RT Robo Welding Torch System

RTKS-2, RTFL-2, KSC-2, FLC-2, RT42, RT52,

RT62, RT72, RT82, RT42-NG, RT82WNG

Priručnik s uputama

0463 373 101 HR 20181227

SADRŽAJ

1

SIGURNOST ................................................................................................ 5

1.1 ZNAČENJE SIMBOLA............................................................................. 5

1.2 Mjere opreza ........................................................................................... 5

2

JAMSTVO .................................................................................................... 8

2.1 Uvjeti načina upotrebe ........................................................................... 8

3

UVOD ........................................................................................................... 9

3.1 Pregled sustava plamenika ................................................................... 9

4

TEHNIČKI PODACI ..................................................................................... 11

4.1 Vrat plamenika za zavarivanje............................................................... 11

4.2 Nazivni napon ......................................................................................... 12

4.2.1 Ograničenja rashladnog sklopa ............................................................ 12

4.3 Nosač plamenika .................................................................................... 13

4.3.1 Montiranje plamenika na standardni RT sustav ................................... 13

4.3.1.1 RTKS-2 sigurnosni mehanizam........................................................ 14

4.3.1.2 RTFL-2 srednja prirubnica................................................................ 14

4.3.2 Nosač plamenika za šuplji zglobni sustav ............................................ 14

4.3.2.1 RTKSC-2 G/W nosač plamenika sa sigurnosnim mehanizmom ...... 16

4.3.2.2 RTFLC-2 G/W nesavitljivi nosač plamenika ..................................... 17

4.4 Adapterske prirubnice ........................................................................... 18

4.5 Kabelski sklopovi ................................................................................... 18

4.5.1 Vrat plamenika za standardni RT sustav .............................................. 18

4.5.2 Kabelski sklop za sustav šupljih zglobova............................................ 19

5

INSTALLATION............................................................................................ 21

5.1 RTKS-2 standard arm installation........................................................ 21

5.1.1 RTKS-2 safety-off mechanism............................................................. 21

5.1.1.1 Torch installation with adjustable mount............................................ 22

5.1.2 Standard arm cable assembly for KS-2 and FL-2 ................................ 24

5.1.3 RTKS-2 wire feeder connection........................................................... 25

5.1.4 RTKS-2 electrical connections ............................................................ 26

5.1.4.1 RTKS-2 safety-off mechanism connection ....................................... 26

5.1.5 RTKS-2 Torch installation .................................................................... 27

5.2 RTFL-2 standard arm installation ........................................................ 28

5.2.1 RTFL-2 rigid mount.............................................................................. 28

5.2.2 RTFL-2 torch installation ..................................................................... 30

5.3 RTKSC-2 hollow wrist system installation.......................................... 30

5.3.1 RTKSC-2 mount with safety off mechanism ........................................ 30

5.3.2 Mounting the cable assembly............................................................... 31

5.3.2.1 RTKSC-2 feeder cabinet connections .............................................. 32

5.3.3 RTKSC-2 cable assembly ................................................................... 34

5.3.3.1 RTKSC-2 cable assembly installation .............................................. 34

5.3.3.2 RTKSC-2 electrical connections....................................................... 37

0463 373 101 © ESAB AB 2018

SADRŽAJ

5.3.4 RTKSC-2 torch installation .................................................................. 38

5.4 RTFLC-2 installation.............................................................................. 39

5.4.1 RTFLC-2 mount................................................................................... 39

5.4.2 RTFLC-2 wire feeder connection......................................................... 39

5.4.2.1 Feeding through the robot arm.......................................................... 39

5.4.2.2 RTFLC-2 feeder cabinet connections............................................... 40

5.4.3 RTFLC-2 cable assembly .................................................................... 42

5.4.3.1 RTFLC-2 cable assembly installation ............................................... 42

5.4.4 RTFLC-2 electrical connections .......................................................... 45

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly........... 45

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly................. 46

5.5 Torch installation.................................................................................... 46

5.5.1 Torch neck equipment .......................................................................... 46

5.5.2 Aristo RT torch neck installation........................................................... 47

5.6 Installing the wire guide for standard and hollow Wrist arm ............. 48

5.6.1 Installing the neck liner......................................................................... 48

5.6.2 Installing a split wire guide in the cable assembly................................ 49

5.6.3 Installing a continuous wire guide in the cable assembly..................... 51

5.7 Adjust the narrow gap contact tip ........................................................ 52

6

OPERATION ................................................................................................ 55

6.1 Important information for programming (hollow wrist system only) 55

7

SERVISIRANJE I ODRŽAVANJE................................................................ 57

7.1 Obavezne provjere i postupci ............................................................... 57

8

OTKLANJANJE POTEŠKOĆA ................................................................... 59

9

NARUČIVANJE REZERVNIH DIJELOVA ................................................... 61

Zadržavamo pravo na preinake bez prethodne obavijesti.

0463 373 101 © ESAB AB 2018

1 SIGURNOST

1 SIGURNOST

1.1 ZNAČENJE SIMBOLA

U cijelom priručniku: Znači oprez! Budite na oprezu!

OPASNOST!

Znači neposrednu opasnost koja će, ako se ne izbjegne, trenutačno dovesti

do ozbiljne tjelesne ozljede ili smrti.

UPOZORENJE!

Znači potencijalnu opasnost koja bi mogla dovesti do tjelesne ozljede ili

smrti.

OPREZ!

Znači opasnost koja bi mogla dovesti do manje ozljede.

UPOZORENJE!

Prije korištenja pročitajte i usvojite priručnik s uputama

te se pridržavajte uputa na svim oznakama, sigurnosnih

praksi poslodavca i sigurnosnih listova (SDS).

1.2 Mjere opreza

Korisnici opreme tvrtke ESAB snose krajnju odgovornost za poštivanje svih odgovarajućih

sigurnosnih mjera opreza od strane osoba koje rade s opremom ili bliskih promatrača.

Sigurnosne mjere opreza moraju ispunjavati zahtjeve za ovu vrstu opreme. Uz standardne

propise za radno mjesto potrebno je poštivati i sljedeće preporuke:

Sav posao mora obavljati obučeno osoblje koje je dobro upoznato s rukovanjem opremom.

Nepravilno rukovanje opremom može stvoriti opasne situacije koje mogu uzrokovati ozljede

rukovatelja i oštetiti opremu.

1. Svatko tko koristi opremu mora biti upoznat:

○ s rukovanjem

○ s položajima uređaja za zaustavljanje u nuždi

○ njenom svrhom

○ s odgovarajućim sigurnosnim mjerama opreza

○ sa zavarivanjem, rezanjem te drugim mogućim primjenama opreme

2. Rukovatelj ne smije dopustiti:

○ da se neovlašteno osoblje zadržava unutar radnog područja opreme nakon

njenog uključivanja

○ prisutnost nezaštićenih osoba nakon ukidanja luka ili početka rada s opremom

3. Radno mjesto mora biti:

○ prikladno za namjenu

○ bez propuha

0463 373 101

- 5 -

© ESAB AB 2018

1 SIGURNOST

4. Osobna zaštitna oprema:

○ Uvijek nosite osobnu zaštitu opremu poput zaštitnih naočala, vatrostalne odjeće i

zaštitnih rukavica

○ Nemojte nositi labave predmete poput šalova, narukvica, prstenja itd. jer se oni

mogu zaglaviti ili uzrokovati opekline

5. Općenite mjere opreza:

○ Povratni kabel mora biti čvrsto priključen

○ Rad na visokonaponskoj opremi smije obavljati samo kvalificirani električar

○ Prikladna oprema za gašenje požara mora biti jasno označena i nadohvat ruke

○ Podmazivanje i održavanje opreme ne smije se obavljati za vrijeme rada

UPOZORENJE!

Zavarivanje i rezanje lukom može uzrokovati osobne ozljede i ozljede drugih.

Prilikom zavarivanja i rezanja poduzmite mjere opreza.

STRUJNI UDAR – može biti smrtonosan

• Jedinicu instalirajte i uzemljite u skladu s priručnikom s uputama.

• Električne dijelove pod naponom ili elektrode nemojte dodirivati golom

kožom, mokrim rukavicama ili mokrom odjećom.

• Izolirajte se od dijelova na kojima radite i uzemljite se.

• Provjerite je li radno mjesto sigurno

ELEKTRIČNA I MAGNETSKA POLJA – mogu biti štetna za zdravlje

• Zavarivači koji nose srčani elektrostimulator trebali bi se savjetovati s

liječnikom prije zavarivanja. Elektromagnetska polja mogu ometati neke

srčane elektrostimulatore.

• Izlaganje elektromagnetskim poljima može imati i druge, još nepoznate

posljedice.

• Zavarivači bi na sljedeće načine trebali smanjiti izlaganje

elektromagnetskim poljima:

○ Kabele elektroda i radne kabele držite s iste strane tijela. Kad je to

moguće, pričvrstite ih ljepljivom trakom. Ne postavljajte se između

kabela plamenika i radnih kabela. Nikada ne omatajte kabel

plamenika ili radni kabel oko tijela. Držite izvor napajanja za

zavarivanje i kabele što dalje od sebe.

○ Radni kabel pričvrstite na radni dio što bliže mjestu koje zavarujete.

PARE I PLINOVI – mogu biti štetni za zdravlje

• Glavu držite izvan isparenja.

• Koristite ventilaciju, izvlačenje na luku ili oboje kako biste pare i plinove

odveli iz područja disanja i bližeg okruženja.

ZRAKE LUKA – mogu ozlijediti oči i opeći kožu

• Zaštitite oči i tijelo. Koristite odgovarajuću masku za zavarivanje i filtarska

stakla te nosite zaštitnu odjeću.

• Zaštitite promatrače odgovarajućim pregradama ili zastorima.

0463 373 101

BUKA – prevelika buka može oštetiti sluh

Zaštitite uši. Koristite naušnjake ili drugu zaštitu za sluh.

- 6 -

© ESAB AB 2018

1 SIGURNOST

POKRETNI DIJELOVI - mogu izazvati ozljede

• Sva vrata, ploče i poklopce držite zatvorene i dobro osigurane. Kada je to

potrebno, neka samo kvalificirani ljudi skidaju poklopce radi održavanja i

otklanjanja poteškoća. Nakon servisiranje, a prije pokretanja motora,

najprije vratite ploče, poklopce i zatvorite vratašca.

• Zaustavite motor prije montiranja ili priključivanja jedinice.

• Ruke, kosu, viseće dijelove odjevnih predmeta i alate držite dalje od

pokretnih dijelova.

OPASNOST OD POŽARA

• Iskre (prskanje) mogu uzrokovati požar. Pobrinite se da u blizini ne bude

zapaljivih materijala

• Nije za upotrebu na zatvorenim spremnicima.

KVAR – u slučaju kvara zatražite stručnu pomoć.

ZAŠTITITE SEBE I DRUGE!

OPREZ!

Proizvod je namijenjen isključivo za lučno zavarivanje.

UPOZORENJE!

Izvor napajanja nemojte koristiti za topljenje zamrznutih cijevi.

OPREZ!

Oprema klase A nije namijenjena za korištenje u

stambenim prostorima u kojima se električna energija

isporučuje javnim niskonaponskim sustavom. U tim

prostorima postoje potencijalni problemi osiguravanja

elektromagnetske kompatibilnosti opreme klase A zbog

vođenih i zračenih smetnji.

NAPOMENA!

Elektroničku opremu odstranite u reciklažnom

postrojenju!

U skladu s Europskom Direktivom 2012/19/EU o

otpadnoj električnoj i elektroničkoj opremi i njenom

primjenom u skladu s nacionalnim zakonom električna

i/ili elektronička roba kojoj je istekao uporabni vijek mora

se zbrinuti u reciklažnom postrojenju.

Kao osoba odgovorna za opremu dužni ste nabaviti

informacije o ovlaštenim sakupljačkim stanicama.

Za dodatne informacije obratite se najbližem distributeru

tvrtke ESAB.

Tvrtka ESAB na prodaju nudi cijeli asortiman dodatne opreme za zavarivanje i osobne

zaštitne opreme. Za informacije o naručivanju obratite se svojem distributeru tvrtke

ESAB ili nas posjetite na našoj internetskoj stranici.

0463 373 101

- 7 -

© ESAB AB 2018

2 JAMSTVO

2 JAMSTVO

Naši proizvodi temeljito su provjereni prije isporuke. ESAB potvrđuje da niti jedan proizvod

nije pokazivao nedostatke u materijalu i izradi u vrijeme isporuke te da svi funkcioniraju u

skladu s propisanom namjenom.

ESAB daje jamstvo za nedostatke u materijalu i izradi u skladu sa zakonskim zahtjevima.

Potrošni materijal čini iznimku od ovog jamstva.

Jamstvo ne obuhvaća štetu ili funkcionalne nedostatke koji mogu nastati kao posljedica:

• preopterećenja, zloupotrebe ili upotrebe proizvoda u svrhe koje se ne poklapaju s

propisanima

• sudara ili nesreća

• nepoštivanja uputa navedenih u ovom priručniku za upotrebu

• nepropisne instalacije ili montaže

• nepropisnog održavanja

• mijenjanja proizvoda iz izvornog stanja

• kemijskih utjecaja

• uobičajeno trošenje i habanje

ESAB ne preuzima nikakvu odgovornost osim za zamjenu ili popravak neispravnih dijelova.

2.1 Uvjeti načina upotrebe

1. Proizvod je namijenjen za industrijsku i komercijalnu upotrebu i mora ga koristiti samo

ovlaštena osoba. Proizvođač nije odgovoran ni za kakvu štetu ili nesreću nastalu zbog

neprimjerene uporabe.

2. Sustav Aristo® RT Robotic Welding osmišljen je i proizveden u skladu s najnovijim

standardima te je siguran i pouzdan za uporabu kada ga montira i održava stručna

osoba. Valja se pridržavati uputa za montiranje, uporabu i održavanje opisanih u ovom

dokumentu.

3. Samo ovlaštena osoba smije montirati i održavati sustav Aristo® RT Robotic Welding

te upravljati njime. Valja se pridržavati propisa o montiranju, uporabi i održavanju iz

ovog priručnika.

4. Sustav Aristo® RT Robotic Welding jedino se smije upotrebljavati u svrhu koju je

propisao proizvođač u okviru tehničkih podataka i sustava za automatsko upravljanje.

Vrsta plamenika mora se odabrati tako da odgovara zadatku zavarivanja.

5. Sustav Aristo® RT Robotic Welding namijenjen je za uporabu kao cjelovit sustav. Nije

dopuštena ugradnja dijelova drugog proizvođača u sustav.

6. RT KS-2 i RT KSC-2 smiju se rabiti samo kao mehanizam za zaustavljanje u nuždi

unutar tehničkih specifikacija i u kombinaciji sa standardnim RT kabelskim sklopom

ruke (KS-2), sklopom Infiniturn ili Helix (KSC-2), ESAB adapterskom prirubnicom, što

obuhvaća RT nosače plamenika (KS-2) i plamenik za zavarivanje Aristo RT.

7. U ispuh plina ne smije se dodavati ulje niti tekućina protiv prskanja. ESAB ne pruža

jamstvo za kemijsku otpornost na ove supstance. ESAB preporučuje uporabu ESAB

jedinice za prskanje kako bi se trošila minimalna količina tekućine protiv prskanja za

plamenik i zbog zaštite okoliša.

8. Proizvod valja čuvati na suhom i u zaštićenim uvjetima prilikom transporta,

skladištenja ili uporabe.

9. Sustav je namijenjen za temperaturu okoliša od 5 °C do 40 °C (41 °F o 104 °F). Ako

se prekorače ograničenja potrebne su sljedeće radnje. U slučaju rizika od smrzavanja

koristiti odgovarajuće rashladno sredstvo.

0463 373 101

- 8 -

© ESAB AB 2018

3 UVOD

3 UVOD

Sustav RT plamenika razvijen je za potpuno automatski MIG/MAG zavarivanje pomoću

robota. Sustav se sastoji od različitih Aristo RT vratova plamenika namijenjenih za robotsko

korištenje, nosača plamenika, kabelskih sklopova optimiziranih za robotsku upotrebu i

postavki sigurnosti da bi se zaštitio sustav od oštećenja u slučaju kolizije.

RT sustav za zavarivanje pruža zaštitu od kolizije uz pomoć RT KS-2 sigurnosne mehaničke

opruge. Ovo se po potrebi može zamijeniti s RT FL-2 kako bi se iskoristila funkcija detekcije

kolizije na robotskom kontrolnom sustavu. RT sustav za zavarivanje može se koristiti s

različitim vrstama kabelskih sklopova.

RTKSC-2 i RTFLC-2 nosač plamenika s kabelskim sklopovima Infiniturn ili Helix namijenjeni

su za uporabu u robotskom šupljem zglobnom sustavu namijenjenom za naprednu primjenu

zavarivanja. Sigurnosni mehanizam kod RTKSC-2 nosača plamenika dozvoljava veliki

elastični otklon plamenika u slučaju kolizije. Kabelski sklopovi Infiniturn i Helix jednostavni su

za montiranje te pružaju visoko pouzdan sustav s preciznim manevarskim mogućnostima.

U kombinaciji s dobro postavljenim Aristo RT robotskim plamenicima, ovi dijelovi tvore visoko

pouzdan i dugotrajan sustav kojem je potrebna minimalna razina održavanja.

Priručnik s uputama dostavlja se uz nosače plamenika i kabelske sklopove.

Na popisu rezervnih dijelova nalaze se: ESAB brojevi za naručivanje, dodatna oprema,

rezervni dijelovi i potrošni dijelovi.

3.1 Pregled sustava plamenika

Standardni RT sustav

Za detaljan opis pratite odgovarajuće

odlomke u poglavlju TEHNIČKI PODACI:

1. Vrat plamenika

Pogledajte "Plamenik za

zavarivanje".

2. Kabelski sklop

Pogledajte "Vrat plamenika za

standardni RT sustav".

3. Montiranje plamenika

Pogledajte "Montiranje plamenika za

standardni RT sustav".

4. RTKS-2 sigurnosni mehanizam

Pogledajte "RTKS-2 sigurnosni

mehanizam".

5. RTFL-2 srednja prirubnica

Pogledajte "RTFL-2 srednja

prirubnica".

6. Adapterska prirubnica (ako je

potrebno)

Pogledajte "Adapterska prirubnica".

0463 373 101

- 9 -

© ESAB AB 2018

3 UVOD

Sustav šupljih zglobova

Za detaljan opis pratite odgovarajuće

odlomke u poglavljima TEHNIČKIH

PODATAKA.

1. Vrat plamenika

Pogledajte "Plamenik za

zavarivanje".

2. Montiranje plamenika RT KSC-2

Pogledajte "RTKS-2 montiranje

plamenika sa sigurnosnim

mehanizmom".

3. Nosač plamenika RTFLC-2

Pogledajte "RTFLC-2 nesavitljivi

nosač plamenika".

4. Adapterska prirubnica

Pogledajte "Adapterska prirubnica".

5. Kabelski sklop Helix ili Infiniturn

Pogledajte "Kabelski sklop za

sustav šupljih zglobova".

0463 373 101

- 10 -

© ESAB AB 2018

4 TEHNIČKI PODACI

4 TEHNIČKI PODACI

4.1 Vrat plamenika za zavarivanje

Izaberite model plamenika sukladno namjeni zavarivanja. Mora se uzeti u obzir potreban

radni ciklus i kapacitet, načini hlađenja i promjer žice. Ako postoje povećani preduvjeti,

primjerice zbog unaprijed zagrijanih dijelova s kojima se radi ili velike refleksije topline u

kutovima itd., ti preduvjeti moraju se uzeti u obzir kako bi se odabrao onaj plamenik za

zavarivanje s adekvatnom rezervom u nazivnom opterećenju.

RT plamenici za zavarivanje namijenjeni su za uporabu s izvorima napajanja usklađenim s

CE za sljedeće procese zavarivanja: zavarivanje MIG postupkom, zavarivanje MAG

postupkom i MIG tvrdo lemljenje s komercijalnim okruglim žicama. Ne rabite plamenik za

druge procese.

RT 82W plamenik hlađen vodom mora se koristiti za impulsno lučno zavarivanje čelika ili

aluminija.

U nastavku pogledajte raspoložive modele plamenika.

Model plamenika Metoda hlađenja Zaštitni plin Vrijednost

RT42G Plinom hlađeni CO

Plinom hlađeni 300A 100%

Plinom hlađeni Mješavina 350A 60%

Plinom hlađeni 250A 100%

RT42W Vodom hlađeni CO

Vodom hlađeni 420A 100%

Vodom hlađeni Mješavina 350A 60%

Vodom hlađeni 350A 100%

RT52G Plinom hlađeni CO

Plinom hlađeni 300A 100%

Plinom hlađeni Mješavina 350A 60%

Plinom hlađeni 250A 100%

RT52W Vodom hlađeni CO

Vodom hlađeni 470A 100%

Vodom hlađeni Mješavina 400A 60%

Vodom hlađeni 400A 100%

RT62G Plinom hlađeni CO

Plinom hlađeni 340A 100%

2

2

2

2

2

420A 60%

420A 60%

420A 60%

470A 60%

500A 60%

Plinom hlađeni Mješavina 420A 60%

Plinom hlađeni 290A 100%

RT62W Vodom hlađeni CO

Vodom hlađeni 530A 100%

Vodom hlađeni Mješavina 450A 60%

Vodom hlađeni 450A 100%

0463 373 101

- 11 -

2

530A 60%

© ESAB AB 2018

4 TEHNIČKI PODACI

Model plamenika Metoda hlađenja Zaštitni plin Vrijednost

RT72G Plinom hlađeni CO

2

480A 60%

Plinom hlađeni 320A 100%

Plinom hlađeni Mješavina 400A 60%

Plinom hlađeni 270A 100%

RT72W Vodom hlađeni CO

2

480A 60%

Vodom hlađeni 430A 100%

Vodom hlađeni Mješavina 480A 60%

Vodom hlađeni 430A 100%

RT82W Vodom hlađeni CO

2

600A 60%

Vodom hlađeni 600A 100%

Vodom hlađeni Mješavina 550A 60%

Vodom hlađeni 550A 100%

Vrijednost nazivnih podataka plamenika i radnog ciklusa vrijede za ciklus od 10 minuta.

Tehnički podaci vrijede za standardne primjene potrošnih i rezervnih dijelova. Nazivni podaci

plamenika smanjuju se pri uporabi načina prijenosa impulsnog lučnog zavarivanja.

Rasponi temperature Pohrana: -15–50°C (5–122°F)

Rad: 5 – 40°C (41 – 104°F)

Ispušni plin Maks. 10 bar, zasebna cijev za plin

Ukupna težina (vrat plamenika, sigurnosni

Približno 5 kg

mehanizam, nosač plamenika i 1 m kabelskih

sklopova)

4.2 Nazivni napon

Maks. dozvoljeni napon / jakost struje

Cijeli sustav plamenika 141 V (najviša vrijednost zavarivanja)

Upravljački sklop RTKS-2 sigurnosnog

mehanizma

RTKS-2 tipka

RT KSC-2 sigurnosni mehanizam

upravljačkog kruga

Korištenje funkcije mlaznice osjetljive na

dodir sa standardnim kabelskim sklopom.

Korištenje mlaznice osjetljive na dodir sa

standardnim kabelskim sklopom.

24 V / 1 A

48 V / 0,1 A

48 V

50 V / 5 A

(Dozvoljeno opterećenje maks. 1 minuta pri

nominalnoj nazivnoj struji)

50 V / 5 A

(Dozvoljeno opterećenje maks. 1 minuta pri

nominalnoj nazivnoj struji)

Nazivna opterećenja odnose se na standardne načine upotrebe.

Za nazivne podatke kabelskog sklopa, pogledajte odjeljak "Kabelski sklopovi".

4.2.1 Ograničenja rashladnog sklopa

Samo za plamenike s vodenim hlađenjem.

0463 373 101

- 12 -

© ESAB AB 2018

4 TEHNIČKI PODACI

Minimalna brzina protoka

vode:

1.0 l/min (1.1 litre/minuti)

minimalni tlak vode: 2,5 bara (36,3 Mpa)

maksimalni tlak vode: 3,5 bara (50,8 Mpa)

Ulazna temperatura: Maks. 40 °C (104 °F)

Povratna temperatura: Maks. 60 °C (140 °F)

Kapacitet hlađenja: Min. 1000 W, ovisno o primjeni

OPREZ!

Povratna temperatura iznad 60 °C (140 °F) može uzrokovati oštećenja ili uništiti

kabelske sklopove.

4.3 Nosač plamenika

Potrebne vrste nosača plamenika ovise o dizajnu sustava RT plamenika i o izboru uređaja

sigurnosnog mehanizma, pogledajte odjeljak "Pregled sustava plamenika za zavarivanje"

Komponenta Približna težina

Nosač plamenika (standardni sustav) 0,43 kg

RTKS-2 sigurnosni mehanizam (za

standardni sustav)

0,85 kg

RTFL-2 srednja prirubnica (za standardni

0,35 kg

sustav)

RTKSC-2 nosač plamenika (za šuplji zglobni

1,90 kg

sustav)

RTFLC-2 nesavitljivi nosač plamenika (za

1,22 kg

šuplji zglobni sustav)

Robotski plamenik za zavarivanje 0,66 kg

4.3.1 Montiranje plamenika na standardni RT sustav

Kod standardnog RT sustava plamenik se montira na RTKS-2 sigurnosni mehanizam

(alternativno može i na RT FL-2 srednju prirubnicu), povezujući kabelski sklop i priključeni

vrat plamenika.

Izaberite nosač plamenika u skladu s vrstom plamenika i njegovom geometrijom. Mogu se

rabiti različite vrste nosača. Pregledajte popis rezervnih dijelova za dostupne nosače

plamenika za RT standardni sustav.

0463 373 101

- 13 -

© ESAB AB 2018

4 TEHNIČKI PODACI

Nosač plamenika za standardne robotske ruke

4.3.1.1 RTKS-2 sigurnosni mehanizam

RTKS-2 sigurnosni mehanizam opruge za podršku uređaja koji štiti robota i sustav za

zavarivanje u slučaju kolizije.

NAPOMENA!

Nemojte rastavljati RTKS-2.

4.3.1.2 RTFL-2 srednja prirubnica

Nesavitljiva srednja prirubnica RTFL-2 može se rabiti umjesto RTKS-2 ukoliko robot ima

elektronički sustav za otkrivanje kolizije.

4.3.2 Nosač plamenika za šuplji zglobni sustav

Kod šupljeg zglobnog sustava Aristo RT vrat plamenika za zavarivanje povezuje se s

nosačem plamenika KSC-2 ili FLC-2.

Nosača plamenika RTKSC-2 omogućuje elastični otklon plamenika u slučaju kolizije.

Istodobno, električni kontakt je otvoren, signalizirajući robotskim kontrolama za se zaustave.

Početna geometrija i Tool Center Point (TCP) plamenika bit će postignuti uz visoku

preciznost nakon poništavanja greške . Sustav funkcionira posve mehanički, uz pomoć

opruga.

Nosač plamenika RTFLC-2 nema ugrađenu sigurnosnu funkciju.

0463 373 101

- 14 -

© ESAB AB 2018

4 TEHNIČKI PODACI

Preporučuje se za šuplje zglobne sustave RTKSC-2 G/W (alternativno RTFLC-2 G/W).

Nosač plamenika može se rabiti i kod plamenika hlađenih plinom i kod plamenika hlađenih

vodom iz Aristo RT serije.

RTKSC-2 G/W RTFLC-2 G/W

Način funkcioniranja

sigurnosnog mehanizma

Mehanički Nije primjenjivo (nesavitljivi

nosač)

Osna otpusna sila (Fz) 650 N Nije primjenjivo (nesavitljivi

nosač)

Otpusna kočnica dijagonalne

osi (Mx)

Ponovno postaviti nakon

otpuštanja

Ponovljivost Bočno ± 0.1 mm na TCP-u

24 Nm Nije primjenjivo (nesavitljivi

nosač)

Automatsko Nije primjenjivo (nesavitljivi

nosač)

Nije primjenjivo (nesavitljivi

standardnog Aristo RT

nosač)

plamenika

Maks. otklon Oko ± 8° Nije primjenjivo (nesavitljivi

nosač)

Sigurnosni prekidač U normalnom stanju

zatvoreno

Električno opterećenje maks.

48 V / 1A

0463 373 101

- 15 -

Nije primjenjivo (nesavitljivi

nosač)

© ESAB AB 2018

4 TEHNIČKI PODACI

Električni upravljački sklop za

funkciju osjetne mlaznice

Vrijednost:

• Za Helix kabelski sklop:

maks. 50 V DC / 5 A,

maks. 1 minuta

Nakon otkrivanja

kontakta brzo isključite

detekciju napona.

• Za Infiniturn kabelski

sklop funkcija

osjetljivosti mlaznice ima

Ocjena:

• Za Helix kabelski sklop:

maks. 50 V DC / 5 A,

maks. 1 minuta

• Za Infiniturn kabelski

sklop: maks. 50 V DC /

1 A, maks. 1 minuta

Nakon otkrivanja kontakta

brzo isključite detekciju

napona.

ograničenu

funkcionalnost.

Kontaktirajte ESAB za

više informacija o

mogućim rješenjima kod

uporabe.

Nazivni napon Maksimalni dopušteni napon

za sigurnost upravljačkog

kruga: 48 V.

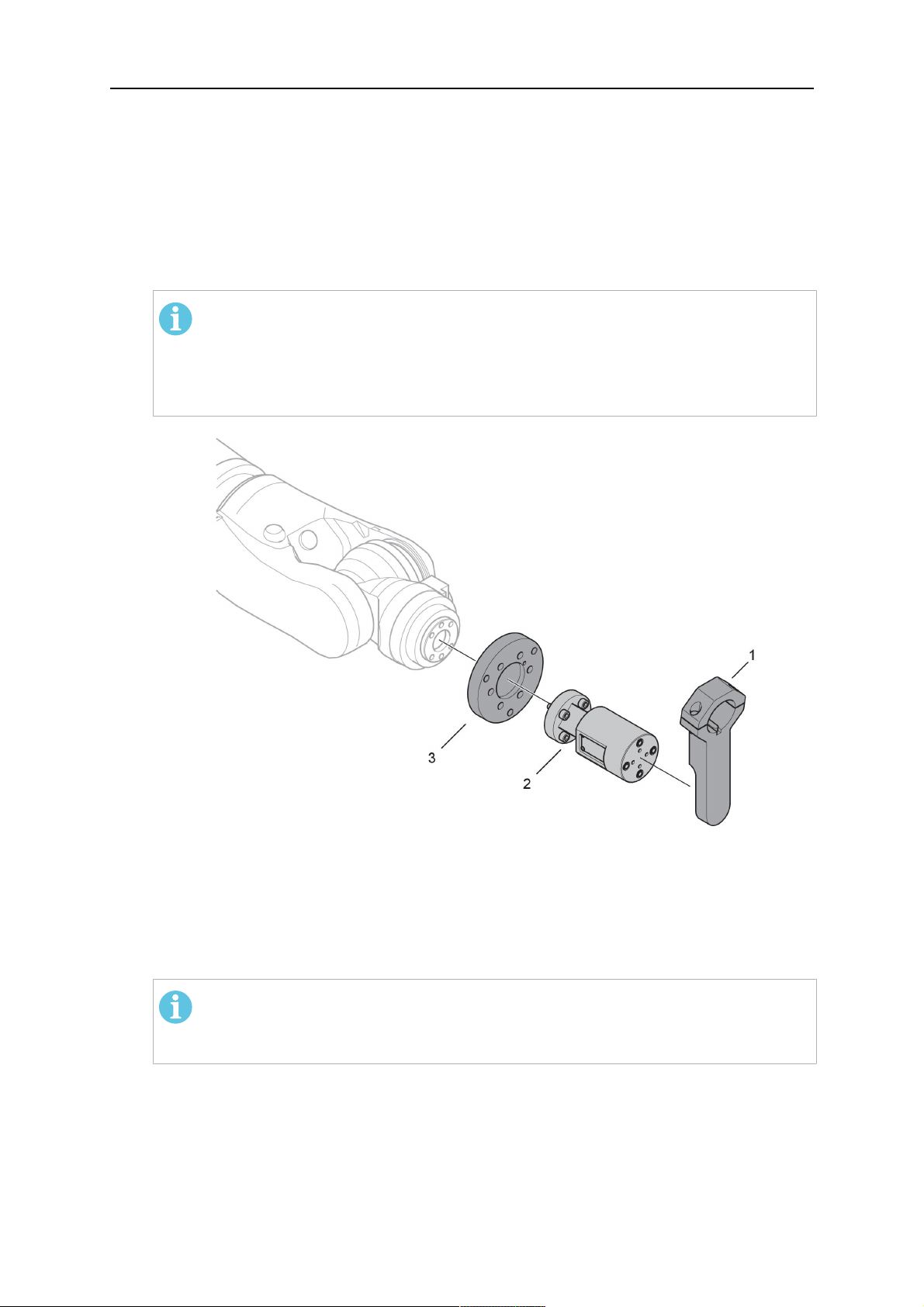

4.3.2.1 RTKSC-2 G/W nosač plamenika sa sigurnosnim mehanizmom

StavkaOpis Funkcija

1 Potporanj vrata plamenika Sučelje Aristo RT plamenika

2 RTKSC-2 poklopac Sklop sa kabelima i sučeljem plamenika

3 Gumene čizme Zaštita za sigurnosni mehanizam

0463 373 101

- 16 -

© ESAB AB 2018

4 TEHNIČKI PODACI

StavkaOpis Funkcija

4 RTKSC-2 glavno tijelo Dozvoljeni mehanički otklon tijekom kolizije

5 Adapterska prirubnica Izolacijsko sučelje za zglob robota (mora odgovarati

određenom robotu)

6 Usmjeravajući zatik Za precizno poravnanje s adapterskom prirubnicom

7 Priključak za upravljački kabel Električno povezivanje signala kolizije i funkcije

osjetne mlaznice

8 Mikrosklopka Senzor za otkrivanje kolizije

4.3.2.2 RTFLC-2 G/W nesavitljivi nosač plamenika

StavkaOpis Funkcija

1 Potporanj vrata plamenika Aristo RT sučelje plamenika

2 RTFLC-2 poklopac Sklop sa kabelima i sučeljem plamenika

3 RTFLC-2 glavno tijelo Dozvoljeni mehanički otklon tijekom kolizije

4 Usmjeravajući zatik Za precizno poravnanje s adapterskom prirubnicom

5 Adapterska prirubnica Izolacijsko sučelje za zglob robota (mora odgovarati

određenom robotu)

6 Priključak za upravljački kabel

(3 polni)

0463 373 101

Električno povezivanje za funkciju osjetne mlaznice

(ako je dostupna)

- 17 -

© ESAB AB 2018

4 TEHNIČKI PODACI

4.4 Adapterske prirubnice

Odaberite adaptersku prirubnicu potrebnu za instalaciju na robotsku ruku ovisno o vrsti

robota. Adapterska prirubnica za sve vrste odgovarajućih standardnih i sustava sa šupljim

zglobovima sustava koji su dostupni, pogledajte popis rezervnih dijelova.

4.5 Kabelski sklopovi

Kabelski sklop ostvaruje vezu s uređajem za dopremanje žice, a dostupne verzije uglavnom

ovise o sustavu dizajna i sredstva za hlađenje (plin ili voda), pogledajte popis rezervnih

dijelova.

Nazivne vrijednosti valjane su za kabele duljine od 1 do 5 m.

Duljina kabela Infiniturn Helix

Vrijednost (ciklus od

10 min.)

Hlađenje plinom

(miješani plin)

Vrijednost (ciklus od

10 min.)

Maks. 500 A / 60 %

radnog ciklusa

Maks. 350 A / 100 %

radnog ciklusa

Maks. 600 A / 100 %

radnog ciklusa

Maks. 400 A / 60 %

radnog ciklusa

Maks. 320 A / 100 %

radnog ciklusa

Maks. 550 A / 100 %

radnog ciklusa

Vodom hlađeni

Rotacijski raspon Ograničena

Neograničeni okret ± 270° od neutralnog

mogućnost rotacije

Težina

Plinom hlađeni

Težina

Vodom hlađeni

Duljina 1,2 m:

2,35 kg

Duljina 1.2 m:

2,35 kg

Duljina 1,0 m:

2,0 kg

Duljina 1.0 m:

2,0 kg

4.5.1 Vrat plamenika za standardni RT sustav

Maks. 400 A / 60 %

radnog ciklusa

Maks. 320 A / 100 %

radnog ciklusa

Maks. 550 A / 100 %

radnog ciklusa

položaja

Duljina 1.0 m:

2,0 kg

Duljina 1.0 m:

2,0 kg

0463 373 101

- 18 -

© ESAB AB 2018

4 TEHNIČKI PODACI

Zatici Burndy priključka

A. Osjetljivost na dodir

kontaktnog vrha

C. Senzor kolizije

F. 0V

G. + Napon motora

H. - Napon motora

D. Senzor kolizije

E. Postupno dopremanje

StavkaOpis Funkcija

1 Prirubnica potpornja vrata

Sučelje plamenika

prirubnice

2 Zaštitni poklopac Štiti kabelski sklop od oštećenja

3 Burndy priključak, 12 polni Električni priključak između sigurnosnog

isključivanja i dopremanja žice

4 Upravljački kabel Za KS-2 (sigurnosno isključivanje i gumb za

pokretanje)

5 EURO priključak Povezivanje dopremljene žice

6 Ispušna cijev (crni čep) Za čišćenje plamenika komprimiranim zrakom

nakon ciklusa čišćenja

7 Dovod vode (plavi čep)

8 Povrat vode (crveni čep)

9 Utikač upravljačkog kabela za

sigurnosni mehanizam

1)

Sustav plamenika hlađen samo vodom

Dovod vode za hlađenje plamenika

Povrat vruće vode iz plamenika

Električni priključak s RTKS-2 sigurnosnim

signalom i funkcijom osjetne mlaznice

1)

1)

4.5.2 Kabelski sklop za sustav šupljih zglobova

Infiniturn kabelski sklop omogućava neograničenu rotaciju plamenika u oba smjera.

Istodobno se prenose tekućina za hlađenje, zaštitni plin, ispušni zrak, izvor napajanja i signal

sigurnosnog mehanizma.

Helix kabelski sklop namijenjen je za rotaciju od ±270° iz neutralnog položaja. Može se rabiti

za vrste zavarivanja koje ne zahtijevaju beskrajnu rotaciju.

Infiniturn kabelski sklopovi dostupni su u verziji s plinskim i vodenim hlađenjem. Helix

kabelski sklopovi mogu se jednako rabiti za plinski ili vodeni sustav hlađenja.

NAPOMENA!

Plinom hlađeni vrat plamenika kod Helix kabelskog sklopa nikada nemojte

povezivati na vrat plamenika vodom hlađenog sustava.

0463 373 101

- 19 -

© ESAB AB 2018

4 TEHNIČKI PODACI

StavkaOpis Funkcija

1 Prirubnica Sučelje nosača plamenika RTKSC-2 / RTFLC-2

2 Usmjeravajući zatik Osigurava ispravno okretanje prilikom spajanja

3 Utikač upravljačkog kabela Električni priključak s RTKSC-2 sigurnosnim

signalom i funkcijom osjetne mlaznice (ako je

dostupna)

4 EURO priključak Povezivanje dopremljene žice

5 Upravljački kabel Električni priključak za sigurnosni signal (od

RTKSC-2) i za funkciju osjetne mlaznice (osjetne

mlaznice standardne su za Helix, ali ne i za

Infiniturn)

6 Povrat vode (crveni čep) Povrat vruće vode iz plamenika

7 Dovod vode (plavi čep) Dovod vode za hlađenje plamenika

8 Ispušna cijev (crni čep) Za čišćenje plamenika komprimiranim zrakom

nakon varenja

9 Spajanje medija Beskonačno rotirajući priključak s medijem prijenosa

10 Zaštitni poklopac Štiti kabelski sklop od oštećenja

0463 373 101

- 20 -

© ESAB AB 2018

5 INSTALLATION

5 INSTALLATION

UPOZORENJE!

For your own safety, make sure that the robot is either in standby or power-less

state before doing maintenance work in the moving radius of the robot.

Follow the assembly instructions exactly. Pay attention during assembly that the cables are

not damaged. Damaged cables can lead to a short circuit, which may damage the electronics

of the robot or the welding torch.

Use only original ESAB components that have been specially developed for this purpose.

Only then the correct functioning of the whole welding torch system can be guaranteed.

5.1 RTKS-2 standard arm installation

5.1.1 RTKS-2 safety-off mechanism

1. Dismount the insulation flange (10) from the RTKS-2 (11) by removing the screws

(12).

2. Position the insulation flange (10) with the index pin on the robot arm and fix it with the

screws (20) included.

The insulation flange (10) is directly compatible with robots with tool flange according

to DIN ISO 9409-1-A40 (diameter 40mm, 4×M6). If the insulation flange (10) does

not fit, use an adapter flange (21).

NAPOMENA!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

3. Mount the RTKS-2 the back on the insulation flange (10).

0463 373 101

- 21 -

© ESAB AB 2018

5 INSTALLATION

4. Position the mount on the RTKS-2 and carefully insert the cylindrical pins (14) into the

holes provided. Take the position of the torch into account. Two mounting positions

may be potentially possible.

5. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (12).

NAPOMENA!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

12 - Cylinder screw with hexagon socket

M6DIN912 (length of the screw depending

on the torch mount)

14 - Cylindrical pins Ø4×20

5.1.1.1 Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. The pins should protrude by approximately 5 mm (0.2 in.).

2. Position the mount on the safety-off mechanism RTKS-2 and carefully insert the

cylindrical pins (1) into the holes provided. In doing so, take the later position of the

torch into account. Two mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

NAPOMENA!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

0463 373 101

- 22 -

© ESAB AB 2018

5 INSTALLATION

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

0463 373 101

- 23 -

© ESAB AB 2018

5 INSTALLATION

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.1.2 Standard arm cable assembly for KS-2 and FL-2

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

0463 373 101

- 24 -

© ESAB AB 2018

5 INSTALLATION

OPREZ!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

1. Unscrew the cylinder screws (1) and lift off the top section (2) of the torch mount.

2. Insert the feather key (4) into the recess of the neck support flange (3) from below.

3. Align the neck support flange (3) including the feather key (4) to the groove (5) of the

torch mount and push into the groove right up to the stop of the flange.

4. Hold the cable assembly in this position and simultaneously place the top section (2)

back onto the torch mount. First screw both cylinder screws (1) loosely in to about the

same length, then tighten alternately. The top section (2) of the mount should have an

even gap to the bottom section.

The front part of the cable assembly is directly clamped into the torch mount (see

illustration below).

1 - Cylinder screws 4 - Feather key

2 - Torch mount top section 5 - Groove for feather key

3 - Neck support flange

5.1.3 RTKS-2 wire feeder connection

In order to be able to create the connection, the cable assembly must be mounted as

described in the "Installing the cable assembly" section and equipped following "Installing the

wire guide" section. Only then can the central and media connection take place. Proceed as

described below:

0463 373 101

- 25 -

© ESAB AB 2018

5 INSTALLATION

1. Connect the central connector of the cable assembly (2) to the wire feeder cabinet

socket. Tighten the central connector sleeve nut fingertight. Do not use tools.

1 - Burndy Connector 4 - Return of heated water (red cap)

2 - EURO central connector 5 - Return of heated water (red cap)

3 - Air blow-out 6 - Main Wire feeder

2. For water cooled systems. Connect the water hoses to the cooling circuit. The end of

the hose marked blue (4) is connected to the water outlet, and the end marked red (5)

is connected to the water return.

3. Connect the blow-out line (3) to the corresponding connection of the feeder.

4. Connect the Burndy Connector to the wire feeder. (1) to the feeder. See section

"Electrical connections".

NAPOMENA!

All hoses and the control line must be installed so they can not bend or get

damaged!

5.1.4 RTKS-2 electrical connections

5.1.4.1 RTKS-2 safety-off mechanism connection

The switch for the safety-off functionality RTKS-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKS-2 unit via the 4-pole plug (4) that

contains circuits for the push-button (6) and the safety-off signal (7).

If a collision is detected, the control circuit for the safety-off signal (7), which is normally

closed, will be interrupted.

Rating of the control circuit: max. 48 V / 1 A

0463 373 101

- 26 -

© ESAB AB 2018

5 INSTALLATION

2 - Burndy connector 5 - RTKS-2 connector for control cable plug

4 - Control cable plug

Zatici Burndy priključka

A. Osjetljivost na dodir

kontaktnog vrha

C. Senzor kolizije

F. 0V

G. + Napon motora

H. - Napon motora

D. Senzor kolizije

E. Postupno dopremanje

If the robot control provides a control circuit for nozzle sense functionality, the connection is

accomplished with a 1-wire connection.

Rating of the control circuit: max 50 V / 5 A.

OPASNOST!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

OPREZ!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

5.1.5 RTKS-2 Torch installation

Continue according to section "Torch installation".

0463 373 101

- 27 -

© ESAB AB 2018

5 INSTALLATION

5.2 RTFL-2 standard arm installation

5.2.1 RTFL-2 rigid mount

1. Position the RT FL-2 (2) with the index pin on the robot arm and fix it with the hexagon

socket screw included.

The FL-2 is directly compatible with robots with tool flange according to DIN ISO

9409-1-A40 (diameter 40mm, 4×M6). If the rigid mount does not fit, use an adapter

flange (3).

NAPOMENA!

Ensure that the index pin is located correctly. The maximum torque of 1.2Nm

(10.5in.lb) must be observed for the fastening of the adapter flange screws.

Prevent self-loosening of the screws by using suitable thread locking

measures.

2. Install torch mount (1). Only torch mounts having a hole pattern equivalent with the

mounting surface may be attached. If necessary, carefully press the cylindrical pins (4)

into the corresponding holes in the bracket. The pins should protrude by

approximately 5mm (0.2in.). Position the torch mount on the RTFL-2 (2) and

carefully insert the cylindrical pins (4) into the holes provided. Take the position of the

torch into account. Two mounting positions may be potentially possible.

3. Screw the mount evenly using the enclosed cylinder screws with hexagon socket (5).

NAPOMENA!

The maximum tightening torque for the cylinder screw (5) is 6Nm (53in.lb)

and the property class category is 8.8.

0463 373 101

- 28 -

© ESAB AB 2018

5 INSTALLATION

4 - Cylindrical pins Ø4×20

5 - Cylinder screw with hexagon socket M6

DIN 912 (length of the screw depending on

the torch mount)

Side view

Torch installation with adjustable mount

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. Avoid the formation of burrs. The pins should protrude by

approximately 5 mm (0.2 in.).

2. Position the mount on the RTFL-2 and carefully insert the cylindrical pins (1) into the

holes provided. In doing so, take the later position of the torch into account. Two

mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws with

hexagon socket (2).

NAPOMENA!

The maximum tightening torque for the cylinder screw (2) is 7.1 Nm (62.8

in.lb) and the property class category is 8.8.

4. Unscrew the axial cylinder screw with hexagon socket (4) out of the mounting flange

together with the washer (3).

1 - Cylindrical pins Ø4×14 3 - Washer Ø9 mm

2 - Cylinder screw with hexagon socket

M6×16

4 - Axial cylinder screw with hexagon

socket M8×16

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

0463 373 101

- 29 -

© ESAB AB 2018

5 INSTALLATION

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it so

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

7. Fix the clamping mandrel from the opposite side using the M6 cylinder screw with

hexagon socket (10) and the Ø22 mm washer (11).

8. Screw the axial cylinder screw (4) with the Ø9 mm washer (3) into the mounting flange

and tighten firmly.

3 - Washer Ø9 mm 8 - Clamping mandrel

4 - Axial cylinder screw with hexagon

9 - Mating surface of mounting flange

socket M8×16

5 - Torch mount 9a - Mating surfaces of clamping mandrel

6 - Mounting flange journal 10 - Cylinder screw with hexagon socket

M6×30

7 - Feather key 11 - Washer Ø22×6.4 mm

7a - Groove for feather key

5.2.2 RTFL-2 torch installation

Continue according to section "Torch installation".

5.3 RTKSC-2 hollow wrist system installation

5.3.1 RTKSC-2 mount with safety off mechanism

OPREZ!

For hollow wrist systems make sure that the clear space around the robot is at least

Ø45 mm (1.8 in.) around the wrist and 50 mm (2.0 in.) near the wire feeder.

0463 373 101

- 30 -

© ESAB AB 2018

5 INSTALLATION

1. Remove the three screws (2) from the front cover (3) of the torch mount and carefully

pull the cover off the RTKSC-2 main body (5). Take care not to damage the micro

switches installed inside the assembly.

1 - Hexagon wrench 4 mm 4 - Rubber boot

2 - 3× M5×12 screws 5 - RT KSC-2 main body

3 - RT KSC-2 front cover

1. Pull off the rubber boot (4) from the RTKSC-2 main body (5) to the front.

2. Now position the RTKSC-2 main body (5) on the adapter flange (7) so that the index

pin is correctly seated. Attach with the screws (6) enclosed.

3. Reinstall the rubber boot (4) on the RTKSC-2 main body (5) and make sure it is

correctly located in the grooves on the front and back flange.

4. Istall the adapter flange (7) on the robot.

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 3 - 3× M5×12 hexagon socket screws

2 - Rubber boot 4 - Adapter flange

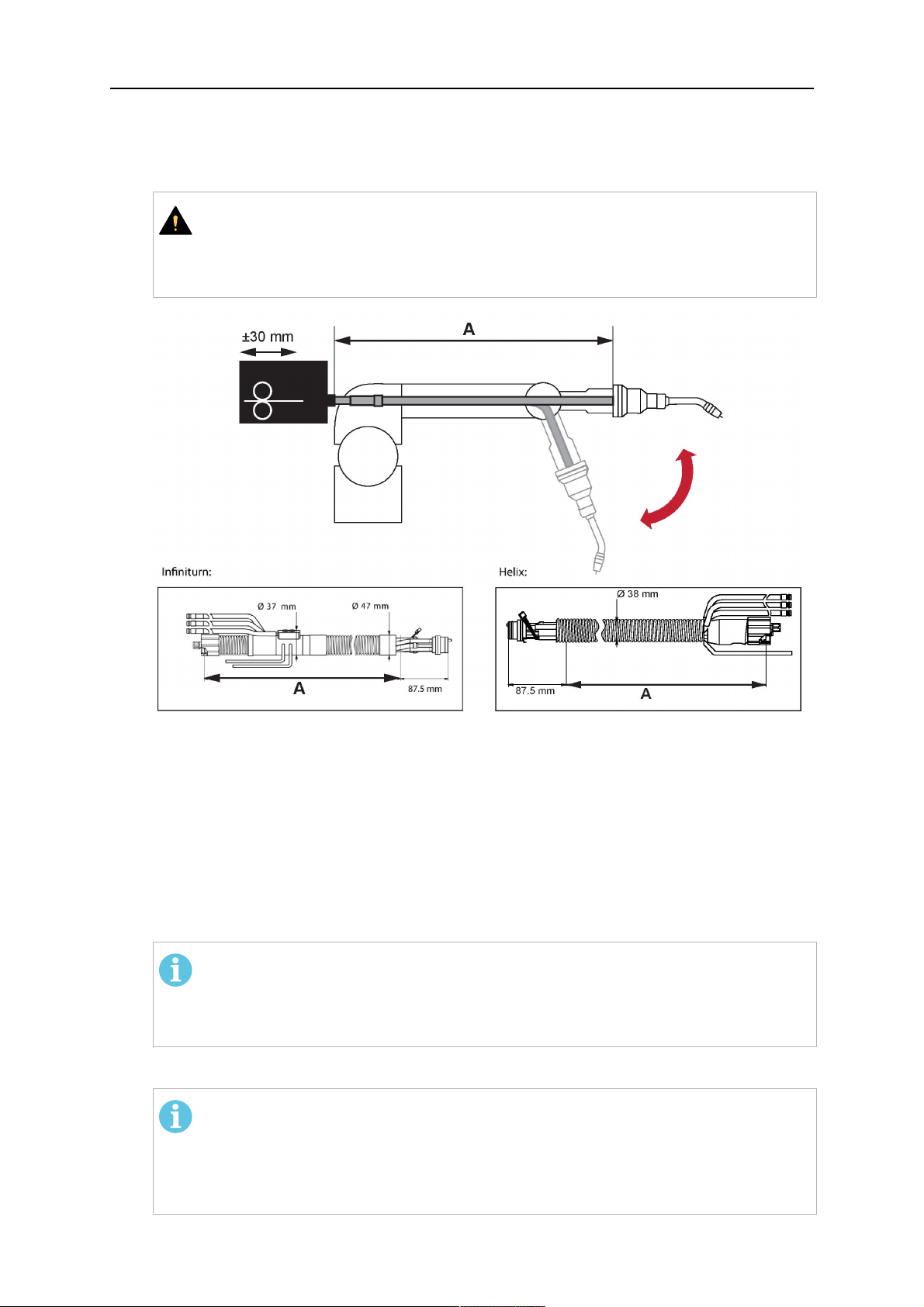

5.3.2 Mounting the cable assembly

NAPOMENA!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ±2-3cm (±1in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

0463 373 101

- 31 -

© ESAB AB 2018

5 INSTALLATION

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

OPREZ!

Axis 6 must be in 0° position.

5.3.2.1 RTKSC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

OPREZ!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 32 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

OPREZ!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connectors are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

NAPOMENA!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

NAPOMENA!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

0463 373 101

- 33 -

© ESAB AB 2018

5 INSTALLATION

5.3.3 RTKSC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

OPREZ!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.3.3.1 RTKSC-2 cable assembly installation

NAPOMENA!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2, then thread the cable from the front through the

robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTKSC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1).

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 34 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

NAPOMENA!

Make sure that the position of the O-rings are not shifted by the index pin

during the assembly.

1 - RTKSC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RTKSC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 35 -

© ESAB AB 2018

5 INSTALLATION

6. If present, insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTKSC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13. Index pin

14. 3× M5×12 screws

0463 373 101

- 36 -

© ESAB AB 2018

5 INSTALLATION

5.3.3.2 RTKSC-2 electrical connections

NAPOMENA!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then

implemented via the power source controller.

RTKSC-2 safety-off mechanism connection

The switch for the safety-off functionality RTKSC-2 is connected through the control cable,

see (3) in the illustration below. This connects to the RTKSC-2 unit via the control cable plug

(1).

The safety-off signal requires a 2-wire connection (black/black) to the safety-off circuit in the

robot control (5).

If a collision is detected, the control circuit (normally closed) will be interrupted (4).

Rating of the control circuit: max. 48 V / 1 A.

1 - Control cable plug 3 - Burndy connector VVV

2 - EURO central connector

Zatici Burndy priključka

A. Osjetljivost na dodir

kontaktnog vrha

C. Senzor kolizije

F. 0V

G. + Napon motora

H. - Napon motora

D. Senzor kolizije

E. Postupno dopremanje

RTKSC-2 nozzle sense function connection

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

0463 373 101

- 37 -

© ESAB AB 2018

5 INSTALLATION

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

OPASNOST!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

OPREZ!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

5.3.4 RTKSC-2 torch installation

Continue according to section "Torch installation".

0463 373 101

- 38 -

© ESAB AB 2018

5 INSTALLATION

5.4 RTFLC-2 installation

5.4.1 RTFLC-2 mount

1. Remove the three M5 screws (2) from the front cover (3) of the RT FLC-2 torch mount

and carefully pull the cover off the main body (4).

1 - Hexagon wrench 4 mm 3 - RT FLC-2 front cover

2 - 3× M5×12 screws 4 - RT FLC-2 main body

2. Now position the RT FLC-2 main body (4) on the adapter flange (6) so that the index

pin is correctly seated. Attach with the screws (5) enclosed

Fastening torque max. 2.2 Nm (19.5 in.lb).

1 - Hexagon wrench 4 mm 5 - 3× M5×12 hexagon socket screws

4 - RT FLC-2 main body 6 - Adapter flange

5.4.2 RTFLC-2 wire feeder connection

5.4.2.1 Feeding through the robot arm

NAPOMENA!

In order to adjust the wire feeder position to the cable assembly length, it must be

mounted on an adjustable support with a possible movement of ± 2-3 cm (± 1 in.) to

the back and to the front. The length of the cable assembly must be determined

from the centred mounting position of the wire feeder.

0463 373 101

- 39 -

© ESAB AB 2018

5 INSTALLATION

1. Move the robot arm into a completely straight position, see illustration below. Make

sure that (1) axis 6 (rotation around the torch axis) is in 0° position.

2. Move the feeder (3) completely to the back in order to create space for inserting the

cable assembly. If it is not possible to move the feeder sufficiently, it should be

removed from the robot.

3. Insert the cable assembly with the coupling (2) first into the robot arm and feed it

through the robot wrist.

4. The feeder should only be installed again after the correct mounting position with

respect to the cable length has been determined. (See section "Installing the cable

assembly").

OPREZ!

Important! Axis 6 must be in 0° position.

5.4.2.2 RTFLC-2 feeder cabinet connections

When installed for the first time, the position of the wire feeder cabinet must be adjusted to

the length of the cable assembly. First, the robot arm must be fully extended (straight).

OPREZ!

As long as the correct position of the feeder corresponding to the length of the cable

assembly has not been determined, be careful when moving the robot arm and

avoid overstretching the cable. It is helpful to loosen the positioning screws of the

feeder before moving the robot arm to allow the feeder to follow the cable assembly.

0463 373 101

- 40 -

© ESAB AB 2018

5 INSTALLATION

1. Loosen the sliding mechanism of the wire feeder and connect the cable assembly.

Refer to the instruction of the feeder manufacturer.

2. Now adjust the position of the wire feeder to suit the length of the Infiniturn or Helix

cable, as indicated with "A" in the illustration below.

OPREZ!

When adjusting the position of the feeder cabinet, make sure that the cable

assembly is not under stress when the robot arm is in stretched-out position.

It is normal for the cable assembly to sag slightly, it should never be taut.

3. Before securing the wire feeder in its permanent position, ensure that the Euro

connections are tightly connected. Then turn the torch mount down and up again

(rotating on the axis 5), in order not to tighten the cable assembly too much against

the feeder (see illustration above). Once this is done, tighten the feeder in that

position.

4. For water cooled systems, connect the water lines to the cooling circuit. See section

"Cable assemblies for hollow wrist systems" in the TECHNICAL DATA chapter for

indications.

The hose with the blue rubber cap is for cooling water to the torch, the hose with the

red rubber cap returns the heated water. Make sure the hoses will not kink or get

otherwise blocked.

NAPOMENA!

A Helix cable assembly used for a gas cooled system must not be connected

to a cooling circuit. As the water connections are not needed, they may be cut

off.

5. Connect the blow-out hose (black rubber cap) to the corresponding outlet of the wire

feeder.

NAPOMENA!

If the blow-out function is not used, the blow-out hose must be sealed with the

rubber cap enclosed. With Infiniturn systems, the blow-out air must be

supplied to the corresponding connection hose, if it is not permitted to connect

blow-out air to the shield gas connection!

0463 373 101

- 41 -

© ESAB AB 2018

5 INSTALLATION

6. Install the necessary plug on the control cable and connect it to the safety off circuit

interface of the wire feeder (see section "Electrical connections").

5.4.3 RTFLC-2 cable assembly

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

OPREZ!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

5.4.3.1 RTFLC-2 cable assembly installation

In a hollow wrist system the recommended order of installation is to feed the cable assembly

through the robot arm before connecting the cables to the torch mount.

When the cable assembly is correctly installed in the hollow wrist, continue the installation

according to the procedure described below.

NAPOMENA!

For some robots, it may be possible to deviate from this order, and first connect the

cable assembly to the RTKSC-2 and RTFLC-2, then thread the cable from the front

through the robot arm. If in doubt, follow the suggested order.

1. Loosen the three screws (7) with the associated washers and remove them from the

RTFLC-2 cover (1). See illustration below.

2. Install the supplied O-rings (4) into the grooves in the cover (1). For gas cooled

systems, only one O-ring (4a) is needed, for water cooled systems all three O-rings

are needed.

3. Pull the cable assembly approximately 15 cm (6 in.) from the main body (3).

0463 373 101

- 42 -

© ESAB AB 2018

5 INSTALLATION

4. Insert the coupling (2) into the socket of the cover (1) as shown. Align the index pin (6)

with the index hole (5) in the main body and insert completely.

NAPOMENA!

Take great care that the position of the O-rings is not shifted by the index pin

during the assembly.

1 - RT FLC-2 cover 5 - Index hole

2 - Coupling 6 - Index pin

3 - RT FLC-2 main body 7 - 3× M5×35 screws

4 - 3× O-ring for water cooled systems 11 - Control cable connector

5. Insert the three screws (7) with the associated washers (8) and tighten gently with the

enclosed hexagonal wrench, see below illustration.

Fastening torque approximately 2 Nm (18 in.lb).

0463 373 101

- 43 -

© ESAB AB 2018

5 INSTALLATION

6. If present insert the control cable plug (10) into the connector (11) and make sure it is

firmly seated.

7 - 3× M5×35 screw 11 - Control cable connector

8 - Washer 12 - 2× Micro switch

10 - Control cable plug 13 - Index pin

7. Gently push back the cable assembly into the robot arm and carefully seat the

RTFLC-2 cover (1) in place. Observe the index pin (13) to be in the correct position.

Make sure the two micro switches (12) are not damaged if present.

8. Insert the three M5 screws (14) and tighten without excessive force.

13 - Index pin 14 - 3x M5x12 screws

0463 373 101

- 44 -

© ESAB AB 2018

5 INSTALLATION

5.4.4 RTFLC-2 electrical connections

NAPOMENA!

After connecting the control cable, secure the cable in order to protect it from getting

caught while the robot is moving.

Usually, the control cable will be directly connected to the wire feeder. See the

documentation of the manufacturer for details. The link to the robot control is then

implemented via the power source controller.

5.4.4.1 RTFLC-2 hollow wrist system with Infiniturn cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 2-wire connection (black/black) to the nozzle sense

circuit in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

OPASNOST!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

OPREZ!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - Control cable

2 - EURO central connector

0463 373 101

- 45 -

© ESAB AB 2018

5 INSTALLATION

5.4.4.2 RTFLC-2 hollow wrist system with Helix cable assembly

Connecting the nozzle sense function

If the robot control provides a control circuit for nozzle sense functionality.

The connection is accomplished with a 1-wire connection (green) to the nozzle sense circuit

in the robot control (5), see illustration below.

Usually, the control cable will be directly connected to the wire feeder. See the

manufacturer's documentation for details. The link to the robot control is then implemented

via the power source robot interface.

Rating of the control circuit: max. 50 V / 5 A.

OPASNOST!

If the nozzle sense function is not being used, the open end of the control cable on

the power source connection side must be properly isolated in order to avoid short

circuits. During certain problems on the torch head, the full welding potential may be

present on this cable.

OPREZ!

After detection of contact (gas nozzle on work piece), quickly reduce or cut off the

maximum current in the nozzle sense circuit in order to avoid overloading of the

system.

Allowed load max. 1 minute at the rated nominal current.

1 - Control cable plug 3 - EURO central connector

2 - Control cable 4 - Burndy connector

5.5 Torch installation

Be sure to use the correct version of the torch mount and cable assembly (water or gas

cooled).

5.5.1 Torch neck equipment

The torch neck, see (1) in the illustration below, must always be equipped to suit the wire

diameter and material.

0463 373 101

- 46 -

© ESAB AB 2018

5 INSTALLATION

1. Select the correct wire guide, contact tip (4), tip holder (2), gas nozzle (5), and gas

diffuser/spatter protection (3). You will find an exact overview and possible alternative

equipment elements for various torch models in the spare parts list. Only use original

ESAB parts; only then is the fitting accuracy ensured.

2. Firmly tighten the tip holder and the contact tip using a suitable tool for example the

enclosed monkey wrench.

3. When using a split wire guide, remove the installed guide nipple including the o-ring

from the torch flange upon delivery if necessary (see section "Installing the neck

liner").

OPREZ!

The torch must be completely equipped before welding, especially the gas

diffuser and/or spatter protection and all necessary insulators have to be

installed according to the spare parts list. Welding without these items may

cause immediate destruction of the torch.

1 - Torch neck 4 - Contact tip

2 - Tip holder 5 - Contact tip

3 - Gas diffuser

5.5.2 Aristo RT torch neck installation

NAPOMENA!

Check the O-rings on the flange of the torch neck before mounting. Replace the

O-rings if damaged or lost. Missing or faulty O-rings will lead to leaks of shielding

gas and coolant.

1. For hollow wrist systems, insert the torch into the torch mount in the correct

orientation, so that the locator pin fits into the slot of the RTKSC-2 or RTFLC-2

interface, see (A) in the illustration below. For standard systems, attach the torch to

the RT flange of the cable assembly, (B) in the illustration below.

Installation is only possible in the correct orientation.

2. Tighten the locking nut of the torch neck.

NAPOMENA!

Only tighten by hand, never use tools or excessive force.

0463 373 101

- 47 -

© ESAB AB 2018

5 INSTALLATION

3. The correct seating of the torch can be checked by means of the window (1). If the

torch has been correctly mounted, no gap should be seen through the window (1).

5.6 Installing the wire guide for standard and hollow Wrist arm

Installing the wire guide

Choose the wire guide or liner depending on the filler wire material and diameter to be used,

see the spare parts list. Accurate performance of the system can only be guaranteed when

using original ESAB wire guides.

The recommended wire guide is the split wire guide, which consists of the neck liner and a

separate guide in the cable assembly. The front part of the wire guide, which is most

stressed, can be exchanged easily and independently of the cable assembly wire guide.

For correct installation, the following steps must be followed (example for Euro central

connector).

5.6.1 Installing the neck liner

The neck liner must be selected to fit the material and diameter of the welding wire, see the

spare parts list.

0463 373 101

- 48 -

© ESAB AB 2018

5 INSTALLATION

1. If present, remove the central guide nipple (1), from the torch neck using a hexagon

wrench (size 6 mm) or a large flat-blade screwdriver.

NAPOMENA!

The guide nipple (1) can only be used with one-piece liners and must not be

used with the standard RT or hollow wrist system.

2. When replacing the neck liner:

Unfasten the sleeve nut and remove the torch neck.

Unfasten the liner nipple using a hexagon wrench (size 6 mm) and remove nipple and

liner from the torch neck.

3. Remove the gas nozzle and the contact tip.

4. Insert the new neck liner (2) into the torch. Carefully tighten the guide nipple using a

suitable tool, e.g. a hex-wrench (size 6 mm) or a large flat-blade screwdriver.

5. Cut the neck liner flush with the tip holder and remove the neck liner from the torch.

6. Install the contact tip.

7. Insert the neck liner again. It will be stopped by the contact tip. Measure the excess

liner sticking out of the neck.

8. Remove the liner again and shorten the front end by the measured length. Carefully

deburr the edge and make sure that the inner hole is not blocked.

9. Reinstall the neck liner and tighten the guide nipple in the neck.

5.6.2 Installing a split wire guide in the cable assembly

The correct liner must be inserted to suit the filler material and the wire diameter, see the

spare parts list.

The wire guide is inserted through the cable assembly from the rear, reaching the guide

nipple that is installed in the flange where the torch neck will be attached. The following

worksteps must be followed in order to correctly determine the wire guide length. (Example

for Euro central connector).

0463 373 101

- 49 -

© ESAB AB 2018

5 INSTALLATION

1. For standard RT system: Install the guide nipple (1) in the center hole of the neck

support flange, see illustration A below.

For hollow wrist system: Install the guide nipple (1) into the torch interface of the

RTKSC-2 / RTFLC-2 cover, see illustration B below.

2. Remove the sleeve nut (2) from the central connector, and remove the old wire guide.

3. Insert the wire guide through the central connection and push forwards as far as it will

go into the guide nipple (1), applying light pressure.

OPREZ!

Ensure that the wire guide has advanced right up to the stop at the front,

rotating and pushing forward gently.

4. Measure the excess length that needs to be cut from the wire guide.

5. Remove the wire guide again and shorten the front end by the measured length.

Steel liner: grind down the burred edges if needed.

Plastic liner: make a clean cut and chamfer the edges (e.g. with a pencil sharpener)

NAPOMENA!

Make sure the inner opening of the liner is not obstructed by the cut wire end.

0463 373 101

- 50 -

© ESAB AB 2018

5 INSTALLATION

6. Reinstall the wire guide and attach the sleeve nut (2).

NAPOMENA!

For hollow wrist systems where Infiniturn and Helix cable assemblies are

used, wire guides should be installed without tension so that the ends of the

liners may rotate freely.

Important note when using a plastic liner:

The wire channel between the drive rolls of the feeder and the central

connector of the torch must be fitted with a plastic liner. Depending on the

design of the feeder, a piece of plastic liner inserted into a brass guide tube

can be used.

During wire run-in, make sure that the wire is fed correctly into the plastic liner

of the torch. If necessary, remove the cable assembly from the feeder and

insert the wire, then reattach.

5.6.3 Installing a continuous wire guide in the cable assembly

Installing a steel liner