RT Robo Welding Torch System

RTKS-2, RTFL-2, KSC-2, FLC-2, RT42, RT52,

RT62, RT72, RT82, RT42-NG, RT82WNG

Navodila za uporabo

0463 373 101 SI 20181227

VSEBINA

1

VARNOST .................................................................................................... 5

1.1 Razlaga simbolov ................................................................................... 5

1.2 Varnostni ukrepi ..................................................................................... 5

2

GARANCIJA ................................................................................................ 8

2.1 Pogoji za predvideno uporabo.............................................................. 8

3

UVOD ........................................................................................................... 9

3.1 Pregled sistemov varilnih gorilnikov.................................................... 9

4

TEHNIČNI PODATKI.................................................................................... 11

4.1 Vrat varilnega gorilnika.......................................................................... 11

4.2 Nazivna napetost .................................................................................... 12

4.2.1 Omejitve hladilnega krogotoka............................................................. 12

4.3 Nosilec gorilnika..................................................................................... 13

4.3.1 Nosilec gorilnika za standardni sistem RT............................................ 13

4.3.1.1 Mehanizem varnostnega izklopa RT KS-2 ........................................ 14

4.3.1.2 Vmesna prirobnica RT FL-2 .............................................................. 14

4.3.2 Nosilci gorilnikov za sistem z votlim zapestjem.................................... 14

4.3.2.1 Nosilec gorilnika RT KSC-2 z mehanizmom varnostnega izklopa..... 16

4.3.2.2 Togi nosilec gorilnika RT FLC-2 G/W ................................................ 17

4.4 Prirobnice nastavkov ............................................................................. 18

4.5 Sklopi kablov .......................................................................................... 18

4.5.1 Sklopi kablov za standardni sistem RT................................................. 18

4.5.2 Sklopi kablov za sisteme z votlim zapestjem ....................................... 19

5

INSTALLATION............................................................................................ 21

5.1 RTKS-2 standard arm installation........................................................ 21

5.1.1 RTKS-2 safety-off mechanism............................................................. 21

5.1.1.1 Torch installation with adjustable mount............................................ 22

5.1.2 Standard arm cable assembly for KS-2 and FL-2 ................................ 24

5.1.3 RTKS-2 wire feeder connection........................................................... 25

5.1.4 RTKS-2 electrical connections ............................................................ 26

5.1.4.1 RTKS-2 safety-off mechanism connection ....................................... 26

5.1.5 RTKS-2 Torch installation .................................................................... 27

5.2 RTFL-2 standard arm installation ........................................................ 28

5.2.1 RTFL-2 rigid mount.............................................................................. 28

5.2.2 RTFL-2 torch installation ..................................................................... 30

5.3 RTKSC-2 hollow wrist system installation.......................................... 30

5.3.1 RTKSC-2 mount with safety off mechanism........................................ 30

5.3.2 Mounting the cable assembly............................................................... 31

5.3.2.1 RTKSC-2 feeder cabinet connections .............................................. 32

5.3.3 RTKSC-2 cable assembly ................................................................... 34

5.3.3.1 RTKSC-2 cable assembly installation .............................................. 34

5.3.3.2 RTKSC-2 electrical connections....................................................... 37

0463 373 101 © ESAB AB 2018

VSEBINA

5.3.4 RTKSC-2 torch installation .................................................................. 38

5.4 RTFLC-2 installation.............................................................................. 39

5.4.1 RTFLC-2 mount................................................................................... 39

5.4.2 RTFLC-2 wire feeder connection......................................................... 39

5.4.2.1 Feeding through the robot arm.......................................................... 39

5.4.2.2 RTFLC-2 feeder cabinet connections............................................... 40

5.4.3 RTFLC-2 cable assembly .................................................................... 42

5.4.3.1 RTFLC-2 cable assembly installation............................................... 42

5.4.4 RTFLC-2 electrical connections .......................................................... 45

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly........... 45

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly................. 46

5.5 Torch installation.................................................................................... 46

5.5.1 Torch neck equipment .......................................................................... 46

5.5.2 Aristo RT torch neck installation ........................................................... 47

5.6 Installing the wire guide for standard and hollow Wrist arm ............. 48

5.6.1 Installing the neck liner......................................................................... 48

5.6.2 Installing a split wire guide in the cable assembly................................ 49

5.6.3 Installing a continuous wire guide in the cable assembly..................... 51

5.7 Adjust the narrow gap contact tip ........................................................ 52

6

OPERATION ................................................................................................ 55

6.1 Important information for programming (hollow wrist system only) 55

7

SERVIS IN VZDRŽEVANJE......................................................................... 57

7.1 Obvezni pregledi in ukrepi..................................................................... 57

8

ODPRAVLJANJE NAPAK ........................................................................... 59

9

NAROČANJE NADOMESTNIH DELOV ..................................................... 61

Pridržane pravice do sprememb tehničnih podatkov brez vnaprejšnjega obvestila.

0463 373 101 © ESAB AB 2018

1 VARNOST

1 VARNOST

1.1 Razlaga simbolov

Kot je uporabljeno v tem priročniku: Pomeni pozor! Bodite pozorni!

NEVARNOST!

Pomeni neposredno nevarnost, ki se ji je treba izogniti, sicer lahko povzroči

takojšnje, hude telesne poškodbe ali izgubo življenja.

POZOR!

Pomeni morebitno nevarnost, ki lahko povzroči telesne poškodbe ali izgubo

življenja.

PREVIDNO!

Pomeni nevarnost, ki lahko povzroči lažje telesne poškodbe.

POZOR!

Pred uporabo morate prebrati in razumeti navodila za

uporabo, upoštevati podatke na nalepkah, upoštevati

varnostne predpise delodajalca in biti seznanjeni z

varnostnimi listi (SDS).

1.2 Varnostni ukrepi

Za to, da vse osebe, ki delajo z varilno opremo ESAB ali okoli nje, upoštevajo vse ustrezne

varnostne ukrepe, odgovarja izključno uporabnik te opreme. Varnostni ukrepi morajo

ustrezati zahtevam, ki veljajo za ta tip varilne opreme. Poleg standardnih predpisov za

varnost na delovnem mestu je treba upoštevati še naslednja priporočila.

Vsa dela mora opravljati usposobljeno osebje, ki je temeljito seznanjeno z delovanjem

varilne opreme. Nepravilno upravljanje opreme lahko izzove nevarnost, ki povzroči telesne

poškodbe delavca in škodo na opremi.

1. Vsakdo, ki uporablja varilno opremo, mora biti seznanjen z:

○ njenim upravljanjem;

○ razmestitvijo gumbov za ustavitev v sili;

○ njenim delovanjem;

○ ustreznimi varnostnimi ukrepi;

○ varjenjem, rezanjem oziroma drugim delom z opremo.

2. Upravljavec mora zagotoviti, da:

○ ob zagonu opreme v njenem delovnem območju ni nobene nepooblaščene

osebe;

○ nihče ni nezaščiten, ko se ustvari oblok oziroma se začne delo z opremo.

3. Delovno mesto mora biti:

○ ustrezno za dela, za katera je predvideno;

○ v njem ne sme biti prepiha.

0463 373 101

- 5 -

© ESAB AB 2018

1 VARNOST

4. Osebna varnostna oprema:

○ Vedno nosite priporočeno osebno zaščitno opremo, v katero spadajo zaščitna

očala, ognjevzdržna obleka in zaščitne rokavice.

○ Ne nosite ohlapnih oblačil ali predmetov, kakor so šali, verižice, prstaniipd., saj

jih lahko oprema zagrabi ali vas opečejo.

5. Splošni varnostni ukrepi:

○ Prepričajte se, da ima kabel mase trden stik.

○ Dela na visokonapetostni opremi sme opravljati le usposobljen elektrikar.

○ Pri roki mora biti pripravljena jasno označena gasilna oprema.

○ Mazanje in vzdrževanje opreme se ne sme izvajati med delovanjem.

POZOR!

Obločno varjenje in rezanje sta lahko nevarna za vas in druge osebe. Pri varjenju in

rezanju izvajajte varnostne ukrepe.

ELEKTRIČNI UDAR – lahko je smrtno nevaren

• Napravo namestite in ozemljite v skladu z navodili za uporabo.

• Ne dotikajte se električnih delov ali elektrod pod napetostjo z golo kožo,

mokrimi rokavicami ali mokrimi oblačili.

• Izolirajte se od obdelovanca in ozemljitve.

• Med delom bodite pozorni na varno ravnanje.

ELEKTRIČNA IN MAGNETNA POLJA – lahko škodujejo zdravju

• Varilci s srčnimi spodbujevalniki se morajo pred varjenjem posvetovati s

svojim zdravnikom. Elektromagnetna polja lahko motijo delovanje

nekaterih spodbujevalnikov.

• Izpostavljenost elektromagnetnim poljem ima lahko do zdaj še nepoznane

posledice.

• Varilci morajo za zmanjšanje izpostavljenosti elektromagnetnim poljem

izvesti naslednje ukrepe:

○ Elektrodo in delovne kable speljite na isti strani telesa. Če je mogoče,

jih pritrdite s trakom. Telo se sme biti med gorilnikom in delovnimi

kabli. Varilnika ali delovnih kablov nikoli ne ovijte okrog svojega

telesa. Varilni transformator in kabli morajo biti čim bolj oddaljeni od

vašega telesa.

○ Delovni kabel namestite na obdelovanec tako, da bo čim bližje

delovnemu območju.

HLAPI IN PLINI – lahko škodujejo zdravju

• Glava naj bo zunaj dosega hlapov.

• S pomočjo prezračevanja, odsesovanja pri obloku ali obojega odstranite

hlape in pline iz območja dihanja in splošnega območja.

SEVANJE IZ OBLOKA – lahko poškoduje oči in povzroči opekline.

0463 373 101

• Zaščitite si oči in telo. Uporabite ustrezno zaščito za varjenje in filtrirno

steklo ter zaščitna oblačila.

• Ljudi v okolici zaščitite z ustreznimi pregradami ali zavesami.

HRUP – premočan hrup lahko poškoduje sluh.

Zaščitite si ušesa. Uporabljajte glušnike ali drugo zaščito za sluh.

- 6 -

© ESAB AB 2018

1 VARNOST

Premikajoči deli – lahko povzročijo poškodbe

• Vsa vratca, plošče in pokrovi morajo biti zaprti in varno pritrjeni. Pokrove

lahko z namenom izvajanja vzdrževalnih del in odpravljanja napak odstrani

le usposobljeno osebje. Po koncu servisnih del in pred zagonom motorja

znova namestite plošče ali pokrove in zaprite vratca.

• Pred namestitvijo ali priklopom enote izklopite motor.

• Z rokami, lasmi, ohlapnimi oblačili in orodji ne segajte v območje delovanja

gibljivih delov.

NEVARNOST POŽARA

• Iskre (brizgajoča talina) lahko povzročijo požar. V bližini ne sme biti

vnetljivih snovi.

• Ne uporabljajte na zaprtih posodah.

NEPRAVILNO DELOVANJE APARATA – ob morebitnem nepravilnem delovanju se

obrnite na strokovnjaka.

ZAŠČITITE SEBE IN DRUGE!

PREVIDNO!

Ta izdelek je namenjen izključno obločnemu varjenju.

POZOR!

Ne uporabljajte varilnega transformatorja za taljenje zamrznjenih cevi.

PREVIDNO!

Oprema razredaA ni namenjena za uporabo v

stanovanjskih prostorih, kjer električno energijo

zagotavlja javno nizkonapetostno omrežje. V takih

prostorih lahko pride do težav pri elektromagnetni

združljivosti opreme razredaA zaradi prevodnih in

sevalnih motenj.

OPOMBA!

Odrabljeno elektronsko opremo oddajte ustanovi za

recikliranje!

Evropska Direktiva2012/19/ES o odpadni električni in

elektronski opremi ter njeni uvedbi v nacionalno

zakonodajo predpisuje ob koncu življenjske dobe

obvezno predelavo električne in/ali elektronske opreme

v ustanovi za recikliranje.

Kot odgovorna oseba za opremo ste odgovorni, da

pridobite informacije o odobrenih zbiralnih mestih.

Za več informacij se obrnite na najbližjega prodajalca

ESAB.

ESAB se ponaša z obsežno ponudbo dodatne varilne opreme in osebne zaščitne

opreme. Za podatke o naročanju se obrnite na najbližjega prodajalca podjetja ESAB ali

obiščite naše spletno mesto.

0463 373 101

- 7 -

© ESAB AB 2018

2 GARANCIJA

2 GARANCIJA

Pred dostavo so naši izdelki pozorno pregledani. ESAB preveri, da je vsak izdelek ob dostavi

brez napak v materialu in izdelavi in da deluje v skladu z namenom uporabe.

ESAB vam skladno z zakonodajnimi zahtevami jamči garancijo za napake v materialu in

izdelavi. Potrošni material je iz te garancije izvzet.

Garancija ne pokriva poškodb ali napak v delovanju, ki bi nastale zaradi:

• preobremenitev, zlorabe ali uporabe izdelka v nepredvidene namene,

• trkov ali nezgod,

• Neskladnosti z navodili, navedenimi v teh navodilih za uporabo,

• nepravilne namestitve ali sestave,

• nezadostnega vzdrževanja,

• predelave originalnega stanja izdelka,

• kemičnih vplivov,

• običajne obrabe.

ESAB ne prevzema nobene odgovornosti, razen za zamenjavo ali popravilo okvarjenih delov.

2.1 Pogoji za predvideno uporabo

1. Izdelek je namenjen uporabi v industrijske in komercialne namene in ga lahko

uporablja le usposobljeno osebje. Proizvajalec ni odgovoren za poškodbe ali nezgode,

ki bi nastale zaradi neustrezne uporabe.

2. Robotski varilni sistem Aristo® RT je vrhunsko zasnovan in izdelan ter deluje varno in

zanesljivo, ko ga uporablja, montira in vzdržuje usposobljeno osebje. Treba je

upoštevati navodila za montažo, uporabo in vzdrževanje v tem dokumentu.

3. Robotski varilni sistem Aristo® RT lahko montira, uporablja in vzdržuje samo

usposobljeno osebje. Treba je upoštevati predpise glede montaže, uporabe in

vzdrževanje, opisane v tem priročniku.

4. Robotski varilni sistem Aristo® RT se lahko uporablja samo v namene, predvidene s

strani proizvajalca, v okviru svojih tehničnih podatkov in z avtomatiziranimi sistemi za

upravljanje. Treba je izbrati vrsto gorilnika, ki ustreza varilnemu opravilu.

5. Robotski varilni sistem Aristo® RT se uporablja kot celoten sistem. Vključevanje

sestavnih delov drugih proizvajalcev v sistem ni dovoljeno.

6. RT KS-2 in RT KSC-2 se lahko uporabljata samo kot mehanizma za zaustavitev v sili

v okviru svojih tehničnih podatkov in v kombinaciji s sklopom kablov za standardno

roko RT (KS-2), sklopoma kablov Infiniturn ali Helix (KSC-2), prirobnico nastavka

ESAB, nosilci gorilnika RT (KS-2) in varilnim gorilnikom Aristo RT.

7. V plin za odpihovanje ne dodajajte olja ali tekočine proti nastajanju varilnih odkruškov.

ESAB ne more zagotoviti kemične odpornosti na te snovi. ESAB priporoča, da s

škropilno enoto ESAB nanesete minimalno količino tekočine proti nastajanju varilnih

odkruškov na gorilnik in tako zaščitite okolje.

8. Poskrbite, da bo izdelek med prevozom, shranjevanjem ali uporabo na suhem in

zaščiten pred vlago.

9. Sistem je zasnovan za temperaturo okolice od 5 °C do 40 °C (od 41 °F do 104 °F). Če

so te omejitve presežene, je treba izvesti določen postopek. V primeru nevarnosti

zamrznitve uporabite ustrezno hladilno sredstvo.

0463 373 101

- 8 -

© ESAB AB 2018

3 UVOD

3 UVOD

Sistemi varilnih gorilnikov RT so razviti za popolnoma samodejno varjenje MIG/MAG s

pomočjo robotov. Sisteme sestavljajo različni vratovi gorilnikov Aristo RT, zasnovani za

robotsko uporabo, nosilci gorilnikov, sklopi kablov, optimizirani za robotsko uporabo, in

funkcije varnostnega izklopa, ki preprečujejo poškodbe sistema v primeru trčenja.

Standardni varilni sistem RT omogoča zaščito v primeru trčenja prek RT KS-2, mehanske

vzmetene funkcije varnostnega izklopa. To je mogoče zamenjati s funkcijo RT FL-2, če želite

izkoristiti funkcijo zaznavanja trčenja robotskega krmilnega sistema. Standardni varilni sistem

RT se lahko uporablja z različnimi vrstami sklopov kablov.

Nosilca gorilnikov RT KSC-2 in RT FLC-2 s sklopoma kablov Infiniturn ali Helix sta

namenjena uporabi z robotskimi varilnimi sistemi z votlim zapestjem, ki so zasnovani za

napredne varilne postopke. Mehanizem varnostnega izklopa v nosilcu gorilnika RT KSC-2

omogoča precejšen elastični odklon gorilnika v primeru trčenja. Sklopa kablov Infiniturn in

Helix je enostavno namestiti in nudita zelo zanesljiv sistem, s katerim je mogoče natančno

upravljati.

V kombinaciji z uveljavljenimi robotskimi varilnimi gorilniki Aristo RT ti sestavni deli tvorijo

zelo zanesljiv in obstojen sistem, ki potrebuje minimalno vzdrževanje.

Navodila za uporabo prejmete ob dostavi nosilcev gorilnikov in sklopov kablov.

Številke za naročanje, razpoložljivo dodatno opremo, nadomestne dele in obrabne

dele najdete na seznamu nadomestnih delov podjetja ESAB.

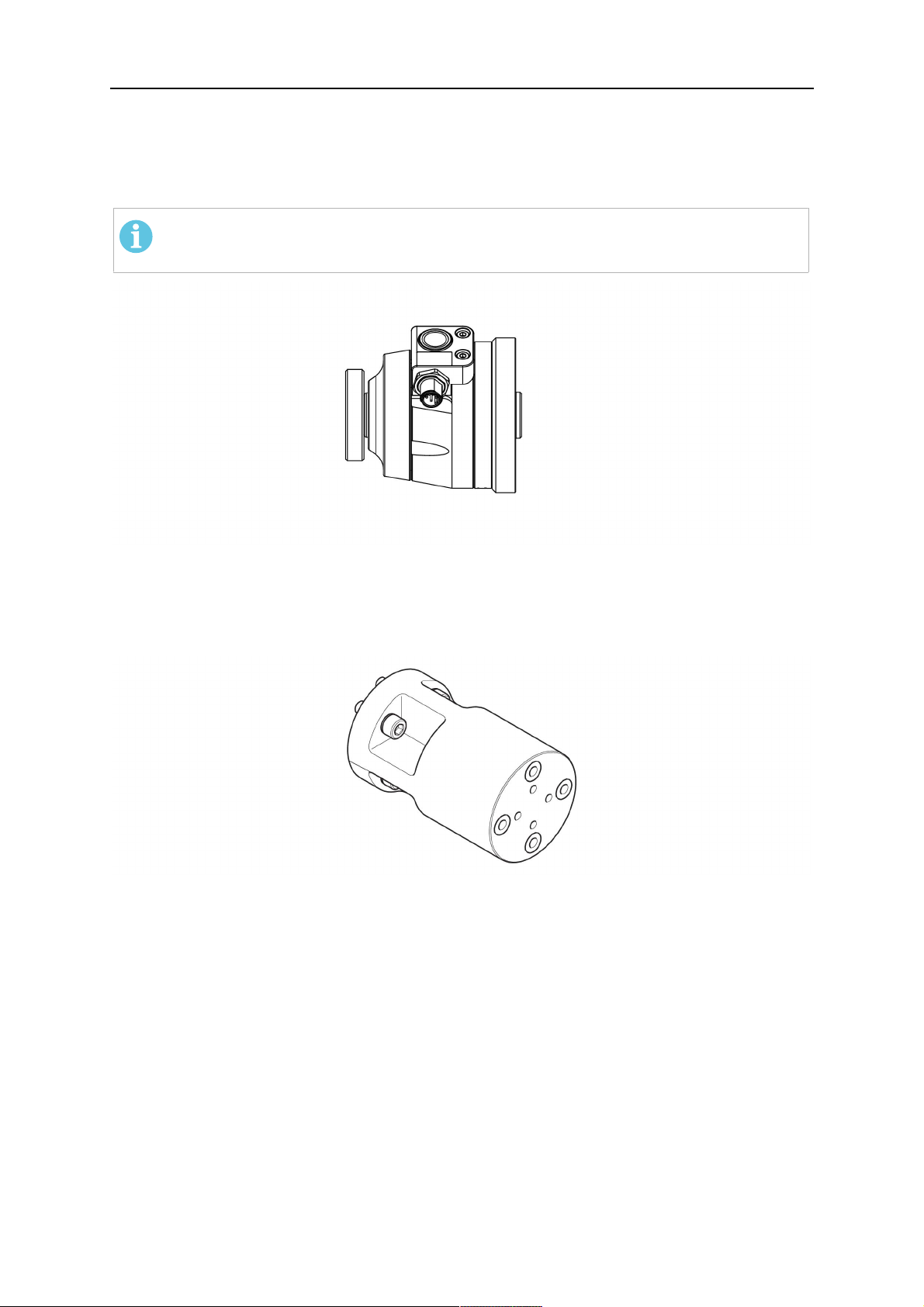

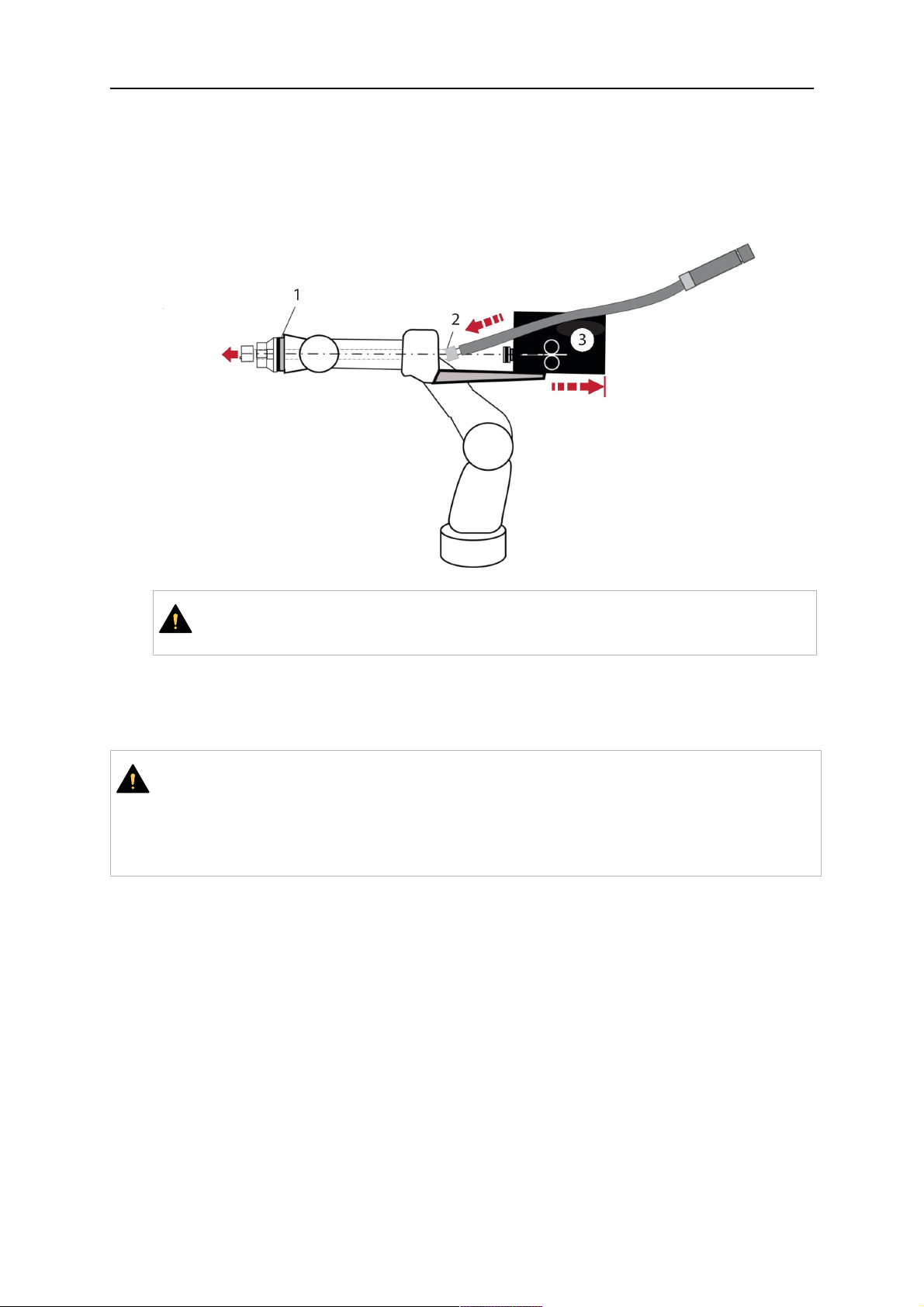

3.1 Pregled sistemov varilnih gorilnikov

Standardni sistem RT

Podroben opis si lahko ogledate v ustreznem

razdelku v poglavju TEHNIČNI PODATKI:

1. Vrat gorilnika

Glejte »Varilni gorilnik«.

2. Sklop kablov

Glejte »Sklopi kablov za standardni

sistem RT«.

3. Nosilec gorilnika

Glejte »Nosilci gorilnikov za

standardni sistem RT«.

4. Mehanizem varnostnega izklopa

RT KS-2

Glejte »Mehanizem varnostnega

izklopa RT KS-2«.

5. Vmesna prirobnica RT FL-2

Glejte »Vmesna prirobnica RT

FL-2«.

6. Prirobnica nastavka (če je

potrebna)

Glejte »Prirobnice nastavkov«.

0463 373 101

- 9 -

© ESAB AB 2018

3 UVOD

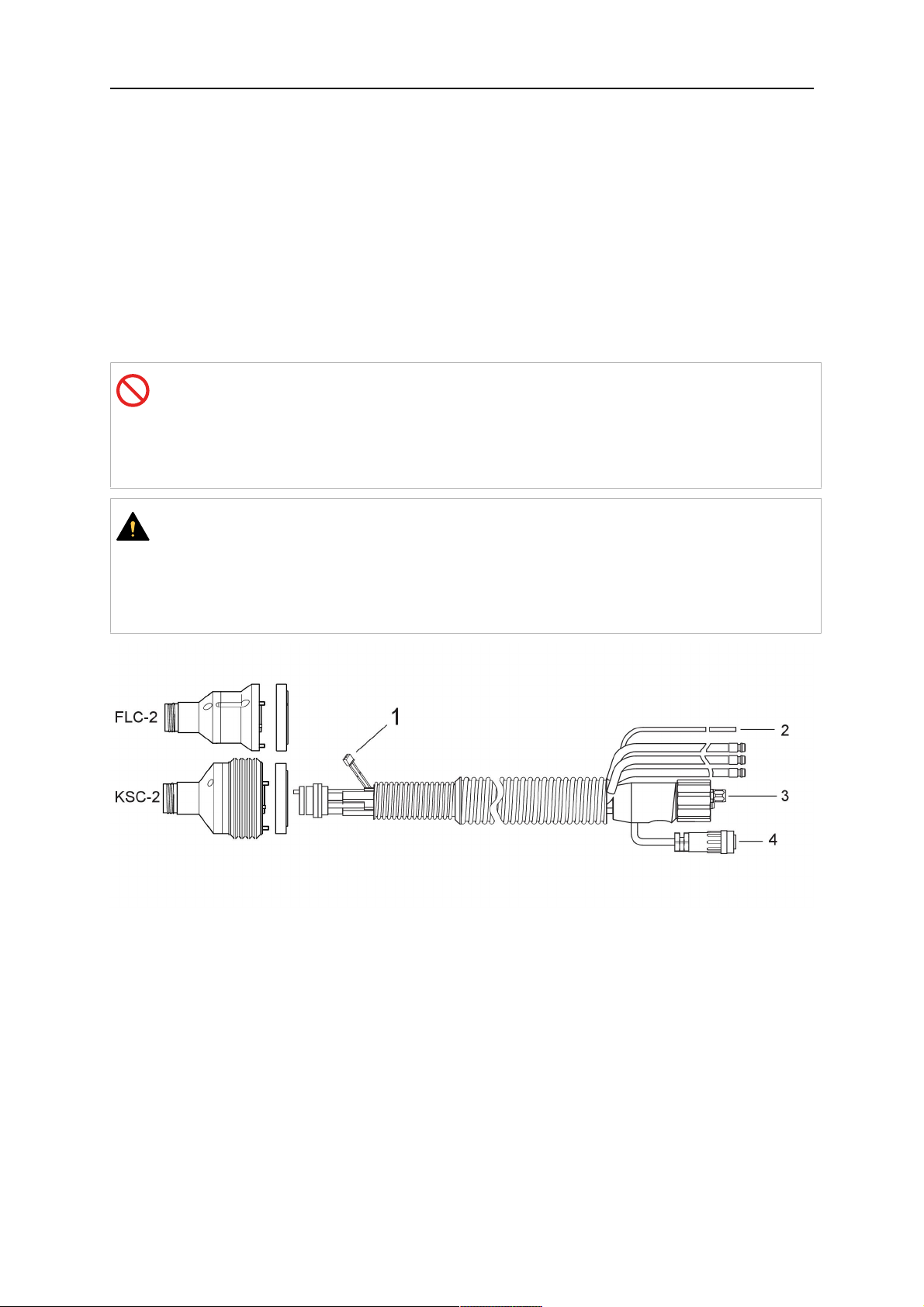

Sistem z votlim zapestjem

Podroben opis si lahko ogledate v ustreznem

razdelku v poglavju TEHNIČNI PODATKI:

1. Vrat gorilnika

Glejte »Varilni gorilnik«.

2. Nosilec gorilnika RT KSC-2

Glejte »Nosilec gorilnika RT KSC-2

z mehanizmom varnostnega

izklopa«.

3. Nosilec gorilnika RT FLC-2

Glejte »Togi nosilec gorilnika RT

FLC-2«.

4. Prirobnica nastavka

Glejte »Prirobnice nastavkov«.

5. Sklop kablov Helix ali Infiniturn

Glejte »Sklopi kablov za sisteme z

votlim zapestjem«.

0463 373 101

- 10 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

4 TEHNIČNI PODATKI

4.1 Vrat varilnega gorilnika

Izberite model gorilnika glede na vrsto varjenja. Upoštevati morate potreben delovni cikel in

obremenitev, način hlajenja in premer žice. Če obstajajo povečane zahteve, na primer zaradi

predgretih obdelovancev ali visokega odboja toplote v kotih, morate upoštevati tudi te

zahteve ter izbrati varilni gorilnik z zadostno rezervno nazivno zmogljivostjo.

Varilni gorilniki RT so namenjeni uporabi z varilnimi transformatorji z oznako CE za varjenje

kovin v inertnem plinu (MIG), varjenje kovin v aktivnem plinu (MAG) in spajkanje MIG s

komercialnimi okroglimi žicami. Gorilnikov ne uporabljajte za druge postopke.

Za obločno varjenje jekla ali aluminija s pulznim tokom je treba uporabiti vodno hlajeni

gorilnik RT 82W.

Spodaj si oglejte modele gorilnikov, ki so na voljo.

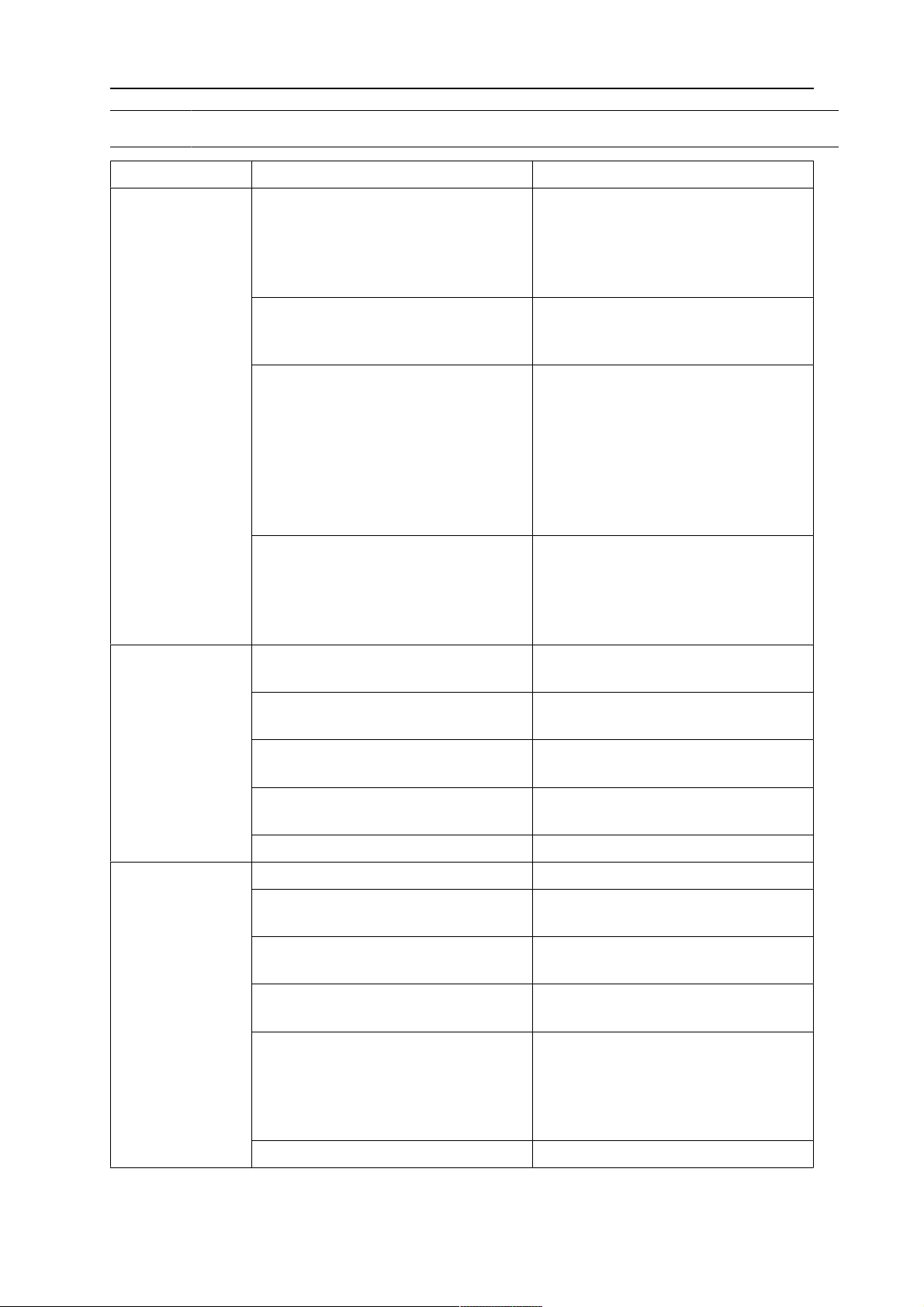

Model gorilnika Način hlajenja Zaščitni plin Naznačena vrednost

RT42G Plinsko hlajenje CO

Plinsko hlajenje 300A/100%

Plinsko hlajenje Mešani 350A/60%

Plinsko hlajenje 250A/100%

RT42W Vodno hlajenje CO

Vodno hlajenje 420A/100%

Vodno hlajenje Mešani 350A/60%

Vodno hlajenje 350A/100%

RT52G Plinsko hlajenje CO

Plinsko hlajenje 300A/100%

Plinsko hlajenje Mešani 350A/60%

Plinsko hlajenje 250A/100%

RT52W Vodno hlajenje CO

Vodno hlajenje 470A/100%

Vodno hlajenje Mešani 400A/60%

Vodno hlajenje 400A/100%

RT62G Plinsko hlajenje CO

Plinsko hlajenje 340A/100%

2

2

2

2

2

420A/60%

420A/60%

420A/60%

470A/60%

500A/60%

Plinsko hlajenje Mešani 420A/60%

Plinsko hlajenje 290A/100%

RT62W Vodno hlajenje CO

Vodno hlajenje 530A/100%

Vodno hlajenje Mešani 450A/60%

Vodno hlajenje 450A/100%

RT72G Plinsko hlajenje CO

Plinsko hlajenje 320A/100%

Plinsko hlajenje Mešani 400A/60%

Plinsko hlajenje 270A/100%

0463 373 101

- 11 -

2

2

530A/60%

480A 60%

© ESAB AB 2018

4 TEHNIČNI PODATKI

Model gorilnika Način hlajenja Zaščitni plin Naznačena vrednost

RT72W Vodno hlajenje CO

2

480A/60%

Vodno hlajenje 430A/100%

Vodno hlajenje Mešani 480A/60%

Vodno hlajenje 430A/100%

RT82W Vodno hlajenje CO

2

600A/60%

Vodno hlajenje 600A/100%

Vodno hlajenje Mešani 550A/60%

Vodno hlajenje 550A/100%

Vrednosti za zmogljivost gorilnika in delovni cikel veljajo za 10-minutni cikel.

Tehnični podatki veljajo za standardiziran namen uporabe s standardnimi

obrabnimi/nadomestnimi deli. Zmogljivost gorilnika je manjša med obločnim varjenjem kovine

s pulznim tokom.

Temperaturna območja Shranjevanje: -15-50°C (5-122°F)

Uporaba: 5–40°C (41–104°F)

Plin za odpihovanje Najv. 10 barov, ločena plinska cev

Skupna teža (vrat gorilnika, mehanizem

Približno 5kg

varnostnega izklopa, nosilec gorilnika in

sklop 1 m dolgega kabla)

4.2 Nazivna napetost

Najv. dovoljena napetost/moč

Celovit sistem varilnih gorilnikov 141V (najvišja vrednost za varjenje)

Krmilno vezje varnostnega izklopa RT KS-2

Gumb RT KS-2

Krmilno vezje varnostnega izklopa RT KSC-2 48 V

Uporaba funkcije zaznavanja šobe s

standardnim sklopom kablov

Uporaba funkcije zaznavanja šobe s

sklopoma kablov Helix ali Infiniturn

Navedene zmogljivosti veljajo za standardizirane primere uporabe.

Za zmogljivosti sklopov kablov glejte razdelek »Sklopi kablov«.

4.2.1 Omejitve hladilnega krogotoka

Velja samo za vodno hlajene različice.

24V / 1A

48V / 0,1A

50V / 5A

(Dovoljena obremenitev najv. 1 minuta pri

nazivnem napajalnem toku)

50V / 5A

(Dovoljena obremenitev najv. 1 minuta pri

nazivnem napajalnem toku)

Najnižja hitrost pretoka vode: 1,0l/min

Najnižji tlak vode: 2,5bara (36,3psi)

Najvišji tlak vode: 3,5bara (50,8psi)

0463 373 101

- 12 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

Temperatura v sesalnem

vodu:

Temperatura v povratnem

vodu:

Najv. 40°C (104°F)

Najv. 60°C (140°F)

Hladilna zmogljivost: Najm. 1000 W, odvisno od namena uporabe

PREVIDNO!

Temperature nad 60°C (140°F)v povratnem vodu lahko poškodujejo ali uničijo

sklop kablov.

4.3 Nosilec gorilnika

Od zasnove sistema varilnega gorilnika in izbire naprav za varnostni izklop je odvisno,

kakšen nosilec gorilnika potrebujete; glejte razdelek »Pregled sistemov varilnih gorilnikov«.

Komponente Približna teža:

Nosilec gorilnika (za standardni sistem) 0,43 kg

Mehanizem varnostnega izklopa RT KS-2 (za

standardni sistem)

Vmesna prirobnica RT FL-2 (za standardni

sistem)

0,85 kg

0,35 kg

Nosilec gorilnika RT KSC-2 (za sistem z

1,90 kg

votlim zapestjem)

Togi nosilec gorilnika RT FLC-2 (za sistem z

1,22 kg

votlim zapestjem)

Robotski varilni gorilnik 0,66 kg

4.3.1 Nosilec gorilnika za standardni sistem RT

Pri standardnih sistemih RT je nosilec gorilnika montiran na mehanizmu varnostnega izklopa

RT KS-2 (ali na vmesni prirobnici RT FL-2), pritrjen na sklop kablov in priključen vrat

gorilnika.

Izberite nosilec gorilnika v skladu z vrsto gorilnika in njegovo geometrijo. Uporabite lahko

različne vrste nosilcev. Nosilce gorilnikov, ki so na voljo za standardni sistem RT, si lahko

ogledate na seznamu nadomestnih delov.

Nosilec gorilnika za standardne robotske roke

0463 373 101

- 13 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

4.3.1.1 Mehanizem varnostnega izklopa RT KS-2

Varnostni mehanizem RT KS-2 je vzmetena priprava, ki zaščiti robota in sistem gorilnika v

primeru trčenja.

OPOMBA!

Ne razstavljajte mehanizma RT KS-2.

4.3.1.2 Vmesna prirobnica RT FL-2

Namesto mehanizma RT KS-2 lahko uporabite togo vmesno prirobnico RT FL-2, če je robot

opremljen z elektronskim sistemom za zaznavanje trčenja.

4.3.2 Nosilci gorilnikov za sistem z votlim zapestjem

Pri sistemu z votlim zapestjem so vratovi varilnih gorilnikov Aristo RT povezani z nosilcem

gorilnika KSC-2 ali FLC-2.

Nosilec gorilnika RT KSC-2 omogoča elastični odklon gorilnika v primeru trčenja. Hkrati se

odpre električni stik, ki pošlje krmilnemu sistemu robota signal za zaustavitev. Po ponastavitvi

napake bosta začetna geometrija in središčna točka orodja (TCP) na gorilniku doseženi z

izjemno natančnostjo. Sistem deluje izključno mehansko in je vzmeten.

Nosilec gorilnika RT FLC-2 nima vgrajene funkcije varnostnega izklopa.

0463 373 101

- 14 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

Za sisteme z votlim zapestjem priporočamo nosilec RT KSC-2 G/W (ali RT FLC-2 G/W). Ta

nosilec gorilnika lahko uporabljate tako s plinsko hlajenimi kot z vodno hlajenimi gorilniki

serije Aristo RT.

RTKSC-2 G/W RTFLC-2 G/W

Načelo delovanja mehanizma

Mehansko Ni relevantno (toga montaža)

varnostnega izklopa

Sila osne sprostitve (Fz) 650 N Ni relevantno (toga montaža)

Sprostitveni moment na

24 Nm Ni relevantno (toga montaža)

prečni osi (Mx)

Ponastavitev po sprostitvi Samodejno Ni relevantno (toga montaža)

Ponovljivost Bočno ± 0,1mm na točki TCP

Ni relevantno (toga montaža)

standardnega gorilnika Aristo

RT

Najv. odklon Pribl. ± 8° Ni relevantno (toga montaža)

Varnostno stikalo Običajno zaprto

Ni relevantno (toga montaža)

Najv. Električna obremenitev

48V / 1A

0463 373 101

- 15 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

Električno krmilno vezje za

funkcijo zaznavanja šobe

Nazivna vrednost:

• Pri sklopih kablov Helix:

najv. 50V DC / 5A,

najv. 1 minuta

Po zaznavanju stika

hitro odklopite napetost

zaznavanja.

• Pri sklopih kablov

Infiniturn ima funkcija

zaznavanja šob

Nazivna vrednost:

• Pri sklopih kablov Helix:

najv. 50V DC / 5A,

najv. 1 minuta

• Pri sklopih kablov

Infiniturn: najv. 50V DC

/ 1 A, najv. 1 minuta

Po zaznavanju stika hitro

odklopite napetost

zaznavanja.

omejeno funkcionalnost.

Obrnite se na ESAB, če

želite podrobno

preiskavo mogočih

rešitev za svoj namen

uporabe.

Nazivna napetost Najvišja dovoljena napetost

za krmilno vezje varnostnega

izklopa: 48V.

4.3.2.1 Nosilec gorilnika RT KSC-2 z mehanizmom varnostnega izklopa

ArtikelOpis Funkcija

1 Nosilec vratu gorilnika Vmesnik gorilnika Aristo RT

2 Pokrov RT KSC-2 Sklop s kablom in vmesniki gorilnikov

3 Gumijasti plašč Zaščita za mehanizem varnostnega izklopa

0463 373 101

- 16 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

ArtikelOpis Funkcija

4 Glavno ohišje RT KSC-2 Omogoča mehanski odklon v primeru trčenja

5 Prirobnica nastavka Izolacijski vmesnik za robotsko zapestje (ustrezati

mora določenemu robotu)

6 Kazalni zatič Za natančno poravnavo prirobnice nastavka

7 Konektor za krmilni kabel Električna povezava za signal v primeru trčenja in

funkcijo zaznavanja šobe

8 Mikrostikalo Tipalo za zaznavanje trčenja

4.3.2.2 Togi nosilec gorilnika RT FLC-2 G/W

ArtikelOpis Funkcija

1 Nosilec vratu gorilnika Vmesnik gorilnika Aristo RT

2 Pokrov RT FLC-2 Sklop s kablom in vmesniki gorilnikov

3 Glavno ohišje RT FLC-2 Omogoča mehanski odklon v primeru trčenja

4 Kazalni zatič Za natančno poravnavo prirobnice nastavka

5 Prirobnica nastavka Izolacijski vmesnik za robotsko zapestje (ustrezati

mora določenemu robotu)

6 Konektor za krmilni kabel

(3-polni)

0463 373 101

Električna povezava za funkcijo zaznavanja šobe

(če je relevantna)

- 17 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

4.4 Prirobnice nastavkov

Izberite prirobnico nastavka, ki je potrebna za montažo na robotsko roko in je odvisna od

vrste robota. Na voljo so prirobnice nastavkov za vse ustrezne standardne sisteme in

sisteme z votlim zapestjem; oglejte si seznam nadomestnih delov.

4.5 Sklopi kablov

Sklop kablov vpliva na povezavo s podajalnikom žice. Različice, ki so na voljo, so večinoma

odvisne od zasnove sistema in hladilnega sredstva (plina ali vode); oglejte si seznam

nadomestnih delov.

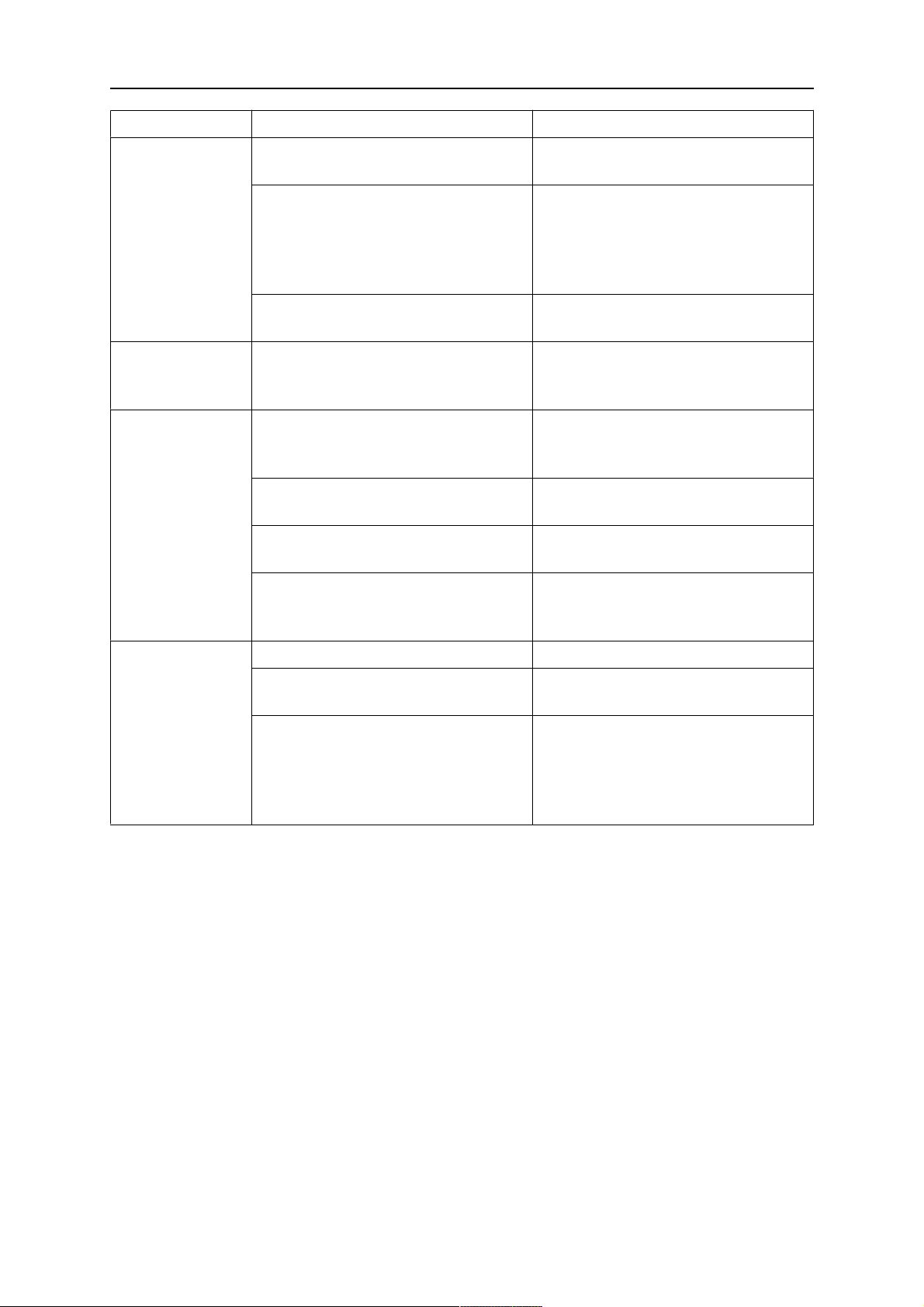

Nazivne vrednosti veljajo za dolžine kabla od 1 do 5 m.

Standardni sklop

Infiniturn Helix

kablov

Moč (10-minutni cikel)

Plinsko hlajenje

(mešani plin)

Moč (10-minutni cikel)

Vodno hlajenje

Razpon kroženja Omejena zmožnost

Teža

Plinsko hlajenje

Teža

Vodno hlajenje

Najv. 500A (60 %

delovni cikel)

Najv. 350 A (100 %

delovni cikel)

Najv. 600 A (100 %

delovni cikel)

kroženja

1,2 m dolgo:

2,35 kg

1,2 m dolgo:

2,35 kg

Najv. 400 A (60 %

delovni cikel)

Najv. 320 A (100 %

delovni cikel)

Najv. 550 A (100 %

delovni cikel)

Neomejena zmožnost

kroženja

1,0 m dolgo:

2,0 kg

1,0 m dolgo:

2,0 kg

4.5.1 Sklopi kablov za standardni sistem RT

Najv. 400 A (60 %

delovni cikel)

Najv. 320 A (100 %

delovni cikel)

Najv. 550 A (100 %

delovni cikel)

± 270° iz nevtralnega

položaja

1,0 m dolgo:

2,0 kg

1,0 m dolgo:

2,0 kg

0463 373 101

- 18 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

Nožice konektorja Burndy

A. Plinska šoba z

zaznavanjem dotika

C. Tipalo za zaznavanje

trčenja

F. 0V

G. + Napetost motorja

H. - Napetost motorja

D. Tipalo za zaznavanje

trčenja

E. Koračno pomikanje

ArtikelOpis Funkcija

1 Prirobnica nosilca vratu Vmesnik gorilnika

2 Zaščitni pokrov Ščiti sklop kablov pred poškodbami

3 Konektor Burndy, 12-polni Električna povezava med funkcijo varnostnega

izklopa in podajalnikom žice

4 Krmilni kabel Za KS-2 (varnostni izklop in gumb)

5 EURO-priključek Povezava za podajalnik žice

6 Cev za izpihovanje (črn

pokrovček)

7 Dovodna odprtina za vodo

Za čiščenje gorilnika s stisnjenim zrakom po ciklu

čiščenja

Dovodna odprtina za vodo za hlajenje gorilnika

(moder pokrovček)

8 Povratni vod za vodo (rdeč

Povratni vod za vodo, ki jo segreje gorilnik

1)

pokrovček)

1)

9 Vtič krmilnega kabla za

mehanizem varnostnega

izklopa

1)

Samo sistemi vodno hlajenih gorilnikov

Električna povezava z mehanizmom RT KS-2 za

signal varnostnega izklopa in funkcijo zaznavanja

šobe

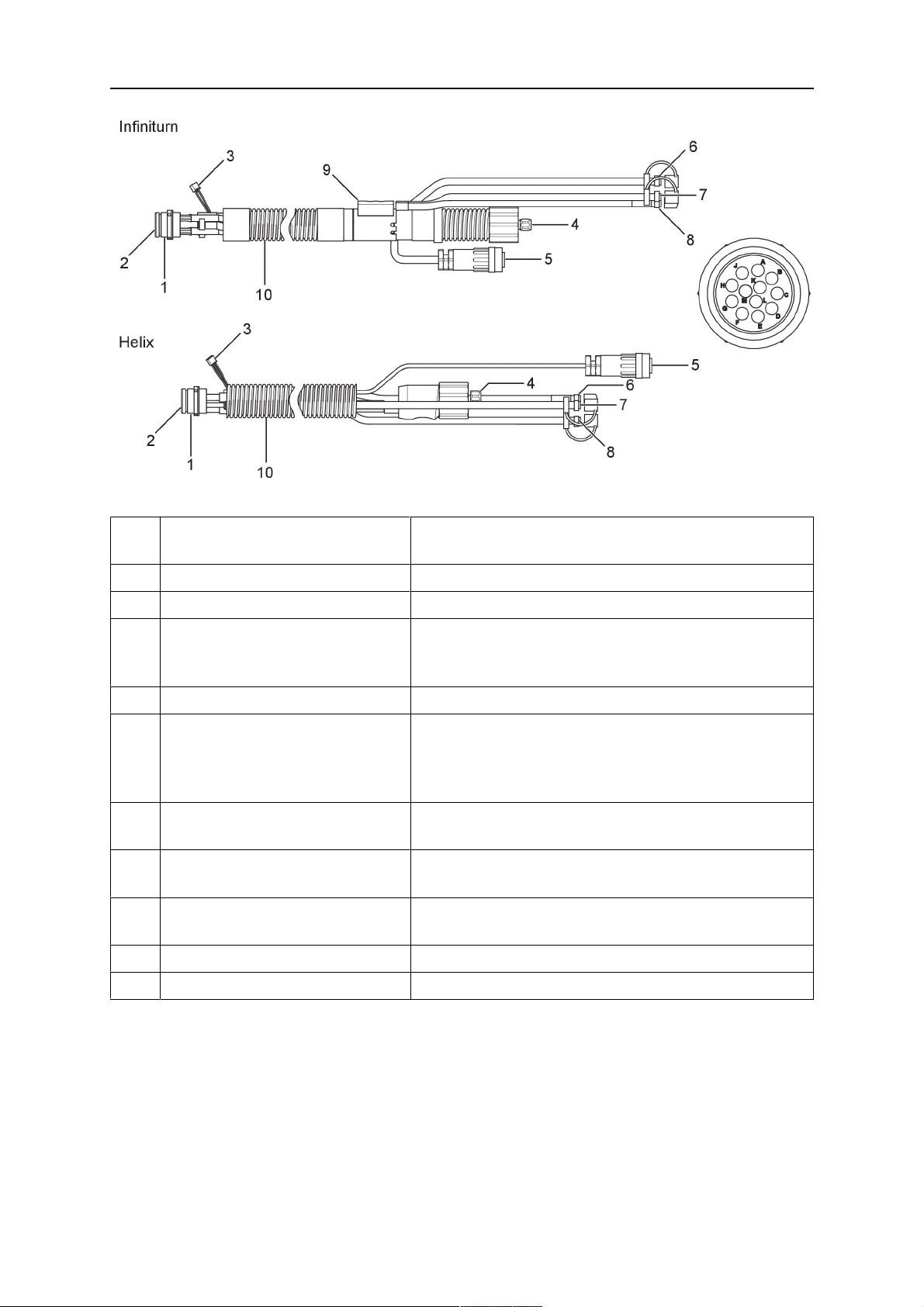

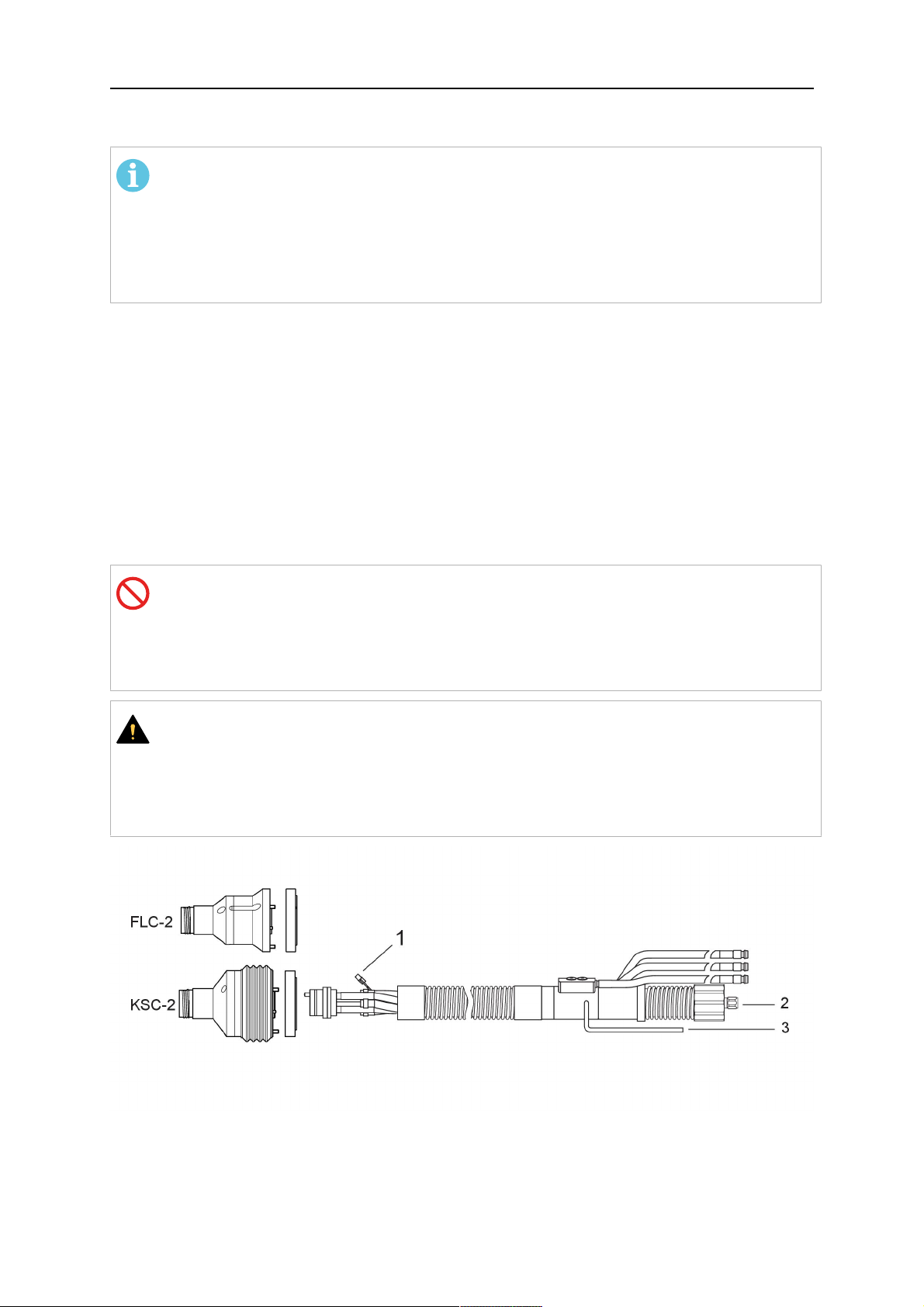

4.5.2 Sklopi kablov za sisteme z votlim zapestjem

Sklop kablov Infiniturn omogoča neomejeno vrtenje gorilnika v obe smeri. Hkrati prihaja do

prenosa hladilne tekočine, zaščitnega plina, zraka za izpihovanje, energije za varjenje in

signala mehanizma varnostnega izklopa.

Sklop kablov Helix je zasnovan za razpon vrtenja ±270° iz nevtralnega položaja. Lahko se

uporablja za varilna opravila, ki ne zahtevajo neomejenega vrtenja.

Sklopi kablov Infiniturn so na voljo v plinsko hlajenih in vodno hlajenih različicah. Sklopi

kablov Helix se lahko univerzalno uporabljajo s plinskim ali vodnim hlajenjem.

OPOMBA!

Ne priključite sklopa kablov Helix s plinsko hlajenim vratom gorilnika na vodno

hlajeni sistem.

0463 373 101

- 19 -

© ESAB AB 2018

4 TEHNIČNI PODATKI

ArtikelOpis Funkcija

1 Prirobnica Vmesnik nosilca gorilnika RT KSC-2 / RT FLC-2

2 Kazalni zatič Zagotavlja pravilno usmerjenost priključka

3 Vtič krmilnega kabla Električna povezava z mehanizmom RT KSC-2 za

signal varnostnega izklopa in funkcijo zaznavanja

šobe (če je relevantna)

4 EURO-priključek Povezava za podajalnik žice

5 Krmilni kabel Električna povezava za signal varnostnega izklopa

(iz mehanizma RT KSC-2) in funkcijo zaznavanja

šobe (zaznavanje šobe je standardno pri sklopu

kablov Helix, ne pa pri sklopu kablov Infiniturn)

6 Povratni vod za vodo (rdeč

Povratni vod za vodo, ki jo segreje gorilnik

pokrovček)

7 Dovodna odprtina za vodo

Dovodna odprtina za vodo za hlajenje gorilnika

(moder pokrovček)

8 Cev za izpihovanje (črn

pokrovček)

Za čiščenje gorilnika s stisnjenim zrakom po

varjenju

9 Priključek za sredstva Neomejeno vrtljiv priključek za prenos sredstev

10 Zaščitni pokrov Ščiti sklop kablov pred poškodbami

0463 373 101

- 20 -

© ESAB AB 2018

5 INSTALLATION

5 INSTALLATION

POZOR!

For your own safety, make sure that the robot is either in standby or power-less

state before doing maintenance work in the moving radius of the robot.

Follow the assembly instructions exactly. Pay attention during assembly that the cables are

not damaged. Damaged cables can lead to a short circuit, which may damage the electronics

of the robot or the welding torch.

Use only original ESAB components that have been specially developed for this purpose.

Only then the correct functioning of the whole welding torch system can be guaranteed.

5.1 RTKS-2 standard arm installation

5.1.1 RTKS-2 safety-off mechanism

1. Dismount the insulation flange (10) from the RTKS-2 (11) by removing the screws

(12).

2. Position the insulation flange (10) with the index pin on the robot arm and fix it with the

screws (20) included.

The insulation flange (10) is directly compatible with robots with tool flange according

to DIN ISO 9409-1-A40 (diameter 40mm, 4×M6). If the insulation flange (10) does

not fit, use an adapter flange (21).

OPOMBA!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

3. Mount the RTKS-2 the back on the insulation flange (10).

0463 373 101

- 21 -

© ESAB AB 2018

5 INSTALLATION

4. Position the mount on the RTKS-2 and carefully insert the cylindrical pins (14) into the

holes provided. Take the position of the torch into account. Two mounting positions

may be potentially possible.

5. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (12).

OPOMBA!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

12 - Cylinder screw with hexagon socket

M6DIN912 (length of the screw depending

on the torch mount)

14 - Cylindrical pins Ø4×20

5.1.1.1 Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. The pins should protrude by approximately 5 mm (0.2 in.).

2. Position the mount on the safety-off mechanism RTKS-2 and carefully insert the

cylindrical pins (1) into the holes provided. In doing so, take the later position of the

torch into account. Two mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

OPOMBA!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

0463 373 101

- 22 -

© ESAB AB 2018

5 INSTALLATION

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

0463 373 101

- 23 -

© ESAB AB 2018

5 INSTALLATION

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.1.2 Standard arm cable assembly for KS-2 and FL-2

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

0463 373 101

- 24 -

© ESAB AB 2018

5 INSTALLATION

PREVIDNO!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

1. Unscrew the cylinder screws (1) and lift off the top section (2) of the torch mount.

2. Insert the feather key (4) into the recess of the neck support flange (3) from below.

3. Align the neck support flange (3) including the feather key (4) to the groove (5) of the

torch mount and push into the groove right up to the stop of the flange.

4. Hold the cable assembly in this position and simultaneously place the top section (2)

back onto the torch mount. First screw both cylinder screws (1) loosely in to about the

same length, then tighten alternately. The top section (2) of the mount should have an

even gap to the bottom section.

The front part of the cable assembly is directly clamped into the torch mount (see

illustration below).

1 - Cylinder screws 4 - Feather key

2 - Torch mount top section 5 - Groove for feather key

3 - Neck support flange

5.1.3 RTKS-2 wire feeder connection

In order to be able to create the connection, the cable assembly must be mounted as

described in the "Installing the cable assembly" section and equipped following "Installing the

wire guide" section. Only then can the central and media connection take place. Proceed as

described below:

0463 373 101

- 25 -

© ESAB AB 2018

5 INSTALLATION

1. Connect the central connector of the cable assembly (2) to the wire feeder cabinet

socket. Tighten the central connector sleeve nut fingertight. Do not use tools.

1 - Burndy Connector 4 - Return of heated water (red cap)

2 - EURO central connector 5 - Return of heated water (red cap)

3 - Air blow-out 6 - Main Wire feeder

2. For water cooled systems. Connect the water hoses to the cooling circuit. The end of

the hose marked blue (4) is connected to the water outlet, and the end marked red (5)

is connected to the water return.

3. Connect the blow-out line (3) to the corresponding connection of the feeder.

4. Connect the Burndy Connector to the wire feeder. (1) to the feeder. See section

"Electrical connections".

OPOMBA!

All hoses and the control line must be installed so they can not bend or get

damaged!

5.1.4 RTKS-2 electrical connections

5.1.4.1 RTKS-2 safety-off mechanism connection

The switch for the safety-off functionality RTKS-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKS-2 unit via the 4-pole plug (4) that

contains circuits for the push-button (6) and the safety-off signal (7).

If a collision is detected, the control circuit for the safety-off signal (7), which is normally

closed, will be interrupted.

Rating of the control circuit: max. 48 V / 1 A

0463 373 101

- 26 -

© ESAB AB 2018

5 INSTALLATION

2 - Burndy connector 5 - RTKS-2 connector for control cable plug

4 - Control cable plug

Nožice konektorja Burndy

A. Plinska šoba z

zaznavanjem dotika

C. Tipalo za zaznavanje

trčenja

F. 0V

G. + Napetost motorja

H. - Napetost motorja

D. Tipalo za zaznavanje

trčenja

E. Koračno pomikanje

If the robot control provides a control circuit for nozzle sense functionality, the connection is

accomplished with a 1-wire connection.

Rating of the control circuit: max 50 V / 5 A.

NEVARNOST!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

PREVIDNO!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

5.1.5 RTKS-2 Torch installation

Continue according to section "Torch installation".

0463 373 101

- 27 -

© ESAB AB 2018

5 INSTALLATION

5.2 RTFL-2 standard arm installation

5.2.1 RTFL-2 rigid mount

1. Position the RT FL-2 (2) with the index pin on the robot arm and fix it with the hexagon

socket screw included.

The FL-2 is directly compatible with robots with tool flange according to DIN ISO

9409-1-A40 (diameter 40mm, 4×M6). If the rigid mount does not fit, use an adapter

flange (3).

OPOMBA!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

2. Install torch mount (1). Only torch mounts having a hole pattern equivalent with the

mounting surface may be attached. If necessary, carefully press the cylindrical pins (4)

into the corresponding holes in the bracket. The pins should protrude by

approximately 5mm (0.2in.). Position the torch mount on the RTFL-2 (2) and

carefully insert the cylindrical pins (4) into the holes provided. Take the position of the

torch into account. Two mounting positions may be potentially possible.

3. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (5).

OPOMBA!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

0463 373 101

- 28 -

© ESAB AB 2018

5 INSTALLATION

4 - Cylindrical pins Ø4×20

5 - Cylinder screw with hexagon socket M6

DIN 912 (length of the screw depending on

the torch mount)

Side view

Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. Avoid the formation of burrs. The pins should protrude by

approximately 5 mm (0.2 in.).

2. Position the mount on the RTFL-2 and carefully insert the cylindrical pins (1) into the

holes provided. In doing so, take the later position of the torch into account. Two

mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

OPOMBA!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

0463 373 101

- 29 -

© ESAB AB 2018

5 INSTALLATION

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 - Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.2.2 RTFL-2 torch installation

Continue according to section "Torch installation".

5.3 RTKSC-2 hollow wrist system installation

5.3.1 RTKSC-2 mount with safety off mechanism

PREVIDNO!

For hollow wrist systems make sure that the clear space around the robot is at least

Ø45 mm (1.8 in.) around the wrist and 50 mm (2.0 in.) near the wire feeder.

0463 373 101

- 30 -

© ESAB AB 2018

5 INSTALLATION

1. Remove the three screws (2) from the front cover (3) of the torch mount and carefully

pull the cover off the RTKSC-2 main body (5). Take care not to damage the micro

switches installed inside the assembly.

1 - Hexagon wrench 4 mm 4 - Rubber boot

2 - 3× M5×12 screws 5 - RT KSC-2 main body

3 - RT KSC-2 front cover

1. Pull off the rubber boot (4) from the RTKSC-2 main body (5) to the front.

2. Now position the RTKSC-2 main body (5) on the adapter flange (7) so that the index

pin is correctly seated. Attach with the screws (6) enclosed.

3. Reinstall the rubber boot (4) on the RTKSC-2 main body (5) and make sure it is

correctly located in the grooves on the front and back flange.

4. Istall the adapter flange (7) on the robot.

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 3 - 3× M5×12 hexagon socket screws

2 - Rubber boot 4 - Adapter flange

5.3.2 Mounting the cable assembly

OPOMBA!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ±2-3cm (±1in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

0463 373 101

- 31 -

© ESAB AB 2018

5 INSTALLATION

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

PREVIDNO!

Axis 6 must be in 0° position.

5.3.2.1 RTKSC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

PREVIDNO!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 32 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

PREVIDNO!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connectors are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

OPOMBA!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

OPOMBA!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

0463 373 101

- 33 -

© ESAB AB 2018

5 INSTALLATION

5.3.3 RTKSC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

PREVIDNO!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.3.3.1 RTKSC-2 cable assembly installation

OPOMBA!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2, then thread the cable from the front through the

robot arm. If in doubt, follow the suggested order.

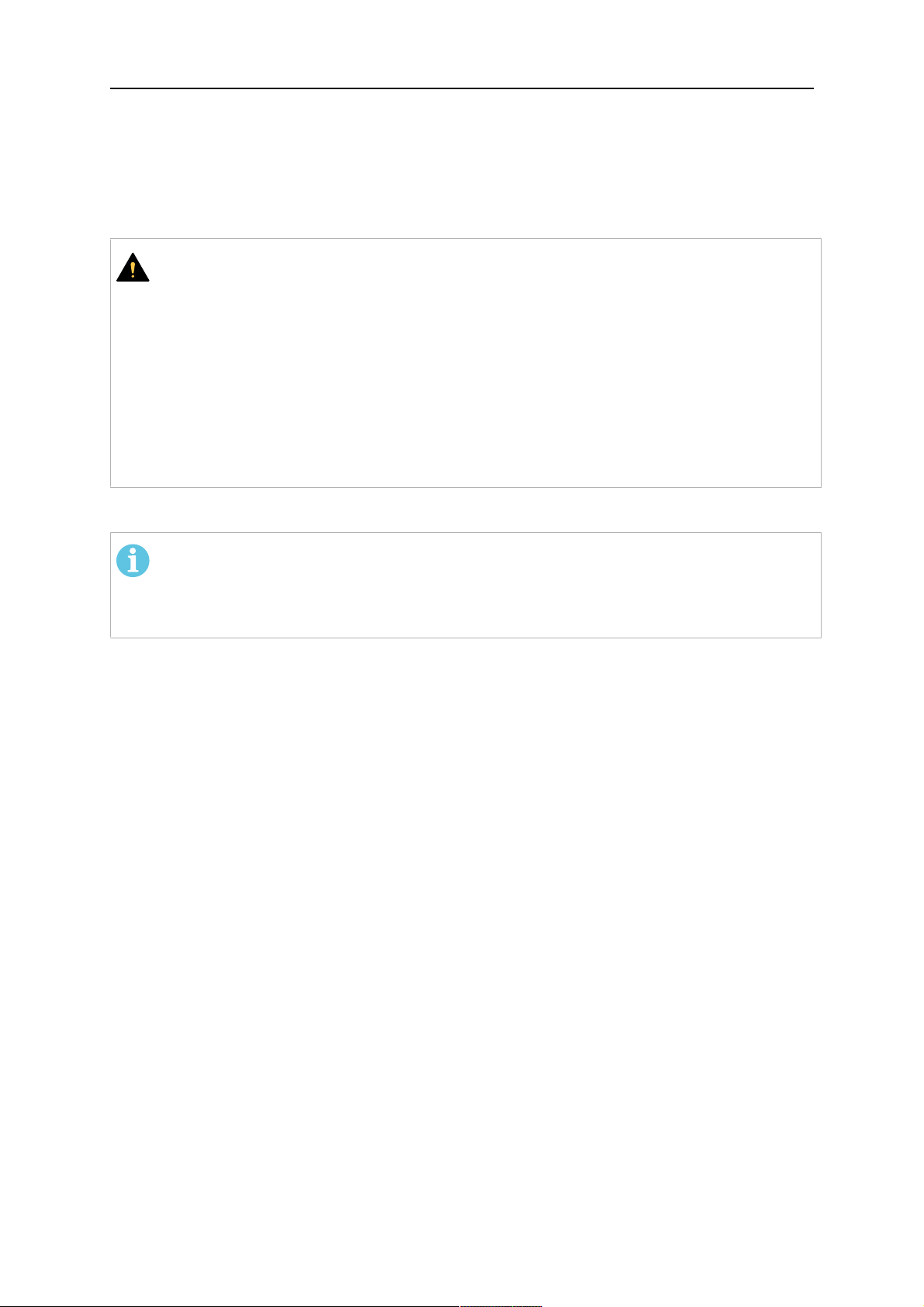

1. Loosen the three screws (7) with the associated washers and remove them from the

RTKSC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1).

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 34 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

OPOMBA!

Make sure that the position of the O-rings are not shifted by the index pin

during the assembly.

1 - RTKSC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RTKSC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 35 -

© ESAB AB 2018

5 INSTALLATION

6. If present, insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTKSC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13. Index pin

14. 3× M5×12 screws

0463 373 101

- 36 -

© ESAB AB 2018

5 INSTALLATION

5.3.3.2 RTKSC-2 electrical connections

OPOMBA!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then

implemented via the power source controller.

RTKSC-2 safety-off mechanism connection

The switch for the safety-off functionality RTKSC-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKSC-2 unit via the control cable plug

(1).

The safety-off signal requires a 2-wire connection (black/black) to the safety-off circuit in the

robot control (5).

If a collision is detected, the control circuit (normally closed) will be interrupted (4).

Rating of the control circuit: max. 48 V / 1 A.

1 - Control cable plug 3 - Burndy connector VVV

2 - EURO central connector

Nožice konektorja Burndy

A. Plinska šoba z

zaznavanjem dotika

C. Tipalo za zaznavanje

trčenja

F. 0V

G. + Napetost motorja

H. - Napetost motorja

D. Tipalo za zaznavanje

trčenja

E. Koračno pomikanje

RTKSC-2 nozzle sense function connection

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

0463 373 101

- 37 -

© ESAB AB 2018

5 INSTALLATION

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

NEVARNOST!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

PREVIDNO!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

5.3.4 RTKSC-2 torch installation

Continue according to section "Torch installation".

0463 373 101

- 38 -

© ESAB AB 2018

5 INSTALLATION

5.4 RTFLC-2 installation

5.4.1 RTFLC-2 mount

1. Remove the three M5 screws (2) from the front cover (3) of the RT FLC-2 torch mount

and carefully pull the cover off the main body (4).

1 - Hexagon wrench 4 mm 3 - RT FLC-2 front cover

2 - 3× M5×12 screws 4 - RT FLC-2 main body

2. Now position the RT FLC-2 main body (4) on the adapter flange (6) so that the index

pin is correctly seated. Attach with the screws (5) enclosed

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 5 - 3× M5×12 hexagon socket screws

4 - RT FLC-2 main body 6 - Adapter flange

5.4.2 RTFLC-2 wire feeder connection

5.4.2.1 Feeding through the robot arm

OPOMBA!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ± 2-3 cm (± 1 in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

0463 373 101

- 39 -

© ESAB AB 2018

5 INSTALLATION

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

PREVIDNO!

Important! Axis 6 must be in 0° position.

5.4.2.2 RTFLC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

PREVIDNO!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 40 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

Refer to the instruction of the feeder manufacturer.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

PREVIDNO!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connections are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

OPOMBA!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

OPOMBA!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

0463 373 101

- 41 -

© ESAB AB 2018

5 INSTALLATION

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

5.4.3 RTFLC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

PREVIDNO!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.4.3.1 RTFLC-2 cable assembly installation

In a hollow wrist system the recommended order of installation is to feed the cable assembly

through the robot arm before connecting the cables to the torch mount.

When the cable assembly is correctly installed in the hollow wrist, continue the installation

according to the procedure described below.

OPOMBA!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2 and RTFLC-2, then thread the cable from the front

through the robot arm. If in doubt, follow the suggested order.

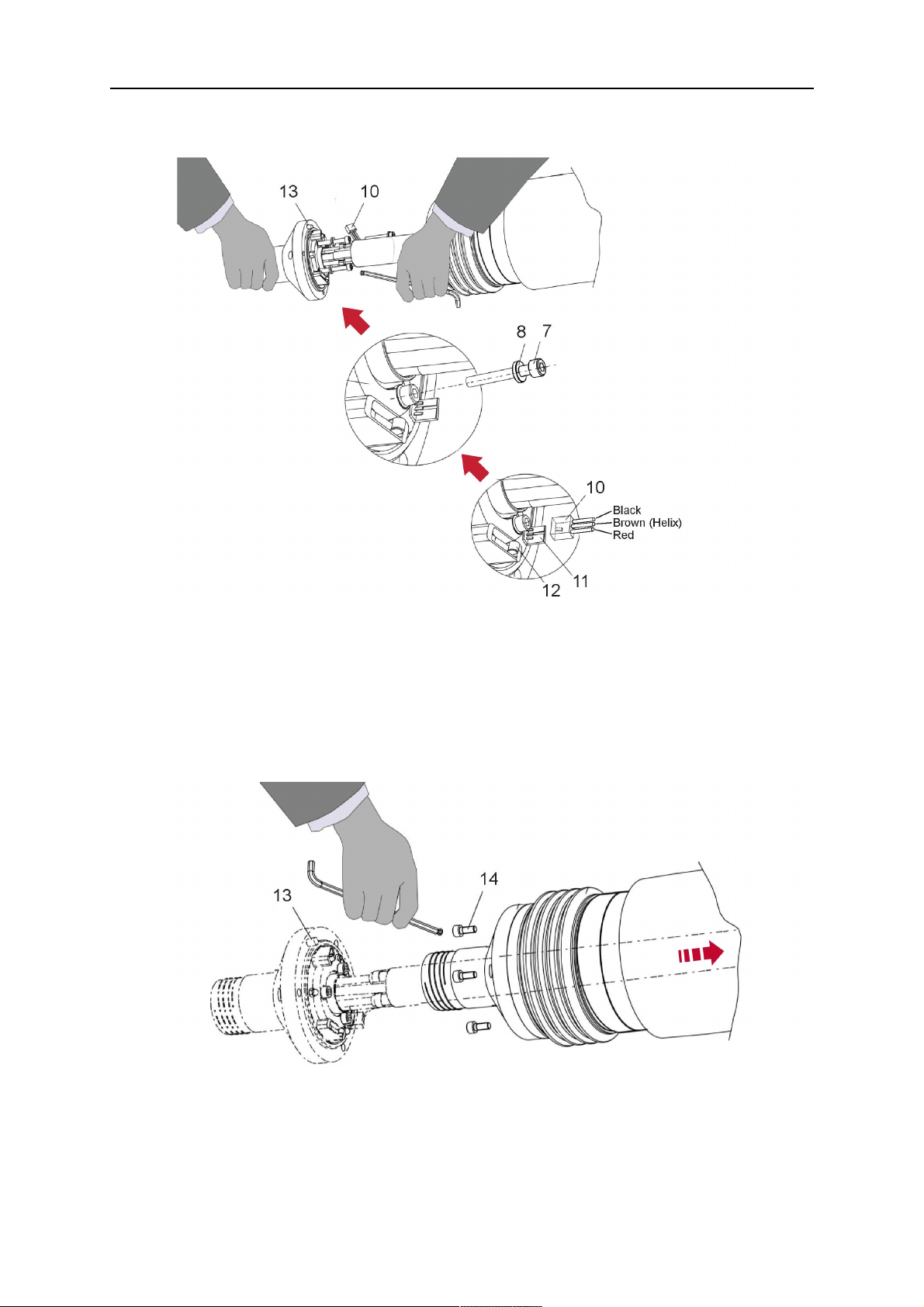

1. Loosen the three screws (7) with the associated washers and remove them from the

RTFLC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1). For gas cooled

systems, only one O-ring (4a) is needed, for water cooled systems all three O-rings

are needed.

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 42 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

OPOMBA!

Take great care that the position of the O-rings is not shifted by the index pin

during the assembly.

1 - RT FLC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RT FLC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 43 -

© ESAB AB 2018

5 INSTALLATION

6. If present insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTFLC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13 - Index pin 14 - 3x M5x12 screws

0463 373 101

- 44 -

© ESAB AB 2018

5 INSTALLATION

5.4.4 RTFLC-2 electrical connections

OPOMBA!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

documentation of the manufacturer for details. The link to the robot control is then

implemented via the power source controller.

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

NEVARNOST!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

PREVIDNO!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

0463 373 101

- 45 -

© ESAB AB 2018

5 INSTALLATION

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 1-wire connection (green) to the nozzle sense circuit

in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

NEVARNOST!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

PREVIDNO!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - EURO central connector

2 - Control cable 4 - Burndy connector

5.5 Torch installation

Be sure to use the correct version of the torch mount and cable assembly (water or gas

cooled).

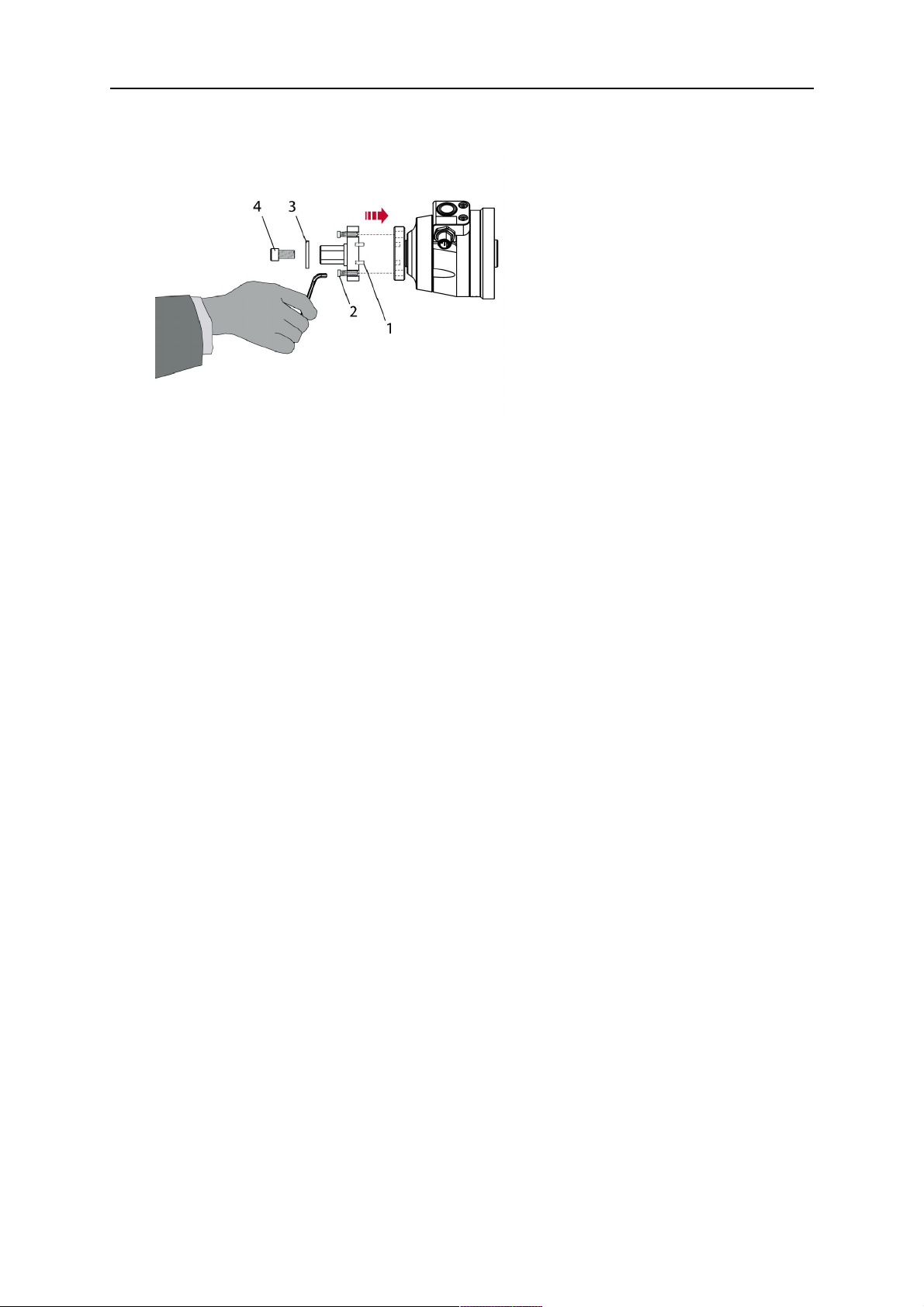

5.5.1 Torch neck equipment

The torch neck, see (1) in the illustration below, must always be equipped to suit the wire

diameter and material.

0463 373 101

- 46 -

© ESAB AB 2018

5 INSTALLATION

1. Select the correct wire guide, contact tip (4), tip holder (2), gas nozzle (5), and gas

diffuser/spatter protection (3). You will find an exact overview and possible alternative

equipment elements for various torch models in the spare parts list. Only use original

ESAB parts; only then is the fitting accuracy ensured.

2. Firmly tighten the tip holder and the contact tip using a suitable tool for example the

enclosed monkey wrench.

3. When using a split wire guide, remove the installed guide nipple including the o-ring

from the torch flange upon delivery if necessary (see section "Installing the neck

liner").

PREVIDNO!

The torch must be completely equipped before welding, especially the gas

diffuser and/or spatter protection and all necessary insulators have to be

installed according to the spare parts list. Welding without these items may

cause immediate destruction of the torch.

1 - Torch neck 4 - Contact tip

2 - Tip holder 5 - Contact tip

3 - Gas diffuser

5.5.2 Aristo RT torch neck installation

OPOMBA!

Check the O-rings on the flange of the torch neck before mounting. Replace the

O-rings if damaged or lost. Missing or faulty O-rings will lead to leaks of shielding

gas and coolant.

1. For hollow wrist systems, insert the torch into the torch mount in the correct

orientation, so that the locator pin fits into the slot of the RTKSC-2 or RTFLC-2

interface, see (A) in the illustration below. For standard systems, attach the torch to

the RT flange of the cable assembly, (B) in the illustration below.

Installation is only possible in the correct orientation.

2. Tighten the locking nut of the torch neck.

OPOMBA!

Only tighten by hand, never use tools or excessive force.

0463 373 101

- 47 -

© ESAB AB 2018

5 INSTALLATION

3. The correct seating of the torch can be checked by means of the window (1). If the

torch has been correctly mounted, no gap should be seen through the window (1).

5.6 Installing the wire guide for standard and hollow Wrist arm

Installing the wire guide

Choose the wire guide or liner depending on the filler wire material and diameter to be used,

see the spare parts list. Accurate performance of the system can only be guaranteed when

using original ESAB wire guides.

The recommended wire guide is the split wire guide, which consists of the neck liner and a

separate guide in the cable assembly. The front part of the wire guide, which is most

stressed, can be exchanged easily and independently of the cable assembly wire guide.

For correct installation, the following steps must be followed (example for Euro central

connector).

5.6.1 Installing the neck liner

The neck liner must be selected to fit the material and diameter of the welding wire, see the

spare parts list.

0463 373 101

- 48 -

© ESAB AB 2018

5 INSTALLATION

1. If present, remove the central guide nipple (1), from the torch neck using a hexagon

wrench (size 6 mm) or a large flat-blade screwdriver.

OPOMBA!

The guide nipple (1) can only be used with one-piece liners and must not be

used with the standard RT or hollow wrist system.

2. When replacing the neck liner:

Unfasten the sleeve nut and remove the torch neck.

Unfasten the liner nipple using a hexagon wrench (size 6 mm) and remove nipple and

liner from the torch neck.

3. Remove the gas nozzle and the contact tip.

4. Insert the new neck liner (2) into the torch. Carefully tighten the guide nipple using a

suitable tool, e.g. a hex-wrench (size 6 mm) or a large flat-blade screwdriver.

5. Cut the neck liner flush with the tip holder and remove the neck liner from the torch.

6. Install the contact tip.

7. Insert the neck liner again. It will be stopped by the contact tip. Measure the excess

liner sticking out of the neck.

8. Remove the liner again and shorten the front end by the measured length. Carefully

deburr the edge and make sure that the inner hole is not blocked.

9. Reinstall the neck liner and tighten the guide nipple in the neck.

5.6.2 Installing a split wire guide in the cable assembly

The correct liner must be inserted to suit the filler material and the wire diameter, see the

spare parts list.

The wire guide is inserted through the cable assembly from the rear, reaching the guide

nipple that is installed in the flange where the torch neck will be attached. The following

worksteps must be followed in order to correctly determine the wire guide length. (Example

for Euro central connector).

0463 373 101

- 49 -

© ESAB AB 2018

5 INSTALLATION

1. For standard RT system: Install the guide nipple (1) in the center hole of the neck

support flange, see illustration A below.

For hollow wrist system: Install the guide nipple (1) into the torch interface of the

RTKSC-2 / RTFLC-2 cover, see illustration B below.

2. Remove the sleeve nut (2) from the central connector, and remove the old wire guide.

3. Insert the wire guide through the central connection and push forwards as far as it will

go into the guide nipple (1), applying light pressure.

PREVIDNO!

Ensure that the wire guide has advanced right up to the stop at the front,

rotating and pushing forward gently.

4. Measure the excess length that needs to be cut from the wire guide.

5. Remove the wire guide again and shorten the front end by the measured length.

Steel liner: grind down the burred edges if needed.

Plastic liner: make a clean cut and chamfer the edges (e.g. with a pencil sharpener)

OPOMBA!

Make sure the inner opening of the liner is not obstructed by the cut wire end.

0463 373 101

- 50 -

© ESAB AB 2018

5 INSTALLATION

6. Reinstall the wire guide and attach the sleeve nut (2).

OPOMBA!

For hollow wrist systems where Infiniturn and Helix cable assemblies are

used, wire guides should be installed without tension so that the ends of the

liners may rotate freely.

Important note when using a plastic liner:

The wire channel between the drive rolls of the feeder and the central

connector of the torch must be fitted with a plastic liner. Depending on the

design of the feeder, a piece of plastic liner inserted into a brass guide tube

can be used.

During wire run-in, make sure that the wire is fed correctly into the plastic liner

of the torch. If necessary, remove the cable assembly from the feeder and