RT Robo Welding Torch System

RTKS-2, RTFL-2, KSC-2, FLC-2, RT42, RT52,

RT62, RT72, RT82, RT42-NG, RT82WNG

Bruksanvisning

0463 373 101 NO 20181227

INNHOLD

1

SIKKERHET................................................................................................. 5

1.1 Symbolforklaring.................................................................................... 5

1.2 Sikkerhetsregler ..................................................................................... 5

2

GARANTI ..................................................................................................... 8

2.1 Betingelser for tiltenkt bruk................................................................... 8

3

INNLEDNING ............................................................................................... 9

3.1 Oversikt over sveisebrennersystemet ................................................. 9

4

TEKNISKE DATA......................................................................................... 11

4.1 Sveisebrennerhals ................................................................................. 11

4.2 Spenningsverdi....................................................................................... 12

4.2.1 Kjølekretsgrenser ................................................................................. 12

4.3 Brennerfeste ........................................................................................... 13

4.3.1 Brennerfester for standard RT-system ................................................. 13

4.3.1.1 RTKS-2-sikkerhetsmekanisme......................................................... 14

4.3.1.2 RTFL-2 mellomliggende flens........................................................... 14

4.3.2 Brennerfester for hollow wrist-system .................................................. 14

4.3.2.1 RTKSC-2 G/W-brennerfeste med sikkerhetsmekanisme................. 16

4.3.2.2 RTFLC-2 G/W stivt brennerfeste...................................................... 17

4.4 Adapterflenser ........................................................................................ 18

4.5 Kabler ...................................................................................................... 18

4.5.1 Kabler for standard RT-system............................................................. 18

4.5.2 Kabler for hollow wrist-systemer .......................................................... 19

5

INSTALLATION............................................................................................ 21

5.1 RTKS-2 standard arm installation........................................................ 21

5.1.1 RTKS-2 safety-off mechanism............................................................. 21

5.1.1.1 Torch installation with adjustable mount............................................ 22

5.1.2 Standard arm cable assembly for KS-2 and FL-2 ................................ 24

5.1.3 RTKS-2 wire feeder connection........................................................... 25

5.1.4 RTKS-2 electrical connections ............................................................ 26

5.1.4.1 RTKS-2 safety-off mechanism connection ....................................... 26

5.1.5 RTKS-2 Torch installation.................................................................... 27

5.2 RTFL-2 standard arm installation ........................................................ 28

5.2.1 RTFL-2 rigid mount.............................................................................. 28

5.2.2 RTFL-2 torch installation ..................................................................... 30

5.3 RTKSC-2 hollow wrist system installation.......................................... 30

5.3.1 RTKSC-2 mount with safety off mechanism........................................ 30

5.3.2 Mounting the cable assembly............................................................... 31

5.3.2.1 RTKSC-2 feeder cabinet connections .............................................. 32

5.3.3 RTKSC-2 cable assembly ................................................................... 34

5.3.3.1 RTKSC-2 cable assembly installation .............................................. 34

5.3.3.2 RTKSC-2 electrical connections....................................................... 37

0463 373 101 © ESAB AB 2018

INNHOLD

5.3.4 RTKSC-2 torch installation .................................................................. 38

5.4 RTFLC-2 installation.............................................................................. 39

5.4.1 RTFLC-2 mount................................................................................... 39

5.4.2 RTFLC-2 wire feeder connection......................................................... 39

5.4.2.1 Feeding through the robot arm.......................................................... 39

5.4.2.2 RTFLC-2 feeder cabinet connections............................................... 40

5.4.3 RTFLC-2 cable assembly.................................................................... 42

5.4.3.1 RTFLC-2 cable assembly installation............................................... 42

5.4.4 RTFLC-2 electrical connections .......................................................... 45

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly........... 45

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly................. 46

5.5 Torch installation.................................................................................... 46

5.5.1 Torch neck equipment .......................................................................... 46

5.5.2 Aristo RT torch neck installation........................................................... 47

5.6 Installing the wire guide for standard and hollow Wrist arm ............. 48

5.6.1 Installing the neck liner......................................................................... 48

5.6.2 Installing a split wire guide in the cable assembly................................ 49

5.6.3 Installing a continuous wire guide in the cable assembly..................... 51

5.7 Adjust the narrow gap contact tip ........................................................ 52

6

OPERATION ................................................................................................ 55

6.1 Important information for programming (hollow wrist system only) 55

7

SERVICE OG VEDLIKEHOLD .................................................................... 57

7.1 Obligatoriske kontroller og tiltak .......................................................... 57

8

FEILSØKING ............................................................................................... 59

9

BESTILLING AV RESERVEDELER ............................................................ 61

Vi forbeholder oss retten til å endre spesifikasjoner uten varsel.

0463 373 101 © ESAB AB 2018

1 SIKKERHET

1 SIKKERHET

1.1 Symbolforklaring

Som brukt i denne bruksanvisningen: Betyr Merk! Vær på vakt!

FARE!

Angir umiddelbare farer som, hvis de ikke unngås, vil medføre umiddelbar

alvorlig personskade eller tap av liv.

ADVARSEL!

Angir mulige farer som kan medføre personskade eller tap av liv.

FORSIKTIG!

Angir farer som kan medføre mindre personskade.

ADVARSEL!

Før bruk skal du lese og forstå bruksanvisningen samt

følge alle skilter, arbeidsgivers sikkerhetsrutiner og

sikkerhetsdatablader (SDS-er).

1.2 Sikkerhetsregler

Brukere av ESAB-utstyr har det endelige ansvaret for å sørge for at alle som arbeider med

eller i nærheten av utstyret, følger alle relevante sikkerhetsanvisninger. Sikkerhetsreglene

må oppfylle kravene som gjelder for denne type utstyr. Anbefalingene nedenfor må følges i

tillegg til standardforskrifter som gjelder på arbeidsplassen.

Alt arbeid må utføres av opplært personale som er fortrolige med bruken av utstyret. Feil

bruk av utstyret kan føre til farlige situasjoner, noe som kan forårsake personskader og

skade på utstyret.

1. Alle som bruker utstyret, må være kjent med følgende:

○ bruken

○ plasseringen av nødstoppene

○ hvordan det fungerer

○ relevante sikkerhetstiltak

○ sveising og skjæring og annen aktuell bruk av utstyret

2. Operatøren må sørge for at:

○ ingen uvedkommende befinner seg innenfor arbeidsområdet for utstyret når det

startes opp

○ ingen er ubeskyttet når lysbuen tennes eller man har begynt å arbeide med

utstyret

3. Arbeidsplassen må:

○ være egnet til formålet

○ være fri for trekk

0463 373 101

- 5 -

© ESAB AB 2018

1 SIKKERHET

4. Personlig verneutstyr:

○ Bruk alltid anbefalt personlig verneutstyr, slik som vernebriller, flammesikre klær,

vernehansker

○ Ikke ha på deg løstsittende klær, slik som skjerf, armbånd, ringer osv, som kan

hekte seg fast eller føre til forbrenninger

5. Generelle forholdsregler:

○ Kontroller at returkabelen er sikkert tilkoblet.

○ Arbeid på høyspenningsutstyr skal alltid utføres av en autorisert elektriker.

○ Egnet brannslokkingsutstyr må være tydelig merket og tilgjengelig i nærheten.

○ Smøring og vedlikehold må ikke utføres på utstyret når det er i bruk.

ADVARSEL!

Buesveising og -skjæring kan være farlig for deg selv og andre. Ta forholdsregler

ved sveising og skjæring.

ELEKTRISK STØT – kan være livsfarlig

• Monter og jord enheten i samsvar med bruksanvisningen.

• Ikke ta i strømførende deler eller elektroder med bare hender eller vått

verneutstyr.

• Isoler deg selv fra jord og arbeidet.

• Sørg for å ha en trygg arbeidsposisjon.

ELEKTRISITET OG MAGNETFELTER – kan være helsefarlige

• Sveisere med pacemaker bør rådføre seg med lege før sveising. EMF kan

forstyrre enkelte pacemakere.

• Eksponering for EMF kan ha andre, ukjente helseeffekter.

• Sveisere skal benytte følgende prosedyre for å minimere eksponeringen

for EMF:

○ Før elektrode- og arbeidskablene sammen på samme side av

kroppen. Sikre dem med tape der dette er mulig. Ikke plasser

kroppen din mellom brenneren og arbeidskablene. Du må aldri kveile

brenner- eller arbeidskabelen rundt kroppen din. Holdt

sveisestrømkilden og kablene så langt borte fra kroppen som mulig.

○ Koble arbeidskabelen til arbeidsemnet så nært området som sveises,

som mulig.

RØYK OG GASSER – kan være helsefarlige

• Vend ansiktet bort fra sveiserøyken.

• Bruk ventilasjon, avtrekk ved lysbuen eller begge deler for å lede røyk og

gasser bort fra pusteområdet og hele området.

STRÅLER FRA LYSBUEN - kan skade øynene og gi brannskader på huden

• Beskytt øynene og kroppen. Bruk riktig sveiseskjerm og filterlinse, og bruk

alltid verneklær.

• Beskytt omgivelsene rundt med egnede beskyttelsesskjermer eller

forheng.

0463 373 101

STØY – for sterk støy kan skade hørselen

Beskytt ørene. Bruk øreklokker eller annet hørselvern.

- 6 -

© ESAB AB 2018

1 SIKKERHET

BEVEGELIGE DELER – kan forårsake personskade

• Hold alle dører, paneler og deksler lukket og godt på plass. Bare kvalifisert

personell skal fjerne deksler for vedlikehold og feilsøking etter behov.

Monter paneler og deksler, og lukk dører, når servicearbeidet er fullført, og

før motoren startes.

• Stopp motoren før du monterer eller kobler til en enhet.

• Hold hender, hår, løstsittende klær og verktøy borte fra bevegelige deler.

BRANNFARE

• Gnister (sprut) kan forårsake brann. Sørg for at det ikke er noen brennbare

materialer i nærheten.

• Ikke bruk på lukkede beholdere.

FUNKSJONSFEIL – tilkall eksperthjelp ved funksjonsfeil.

BESKYTT DEG SELV OG ANDRE!

FORSIKTIG!

Dette produktet er bare beregnet til buesveising.

ADVARSEL!

Ikke bruk strømkilden til å tine frosne rør.

FORSIKTIG!

Klasse A-utstyr er ikke beregnet på bruk i boligområder

der strømmen leveres av den offentlige

lavspenningsstrømforsyningen. Det kan være vanskelig

å sikre elektromagnetisk kompatibilitet for klasse

A-utstyr i slike omgivelser på grunn av ledningsbårne

forstyrrelser og strålingsforstyrrelser.

OBS!

Lever elektronisk utstyr inn til et mottak for

gjenvinning!

I henhold til EU-direktivet 2012/19/EF om elektrisk og

elektronisk avfall og direktivets implementering i

samsvar med nasjonale lovregler, skal elektrisk og/eller

elektronisk utstyr etter endt levetid leveres inn til et

mottak for gjenvinning.

Som ansvarlig for utstyret er det ditt ansvar å skaffe til

veie informasjon om godkjente innsamlingsstasjoner.

Kontakt nærmeste ESAB-forhandler for mer

informasjon.

ESAB har et utvalg sveisetilbehør og personlig verneutstyr til salgs. Ta kontakt med

en lokal ESAB-forhandler eller gå til nettsiden vår for å finne bestillingsinformasjon.

0463 373 101

- 7 -

© ESAB AB 2018

2 GARANTI

2 GARANTI

Produktene våre kontrolleres nøye før levering. ESAB verifiserer at hvert enkelt produkt er

uten defekter i materiale og utførelse ved levering og fungerer i henhold til tiltenkt bruk.

ESAB gir garanti mot defekter i materiale og utførelse i henhold til juridiske krav.

Forbruksartikler er unntatt fra denne garantien.

Garantien dekker ikke eventuelle skader eller funksjonelle defekter som skyldes:

• overbelastning, misbruk eller avvik fra tiltenkt bruk av produktet

• kollisjoner eller ulykker

• manglende samsvar med instruksjoner angitt i disse brukerinstruksjonene

• feilaktig installasjon eller montering

• utilstrekkelig vedlikehold

• modifisering av produktet fra den opprinnelige tilstanden

• kjemisk påvirkning

• normal slitasje

ESAB påtar seg ikke ansvar for annet enn utskifting eller reparasjon av defekte deler.

2.1 Betingelser for tiltenkt bruk

1. Produktet er beregnet på industriell og kommersiell bruk og må bare brukes av

kvalifisert personell. Produsenten er ikke ansvarlig for skader eller ulykker som følge

av feil bruk.

2. Aristo® RT-robotsveisesystem er utformet og produsert med toppmoderne materialer

og metoder og er trygt og pålitelig i drift når det håndteres, monteres og vedlikeholdes

av kvalifisert personell. Instruksjonene for installasjon, drift og vedlikehold som er

beskrevet i dette dokumentet, må følges.

3. Aristo® RT-robotsveisesystemet må bare monteres, drives og vedlikeholdes av

kvalifisert personell. Installasjons-, drifts- og vedlikeholdsforskriftene som er beskrevet

i denne håndboken, må følges.

4. Aristo® RT-robotsveisesystemet må utelukkende brukes til det formålet det er tiltenkt

av produsenten, innenfor rammen av de tekniske dataene og med automatiserte

håndteringssystemer. Brennertypen må velges for å passe til sveiseoppgaven.

5. Aristo® RT-robotsveisesystemet ble utformet for å brukes som et komplett system.

Det er ikke tillatt å inkluder komponenter fra andre produsenter.

6. RT KS-2 og RT KSC-2 skal bare brukes som nødstoppmekanismer innenfor deres

tekniske spesifikasjoner og i kombinasjon med en standard RT-armkabel (KS-2),

Infiniturn eller Helix (KSC-2), ESAB-adapterflens, inkludert RT-brennerfester (KS-2) og

en Aristo RT-sveisebrenner.

7. Ingen olje eller antisprutvæske skal tilsettes utblåsningsgassen. ESAB garanterer ikke

kjemisk resistens mot disse stoffene. ESAB anbefaler å bruke ESAB-sprayenheten for

å påføre minimumsmengden med antisprutvæske på brenneren og derfor beskytte

miljøet.

8. Produktet må holdes tørt og beskyttes mot fuktighet når det transporteres, lagres eller

brukes.

9. Systemet er konstruert for omgivelsestemperaturer fra 5 til 40°C. Hvis disse grensene

overskrides, kreves det spesifikke tiltak. Bruk en egnet kjølevæske ved fare for frost.

0463 373 101

- 8 -

© ESAB AB 2018

3 INNLEDNING

3 INNLEDNING

RT-sveisebrennersystemene er utviklet for helautomatisk MIG-/MAG-sveising med roboter.

Systemene består av en rekke Aristo RT-brennerhalser som er designet for robotbruk,

brennerfester, kabler som er optimalisert for robotbruk, og sikkerhetsfunksjoner for å

forhindre skade på systemet i tilfelle kollisjoner.

Det standard RT-sveisesystemet gir kollisjonsbeskyttelse ved bruk av RT KS-2, som er en

mekanisk fjærbelastet sikkerhetsfunksjon. Dette kan eventuelt erstattes av RTFL-2 for å dra

fordel av robotstyresystemets kollisjonsdetekteringsfunksjon. Det standard

RT-sveisesystemet kan brukes med en rekke kabeltyper.

RTKSC-2 og RTFLC-2 brennerfester med Infiniturn- eller Helix-kabler er beregnet for bruk i

robotsveisehollow wrist-systemer for avanserte sveiseoppgaver. Sikkerhetsmekanismen i

RTKSC-2-brennerfestet muliggjør stor elastisk avbøyning av brenneren i tilfelle kollisjon.

Infiniturn- og Helix-kabelene er enkle å montere og gir et svært pålitelig system med presise

manøvreringsegenskaper.

I kombinasjon med veletablerte Aristo RT-robotsveisebrennere skaper disse bestanddelene

et svært pålitelig og langvarig system som bare trenger et minimum av vedlikehold.

Bruksanvisningen er inkludert ved levering av brennerfester og kabler.

ESAB-ordrenumre, tilgjengelig tilbehør, reservedeler og slitasjedeler finnes i

reservedelslisten.

3.1 Oversikt over sveisebrennersystemet

Standard RT-system

For en detaljert beskrivelse kan du se den

tilsvarende delen i kapittelet TEKNISKE

DATA:

1. Brennerhals

Se Sveisebrenner.

2. Kabel

Se Kabler for standard RT-system.

3. Brennerfeste

Se Brennerfester for standard

RT-system.

4. RTKS-2-sikkerhetsmekanisme

Se RTKS-2-sikkerhetsmekanisme.

5. RTFL-2 mellomliggende flens

Se RTFL-2 mellomliggende flens.

6. Adapterflens (hvis nødvendig)

Se Adapterflenser.

0463 373 101

- 9 -

© ESAB AB 2018

3 INNLEDNING

Hollow wrist-system

For en detaljert beskrivelse kan du se den

tilsvarende delen i kapittelet TEKNISKE

DATA:

1. Brennerhals

Se Sveisebrenner.

2. Brennerfeste RTKSC-2

Se RTKSC-2-brenner feste med

sikkerhetsmekanisme.

3. Brennerfeste RTFLC-2

Se RTFLC-2 stivt brennerfeste.

4. Adapterflens

Se Adapterflenser.

5. Helix- eller Infiniturn-kabel

Se Kabler for hollow wrist-systemer.

0463 373 101

- 10 -

© ESAB AB 2018

4 TEKNISKE DATA

4 TEKNISKE DATA

4.1 Sveisebrennerhals

Velg brennermodellen i henhold til sveiseoppgaven. Den nødvendige driftssyklusen og

kapasiteten, kjølemetoden og tråddiameteren må tas i betraktning. Hvis det er økte krav, for

eksempel forårsaket av forvarmede arbeidsstykker eller høy varmerefleksjon i hjørner, må

disse tas hensyn til ved å velge en sveisebrenner med tilstrekkelig reserve i nominell effekt.

RT-sveisebrennerne er beregnet på bruk med CE-kompatible sveisestrømkilder for

prosessene gassmetallbuesveising med inert beskyttelsesgass (MIG),

gassmetallbuesveising med aktiv beskyttelsesgass (MAG) og MIG-lodding med

kommersielle rundtråder. Ikke bruk brenneren til andre prosesser.

For pulserende buesveising av stål eller aluminiumssveising må RT 82W vannkjølt brenner

brukes.

Se tilgjengelige brennermodeller under.

Brennermodell Kjølemetode Dekkgass Klassifisering

RT42G Gasskjølt CO

Gasskjølt 300A/ 100%

Gasskjølt Blanding 350A/ 60%

Gasskjølt 250A/ 100%

RT42W Vannkjølt CO

Vannkjølt 420A/ 100%

Vannkjølt Blanding 350A/ 60%

Vannkjølt 350A/ 100%

RT52G Gasskjølt CO

Gasskjølt 300A/ 100%

Gasskjølt Blanding 350A/ 60%

Gasskjølt 250A/ 100%

RT52W Vannkjølt CO

Vannkjølt 470A/ 100%

Vannkjølt Blanding 400A/ 60%

Vannkjølt 400A/ 100%

RT62G Gasskjølt CO

Gasskjølt 340A/ 100%

2

2

2

2

2

420A/ 60%

420A/ 60%

420A/ 60%

470A/ 60%

500A/ 60%

Gasskjølt Blanding 420A/ 60%

Gasskjølt 290A/ 100%

RT62W Vannkjølt CO

Vannkjølt 530A/ 100%

Vannkjølt Blanding 450A/ 60%

Vannkjølt 450A/ 100%

0463 373 101

- 11 -

2

530A/ 60%

© ESAB AB 2018

4 TEKNISKE DATA

Brennermodell Kjølemetode Dekkgass Klassifisering

RT72G Gasskjølt CO

2

480A/ 60%

Gasskjølt 320A/ 100%

Gasskjølt Blanding 400A/ 60%

Gasskjølt 270A/ 100%

RT72W Vannkjølt CO

2

480A/ 60%

Vannkjølt 430A/ 100%

Vannkjølt Blanding 480A/ 60%

Vannkjølt 430A/ 100%

RT82W Vannkjølt CO

2

600A/ 60%

Vannkjølt 600A/ 100%

Vannkjølt Blanding 550A/ 60%

Vannkjølt 550A/ 100%

Verdiene for brennerytelse og arbeidssyklus er gyldige i en 10-minutters syklus.

De tekniske dataene er gyldige for et standardisert bruksområde som bruker standard

slitasjedeler/reservedeler. Brennerytelsen reduseres når du bruker metalloverføringsmodus

med pulserende bue.

Temperaturområder Oppbevaring: –15–50°C (5–122°F)

Betjening: 5–40°C (41–104°F)

Utblåsningsgass Maks. 10bar, separat gasslange

Total vekt (brennerhals,

Ca. 5kg

sikkerhetsmekanisme, brennerfeste og 1m

kabel)

4.2 Spenningsverdi

Maks. tillatt spenning/strømstyrke

Komplett sveisebrennersystem 141V (toppverdi for sveising)

RTKS-2 sikkerhetskontrollkrets

RTKS-2 trykknapp

RTKSC-2 sikkerhetskontrollkrets 48V

Bruker dysesensorfunksjonalitet med en

standard kabel

Bruker dysesensorfunksjonalitet med Helixeller Infiniturn-kabler

24V/ 1A

48V/ 0,1A

50V/ 5A

(Tillatt belastning maks. 1 minutt ved nominell

strøm)

50V/ 5A

(Tillatt belastning maks. 1 minutt ved nominell

strøm)

Den angitte ytelsen viser til en standardisert bruk.

For kabelklassifisering kan du se avsnittet Kabler.

4.2.1 Kjølekretsgrenser

Gjelder kun for vannkjølt versjon.

0463 373 101

- 12 -

© ESAB AB 2018

4 TEKNISKE DATA

Min. vanngjennomstrømning: 1,0l/min

Min. vanntrykk: 2,5bar

Maks vanntrykk: 3,5bar

Inntakstemperatur: Maks 40°C

Tilbakeløpstemperatur: Maks 60°C

Kjølekapasitet: Min. 1000W, avhengig av bruksområde

FORSIKTIG!

Tilbakeløpstemperaturer på over 60°C kan føre til skade eller ødelegge kabelen.

4.3 Brennerfeste

Typen brennerfeste som kreves avhenger av utformingen av RT-sveisebrennersystemet og

valg av sikkerhetsutstyr. Se avsnittet Oversikt over sveisebrennersystemer.

Komponent Omtrentlig vekt

Brennerfeste (for standardsystem) 0,43 kg

RTKS-2-sikkerhetsmekanisme (for

0,85 kg

standardsystem)

RTFL-2 mellomliggende flens (for

0,35 kg

standardsystem)

RTKSC-2-brennerfeste (for hollow

1,90 kg

wrist-system)

RTFLC-2 stivt brennerfeste (for hollow

1,22 kg

wrist-system)

Robotsveisebrenner 0,66 kg

4.3.1 Brennerfester for standard RT-system

For standard RT-systemer er brennerfestet montert på RTKS-2-sikkerhetsmekanismen

(alternativt på RTFL-2 mellomliggende flens), som klemmer kabelen og den tilkoblede

brennerhalsen.

Velg brennerfestet i henhold til brennertypen og dens geometri. Ulike festetyper kan brukes.

Se reservedelslisten over tilgjengelige brennerfester for standard RT-system.

Brennerfeste for roboter med standardarm

0463 373 101

- 13 -

© ESAB AB 2018

4 TEKNISKE DATA

4.3.1.1 RTKS-2-sikkerhetsmekanisme

RT KS-2-sikkerhetsmekanismen er en fjærstøttet enhet som beskytter roboten og

brennersystemet i tilfelle kollisjon.

OBS!

Ikke demonter RTKS-2.

4.3.1.2 RTFL-2 mellomliggende flens

Den stive mellomliggende flensen RTFL-2 kan brukes i stedet for RTKS-2 hvis roboten har

et elektronisk kollisjonsdetekteringssystem.

4.3.2 Brennerfester for hollow wrist-system

I hollow wrist-system er Aristo RT-sveisebrennerhalsene koblet til brennerfestet KSC-2 eller

FLC-2.

Brennerfestet RT KSC-2 muliggjør elastisk avbøyning av brenneren i tilfelle kollisjon.

Samtidig åpnes en elektrisk kontakt som signaliserer at robotstyringen skal stoppe. Etter

tilbakestilling av feilen vil den første geometrien og verktøysenterpunktet (TCP) til brenneren

nås med høy presisjon. Systemet fungerer rent mekanisk og er fjærbelastet.

Brennerfestet RTFLC-2 har ingen innebygd sikkerhetsfunksjon.

0463 373 101

- 14 -

© ESAB AB 2018

4 TEKNISKE DATA

For hollow wrist-system anbefales RTKSC-2 G/W (alternativt RTFLC-2 G/W). Dette

brennerfestet kan brukes med både gasskjølte og vannkjølte brennere i Aristo RT-serien.

RTKSC-2 G/W RTFLC-2 G/W

Funksjonelt prinsipp for

Mekanisk Ikke aktuelt (stivt feste)

sikkerhetsmekanismen

Aksial frigjøringskraft (Fz) 650 N Ikke aktuelt (stivt feste)

Frigjør dreiemoment på

24Nm Ikke aktuelt (stivt feste)

tverrgående akse (Mx)

Tilbakestill etter frigjøring Automatisk Ikke aktuelt (stivt feste)

Repeterbarhet Lateral ±0,1mm ved TCP til

Ikke aktuelt (stivt feste)

en standard Aristo

RT-brenner

Maks. avbøyning Omtrent ±8° Ikke aktuelt (stivt feste)

Sikkerhetsbryter Normalt lukket

Ikke aktuelt (stivt feste)

Elektrisk belastning maks.

48V / 1A

0463 373 101

- 15 -

© ESAB AB 2018

4 TEKNISKE DATA

Elektrisk kontrollkrets for

dysesensorfunksjonalitet

Klassifisering:

• For Helix-kabler: maks

50VDC/ 5A, maks.

1minutt

Koble fra

sensorspenningen raskt

etter registrering av

kontakt.

• For Infiniturn-kabler har

dysesensorfunksjonen

Klassifisering:

• For Helix-kabler: maks

50VDC/ 5A, maks.

1minutt

• For Infiniturn-kabler:

maks 50VDC / 1 A,

maks. 1minutt

Koble fra sensorspenningen

raskt etter registrering av

kontakt.

begrenset funksjon.

Kontakt ESAB for en

detaljert undersøkelse

av mulige løsninger for

bruksområdet ditt.

Spenningsverdi Maksimal tillatt spenning for

sikkerhetskontrollkretsen:

48V.

4.3.2.1 RTKSC-2 G/W-brennerfeste med sikkerhetsmekanisme

PunktBeskrivelse Funksjon

1 Brennerhalsstøtte Aristo RT-brennerberøringspunkt

2 RTKSC-2-deksel Modul med kabel og brennerberøringspunkt

3 Gummikappe Beskyttelse for sikkerhetsmekanisme

0463 373 101

- 16 -

© ESAB AB 2018

4 TEKNISKE DATA

PunktBeskrivelse Funksjon

4 RTKSC-2-hoveddel Gjør det mulig med mekanisk avbøyning under en

kollisjon

5 Adapterflens Isolasjonsmodul til robothåndledd (må passe til den

spesifikke roboten)

6 Registerpinne For nøyaktig justering etter adapterflensen

7 Tilkobling for kontrollkabel Elektrisk tilkobling for kollisjonssignal og

dysesensorfunksjonalitet

8 Mikrobryter Sensor for kollisjonsdetektering

4.3.2.2 RTFLC-2 G/W stivt brennerfeste

PunktBeskrivelse Funksjon

1 Brennerhalsstøtte Aristo RT-brennerberøringspunkt

2 RTFLC-2-deksel Modul med kabel og brennerberøringspunkt

3 RTFLC-2-hoveddel Gjør det mulig med mekanisk avbøyning under en

kollisjon

4 Registerpinne For nøyaktig justering etter adapterflensen

5 Adapterflens Isolasjonsmodul til robothåndledd (må passe til den

spesifikke roboten)

6 Tilkobling for kontrollkabel

(3-polet)

0463 373 101

Elektrisk tilkobling for dysesensorfunksjonalitet (hvis

aktuelt)

- 17 -

© ESAB AB 2018

4 TEKNISKE DATA

4.4 Adapterflenser

Velg adapterflensen som er nødvendig for installasjon på robotarmen avhengig av

robottypen. Adapterflenser for alle passende standardsystemer og hollow wrist-systemer er

tilgjengelige. Se reservedelslisten.

4.5 Kabler

Tilkoblingen til trådmatingen påvirkes av kabelen. De tilgjengelige versjonene avhenger

hovedsakelig av systemdesign og kjølemedier (gass eller vann). Se reservedelslisten.

Klassifiseringene er gyldige for kabellengder fra 1 til 5 m.

Standard kabel Infiniturn Helix

Klassifisering (10min

syklus)

Gasskjølt (blandet

gass)

Klassifisering (10min

syklus)

Maks. 500A/ 60%

arbeidssyklus

Maks. 350A/ 100%

arbeidssyklus

Maks. 600A/ 100%

arbeidssyklus

Maks. 400A/ 60%

arbeidssyklus

Maks. 320A/ 100%

arbeidssyklus

Maks. 550A/ 100%

arbeidssyklus

Maks. 400A/ 60%

arbeidssyklus

Maks. 320A/ 100%

arbeidssyklus

Maks. 550A/ 100%

arbeidssyklus

Vannkjølt

Rotasjonsområde Begrenset roterbarhet Uendelig roterbar ±270° fra nøytral

posisjon

Vekt

Gasskjølt

Vekt

Vannkjølt

1,2m lang:

2,35 kg

1,2m lang:

2,35 kg

1,0m lang:

2,0 kg

1,0m lang:

2,0 kg

1,0m lang:

2,0 kg

1,0m lang:

2,0 kg

4.5.1 Kabler for standard RT-system

Burndy-kontaktpinner

A. Touch sense-gassdyse

C. Kollisjonssensor

D. Kollisjonssensor

E. Justering

0463 373 101

F. 0V

G. motorspenning +

G. motorspenning –

- 18 -

© ESAB AB 2018

4 TEKNISKE DATA

PunktBeskrivelse Funksjon

1 Halsfesteflens Brennerberøringspunkt

2 Beskyttelsesdeksel Beskytter kabelen fra skade

3 Burndy-kontakt, 12-polet Elektrisk tilkobling mellom sikkerhetsutkobling og

trådmater

4 Styreledning For KS-2 (sikkerhetsmekaniske og trykknapp)

5 EURO-kontakt Trådmatertilkobling

6 Blåseslange (sort hette) For rengjøring av brenneren med trykkluft etter

rengjøring

7 Vanninntak (blå hette)

8 Vanntilbakeløp (rød hette)

Vanninntak for brennerkjøling

Vanntilbakeløp av oppvarmet vann fra brenneren

1)

1)

9 Kontrollkabelplugg for

sikkerhetsmekanisme

Elektrisk tilkobling med RTKS-2 for

sikkerhetsutkoblingssignal og

dysesensorfunksjonalitet

1)

Bare for vannkjølte brennersystemer

4.5.2 Kabler for hollow wrist-systemer

Infiniturn-kabel tillater uendelig rotasjon av brenneren i begge retninger. Samtidig overføres

kjølevæske, beskyttelsesgass, utblåsingsluft, sveisekraften og signalet fra

sikkerhetsmekanismen.

Helix-kabelen er utformet for et rotasjonsområde på ±270° fra nøytral posisjon. Den kan

brukes til sveiseoppgaver som ikke krever uendelig rotasjon.

Infiniturn-kabler er tilgjengelige i gass- og vannkjølte versjoner. Helix-kabler kan brukes

universelt til gass- eller vannkjølte bruksområder.

OBS!

Ikke koble en Helix-kabel som drives av en gasskjølt brennerhals til et

vannkjølingssystem.

0463 373 101

- 19 -

© ESAB AB 2018

4 TEKNISKE DATA

PunktBeskrivelse Funksjon

1 Flens Brennerfeste RTKSC-2 / RTFLC-2-berøringspunkt

2 Registerpinne Sikrer riktig koblingsretning

3 Kontrollkabelplugg Elektrisk tilkobling til RTKSC-2 for

sikkerhetsutkoblingssignal og

dysesensorfunksjonalitet (hvis aktuelt)

4 EURO-kontakt Trådmatertilkobling

5 Styreledning Elektrisk tilkobling for sikkerhetsutkoblingssignal (fra

RTKSC-2) og dysesensorfunksjonalitet (dysesensor

er standard for Helix, ikke for Infiniturn)

6 Vanntilbakeløp (rød hette) Vanntilbakeløp av oppvarmet vann fra brenneren

7 Vanninntak (blå hette) Vanninntak for brennerkjøling

8 Blåseslange (sort hette) For rengjøring av brenneren med trykkluft etter

sveising

9 Mediakobling Uendelig roterbar kobling med mediaoverføring

10 Beskyttelsesdeksel Beskytter kabelen fra skade

0463 373 101

- 20 -

© ESAB AB 2018

5 INSTALLATION

5 INSTALLATION

ADVARSEL!

For your own safety, make sure that the robot is either in standby or power-less

state before doing maintenance work in the moving radius of the robot.

Follow the assembly instructions exactly. Pay attention during assembly that the cables are

not damaged. Damaged cables can lead to a short circuit, which may damage the electronics

of the robot or the welding torch.

Use only original ESAB components that have been specially developed for this purpose.

Only then the correct functioning of the whole welding torch system can be guaranteed.

5.1 RTKS-2 standard arm installation

5.1.1 RTKS-2 safety-off mechanism

1. Dismount the insulation flange (10) from the RTKS-2 (11) by removing the screws

(12).

2. Position the insulation flange (10) with the index pin on the robot arm and fix it with the

screws (20) included.

The insulation flange (10) is directly compatible with robots with tool flange according

to DIN ISO 9409-1-A40 (diameter 40mm, 4×M6). If the insulation flange (10) does

not fit, use an adapter flange (21).

OBS!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

3. Mount the RTKS-2 the back on the insulation flange (10).

0463 373 101

- 21 -

© ESAB AB 2018

5 INSTALLATION

4. Position the mount on the RTKS-2 and carefully insert the cylindrical pins (14) into the

holes provided. Take the position of the torch into account. Two mounting positions

may be potentially possible.

5. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (12).

OBS!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

12 - Cylinder screw with hexagon socket

M6DIN912 (length of the screw depending

on the torch mount)

14 - Cylindrical pins Ø4×20

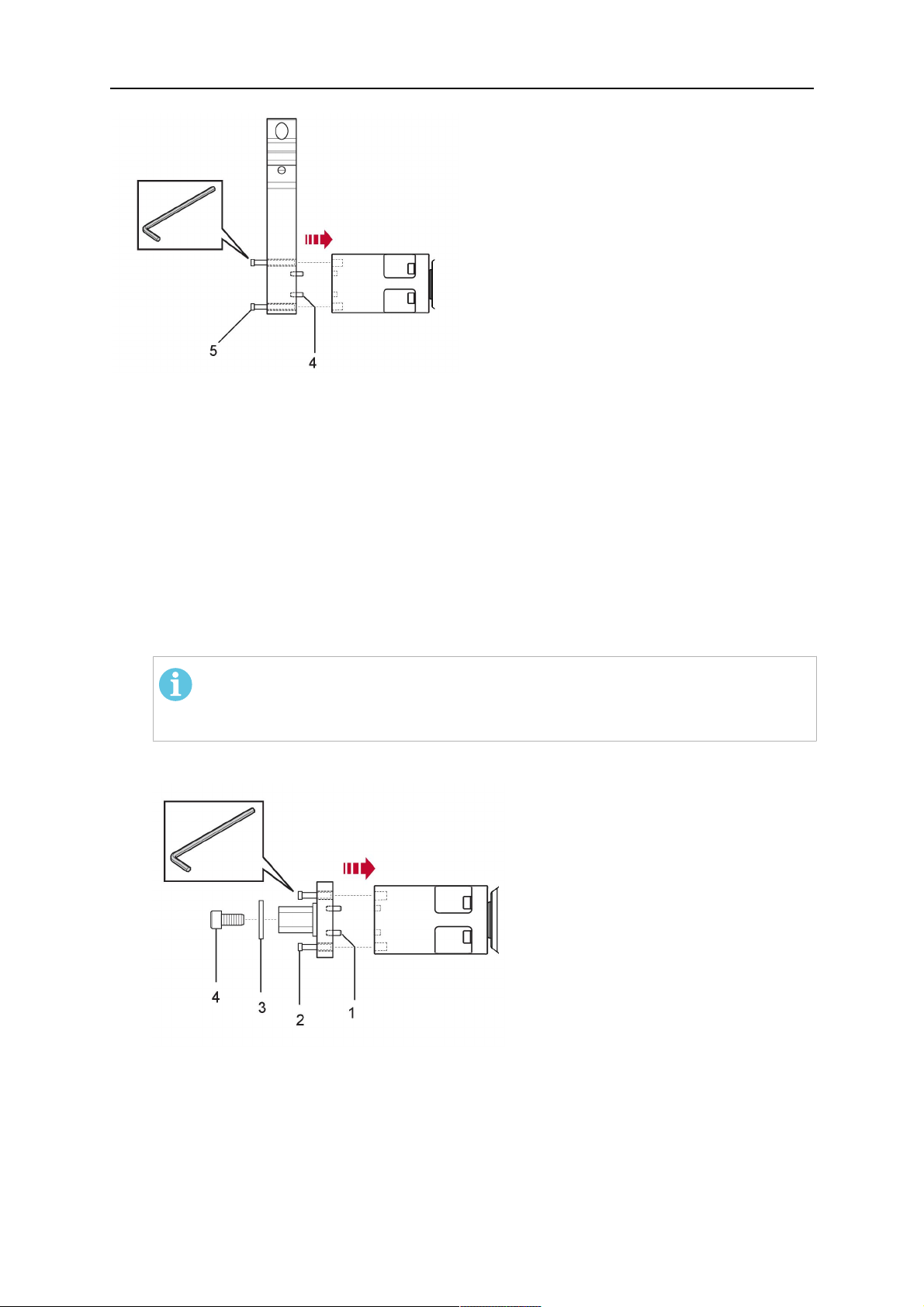

5.1.1.1 Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. The pins should protrude by approximately 5 mm (0.2 in.).

2. Position the mount on the safety-off mechanism RTKS-2 and carefully insert the

cylindrical pins (1) into the holes provided. In doing so, take the later position of the

torch into account. Two mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

OBS!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

0463 373 101

- 22 -

© ESAB AB 2018

5 INSTALLATION

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

0463 373 101

- 23 -

© ESAB AB 2018

5 INSTALLATION

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.1.2 Standard arm cable assembly for KS-2 and FL-2

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

0463 373 101

- 24 -

© ESAB AB 2018

5 INSTALLATION

FORSIKTIG!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

1. Unscrew the cylinder screws (1) and lift off the top section (2) of the torch mount.

2. Insert the feather key (4) into the recess of the neck support flange (3) from below.

3. Align the neck support flange (3) including the feather key (4) to the groove (5) of the

torch mount and push into the groove right up to the stop of the flange.

4. Hold the cable assembly in this position and simultaneously place the top section (2)

back onto the torch mount. First screw both cylinder screws (1) loosely in to about the

same length, then tighten alternately. The top section (2) of the mount should have an

even gap to the bottom section.

The front part of the cable assembly is directly clamped into the torch mount (see

illustration below).

1 - Cylinder screws 4 - Feather key

2 - Torch mount top section 5 - Groove for feather key

3 - Neck support flange

5.1.3 RTKS-2 wire feeder connection

In order to be able to create the connection, the cable assembly must be mounted as

described in the "Installing the cable assembly" section and equipped following "Installing the

wire guide" section. Only then can the central and media connection take place. Proceed as

described below:

0463 373 101

- 25 -

© ESAB AB 2018

5 INSTALLATION

1. Connect the central connector of the cable assembly (2) to the wire feeder cabinet

socket. Tighten the central connector sleeve nut fingertight. Do not use tools.

1 - Burndy Connector 4 - Return of heated water (red cap)

2 - EURO central connector 5 - Return of heated water (red cap)

3 - Air blow-out 6 - Main Wire feeder

2. For water cooled systems. Connect the water hoses to the cooling circuit. The end of

the hose marked blue (4) is connected to the water outlet, and the end marked red (5)

is connected to the water return.

3. Connect the blow-out line (3) to the corresponding connection of the feeder.

4. Connect the Burndy Connector to the wire feeder. (1) to the feeder. See section

"Electrical connections".

OBS!

All hoses and the control line must be installed so they can not bend or get

damaged!

5.1.4 RTKS-2 electrical connections

5.1.4.1 RTKS-2 safety-off mechanism connection

The switch for the safety-off functionality RTKS-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKS-2 unit via the 4-pole plug (4) that

contains circuits for the push-button (6) and the safety-off signal (7).

If a collision is detected, the control circuit for the safety-off signal (7), which is normally

closed, will be interrupted.

Rating of the control circuit: max. 48 V / 1 A

0463 373 101

- 26 -

© ESAB AB 2018

5 INSTALLATION

2 - Burndy connector 5 - RTKS-2 connector for control cable plug

4 - Control cable plug

Burndy-kontaktpinner

A. Touch sense-gassdyse

C. Kollisjonssensor

D. Kollisjonssensor

F. 0V

G. motorspenning +

G. motorspenning –

E. Justering

If the robot control provides a control circuit for nozzle sense functionality, the connection is

accomplished with a 1-wire connection.

Rating of the control circuit: max 50 V / 5 A.

FARE!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

FORSIKTIG!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

5.1.5 RTKS-2 Torch installation

Continue according to section "Torch installation".

0463 373 101

- 27 -

© ESAB AB 2018

5 INSTALLATION

5.2 RTFL-2 standard arm installation

5.2.1 RTFL-2 rigid mount

1. Position the RT FL-2 (2) with the index pin on the robot arm and fix it with the hexagon

socket screw included.

The FL-2 is directly compatible with robots with tool flange according to DIN ISO

9409-1-A40 (diameter 40mm, 4×M6). If the rigid mount does not fit, use an adapter

flange (3).

OBS!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

2. Install torch mount (1). Only torch mounts having a hole pattern equivalent with the

mounting surface may be attached. If necessary, carefully press the cylindrical pins (4)

into the corresponding holes in the bracket. The pins should protrude by

approximately 5mm (0.2in.). Position the torch mount on the RTFL-2 (2) and

carefully insert the cylindrical pins (4) into the holes provided. Take the position of the

torch into account. Two mounting positions may be potentially possible.

3. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (5).

OBS!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

0463 373 101

- 28 -

© ESAB AB 2018

5 INSTALLATION

4 - Cylindrical pins Ø4×20

5 - Cylinder screw with hexagon socket M6

DIN 912 (length of the screw depending on

the torch mount)

Side view

Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. Avoid the formation of burrs. The pins should protrude by

approximately 5 mm (0.2 in.).

2. Position the mount on the RTFL-2 and carefully insert the cylindrical pins (1) into the

holes provided. In doing so, take the later position of the torch into account. Two

mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

OBS!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

0463 373 101

- 29 -

© ESAB AB 2018

5 INSTALLATION

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 - Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.2.2 RTFL-2 torch installation

Continue according to section "Torch installation".

5.3 RTKSC-2 hollow wrist system installation

5.3.1 RTKSC-2 mount with safety off mechanism

FORSIKTIG!

For hollow wrist systems make sure that the clear space around the robot is at least

Ø45 mm (1.8 in.) around the wrist and 50 mm (2.0 in.) near the wire feeder.

0463 373 101

- 30 -

© ESAB AB 2018

5 INSTALLATION

1. Remove the three screws (2) from the front cover (3) of the torch mount and carefully

pull the cover off the RTKSC-2 main body (5). Take care not to damage the micro

switches installed inside the assembly.

1 - Hexagon wrench 4 mm 4 - Rubber boot

2 - 3× M5×12 screws 5 - RT KSC-2 main body

3 - RT KSC-2 front cover

1. Pull off the rubber boot (4) from the RTKSC-2 main body (5) to the front.

2. Now position the RTKSC-2 main body (5) on the adapter flange (7) so that the index

pin is correctly seated. Attach with the screws (6) enclosed.

3. Reinstall the rubber boot (4) on the RTKSC-2 main body (5) and make sure it is

correctly located in the grooves on the front and back flange.

4. Istall the adapter flange (7) on the robot.

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 3 - 3× M5×12 hexagon socket screws

2 - Rubber boot 4 - Adapter flange

5.3.2 Mounting the cable assembly

OBS!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ±2-3cm (±1in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

0463 373 101

- 31 -

© ESAB AB 2018

5 INSTALLATION

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

FORSIKTIG!

Axis 6 must be in 0° position.

5.3.2.1 RTKSC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

FORSIKTIG!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 32 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

FORSIKTIG!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connectors are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

OBS!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

OBS!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

0463 373 101

- 33 -

© ESAB AB 2018

5 INSTALLATION

5.3.3 RTKSC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

FORSIKTIG!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.3.3.1 RTKSC-2 cable assembly installation

OBS!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2, then thread the cable from the front through the

robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTKSC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1).

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 34 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

OBS!

Make sure that the position of the O-rings are not shifted by the index pin

during the assembly.

1 - RTKSC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RTKSC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 35 -

© ESAB AB 2018

5 INSTALLATION

6. If present, insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTKSC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13. Index pin

14. 3× M5×12 screws

0463 373 101

- 36 -

© ESAB AB 2018

5 INSTALLATION

5.3.3.2 RTKSC-2 electrical connections

OBS!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then

implemented via the power source controller.

RTKSC-2 safety-off mechanism connection

The switch for the safety-off functionality RTKSC-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKSC-2 unit via the control cable plug

(1).

The safety-off signal requires a 2-wire connection (black/black) to the safety-off circuit in the

robot control (5).

If a collision is detected, the control circuit (normally closed) will be interrupted (4).

Rating of the control circuit: max. 48 V / 1 A.

1 - Control cable plug 3 - Burndy connector VVV

2 - EURO central connector

Burndy-kontaktpinner

A. Touch sense-gassdyse

C. Kollisjonssensor

D. Kollisjonssensor

F. 0V

G. motorspenning +

G. motorspenning –

E. Justering

RTKSC-2 nozzle sense function connection

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

0463 373 101

- 37 -

© ESAB AB 2018

5 INSTALLATION

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

FARE!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

FORSIKTIG!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

5.3.4 RTKSC-2 torch installation

Continue according to section "Torch installation".

0463 373 101

- 38 -

© ESAB AB 2018

5 INSTALLATION

5.4 RTFLC-2 installation

5.4.1 RTFLC-2 mount

1. Remove the three M5 screws (2) from the front cover (3) of the RT FLC-2 torch mount

and carefully pull the cover off the main body (4).

1 - Hexagon wrench 4 mm 3 - RT FLC-2 front cover

2 - 3× M5×12 screws 4 - RT FLC-2 main body

2. Now position the RT FLC-2 main body (4) on the adapter flange (6) so that the index

pin is correctly seated. Attach with the screws (5) enclosed

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 5 - 3× M5×12 hexagon socket screws

4 - RT FLC-2 main body 6 - Adapter flange

5.4.2 RTFLC-2 wire feeder connection

5.4.2.1 Feeding through the robot arm

OBS!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ± 2-3 cm (± 1 in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

0463 373 101

- 39 -

© ESAB AB 2018

5 INSTALLATION

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

FORSIKTIG!

Important! Axis 6 must be in 0° position.

5.4.2.2 RTFLC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

FORSIKTIG!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 40 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

Refer to the instruction of the feeder manufacturer.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

FORSIKTIG!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connections are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

OBS!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

OBS!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

0463 373 101

- 41 -

© ESAB AB 2018

5 INSTALLATION

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

5.4.3 RTFLC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

FORSIKTIG!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.4.3.1 RTFLC-2 cable assembly installation

In a hollow wrist system the recommended order of installation is to feed the cable assembly

through the robot arm before connecting the cables to the torch mount.

When the cable assembly is correctly installed in the hollow wrist, continue the installation

according to the procedure described below.

OBS!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2 and RTFLC-2, then thread the cable from the front

through the robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTFLC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1). For gas cooled

systems, only one O-ring (4a) is needed, for water cooled systems all three O-rings

are needed.

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 42 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

OBS!

Take great care that the position of the O-rings is not shifted by the index pin

during the assembly.

1 - RT FLC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RT FLC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 43 -

© ESAB AB 2018

5 INSTALLATION

6. If present insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTFLC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13 - Index pin 14 - 3x M5x12 screws

0463 373 101

- 44 -

© ESAB AB 2018

5 INSTALLATION

5.4.4 RTFLC-2 electrical connections

OBS!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

documentation of the manufacturer for details. The link to the robot control is then

implemented via the power source controller.

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

FARE!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

FORSIKTIG!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

0463 373 101

- 45 -

© ESAB AB 2018

5 INSTALLATION

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 1-wire connection (green) to the nozzle sense circuit

in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

FARE!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

FORSIKTIG!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - EURO central connector

2 - Control cable 4 - Burndy connector

5.5 Torch installation

Be sure to use the correct version of the torch mount and cable assembly (water or gas

cooled).

5.5.1 Torch neck equipment

The torch neck, see (1) in the illustration below, must always be equipped to suit the wire

diameter and material.

0463 373 101

- 46 -

© ESAB AB 2018

5 INSTALLATION

1. Select the correct wire guide, contact tip (4), tip holder (2), gas nozzle (5), and gas

diffuser/spatter protection (3). You will find an exact overview and possible alternative

equipment elements for various torch models in the spare parts list. Only use original

ESAB parts; only then is the fitting accuracy ensured.

2. Firmly tighten the tip holder and the contact tip using a suitable tool for example the

enclosed monkey wrench.

3. When using a split wire guide, remove the installed guide nipple including the o-ring

from the torch flange upon delivery if necessary (see section "Installing the neck

liner").

FORSIKTIG!

The torch must be completely equipped before welding, especially the gas

diffuser and/or spatter protection and all necessary insulators have to be

installed according to the spare parts list. Welding without these items may

cause immediate destruction of the torch.

1 - Torch neck 4 - Contact tip

2 - Tip holder 5 - Contact tip

3 - Gas diffuser

5.5.2 Aristo RT torch neck installation

OBS!

Check the O-rings on the flange of the torch neck before mounting. Replace the

O-rings if damaged or lost. Missing or faulty O-rings will lead to leaks of shielding

gas and coolant.

1. For hollow wrist systems, insert the torch into the torch mount in the correct

orientation, so that the locator pin fits into the slot of the RTKSC-2 or RTFLC-2

interface, see (A) in the illustration below. For standard systems, attach the torch to

the RT flange of the cable assembly, (B) in the illustration below.

Installation is only possible in the correct orientation.

2. Tighten the locking nut of the torch neck.

OBS!

Only tighten by hand, never use tools or excessive force.

0463 373 101

- 47 -

© ESAB AB 2018

5 INSTALLATION

3. The correct seating of the torch can be checked by means of the window (1). If the

torch has been correctly mounted, no gap should be seen through the window (1).

5.6 Installing the wire guide for standard and hollow Wrist arm

Installing the wire guide

Choose the wire guide or liner depending on the filler wire material and diameter to be used,

see the spare parts list. Accurate performance of the system can only be guaranteed when

using original ESAB wire guides.

The recommended wire guide is the split wire guide, which consists of the neck liner and a

separate guide in the cable assembly. The front part of the wire guide, which is most

stressed, can be exchanged easily and independently of the cable assembly wire guide.

For correct installation, the following steps must be followed (example for Euro central

connector).

5.6.1 Installing the neck liner

The neck liner must be selected to fit the material and diameter of the welding wire, see the

spare parts list.

0463 373 101

- 48 -

© ESAB AB 2018

5 INSTALLATION

1. If present, remove the central guide nipple (1), from the torch neck using a hexagon

wrench (size 6 mm) or a large flat-blade screwdriver.

OBS!

The guide nipple (1) can only be used with one-piece liners and must not be

used with the standard RT or hollow wrist system.

2. When replacing the neck liner:

Unfasten the sleeve nut and remove the torch neck.

Unfasten the liner nipple using a hexagon wrench (size 6 mm) and remove nipple and

liner from the torch neck.

3. Remove the gas nozzle and the contact tip.

4. Insert the new neck liner (2) into the torch. Carefully tighten the guide nipple using a

suitable tool, e.g. a hex-wrench (size 6 mm) or a large flat-blade screwdriver.

5. Cut the neck liner flush with the tip holder and remove the neck liner from the torch.

6. Install the contact tip.

7. Insert the neck liner again. It will be stopped by the contact tip. Measure the excess

liner sticking out of the neck.

8. Remove the liner again and shorten the front end by the measured length. Carefully

deburr the edge and make sure that the inner hole is not blocked.

9. Reinstall the neck liner and tighten the guide nipple in the neck.

5.6.2 Installing a split wire guide in the cable assembly

The correct liner must be inserted to suit the filler material and the wire diameter, see the

spare parts list.

The wire guide is inserted through the cable assembly from the rear, reaching the guide

nipple that is installed in the flange where the torch neck will be attached. The following

worksteps must be followed in order to correctly determine the wire guide length. (Example

for Euro central connector).

0463 373 101

- 49 -

© ESAB AB 2018

5 INSTALLATION

1. For standard RT system: Install the guide nipple (1) in the center hole of the neck

support flange, see illustration A below.

For hollow wrist system: Install the guide nipple (1) into the torch interface of the

RTKSC-2 / RTFLC-2 cover, see illustration B below.

2. Remove the sleeve nut (2) from the central connector, and remove the old wire guide.

3. Insert the wire guide through the central connection and push forwards as far as it will

go into the guide nipple (1), applying light pressure.

FORSIKTIG!

Ensure that the wire guide has advanced right up to the stop at the front,

rotating and pushing forward gently.

4. Measure the excess length that needs to be cut from the wire guide.

5. Remove the wire guide again and shorten the front end by the measured length.

Steel liner: grind down the burred edges if needed.

Plastic liner: make a clean cut and chamfer the edges (e.g. with a pencil sharpener)

OBS!

Make sure the inner opening of the liner is not obstructed by the cut wire end.

0463 373 101

- 50 -

© ESAB AB 2018

5 INSTALLATION

6. Reinstall the wire guide and attach the sleeve nut (2).

OBS!

For hollow wrist systems where Infiniturn and Helix cable assemblies are

used, wire guides should be installed without tension so that the ends of the

liners may rotate freely.

Important note when using a plastic liner:

The wire channel between the drive rolls of the feeder and the central

connector of the torch must be fitted with a plastic liner. Depending on the

design of the feeder, a piece of plastic liner inserted into a brass guide tube

can be used.

During wire run-in, make sure that the wire is fed correctly into the plastic liner

of the torch. If necessary, remove the cable assembly from the feeder and

insert the wire, then reattach.

5.6.3 Installing a continuous wire guide in the cable assembly

Installing a steel liner

The wire guide is inserted through the cable assembly from the rear and reaches to the

contact tip. The following worksteps must be followed for the correct calculation of the length

(example for Euro central connector):

1. Install the torch (see section "Torch neck equipment").

2. Remove the gas nozzle and contact tip from the torch.

3. Remove the sleeve nut (D) from the Euro connector.

4. Push in the liner through the central connector and fix with the sleeve nut.

5. Cut off the liner flush with the nozzle holder. To determine the thread projection of the

contact tip, pull the liner backwards and screw in the contact tip.

6. Push the liner forwards as far as it will go to the contact tip applying light pressure on

the liner and measure the length to be shortened at the rear.

7. Now remove the liner again and cut the excess length measured off it’s front end. If

needed, grind down the burred edges. Make sure the inner opening of the liner is not

obstructed by the cut wire end.

8. The insulation of the liner must be removed after cutting off in the front area, such that

the insulation protrudes out of the RM2 flange by approx. 5 cm. For this, briefly

remove the torch neck.

9. Push the liner back in again and fix with the sleeve nut (D), see above. Re-install the

gas nozzle.

0463 373 101

- 51 -

© ESAB AB 2018

5 INSTALLATION

Installing a plastic liner

1. Mount the torch neck (see section "Torch neck equipment") and equip it with a gas

nozzle and contact tip.

2. Remove the sleeve nut (D) from the Euro connector.

3. Cleanly cut off the liner, slightly break the outer edges, point slightly (e.g. with a pencil

sharpener).

4. Insert the liner through the central connector into the cable assembly with fitted torch.

If it gets stuck, rotate the liner to free it and facilitate installation.

OBS!

Make sure the liner is completely inserted by rotating it and slightly pushing it

forward, until you can feel it has reached its stop.

5. Mount the nipple (B) and the O-Ring (C), move it to the right position and fix it with the

sleeve nut (D) of the Euro central connector.

6. Measure the required overlap needed inside the wire feeder cabinet and cut the liner