RT Robo Welding Torch System

Instruction manual

0463 373 001 GB 20131212

TABLE OF CONTENTS

1 SAFETY ................................................................................................................ 4

2 WARRANTY.......................................................................................................... 6

3 TECHNICAL DATA ............................................................................................... 7

3.1 Application............................................................................................................ 7

3.2 Compatibility ........................................................................................................ 7

3.3 Overview of the RT welding torch system.........................................................7

3.4 Specifications.......................................................................................................8

3.4.1 Field of use.........................................................................................................8

3.4.2 Torch rating ........................................................................................................ 8

3.4.3 Voltage rating .....................................................................................................9

3.4.4 Torch cooling circuit limits (water cooled version only) ...................................... 9

3.5 Selection of a suitable torch ...............................................................................9

3.6 Selection of a suitable torch mount for the torch neck....................................9

3.7 Conditions of intended use...............................................................................10

4 INSTALLATION................................................................................................... 11

4.1 Preparation ......................................................................................................... 11

4.2 Installing the RT KS-1 on the robot arm .......................................................... 11

4.3 Installation of torch mount................................................................................ 11

4.3.1 Direct mounting to KS-1 ................................................................................... 11

4.3.2 Installation of the mounting flange on the RT KS-1..........................................12

4.4 Cable assembly installation .............................................................................. 13

4.4.1 Installing the cable assembly (RT flange) in the torch mount ..........................13

4.5 Robot welding torch ..........................................................................................14

4.5.1 Equipping the torch neck.................................................................................. 14

4.5.2 Mounting the torch neck...................................................................................15

4.6 Wire guide installation in cable assembly ....................................................... 16

4.6.1 Installation of a split wire guide (cable assembly) ............................................16

4.6.2 Installation of a continuous wire guide (cable assembly) .................................17

4.7 Connection at the wire feeder cabinet .............................................................18

5 INITIAL OPERATION..........................................................................................20

6 SERVICING AND MAINTENANCE .................................................................... 21

7 SPARE PARTS LIST........................................................................................... 23

7.1 Robot Welding Torch ......................................................................................... 23

7.2 System components ..........................................................................................23

7.3 Wire Guides ........................................................................................................23

8 TROUBLESHOOTING ........................................................................................ 25

Rights reserved to alter specifications without notice.

0463 373 001 © ESAB AB 2013

1 SAFETY

1 SAFETY

Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who

works on or near the equipment observes all the relevant safety precautions. Safety

precautions must meet the requirements that apply to this type of equipment. The following

recommendations should be observed in addition to the standard regulations that apply to

the workplace.

All work must be carried out by trained personnel well-acquainted with the operation of the

equipment. Incorrect operation of the equipment may lead to hazardous situations which can

result in injury to the operator and damage to the equipment.

1. Anyone who uses the equipment must be familiar with:

○ its operation

○ location of emergency stops

○ its function

○ relevant safety precautions

○ welding and cutting or other applicable operation of the equipment

2. The operator must ensure that:

○ no unauthorised person is stationed within the working area of the equipment when it

is started up

○ no-one is unprotected when the arc is struck or work is started with the equpment

3. The workplace must:

○ be suitable for the purpose

○ be free from drafts

4. Personal safety equipment:

○ Always wear recommended personal safety equipment, such as safety glasses,

flame-proof clothing, safety gloves

○ Do not wear loose-fitting items, such as scarves, bracelets, rings, etc., which could

become trapped or cause burns

5. General precautions:

○ Make sure the return cable is connected securely

○ Work on high voltage equipment may only be carried out by a qualified

electrician

○ Appropriate fire extinquishing equipment must be clearly marked and close at hand

○ Lubrication and maintenance must not be carried out on the equipment during

operation

0463 373 001

- 4 -

© ESAB AB 2013

1 SAFETY

WARNING!

Arc welding and cutting can be injurious to yourself and others. Take precautions

when welding and cutting. Ask for your employer's safety practices which should

be based on manufacturers' hazard data.

ELECTRIC SHOCK - Can kill

• Install and earth the unit in accordance with applicable standards

• Do not touch live electrical parts or electrodes with bare skin, wet gloves or

wet clothing

• Insulate yourself from earth and the workpiece

• Ensure your working stance is safe

FUMES AND GASES - Can be dangerous to health

• Keep your head out of the fumes

• Use ventilation, extraction at the arc, or both, to take fumes and gases away

from your breathing zone and the general area

ARC RAYS - Can injure eyes and burn skin

• Protect your eyes and body. Use the correct welding screen and filter lens

and wear protective clothing

• Protect bystanders with suitable screens or curtains

FIRE HAZARD

• Sparks (spatter) can cause fire. Make sure therefore that there are no

inflammable materials nearby

NOISE - Excessive noise can damage hearing

• Protect your ears. Use earmuffs or other hearing protection. Protect your

ears. Use earmuffs or other hearing protection

• Warn bystanders of the risk

MALFUNCTION - Call for expert assistance in the event of malfunction.

Read and understand the instruction manual before installing or operating.

PROTECT YOURSELF AND OTHERS!

CAUTION!

Read and understand the instruction manual before

installing or operating.

0463 373 001

- 5 -

© ESAB AB 2013

2 WARRANTY

2 WARRANTY

Before delivery, our products are carefully checked. We guarantee, that each product is free

from defects of material and workmanship at the time of delivery and is functioning according

to its intended use.

ESAB provides warranty on defects of material and workmanship according to legal

requirements. Consumables are exempt from this warranty.

The warranty does not cover any damages or functional defects resulting from

• overloading, abusing or diverting from intended use of the product

• collisions or accidents

• non compliance with instructions stated in these operating instructions

• improper installation or assembly

• insufficient maintenance

• modifying the product from its original state

• chemical influences

• normal wear and tear

ESAB assumes no liability other than for replacement or repair of faulty parts.

0463 373 001

- 6 -

© ESAB AB 2013

3 TECHNICAL DATA

3 TECHNICAL DATA

3.1 Application

The RT welding torch system is developed for fully-automatic MIG/MAG welding using

welding robots. Its components consist of:

• an RT welding torch

• cable assembly

• torch mount

• safety-off mechanism or rigid intermediate flange

It is possible to use gas or water cooling. For different needs in the welding process a large

selection of suitable torches with different geometries can be used.

3.2 Compatibility

Depending on the type of robot, an adapter flange is required for the assembly of the system

at the robot wrist. The robot should have a load-bearing capacity of at least approximately 5

kg at its wrist.

NOTE!

Correct selection of the system components to suit the welding task is the

prerequisite for the faultless functioning of the system.

3.3 Overview of the RT welding torch system

Item Description Function

1 RT welding torch Different versions available

A RT flange Interface to the RT welding torch

2 Cable assembly Different versions available, gas or water

cooled

3 Torch mount In various designs to fit the torch necks (for

example torch bent by 45°)

- Mounting flange (not shown) Only needed for some versions of the torch

mount (3)

(see "Installation" section)

0463 373 001

- 7 -

© ESAB AB 2013

3 TECHNICAL DATA

4 RT KS-1 Fully mechanical, spring supported safety-off

mechanism

Alternatively:

Rigid intermediate flange RT

FL-1

Rigid intermediate flange for robots with

electronic collision detection system, can be

used instead of the RT KS-1

(not shown)

5 Control plug Electrical connection to RT KS-1 for the signal

for collision monitoring

6 EURO central connector or

Connection to the wire feeder

other connector

7 Control cable with connecting

plug

Electrical connection for the safety-off signal

RT KS-1 (4-wire) and signal “nozzle sense”

(1-wire)

8 Blow out hose For cleaning the torch with compressed air

after welding

9 Water inlet (blue cap)

Water inlet for cooling of the torch

(water cooled version only)

10 Water return (red cap)

Water return of heated water from the torch

(water cooled version only)

3.4 Specifications

3.4.1 Field of use

The RT welding torches are intended for the use with CE-conform welding power sources for

the processes of metal inert gas welding (MIG), metal active gas welding (MAG) and metal

inert gas soldering with commercial round wires. Do not use the torch for other processes.

3.4.2 Torch rating

For detailed information regarding the rating and technical specifications of your torch please

see the spare parts list included with the torch. The ratings are valid for cable lengths from 1

to 5 m. The values for torch rating and duty cycle are valid for a 10 min. cycle.

The indicated ratings refer to a standardized case of use. In special cases, e.g. incase of an

especially high heat reflection on the torch, the torch may overheat at lower currents than

indicated. In this case, please use a more powerful model or reduce the duty cycle.

The rating will be notably reduced with the use of pulsed arc power sources.

Type of guidance Guidance by machine only

Weights

• Robot welding torch

• Cable assembly, 1,2 m long, G

• Cable assembly, 1,2 m long, W

• Torch Mount (Std.)

• RT KS-1

• RT FL-1

Approximately

• 0,66 kg

• 2,35 kg

• 2,35 kg

• 0,43 kg

• 1,96 kg

• 0,37 kg

Environmental temperature Storage -15° to 50°C (5° to 122°F)

Operation 5° to 40°C (41° to 104°F)

0463 373 001

- 8 -

© ESAB AB 2013

3 TECHNICAL DATA

Rating Cable assemblies

• gas cooled

• water cooled

Blow-out gas pressure max. 10 bar, separate gas hose

Rating/Duty cycle (Mixed gas, 10 min. cycle)

500 A/60 %, 350 A/100 %

600 A/100 %

3.4.3 Voltage rating

• The maximum permitted welding voltage for the system is 141 V (peak value).

• The maximum permitted voltage for the safety-off control circuit is 24 V, max 1 A, for the

push-button 48 V and max. 0,1 A

• The maximum permitted voltage for the push-button (cable assembly) is 48 V and max.

0,1 A

3.4.4 Torch cooling circuit limits (water cooled version only)

min. water flow rate: 1,0 l/min / 1,1 quarts/min

min. water pressure: 2,5 bar / 36,3 PSI

max. water pressure: 3,5 bar / 50,8 PSI

inlet temperature: max. 40°C / 104°F

return temperature: max. 60°C / 140°F

cooling capacity: min. 1000 W, depending on application

CAUTION!

Return temperatures of more than 60°C / 140°F may cause damage or destroy

the cable assembly. The cooler must always be filled with sufficient cooling liquid,

please consult the user manual of the cooling unit. In case of a high thermal load

on the torch, please use a cooler with sufficient capacity.

The ESAB products have been designed and manufactured according to the state-of-the-art.

They are safe and reliable when used according to their specifications. The RT torches are in

compliance with the European Norm IEC 60974-7 and marked with the CE-sign.

3.5 Selection of a suitable torch

The torch model must be chosen according to the welding application. The required

duty-cycle and capacity, the cooling method and the wire diameter have to be considered. If

there are increased requirements, for example caused by preheated work pieces, high heat

reflection in corners etc., these must be taken into account by choosing a welding torch with

adequate reserve in power rating.

3.6 Selection of a suitable torch mount for the torch neck

Torch mounts must always be selected in accordance with the type of torch and its geometry.

Various mount types may be used. Choosing the right one is important.

0463 373 001

- 9 -

© ESAB AB 2013

3 TECHNICAL DATA

3.7 Conditions of intended use

1. The product is intended for industrial and commercial use and must only be utilized by

trained personnel. The manufacturer is not liable for any damage or accidents resulting

from improper usage.

2. The RT System may solely be used for the purpose intended by the manufacturer within

the framework of its technical data and with automated handling systems. The type of

torch must be selected to suit the welding task. The maximum required duty cycle, load

capacity, type of cooling, type of guidance and wire diameter must be taken into

consideration for this. In case of higher demands, for example due to pre-heated

workpieces, high heat reflection in corners, etc. a type of torch must be selected with a

corresponding reserve capacity.

3. The RT System was designed for use as a complete system. The incorporation of

components from other manufacturers into the system is not permissible.

4. The RT System may only be installed, operated and serviced by trained personnel. The

installation, operation and maintenance regulations detailed in this manual are to be

followed.

5. The product must be kept dry and protected from humidity when transported, stored or

used.

6. The system is designed for environmental temperatures range from 5° and 40°C (41 to

104°F). In case these limits are exceeded, specific action is needed. In case of frost risks

use a suitable coolant.

0463 373 001

- 10 -

© ESAB AB 2013

4 INSTALLATION

4 INSTALLATION

4.1 Preparation

DANGER!

For you own safety, prior to starting maintenance work in the moving radius of the

robot, make sure that all necessary safety measures have been taken will stay

effective while in the danger area. Please refer to the chapter “Safety

instructions“ in the beginning of this manual.

The following assembly instructions must be exactly adhered to. Attention is to be paid

during assembly that the cables are not damaged. This can lead to a short circuit, which may

damage the electronics of the robot or the welding torch.

To obtain the best repeatability and stability of the system, only use original ESAB

components that have been specially developed for this purpose. Only then can the correct

functioning of the whole welding torch system be guaranteed.

4.2 Installing the RT KS-1 on the robot arm

Use the separate installation and operating instructions for the RT KS-1 safety-off

mechanism for installation of the RT KS-1 on the robot arm.

4.3 Installation of torch mount

Various mounts are available for mounting the RT torch. Depending on the design of the

mount, it may be attached directly or via a mounting flange (a) on the mounting surface (b) of

the safety-off mechanism RT KS-1 or, if applicable, on the intermediate flange RT FL-1.

Only torch mounts having a hole pattern coinciding with that of the mounting surface may be

attached.

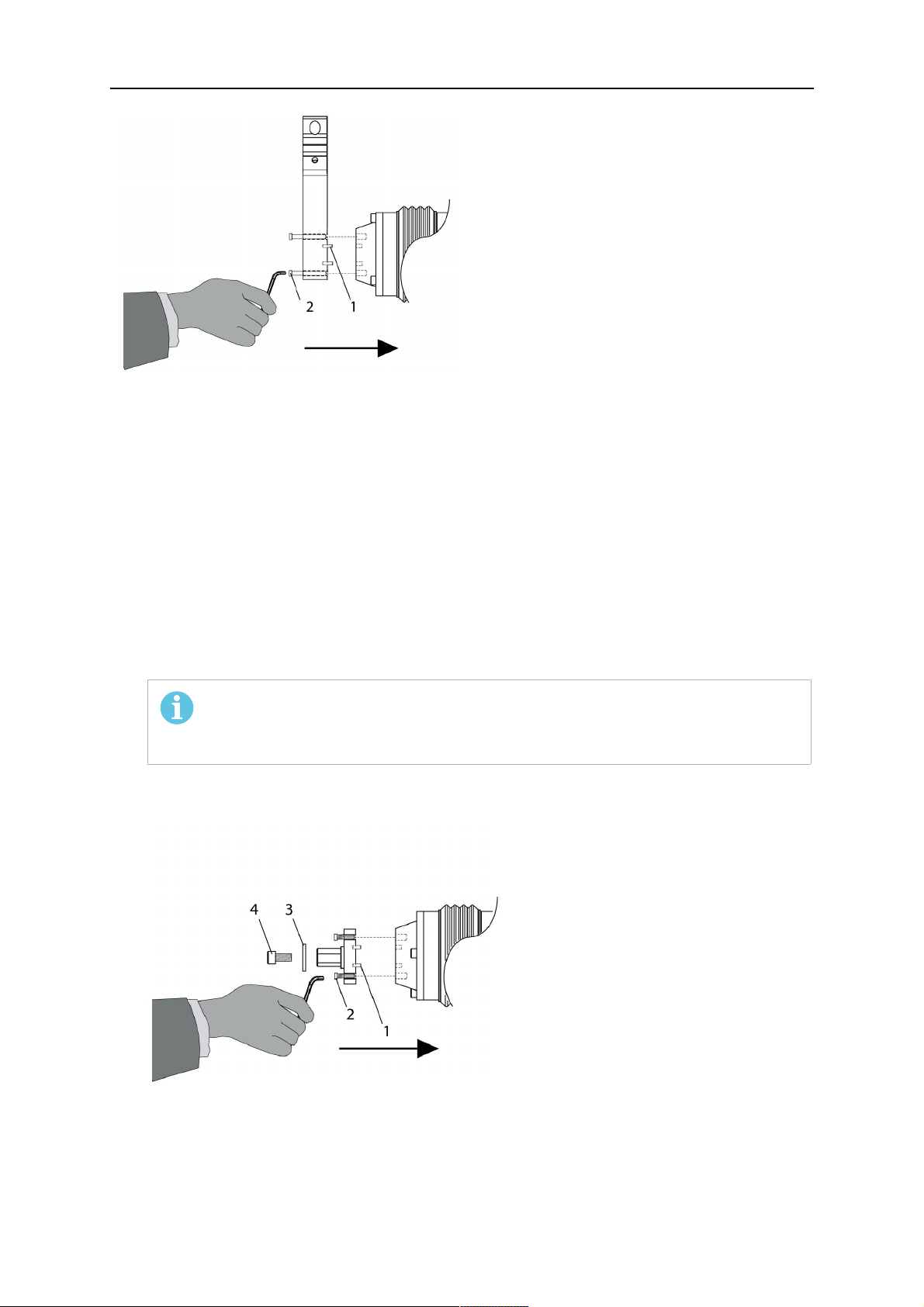

4.3.1 Direct mounting to KS-1

1. If necessary, carefully press the cylindrical pins (1) into the corresponding holes in the

bracket. Avoid the formation of burrs. The pins (Ø4×20) should protrude by

approximately 5 mm.

2. Position the mount on the safety-off mechanism KS-1 and carefully insert the cylindrical

pins (1) into the holes provided. In doing so, take the later position of the torch into

account; 2 mounting positions may be potentially possible.

3. Then screw down the mount evenly using the enclosed cylinder screws (M6×20) with

hexagon socket (2). For further information please refer to the RT KS-1 Installation and

Operating Instructions, Chapter “Installation of torch mount”.

0463 373 001

NOTE!

The maximum tightening torque for the cylinder screw is 7 Nm and the

property class category is 8.8.

- 11 -

© ESAB AB 2013

4 INSTALLATION

Side view

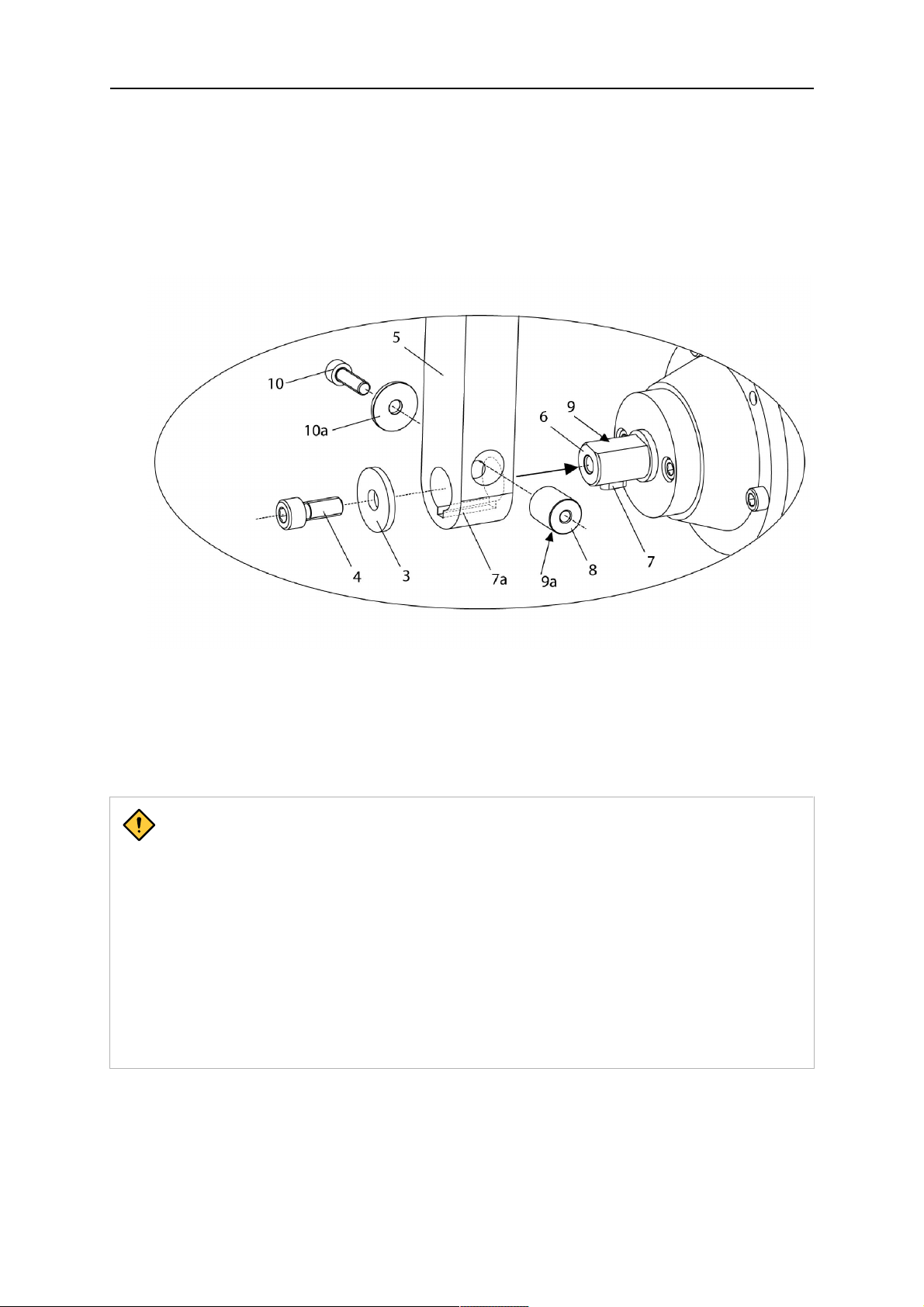

4.3.2 Installation of the mounting flange on the RT KS-1

Torch mounts with a central clamping assembly can only be fastened on the journal of the

mounting flange. For this, the mounting flange must be fastened first.

1. If applicable, carefully press the cylindrical pins (1) into the corresponding holes in the

mounting flange. Avoid the formation of burrs. The pins (Ø4×14) should protrude by

approximately 5 mm.

2. Position the mount on the safety-off mechanism RT KS-1 and carefully insert the

cylindrical pins (1) into the holes provided. In doing so, take the later position of the

torch into account; 2 mounting positions may be potentially possible.

3. Then screw down the mounting flange evenly using the enclosed cylinder screws

(M6×16) with hexagon socket (2). For further information please refer to the RT KS-1

Installation and Operating Instructions, Chapter “Installation of torch mount”.

NOTE!

The maximum tightening torque for the cylinder screws (M6×16) is 7.1 Nm

and the property class category is 8.8.

4. Unscrew the axial cylinder screw (M8×16) with hexagon socket (4) out of the mounting

flange together with the Ø9mm washer (3).

Top view

5. Place the torch mount (5) onto the journal (6) of the mounting flange, paying attention

while doing so to the exact alignment of the feather key (7) and the corresponding

groove (7a).

0463 373 001

- 12 -

© ESAB AB 2013

4 INSTALLATION

6. Insert the clamping mandrel (8) into the lateral hole (see illustration) and position it such

that the mating surfaces (9a) of the clamping mandrel rest on the mating surface (9) of

the journal.

7. Then fix the clamping mandrel from the opposite side using the cylinder screw (M6×30)

with hexagon socket (10) and the Ø22×6.4 mm washer (10a).

8. Finally, screw the axial cylinder screw (4) with the washer (3) into the mounting flange

and tighten firmly.

4.4 Cable assembly installation

The cable assembly must be aligned to the intended use in length and design. The type of

cooling for the torch and the cable assembly must be the same (either gas or water cooled

respectively). In order to prevent damage to the torch system and other components, it is

imperative to observe the following instructions.

CAUTION!

• Coordinate the length and design of the cable assembly to suit the range of

action of the robot.

• Do not bend, compress or overstretch the cable assembly.

• Fix the cable assembly such that is can be moved freely and cannot become

entangled.

• Any additional holding devices possibly installed, for example a balancer,

must not crush or bend the cable assembly.

• Extreme turning movements must be avoided in which the cable assembly

may become twisted.

• Chafing on the robot or other objects must be excluded.

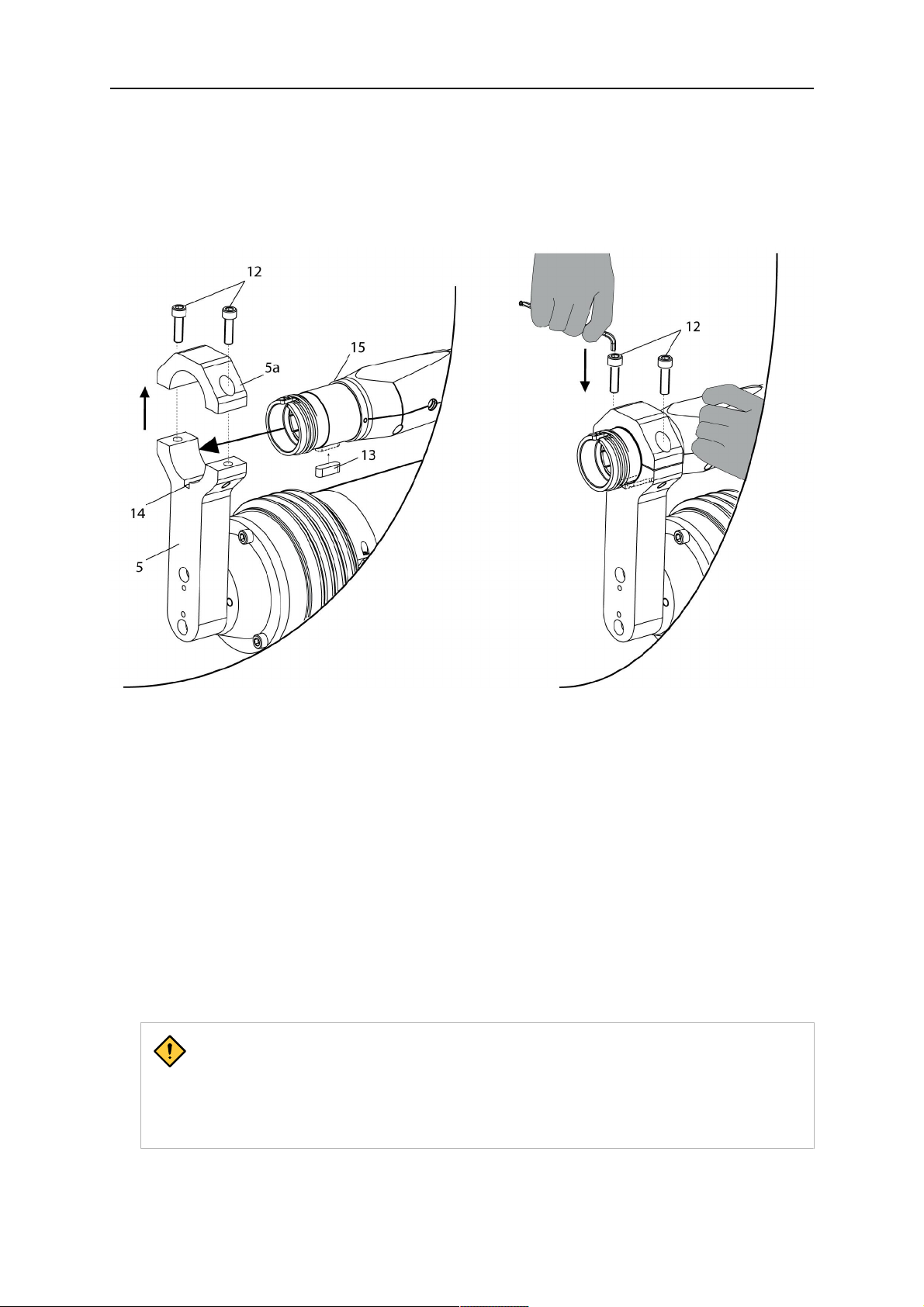

4.4.1 Installing the cable assembly (RT flange) in the torch mount

The front part of the cable assembly is directly clamped into the torch mount.

1. Unscrew the cylinder screws (12) and lift off the top section (5a) of the torch mount.

2. Insert the feather key (13) into the recess of the RT flange (cable assembly) from below.

0463 373 001

- 13 -

© ESAB AB 2013

4 INSTALLATION

3. Align the RT flange including the feather key (13) to the groove (14) of the torch mount

and push into the groove right up to the stop (15).

4. Hold the cable assembly in this position and simultaneously place the top section (5a)

back onto the torch mount. First screw both cylinder screws (12) loosely in to about the

same length, then tighten alternately. The top section (5a) of the mount should have an

even gap to the bottom section (see illustration below).

4.5 Robot welding torch

4.5.1 Equipping the torch neck

The torch must always be equipped to suit the wire diameter and material.

1. For this, select the correct wire guide, contact tip, nozzle holder, gas nozzle, gas diffuser

and spatter protection. You will find an exact overview and possible alternative

equipment elements for various torch models in the spare parts list of your torch. Only

use original ESAB parts; only then is the fitting accuracy ensured.

2. Firmly tighten the nozzle holder and the contact tip using a suitable tool for example the

enclosed monkey wrench.

3. When using a split wire guide, remove the installed guide nipple including the o-ring (16)

from the torch flange upon delivery if necessary (see illustration under

"Installation/removal of the wire guide in the torch neck in case of continuous wire

guidance" section)

CAUTION!

The torch must be completely equipped before welding, especially the gas

diffuser and/or spatter protection and all necessary insulators have to be

installed according to the spare parts list. Welding without these items may

cause immediate destruction of the torch.

Installation or replacement of the wire guide in the torch neck in the case of a separate

wire guide

0463 373 001

- 14 -

© ESAB AB 2013

4 INSTALLATION

The wire guide must be selected to fit the material and diameter of the welding wire. (See

spare parts list)

1. Unfasten sleeve nut and remove torch neck.

2. If applicable, loosen the screw connection of the connecting nipple and pull the neck liner

(wire guide) out of the torch neck from the rear.

3. Remove the gas nozzle and contact tip from the torch.

4. Blow down torch neck with compressed air.

5. Insert the new neck liner into the torch neck from the rear and fasten with the connecting

nipple. Cut the wire guide at the tip holder.

6. For the determination of the thread projection of the contact tip, loosen the connecting

nipple and pull the liner back again; then screw in the contact tip.

7. Insert the neck liner into the torch again until it reaches the contact tip. Now measure the

remaining length that needs to be cut from the liner.

8. Now remove the neck liner again and cut the additional length measured off it’s front

end. If needed, grind down the burred edges.

9. Insert the shortened neck liner into the torch neck again from the rear and screw in the

connecting nipple. Position or screw on the gas nozzle again.

10. Check o-rings on the flange of the torch neck for damage or wear, replace as required.

11. Mount the torch neck as described in "Mounting the torch neck" section. Do not use tools

to tighten the sleeve nut!

Installation/removal of the wire guide in the torch neck in case of continuous wire

guidance

A continuous wire guide, which reaches from the central connection of the cable assembly to

the contact tip of the torch, can be installed as an alternative to the separate wire guide. For

this, the description in "Wire guide installation in cable assembly" section applies. The guide

nipple including o-ring (16) must be inserted in the torch neck for this.

4.5.2 Mounting the torch neck

Check the o-rings on the flange of the torch neck before each mounting for damage or loss

and replace the o-rings if necessary. Missing or faulty o-rings lead to leaks of shielding gas

and coolant. Depending on the wire guide the torch neck must be equipped as described in

"Equipping the torch neck" section and the cable assembly as in "Installation of a split wire

guide (cable assembly)" section.

0463 373 001

- 15 -

© ESAB AB 2013

4 INSTALLATION

1. Position the torch necks as shown below and tighten the sleeve nut by hand in clockwise

direction. Do not use tools!

2. The correct seating of the torch at the RT flange of the cable assembly can be checked

by means of the window (11). If the torch has been correctly mounted, no gap should be

able to be seen through the window (11).

4.6 Wire guide installation in cable assembly

The wire guide is inserted through the cable assembly from the rear. The correct liner must

be selected to suit the filler material used and wire diameter. The correct function of the total

system can only be guaranteed if original ESAB wire guides are used. It is possible to use a

continuous wire guide from the cable assembly to the contact tip or a split wire guide (torch

neck extra, cable assembly extra).

4.6.1 Installation of a split wire guide (cable assembly)

Installing a steel liner

The wire guide is inserted through the cable assembly from the rear and reaches to the RT

flange. The following worksteps must be followed for the correct calculation of the length

(example for Euro central connector):

1. Install the guide nipple with stop (E) in the center hole of the RT flange.

2. Remove the sleeve nut (D) from the Euro connector.

3. Insert the liner through the central connection and push forwards as far as it will go in the

guide nipple (E) applying light pressure.

CAUTION!

Ensure that the wire guide has advanced right up to on the stop at the front.

To do this, rotate the wire guide and push forward again gently.

4. Now measure the excess length that needs to be cut from the liner.

0463 373 001

- 16 -

© ESAB AB 2013

4 INSTALLATION

5. Now remove the liner again and cut the additional length measured off it’s front end. If

needed, grind down the burred edges. Make sure the inner opening of the liner is not

obstructed by the cut wire end.

6. Reinstall the wire guide and attach the sleeve nut (D).

Installing a plastic liner

1. Install the guide nipple with stop (E) in the center hole of the RT flange.

2. Remove the sleeve nut (D) from the Euro connector.

3. Make a clean cut at the front end of the liner and chamfer the edges (for example with a

pencil sharpener).

4. Insert the liner (E) through the central connector into the cable assembly until it reaches

the stop. If it gets stuck, rotate the liner to free it and facilitate installation. Note: Make

sure the liner is completely inserted by rotating it and slightly pushing it forward, until you

can feel it has reached its stop.

5. Mount the nipple (B) and the o-ring (C), move it to the right position and fix it with the

sleeve nut (D) of the euro central connector.

6. Measure the required overlap needed inside the wire feeder cabinet and cut the liner

accordingly.

4.6.2 Installation of a continuous wire guide (cable assembly)

Installing a steel liner

The wire guide is inserted through the cable assembly from the rear and reaches to the

contact tip. The following worksteps must be followed for the correct calculation of the length

(example for Euro central connector):

1. Install the torch (see "Mounting the torch neck" section).

2. Remove the gas nozzle and contact tip from the torch.

3. Remove the sleeve nut (D) from the Euro connector.

4. Push in the liner through the central connector and fix with the sleeve nut.

5. Cut off the liner flush with the nozzle holder. To determine the thread projection of the

contact tip, pull the liner backwards and screw in the contact tip.

6. Push the liner forwards as far as it will go to the contact tip applying light pressure on the

liner and measure the length to be shortened at the rear.

7. Now remove the liner again and cut the excess length measured off it’s front end. If

needed, grind down the burred edges. Make sure the inner opening of the liner is not

obstructed by the cut wire end.

0463 373 001

- 17 -

© ESAB AB 2013

4 INSTALLATION

8. The insulation of the liner must be removed after cutting off in the front area, such that

the insulation protrudes out of the RT flange by approximately 5 cm. For this, briefly

remove the torch neck.

9. Push the liner back in again and fix with the sleeve nut (D). Re-install the gas nozzle.

Installing a plastic liner

1. Mount the torch neck (see "Mounting the torch neck" section) and equip it with a gas

nozzle and contact tip.

2. Remove the sleeve nut (D) from the Euro connector.

3. Cleanly cut off the liner, slightly break the outer edges, point slightly. (for example with a

pencil sharpener).

4. Insert the liner through the central connector into the cable assembly with fitted torch. If it

gets stuck, rotate the liner to free it and facilitate installation. Note: Make sure the liner is

completely inserted by rotating it and slightly pushing it forward, until you can feel it has

reached its stop.

5. Mount the nipple (B) and the o-ring (C), move it to the right position and fix it with the

sleeve nut (D) of the euro central connector.

6. Measure the required overlap needed inside the wire feeder cabinet and cut the liner

accordingly.

4.7 Connection at the wire feeder cabinet

In order to be able to create the connection, the cable assembly must be mounted as

described in "Cable assembly installation" section and equipped following "Wire guide

installation in cable assembly" section. Only then can the central and media connection take

place. Proceed as described below:

0463 373 001

- 18 -

© ESAB AB 2013

4 INSTALLATION

1. Connect the central connector of the cable assembly to the wire feeder cabinet socket.

Tighten the central connector sleeve nut fingertight. Do not use tools!

2. Connect the water hoses to the cooling circuit in water cooled systems. The end of the

hose marked blue to the water outlet, and the end marked red to the water return.

3. Connect the blow-out line to the corresponding connection of the wire feeder cabinet.

4. Connect the control line plug to the wire feeder cabinet.

0463 373 001

NOTE!

All hoses and the control line must be installed such that they cannot bend or be

damaged!

- 19 -

© ESAB AB 2013

5 INITIAL OPERATION

5 INITIAL OPERATION

CAUTION!

Before starting the system, check the whole installation according to the

manufacturer's instructions and applicable safety regulations.

Check the following to make sure that the system has been installed correctly:

1. Are all parts securely attached (torch, torch mount, cable assembly, RT KS-1 safety-off

mechanism or RT FL-1 rigid intermediate flange and wire feeder)?

2. Are all media hoses connected correctly and protected from damage?

3. Is the Euro central connector or direct connector fastened tightly?

4. Is the cable assembly length correct and suitable for the installation? The cable must not

be bent sharply, any risk of the cable catching on another object must be eliminated.

5. Is the safety-off circuit of the RT KS-1 connected correctly and functional? (move torch

by hand to test).

6. Is the torch firmly attached and is it completely equipped?

7. Is the wire guide installed according to the manual?

8. Are all lines and tubes arranged so they can not be damaged or bent?

Take the necessary safety precautions before starting up the welding process!

The wire run-in can now be started either via the wire run-in pushbutton (2a) see "Overview

of the RT welding torch system" section or via the wire run-in at the wire feeder cabinet.

0463 373 001

- 20 -

© ESAB AB 2013

6 SERVICING AND MAINTENANCE

6 SERVICING AND MAINTENANCE

DANGER!

• Before performing maintenance on the system, the main power of the

installation must be turned off. Note the safety regulations at the beginning of

this manual!

• Damaged torches or cable assemblies must no be used any more! Known

defects must be repaired by qualified personnel prior to the next use of the

equipment.

• In order to avoid damage to the system or injuries to persons, the following

must be observed: Repairs on the RT KS-1 safety-off mechanism may only

be carried out by ESAB!

DANGER!

Risk of burn injuries

Gas nozzle and torch head get very hot during welding. Let the torch cool down

prior to doing maintenance work!

To assure a faultless function and long life of the equipment, torch and cable assembly must

be checked and serviced regularly.

Cleaning and maintenance work must be done at the latest, if the welding performance is

degrading.

1. Check the torch and cable assembly for damages before every use. Damages must be

repaired by qualified personnel prior to further use of the product. This is especially

important in regard of damages on the electrical insulation of the torch or cable.

2. Worn out and damaged parts on the torch have to be exchanged immediately against

original spare parts and consumables.

3. The contact tip should be exchanged if the inner hole is countersunk or if there are

ignition problems.

4. Change the contact tip and the liner if there are wire feeding problems. Take care to

install the new liner correctly and precisely fit it to the length of the cable.

5. When changing the liner, or more often if necessary, blow out the liner guide tube of the

torch with compressed air to remove dust and wire grit.

6. The use of a high quality anti-spatter spray, for example RT Anti spatter liquid, is highly

recommended and will tremendously increase the life time of the consumables.

7. Contact tip and gas nozzle should be cleaned as soon as there is noticeable spatter

adhesion. It must be avoided that a spatter bridge will build up between contact tip and

gas nozzle, the torch could be damaged.

8. The gas nozzle should be cleaned regularly on the inside to prevent adhering spatter

from causing gas swirling.

9. Make sure that the cooling liquid is clean, if required exchange it. Impurities in the

cooling liquid can obstruct the water channels of the torch.

The following service intervals apply to the ESAB RT welding torch system:

Daily:

• Visual inspection for damages – for example bends or cracks.

• Verify the correct position of the cable assembly, it should be neither under tension, nor

compression.

• Inspect the media connections for leakage.

0463 373 001

- 21 -

© ESAB AB 2013

6 SERVICING AND MAINTENANCE

Monthly or more often in heavy use:

• Blow out the wire guide channel with compressed air (remove contact tip and wire

guide).

• Ascertain that all screws are tightened.

• If necessary: Inspect all connections and hoses for damages.

0463 373 001

- 22 -

© ESAB AB 2013

7 SPARE PARTS LIST

7 SPARE PARTS LIST

7.1 Robot Welding Torch

For spare and wearing parts, refer to the enclosed respective spare parts list of your RT

torch. Only use original ESAB parts; only then is the fitting accuracy ensured.

7.2 System components

Item Part No. Designation

4 700300434 RT KS-1 safety-off mechanism complete

17 on request Rubber boot for KS-1 safety-off mechanism

E on request Fitting with stop

18 on request Connector cover, red

19 on request Connector cover, blue

20 on request Quick connector (for water)

21 on request Quick connector 6 mm (for gas)

22 on request O-ring 4.0 x 1.0 mm (for gas)

23 on request O-ring 4.0 x 1.0 mm (for gas)

24 on request Nut M10x1

7.3 Wire Guides

Please choose the wire guide suitable for the wire diameter and material. Only use original

ESAB parts; only then is proper functioning ensured.

0463 373 001

- 23 -

© ESAB AB 2013

7 SPARE PARTS LIST

Item Part No. Designation

A (for steel wire) 700300498 Liner blue 1.50m, wire 0.8-1.0 mm

700300499 Liner blue 1.70m, wire 0.8-1.0 mm

700300500 Liner blue 2.00m, wire 0.8-1.0 mm

700300322 Liner blue 3.50m wire 0.8-1.0 mm

700300501 Liner red, 1.50m, wire 1.0-1.2 mm

700300502 Liner red, 1.70m, wire 1.0-1.2 mm

700300503 Liner red, 2.00m, wire 1.0-1.2 mm

700300507 Liner red, 2.50m, wire 1.0-1.2 mm

700300508 Liner red, 3.50m, wire 1.0-1.2 mm

700300504 Liner yellow, 1.50m, wire 1.2-1.6 mm

700300505 Liner yellow, 1.70m, wire 1.2-1.6 mm

700300506 Liner yellow, 2.00m, wire 1.2-1.6 mm

B (for alu and

stainless steel

700300320 PTFE Liner, 3.50m wire 1.0-1.2 mm

700300321 PA Liner, 3.50m, wire 1.0-1,2 mm

wire)

D (for alu and

stainless steel

700300468 Neck liner bronze, 217 mm, wire 1.2-1.6 mm

700300469 Neck liner steel, 217 mm, wire 0.8-1.2 mm

wire)

D (for steel wire) 700300470 Neck liner steel, 217 mm, wire 1.2-1.6 mm

700300472 Neck liner bronze, 217 mm, wire 0.8-1.0 mm

E 700300473 Fitting with stop size 4.0-4.7 mm

0463 373 001

- 24 -

© ESAB AB 2013

8 TROUBLESHOOTING

8 TROUBLESHOOTING

Fault Possible cause Action

Cannot feed in

the wire

Torch is

getting too hot

Have you straightened the welding

wire before feeding into the cable

assembly?

Were the RT torch and the cable

assembly equipped correctly for the

wire diameter and wire material?

Only when using a split wire guide:

Has the wire guide been correctly

inserted into the cable assembly?

Is the contact tip blocked with wire

debris or the wire guide worn, is the

wire feed impeded by dirt and debris

in the torch?

Contact tip or tip holder are not

tightened correctly.

If necessary, pull the welding wire

out again, cut off and deburr the end

and straighten the first 10 cm of the

wire. Then thread back into the

cable assembly.

Check wire guide (cable assembly

and torch neck) and the contact tip.

Pull the wire guide a short way out of

the Euro-connector. When inserting

you should feel the last centimetre

slip into the guide nipple in the torch

interface. Otherwise the wire guide

may be too short and not fully

inserted.

Replace the contact tip and/or wire

guide, blow out torch neck, wire

guide conduit and wire guide with

compressed air.

Use a suitable tool for tightening

hand-tight.

Wire feeding

problems

Cooling system is not working well. Check water flow, filling level and

cleanliness.

Cooling system is not correctly

connected.

Check connections (water inlet and

return).

Torch overstrained. Observe technical data, if needed,

choose a different type.

Cable assembly defective. Check cables, tubes and

connections.

Contact tip is worn. Exchange contact tip.

Liner is worn / dirty. Check the liner, blow it out, if needed

exchange it.

Consumables used are not suitable

Check with spare part list.

for the wire diameter or material.

Wire feeder not set-up properly. Check the wire feeding rolls, the

contact pressure and the spool

brake.

Cable assembly is bent or laid out in

too small radii or flexed.

Check the cable assembly for

damages. Can the liner be inserted

easily? Install as instructed (see

"Cable assembly installation"

section).

0463 373 001

Wire is contaminated. Use a cleaning felt.

- 25 -

© ESAB AB 2013

8 TROUBLESHOOTING

Wire feed

stops during

welding

Welding

process is

stopping

Pores in the

seam

Wire spool is empty? Check the quantity of the welding

wire on the spool in the wire feeder.

Is there a wire blockage in the cable

assembly?

Check wire feed (possibly too fast),

check the contact tip for

contamination/clogging, clean or

replace the contact tip if required.

Wire burn back into the contact tip or

Replace the contact tip.

worn contact tip.

Safety-off mechanism has triggered. Search for collision points and

prevent them. Check control line for

a loose contact .

Safety-off mechanism has triggered

without collision.

Gas swirl caused by spatter

adherence.

Too small or extremely high gas flow

in the torch.

Check control line for cable

breakage/loose contact.

Clean the torch head, use gas

diffuser/spatter protection.

Check flow rate with measurement

tool.

Gas supply defective. Check flow rate and possible

leakage.

Moisture or contamination on the

wire or on the work piece.

Check the wire and the work piece,

use less or different antispatter

liquid.

Arc is not

stable

Contact tip is worn. Exchange contact tip.

Wrong welding parameters. Check the set-up of the welding

torch.

Insufficient electrical connections in

the circuit.

Check all electrical connections

(including ground cable) between

the power source torch or workpiece

for firm seating.

0463 373 001

- 26 -

© ESAB AB 2013

8 TROUBLESHOOTING

0463 373 001

- 27 -

© ESAB AB 2013

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna-Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 745 11 28

BULGARIA

ESAB Kft Representative Office

Sofia

Tel: +359 2 974 42 88

Fax: +359 2 974 42 88

THE CZECH REPUBLIC

ESAB VAMBERK s.r.o.

Vamberk

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Herlev

Tel: +45 36 30 01 11

Fax: +45 36 30 40 03

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel: +33 1 30 75 55 00

Fax: +33 1 30 75 55 24

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 218

HUNGARY

ESAB Kft

Budapest

Tel: +36 1 20 44 182

Fax: +36 1 20 44 186

ITALY

ESAB Saldatura S.p.A.

Bareggio (Mi)

Tel: +39 02 97 96 8.1

Fax: +39 02 97 96 87 01

THE NETHERLANDS

ESAB Nederland B.V.

Amersfoort

Tel: +31 33 422 35 55

Fax: +31 33 422 35 44

NORWAY

AS ESAB

Larvik

Tel: +47 33 12 10 00

Fax: +47 33 11 52 03

POLAND

ESAB Sp.zo.o.

Katowice

Tel: +48 32 351 11 00

Fax: +48 32 351 11 20

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 8 310 960

Fax: +351 1 859 1277

ROMANIA

ESAB Romania Trading SRL

Bucharest

Tel: +40 316 900 600

Fax: +40 316 900 601

RUSSIA

LLC ESAB

Moscow

Tel: +7 (495) 663 20 08

Fax: +7 (495) 663 20 09

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel: +421 7 44 88 24 26

Fax: +421 7 44 88 87 41

SPAIN

ESAB Ibérica S.A.

Alcalá de Henares (MADRID)

Tel: +34 91 878 3600

Fax: +34 91 802 3461

SWEDEN

ESAB Sverige AB

Gothenburg

Tel: +46 31 50 95 00

Fax: +46 31 50 92 22

ESAB International AB

Gothenburg

Tel: +46 31 50 90 00

Fax: +46 31 50 93 60

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

UKRAINE

ESAB Ukraine LLC

Kiev

Tel: +38 (044) 501 23 24

Fax: +38 (044) 575 21 88

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem-MG

Tel: +55 31 2191 4333

Fax: +55 31 2191 4440

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting

Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 57 48

Asia/Pacific

AUSTRALIA

ESAB South Pacific

Archerfield BC QLD 4108

Tel: +61 1300 372 228

Fax: +61 7 3711 2328

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 2326 3000

Fax: +86 21 6566 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. ESABindo Pratama

Jakarta

Tel: +62 21 460 0188

Fax: +62 21 461 2929

JAPAN

ESAB Japan

Tokyo

Tel: +81 45 670 7073

Fax: +81 45 670 7001

MALAYSIA

ESAB (Malaysia) Snd Bhd

USJ

Tel: +603 8023 7835

Fax: +603 8023 0225

SINGAPORE

ESAB Asia/Pacific Pte Ltd

Singapore

Tel: +65 6861 43 22

Fax: +65 6861 31 95

SOUTH KOREA

ESAB SeAH Corporation

Kyungnam

Tel: +82 55 269 8170

Fax: +82 55 289 8864

UNITED ARAB EMIRATES

ESAB Middle East FZE

Dubai

Tel: +971 4 887 21 11

Fax: +971 4 887 22 63

Africa

EGYPT

ESAB Egypt

Dokki-Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

SOUTH AFRICA

ESAB Africa Welding & Cutting

Ltd

Durbanvill 7570 - Cape Town

Tel: +27 (0)21 975 8924

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.com

www.esab.com

Loading...

Loading...