RT Robo Welding Torch System

RTKS-2, RTFL-2, KSC-2, FLC-2, RT42, RT52,

RT62, RT72, RT82, RT42-NG, RT82WNG

Instrukcijos

0463 373 101 LT 20181227

TURINYS

1

SAUGA ........................................................................................................ 5

1.1 Simbolių reikšmė.................................................................................... 5

1.2 Saugos priemonės ................................................................................. 5

2

GARANTIJA ................................................................................................ 8

2.1 Numatyto naudojimo sąlygos ............................................................... 8

3

ĮVADAS ........................................................................................................ 9

3.1 Suvirinimo degiklio sistemų apžvalga ................................................. 9

4

TECHNINIAI DUOMENYS ........................................................................... 11

4.1 Suvirinimo degiklio kaklelis .................................................................. 11

4.2 Vardinė įtampa........................................................................................ 12

4.2.1 Aušinimo kontūro apribojimai ............................................................... 12

4.3 Degiklio tvirtinimo detalė....................................................................... 13

4.3.1 Standartinei RT sistemai skirtos degiklio tvirtinimo detalės.................. 13

4.3.1.1 RTKS-2 apsauginis mechanizmas ................................................... 14

4.3.1.2 RTFL-2 tarpinė jungė........................................................................ 14

4.3.2 Sistemai su tuščiaviduriu riešu skirtos degiklio tvirtinimo detalės ........ 15

4.3.2.1 RTKSC-2 G/W degiklio tvirtinimo detalė su apsauginiu

mechanizmu ......................................................................................

4.3.2.2 RTFLC-2 G/W standi degiklio tvirtinimo detalė................................. 17

4.4 Adapterio jungės .................................................................................... 18

4.5 Kabelio įtaisai ......................................................................................... 18

4.5.1 Standartinės RT sistemos kabelio įtaisai.............................................. 18

4.5.2 Sistemoms su tuščiaviduriu riešu skirti kabelio įtaisai .......................... 19

5

INSTALLATION............................................................................................ 21

5.1 RTKS-2 standard arm installation........................................................ 21

5.1.1 RTKS-2 safety-off mechanism............................................................. 21

5.1.1.1 Torch installation with adjustable mount ............................................ 22

5.1.2 Standard arm cable assembly for KS-2 and FL-2 ................................ 24

5.1.3 RTKS-2 wire feeder connection........................................................... 25

5.1.4 RTKS-2 electrical connections ............................................................ 26

5.1.4.1 RTKS-2 safety-off mechanism connection ....................................... 26

5.1.5 RTKS-2 Torch installation.................................................................... 27

5.2 RTFL-2 standard arm installation ........................................................ 28

16

5.2.1 RTFL-2 rigid mount.............................................................................. 28

5.2.2 RTFL-2 torch installation ..................................................................... 30

5.3 RTKSC-2 hollow wrist system installation.......................................... 30

5.3.1 RTKSC-2 mount with safety off mechanism........................................ 30

5.3.2 Mounting the cable assembly............................................................... 31

5.3.2.1 RTKSC-2 feeder cabinet connections .............................................. 32

5.3.3 RTKSC-2 cable assembly ................................................................... 34

5.3.3.1 RTKSC-2 cable assembly installation .............................................. 34

0463 373 101 © ESAB AB 2018

TURINYS

5.3.3.2 RTKSC-2 electrical connections....................................................... 37

5.3.4 RTKSC-2 torch installation .................................................................. 38

5.4 RTFLC-2 installation.............................................................................. 39

5.4.1 RTFLC-2 mount................................................................................... 39

5.4.2 RTFLC-2 wire feeder connection......................................................... 39

5.4.2.1 Feeding through the robot arm.......................................................... 39

5.4.2.2 RTFLC-2 feeder cabinet connections............................................... 40

5.4.3 RTFLC-2 cable assembly .................................................................... 42

5.4.3.1 RTFLC-2 cable assembly installation ............................................... 42

5.4.4 RTFLC-2 electrical connections .......................................................... 45

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly........... 45

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly................. 46

5.5 Torch installation.................................................................................... 46

5.5.1 Torch neck equipment .......................................................................... 46

5.5.2 Aristo RT torch neck installation........................................................... 47

5.6 Installing the wire guide for standard and hollow Wrist arm ............. 48

5.6.1 Installing the neck liner......................................................................... 48

5.6.2 Installing a split wire guide in the cable assembly ................................ 49

5.6.3 Installing a continuous wire guide in the cable assembly ..................... 51

5.7 Adjust the narrow gap contact tip ........................................................ 52

6

OPERATION ................................................................................................ 55

6.1 Important information for programming (hollow wrist system only) 55

7

TECHNINĖ PRIEŽIŪRA............................................................................... 57

7.1 Privalomos patikros ir veiksmai ........................................................... 57

8

GEDIMŲ ŠALINIMAS .................................................................................. 59

9

ATSARGINIŲ DALIŲ UŽSAKYMAS............................................................ 61

Gamintojas pasilieka teisę keisti specifikacijas be perspėjimo.

0463 373 101 © ESAB AB 2018

1 SAUGA

1 SAUGA

1.1 Simbolių reikšmė

Kaip naudojama šiame vadove: Reiškia „Dėmesio“! Būkite atsargūs!

PAVOJUS!

Reiškia tiesiogiai gresiantį pavojų, kuris, jei jo nebus išvengta, nedelsiant

sukels sunkų arba mirtiną asmens sužalojimą.

ĮSPĖJIMAS!

Reiškia galimą pavojų, kuris gali sukelti asmens sužalojimą arba mirtį.

DĖMESIO!

Reiškia pavojus, kurie gali sukelti nesunkų asmens sužalojimą.

ĮSPĖJIMAS!

Prieš naudodami perskaitykite naudojimo instrukciją ir

atsižvelkite į visose etiketėse nurodytą informaciją,

darbdavio saugias praktikas ir saugos duomenų lapų

(SDS) informaciją.

1.2 Saugos priemonės

Kad su įranga ar šalia jos dirbantys asmenys laikytųsi atitinkamų saugos priemonių, atsako

ESAB įrangos naudotojai. Saugos priemonės turi tenkinti šio tipo įrangai keliamus

reikalavimus. Be standartinių taisyklių, taikomų darbo vietoje, atsižvelkite į toliau pateikiamas

rekomendacijas.

Visus darbus turi atlikti specialiai parengti darbuotojai, gerai išmanantys įrangos veikimą.

Netinkamai naudojama įranga gali lemti pavojingas situacijas, dėl kurių gali susižeisti

naudotojas arba sugesti įranga.

1. Kiekvienas asmuo, naudojantis įrangą, turi žinoti:

○ kaip ji veikia

○ avarinių išjungiklių vietas

○ jos funkcijas

○ susijusias saugos priemones

○ suvirinimo, pjovimo ar kitus su šia įranga atliekamus veiksmus

2. Naudotojas turi pasirūpinti, kad:

○ pradėjus dirbti, įrangos naudojimo vietoje nebūtų pašalinių asmenų

○ visi yra saugūs atliekant elektros lanko taktą arba pradėjus darbą su įranga

3. Darbo vieta turi būti:

○ tinkama tam tikslui

○ be skersvėjų

0463 373 101

- 5 -

© ESAB AB 2018

1 SAUGA

4. Asmeninės apsaugos priemonės:

○ Visuomet naudokite rekomenduojamas asmens apsaugos priemones, pvz.,

apsauginius akinius, ugniai atsparius drabužius, apsaugines pirštines

○ Nedėvėkite palaidų daiktų, pvz., šalikų, apyrankių, žiedų ir t. t., kurie gali įstrigti ir

nudeginti

5. Bendrosios saugos priemonės:

○ Patikrinkite, ar grįžtamasis kabelis tvirtai prijungtas

○ Darbus su aukštos įtampos įranga gali atlikti tik kvalifikuotas elektrikas

○ Atitinkama gaisro gesinimo įranga turi būti aiškiai pažymėta ir laikoma netoliese

○ Darbo metu negalima įrangos sutepti ir atlikti kitų priežiūros darbų

ĮSPĖJIMAS!

Virindami ir pjaudami elektros lanku galite susižaloti patys ir sužaloti kitus. Virindami

ir pjaudami imkitės atsargumo priemonių.

ELEKTROS SMŪGIS gali būti mirties priežastis

• Prietaisą sumontuokite ir įžeminkite atsižvelgdami į naudojimo instrukciją.

• Nelieskite veikiančių elektrinių dalių arba elektrodų plika oda, šlapiomis

pirštinėmis arba šlapiais drabužiais.

• Izoliuokite save nuo darbo vietos ir nuo grindų.

• Įsitikinkite, kad jūsų darbinė padėtis yra saugi.

ELEKTRINIAI IR MAGNETINIAI LAUKAI gali būti pavojingi sveikatai

• Suvirintojai, turinys širdies simuliatorius, prieš pradėdami virinti turėtų

pasitarti su savo gydytoju. EMF gali trikdyti kai kurių širdies stimuliatorių

darbą.

• EMF veikimas gali turėti sveikatai kitą poveikį, kuris nežinomas.

• Siekdami sumažinti EMF poveikį, suvirintojai turėtų atlikti toliau nurodytas

procedūras:

○ Elektrodo ir darbinius kabelius nutiesti toje pačioje kūno pusėje. Jei

įmanoma, pritvirtinti juos lipnia juosta. Nebūkite tarp degiklio ir

darbinių kabelių. Niekuomet nevyniokite degiklio arba darbinio

kabelio apie savo kūną. Laikykite suvirinimo maitinimo šaltinį ir

kabelius kuo toliau nuo kūno.

○ Prijunkite darbinį kabelį kuo arčiau apdirbamos detalės suvirinimo

vietos.

DŪMAI IR DUJOS gali būti pavojingi sveikatai

• Nelaikykite galvos garų debesyje.

• Naudokite ventiliaciją, ištraukimą ties lanku arba abu, kad pašalintumėte

smalkes ir dujas iš kvėpavimo zonos ir visos aplinkos.

ELEKTROS LANKO SPINDULIAI gali pažeisti akis ir nudeginti odą

• Apsaugokite savo akis ir odą. Naudokite tinkamą virinimo kaukę ir lęšius su

filtrais bei dėvėkite apsauginius drabužius.

• Apsaugokite aplinkinius įrengdami atitinkamus ekranus bei uždangas.

0463 373 101

TRIUKŠMAS. Per didelis triukšmas gali pažeisti klausos organus

Apsaugokite savo ausis. Naudokite ausines ar kitas klausos apsaugos

priemones.

- 6 -

© ESAB AB 2018

1 SAUGA

JUDANČIOS DALYS gali sužeisti

• Visas dureles, skydus ir gaubtus laikykite uždarę ir tinkamai užfiksavę. Jei

reikia atlikti priežiūros arba remonto darbus, gaubtus turėtų nuimti tik

kvalifikuoti specialistai. Baigę priežiūros darbus ir prieš paleisdami variklį,

pritvirtinkite skydus arba gaubtus ir uždarykite dureles.

• Prieš montuodami arba prijungdami įrenginį, sustabdykite variklį.

• Nekiškite rankų, plaukų, palaidų drabužių ir įrankių prie judančių dalių.

GAISRO PAVOJUS

• Kibirkštys (tiškalai) gali sukelti gaisrą. Prieš tai patikrinkite, ar arti nėra

degių medžiagų.

• Nenaudokite uždarytoms talpykloms.

GEDIMAS. Įvykus gedimui, į pagalbą pasikvieskite specialistą.

SAUGOKITE SAVE IR KITUS!

DĖMESIO!

Šis gaminys skirtas tik virinti lanku.

ĮSPĖJIMAS!

Nenaudokite maitinimo šaltinio užšalusiems vamzdžiams atšildyti.

DĖMESIO!

„Class A“ tipo įranga neskirta naudoti gyvenamosiose

patalpose, kur elektros srovė tiekiama viešaisiais

žemosios įtampos elektros tinklais. Gali kilti sunkumų

tokiose patalpose nustatant elektromagnetinį „class A“

įrangos suderinamumą dėl laidais sklindančių, taip pat ir

spinduliuojamų trikdžių.

PASTABA!

Nebenaudojamą elektroninę įrangą pateikite

perdirbimo įmonei!

Pagal Europos Direktyvą 2012/19/EB dėl elektrinių ir

elektroninių atliekų ir jos pritaikymą pagal nacionalinius

įstatymus, nebetinkama naudoti elektros ir (arba)

elektroninė įranga turi būti pateikta perdirbimo įmonei.

Esate už įrangą atsakingas asmuo, todėl įsipareigojate

gauti informacijos apie patvirtintas surinkimo stotis.

Dėl išsamesnės informacijos kreipkitės į artimiausią

ESAB platintoją.

ESAB turi didelį suvirinimo priedų ir asmens apsaugos priemonių asortimentą.

Norėdami gauti užsakymo informacijos, kreipkitės į vietinį ESAB platintoją arba

apsilankykite mūsų svetainėje.

0463 373 101

- 7 -

© ESAB AB 2018

2 GARANTIJA

2 GARANTIJA

Prieš pristatymą mūsų gaminiai yra kruopščiai patikrinami. ESAB patvirtina, kad visi

produktai pristatymo metu yra be medžiagų ir gaminimo defektų ir veikia pagal numatytąją

paskirtį.

ESAB suteikia garantiją dėl medžiagų ir gaminimo defektų pagal teisinius reikalavimus.

Vartojimo reikmenims garantija netaikoma.

Garantija netaikoma jokiems pažeidimams arba funkciniams defektams, atsiradusiems dėl:

• per didelės produkto apkrovos, netinkamo naudojimo arba naudojimo ne pagal paskirtį;

• susidūrimų ar nelaimingų atsitikimų;

• nesilaikymo šiose naudojimo instrukcijose pateiktų nurodymų;

• netinkamo montavimo arba surinkimo;

• nepakankamos priežiūros;

• produkto originalios būsenos modifikavimo;

• cheminio poveikio;

• įprasto dėvėjimosi.

ESAB neprisiima jokios atsakomybės, išskyrus sugedusių dalių pakeitimą arba remontą.

2.1 Numatyto naudojimo sąlygos

1. Produktas yra skirtas naudoti pramoniniams ir komerciniams tikslams, jį gali naudoti

tik parengti darbuotojai. Gamintojas nėra atsakingas už bet kokią žalą arba

nelaimingus atsitikimus, kilusius netinkamai naudojant.

2. „Aristo® RT“ robotizuoto suvirinimo sistema yra suprojektuota ir pagaminta taikant

pažangiausius metodus ir yra saugi bei patikima, jei ją naudoja, montuoja ir prižiūri

parengti darbuotojai. Būtina laikytis šiame dokumente pateiktų montavimo, darbo ir

priežiūros instrukcijų.

3. Tik parengti darbuotojai gali montuoti, naudoti ir prižiūrėti „Aristo® RT“ robotizuoto

suvirinimo sistemą. Būtina laikytis šiame vadove pateiktų montavimo, darbo ir

priežiūros reikalavimų.

4. „Aristo® RT“ robotizuoto suvirinimo sistemą galima naudoti ik gamintojo numatytiems

tikslams, atsižvelgiant į techninius duomenis ir kartu su automatinėmis apdorojimo

sistemomis. Degiklio tipas turi atitikti suvirinimo pobūdį.

5. „Aristo® RT“ robotizuoto suvirinimo sistema suprojektuota taip, kad ją būtų galima

naudoti be papildomos įrangos. Neleidžiama sistemos naudoti kartu su kitų gamintojų

komponentais.

6. RT KS-2 ir RT KSC-2 gali būti naudojami tik kaip avarinio išjungimo mechanizmai,

atsižvelgiant į jų techninius duomenis ir kartu su RT standartinės rankos kabelio įtaisu

(KS-2), „Infiniturn“ arba „Helix“ (KSC-2), ESAB adapterio junge, įskaitant RT degiklio

tvirtinimo detales (KS-2) ir „Aristo RT“ suvirinimo degiklį.

7. Į prapūtimo dujas negalima įmaišyti alyvos arba nuo purslų apsaugančio skysčio.

ESAB negali užtikrinti cheminio atsparumo šioms medžiagoms. ESAB rekomenduoja

naudoti ESAB purkštuvą, kuris leidžia naudoti mažesnį nuo purslų apsaugančio

skysčio kiekį ir tokiu būdu saugoti aplinką.

8. Gabenimo, laikymo ir naudojimo metu produktas turi būti sausas ir apsaugotas nuo

drėgmės.

9. Sistema pritaikyta aplinkos temperatūros intervalui nuo 5 °C iki 40 °C (nuo 41 °F iki

104 °F). Nesilaikant šių apribojimų, būtina imtis veiksmų. Jei yra šalčio pavojus,

naudokite tinkamą aušinimo skystį.

0463 373 101

- 8 -

© ESAB AB 2018

3 ĮVADAS

3 ĮVADAS

RT suvirinimo degiklio sistemos skirtos visiškai automatiniam MIG/MAG suvirinimui

naudojant robotus. Sistemą sudaro įvairūs „Aristo RT“ degiklio kakleliai, skirti naudoti kartu

su robotais, degiklio tvirtinimo detalės, robotams pritaikyti kabelio įtaisai ir apsaugos

funkcijos, skirtos apsaugoti sistemą nuo pažeidimų susidūrimo atveju.

Standartinę RT suvirinimo sistemą nuo susidūrimo saugo RTKS-2, t.y. mechaninis

spyruoklinis apsauginis mechanizmas. Jį galima pakeisti RTFL-2 mechanizmu, kuris leidžia

naudoti roboto valdymo sistemos įspėjimo apie susidūrimą funkciją. Standartinę RT

suvirinimo sistemą galima naudoti su įvairių tipų kabelio įtaisais.

RTKSC-2 ir RTFLC-2 degiklio tvirtinimo detalės su „Infiniturn“ arba „Helix“ kabelio įtaisais

yra skirtos sudėtingiems suvirinimo darbams pritaikytoms robotizuotoms suvirinimo

sistemoms su tuščiaviduriu riešu. RTKSC-2 degiklio tvirtinimo detalės apsauginis

mechanizmas leidžia dideliu kampu pakreipti degiklį įvykus susidūrimui. „Infiniturn“ ir „Helix“

kabelio įtaisus paprasta sumontuoti, todėl galite turėti ypač patikimą ir tikslų manevravimą

užtikrinančią sistemą.

Kartu su išbandytais „Aristo RT“ robotizuoto suvirinimo degikliais šios dalys sudaro ypač

patikimą ir ilgai tarnaujančią sistemą, kurios beveik nereikia prižiūrėti.

Instrukcijų vadovas pateikiamas kartu su degiklio tvirtinimo detalėmis ir kabelio įtaisais.

ESAB užsakymo numeriai, galimi priedai, atsarginės dalys ir keičiamos dalys

išvardytos atsarginių dalių sąraše.

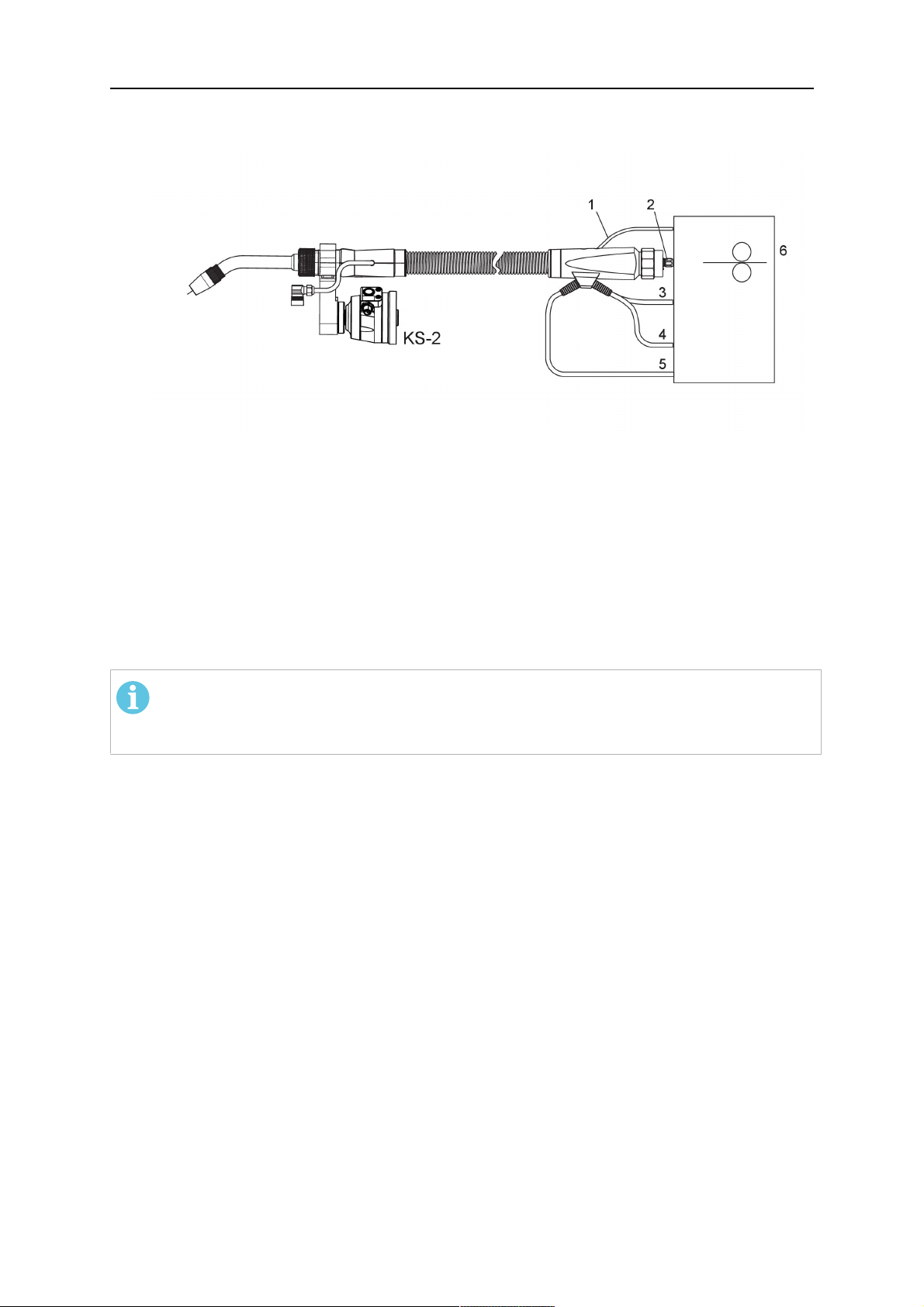

3.1 Suvirinimo degiklio sistemų apžvalga

Standartinė RT sistema

Išsamų aprašą žr. atitinkamoje TECHNINIŲ

DUOMENŲ skyriaus dalyje:

1. Degiklio kaklelis

Žr. „Suvirinimo degiklis“.

2. Kabeliai

Žr. „Standartinės RT sistemos

kabelio įtaisai“.

3. Degiklio tvirtinimo detalė

Žr. „Standartinės RT sistemos

degiklio tvirtinimo detalės“.

4. RTKS-2 apsauginis mechanizmas

Žr. „RTKS-2 apsauginis

mechanizmas“.

5. RTFL-2 tarpinė jungė

Žr. „RTFL-2 tarpinė jungė“.

6. Adapterio jungė (jei reikia)

Žr. „Adapterio jungės“.

0463 373 101

- 9 -

© ESAB AB 2018

3 ĮVADAS

Sistema su tuščiaviduriu riešu

Išsamų aprašą žr. atitinkamoje TECHNINIŲ

DUOMENŲ skyriaus dalyje:

1. Degiklio kaklelis

Žr. „Suvirinimo degiklis“.

2. Degiklio tvirtinimo detalė

RTKSC-2

Žr. „RTKSC-2 degiklio tvirtinimo

detalė su apsauginiu mechanizmu“.

3. Degiklio tvirtinimo detalė

RTFLC-2

Žr. „RTFLC-2 “standi degiklio

tvirtinimo detalė.

4. Adapterio jungė

Žr. „Adapterio jungės“.

5. „Helix“ arba „Infiniturn“ kabelio

įtaisas

Žr. „Sistemoms su tuščiaviduriu

riešu skirti kabelio įtaisai“.

0463 373 101

- 10 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

4 TECHNINIAI DUOMENYS

4.1 Suvirinimo degiklio kaklelis

Degiklio modelį pasirinkite atsižvelgdami į atliekamus suvirinimo darbus. Būtina atsižvelgti į

darbo ciklą ir apkrovą, aušinimo metodą ir vielos skersmenį. Jei taikomi aukštesni

reikalavimai, pvz., dėl įkaitusių ruošinių ar stipraus šilumos atspindžio ties kampais, į juos

atsižvelkite ir rinkitės suvirinimo degiklį su atitinkamu galios rezervu.

RT suvirinimo degikliai yra skirti naudoti su CE reikalavimus atitinkančiais suvirinimo

šaltiniais, skirtais lankinio suvirinimo lydžiuoju elektrodu inertinėse dujose (MIG), lankinio

suvirinimo lydžiuoju elektrodu aktyviosiose dujose (MAG) ir MIG litavimo procesams

naudojant parduodamas apskrito profilio vielas. Nenaudokite degiklio kitiems procesams.

Plieno suvirinimui naudojant impulsinį lankinį suvirinimą arba aliuminio suvirinimui turi būti

naudojamas RT82W vandeniu aušinamas degiklis.

Galimus degiklių modelius žr. toliau.

Degiklio modelis Aušinimo metodas Apsauginės dujos Srovė

RT42G Aušinamas dujomis CO

Aušinamas dujomis 300A / 100%

Aušinamas dujomis Mišinys 350A / 60%

Aušinamas dujomis 250A / 100%

RT42W Aušinamas vandeniu CO

Aušinamas vandeniu 420A / 100%

Aušinamas vandeniu Mišinys 350A / 60%

Aušinamas vandeniu 350A / 100%

RT52G Aušinamas dujomis CO

Aušinamas dujomis 300A / 100%

Aušinamas dujomis Mišinys 350A / 60%

Aušinamas dujomis 250A / 100%

RT52W Aušinamas vandeniu CO

Aušinamas vandeniu 470A / 100%

Aušinamas vandeniu Mišinys 400A / 60%

Aušinamas vandeniu 400A / 100%

RT62G Aušinamas dujomis CO

Aušinamas dujomis 340A / 100%

2

2

2

2

2

420A / 60%

420A / 60%

420A / 60%

470A / 60%

500A / 60%

Aušinamas dujomis Mišinys 420A / 60%

Aušinamas dujomis 290A / 100%

RT62W Aušinamas vandeniu CO

Aušinamas vandeniu 530A / 100%

Aušinamas vandeniu Mišinys 450A / 60%

Aušinamas vandeniu 450A / 100%

0463 373 101

- 11 -

2

530A / 60%

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

Degiklio modelis Aušinimo metodas Apsauginės dujos Srovė

RT72G Aušinamas dujomis CO

2

480A / 60%

Aušinamas dujomis 320A / 100%

Aušinamas dujomis Mišinys 400A / 60%

Aušinamas dujomis 270A / 100%

RT72W Aušinamas vandeniu CO

2

480A / 60%

Aušinamas vandeniu 430A / 100%

Aušinamas vandeniu Mišinys 480A / 60%

Aušinamas vandeniu 430A / 100%

RT82W Aušinamas vandeniu CO

2

600A / 60%

Aušinamas vandeniu 600A / 100%

Aušinamas vandeniu Mišinys 550A / 60%

Aušinamas vandeniu 550A / 100%

Degiklio srovės ir darbo ciklo reikšmės nurodytos 10 minučių ciklui.

Techniniai duomenys pateikti laikant, kad dirbama įprastai ir naudojamos standartinės

keičiamos (atsarginės) dalys. Atliekant impulsinį lankinį suvirinimą su metalo pernešimu,

degiklio srovės reikšmės yra mažesnės.

Temperatūros intervalas Laikymas: -15-50°C (5-122°F)

Darbas: 5–40°C (41–104°F)

Prapūtimo dujos Maks. 10 barų, atskira dujų žarna

Bendras svoris (degiklio kaklelis, apsauginis

Apie 5 kg

mechanizmas, degiklio tvirtinimo detalė ir 1 m

kabelio įtaisas)

4.2 Vardinė įtampa

Maks. leidžiamoji įtampa / stipris

Visa suvirinimo degiklio sistema 141 V (didžiausia reikšmė suvirinant)

RTKS-2 apsauginė valdymo grandinė

RTKS-2 mygtukinis jungiklis

RT KSC-2 apsauginė valdymo grandinė 48 V

Naudojant purkštuko jutimo funkciją su

standartiniu kabelio įtaisu

Naudojant purkštuko jutimo funkciją su

„Helix“ arba „Infiniturn“ kabelio įtaisais

24 V / 1 A

48 V / 0,1 A

50 V / 5 A

(Apkrova esant vardinei srovei leidžiama ne

ilgiau nei 1 minutę)

50 V / 5 A

(Apkrova esant vardinei srovei leidžiama ne

ilgiau nei 1 minutę)

Nurodytos reikšmės įprasto darbo metu.

Kebelio įtaisų reikšmes žr. dalyje „Kabelio įtaisai“.

4.2.1 Aušinimo kontūro apribojimai

Taikoma tik vandeniu aušinamai versijai.

0463 373 101

- 12 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

Min. vandens srautas: 1,0 l/min. (1,1 kvart./min.)

Min. vandens slėgis: 2,5 baro (36,3 PSI)

Maks. vandens slėgis: 3,5 baro (50,8 PSI)

Įleidžiamo srauto

temperatūra:

Grąžinamo srauto

temperatūra:

Maks. 40 °C (104 °F)

Maks. 60 °C (140 °F)

Aušinimo galia: Min. 1000 W, atsižvelgiant į panaudojimą

DĖMESIO!

Kai grąžinamo srauto temperatūra yra didesnė nei 60 °C (140 °F), gali būti

pažeistas arba sugadintas kabelio įtaisas.

4.3 Degiklio tvirtinimo detalė

Reikalingas degiklio tvirtinimo detalės tipas priklauso nuo RT suvirinimo degiklio sistemos

konstrukcijos ir pasirinktų apsauginių įrenginių, žr. dalį „Suvirinimo degiklio sistemų

apžvalga“.

Komponentas Apytikslis svoris

Degiklio tvirtinimo detalė (standartinei

sistemai)

RTKS-2 apsauginis mechanizmas

(standartinei sistemai)

0,43 kg

0,85 kg

RTFL-2 tarpinė jungė (standartinei sistemai) 0,35 kg

RTKSC-2 degiklio tvirtinimo detalė (sistemai

1,90 kg

su tuščiaviduriu riešu)

RTFLC-2 standi degiklio tvirtinimo detalė

1,22 kg

(sistemai su tuščiaviduriu riešu)

Robotizuoto suvirinimo degiklis 0,66 kg

4.3.1 Standartinei RT sistemai skirtos degiklio tvirtinimo detalės

Standartinėms RT sistemoms skirta degiklio tvirtinimo detalė montuojama ant RTKS-2

apsauginio mechanizmo (arba ant RTFL-2 tarpinės jungės) ir užfiksuoja kabelio įtaisą bei

prijungto degiklio kaklelį.

Degiklio tvirtinimo detalę pasirinkite atsižvelgdami į degiklio tipą ir geometriją. Gali būti

naudojamos skirtingų tipų tvirtinimo detalės. Informacijos apie standartinėms RT sistemoms

tinkamas degiklio tvirtinimo detales žr. atsarginių dalių sąraše.

0463 373 101

- 13 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

Standartiniams robotams su ranka skirta degiklio tvirtinimo detalė

4.3.1.1 RTKS-2 apsauginis mechanizmas

RTKS-2 apsauginis mechanizmas yra spyruoklinis įrenginys, saugantis robotą ir degiklio

sistemą susidūrimo atveju.

PASTABA!

Neardykite RTKS-2.

4.3.1.2 RTFL-2 tarpinė jungė

Standžią tarpinę jungę RTFL-2 galima naudoti vietoje RTKS-2, jei robotas turi elektroninę

įspėjimo apie susidūrimą sistemą.

0463 373 101

- 14 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

4.3.2 Sistemai su tuščiaviduriu riešu skirtos degiklio tvirtinimo detalės

Naudojant sistemą su tuščiaviduriu riešu, „Aristo RT“ suvirinimo degiklio kakleliai yra jungiami

prie degiklio tvirtinimo detalės KSC-2 arba FLC-2.

Degiklio tvirtinimo detalė RTKSC-2 leidžia pakreipti degiklį susidūrimo atveju. Tuo pačiu

metu sudaromas elektrinis kontaktas, signalizuojantis roboto valdymo sistemai sustoti.

Ištaisius klaidą, labai tiksliai atkuriama pradinė geometrija ir degiklio centrinis taškas (CT).

Sistemos veikimo principas yra išimtinai mechaninis; joje įrengta spyruoklė.

Degiklio tvirtinimo detalėje RTFLC-2 nėra integruotos apsauginės funkcijos.

Sistemoms su tuščiaviduriu riešu rekomenduojama naudoti RTKSC-2 G/W (arba RTFLC-2

G/W). Šią degiklio tvirtinimo detalę galima naudoti tiek su dujomis aušinamais, tiek su

vandeniu aušinamais „Aristo RT“ serijos degikliais.

RTKSC-2 G/W RTFLC-2 G/W

Apsauginio mechanizmo

veikimo principas

Mechaninis Netaikoma (standus

tvirtinimas)

Ašinė atleidimo jėga (Fz) 650 N Netaikoma (standus

tvirtinimas)

Atleidimo momentas

skersinėje ašyje (Mx)

24 Nm Netaikoma (standus

tvirtinimas)

Atkūrimas atleidus Automatinis Netaikoma (standus

tvirtinimas)

Atkuriamumas Šoninis ± 0,1 mm standartinio

„Aristo RT“ degiklio CT

Netaikoma (standus

tvirtinimas)

Maks. pokrypis Apie ± 8° Netaikoma (standus

tvirtinimas)

Apsauginis jungiklis Įprastai uždarytas

Maks. 48 V / 1A elektrinė

Netaikoma (standus

tvirtinimas)

apkrova

0463 373 101

- 15 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

Elektrinė valdymo grandinė

purkštuko jutimo funkcijai

Srovė:

• „Helix“ kabelio įtaisams:

maks. 50 V DC / 5 A,

maks. 1 minutė

Nustačius kontaktą,

greitai atjunkite jutimo

įtampą.

• Naudojant „Infiniturn“

kabelio įtaisus,

purkštuko jutimo funkcija

Srovė:

• „Helix“ kabelio įtaisams:

maks. 50 V DC / 5 A,

maks. 1 minutė

• „Infiniturn“ kabelio

įtaisams: maks. 50 V

DC / 1 A, maks. 1

minutė

Nustačius kontaktą, greitai

atjunkite jutimo įtampą.

yra ribojama. Norėdami

gauti daugiau

informacijos apie

galimus sprendimus

konkrečioje jūsų

situacijoje, kreipkitės į

ESAB.

Vardinė įtampa Didžiausia leidžiama

apsauginės valdymo

grandinės įtampa: 48 V.

4.3.2.1 RTKSC-2 G/W degiklio tvirtinimo detalė su apsauginiu mechanizmu

Elem

Aprašymas Funkcija

enta

s

1 Degiklio kaklelio atrama „Aristo RT“ degiklio jungtis

2 RTKSC-2 gaubtas Mechanizmas su kabelio ir degiklio jungtimis

0463 373 101

- 16 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

Elem

Aprašymas Funkcija

enta

s

3 Guminis apvalkalas Apsauginio mechanizmo apsauga

4 RTKSC-2 pagrindinis korpusas Leidžia pakreipti mechaniškai susidūrimo atveju

5 Adapterio jungė Skiriamoji jungtis su roboto riešu (pritaikyta pagal

konkretų robotą)

6 Kaištis Tiksliam sulygiavimui su adapterio junge

7 Valdymo kabelio jungtis Elektrinė jungtis, skirta susidūrimo signalui ir

purkštuko jutimo funkcijai

8 Mikrojungiklis Jutiklis įspėjimui apie susidūrimą

4.3.2.2 RTFLC-2 G/W standi degiklio tvirtinimo detalė

Elem

Aprašymas Funkcija

enta

s

1 Degiklio kaklelio atrama „Aristo RT“ degiklio jungtis

2 RTFLC-2 gaubtas Mechanizmas su kabelio ir degiklio jungtimis

3 RTFLC-2 pagrindinis korpusas Leidžia pakreipti mechaniškai susidūrimo atveju

4 Kaištis Tiksliam sulygiavimui su adapterio junge

5 Adapterio jungė Skiriamoji jungtis su roboto riešu (pritaikyta pagal

konkretų robotą)

6 Valdymo kabelio jungtis (3

kontaktų)

0463 373 101

Elektrinė jungtis, skirta purkštuko jutimo funkcijai (jei

taikoma)

- 17 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

4.4 Adapterio jungės

Pasirinkite montavimui ant roboto rankos reikalingą adapterio jungę pagal roboto tipą.

Norėdami gauti informacijos apie visoms standartinėms sistemoms ir sistemoms su

tuščiaviduriu riešu skirtas adapterio junges, žr. atsarginių dalių sąrašą.

4.5 Kabelio įtaisai

Jungimo prie vielos tiektuvo būdas priklauso nuo kabelio įtaiso – galimos versijos priklauso

nuo sistemos konstrukcijos ir aušinimo medžiagos (dujų arba vandens); žr. atsarginių dalių

sąrašą.

Įverčiai galioja kabeliams nuo 1 iki 5 m ilgio.

Standartinis kabelio

„Infiniturn“ „Helix“

įtaisas

Srovė (10 min. ciklas)

Aušinamas dujomis

(dujų mišinys)

Srovė (10 min. ciklas)

Aušinamas vandeniu

Pasukamumas Ribotas

Maks. 500 A / 60 %

darbo ciklas

Maks. 350 A / 100 %

darbo ciklas

Maks. 600 A / 100 %

darbo ciklas

Maks. 400 A / 60 %

darbo ciklas

Maks. 320 A / 100 %

darbo ciklas

Maks. 550 A / 100 %

darbo ciklas

Neribotai pasukamas ± 270° iš neutralios

pasukamumas

Svoris

Aušinamas dujomis

Svoris

Aušinamas vandeniu

1,2 m ilgio:

2,35 kg

1,2 m ilgio:

2,35 kg

1,0 m ilgio:

2,0 kg

1,0 m ilgio:

2,0 kg

4.5.1 Standartinės RT sistemos kabelio įtaisai

Maks. 400 A / 60 %

darbo ciklas

Maks. 320 A / 100 %

darbo ciklas

Maks. 550 A / 100 %

darbo ciklas

padėties

1,0 m ilgio:

2,0 kg

1,0 m ilgio:

2,0 kg

0463 373 101

- 18 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

„Burndy“ jungties kontaktai

A. Dujų purkštuko jutimas

C. Susidūrimo jutiklis

D. Susidūrimo jutiklis

F. 0V

G. + Variklio įtampa

H. - Variklio įtampa

E. Trūkčiojimas

Elem

Aprašymas Funkcija

enta

s

1 Kaklelio atraminė jungė Degiklio jungtis

2 Apsauginis gaubtas Saugo kabelio įtaisą nuo pažeidimų

3 „Burndy“ jungtis, 12 kontaktų Elektrinė jungtis tarp apsauginio mechanizmo ir

vielos tiektuvo

4 Valdymo kabelis Skirta KS-2 (apsauginis mechanizmas ir mygtukinis

jungiklis)

5 EURO jungtis Vielos tiektuvo jungtis

6 Prapūtimo žarna (juodas

dangtelis)

7 Vandens įleidimo anga

Degiklio valymui suslėgtu oru pasibaigus valymo

ciklui

Vandens įleidimo anga, skirta degiklio aušinimui

1)

(mėlynas dangtelis)

8 Vandens grąžinimo anga

Pašildyto vandens grąžinimas iš degiklio

1)

(raudonas dangtelis)

9 Valdymo kabelio kištukas,

prijungimui prie apsauginio

Elektrinė jungtis su RTKS-2, skirta apsauginio

mechanizmo signalui ir purkštuko jutimo funkcijai

mechanizmo

1)

Tik vandeniu aušinamoms degiklio sistemoms

4.5.2 Sistemoms su tuščiaviduriu riešu skirti kabelio įtaisai

„Infiniturn“ kabelio įtaisas leidžia be apribojimų sukti degiklį abiem kryptimis. Tuo pačiu metu

tiekiamas aušinimo skystis, apsauginės dujos, prapūtimo oras, suvirinimo srovė ir apsauginio

mechanizmo signalas.

„Helix“ kabelio įtaisas suprojektuotas taip, kad leistų pasukti ±270° kampu nuo neutralios

padėties. Jį galima naudoti suvirinimo darbams, kuriems nebūtinas pasukimas be apribojimų.

„Infiniturn“ kabelio įtaisai gali būti skirti dujomis arba vandeniu aušinamoms versijoms. „Helix“

kabelio įtaisus galima naudoti tiek dujomis, tiek vandeniu aušinamoms versijoms.

PASTABA!

Nejunkite „Helix“ kabelio įtaiso, naudojamo kartu su dujomis aušinamo degiklio

kakleliu, prie aušinamos vandeniu sistemos.

0463 373 101

- 19 -

© ESAB AB 2018

4 TECHNINIAI DUOMENYS

Elem

Aprašymas Funkcija

enta

s

1 Jungė Degiklio tvirtinimo detalės RTKSC-2 / RTFLC-2

jungtis

2 Kaištis Užtikrina tinkamą jungties padėtį

3 Valdymo kabelio kištukas Elektrinė jungtis su RT KSC-2, skirta apsauginio

mechanizmo signalui ir purkštuko jutimo funkcijai (jei

taikoma)

4 EURO jungtis Vielos tiektuvo jungtis

5 Valdymo kabelis Elektrinė jungtis, skirta apsauginio mechanizmo

signalui (iš RTKSC-2) ir purkštuko jutimo funkcijai

(purkštuko jutimo funkcija standartiškai veikia su

„Helix“, bet ne su „Infiniturn“)

6 Vandens grąžinimo anga

Pašildyto vandens grąžinimas iš degiklio

(raudonas dangtelis)

7 Vandens įleidimo anga

Vandens įleidimo anga, skirta degiklio aušinimui

(mėlynas dangtelis)

8 Prapūtimo žarna (juodas

Degiklio valymui suslėgtu oru baigus suvirinimą

dangtelis)

9 Medžiagų tiekimo jungtis Be apribojimų pasukama jungtis medžiagų tiekimui

10 Apsauginis gaubtas Saugo kabelio įtaisą nuo pažeidimų

0463 373 101

- 20 -

© ESAB AB 2018

5 INSTALLATION

5 INSTALLATION

ĮSPĖJIMAS!

For your own safety, make sure that the robot is either in standby or power-less

state before doing maintenance work in the moving radius of the robot.

Follow the assembly instructions exactly. Pay attention during assembly that the cables are

not damaged. Damaged cables can lead to a short circuit, which may damage the electronics

of the robot or the welding torch.

Use only original ESAB components that have been specially developed for this purpose.

Only then the correct functioning of the whole welding torch system can be guaranteed.

5.1 RTKS-2 standard arm installation

5.1.1 RTKS-2 safety-off mechanism

1. Dismount the insulation flange (10) from the RTKS-2 (11) by removing the screws

(12).

2. Position the insulation flange (10) with the index pin on the robot arm and fix it with the

screws (20) included.

The insulation flange (10) is directly compatible with robots with tool flange according

to DIN ISO 9409-1-A40 (diameter 40mm, 4×M6). If the insulation flange (10) does

not fit, use an adapter flange (21).

PASTABA!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

3. Mount the RTKS-2 the back on the insulation flange (10).

0463 373 101

- 21 -

© ESAB AB 2018

5 INSTALLATION

4. Position the mount on the RTKS-2 and carefully insert the cylindrical pins (14) into the

holes provided. Take the position of the torch into account. Two mounting positions

may be potentially possible.

5. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (12).

PASTABA!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

12 - Cylinder screw with hexagon socket

M6DIN912 (length of the screw depending

on the torch mount)

14 - Cylindrical pins Ø4×20

5.1.1.1 Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. The pins should protrude by approximately 5 mm (0.2 in.).

2. Position the mount on the safety-off mechanism RTKS-2 and carefully insert the

cylindrical pins (1) into the holes provided. In doing so, take the later position of the

torch into account. Two mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

PASTABA!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

0463 373 101

- 22 -

© ESAB AB 2018

5 INSTALLATION

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

0463 373 101

- 23 -

© ESAB AB 2018

5 INSTALLATION

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.1.2 Standard arm cable assembly for KS-2 and FL-2

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

0463 373 101

- 24 -

© ESAB AB 2018

5 INSTALLATION

DĖMESIO!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

1. Unscrew the cylinder screws (1) and lift off the top section (2) of the torch mount.

2. Insert the feather key (4) into the recess of the neck support flange (3) from below.

3. Align the neck support flange (3) including the feather key (4) to the groove (5) of the

torch mount and push into the groove right up to the stop of the flange.

4. Hold the cable assembly in this position and simultaneously place the top section (2)

back onto the torch mount. First screw both cylinder screws (1) loosely in to about the

same length, then tighten alternately. The top section (2) of the mount should have an

even gap to the bottom section.

The front part of the cable assembly is directly clamped into the torch mount (see

illustration below).

1 - Cylinder screws 4 - Feather key

2 - Torch mount top section 5 - Groove for feather key

3 - Neck support flange

5.1.3 RTKS-2 wire feeder connection

In order to be able to create the connection, the cable assembly must be mounted as

described in the "Installing the cable assembly" section and equipped following "Installing the

wire guide" section. Only then can the central and media connection take place. Proceed as

described below:

0463 373 101

- 25 -

© ESAB AB 2018

5 INSTALLATION

1. Connect the central connector of the cable assembly (2) to the wire feeder cabinet

socket. Tighten the central connector sleeve nut fingertight. Do not use tools.

1 - Burndy Connector 4 - Return of heated water (red cap)

2 - EURO central connector 5 - Return of heated water (red cap)

3 - Air blow-out 6 - Main Wire feeder

2. For water cooled systems. Connect the water hoses to the cooling circuit. The end of

the hose marked blue (4) is connected to the water outlet, and the end marked red (5)

is connected to the water return.

3. Connect the blow-out line (3) to the corresponding connection of the feeder.

4. Connect the Burndy Connector to the wire feeder. (1) to the feeder. See section

"Electrical connections".

PASTABA!

All hoses and the control line must be installed so they can not bend or get

damaged!

5.1.4 RTKS-2 electrical connections

5.1.4.1 RTKS-2 safety-off mechanism connection

The switch for the safety-off functionality RTKS-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKS-2 unit via the 4-pole plug (4) that

contains circuits for the push-button (6) and the safety-off signal (7).

If a collision is detected, the control circuit for the safety-off signal (7), which is normally

closed, will be interrupted.

Rating of the control circuit: max. 48 V / 1 A

0463 373 101

- 26 -

© ESAB AB 2018

5 INSTALLATION

2 - Burndy connector 5 - RTKS-2 connector for control cable plug

4 - Control cable plug

„Burndy“ jungties kontaktai

A. Dujų purkštuko jutimas

C. Susidūrimo jutiklis

D. Susidūrimo jutiklis

F. 0V

G. + Variklio įtampa

H. - Variklio įtampa

E. Trūkčiojimas

If the robot control provides a control circuit for nozzle sense functionality, the connection is

accomplished with a 1-wire connection.

Rating of the control circuit: max 50 V / 5 A.

PAVOJUS!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

DĖMESIO!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

5.1.5 RTKS-2 Torch installation

Continue according to section "Torch installation".

0463 373 101

- 27 -

© ESAB AB 2018

5 INSTALLATION

5.2 RTFL-2 standard arm installation

5.2.1 RTFL-2 rigid mount

1. Position the RT FL-2 (2) with the index pin on the robot arm and fix it with the hexagon

socket screw included.

The FL-2 is directly compatible with robots with tool flange according to DIN ISO

9409-1-A40 (diameter 40mm, 4×M6). If the rigid mount does not fit, use an adapter

flange (3).

PASTABA!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

2. Install torch mount (1). Only torch mounts having a hole pattern equivalent with the

mounting surface may be attached. If necessary, carefully press the cylindrical pins (4)

into the corresponding holes in the bracket. The pins should protrude by

approximately 5mm (0.2in.). Position the torch mount on the RTFL-2 (2) and

carefully insert the cylindrical pins (4) into the holes provided. Take the position of the

torch into account. Two mounting positions may be potentially possible.

3. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (5).

PASTABA!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

0463 373 101

- 28 -

© ESAB AB 2018

5 INSTALLATION

4 - Cylindrical pins Ø4×20

5 - Cylinder screw with hexagon socket M6

DIN 912 (length of the screw depending on

the torch mount)

Side view

Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. Avoid the formation of burrs. The pins should protrude by

approximately 5 mm (0.2 in.).

2. Position the mount on the RTFL-2 and carefully insert the cylindrical pins (1) into the

holes provided. In doing so, take the later position of the torch into account. Two

mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

PASTABA!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

0463 373 101

- 29 -

© ESAB AB 2018

5 INSTALLATION

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 - Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.2.2 RTFL-2 torch installation

Continue according to section "Torch installation".

5.3 RTKSC-2 hollow wrist system installation

5.3.1 RTKSC-2 mount with safety off mechanism

DĖMESIO!

For hollow wrist systems make sure that the clear space around the robot is at least

Ø45 mm (1.8 in.) around the wrist and 50 mm (2.0 in.) near the wire feeder.

0463 373 101

- 30 -

© ESAB AB 2018

5 INSTALLATION

1. Remove the three screws (2) from the front cover (3) of the torch mount and carefully

pull the cover off the RTKSC-2 main body (5). Take care not to damage the micro

switches installed inside the assembly.

1 - Hexagon wrench 4 mm 4 - Rubber boot

2 - 3× M5×12 screws 5 - RT KSC-2 main body

3 - RT KSC-2 front cover

1. Pull off the rubber boot (4) from the RTKSC-2 main body (5) to the front.

2. Now position the RTKSC-2 main body (5) on the adapter flange (7) so that the index

pin is correctly seated. Attach with the screws (6) enclosed.

3. Reinstall the rubber boot (4) on the RTKSC-2 main body (5) and make sure it is

correctly located in the grooves on the front and back flange.

4. Istall the adapter flange (7) on the robot.

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 3 - 3× M5×12 hexagon socket screws

2 - Rubber boot 4 - Adapter flange

5.3.2 Mounting the cable assembly

PASTABA!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ±2-3cm (±1in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

0463 373 101

- 31 -

© ESAB AB 2018

5 INSTALLATION

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

DĖMESIO!

Axis 6 must be in 0° position.

5.3.2.1 RTKSC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

DĖMESIO!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 32 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

DĖMESIO!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connectors are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

PASTABA!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

PASTABA!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

0463 373 101

- 33 -

© ESAB AB 2018

5 INSTALLATION

5.3.3 RTKSC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

DĖMESIO!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.3.3.1 RTKSC-2 cable assembly installation

PASTABA!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2, then thread the cable from the front through the

robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTKSC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1).

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 34 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

PASTABA!

Make sure that the position of the O-rings are not shifted by the index pin

during the assembly.

1 - RTKSC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RTKSC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 35 -

© ESAB AB 2018

5 INSTALLATION

6. If present, insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTKSC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13. Index pin

14. 3× M5×12 screws

0463 373 101

- 36 -

© ESAB AB 2018

5 INSTALLATION

5.3.3.2 RTKSC-2 electrical connections

PASTABA!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then

implemented via the power source controller.

RTKSC-2 safety-off mechanism connection

The switch for the safety-off functionality RTKSC-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKSC-2 unit via the control cable plug

(1).

The safety-off signal requires a 2-wire connection (black/black) to the safety-off circuit in the

robot control (5).

If a collision is detected, the control circuit (normally closed) will be interrupted (4).

Rating of the control circuit: max. 48 V / 1 A.

1 - Control cable plug 3 - Burndy connector VVV

2 - EURO central connector

„Burndy“ jungties kontaktai

A. Dujų purkštuko jutimas

C. Susidūrimo jutiklis

D. Susidūrimo jutiklis

F. 0V

G. + Variklio įtampa

H. - Variklio įtampa

E. Trūkčiojimas

RTKSC-2 nozzle sense function connection

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

0463 373 101

- 37 -

© ESAB AB 2018

5 INSTALLATION

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

PAVOJUS!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

DĖMESIO!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

5.3.4 RTKSC-2 torch installation

Continue according to section "Torch installation".

0463 373 101

- 38 -

© ESAB AB 2018

5 INSTALLATION

5.4 RTFLC-2 installation

5.4.1 RTFLC-2 mount

1. Remove the three M5 screws (2) from the front cover (3) of the RT FLC-2 torch mount

and carefully pull the cover off the main body (4).

1 - Hexagon wrench 4 mm 3 - RT FLC-2 front cover

2 - 3× M5×12 screws 4 - RT FLC-2 main body

2. Now position the RT FLC-2 main body (4) on the adapter flange (6) so that the index

pin is correctly seated. Attach with the screws (5) enclosed

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 5 - 3× M5×12 hexagon socket screws

4 - RT FLC-2 main body 6 - Adapter flange

5.4.2 RTFLC-2 wire feeder connection

5.4.2.1 Feeding through the robot arm

PASTABA!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ± 2-3 cm (± 1 in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

0463 373 101

- 39 -

© ESAB AB 2018

5 INSTALLATION

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

DĖMESIO!

Important! Axis 6 must be in 0° position.

5.4.2.2 RTFLC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

DĖMESIO!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 40 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

Refer to the instruction of the feeder manufacturer.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

DĖMESIO!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connections are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

PASTABA!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

PASTABA!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

0463 373 101

- 41 -

© ESAB AB 2018

5 INSTALLATION

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

5.4.3 RTFLC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

DĖMESIO!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.4.3.1 RTFLC-2 cable assembly installation

In a hollow wrist system the recommended order of installation is to feed the cable assembly

through the robot arm before connecting the cables to the torch mount.

When the cable assembly is correctly installed in the hollow wrist, continue the installation

according to the procedure described below.

PASTABA!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2 and RTFLC-2, then thread the cable from the front

through the robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTFLC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1). For gas cooled

systems, only one O-ring (4a) is needed, for water cooled systems all three O-rings

are needed.

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 42 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

PASTABA!

Take great care that the position of the O-rings is not shifted by the index pin

during the assembly.

1 - RT FLC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RT FLC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 43 -

© ESAB AB 2018

5 INSTALLATION

6. If present insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTFLC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13 - Index pin 14 - 3x M5x12 screws

0463 373 101

- 44 -

© ESAB AB 2018

5 INSTALLATION

5.4.4 RTFLC-2 electrical connections

PASTABA!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

documentation of the manufacturer for details. The link to the robot control is then

implemented via the power source controller.

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

PAVOJUS!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

DĖMESIO!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

0463 373 101

- 45 -

© ESAB AB 2018

5 INSTALLATION

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 1-wire connection (green) to the nozzle sense circuit

in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

PAVOJUS!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

DĖMESIO!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - EURO central connector

2 - Control cable 4 - Burndy connector

5.5 Torch installation

Be sure to use the correct version of the torch mount and cable assembly (water or gas

cooled).

5.5.1 Torch neck equipment

The torch neck, see (1) in the illustration below, must always be equipped to suit the wire

diameter and material.

0463 373 101

- 46 -

© ESAB AB 2018

5 INSTALLATION

1. Select the correct wire guide, contact tip (4), tip holder (2), gas nozzle (5), and gas

diffuser/spatter protection (3). You will find an exact overview and possible alternative

equipment elements for various torch models in the spare parts list. Only use original

ESAB parts; only then is the fitting accuracy ensured.

2. Firmly tighten the tip holder and the contact tip using a suitable tool for example the

enclosed monkey wrench.

3. When using a split wire guide, remove the installed guide nipple including the o-ring

from the torch flange upon delivery if necessary (see section "Installing the neck

liner").

DĖMESIO!

The torch must be completely equipped before welding, especially the gas

diffuser and/or spatter protection and all necessary insulators have to be

installed according to the spare parts list. Welding without these items may

cause immediate destruction of the torch.

1 - Torch neck 4 - Contact tip

2 - Tip holder 5 - Contact tip

3 - Gas diffuser

5.5.2 Aristo RT torch neck installation

PASTABA!

Check the O-rings on the flange of the torch neck before mounting. Replace the

O-rings if damaged or lost. Missing or faulty O-rings will lead to leaks of shielding

gas and coolant.

1. For hollow wrist systems, insert the torch into the torch mount in the correct

orientation, so that the locator pin fits into the slot of the RTKSC-2 or RTFLC-2

interface, see (A) in the illustration below. For standard systems, attach the torch to

the RT flange of the cable assembly, (B) in the illustration below.

Installation is only possible in the correct orientation.

2. Tighten the locking nut of the torch neck.

PASTABA!

Only tighten by hand, never use tools or excessive force.

0463 373 101

- 47 -

© ESAB AB 2018

5 INSTALLATION

3. The correct seating of the torch can be checked by means of the window (1). If the

torch has been correctly mounted, no gap should be seen through the window (1).

5.6 Installing the wire guide for standard and hollow Wrist arm

Installing the wire guide

Choose the wire guide or liner depending on the filler wire material and diameter to be used,

see the spare parts list. Accurate performance of the system can only be guaranteed when

using original ESAB wire guides.

The recommended wire guide is the split wire guide, which consists of the neck liner and a

separate guide in the cable assembly. The front part of the wire guide, which is most

stressed, can be exchanged easily and independently of the cable assembly wire guide.

For correct installation, the following steps must be followed (example for Euro central

connector).

5.6.1 Installing the neck liner

The neck liner must be selected to fit the material and diameter of the welding wire, see the

spare parts list.

0463 373 101

- 48 -

© ESAB AB 2018

5 INSTALLATION

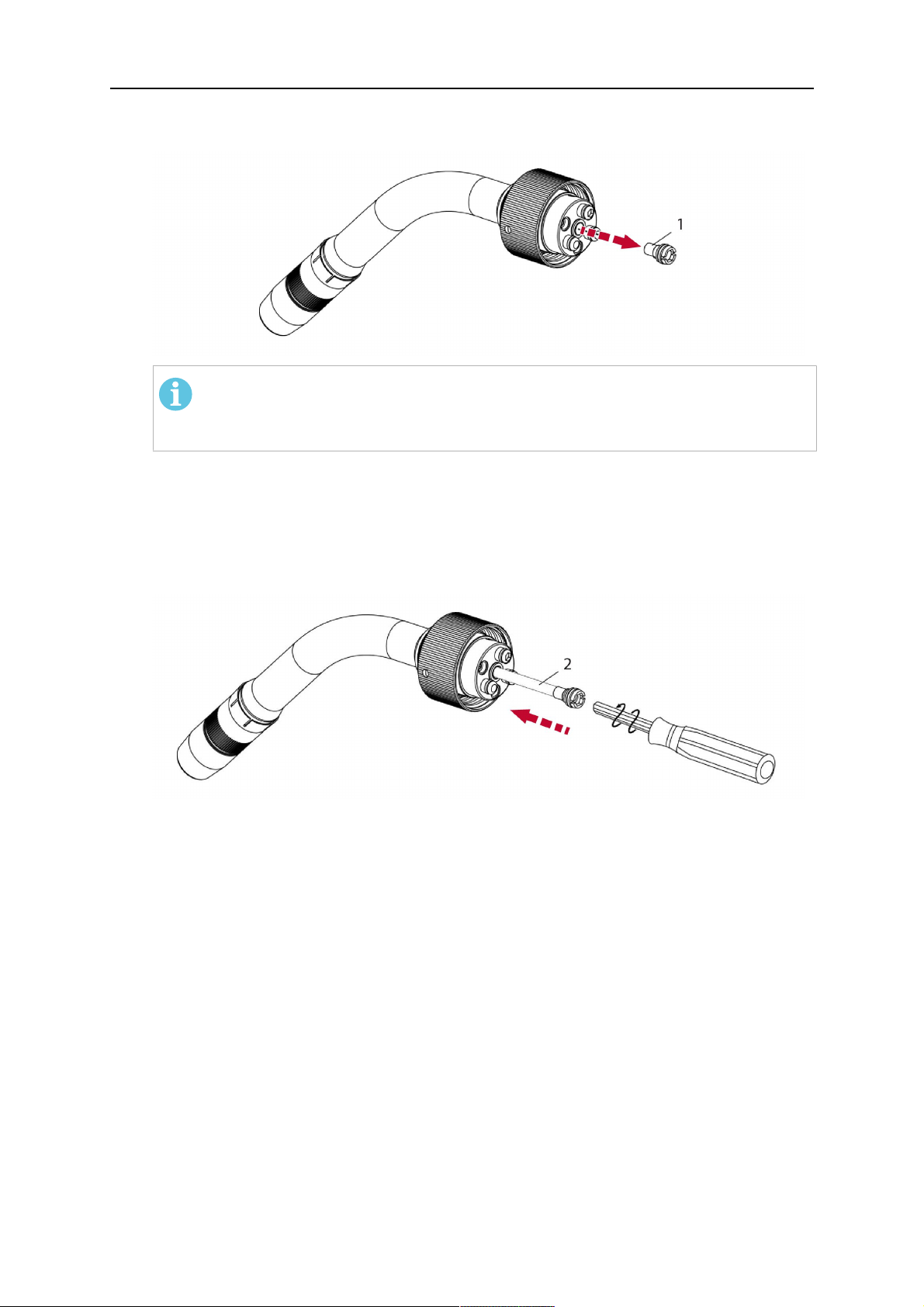

1. If present, remove the central guide nipple (1), from the torch neck using a hexagon

wrench (size 6 mm) or a large flat-blade screwdriver.

PASTABA!

The guide nipple (1) can only be used with one-piece liners and must not be

used with the standard RT or hollow wrist system.

2. When replacing the neck liner:

Unfasten the sleeve nut and remove the torch neck.

Unfasten the liner nipple using a hexagon wrench (size 6 mm) and remove nipple and

liner from the torch neck.

3. Remove the gas nozzle and the contact tip.

4. Insert the new neck liner (2) into the torch. Carefully tighten the guide nipple using a

suitable tool, e.g. a hex-wrench (size 6 mm) or a large flat-blade screwdriver.

5. Cut the neck liner flush with the tip holder and remove the neck liner from the torch.

6. Install the contact tip.

7. Insert the neck liner again. It will be stopped by the contact tip. Measure the excess

liner sticking out of the neck.

8. Remove the liner again and shorten the front end by the measured length. Carefully

deburr the edge and make sure that the inner hole is not blocked.

9. Reinstall the neck liner and tighten the guide nipple in the neck.

5.6.2 Installing a split wire guide in the cable assembly

The correct liner must be inserted to suit the filler material and the wire diameter, see the

spare parts list.

The wire guide is inserted through the cable assembly from the rear, reaching the guide

nipple that is installed in the flange where the torch neck will be attached. The following

worksteps must be followed in order to correctly determine the wire guide length. (Example

for Euro central connector).

0463 373 101

- 49 -

© ESAB AB 2018

5 INSTALLATION

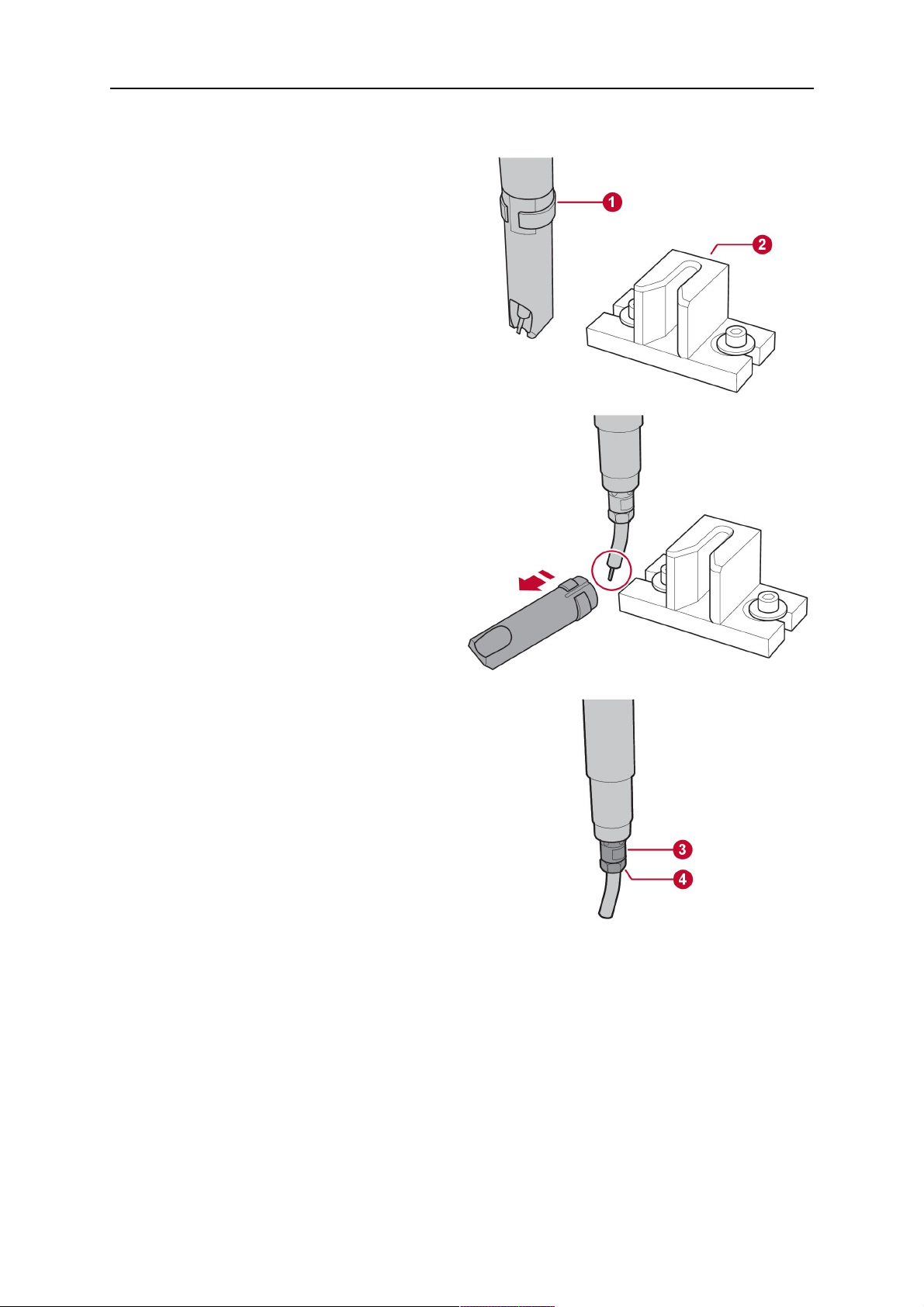

1. For standard RT system: Install the guide nipple (1) in the center hole of the neck

support flange, see illustration A below.

For hollow wrist system: Install the guide nipple (1) into the torch interface of the

RTKSC-2 / RTFLC-2 cover, see illustration B below.

2. Remove the sleeve nut (2) from the central connector, and remove the old wire guide.

3. Insert the wire guide through the central connection and push forwards as far as it will

go into the guide nipple (1), applying light pressure.

DĖMESIO!

Ensure that the wire guide has advanced right up to the stop at the front,

rotating and pushing forward gently.

4. Measure the excess length that needs to be cut from the wire guide.

5. Remove the wire guide again and shorten the front end by the measured length.

Steel liner: grind down the burred edges if needed.

Plastic liner: make a clean cut and chamfer the edges (e.g. with a pencil sharpener)

PASTABA!

Make sure the inner opening of the liner is not obstructed by the cut wire end.

0463 373 101

- 50 -

© ESAB AB 2018

5 INSTALLATION

6. Reinstall the wire guide and attach the sleeve nut (2).

PASTABA!