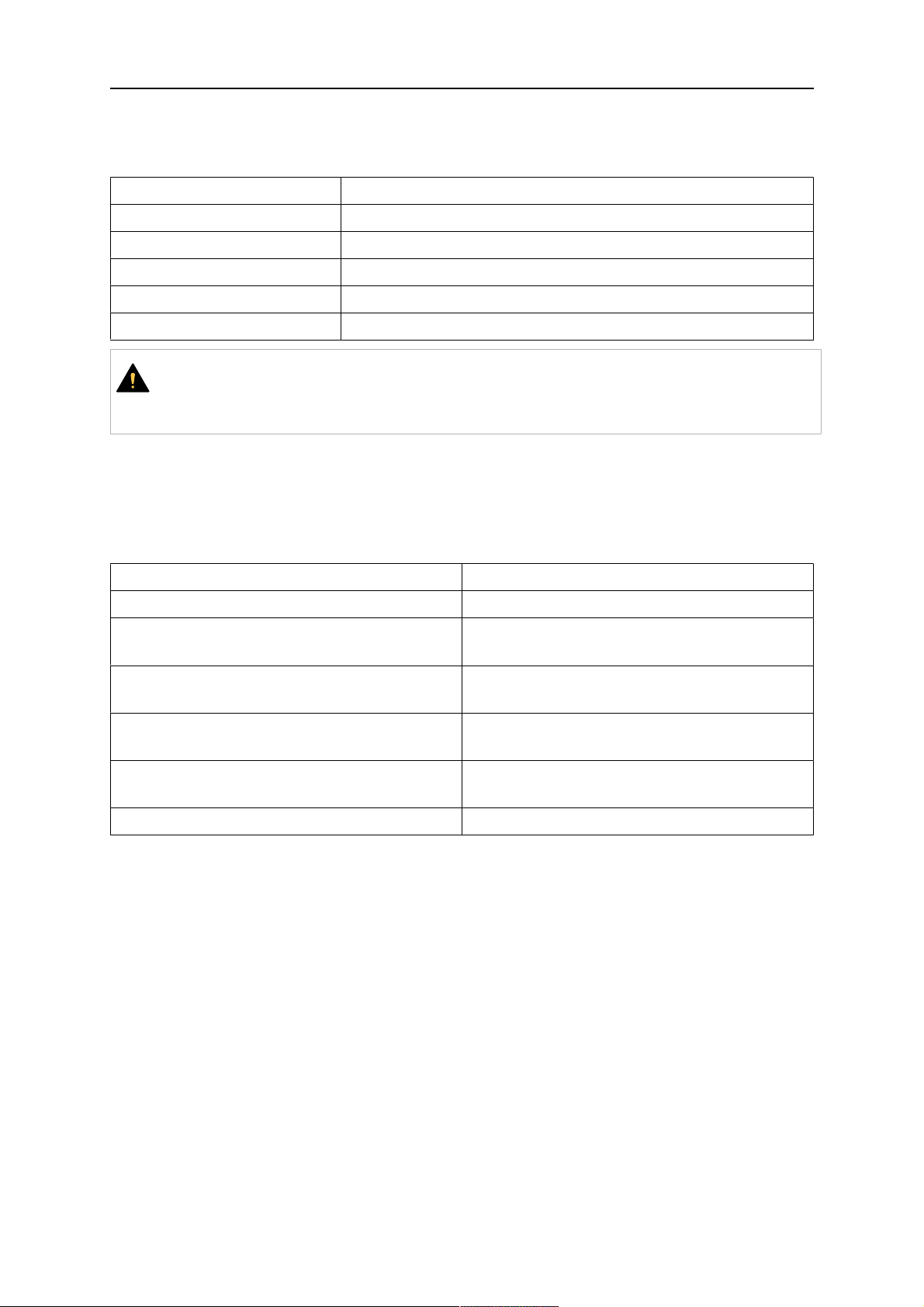

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

0463 373 101

- 24 -

© ESAB AB 2018

5 INSTALLATION

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.1.2 Standard arm cable assembly for KS-2 and FL-2

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

0463 373 101

- 25 -

© ESAB AB 2018

5 INSTALLATION

UPOZORNENIE!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

1. Unscrew the cylinder screws (1) and lift off the top section (2) of the torch mount.

2. Insert the feather key (4) into the recess of the neck support flange (3) from below.

3. Align the neck support flange (3) including the feather key (4) to the groove (5) of the

torch mount and push into the groove right up to the stop of the flange.

4. Hold the cable assembly in this position and simultaneously place the top section (2)

back onto the torch mount. First screw both cylinder screws (1) loosely in to about the

same length, then tighten alternately. The top section (2) of the mount should have an

even gap to the bottom section.

The front part of the cable assembly is directly clamped into the torch mount (see

illustration below).

1 - Cylinder screws 4 - Feather key

2 - Torch mount top section 5 - Groove for feather key

3 - Neck support flange

5.1.3 RTKS-2 wire feeder connection

In order to be able to create the connection, the cable assembly must be mounted as

described in the "Installing the cable assembly" section and equipped following "Installing the

wire guide" section. Only then can the central and media connection take place. Proceed as

described below:

0463 373 101

- 26 -

© ESAB AB 2018

5 INSTALLATION

1. Connect the central connector of the cable assembly (2) to the wire feeder cabinet

socket. Tighten the central connector sleeve nut fingertight. Do not use tools.

1 - Burndy Connector 4 - Return of heated water (red cap)

2 - EURO central connector 5 - Return of heated water (red cap)

3 - Air blow-out 6 - Main Wire feeder

2. For water cooled systems. Connect the water hoses to the cooling circuit. The end of

the hose marked blue (4) is connected to the water outlet, and the end marked red (5)

is connected to the water return.

3. Connect the blow-out line (3) to the corresponding connection of the feeder.

4. Connect the Burndy Connector to the wire feeder. (1) to the feeder. See section

"Electrical connections".

POZOR!

All hoses and the control line must be installed so they can not bend or get

damaged!

5.1.4 RTKS-2 electrical connections

5.1.4.1 RTKS-2 safety-off mechanism connection

The switch for the safety-off functionality RTKS-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKS-2 unit via the 4-pole plug (4) that

contains circuits for the push-button (6) and the safety-off signal (7).

If a collision is detected, the control circuit for the safety-off signal (7), which is normally

closed, will be interrupted.

Rating of the control circuit: max. 48 V / 1 A

0463 373 101

- 27 -

© ESAB AB 2018

5 INSTALLATION

2 - Burndy connector 5 - RTKS-2 connector for control cable plug

4 - Control cable plug

Kolíky konektora Burndy

A. Plynová dýza sdotykovým

snímačom

C. Kolízny snímač

F. 0V

G. + napätie motora

H. - napätie motora

D. Kolízny snímač

E. Posúvanie

If the robot control provides a control circuit for nozzle sense functionality, the connection is

accomplished with a 1-wire connection.

Rating of the control circuit: max 50 V / 5 A.

NEBEZPEČENSTVO!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

UPOZORNENIE!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

5.1.5 RTKS-2 Torch installation

Continue according to section "Torch installation".

0463 373 101

- 28 -

© ESAB AB 2018

5 INSTALLATION

5.2 RTFL-2 standard arm installation

5.2.1 RTFL-2 rigid mount

1. Position the RT FL-2 (2) with the index pin on the robot arm and fix it with the hexagon

socket screw included.

The FL-2 is directly compatible with robots with tool flange according to DIN ISO

9409-1-A40 (diameter 40mm, 4×M6). If the rigid mount does not fit, use an adapter

flange (3).

POZOR!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

2. Install torch mount (1). Only torch mounts having a hole pattern equivalent with the

mounting surface may be attached. If necessary, carefully press the cylindrical pins (4)

into the corresponding holes in the bracket. The pins should protrude by

approximately 5mm (0.2in.). Position the torch mount on the RTFL-2 (2) and

carefully insert the cylindrical pins (4) into the holes provided. Take the position of the

torch into account. Two mounting positions may be potentially possible.

3. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (5).

POZOR!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

0463 373 101

- 29 -

© ESAB AB 2018

5 INSTALLATION

4 - Cylindrical pins Ø4×20

5 - Cylinder screw with hexagon socket M6

DIN 912 (length of the screw depending on

the torch mount)

Side view

Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. Avoid the formation of burrs. The pins should protrude by

approximately 5 mm (0.2 in.).

2. Position the mount on the RTFL-2 and carefully insert the cylindrical pins (1) into the

holes provided. In doing so, take the later position of the torch into account. Two

mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

POZOR!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

0463 373 101

- 30 -

© ESAB AB 2018

5 INSTALLATION

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 - Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.2.2 RTFL-2 torch installation

Continue according to section "Torch installation".

5.3 RTKSC-2 hollow wrist system installation

5.3.1 RTKSC-2 mount with safety off mechanism

UPOZORNENIE!

For hollow wrist systems make sure that the clear space around the robot is at least

Ø45 mm (1.8 in.) around the wrist and 50 mm (2.0 in.) near the wire feeder.

0463 373 101

- 31 -

© ESAB AB 2018

5 INSTALLATION

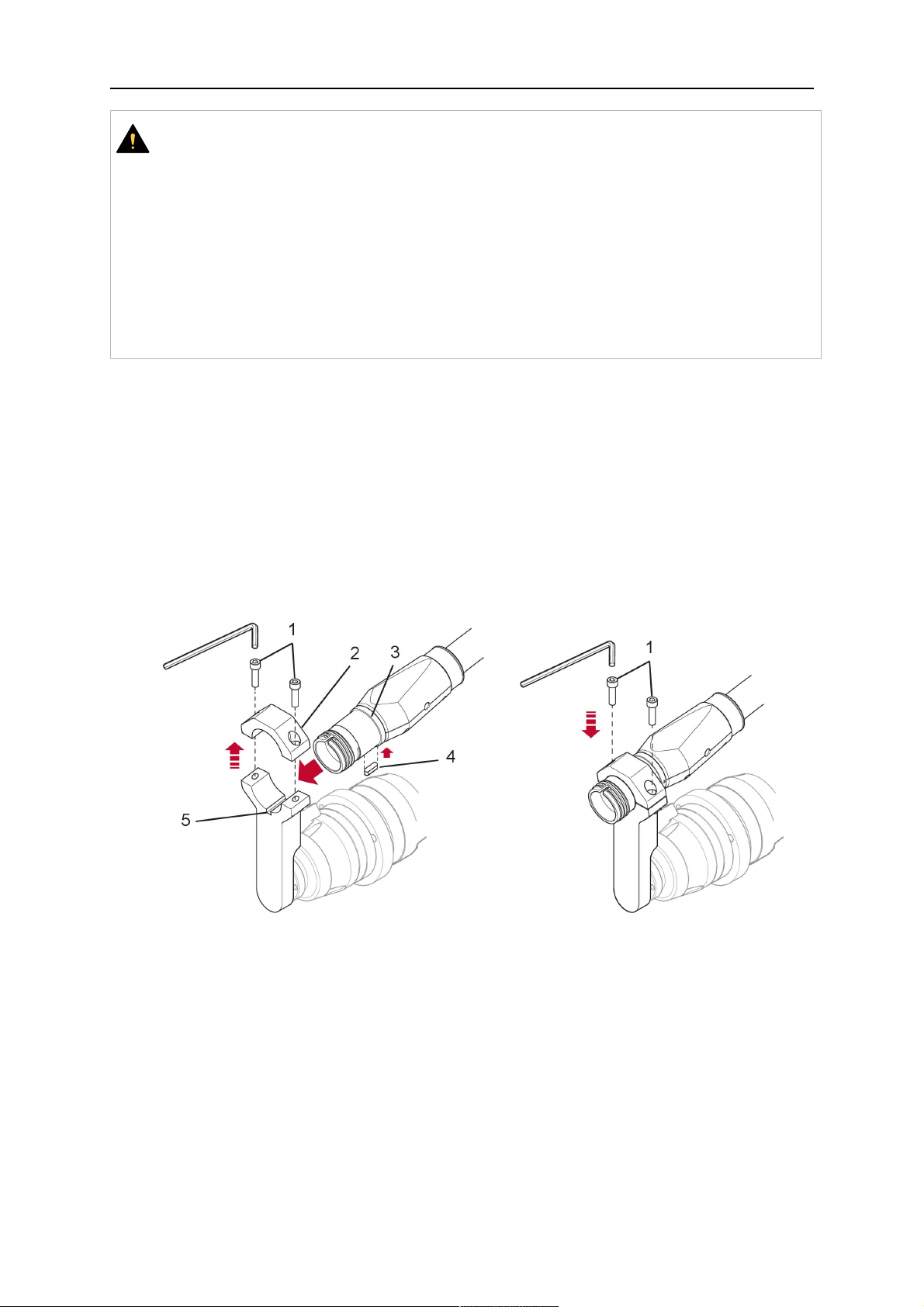

1. Remove the three screws (2) from the front cover (3) of the torch mount and carefully

pull the cover off the RTKSC-2 main body (5). Take care not to damage the micro

switches installed inside the assembly.

1 - Hexagon wrench 4 mm 4 - Rubber boot

2 - 3× M5×12 screws 5 - RT KSC-2 main body

3 - RT KSC-2 front cover

1. Pull off the rubber boot (4) from the RTKSC-2 main body (5) to the front.

2. Now position the RTKSC-2 main body (5) on the adapter flange (7) so that the index

pin is correctly seated. Attach with the screws (6) enclosed.

3. Reinstall the rubber boot (4) on the RTKSC-2 main body (5) and make sure it is

correctly located in the grooves on the front and back flange.

4. Istall the adapter flange (7) on the robot.

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 3 - 3× M5×12 hexagon socket screws

2 - Rubber boot 4 - Adapter flange

5.3.2 Mounting the cable assembly

POZOR!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ±2-3cm (±1in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

0463 373 101

- 32 -

© ESAB AB 2018

5 INSTALLATION

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

UPOZORNENIE!

Axis 6 must be in 0° position.

5.3.2.1 RTKSC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

UPOZORNENIE!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 33 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

UPOZORNENIE!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connectors are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

POZOR!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

POZOR!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

0463 373 101

- 34 -

© ESAB AB 2018

5 INSTALLATION

5.3.3 RTKSC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

UPOZORNENIE!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.3.3.1 RTKSC-2 cable assembly installation

POZOR!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2, then thread the cable from the front through the

robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTKSC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1).

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 35 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

POZOR!

Make sure that the position of the O-rings are not shifted by the index pin

during the assembly.

1 - RTKSC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RTKSC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 36 -

© ESAB AB 2018

5 INSTALLATION

6. If present, insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTKSC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13. Index pin

14. 3× M5×12 screws

0463 373 101

- 37 -

© ESAB AB 2018

5 INSTALLATION

5.3.3.2 RTKSC-2 electrical connections

POZOR!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then

implemented via the power source controller.

RTKSC-2 safety-off mechanism connection

The switch for the safety-off functionality RTKSC-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKSC-2 unit via the control cable plug

(1).

The safety-off signal requires a 2-wire connection (black/black) to the safety-off circuit in the

robot control (5).

If a collision is detected, the control circuit (normally closed) will be interrupted (4).

Rating of the control circuit: max. 48 V / 1 A.

1 - Control cable plug 3 - Burndy connector VVV

2 - EURO central connector

Kolíky konektora Burndy

A. Plynová dýza sdotykovým

snímačom

C. Kolízny snímač

F. 0V

G. + napätie motora

H. - napätie motora

D. Kolízny snímač

E. Posúvanie

RTKSC-2 nozzle sense function connection

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

0463 373 101

- 38 -

© ESAB AB 2018

5 INSTALLATION

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

NEBEZPEČENSTVO!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

UPOZORNENIE!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

5.3.4 RTKSC-2 torch installation

Continue according to section "Torch installation".

0463 373 101

- 39 -

© ESAB AB 2018

5 INSTALLATION

5.4 RTFLC-2 installation

5.4.1 RTFLC-2 mount

1. Remove the three M5 screws (2) from the front cover (3) of the RT FLC-2 torch mount

and carefully pull the cover off the main body (4).

1 - Hexagon wrench 4 mm 3 - RT FLC-2 front cover

2 - 3× M5×12 screws 4 - RT FLC-2 main body

2. Now position the RT FLC-2 main body (4) on the adapter flange (6) so that the index

pin is correctly seated. Attach with the screws (5) enclosed

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 5 - 3× M5×12 hexagon socket screws

4 - RT FLC-2 main body 6 - Adapter flange

5.4.2 RTFLC-2 wire feeder connection

5.4.2.1 Feeding through the robot arm

POZOR!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ± 2-3 cm (± 1 in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

0463 373 101

- 40 -

© ESAB AB 2018

5 INSTALLATION

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

UPOZORNENIE!

Important! Axis 6 must be in 0° position.

5.4.2.2 RTFLC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

UPOZORNENIE!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 41 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

Refer to the instruction of the feeder manufacturer.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

UPOZORNENIE!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connections are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

POZOR!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

POZOR!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

0463 373 101

- 42 -

© ESAB AB 2018

5 INSTALLATION

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

5.4.3 RTFLC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

UPOZORNENIE!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.4.3.1 RTFLC-2 cable assembly installation

In a hollow wrist system the recommended order of installation is to feed the cable assembly

through the robot arm before connecting the cables to the torch mount.

When the cable assembly is correctly installed in the hollow wrist, continue the installation

according to the procedure described below.

POZOR!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2 and RTFLC-2, then thread the cable from the front

through the robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTFLC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1). For gas cooled

systems, only one O-ring (4a) is needed, for water cooled systems all three O-rings

are needed.

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 43 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

POZOR!

Take great care that the position of the O-rings is not shifted by the index pin

during the assembly.

1 - RT FLC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RT FLC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 44 -

© ESAB AB 2018

5 INSTALLATION

6. If present insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTFLC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13 - Index pin 14 - 3x M5x12 screws

0463 373 101

- 45 -

© ESAB AB 2018

5 INSTALLATION

5.4.4 RTFLC-2 electrical connections

POZOR!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

documentation of the manufacturer for details. The link to the robot control is then

implemented via the power source controller.

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

NEBEZPEČENSTVO!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

UPOZORNENIE!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

0463 373 101

- 46 -

© ESAB AB 2018

5 INSTALLATION

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 1-wire connection (green) to the nozzle sense circuit

in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

NEBEZPEČENSTVO!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

UPOZORNENIE!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - EURO central connector

2 - Control cable 4 - Burndy connector

5.5 Torch installation

Be sure to use the correct version of the torch mount and cable assembly (water or gas

cooled).

5.5.1 Torch neck equipment

The torch neck, see (1) in the illustration below, must always be equipped to suit the wire

diameter and material.

0463 373 101

- 47 -

© ESAB AB 2018

5 INSTALLATION

1. Select the correct wire guide, contact tip (4), tip holder (2), gas nozzle (5), and gas

diffuser/spatter protection (3). You will find an exact overview and possible alternative

equipment elements for various torch models in the spare parts list. Only use original

ESAB parts; only then is the fitting accuracy ensured.

2. Firmly tighten the tip holder and the contact tip using a suitable tool for example the

enclosed monkey wrench.

3. When using a split wire guide, remove the installed guide nipple including the o-ring

from the torch flange upon delivery if necessary (see section "Installing the neck

liner").

UPOZORNENIE!

The torch must be completely equipped before welding, especially the gas

diffuser and/or spatter protection and all necessary insulators have to be

installed according to the spare parts list. Welding without these items may

cause immediate destruction of the torch.

1 - Torch neck 4 - Contact tip

2 - Tip holder 5 - Contact tip

3 - Gas diffuser

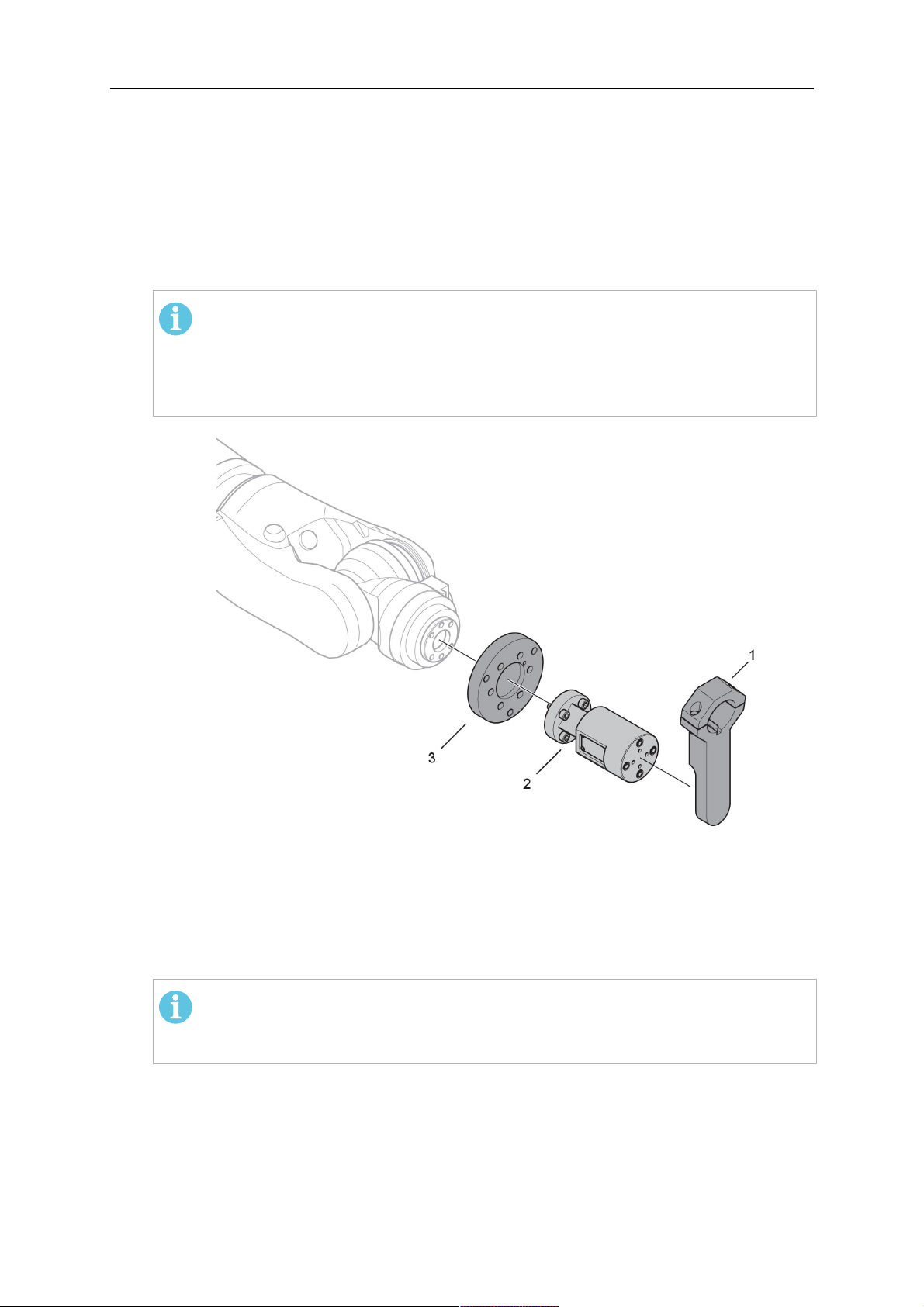

5.5.2 Aristo RT torch neck installation

POZOR!

Check the O-rings on the flange of the torch neck before mounting. Replace the

O-rings if damaged or lost. Missing or faulty O-rings will lead to leaks of shielding

gas and coolant.

1. For hollow wrist systems, insert the torch into the torch mount in the correct

orientation, so that the locator pin fits into the slot of the RTKSC-2 or RTFLC-2

interface, see (A) in the illustration below. For standard systems, attach the torch to

the RT flange of the cable assembly, (B) in the illustration below.

Installation is only possible in the correct orientation.

2. Tighten the locking nut of the torch neck.

POZOR!

Only tighten by hand, never use tools or excessive force.

0463 373 101

- 48 -

© ESAB AB 2018

5 INSTALLATION

3. The correct seating of the torch can be checked by means of the window (1). If the

torch has been correctly mounted, no gap should be seen through the window (1).

5.6 Installing the wire guide for standard and hollow Wrist arm

Installing the wire guide

Choose the wire guide or liner depending on the filler wire material and diameter to be used,

see the spare parts list. Accurate performance of the system can only be guaranteed when

using original ESAB wire guides.

The recommended wire guide is the split wire guide, which consists of the neck liner and a

separate guide in the cable assembly. The front part of the wire guide, which is most

stressed, can be exchanged easily and independently of the cable assembly wire guide.

For correct installation, the following steps must be followed (example for Euro central

connector).

5.6.1 Installing the neck liner

The neck liner must be selected to fit the material and diameter of the welding wire, see the

spare parts list.

0463 373 101

- 49 -

© ESAB AB 2018

5 INSTALLATION

1. If present, remove the central guide nipple (1), from the torch neck using a hexagon

wrench (size 6 mm) or a large flat-blade screwdriver.

POZOR!

The guide nipple (1) can only be used with one-piece liners and must not be

used with the standard RT or hollow wrist system.

2. When replacing the neck liner:

Unfasten the sleeve nut and remove the torch neck.

Unfasten the liner nipple using a hexagon wrench (size 6 mm) and remove nipple and

liner from the torch neck.

3. Remove the gas nozzle and the contact tip.

4. Insert the new neck liner (2) into the torch. Carefully tighten the guide nipple using a

suitable tool, e.g. a hex-wrench (size 6 mm) or a large flat-blade screwdriver.

5. Cut the neck liner flush with the tip holder and remove the neck liner from the torch.

6. Install the contact tip.

7. Insert the neck liner again. It will be stopped by the contact tip. Measure the excess

liner sticking out of the neck.

8. Remove the liner again and shorten the front end by the measured length. Carefully

deburr the edge and make sure that the inner hole is not blocked.

9. Reinstall the neck liner and tighten the guide nipple in the neck.

5.6.2 Installing a split wire guide in the cable assembly

The correct liner must be inserted to suit the filler material and the wire diameter, see the

spare parts list.

The wire guide is inserted through the cable assembly from the rear, reaching the guide

nipple that is installed in the flange where the torch neck will be attached. The following

worksteps must be followed in order to correctly determine the wire guide length. (Example

for Euro central connector).

0463 373 101

- 50 -

© ESAB AB 2018

5 INSTALLATION

1. For standard RT system: Install the guide nipple (1) in the center hole of the neck

support flange, see illustration A below.

For hollow wrist system: Install the guide nipple (1) into the torch interface of the

RTKSC-2 / RTFLC-2 cover, see illustration B below.

2. Remove the sleeve nut (2) from the central connector, and remove the old wire guide.

3. Insert the wire guide through the central connection and push forwards as far as it will

go into the guide nipple (1), applying light pressure.

UPOZORNENIE!

Ensure that the wire guide has advanced right up to the stop at the front,

rotating and pushing forward gently.

4. Measure the excess length that needs to be cut from the wire guide.

5. Remove the wire guide again and shorten the front end by the measured length.

Steel liner: grind down the burred edges if needed.

Plastic liner: make a clean cut and chamfer the edges (e.g. with a pencil sharpener)

POZOR!

Make sure the inner opening of the liner is not obstructed by the cut wire end.

0463 373 101

- 51 -

© ESAB AB 2018

5 INSTALLATION

6. Reinstall the wire guide and attach the sleeve nut (2).

POZOR!

For hollow wrist systems where Infiniturn and Helix cable assemblies are

used, wire guides should be installed without tension so that the ends of the

liners may rotate freely.

Important note when using a plastic liner:

The wire channel between the drive rolls of the feeder and the central

connector of the torch must be fitted with a plastic liner. Depending on the

design of the feeder, a piece of plastic liner inserted into a brass guide tube

can be used.

During wire run-in, make sure that the wire is fed correctly into the plastic liner

of the torch. If necessary, remove the cable assembly from the feeder and

insert the wire, then reattach.

5.6.3 Installing a continuous wire guide in the cable assembly