RT Robo Welding Torch System

RTKS-2, RTFL-2, KSC-2, FLC-2, RT42, RT52,

RT62, RT72, RT82, RT42-NG, RT82WNG

Lietošanas pamācība

0463 373 101 LV 20181227

SATR-TRS

1

DROŠĪBA..................................................................................................... 5

1.1 Simbolu nozīme...................................................................................... 5

1.2 Drošības pasākumi ................................................................................ 5

2

GARANTIJA ................................................................................................ 8

2.1 Paredzētās lietošanas nosacījumi ........................................................ 8

3

IEVADS ........................................................................................................ 9

3.1 Metināšanas degļu sistēmu pārskats................................................... 10

4

TEHNISKIE DATI ......................................................................................... 12

4.1 Metināšanas degļa kakls ....................................................................... 12

4.2 Sprieguma nominālie parametri............................................................ 13

4.2.1 Dzesēšanas kontūra robežvērtības...................................................... 13

4.3 Degļa stiprinājums ................................................................................. 14

4.3.1 Degļa stiprinājumi standarta RT sistēmai ............................................. 14

4.3.1.1 RTKS-2 aizsargizslēgšanas mehānisms .......................................... 15

4.3.1.2 RTFL-2 vidējais atloks ...................................................................... 15

4.3.2 Degļa stiprinājumi dobā satvērēja sistēmai .......................................... 15

4.3.2.1 RTKSC-2 G/W degļa stiprinājums ar aizsargizslēgšanas

mehānismu........................................................................................

4.3.2.2 RTFLC-2 G/W nekustīgais degļa stiprinājums ................................. 18

4.4 Adaptera atloki ....................................................................................... 19

4.5 Kabeļa bloki ............................................................................................ 19

4.5.1 Kabeļa bloki standarta RT sistēmai ...................................................... 19

4.5.2 Kabeļa bloki dobā satvērēja sistēmām................................................. 20

5

INSTALLATION............................................................................................ 22

5.1 RTKS-2 standard arm installation........................................................ 22

5.1.1 RTKS-2 safety-off mechanism............................................................. 22

5.1.1.1 Torch installation with adjustable mount............................................ 23

5.1.2 Standard arm cable assembly for KS-2 and FL-2 ................................ 25

5.1.3 RTKS-2 wire feeder connection........................................................... 26

5.1.4 RTKS-2 electrical connections ............................................................ 27

5.1.4.1 RTKS-2 safety-off mechanism connection ....................................... 27

5.1.5 RTKS-2 Torch installation.................................................................... 28

5.2 RTFL-2 standard arm installation ........................................................ 29

17

5.2.1 RTFL-2 rigid mount.............................................................................. 29

5.2.2 RTFL-2 torch installation ..................................................................... 31

5.3 RTKSC-2 hollow wrist system installation.......................................... 31

5.3.1 RTKSC-2 mount with safety off mechanism........................................ 31

5.3.2 Mounting the cable assembly............................................................... 32

5.3.2.1 RTKSC-2 feeder cabinet connections .............................................. 33

5.3.3 RTKSC-2 cable assembly ................................................................... 35

5.3.3.1 RTKSC-2 cable assembly installation .............................................. 35

0463 373 101 © ESAB AB 2018

SATR-TRS

5.3.3.2 RTKSC-2 electrical connections....................................................... 38

5.3.4 RTKSC-2 torch installation .................................................................. 39

5.4 RTFLC-2 installation.............................................................................. 40

5.4.1 RTFLC-2 mount................................................................................... 40

5.4.2 RTFLC-2 wire feeder connection......................................................... 40

5.4.2.1 Feeding through the robot arm.......................................................... 40

5.4.2.2 RTFLC-2 feeder cabinet connections............................................... 41

5.4.3 RTFLC-2 cable assembly .................................................................... 43

5.4.3.1 RTFLC-2 cable assembly installation ............................................... 43

5.4.4 RTFLC-2 electrical connections .......................................................... 46

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly........... 46

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly................. 47

5.5 Torch installation.................................................................................... 47

5.5.1 Torch neck equipment .......................................................................... 47

5.5.2 Aristo RT torch neck installation ........................................................... 48

5.6 Installing the wire guide for standard and hollow Wrist arm ............. 49

5.6.1 Installing the neck liner......................................................................... 49

5.6.2 Installing a split wire guide in the cable assembly................................ 50

5.6.3 Installing a continuous wire guide in the cable assembly..................... 52

5.7 Adjust the narrow gap contact tip ........................................................ 53

6

OPERATION ................................................................................................ 56

6.1 Important information for programming (hollow wrist system only) 56

7

SERVISS UN APKOPE................................................................................ 58

7.1 Obligātās pārbaudes un darbības ........................................................ 58

8

TRAUCĒJUMMEKLĒŠANA ........................................................................ 60

9

REZERVES DAĻU PASŪTĪŠANA............................................................... 62

Tiek paturētas tiesības bez brīdinājuma veikt izmaiņas specifikācijās.

0463 373 101 © ESAB AB 2018

1 DROŠĪBA

1 DROŠĪBA

1.1 Simbolu nozīme

Izmantoti šajā rokasgrāmatā: Uzmanību! Ievērojiet piesardzību!

BĪSTAMI

Apzīmē tūlītēju apdraudējumu, kas, ja netiek novērsts, izraisa nopietnas vai

nāvējošas traumas.

BRĪDINĀJUMS!

Apzīmē iespējamu apdraudējumu, kas var izraisīt traumas vai nāvi.

UZMANĪBU!

Apzīmē apdraudējumu, kas var izraisīt vieglas traumas.

BRĪDINĀJUMS!

Pirms iekārtas lietošanas izlasiet un izprotiet lietošanas

instrukciju, kā arī ievērojiet visās uzlīmēs sniegtos

norādījumus, darba devēja noteiktos drošības

pasākumus un drošības datu lapās (Safety Data

Sheets— SDS) norādīto informāciju.

1.2 Drošības pasākumi

ESAB iekārtas lietotāji pilnībā atbild par to, lai tiktu nodrošināts, ka visi, kas strādā ar iekārtu

vai pie tās, ievērotu visus attiecīgos drošības pasākumus. Drošības pasākumiem jāatbilst

prasībām, kas attiecas uz šī tipa iekārtām. Papildus standarta noteikumiem, kas attiecas uz

darba vietu, jāievēro šādi ieteikumi.

Visus darbus veic kvalificēts personāls, kas labi pārzina iekārtas darbību. Nepareizi

ekspluatējot iekārtu, var rasties bīstamas situācijas, kuru dēļ iekārtas operators var gūt

ievainojumus un iekārtu var sabojāt.

1. Visiem, kas lieto iekārtu, jāpārzina:

○ tās darbība;

○ kur atrodas avārijas slēdži;

○ iekārtas funkcijas;

○ attiecīgie drošības pasākumi;

○ metināšana un griešana vai citas ar iekārtu veicamās darbības.

2. Operatoram jānodrošina, lai:

○ neviena nepiederoša persona iedarbināšanas brīdī neatrodas iekārtas darbības

zonā;

○ neviens nav neaizsargāts, kad rodas elektriskais loks vai tiek sākts darbs ar

iekārtu.

3. Darba vietā:

○ jābūt metināšanai piemērotiem apstākļiem;

○ nedrīkst būt caurvējš.

0463 373 101

- 5 -

© ESAB AB 2018

1 DROŠĪBA

4. Individuālās aizsardzības līdzekļi:

○ Vienmēr lietojiet ieteiktos drošības līdzekļus, piemēram, aizsargbrilles,

ugunsdrošu apģērbu, aizsargcimdus

○ Nevalkājiet nepieguļošus aksesuārus, tādus kā šalles, rokassprādzes,

gredzenus utt., kas var aizķerties vai radīt apdegumus

5. Vispārīgi drošības pasākumi:

○ Pārliecinieties, vai atpakaļstrāvas kabelis ir pievienots droši

○ Darbu ar augstsprieguma iekārtu drīkst veikt tikai kvalificēts elektriķis

○ Piemērotai ugunsdzēšanas iekārtai jābūt skaidri apzīmētai un jāatrodas ļoti tuvu

○ Eļļošanu un apkopi nedrīkst veikt iekārtas darbības laikā

BRĪDINĀJUMS!

Loka metināšana un griešana var radīt traumas jums un citām personām.

Metināšanas un griešanas laikā ievērojiet drošības pasākumus.

ELEKTROŠOKS— bīstams dzīvībai

• Uzstādiet un iezemējiet iekārtu atbilstoši lietošanas instrukcijai.

• Nepieskarieties elektrību vadošajām daļām un elektrodiem ar kailu ādu,

slapjiem cimdiem vai slapju apģērbu.

• Izolējiet sevi no darba materiāla un zemes.

• Strādājiet drošā pozā.

ELEKTROMAGNĒTISKIE LAUKI— var būt kaitīgi veselībai

• Metinātājiem, kuriem ir elektrokardiostimulators, pirms metināšanas ir

ieteicams konsultēties ar ārstu. Elektromagnētiskie lauki (EML) var izraisīt

elektrokardiostimulatora darbības traucējumus.

• EML var izraisīt arī citu, pagaidām nezināmu ietekmi uz veselību.

• Metinātājiem jāveic tālāk minētās darbības, lai mazinātu iespēju tikt

pakļautiem EML ietekmei.

○ Izvelciet elektrodu un darba kabeļus tā, lai tie būtu jums vienā pusē.

Ja iespējams, nostipriniet kabeļus ar līmlenti. Uzmanieties, lai jūsu

ķermenis neatrastos starp metināšanas degli un darba kabeļiem.

Nekādā gadījumā neapvijiet metināšanas degli vai darba kabeli ap

sevi. Turiet metināšanas strāvas avotu un kabeļus pēc iespējas tālāk

no sevis.

○ Pievienojiet darba kabeli sagatavei pēc iespējas tuvāk metināšanas

apgabalam.

DŪMI UN GĀZES— var būt kaitīgi veselībai

• Neturiet galvu dūmos.

• Lai aizvadītu dūmus un gāzes no elpošanas zonas un apkārtējās

teritorijas, ieslēdziet ventilāciju, nosūcēju pie loka vai abus.

LOKA STARI - var savainot acis un apdedzināt ādu

0463 373 101

• Sargājiet acis un ķermeni. Lietojiet piemērotu metināšanas masku un

aizsarglēcas un nēsājiet aizsargapģērbu.

• Aizsargājiet blakus esošās personas ar piemērotām maskām vai

aizslietņiem.

TROKSNIS— pārmērīgs troksnis var bojāt dzirdi

Sargājiet ausis. Lietojiet austiņas vai citus dzirdes aizsarglīdzekļus.

- 6 -

© ESAB AB 2018

1 DROŠĪBA

KUSTĪGAS DAĻAS— var izraisīt savainojumus

• Visām durvīm, paneļiem un pārsegiem jābūt aizvērtiem un nostiprinātiem.

Tikai kvalificēti darbinieki drīkst noņemt pārsegus, lai nepieciešamības

gadījumā veiktu apkopi un remontu. Pēc apkopes pabeigšanas uzstādiet

atpakaļ paneļus vai pārsegus un aizveriet durvis, pirms iedarbināt dzinēju.

• Pirms ierīces uzstādīšanas vai pievienošanas izslēdziet dzinēju.

• Kustīgu daļu tuvumā nedrīkst atrasties rokas, mati, vaļīgs apģērbs un rīki.

UGUNSBĪSTAMĪBA

• Dzirksteļu dēļ var izcelties ugunsgrēks. Pārliecinieties, vai tuvumā nav

viegli uzliesmojošu materiālu.

• Neizmantojiet iekārtu darbam ar slēgtām tvertnēm.

DARBĪBAS TRAUCĒJUMI— rodoties darbības traucējumiem, meklējiet profesionālu

palīdzību

SARGĀJIET SEVI UN CITUS!

UZMANĪBU!

Šis produkts paredzēts tikai elektriskā loka metināšanai.

BRĪDINĀJUMS!

Neizmantojiet barošanas avotu, lai atkausētu sasalušas caurules.

UZMANĪBU!

A klases iekārtas nav paredzētas lietošanai dzīvojamās

mājās, kurās elektriskā strāva tiek piegādāta, izmantojot

publisko zemsprieguma elektrotīklu. Šādās vietās var

būt grūtības nodrošināt A klases iekārtu

elektromagnētisko saderību, ņemot vērā pārvades un

starojuma izraisītos traucējumus.

IEVĒROJIET!

Utilizējiet elektronisko aprīkojumu, nododot to

otrreizējās pārstrādes punktā!

Ievērojot Eiropas Direktīvu 2012/19/EK par elektriskā un

elektroniskā aprīkojuma atkritumiem un īstenojot to

saskaņā ar valsts tiesību aktiem, elektriskās un/vai

elektroniskās iekārtas, kam beidzies kalpošanas laiks,

jānodod utilizācijai otrreizējās pārstrādes punktos.

Kā par iekārtu atbildīgajai personai, jums ir pienākums

iegūt informāciju par apstiprinātajām savākšanas

vietām.

Lai iegūtu plašāku informāciju, sazinieties ar tuvāko

ESAB izplatītāju.

ESAB piedāvā iegādāties dažādas metināšanas piederumu un personiskās

aizsardzības aprīkojuma preces. Lai saņemtu informāciju par pasūtīšanu, sazinieties

ar vietējo ESAB izplatītāju vai apmeklējiet mūsu uzņēmuma tīmekļa vietni.

0463 373 101

- 7 -

© ESAB AB 2018

2 GARANTIJA

2 GARANTIJA

Pirms piegādes mūsu produkti tiek rūpīgi pārbaudīti. ESAB apliecina, ka piegādes brīdī

nevienam produktam nav materiāla vai izgatavošanas defektu un tas darbojas atbilstoši

paredzētajam lietošanas mērķim.

ESAB nodrošina garantiju materiālu un izgatavošanas defektu gadījumā atbilstoši

likumdošanas normu prasībām. Garantija neattiecas uz palīgmateriāliem.

Garantija nav spēkā, ja bojājumi vai darbības traucējumi radušies šādu iemeslu dēļ:

• produkta pārslogošana, nepareiza ekspluatācija vai mērķim neatbilstoša lietošana;

• triecieni vai negadījumi;

• šajā lietošanas instrukcijā sniegto norādījumu neievērošana;

• nepareiza uzstādīšana vai montāža;

• nepietiekama apkope;

• produkta oriģinālā stāvokļa pārveidošana;

• ķīmisku vielu ietekme;

• normāls nodilums un nolietošanās.

ESAB uzņemas atbildību tikai par bojātu daļu nomaiņu vai remontu.

2.1 Paredzētās lietošanas nosacījumi

1. Produkts ir paredzēts rūpnieciskai un komerciālai lietošanai, un to drīkst izmantot tikai

apmācīts personāls. Ražotājs nav atbildīgs ne par kādiem bojājumiem vai

negadījumiem, kas radušies nepareizas lietošanas dēļ.

2. Aristo® RT robotizētā metināšanas sistēma ir izstrādāta un izgatavota atbilstoši

mūsdienu tehnikas attīstības līmenim, un tās darbība ir droša un uzticama, ja ar to

rīkojas, to uzstāda un apkopi veic apmācīts personāls. Ir jāievēro uzstādīšanas,

lietošanas un apkopes norādījumi, kas aprakstīti šajā dokumentā.

3. Aristo® RT robotizēto metināšanas sistēmu drīkst uzstādīt, lietot un apkopt tikai

apmācīts personāls. Ir jāievēro šajā rokasgrāmatā detalizēti aprakstītie uzstādīšanas,

lietošanas un apkopes noteikumi.

4. Aristo® RT robotizēto metināšanas sistēmu drīkst lietot tikai ražotāja norādītajam

mērķim, ievērojot sistēmas tehniskos datus un izmantojot automatizētas apstrādes

sistēmas. Degļa tips jāizvēlas atbilstoši metināšanas uzdevumam.

5. Aristo® RT robotizētā metināšanas sistēma ir izstrādāta lietošanai kā pilnībā

komplektēta sistēma. Citu ražotāju izgatavotu komponentu iebūvēšana sistēmā nav

atļauta.

6. RT KS-2 un RT KSC-2 ir paredzēti izmantošanai tikai kā avārijas apturēšanas

mehānismi, ievērojot tehniskās specifikācijas un kombinācijā ar RT standarta sviras

kabeļa bloku (KS-2), Infiniturn vai Helix (KSC-2), ESAB adaptera atloku kopā ar RT

degļa stiprinājumiem (KS-2) un Aristo RT metināšanas degli.

7. Izpūtes gāzei nedrīkst pievienot eļļu vai pretšļakstu šķidrumu. ESAB negarantē

ķīmisko izturību pret šīm vielām. ESAB iesaka izmantot ESAB smidzināšanas ierīci, lai

padotu deglim minimālo daudzumu pretšļakstu šķidruma un tādējādi aizsargātu

apkārtējo vidi.

8. Transportēšanas, glabāšanas un lietošanas laikā produkts jātur sausumā un jāsargā

no mitruma.

9. Sistēma ir paredzēta vides temperatūrai diapazonā no 5°C līdz 40°C (41°F līdz

104°F). Ja šīs robežvērtības tiek pārsniegtas, ir nepieciešama īpaša rīcība. Sala riska

gadījumā lietojiet piemērotu dzesēšanas šķidrumu.

0463 373 101

- 8 -

© ESAB AB 2018

3 IEVADS

3 IEVADS

RT metināšanas degļu sistēmas ir izstrādātas pilnībā automātiskai MIG/MAG metināšanai,

izmantojot robotus. Sistēma sastāv no dažādiem Aristo RT degļa kakliem, kas paredzēti

robotizētai lietošanai, degļa stiprinājumiem, kabeļa blokiem, kas optimizēti robotizētai

lietošanai, un aizsargizslēgšanas funkcijām, lai nepieļautu sistēmas bojājumus sadursmes

gadījumā.

Standarta RT metināšanas sistēma nodrošina aizsardzību pret sadursmēm, izmantojot

RTKS-2, kas ir mehāniska, ar atsperi darbināma aizsargizslēgšanas funkcija. Pēc izvēles to

var aizstāt ar RTFL-2, lai izmantotu robota vadības sistēmas nodrošinātās sadursmes

noteikšanas funkcijas priekšrocības. Standarta RT metināšanas sistēmu var izmantot ar

dažādiem kabeļa bloku tipiem.

RTKSC-2 un RTFLC-2 degļu stiprinājumi ar Infiniturn vai Helix kabeļa blokiem ir paredzēti

lietošanai ar dobā satvērēja robotizētajām metināšanas sistēmām, kas izstrādātas

sarežģītiem metināšanas lietojumiem. Aizsargizslēgšanas mehānisms RTKSC-2 degļa

stiprinājumā nodrošina plašu, elastīgu degļa nolieci sadursmes gadījumā. Infiniturn un Helix

kabeļa bloki ir viegli uzstādāmi un nodrošina augstu sistēmas uzticamību un precīzas

manevrēšanas spēju.

Kombinācijā ar vispāratzītajiem RT robotizētajiem metināšanas degļiem šīs sastāvdaļas

veido ļoti uzticamu un ilgtspējīgu sistēmu, kam nepieciešama tikai minimāla apkope.

Šī lietošanas rokasgrāmata ir iekļauta degļa stiprinājumu un kabeļa bloku piegādes

komplektācijā.

ESAB pasūtījuma numuri, pieejamie piederumi, rezerves daļas un dilstošās daļas ir

atrodamas rezerves daļu sarakstā.

0463 373 101

- 9 -

© ESAB AB 2018

3 IEVADS

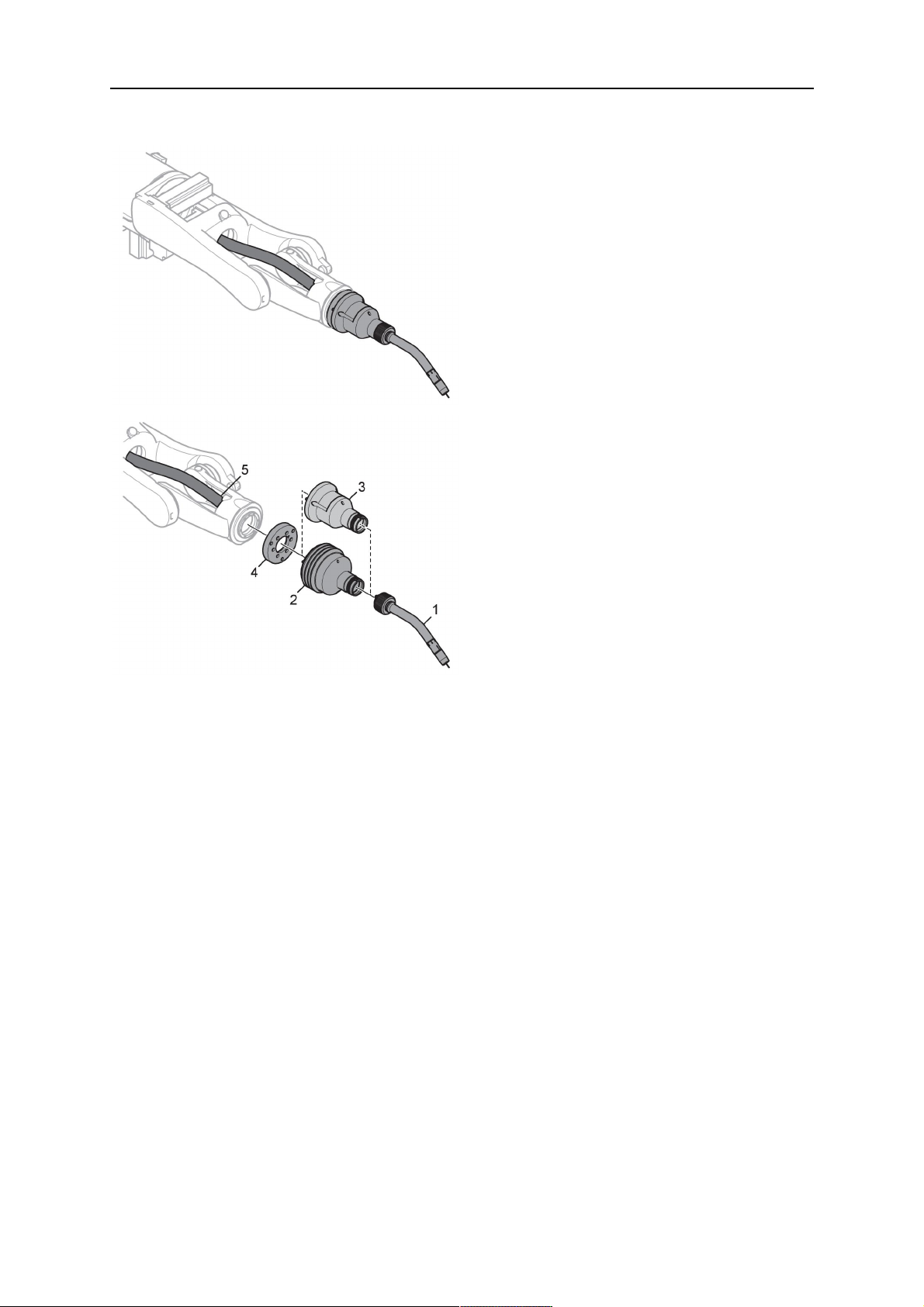

3.1 Metināšanas degļu sistēmu pārskats

Standarta RT sistēma

Detalizētu aprakstu skatiet nodaļas

TEHNISKIE DATI atbilstošajā sadaļā.

1. Degļa kakls

Skatiet sadaļu "Metināšanas deglis".

2. Kabeļa bloks

Skatiet "Kabeļa bloki standarta RT

sistēmai".

3. Degļa stiprinājums

Skatiet sadaļu "Degļa stiprinājumi

standarta RT sistēmai".

4. RTKS-2 aizsargizslēgšanas

mehānisms

Skatiet sadaļu "RTKS-2

aizsargizslēgšanas mehānisms".

5. RTFL-2 vidējais atloks

Skatiet sadaļu "RTFL-2 vidējais

atloks".

6. Adaptera atloks (ja nepieciešams)

Skatiet sadaļu "Adaptera atloki".

0463 373 101

- 10 -

© ESAB AB 2018

3 IEVADS

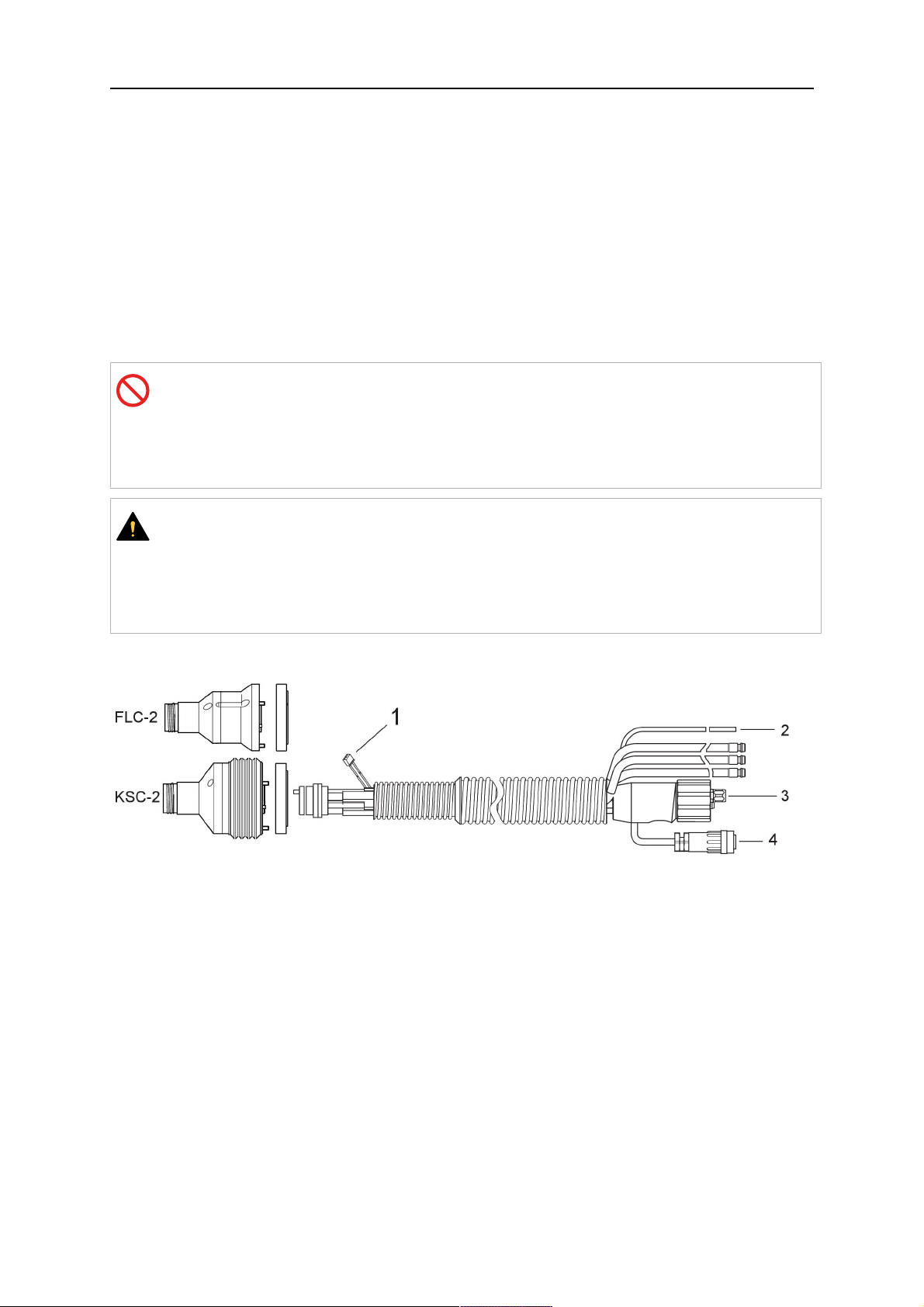

Dobā satvērēja sistēma

Detalizētu aprakstu skatiet nodaļas

TEHNISKIE DATI atbilstošajā sadaļā.

1. Degļa kakls

Skatiet sadaļu "Metināšanas deglis".

2. Degļa stiprinājums RTKSC-2

Skatiet sadaļu "RTKSC-2 degļa

stiprinājums ar aizsargizslēgšanas

mehānismu".

3. Degļa stiprinājums RTFLC-2

Skatiet sadaļu "RTFLC-2

nekustīgais degļa stiprinājums".

4. Adaptera atloks

Skatiet sadaļu "Adaptera atloki".

5. Kabeļa bloki Helix vai Infiniturn

Skatiet "Kabeļa bloki dobā satvērēja

sistēmām".

0463 373 101

- 11 -

© ESAB AB 2018

4 TEHNISKIE DATI

4 TEHNISKIE DATI

4.1 Metināšanas degļa kakls

Izvēlieties degļa modeli atbilstoši metināšanas lietojumam. Jāņem vērā nepieciešamais

darba režīma cikls un jauda, dzesēšanas veids un stieples diametrs. Ja pastāv

paaugstinātas prasības, piemēram, iepriekš uzkarsēts apstrādājamais priekšmets, liels

karstuma atstarojums stūros, tās ir jāņem vērā, un jāizvēlas metināšanas deglis ar atbilstošu

nominālās slodzes rezervi.

RT metināšanas degļi ir paredzēti lietošanai ar CE prasībām atbilstošiem metināšanas

barošanas avotiem metāla inerto gāzu (MIG) metināšanas, metāla aktīvo gāzu (MAG)

metināšanas un MIG cietlodēšanas procesos ar rūpnieciskajām apaļajām stieplēm.

Neizmantojiet degli citiem procesiem.

Tērauda impulsa loka metināšanai vai alumīnija metināšanai jāizmanto RT82W deglis ar

ūdens dzesēšanu.

Pieejamos degļa modeļus skatiet tālāk.

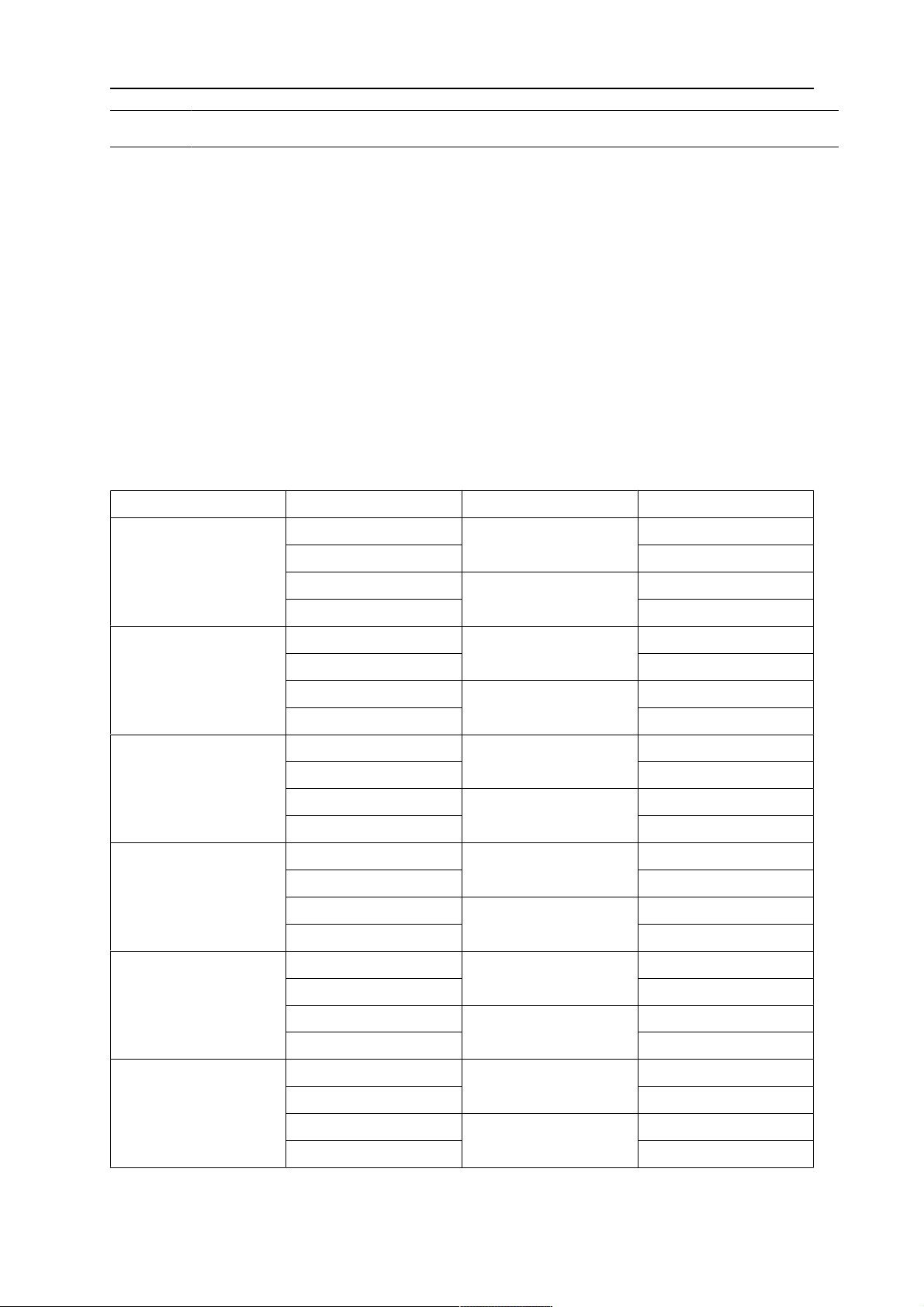

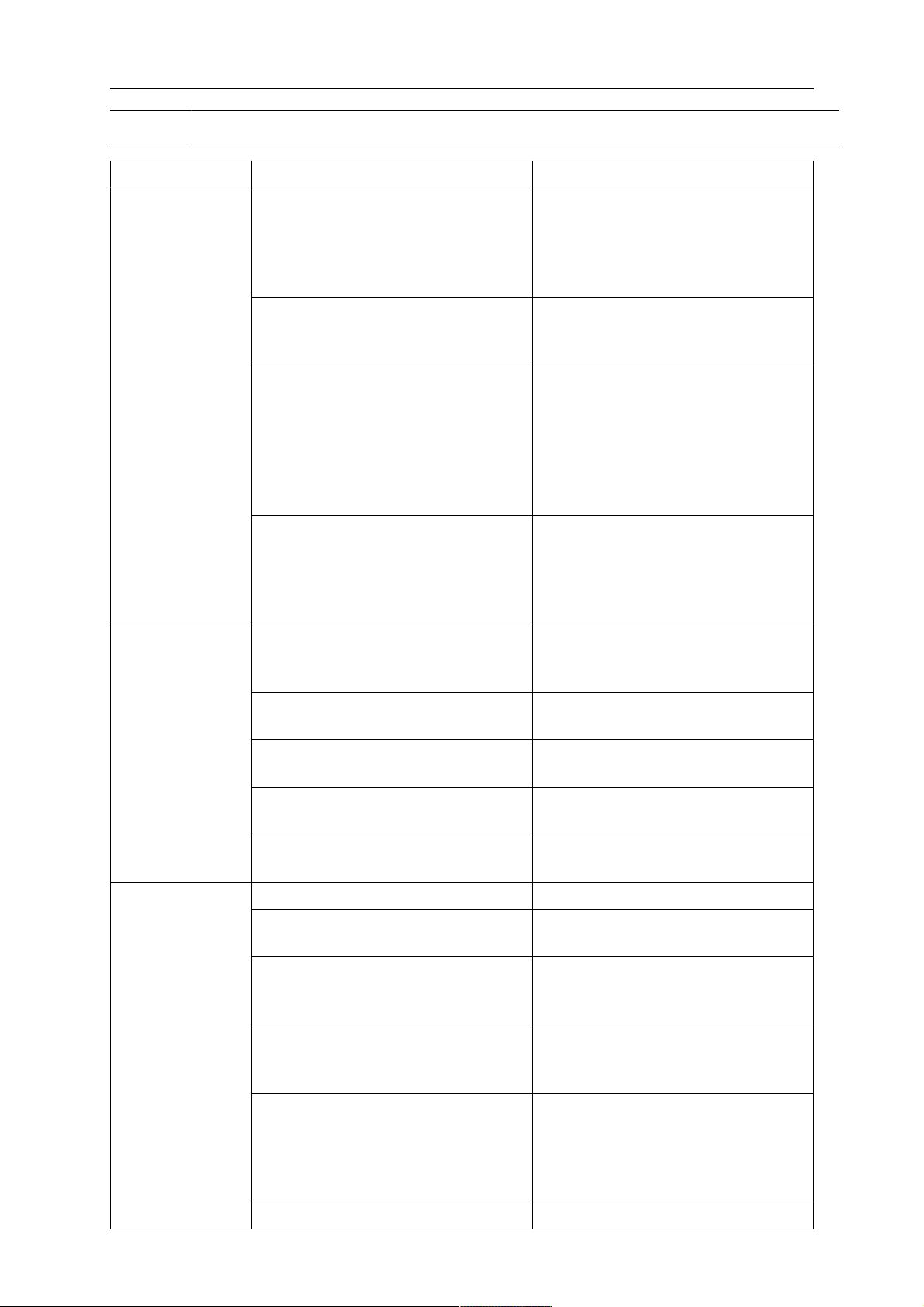

Degļa modelis Dzesēšanas veids Ekranējošā gāze Nominālie parametri

RT42G Dzesēšana ar gāzi CO

Dzesēšana ar gāzi 300A/100%

Dzesēšana ar gāzi Maisījums 350A/60%

Dzesēšana ar gāzi 250A/100%

RT42W Dzesēšana ar ūdeni CO

Dzesēšana ar ūdeni 420A/100%

Dzesēšana ar ūdeni Maisījums 350A/60%

Dzesēšana ar ūdeni 350A/100%

RT52G Dzesēšana ar gāzi CO

Dzesēšana ar gāzi 300A/100%

Dzesēšana ar gāzi Maisījums 350A/60%

Dzesēšana ar gāzi 250A/100%

RT52W Dzesēšana ar ūdeni CO

Dzesēšana ar ūdeni 470A/100%

Dzesēšana ar ūdeni Maisījums 400A/60%

Dzesēšana ar ūdeni 400A/100%

RT62G Dzesēšana ar gāzi CO

Dzesēšana ar gāzi 340A/100%

2

2

2

2

2

420A/60%

420A/60%

420A/60%

470A/60%

500A/60%

Dzesēšana ar gāzi Maisījums 420A/60%

Dzesēšana ar gāzi 290A/100%

RT62W Dzesēšana ar ūdeni CO

Dzesēšana ar ūdeni 530A/100%

Dzesēšana ar ūdeni Maisījums 450A/60%

Dzesēšana ar ūdeni 450A/100%

0463 373 101

- 12 -

2

530A/60%

© ESAB AB 2018

4 TEHNISKIE DATI

Degļa modelis Dzesēšanas veids Ekranējošā gāze Nominālie parametri

RT72G Dzesēšana ar gāzi CO

2

480A/60%

Dzesēšana ar gāzi 320A/100%

Dzesēšana ar gāzi Maisījums 400A/60%

Dzesēšana ar gāzi 270A/100%

RT72W Dzesēšana ar ūdeni CO

2

480A/60%

Dzesēšana ar ūdeni 430A/100%

Dzesēšana ar ūdeni Maisījums 480A/60%

Dzesēšana ar ūdeni 430A/100%

RT82W Dzesēšana ar ūdeni CO

2

600A/60%

Dzesēšana ar ūdeni 600A/100%

Dzesēšana ar ūdeni Maisījums 550A/60%

Dzesēšana ar ūdeni 550A/100%

Degļa rādītāju un darba režīma cikla vērtības attiecas uz 10minūšu ciklu.

Tehniskie dati attiecas uz standarta lietojumu, izmantojot standarta dilstošās/rezerves daļas.

Degļa rādītāji ir samazināti, ja tiek izmantots impulsu arkas metāla pārneses režīms.

Temperatūras diapazoni Uzglabāšana: -15-50°C (5-122°F)

Darbība: 5–40°C (41–104°F)

Izpūtes gāze Maks. 10bāri, atsevišķa gāzes šļūtene

Kopējais svars (degļa kakls,

Aptuveni 5kg

aizsargizslēgšanas mehānisms, degļa

stiprinājums un 1m kabeļa bloks)

4.2 Sprieguma nominālie parametri

Maks. atļautais spriegums/strāva

Visa metināšanas degļa sistēma 141V (maksimālā vērtība metināšanai)

RTKS-2 aizsargizslēgšanas vadības ķēde

RTKS-2 spiedpoga

RTKSC-2 aizsargizslēgšanas vadības ķēde 48 V

Izmantojot sprauslas uztveršanas funkciju ar

standarta kabeļa bloku

Izmantojot sprauslas uztveršanas funkciju ar

Helix vai Infiniturn kabeļa bloku

24V/1A

48V/0,1 A

50V/5A

(Atļautais slodzes maksimums 1minūti pie

nominālās strāvas)

50V/5A

(Atļautais slodzes maksimums 1minūti pie

nominālās strāvas)

Norādītie rādītāji attiecas uz standarta lietojuma gadījumiem.

Kabeļa bloku rādītājus skatiet sadaļā "Kabeļa bloki".

4.2.1 Dzesēšanas kontūra robežvērtības

Attiecas tikai uz versiju ar ūdens dzesēšanu.

0463 373 101

- 13 -

© ESAB AB 2018

4 TEHNISKIE DATI

Min. ūdens plūsmas līmenis: 1,0l/min (1,1kvarts/min)

Min. ūdens spiediens: 2,5bāri (36,3PSI)

Maks. ūdens spiediens: 3,5bāri (50,8PSI)

Ieplūdes temperatūra: Maks. 40°C (104°F)

Atplūdes temperatūra: Maks. 60°C (140°F)

Dzesēšanas jauda: Min. 1000W, atkarībā no lietojuma

UZMANĪBU!

Atplūdes temperatūra virs 60°C (140°F) var izraisīt kabeļa bloka bojājumus vai to

iznīcināt

4.3 Degļa stiprinājums

Nepieciešamais degļa stiprinājuma veids ir atkarīgs no RT metināšanas degļu sistēmas

konstrukcijas un izvēlētajām aizsargizslēgšanas ierīcēm; skatiet sadaļu "Metināšanas degļu

sistēmu pārskats".

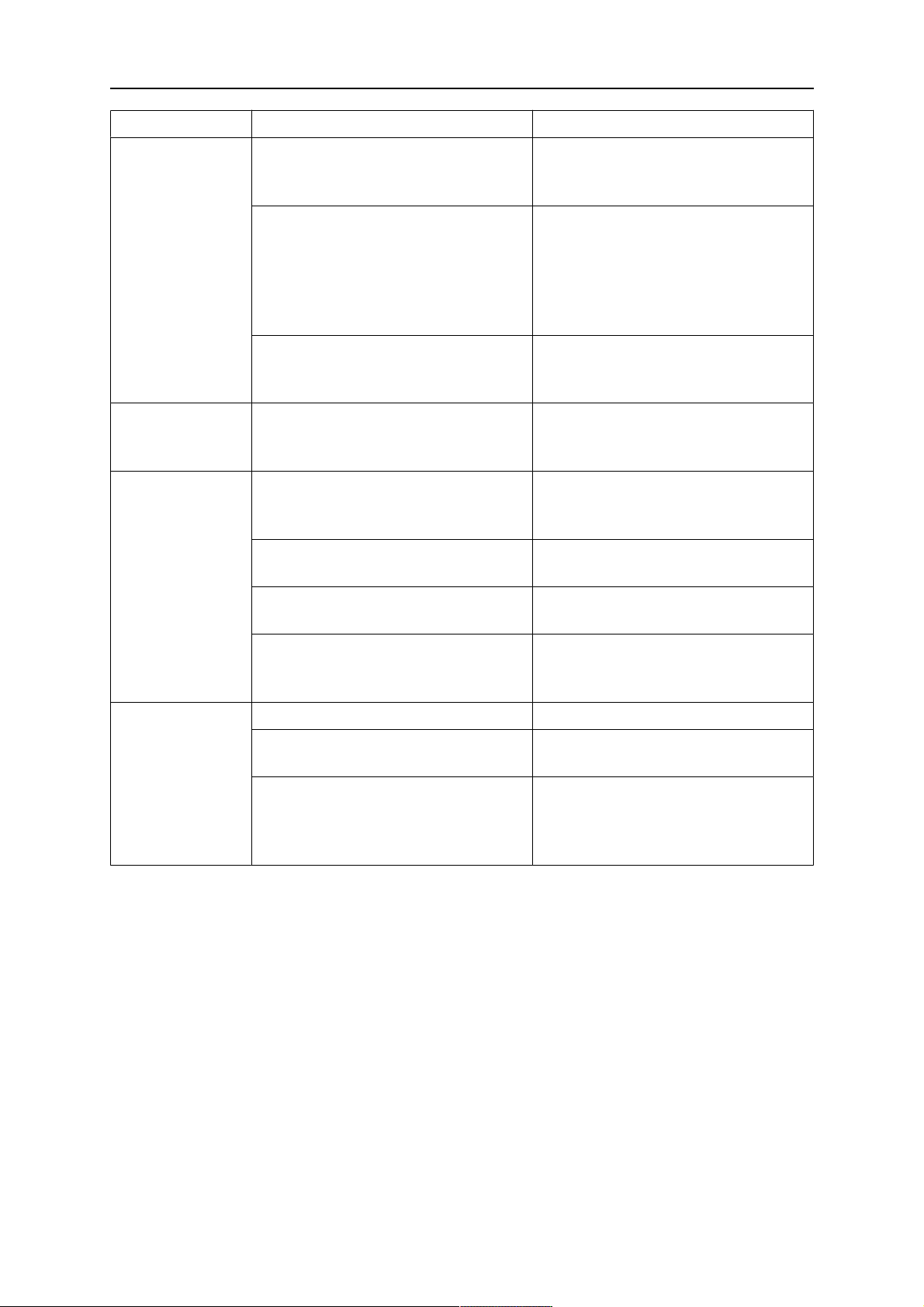

Komponents Aptuvenais svars

Degļa stiprinājums (standarta sistēmai) 0,43 kg

RTKS-2 aizsargizslēgšanas mehānisms

0,85 kg

(standarta sistēmai)

RTFL-2 vidējais atloks (standarta sistēmai) 0,35 kg

RTKSC-2 degļa stiprinājums (dobā satvērēja

1,90 kg

sistēmai)

RTFLC-2 nekustīgais degļa stiprinājums

1,22 kg

(dobā satvērēja sistēmai)

Robotizētais metināšanas deglis 0,66 kg

4.3.1 Degļa stiprinājumi standarta RT sistēmai

Standarta RT sistēmās degļa stiprinājums ir uzstādīts uz RTKS-2 aizsargizslēgšanas

mehānisma (alternatīvi uz RTFL-2 vidējā atloka), nostiprinot kabeļa bloku un pievienoto

degļa kaklu.

Izvēlieties degļa stiprinājumu atbilstoši degļa veidam un tā ģeometrijai. Var izmantot dažādus

stiprinājuma veidus. Standarta RT sistēmai pieejamos degļa stiprinājumu veidus skatiet

rezerves daļu sarakstā.

Degļa stiprinājums standarta sviras robotiem

0463 373 101

- 14 -

© ESAB AB 2018

4 TEHNISKIE DATI

4.3.1.1 RTKS-2 aizsargizslēgšanas mehānisms

RTKS-2 aizsargmehānisms ir ar atsperi aprīkota ierīce, kas pasargā robotu un degļa

sistēmu sadursmes gadījumā.

IEVĒROJIET!

Nedemontējiet RTKS-2.

4.3.1.2 RTFL-2 vidējais atloks

Ja robotam ir elektroniska sadursmes noteikšanas sistēma, RTKS-2 vietā var izmantot

nekustīgo vidējo atloku RTFL-2.

4.3.2 Degļa stiprinājumi dobā satvērēja sistēmai

Dobā satvērēja sistēmā Aristo RT metināšanas degļa kakls ir savienots ar degļa stiprinājumu

KSC-2 vai FLC-2.

Degļa stiprinājums RTKSC-2 nodrošina elastīgu degļa nolieci sadursmes gadījumā.

Vienlaikus tiek atvērts elektriskais kontakts, signalizējot, ka robota vadības ierīcei jāaptur

darbība. Pēc kļūdas atiestatīšanas degļa sākotnējā ģeometrija un instrumenta centra punkts

(Tool Center Point– TCP) tiek atjaunots ar augstu precizitāti. Sistēma darbojas pilnībā

mehāniski un tiek darbināta ar atsperi.

Degļa stiprinājumam RTFLC-2 nav iebūvētas aizsargizslēgšanas funkcijas.

0463 373 101

- 15 -

© ESAB AB 2018

4 TEHNISKIE DATI

Dobā satvērēja sistēmām ir ieteicams RTKSC-2 G/W (alternatīvi RTFLC-2 G/W). Šo degļa

stiprinājumu var lietot gan ar gāzi dzesējamiem, gan ar ūdeni dzesējamiem Aristo RT sērijas

degļiem.

RTKSC-2 G/W RTFLC-2 G/W

Aizsargizslēgšanas

mehānisma darbības princips

Aksiāls atbrīvošanas spēks

(Fz)

Degļa atbrīvošana uz

šķērsvirziena ass (Mx)

Atiestatīšana pēc

atbrīvošanas

Atkārtojamība Sāniski ± 0,1mm pie

Mehānisks Nav piemērojams (nekustīgs

stiprinājums)

650 N Nav piemērojams (nekustīgs

stiprinājums)

24Nm Nav piemērojams (nekustīgs

stiprinājums)

Automātiskā Nav piemērojams (nekustīgs

stiprinājums)

Nav piemērojams (nekustīgs

standarta Aristo RT degļa

stiprinājums)

TCP

Maks. noliece Apt. ± 8° Nav piemērojams (nekustīgs

stiprinājums)

Drošības slēdzis Parasti aizvērts

Elektriskā slodze maks.

48V/1A

0463 373 101

- 16 -

Nav piemērojams (nekustīgs

stiprinājums)

© ESAB AB 2018

4 TEHNISKIE DATI

Elektriskās vadības ķēde

sprauslas uztveršanas

funkcijai

Sprieguma nominālie

parametri

Nominālie parametri:

• Helix kabeļa blokiem:

maks. 50V DC/5A,

maks. 1minūte

Pēc kontakta

noteikšanas ātri

atvienojiet uztveršanas

spriegumu.

• Infiniturn kabeļa blokiem

sprauslas noteikšanas

funkcijai ir ierobežota

darbība. Lai iegūtu

detalizētu informāciju

par iespējamiem

risinājumiem jūsu

lietojumu veidiem,

sazinieties ar

uzņēmumu ESAB.

Maksimālais atļautais

spriegums aizsargizslēgšanas

vadības ķēdē: 48V

Nominālie parametri:

• Helix kabeļa blokiem:

maks. 50V DC/5A,

maks. 1minūte

• Infiniturn kabeļa

blokiem: maks. 50V

DC/1A, maks. 1minūte

Pēc kontakta noteikšanas ātri

atvienojiet uztveršanas

spriegumu.

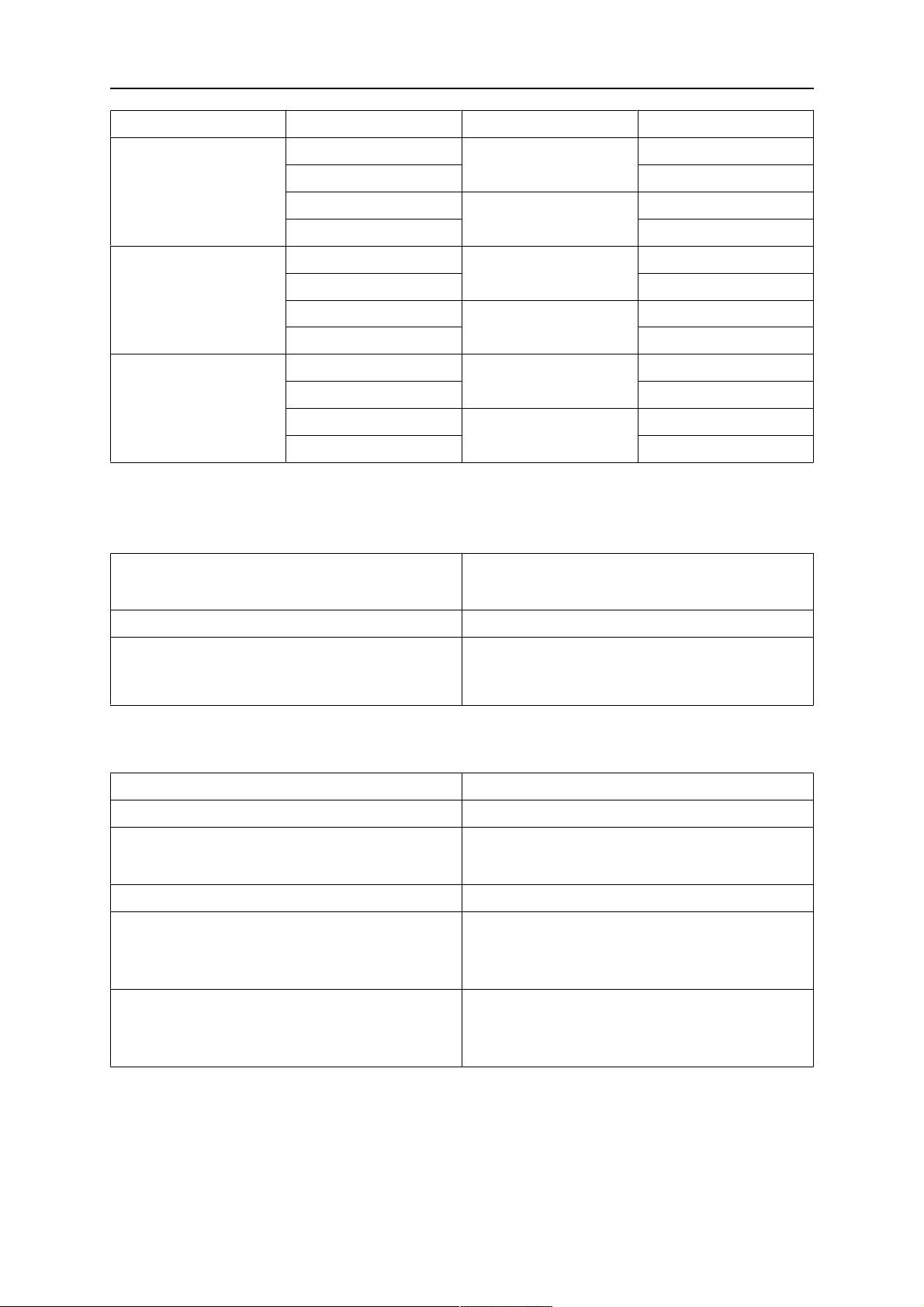

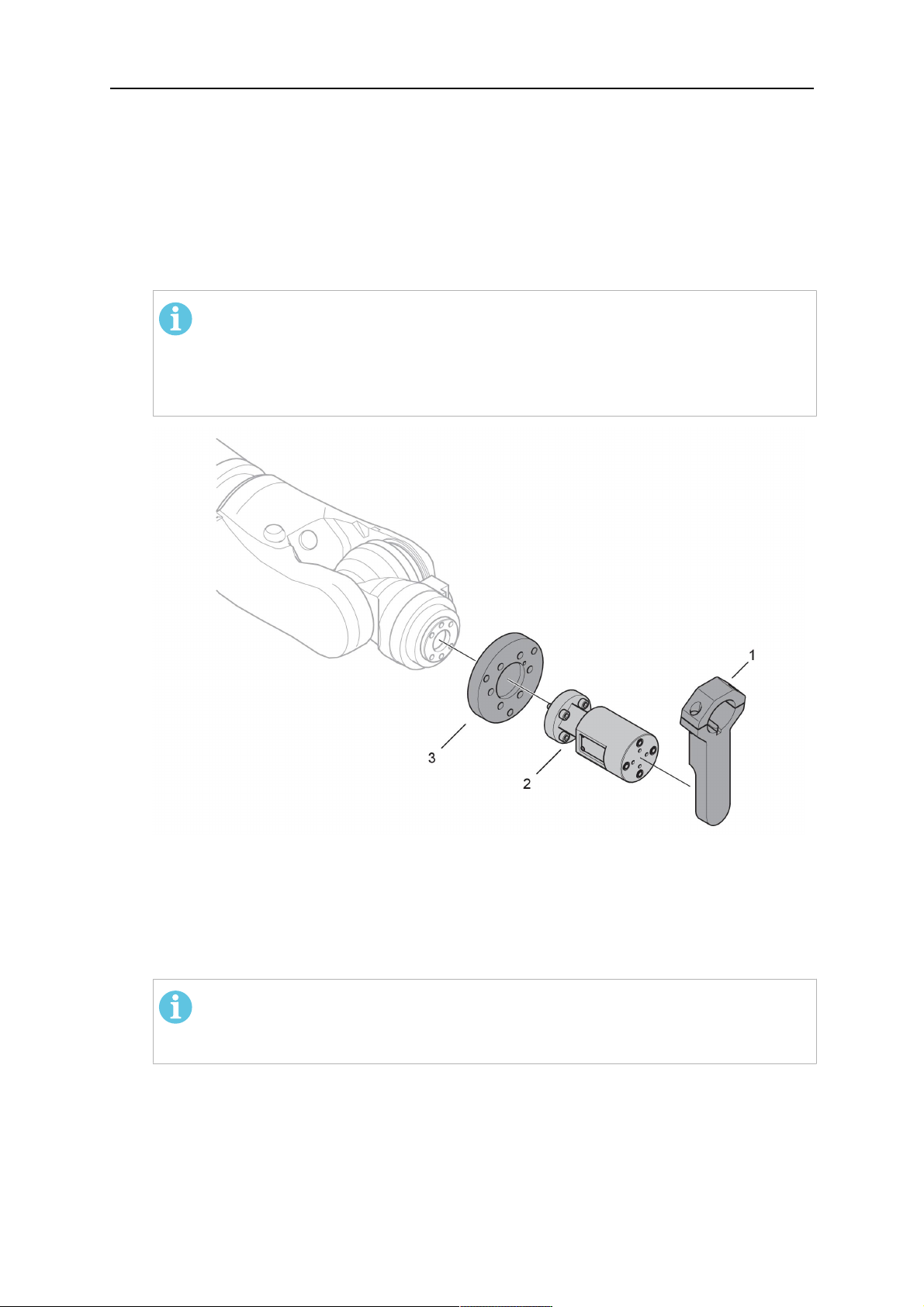

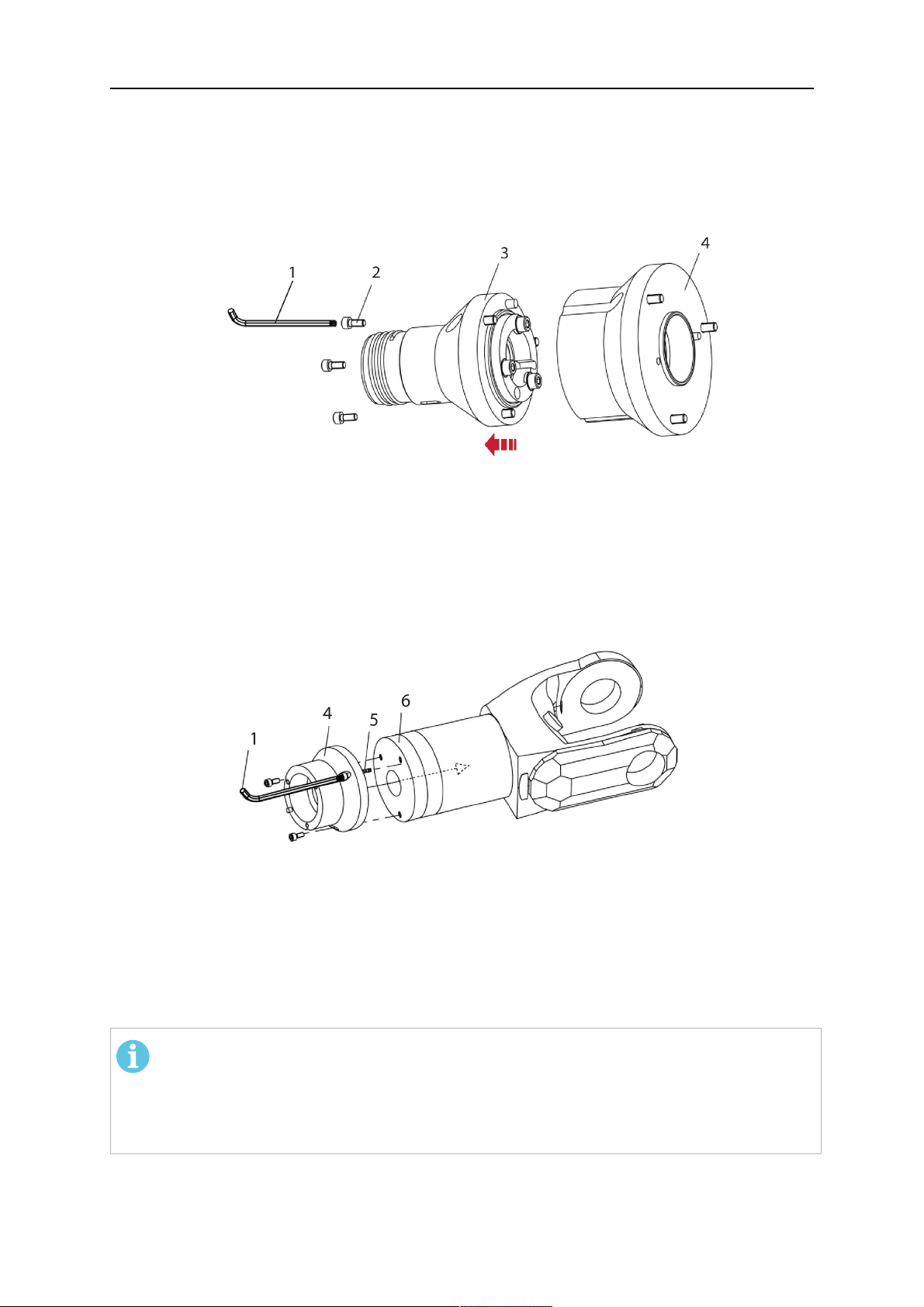

4.3.2.1 RTKSC-2 G/W degļa stiprinājums ar aizsargizslēgšanas mehānismu

Num

Apraksts Function

urs

1 Degļa kakla turētājs Aristo RT degļa savienojums

2 RTKSC-2 pārsegs Bloks ar kabeļa un degļa savienojumiem

0463 373 101

- 17 -

© ESAB AB 2018

4 TEHNISKIE DATI

Num

Apraksts Function

urs

3 Gumijas apvalks Aizsargizslēgšanas mehānisma aizsardzība

4 RTKSC-2 galvenais korpuss Nodrošina mehānisku nolieci sadursmes laikā

5 Adaptera atloks Izolējošs savienojums ar robotizēto satvērēju

(jāatbilst attiecīgajam robotam)

6 Rādītāja tapa Adaptera atloka precīzai regulēšanai

7 Vadības kabeļa savienotājs Sadursmes signāla un sprauslas uztveršanas

funkcijas elektriskais savienojums

8 Mikro slēdzis Sadursmes noteikšanas sensors

4.3.2.2 RTFLC-2 G/W nekustīgais degļa stiprinājums

Num

Apraksts Function

urs

1 Degļa kakla turētājs Aristo RT degļa savienojums

2 RTFLC-2 pārsegs Bloks ar kabeļa un degļa savienojumiem

3 RTFLC-2 galvenais korpuss Nodrošina mehānisku nolieci sadursmes laikā

4 Rādītāja tapa Adaptera atloka precīzai regulēšanai

5 Adaptera atloks Izolējošs savienojums ar robotizēto satvērēju

(jāatbilst attiecīgajam robotam)

6 Vadības kabeļa savienotājs

(3polu)

0463 373 101

Sprauslas uztveršanas funkcijas elektriskais

savienojums (ja piemērojams)

- 18 -

© ESAB AB 2018

4 TEHNISKIE DATI

4.4 Adaptera atloki

Izvēlieties uzstādīšanai uz robota sviras nepieciešamo adaptera atloku atkarībā no robota

veida. Ir pieejami adaptera atloki visām piemērotajām standarta un dobā satvērēja sistēmām;

skatiet rezerves daļu sarakstu.

4.5 Kabeļa bloki

Savienojumu ar stieples padevēju nodrošina kabeļa bloks; pieejamās versijas galvenokārt

nosaka sistēmas konstrukcija un dzesēšanas līdzeklis (gāze vai ūdens); skatiet rezerves

daļu sarakstu.

Rādītāji attiecas uz kabeļu garumiem no 1 līdz 5m.

Standarta kabeļa

Infiniturn Helix

bloks

Nominālie parametri

(10min cikls)

Dzesēšana ar gāzi

(gāzu maisījums)

Nominālie parametri

(10min cikls)

Maks. 500A/60%

darba cikls

Maks. 350A/100%

darba cikls

Maks. 600A/100%

darba cikls

Maks. 400A/60%

darba cikls

Maks. 320A/100%

darba cikls

Maks. 550A/100%

darba cikls

Dzesēšana ar ūdeni

Rotācijas diapazons Ierobežota

pagriežamība

Svars

Dzesēšana ar gāzi

Svars

Dzesēšana ar ūdeni

1,2m garš:

2,35 kg

1,2m garš:

2,35 kg

Neierobežoti

pagriežams

1,0m garš:

2,0 kg

1,0m garš:

2,0 kg

4.5.1 Kabeļa bloki standarta RT sistēmai

Maks. 400A/60%

darba cikls

Maks. 320A/100%

darba cikls

Maks. 550A/100%

darba cikls

± 270° no neitrālas

pozīcijas

1,0m garš:

2,0 kg

1,0m garš:

2,0 kg

0463 373 101

- 19 -

© ESAB AB 2018

4 TEHNISKIE DATI

Burndy savienotāja tapas

A. Gāzes sprauslas

pieskāriena uztvērējs

C. Sadursmes sensors

F. 0V

G. + motora spriegums

H. - motora spriegums

D. Sadursmes sensors

E. Pakāpeniska padeve

Num

Apraksts Function

urs

1 Kakla turētāja atloks Degļa savienojums

2 Aizsargpārsegs Pasargā kabeļa bloku no bojājumiem

3 Burndy, savienotājs, 12polu Elektriskais savienojums starp aizsargizslēgšanu un

stieples padeves ierīci

4 Kontroles kabelis Paredzēts KS-2 (aizsargizslēgšana un spiedpoga)

5 EURO savienotājs Stieples padeves ierīces savienojums

6 Izpūtes šļūtene (melns vāciņš) Degļa tīrīšanai ar saspiestu gaisu pēc tīrīšanas cikla

7 Ūdens ieplūde (zils vāciņš)

8 Ūdens atplūde (sarkans vāciņš)

Ūdens ieplūde degļa dzesēšanai

Sakarsušā ūdens atplūde no degļa

1)

1)

9 Aizsargizslēgšanas mehānisma

vadības kabeļa spraudnis

Elektriskais savienojums ar RTKS-2

aizsargizslēgšanas signāla un sprauslas

uztveršanas funkcijas nodrošināšanai

1)

Tikai degļa sistēmām ar ūdens dzesēšanu

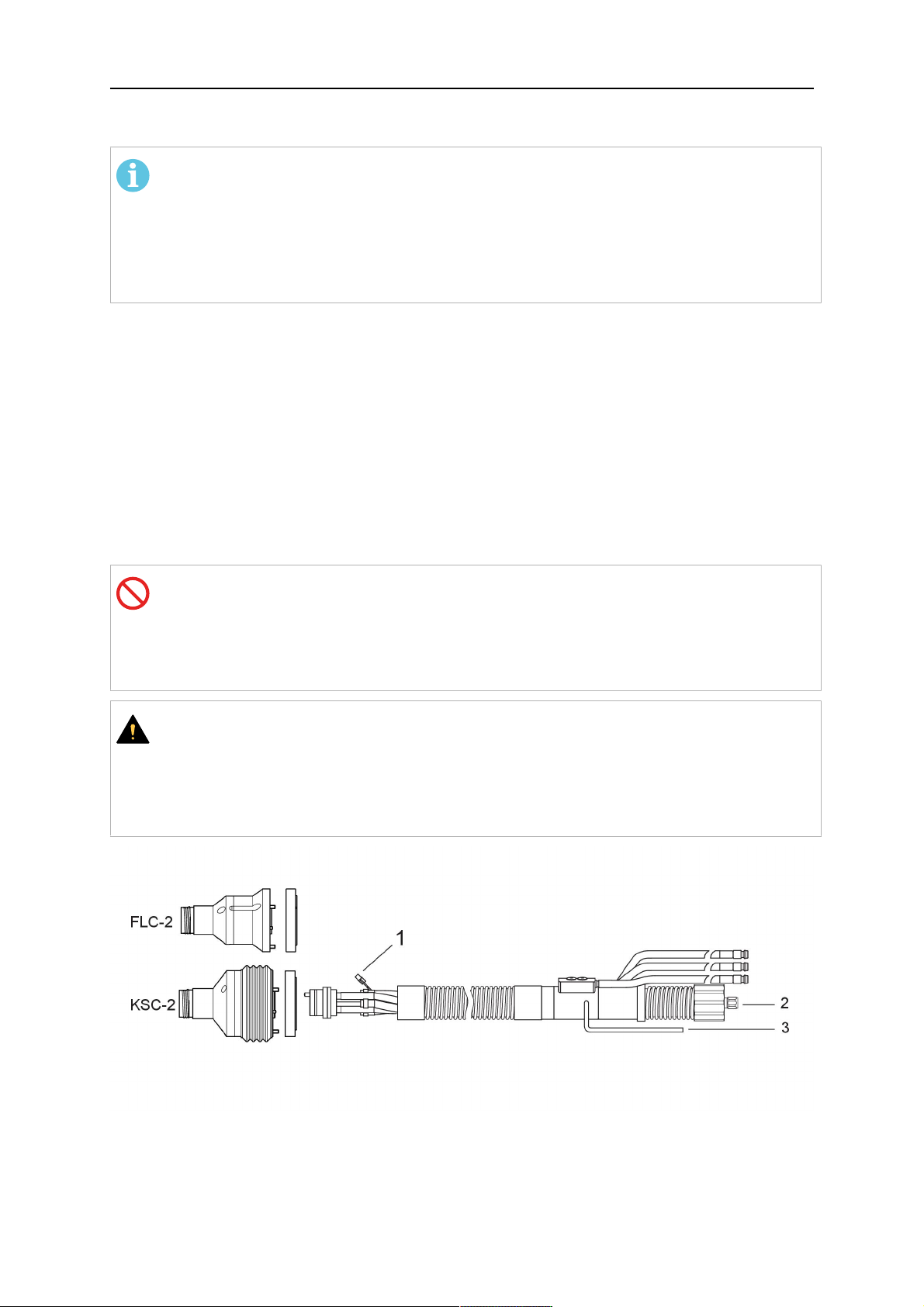

4.5.2 Kabeļa bloki dobā satvērēja sistēmām

Infiniturn kabeļa bloks nodrošina bezgalīgu degļa pagriešanas iespēju abos virzienos.

Vienlaikus tiek padots dzesēšanas šķidrums, aizsarggāze, izpūtes gaiss, metināšanas jauda

un aizsargizslēgšanas mehānisma signāls.

Helix kabeļa bloks ir izstrādāts rotācijas diapazonam ±270° no neitrālas pozīcijas. To var

izmantot metināšanas darbiem, kuros nav nepieciešama bezgalīgas pagriešanas iespēja.

Infiniturn kabeļa blokiem ir pieejama versija ar gāzes dzesēšanu un versija ar ūdens

dzesēšanu. Helix kabeļa blokus var universāli izmantot gan lietojumos ar gāzes dzesēšanu,

gan ar ūdens dzesēšanu.

IEVĒROJIET!

Nedrīkst pievienot Helix kabeļa bloku, kas darbojas ar degļa kaklu, kas tiek dzesēts

ar gāzi, pie sistēmas, kam ir ūdens dzesēšana.

0463 373 101

- 20 -

© ESAB AB 2018

4 TEHNISKIE DATI

Num

Apraksts Function

urs

1 Atloks Degļa stiprinājuma RTKSC-2/RTFLC-2

savienojums

2 Rādītāja tapa Nodrošina pareizu savienojuma orientāciju

3 Vadības kabeļa spraudnis Elektriskais savienojums ar RTKSC-2

aizsargizslēgšanas signāla un sprauslas

uztveršanas funkcijas nodrošināšanai (ja

piemērojams)

4 EURO savienotājs Stieples padeves ierīces savienojums

5 Kontroles kabelis Elektriskais savienojums aizsargizslēgšanas signāla

nodrošināšanai (no RTKSC-2) un sprauslas

uztveršanas funkcijai (sprauslas uztveršana ir

standarta funkcija Helix, bet ne Infiniturn)

6 Ūdens atplūde (sarkans vāciņš) Sakarsušā ūdens atplūde no degļa

7 Ūdens ieplūde (zils vāciņš) Ūdens ieplūde degļa dzesēšanai

8 Izpūtes šļūtene (melns vāciņš) Degļa tīrīšanai ar saspiestu gaisu pēc metināšanas

9 Darba līdzekļu padeves

savienojums

Bezgalīgi pagriežams savienojums ar darba līdzekļu

padevi

10 Aizsargpārsegs Pasargā kabeļa bloku no bojājumiem

0463 373 101

- 21 -

© ESAB AB 2018

5 INSTALLATION

5 INSTALLATION

BRĪDINĀJUMS!

For your own safety, make sure that the robot is either in standby or power-less

state before doing maintenance work in the moving radius of the robot.

Follow the assembly instructions exactly. Pay attention during assembly that the cables are

not damaged. Damaged cables can lead to a short circuit, which may damage the electronics

of the robot or the welding torch.

Use only original ESAB components that have been specially developed for this purpose.

Only then the correct functioning of the whole welding torch system can be guaranteed.

5.1 RTKS-2 standard arm installation

5.1.1 RTKS-2 safety-off mechanism

1. Dismount the insulation flange (10) from the RTKS-2 (11) by removing the screws

(12).

2. Position the insulation flange (10) with the index pin on the robot arm and fix it with the

screws (20) included.

The insulation flange (10) is directly compatible with robots with tool flange according

to DIN ISO 9409-1-A40 (diameter 40mm, 4×M6). If the insulation flange (10) does

not fit, use an adapter flange (21).

IEVĒROJIET!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

3. Mount the RTKS-2 the back on the insulation flange (10).

0463 373 101

- 22 -

© ESAB AB 2018

5 INSTALLATION

4. Position the mount on the RTKS-2 and carefully insert the cylindrical pins (14) into the

holes provided. Take the position of the torch into account. Two mounting positions

may be potentially possible.

5. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (12).

IEVĒROJIET!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

12 - Cylinder screw with hexagon socket

M6DIN912 (length of the screw depending

on the torch mount)

14 - Cylindrical pins Ø4×20

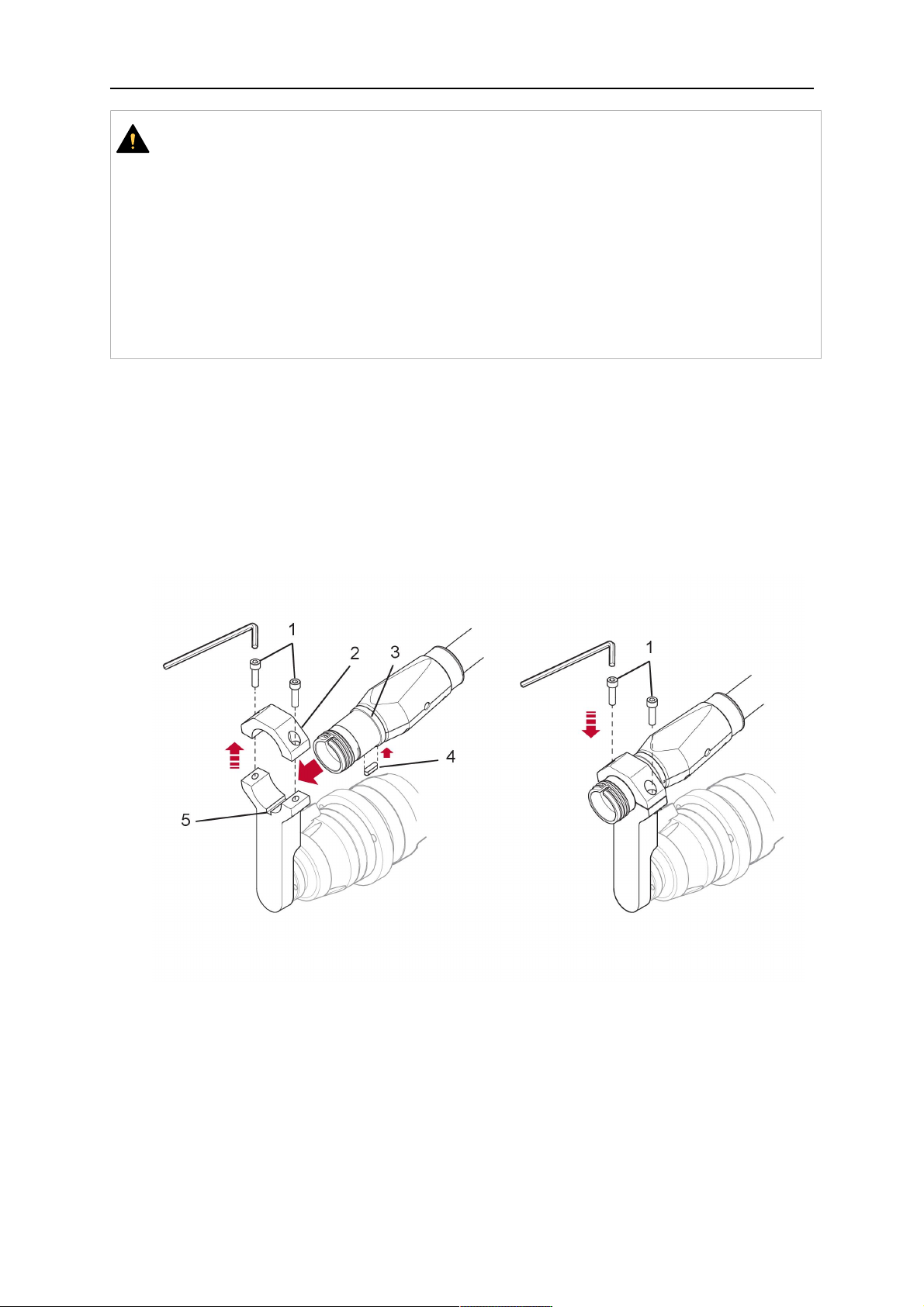

5.1.1.1 Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. The pins should protrude by approximately 5 mm (0.2 in.).

2. Position the mount on the safety-off mechanism RTKS-2 and carefully insert the

cylindrical pins (1) into the holes provided. In doing so, take the later position of the

torch into account. Two mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

IEVĒROJIET!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

0463 373 101

- 23 -

© ESAB AB 2018

5 INSTALLATION

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

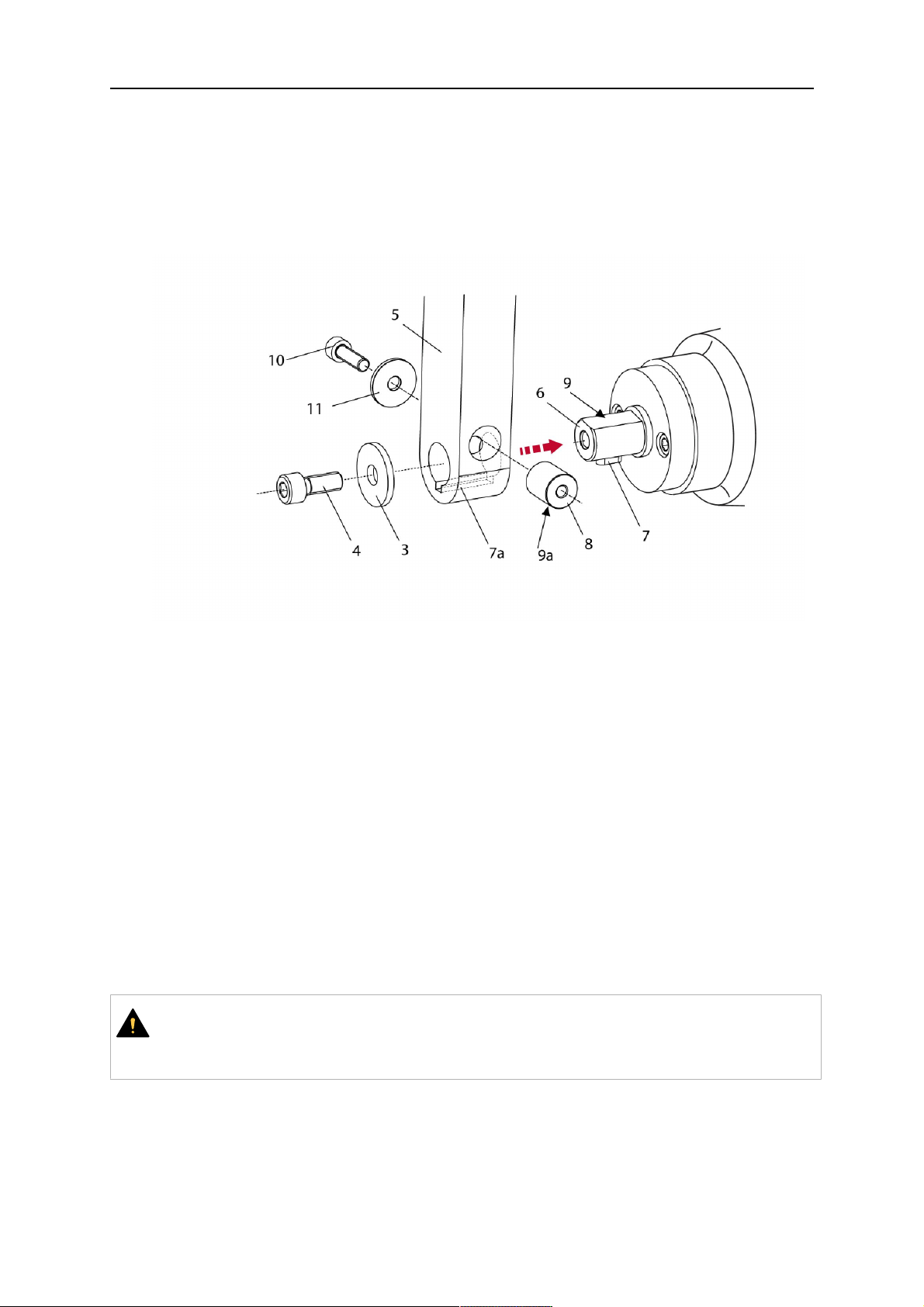

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

0463 373 101

- 24 -

© ESAB AB 2018

5 INSTALLATION

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.1.2 Standard arm cable assembly for KS-2 and FL-2

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

0463 373 101

- 25 -

© ESAB AB 2018

5 INSTALLATION

UZMANĪBU!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

1. Unscrew the cylinder screws (1) and lift off the top section (2) of the torch mount.

2. Insert the feather key (4) into the recess of the neck support flange (3) from below.

3. Align the neck support flange (3) including the feather key (4) to the groove (5) of the

torch mount and push into the groove right up to the stop of the flange.

4. Hold the cable assembly in this position and simultaneously place the top section (2)

back onto the torch mount. First screw both cylinder screws (1) loosely in to about the

same length, then tighten alternately. The top section (2) of the mount should have an

even gap to the bottom section.

The front part of the cable assembly is directly clamped into the torch mount (see

illustration below).

1 - Cylinder screws 4 - Feather key

2 - Torch mount top section 5 - Groove for feather key

3 - Neck support flange

5.1.3 RTKS-2 wire feeder connection

In order to be able to create the connection, the cable assembly must be mounted as

described in the "Installing the cable assembly" section and equipped following "Installing the

wire guide" section. Only then can the central and media connection take place. Proceed as

described below:

0463 373 101

- 26 -

© ESAB AB 2018

5 INSTALLATION

1. Connect the central connector of the cable assembly (2) to the wire feeder cabinet

socket. Tighten the central connector sleeve nut fingertight. Do not use tools.

1 - Burndy Connector 4 - Return of heated water (red cap)

2 - EURO central connector 5 - Return of heated water (red cap)

3 - Air blow-out 6 - Main Wire feeder

2. For water cooled systems. Connect the water hoses to the cooling circuit. The end of

the hose marked blue (4) is connected to the water outlet, and the end marked red (5)

is connected to the water return.

3. Connect the blow-out line (3) to the corresponding connection of the feeder.

4. Connect the Burndy Connector to the wire feeder. (1) to the feeder. See section

"Electrical connections".

IEVĒROJIET!

All hoses and the control line must be installed so they can not bend or get

damaged!

5.1.4 RTKS-2 electrical connections

5.1.4.1 RTKS-2 safety-off mechanism connection

The switch for the safety-off functionality RTKS-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKS-2 unit via the 4-pole plug (4) that

contains circuits for the push-button (6) and the safety-off signal (7).

If a collision is detected, the control circuit for the safety-off signal (7), which is normally

closed, will be interrupted.

Rating of the control circuit: max. 48 V / 1 A

0463 373 101

- 27 -

© ESAB AB 2018

5 INSTALLATION

2 - Burndy connector 5 - RTKS-2 connector for control cable plug

4 - Control cable plug

Burndy savienotāja tapas

A. Gāzes sprauslas

pieskāriena uztvērējs

C. Sadursmes sensors

F. 0V

G. + motora spriegums

H. - motora spriegums

D. Sadursmes sensors

E. Pakāpeniska padeve

If the robot control provides a control circuit for nozzle sense functionality, the connection is

accomplished with a 1-wire connection.

Rating of the control circuit: max 50 V / 5 A.

BĪSTAMI

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

UZMANĪBU!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

5.1.5 RTKS-2 Torch installation

Continue according to section "Torch installation".

0463 373 101

- 28 -

© ESAB AB 2018

5 INSTALLATION

5.2 RTFL-2 standard arm installation

5.2.1 RTFL-2 rigid mount

1. Position the RT FL-2 (2) with the index pin on the robot arm and fix it with the hexagon

socket screw included.

The FL-2 is directly compatible with robots with tool flange according to DIN ISO

9409-1-A40 (diameter 40mm, 4×M6). If the rigid mount does not fit, use an adapter

flange (3).

IEVĒROJIET!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

2. Install torch mount (1). Only torch mounts having a hole pattern equivalent with the

mounting surface may be attached. If necessary, carefully press the cylindrical pins (4)

into the corresponding holes in the bracket. The pins should protrude by

approximately 5mm (0.2in.). Position the torch mount on the RTFL-2 (2) and

carefully insert the cylindrical pins (4) into the holes provided. Take the position of the

torch into account. Two mounting positions may be potentially possible.

3. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (5).

IEVĒROJIET!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

0463 373 101

- 29 -

© ESAB AB 2018

5 INSTALLATION

4 - Cylindrical pins Ø4×20

5 - Cylinder screw with hexagon socket M6

DIN 912 (length of the screw depending on

the torch mount)

Side view

Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. Avoid the formation of burrs. The pins should protrude by

approximately 5 mm (0.2 in.).

2. Position the mount on the RTFL-2 and carefully insert the cylindrical pins (1) into the

holes provided. In doing so, take the later position of the torch into account. Two

mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

IEVĒROJIET!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

0463 373 101

- 30 -

© ESAB AB 2018

5 INSTALLATION

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 - Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.2.2 RTFL-2 torch installation

Continue according to section "Torch installation".

5.3 RTKSC-2 hollow wrist system installation

5.3.1 RTKSC-2 mount with safety off mechanism

UZMANĪBU!

For hollow wrist systems make sure that the clear space around the robot is at least

Ø45 mm (1.8 in.) around the wrist and 50 mm (2.0 in.) near the wire feeder.

0463 373 101

- 31 -

© ESAB AB 2018

5 INSTALLATION

1. Remove the three screws (2) from the front cover (3) of the torch mount and carefully

pull the cover off the RTKSC-2 main body (5). Take care not to damage the micro

switches installed inside the assembly.

1 - Hexagon wrench 4 mm 4 - Rubber boot

2 - 3× M5×12 screws 5 - RT KSC-2 main body

3 - RT KSC-2 front cover

1. Pull off the rubber boot (4) from the RTKSC-2 main body (5) to the front.

2. Now position the RTKSC-2 main body (5) on the adapter flange (7) so that the index

pin is correctly seated. Attach with the screws (6) enclosed.

3. Reinstall the rubber boot (4) on the RTKSC-2 main body (5) and make sure it is

correctly located in the grooves on the front and back flange.

4. Istall the adapter flange (7) on the robot.

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 3 - 3× M5×12 hexagon socket screws

2 - Rubber boot 4 - Adapter flange

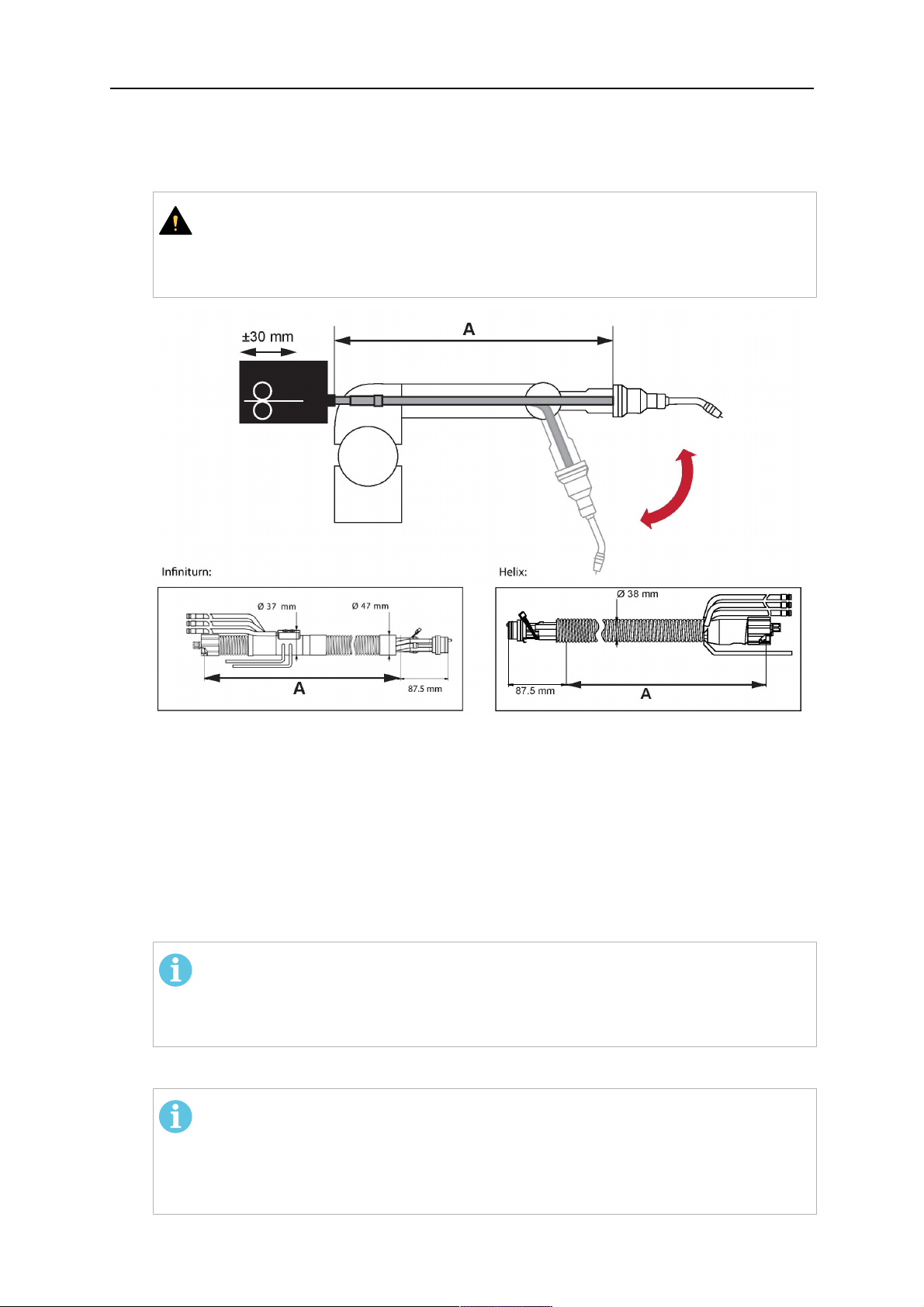

5.3.2 Mounting the cable assembly

IEVĒROJIET!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ±2-3cm (±1in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

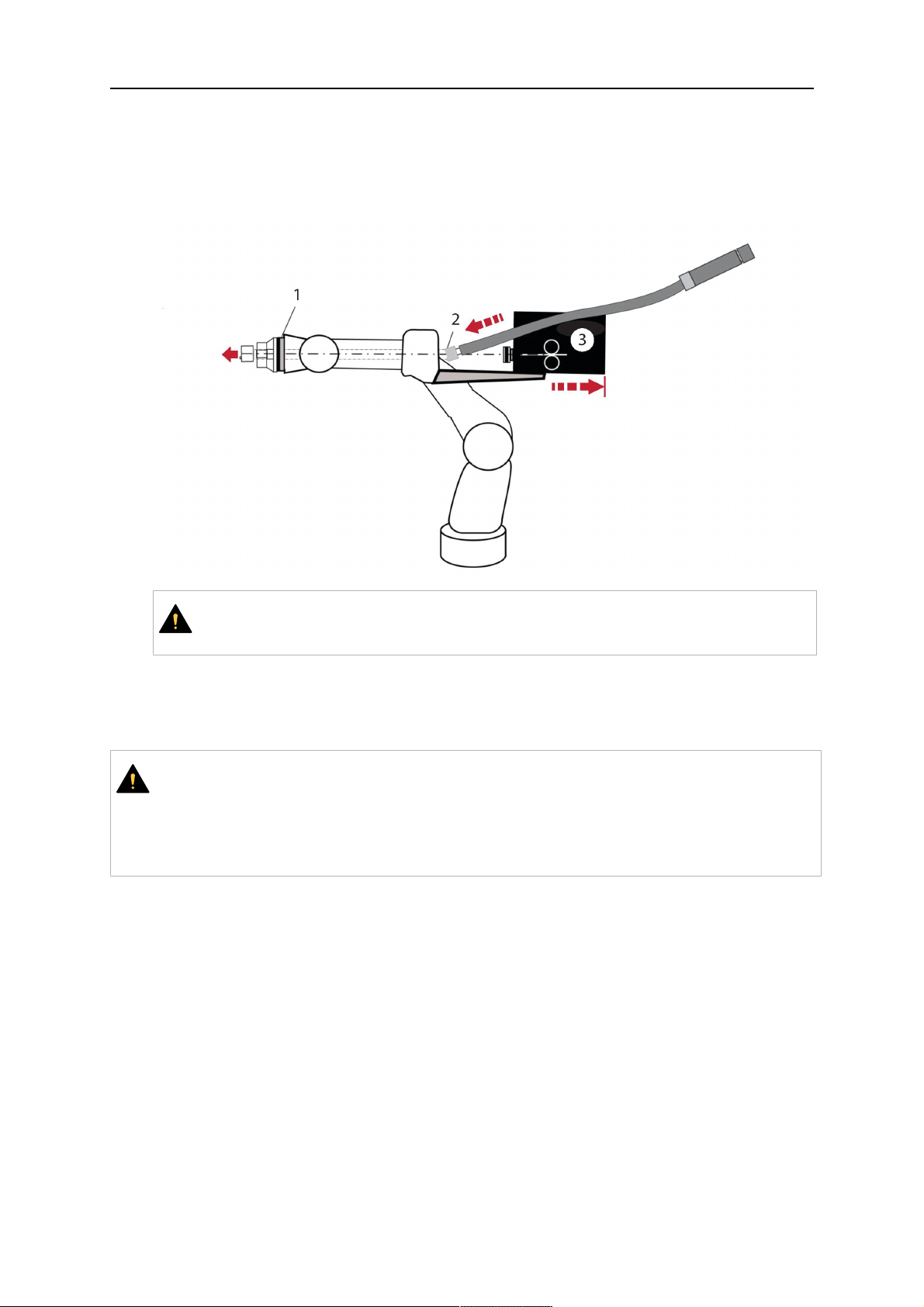

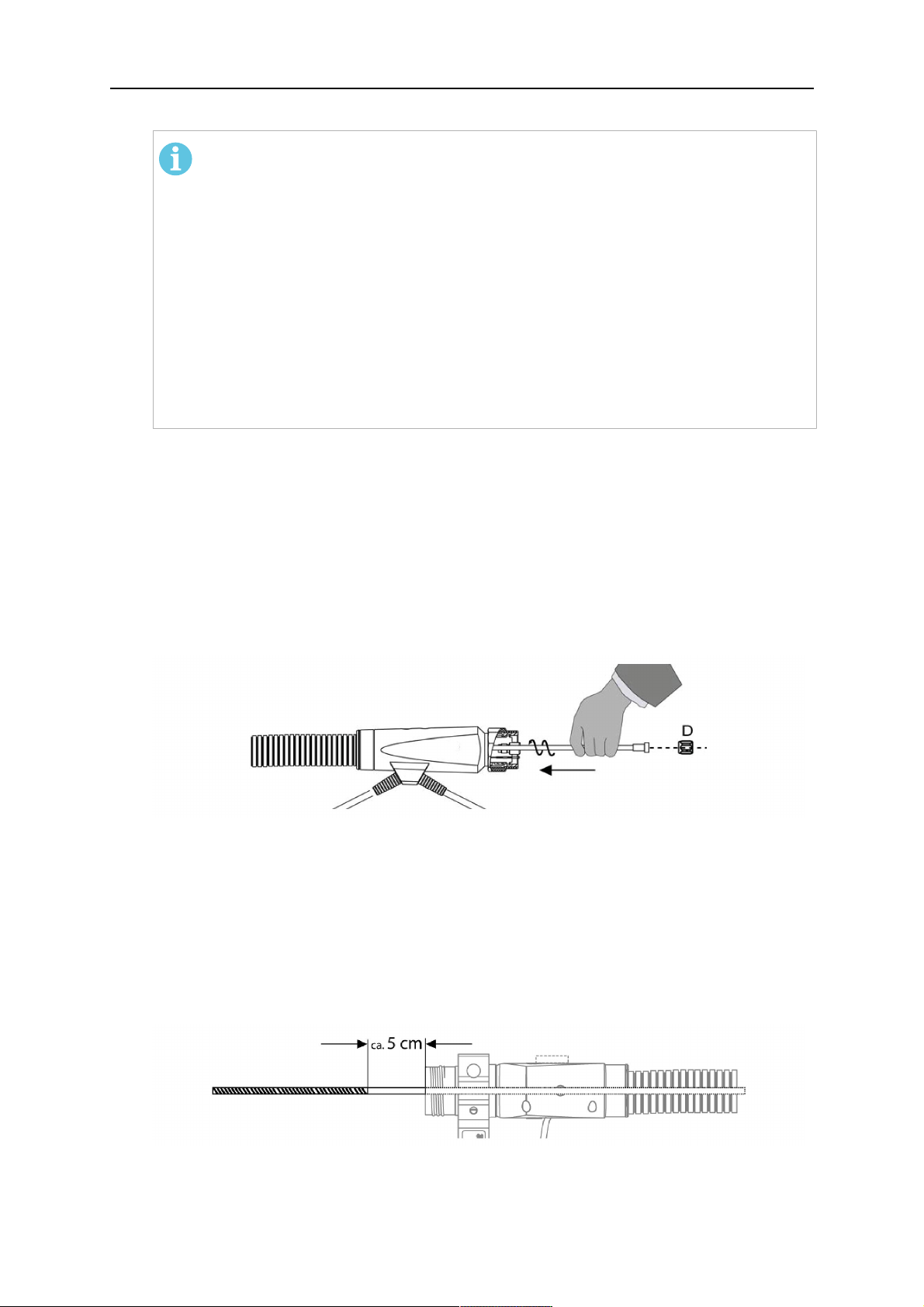

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

0463 373 101

- 32 -

© ESAB AB 2018

5 INSTALLATION

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

UZMANĪBU!

Axis 6 must be in 0° position.

5.3.2.1 RTKSC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

UZMANĪBU!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 33 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

UZMANĪBU!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connectors are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

IEVĒROJIET!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

IEVĒROJIET!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

0463 373 101

- 34 -

© ESAB AB 2018

5 INSTALLATION

5.3.3 RTKSC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

UZMANĪBU!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

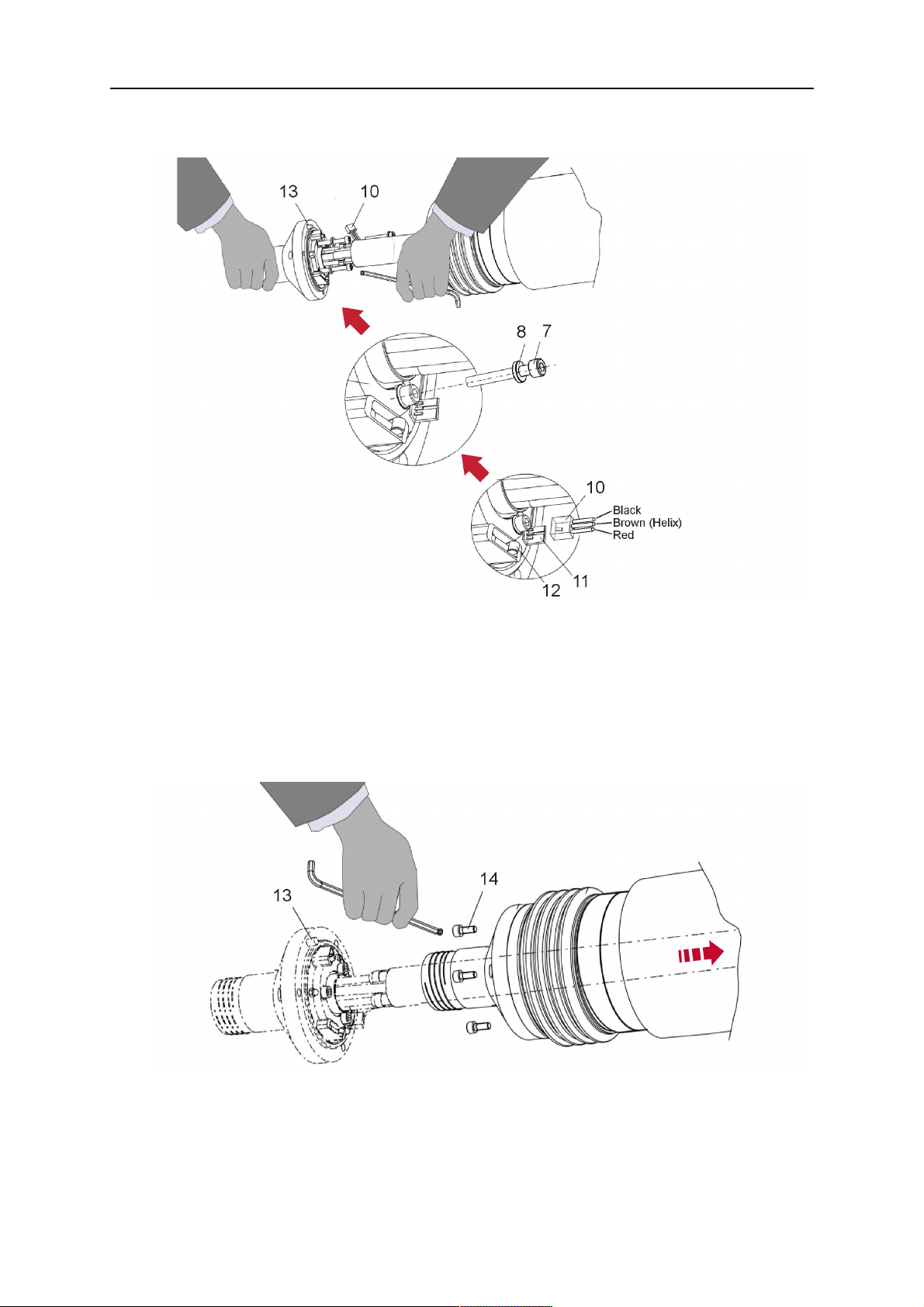

5.3.3.1 RTKSC-2 cable assembly installation

IEVĒROJIET!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2, then thread the cable from the front through the

robot arm. If in doubt, follow the suggested order.

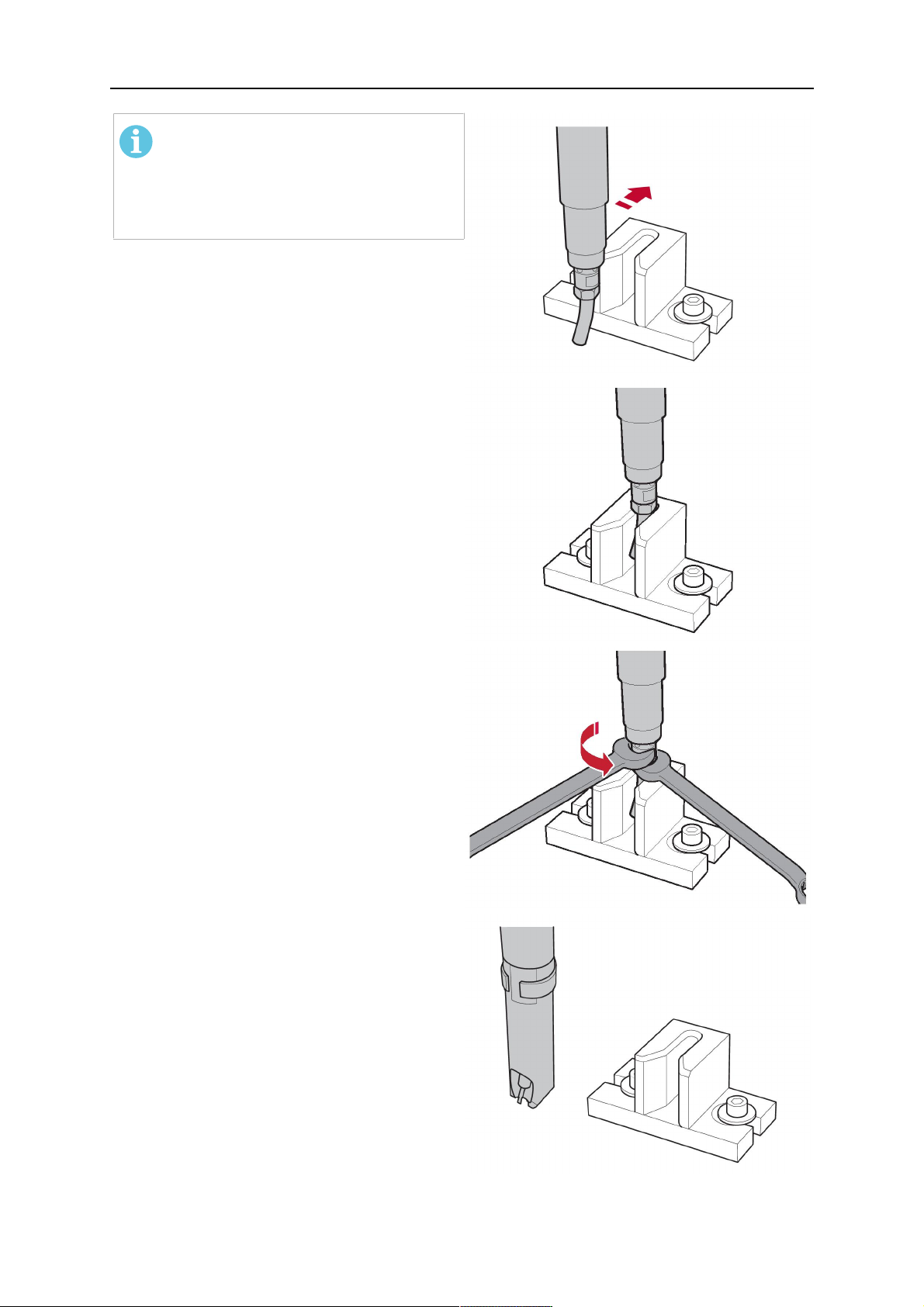

1. Loosen the three screws (7) with the associated washers and remove them from the

RTKSC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1).

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 35 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

IEVĒROJIET!

Make sure that the position of the O-rings are not shifted by the index pin

during the assembly.

1 - RTKSC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RTKSC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 36 -

© ESAB AB 2018

5 INSTALLATION

6. If present, insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTKSC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13. Index pin

14. 3× M5×12 screws

0463 373 101

- 37 -

© ESAB AB 2018

5 INSTALLATION

5.3.3.2 RTKSC-2 electrical connections

IEVĒROJIET!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then

implemented via the power source controller.

RTKSC-2 safety-off mechanism connection

The switch for the safety-off functionality RTKSC-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKSC-2 unit via the control cable plug

(1).

The safety-off signal requires a 2-wire connection (black/black) to the safety-off circuit in the

robot control (5).

If a collision is detected, the control circuit (normally closed) will be interrupted (4).

Rating of the control circuit: max. 48 V / 1 A.

1 - Control cable plug 3 - Burndy connector VVV

2 - EURO central connector

Burndy savienotāja tapas

A. Gāzes sprauslas

pieskāriena uztvērējs

C. Sadursmes sensors

F. 0V

G. + motora spriegums

H. - motora spriegums

D. Sadursmes sensors

E. Pakāpeniska padeve

RTKSC-2 nozzle sense function connection

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

0463 373 101

- 38 -

© ESAB AB 2018

5 INSTALLATION

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

BĪSTAMI

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

UZMANĪBU!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

5.3.4 RTKSC-2 torch installation

Continue according to section "Torch installation".

0463 373 101

- 39 -

© ESAB AB 2018

5 INSTALLATION

5.4 RTFLC-2 installation

5.4.1 RTFLC-2 mount

1. Remove the three M5 screws (2) from the front cover (3) of the RT FLC-2 torch mount

and carefully pull the cover off the main body (4).

1 - Hexagon wrench 4 mm 3 - RT FLC-2 front cover

2 - 3× M5×12 screws 4 - RT FLC-2 main body

2. Now position the RT FLC-2 main body (4) on the adapter flange (6) so that the index

pin is correctly seated. Attach with the screws (5) enclosed

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 5 - 3× M5×12 hexagon socket screws

4 - RT FLC-2 main body 6 - Adapter flange

5.4.2 RTFLC-2 wire feeder connection

5.4.2.1 Feeding through the robot arm

IEVĒROJIET!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ± 2-3 cm (± 1 in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

0463 373 101

- 40 -

© ESAB AB 2018

5 INSTALLATION

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

UZMANĪBU!

Important! Axis 6 must be in 0° position.

5.4.2.2 RTFLC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

UZMANĪBU!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 41 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

Refer to the instruction of the feeder manufacturer.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

UZMANĪBU!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connections are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

IEVĒROJIET!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

IEVĒROJIET!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

0463 373 101

- 42 -

© ESAB AB 2018

5 INSTALLATION

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

5.4.3 RTFLC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

UZMANĪBU!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.4.3.1 RTFLC-2 cable assembly installation

In a hollow wrist system the recommended order of installation is to feed the cable assembly

through the robot arm before connecting the cables to the torch mount.

When the cable assembly is correctly installed in the hollow wrist, continue the installation

according to the procedure described below.

IEVĒROJIET!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2 and RTFLC-2, then thread the cable from the front

through the robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTFLC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1). For gas cooled

systems, only one O-ring (4a) is needed, for water cooled systems all three O-rings

are needed.

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 43 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

IEVĒROJIET!

Take great care that the position of the O-rings is not shifted by the index pin

during the assembly.

1 - RT FLC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RT FLC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 44 -

© ESAB AB 2018

5 INSTALLATION

6. If present insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTFLC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13 - Index pin 14 - 3x M5x12 screws

0463 373 101

- 45 -

© ESAB AB 2018

5 INSTALLATION

5.4.4 RTFLC-2 electrical connections

IEVĒROJIET!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

documentation of the manufacturer for details. The link to the robot control is then

implemented via the power source controller.

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

BĪSTAMI

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

UZMANĪBU!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

0463 373 101

- 46 -

© ESAB AB 2018

5 INSTALLATION

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 1-wire connection (green) to the nozzle sense circuit

in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

BĪSTAMI

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

UZMANĪBU!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - EURO central connector

2 - Control cable 4 - Burndy connector

5.5 Torch installation

Be sure to use the correct version of the torch mount and cable assembly (water or gas

cooled).

5.5.1 Torch neck equipment

The torch neck, see (1) in the illustration below, must always be equipped to suit the wire

diameter and material.

0463 373 101

- 47 -

© ESAB AB 2018

5 INSTALLATION

1. Select the correct wire guide, contact tip (4), tip holder (2), gas nozzle (5), and gas

diffuser/spatter protection (3). You will find an exact overview and possible alternative

equipment elements for various torch models in the spare parts list. Only use original

ESAB parts; only then is the fitting accuracy ensured.

2. Firmly tighten the tip holder and the contact tip using a suitable tool for example the

enclosed monkey wrench.

3. When using a split wire guide, remove the installed guide nipple including the o-ring

from the torch flange upon delivery if necessary (see section "Installing the neck

liner").

UZMANĪBU!

The torch must be completely equipped before welding, especially the gas

diffuser and/or spatter protection and all necessary insulators have to be

installed according to the spare parts list. Welding without these items may

cause immediate destruction of the torch.

1 - Torch neck 4 - Contact tip

2 - Tip holder 5 - Contact tip

3 - Gas diffuser

5.5.2 Aristo RT torch neck installation

IEVĒROJIET!

Check the O-rings on the flange of the torch neck before mounting. Replace the

O-rings if damaged or lost. Missing or faulty O-rings will lead to leaks of shielding

gas and coolant.

1. For hollow wrist systems, insert the torch into the torch mount in the correct

orientation, so that the locator pin fits into the slot of the RTKSC-2 or RTFLC-2

interface, see (A) in the illustration below. For standard systems, attach the torch to

the RT flange of the cable assembly, (B) in the illustration below.

Installation is only possible in the correct orientation.

2. Tighten the locking nut of the torch neck.

IEVĒROJIET!

Only tighten by hand, never use tools or excessive force.

0463 373 101

- 48 -

© ESAB AB 2018

5 INSTALLATION

3. The correct seating of the torch can be checked by means of the window (1). If the

torch has been correctly mounted, no gap should be seen through the window (1).

5.6 Installing the wire guide for standard and hollow Wrist arm

Installing the wire guide

Choose the wire guide or liner depending on the filler wire material and diameter to be used,

see the spare parts list. Accurate performance of the system can only be guaranteed when

using original ESAB wire guides.

The recommended wire guide is the split wire guide, which consists of the neck liner and a

separate guide in the cable assembly. The front part of the wire guide, which is most

stressed, can be exchanged easily and independently of the cable assembly wire guide.

For correct installation, the following steps must be followed (example for Euro central

connector).

5.6.1 Installing the neck liner

The neck liner must be selected to fit the material and diameter of the welding wire, see the

spare parts list.

0463 373 101

- 49 -

© ESAB AB 2018

5 INSTALLATION

1. If present, remove the central guide nipple (1), from the torch neck using a hexagon

wrench (size 6 mm) or a large flat-blade screwdriver.

IEVĒROJIET!

The guide nipple (1) can only be used with one-piece liners and must not be

used with the standard RT or hollow wrist system.

2. When replacing the neck liner:

Unfasten the sleeve nut and remove the torch neck.

Unfasten the liner nipple using a hexagon wrench (size 6 mm) and remove nipple and

liner from the torch neck.

3. Remove the gas nozzle and the contact tip.

4. Insert the new neck liner (2) into the torch. Carefully tighten the guide nipple using a

suitable tool, e.g. a hex-wrench (size 6 mm) or a large flat-blade screwdriver.

5. Cut the neck liner flush with the tip holder and remove the neck liner from the torch.

6. Install the contact tip.

7. Insert the neck liner again. It will be stopped by the contact tip. Measure the excess

liner sticking out of the neck.

8. Remove the liner again and shorten the front end by the measured length. Carefully

deburr the edge and make sure that the inner hole is not blocked.

9. Reinstall the neck liner and tighten the guide nipple in the neck.

5.6.2 Installing a split wire guide in the cable assembly

The correct liner must be inserted to suit the filler material and the wire diameter, see the

spare parts list.

The wire guide is inserted through the cable assembly from the rear, reaching the guide

nipple that is installed in the flange where the torch neck will be attached. The following

worksteps must be followed in order to correctly determine the wire guide length. (Example

for Euro central connector).

0463 373 101

- 50 -

© ESAB AB 2018

5 INSTALLATION

1. For standard RT system: Install the guide nipple (1) in the center hole of the neck

support flange, see illustration A below.

For hollow wrist system: Install the guide nipple (1) into the torch interface of the

RTKSC-2 / RTFLC-2 cover, see illustration B below.

2. Remove the sleeve nut (2) from the central connector, and remove the old wire guide.

3. Insert the wire guide through the central connection and push forwards as far as it will

go into the guide nipple (1), applying light pressure.

UZMANĪBU!

Ensure that the wire guide has advanced right up to the stop at the front,

rotating and pushing forward gently.

4. Measure the excess length that needs to be cut from the wire guide.

5. Remove the wire guide again and shorten the front end by the measured length.

Steel liner: grind down the burred edges if needed.

Plastic liner: make a clean cut and chamfer the edges (e.g. with a pencil sharpener)

IEVĒROJIET!