Page 1

PUA 1

Programming manual

0456 685 174 010815

Valid for program version 3.00V, 3.01V, 3.02V, 3.03V

Page 2

ENGLISH

1 INTRODUCTION 4...................................................

1.1 Main menu 4...............................................................

1.2 Using the controller 4........................................................

1.3 Choice of language 5........................................................

1.4 Display 7...................................................................

1.5 Keys 8.....................................................................

1.6 Settings in general 8.........................................................

1.7 ENTER and QUIT 9.........................................................

2 MIG/MAG welding 10..................................................

2.1 The expression “wire“ 10......................................................

2.2 Synergic welding 10..........................................................

2.3 Basic settings 10.............................................................

2.4 Welding data settings 13......................................................

2.5 Start and stop settings 13.....................................................

2.6 Gas purge, cold wire feed and trigger latch 14....................................

2.7 MIG/MAG configuration 16....................................................

2.8 Setting--up example MIG/MAG 16..............................................

3 MMA welding 25......................................................

3.1 Synergic mode 25............................................................

3.2 Basic settings 25.............................................................

3.3 Welding data 26..............................................................

3.4 MMA--configuration 27........................................................

3.5 Setting--up example MMA 27..................................................

4 TIG welding 29.......................................................

4.1 Basic settings 29.............................................................

4.2 Welding data settings 30......................................................

4.3 TIG--configuration 32.........................................................

4.4 Setting--up example TIG 32....................................................

5 Arc air gouging 37....................................................

5.1 Synergic mode 37............................................................

5.2 Basic settings 37.............................................................

5.3 Welding data 37..............................................................

5.4 Setting--up example for arc air gouging 38.......................................

6 MEASURED VALUE DISPLA Y 40.......................................

6.1 Description of measured value display 40........................................

6.2 Changing set values 41.......................................................

7MEMORY 42..........................................................

7.1 Store 42....................................................................

7.2 Delete 44...................................................................

7.3 Recall 45....................................................................

7.4 Copy 45.....................................................................

7.5 Remote control 47............................................................

8FASTMODE 48.......................................................

8.1 Description of fast mode 48....................................................

8.2 Configuring the fast mode keys 48..............................................

TOCe

-- 2 --

Page 3

ENGLISH

9 AUXILIARY FUNCTIONS 49............................................

9.1 Memory card operations 49....................................................

9.2 Configuration 51.............................................................

9.3 Quality functions 65..........................................................

9.4 Production statistics 66.......................................................

9.5 Error log 67..................................................................

9.6 User--defined synergic lines for MIG/MAG 70....................................

9.7 Serial communication 73......................................................

9.8 Program Upgrades 74........................................................

10 APPENDIX 77.........................................................

10.1 Setting ranges and setting steps 77.............................................

10.2 Menu structure 79............................................................

TOCe

-- 3 --

Page 4

GB

1 INTRODUCTION

ARISTO 2000 is one of the most practical welding power sources on the market.

In order to get the maximum benefit from your welding equipment we recommend

that you read this manual carefully.

You will find that there are many features to improve your work and make it easier.

All settings are made using the PUA 1 controller.

You will quickly find this very easy to use. To help you find the sections of the manual

that are of special interest see the following:

Section 1: Introduction and basics

Sections 2--5: MIG/MAG, MMA, TIG and arc--air gouging, settings directly

related to these parameters.

Sections 6--8: Measured value display, using the memory and quick settings.

Sections 9--10: Auxiliary functions and appendix.

See also the menu structure on the last page of this manual.

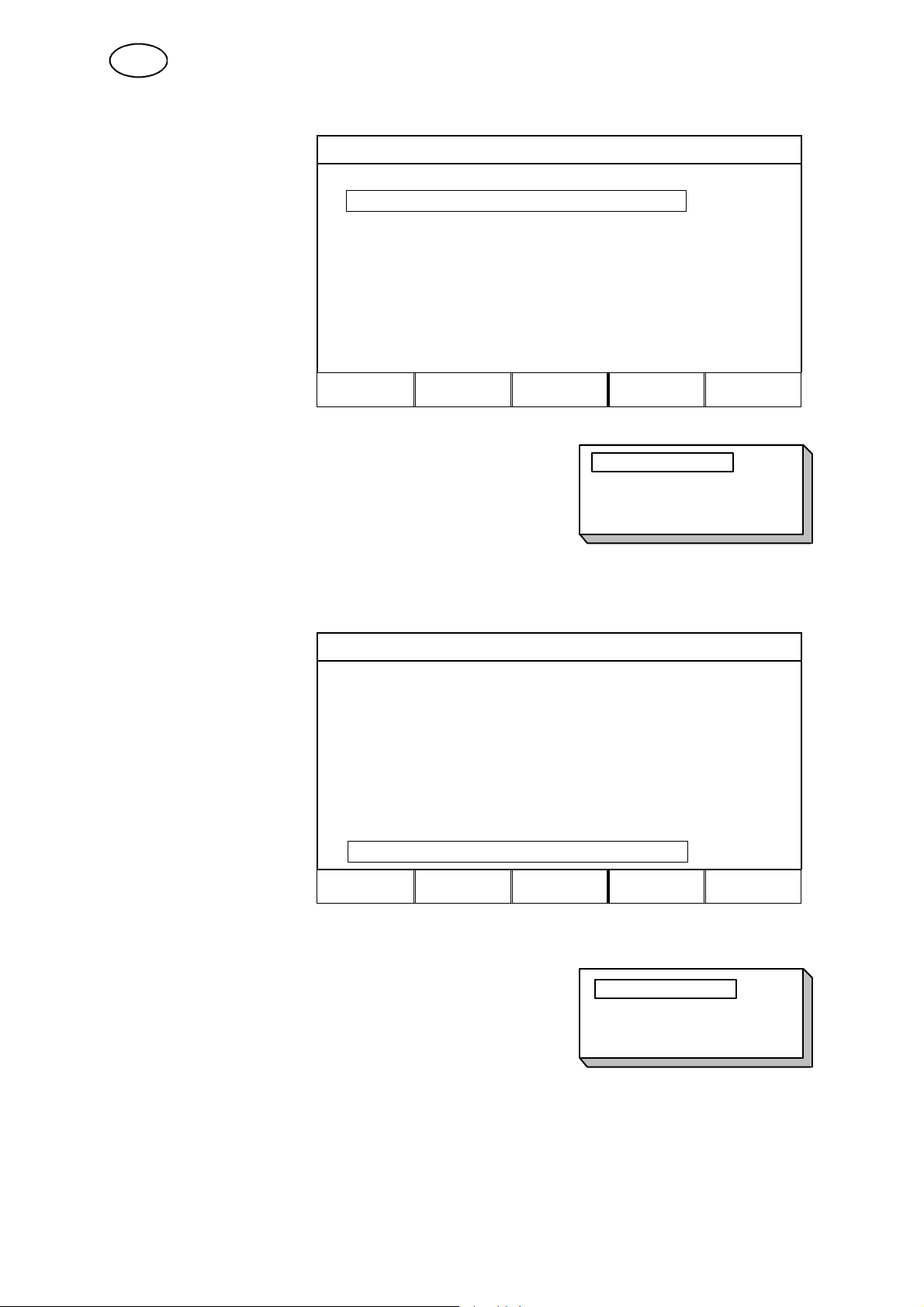

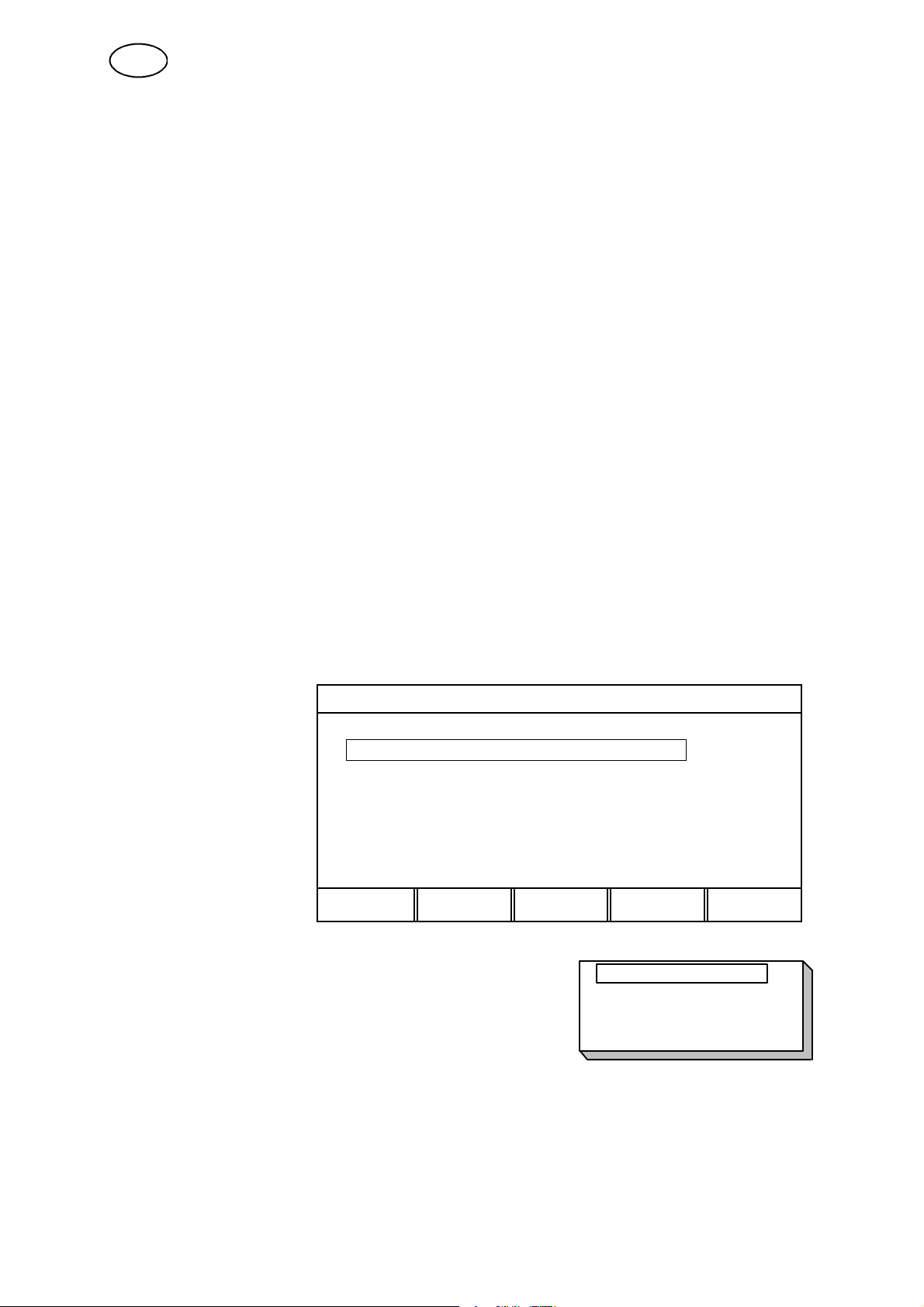

1.1 Main menu

ESAB LUD 450

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: Fe

SHIELDING GAS: Ar+2O% CO2

WIRE DIMENSION: 1.2 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

FAST

MODE

ENTER

1.2 Using the controller

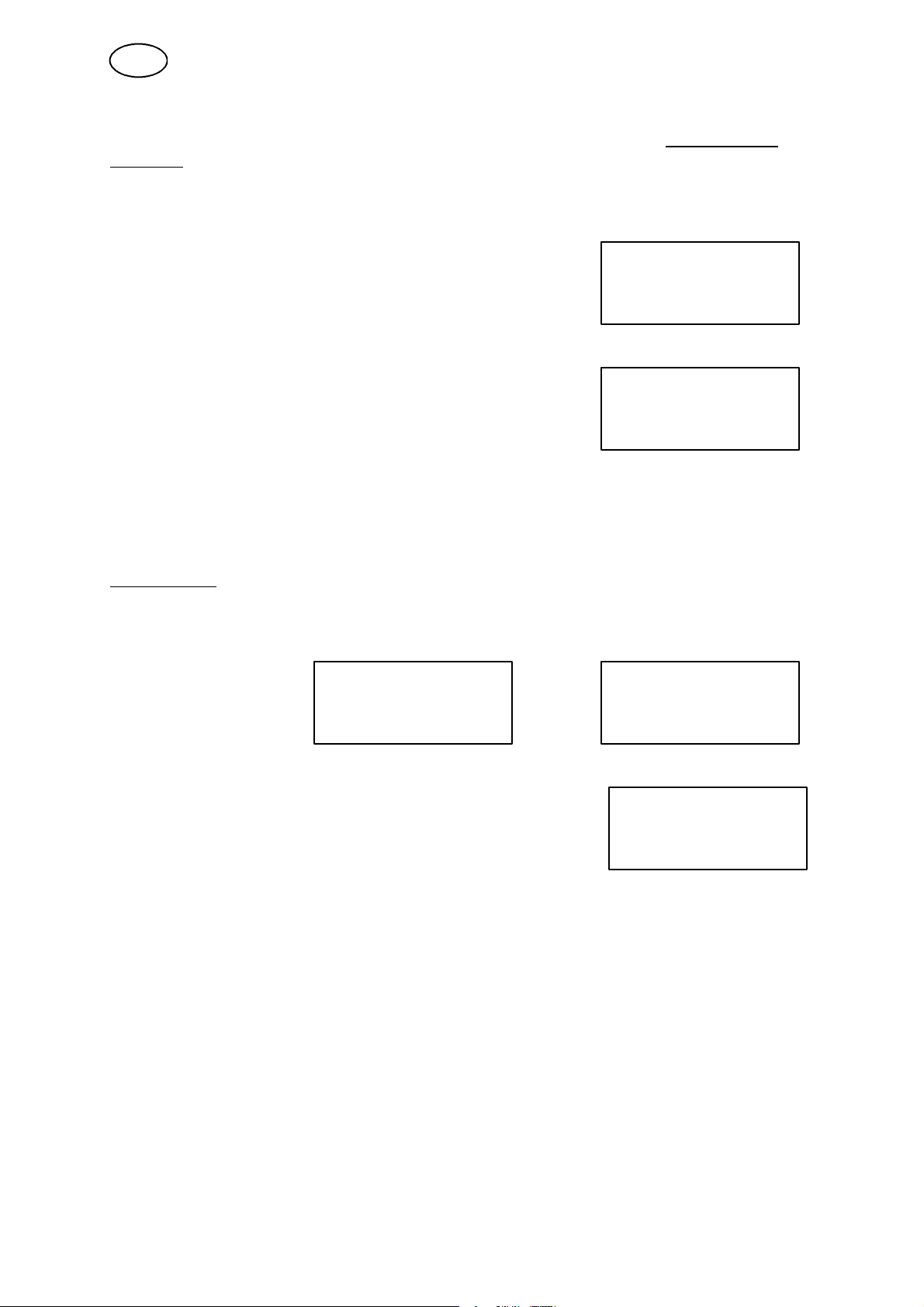

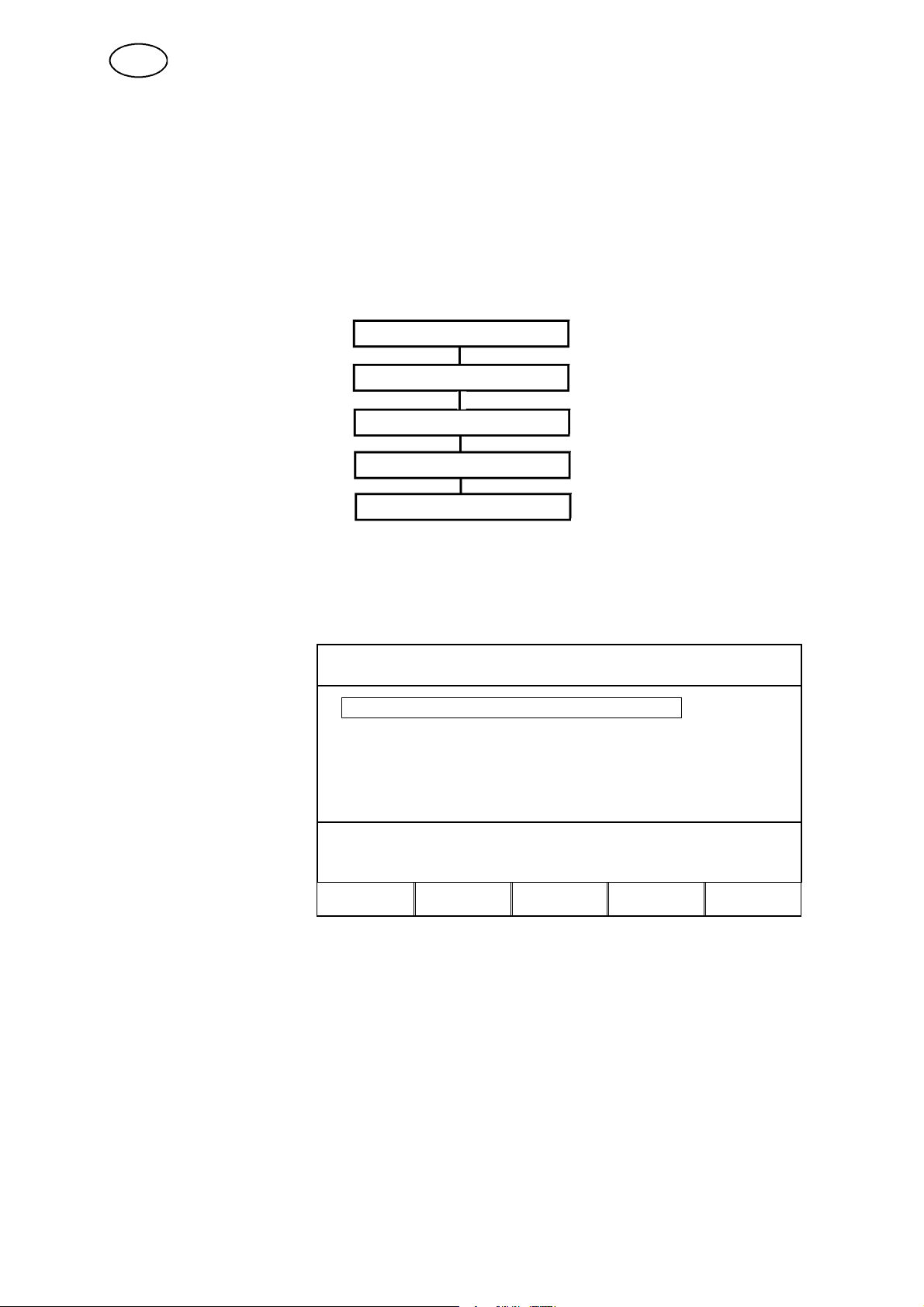

The controller can be said to consist of two units; the working memory and the

weld data memory.

COLLECT

WELD DATA

MEMORY

STORE

WORKING

MEMORY

The working memory is used to store a complete set of welding parameters, which

can then be saved in the weld data memory.

The welding process is always controlled by the contents of the working memory.

This also makes it possible to download a set of welding parameters from the weld

data memory to the working memory.

Note that the working memory always contains the last set of welding parameters

that were used, in other words the working memory is never empty or “initialised“.

bu14d01e

-- 4 --

Page 5

GB

1.3 Choice of language

The controller is programmed in up to four different languages, one of which is

always English.

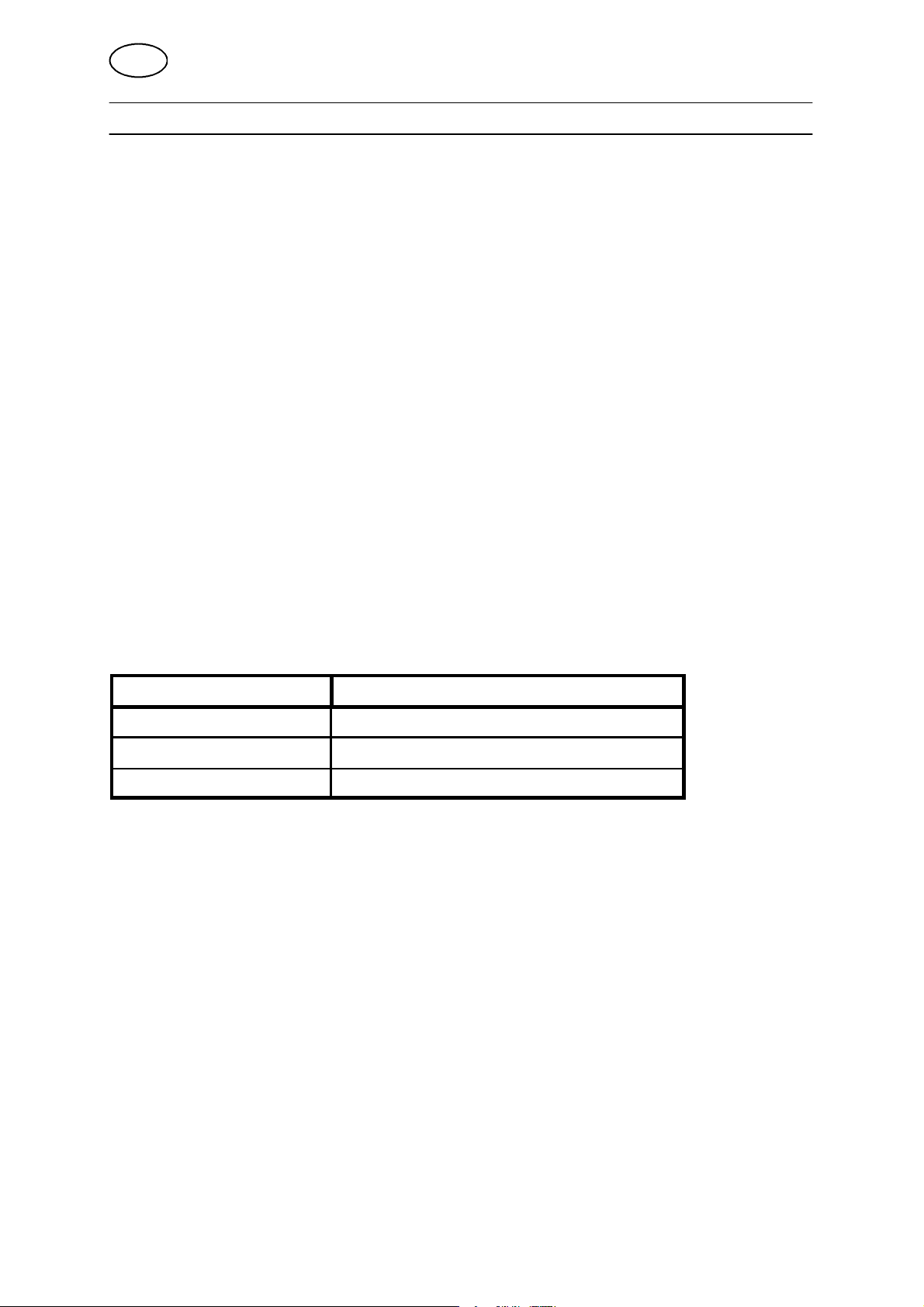

Controller 456 290--881 Controller 456 290--882 Controller 456 290--883

English English English

German Swedish Dutch

French Finnish Spanish

Italian Danish Portuguese

Controller 456 290--884 Controller 456 290--885

English US English

Hungarian Spanish

Polish French

Czech Portuguese

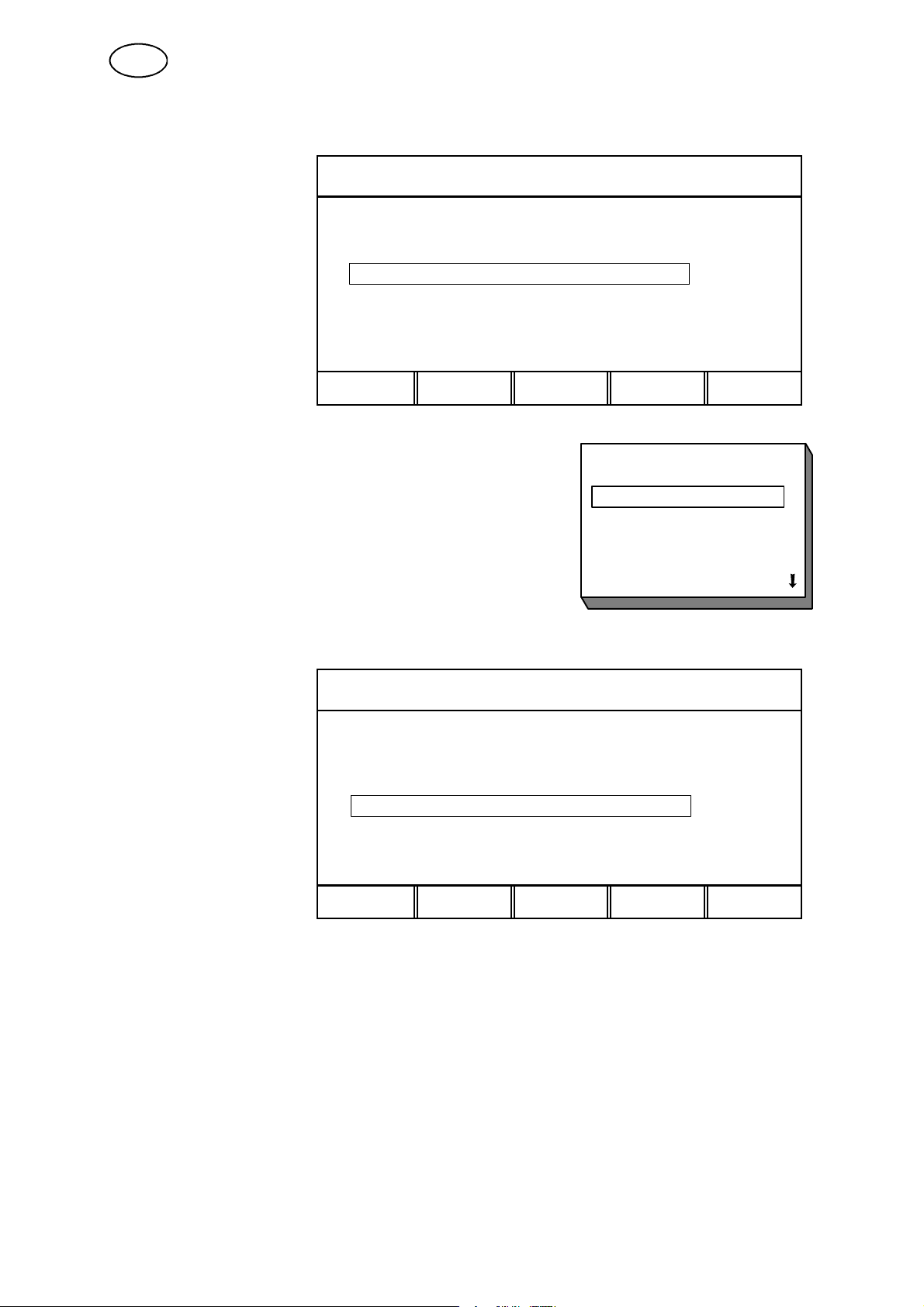

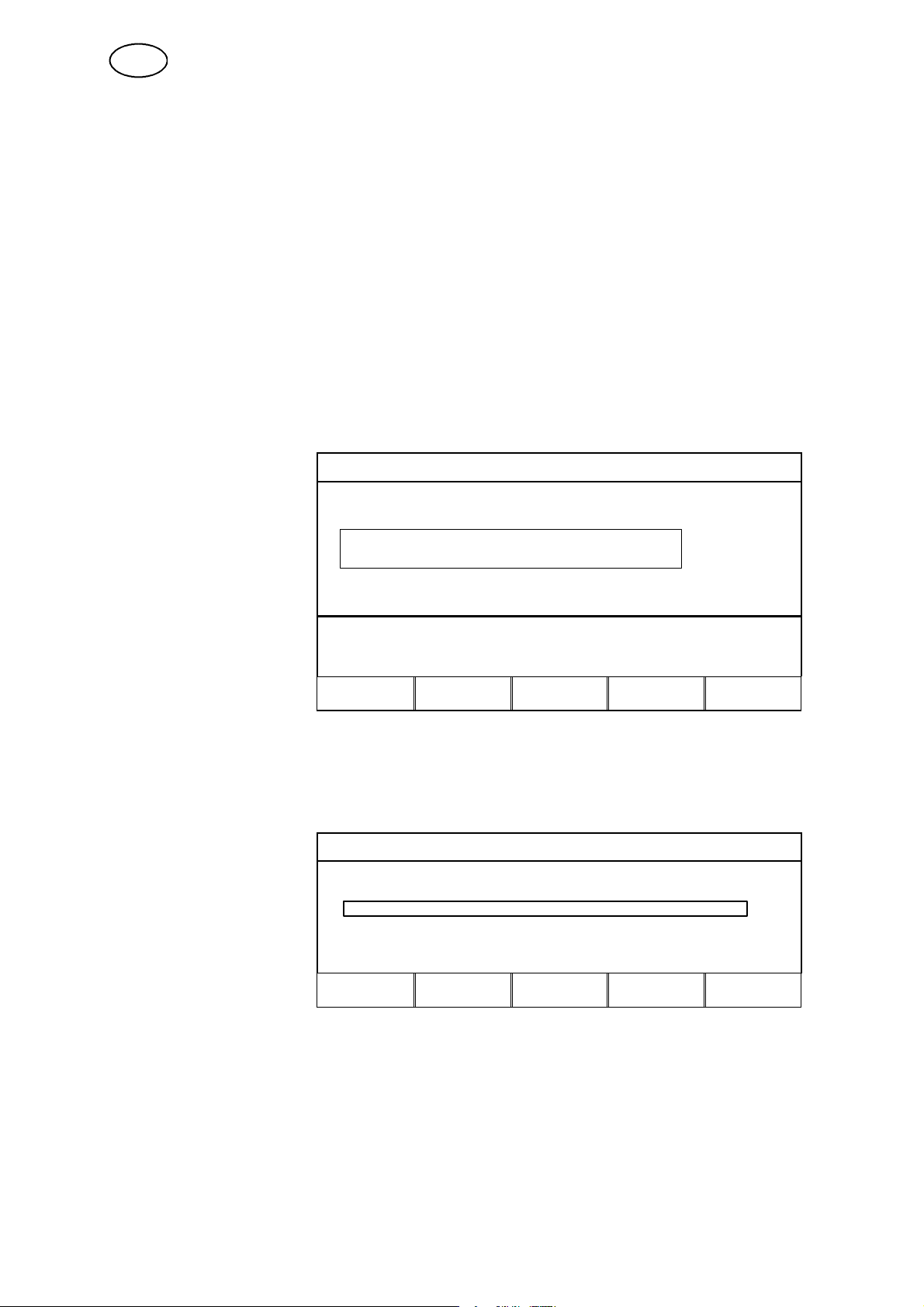

How to Choose the Language and Unit of length (Metric,Inch):

We start by pressing the MENU key to call up the main menu.

ESAB LUD 450

Using the arrow

keys, move the

cursor to the

line AUXILIARY

FUNCTIONS

and press

ENTER.

Position the cursor

on the line

CONFIGURATION

and press ENTER.

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: Fe

SHIELDING GAS: Ar+8%CO2

WIRE DIMENSION: 1.2 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

AUXILIARY FUNCTIONS

MEMORY CARDS OPERATIONS

CONFIGURATION

QUALITY FUNCTIONS

PRODUCTION STATISTICS

ERROR LOG

USER DEFINED SYNERGIC DATA

SERIAL COMMUNICATION

SOFTWARE UPGRADE

"

FAST

MODE

ENTER

bu14d01e

QUIT ENTER

-- 5 --

Page 6

GB

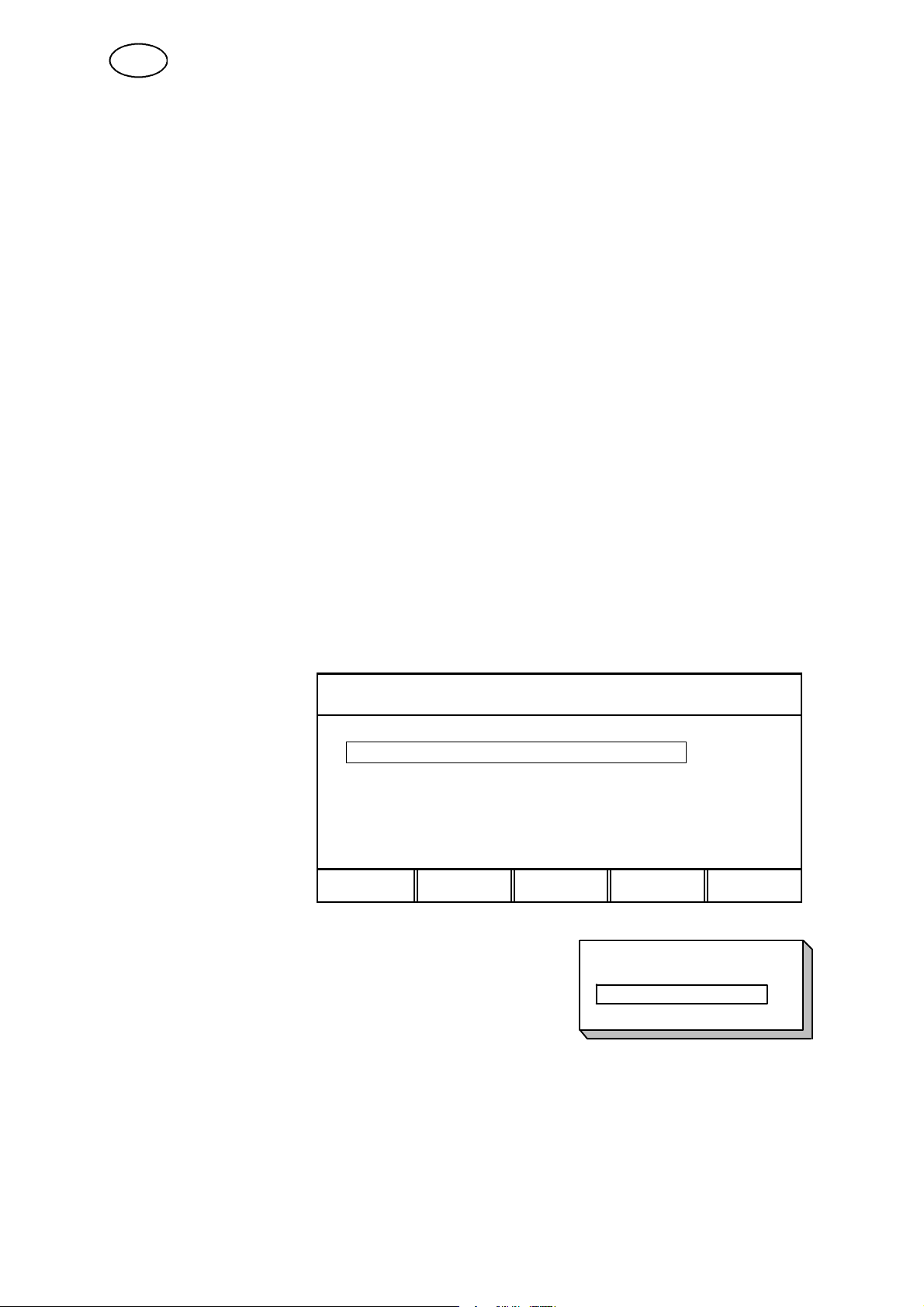

Press ENTER to

display the list of

options.

AUXILIARY FUNCTIONS -- CONFIGURATION

LANGUAGE: SVENSKA

LOCK FUNCTION: OFF

REMOTE CONTROLS

MIG/MAG DEFAULTS

MMA DEFAULTS

TIG DEFAULTS

GENERAL DEFAULTS

MULTIPLE WIRE FEEDERS

UNITOFLENGTH

QUIT ENTER

Position the cursor on the line for

choice of language in the list and press ENTER.

AUXILIARY FUNCTIONS -- CONFIGURATION

Press ENTER to

display the list of

options.

LANGUAGE: SVENSKA

LOCK FUNCTION: OFF

REMOTE CONTROLS

MIG/MAG DEFAULTS

MMA DEFAULTS

TIG DEFAULTS

GENERAL DEFAULTS

MULTIPLE WIRE FEEDERS

UNITOFLENGTH Inch

ENGLISH

SVENSKA

SUOMI

DANISH

QUIT ENTER

Position the cursor on the line for

choice of UNIT OF LENGTH in the list and

press ENTER.

-- 6 --

bu14d01e

METRIC

INCH

Page 7

GB

1.4 Display

ESAB LUD 450

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: Fe

SHIELDING GAS: Ar+2O%CO2

WIRE DIMENSION: 1.2 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

FAST

MODE

ENTER

Cursor

The cursor is shown in this manual as a box around the selected text. The controller

cursor actually appears as a shaded field with the selected text highlighted in white.

Text boxes

At the bottom of the display are five boxes containing text that explains the current

functions of the five keys in a line below them.

Saver mode

To extend the life of the display illumination it is switched off after three minutes if

thereisnoactivity.

bu14d01e

-- 7 --

Page 8

GB

1.5 Keys

By using the cursor keys you can move the cursor to different lines in

the display.

Pressing the menu key always brings you back to the main menu.

The plus/minus keys are used to increase (+) or decrease (--) the value of

a setting.

The two plus/minus keys are each marked with their own symbol. Most settings can

be entered with either the plus or minus key, but certain settings must be made with

the key marked or the key marked (the symbols are visible in the display).

Pressing a key rapidly increases or decreases a setting in small steps. If the key is

held down for longer the size of the steps increases.

Soft keys

The five keys in a row under the display have

a variety of functions, these are “soft

keys“, i.e. they can have different functions

depending on which menu you are using. The

current functions of these keys are shown by

the text in the bottom line of the display

(when a function is active this is shown by a

white dot alongside the text).

CRATR

D

FILL

1.6 Settings in general

There are three main types of settings:

S Settings with numerical values

S Settings with fixed options

S Settings of the type ON/OFF or YES/NO

1.6.1 Numerical settings

To set a numerical value you use either the plus or minus key to increase or

decrease the existing setting.

bu14d01e

-- 8 --

Page 9

GB

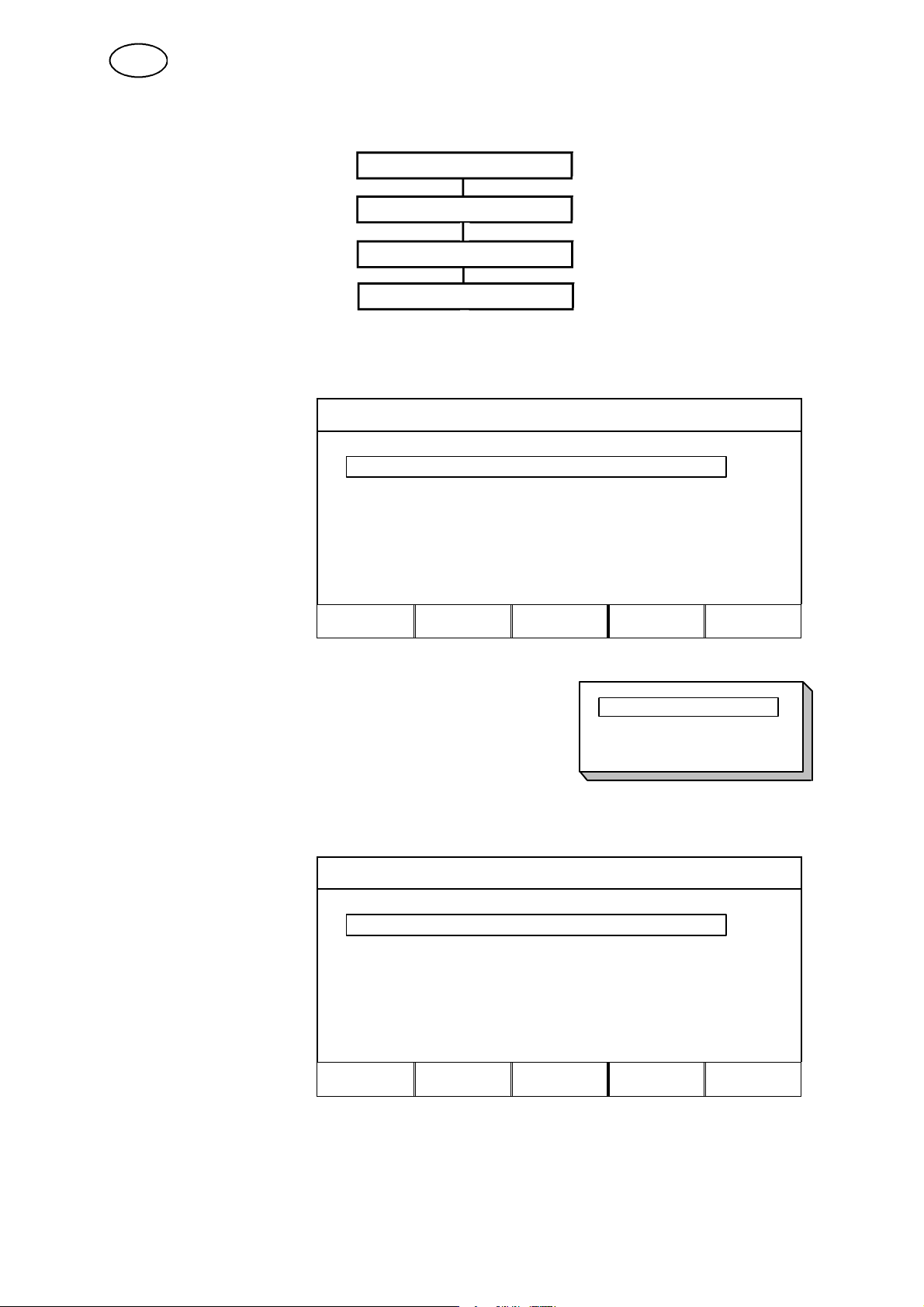

1.6.2 Settings with fixed options

Certain settings are made by selecting an alternative from a list. The list might look

like this:

MIG/MAG

MMA

TIG

CARBON, ArcAir

Here the cursor is positioned on the line for MIG/MAG. By pressing the ENTER key

now you would select the MIG/MAG option.

If instead you wanted to choose another option then you would move the cursor to

the chosen line by moving up or down using the cursor keys . Then you press

the ENTER key.

If you wanted to exit the list without making a selection you would simply press the

QUIT key.

For some settings there are so many options that they cannot all be displayed at the

same time. An arrow at the top or bottom of the list indicates that more options will

become visible if you scroll up or down using the cursor keys.

1.6.3 ON/OFF or YES/NO settings

With certain functions you can switch the setting to ON or OFF, or to YES or NO. The

synergic function in MIG/MAG and MMA welding is an example of such a function.

ON/OFF or YES/NO settings can be selected in either of two ways:

You can select ON or OFF or YES or NO from a list of options as described above.

Or you can use the plus/minus keys to select ON/OFF or YES/NO.

S + (plus) = ON or YES

S --(minus)=OFForNO

1.7 ENTER and QUIT

Both of the “soft“ keys at the bottom right are reserved for ENTER and QUIT.

S By pressing ENTER you confirm the selected option in a menu or list.

S By pressing QUIT you return to the previous menu or display.

bu14d01e

-- 9 --

Page 10

GB

2 MIG/MAG welding

2.1 The expression “wire“

In MIG/MAG welding you use an electrode that is wound on a reel (or drum). In this

manual this type of electrode is always referred to as wire.

2.2 Synergic welding

Each combination of wire type, wire diameter and gas mixture requires its own

unique combination of wire feed speed and voltage (arc length) in order to produce a

stable arc. ARISTO 2000 has several pre--programmed “synergic lines“.

Once you have chosen the pre--programmed synergic line that matches your choice

of wire type, wire diameter and gas mixture all you need to do is select a suitable

wire feed speed for the welding job. The voltage (arc length) automatically follows

the pre--programmed synergic line you have chosen, which makes it much easier to

find the right welding parameters quickly.

In MIG/MAG welding there is an option to use the welding power source in synergic

mode. This means that the user chooses a setting or value for:

S method

S wire type

S shielding gas

S wire diameter

On the basis of these basic settings and the selected value of wire feed speed a

microprocessor then selects appropriate values for the various welding parameters.

The values of these parameters are linked to the method you have chosen;

dip/spray or pulse. See also “Weld data settings“ under section 2.4.

It is also possible to weld with a combination of wire and shielding gas other than

those offered by the controller. This could however mean that the user will have to

set one or more parameters himself.

2.3 Basic settings

Basic settings are chosen from the controller’s main menu.

1. Welding process = MIG/MAG

2. Welding method

In the case of MIG/MAG welding you can choose between two different welding

methods.

S Dip/spray

S Short/Pulse

3. Wire type, shielding gas, wire size

The following tables show the combinations of wire type, shielding gas and wire

size that can be selected when the welding power source is in synergic mode.

bu14d01e

-- 1 0 --

Page 11

GB

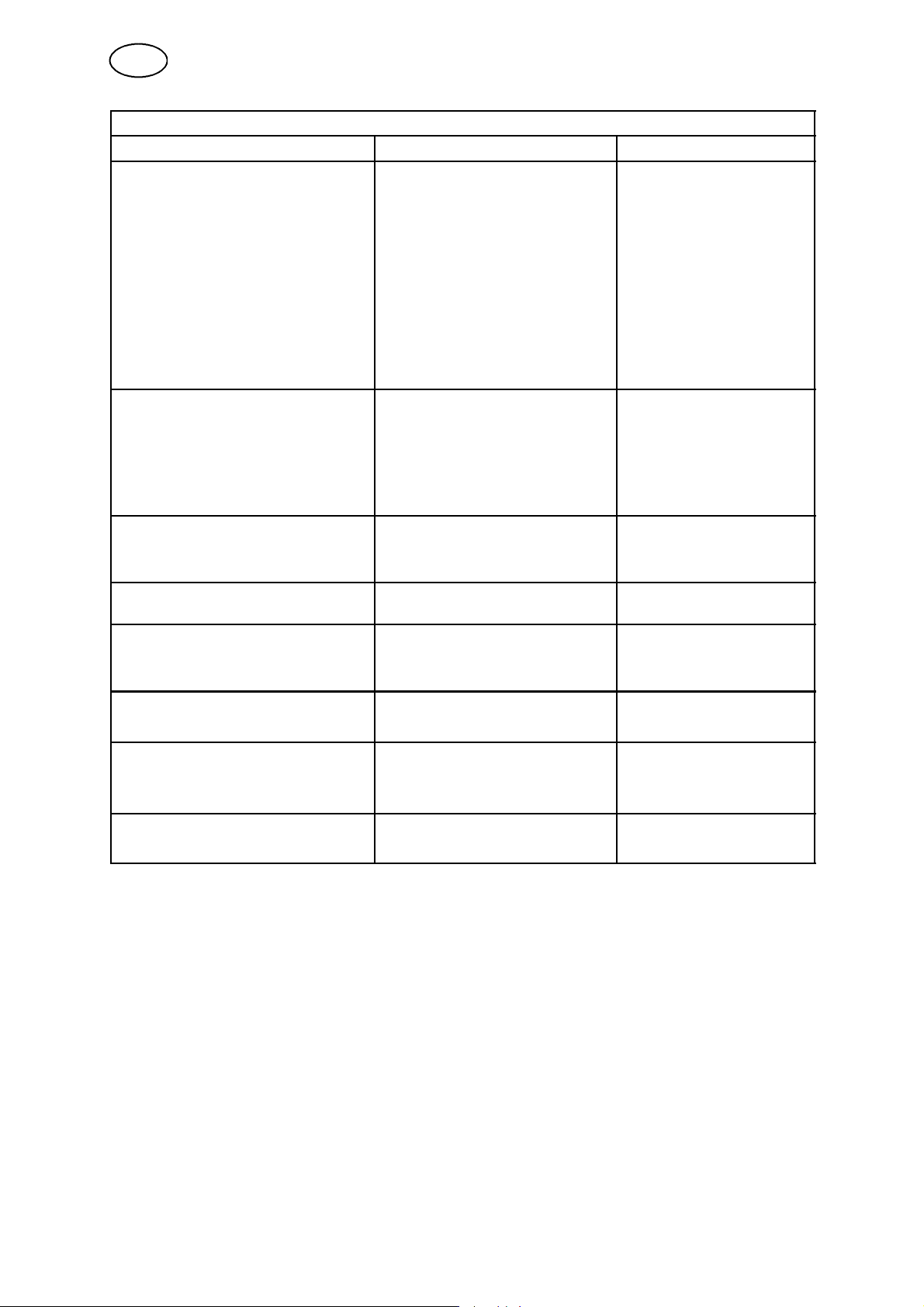

DIP/SPRAY

Wire type Shielding gas

Low alloy or unalloyed wire (Fe) CO

Stainless solid wire (SS) Ar + 2%O

Stainless duplex wire (Ss duplex) Ar + 2% O

Magnesium--alloyed aluminium wire

(AlMg)

Silicon--alloyed aluminium wire (AlSi)

Metal powder cored wire (Fe)10 Ar + 20% CO

2

Ar + 23% CO

Ar + 25% CO

Ar + 20% CO

Ar + 15% CO2+5%O

Ar +16% CO

Ar + 5%O2+5%CO

Ar + 8% CO

Ar + 2% CO

Ar + 2% O

2

2

Ar + 2% CO

Ar + 3%CO2+1%H

Ar + 30%He + 1%O

Ar + 32%He + 3%CO2+1%H20,8 0,9 1,0 1,2 (1,6*)

2

Ar +30% He +1%O

Ar 0,9 1,0 1,2 1,6

Ar 0,9 1,0 1,2 1,6

Ar + 50% He 0,9 1,0 1,2 1,6

Wire diameter (mm)

0,8 0,9 1,0 1,2 1,6

2

2

2

2

2

2

2

2

0,8 1,0 1,2 1,6

0,8 0,9 1,0 1,2 1,6

0,8 0,9 1,0 1,2 1,6

0,8 0,9 1,0 1,2 1,6

0,8 1,0 1,2 1,6

0,8 1,0 1,2 1,6

0,8 0,9 1,0 1,2 1,6

0,8 1,0 1,2 1,6

0,8 0,9 1,0 1,2 1,6

0,8 1,0 1,2 (1,6*)

2

2

2

0,8 0,9 1,0 1,2 (1,6*)

0,8 0,9 1,0 1,2 1,6

0,8 1,0 1,2 (1,6*)

1,0

2

2

1,0

1,0 1,2 1,4 1,6

Rutile flux cored wire

Ar+ 8% CO

CO

2

2

(Fe)

Basic flux cored wire

Ar + 20% CO

CO

2

2

(Fe)

Ar + 20% CO

Stainless flux cored wire (SS) Ar + 20% CO

Ar + 8% CO

2

2

2

SELF SHIELDED 1,6 2,4

Duplex rutile flux cored wire SS Ar + 20% CO

Metal powder cored stainless wire Ar + 2% O

Ar +2% CO

Ar +8% CO

Ar + 20% CO

2

2

2

2

2

Nickel base Ar + 50% He 0,9

*) LUD 450

1,0 1,2 1,4 1,6

1,2 1,4 1,6

1,2 1,4 1,6

1,0 1,2 1,4 1,6

1,0 1,2 1,4 1,6

1,2

1,2

1,2

1,2

1,2

1,2

1,2

bu14d01e

-- 1 1 --

Page 12

GB

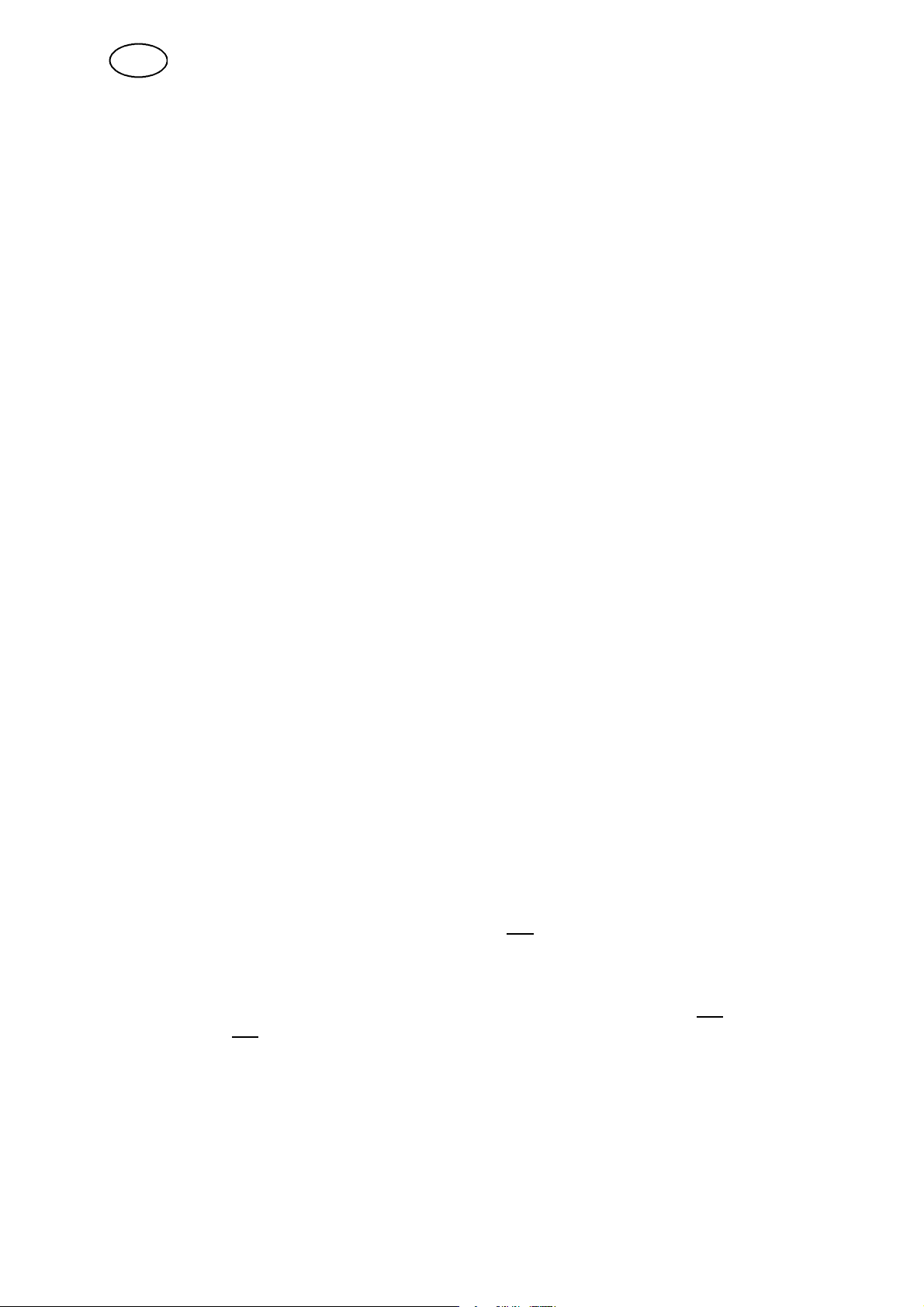

PULSE

Wire type Shielding gas Wire diameter (mm)

Low alloy or unalloyed wire (Fe) Ar + CO

Ar + 25% CO

Ar + 20% CO

Ar + 23% CO

Ar +16% CO

Ar + 5%O2+5%CO

Ar + 8% CO

Ar + 2% CO

Ar + 2% O

Stainless wire (SS) Ar + 2%O

Ar + 2% CO

Ar + 30%He + 1%O

Ar +3% CO2+1%H

2

2

2

2

2

2

2

2

2

2

2

2

2

Ar + 32%He + 3%CO2+1%H20,8 1,0 1,2 1,6

Stainless duplex wire

Ar + 30%He +1%O

2

(SS Duplex)

Magnesium--alloyed aluminium wire

Ar + 2% O

Ar 0,8 0,9 1,0 1,2 1,6

2

(AlMg)

Silicon--alloyed aluminium wire (Al-

Ar 0,9 1,0 1,2 1,6

Si)

Ar + 50% He 0,9 1,0 1,2 1,6

Metal powder cored wire (Fe) Ar + 20% CO

Ar + 8% CO

Metal powder cored stainless wire

(SS)

Ar + 2% O

Ar +2% CO

Ar +8% CO

2

2

2

2

2

Nickel alloy wire Ar 0,9 1,0 1,2

(Nickel base) Ar + 50% He 0,9 1,0 1,2

0,8 1,0 1,2 1,6

0,9

0,8 0,9 1,0 1,2 (1,6*)

0,8 1,0 1,2 (1,6*)

0,8 1,0 1,2 (1,6*)

0,8 0,9 1,0 1,2 (1,6*)

0,8 0,9 1,0 1,2 (1,6*)

0,8 1,0 1,2 (1,6*)

0,8 0,9 1,0 1,2 (1,6*)

0,8 1,0 1,2 1,6

0,8 0,9 1,0 1,2 1,6

0,8 1,0 1,2 1,6

0,8 1,0 1,2 1,6

1,0

1,0

1,0 1,2 1,4 1,6

1,2 1,2 1,4 1,6

1,2

1,2

1,2

*) LUD 450

bu14d01e

-- 1 2 --

Page 13

GB

2.4 Welding data settings

The following is an summary of the welding parameters that affect the welding

process when using MIG and MAG welding methods.

With the power source in synergic mode it is only necessary to set the wire feed

speed.

The voltage parameter may also be adjusted if required.

When the wire feed speed is adjusted the synergic control system automatically

adjusts certain other parameters to compensate. The parameters in italics remain

constant and are unaffected by changes in the wire feed speed.

Method DIP/SPRAY Method PULSING

S Wire feed speed S Wire feed speed

S Voltage S Voltage

S Inductance S Pulse current

S Control type S Pulse time

S Pulse frequency

S Background current

S Ka

S Ki

A table of parameter setting ranges is given in the APPENDIX see step 10.

2.5 Start and stop settings

The following settings affect the start and stop cycle during MIG/MAG welding.

All the settings that affect the start/stop cycle and the way welding finishes are

described under the following headings.

Start settings Stop settings

S Gas pre--flow S Gas post--flow

S Creep start

S Hot start

S Hot start time

S Increase wire feed speed

(2 m/min unless stated

otherwise)

S Increase voltage (only

when not in synergic

mode)

S Burnback time

S Shake--off pulse (only for DIP/SPRAY

when not in synergic mode)

S Crater fill

S Crater fill time

S Final wire feed speed

S Final voltage (only when not in

synergic mode)

There are three different functions that are designed to meet special requirements at

the start and end of welding. These functions and auxiliary settings are made in the

start data menu and stop data menu.

bu14d01e

-- 1 3 --

Page 14

GB

Hot start

Hot start should be selected if you want a hotter arc at the start of the welding cycle

to prevent welding defects at the start of the weld.

Crater fill

The crater fill function makes it easier to avoid porosity, hot cracks and crater

cracking in the weld when you stop welding.

Creep start

The creep start function gives a lower wire feed speed and is suitable to use when

wanting to obtain the best possible start. The creep start speed is 50% of the set

wire feed speed. The function is activated on delivery.

TIP! The hot start, creep start and crater fill functions can be switched on or off using

the “soft keys“, see the section on “MIG/MAG configuration“ see step 9.2.4.2.

The start data and stop data menus are used to set the values for the following

parameters.

Gas pre-- and post--flow

The parameters gas pre--flow and gas post--flow specify the length of time that the

gas continues to flow before and after welding.

Burnback time

Burn--back time is used to adjust the electrode stick--out at the end of welding.

2.6 Gas purge, cold wire feed and trigger latch

Like hot start and the others the following three functions can be controlled using the

soft keys. To find out how to do this see “MIG/MAG configuration“ see step 9.2.4.2.

Gas purge

The gas purge function is used to fill the gas hoses with shielding gas, or in order to

measure the gas flow rate. The gas flows when you press the key and stops when

you release it.

Cold wire feed

This function is used to feed wire out manually when fitting a new reel of wire. When

the key is pressed the wire is fed forward, and when it is released the wire stops.

Gun trigger mode

In MIG/MAG welding the torch switch can operate in two ways; with trigger latch off

or trigger latch on. Trigger latch off/on can be assigned to one of the soft keys.

The difference between having the trigger latch off or on is illustrated in the following

diagrams, together with other functions in the start/stop cycle.

bu14d01e

-- 1 4 --

Page 15

GB

Trigger latch off (2--Stroke)

2

Craterfill stop data

1

Gas pre-flow

Hot

Start

Welding

Craterfill

Gas post-flow

With the trigger latch off the gas pre--flow (if set) begins when the gun trigger is

pressed (1). The welding parameters then rise to their set values or (if set) Hot start

values.

When the gun trigger is released (2) the crater fill period begins. After this has

elapsed the welding parameters drop to back zero and the gas post--flow (if set)

finishes the welding sequence.

TIP! If the gun trigger is pressed in again during the crater fill period then you can

continue welding using the final crater fill parameters for as long as required (dotted

line). Crater fill can also be cut short by pressing and releasing the gun trigger

quickly during the crater fill period.

Trigger latch on (4--Stroke)

2

3

4

Craterfill stop data

1

Gas pre-flow

Hot

Start

Welding

Craterfill

Gas post-flow

When the trigger latch is on the gas pre--flow begins when the gun trigger is pressed

(1). When the trigger latch is released (2) the welding parameters rise to their set

values. When the gun trigger is pressed again (3) the crater fill period begins. When

this has elapsed the values of the welding parameters drop to stop data.

The gas post--flow period begins when the gun trigger is released (4).

TIP! Crater fill stops when the gun trigger is released (4). If instead the trigger is held

in for longer then you can continue welding using the final crater fill parameters

(dotted line).

bu14d01e

-- 1 5 --

Page 16

GB

2.7 MIG/MAG configuration

See step 9.2.4.

2.8 Setting--up example MIG/MAG

The following is an example of how to set up the controller for MIG/MAG welding

using dip/spray transfer. Setting up for pulse welding is done in a similar way. The

example assumes that the power source is in synergic mode.

2.8.1 Basic settings

You use the main menu to make settings such as wire, method and material type.

We start by pressing the MENU key to call up the main menu.

We will make the following five settings:

S PROCESS = MIG/MAG

S METHOD = DIP/SPRAY

S WIRE TYPE = Fe

S SHIELDING GAS = Ar+8%CO2

S WIRE DIAMETER = 1.2 mm

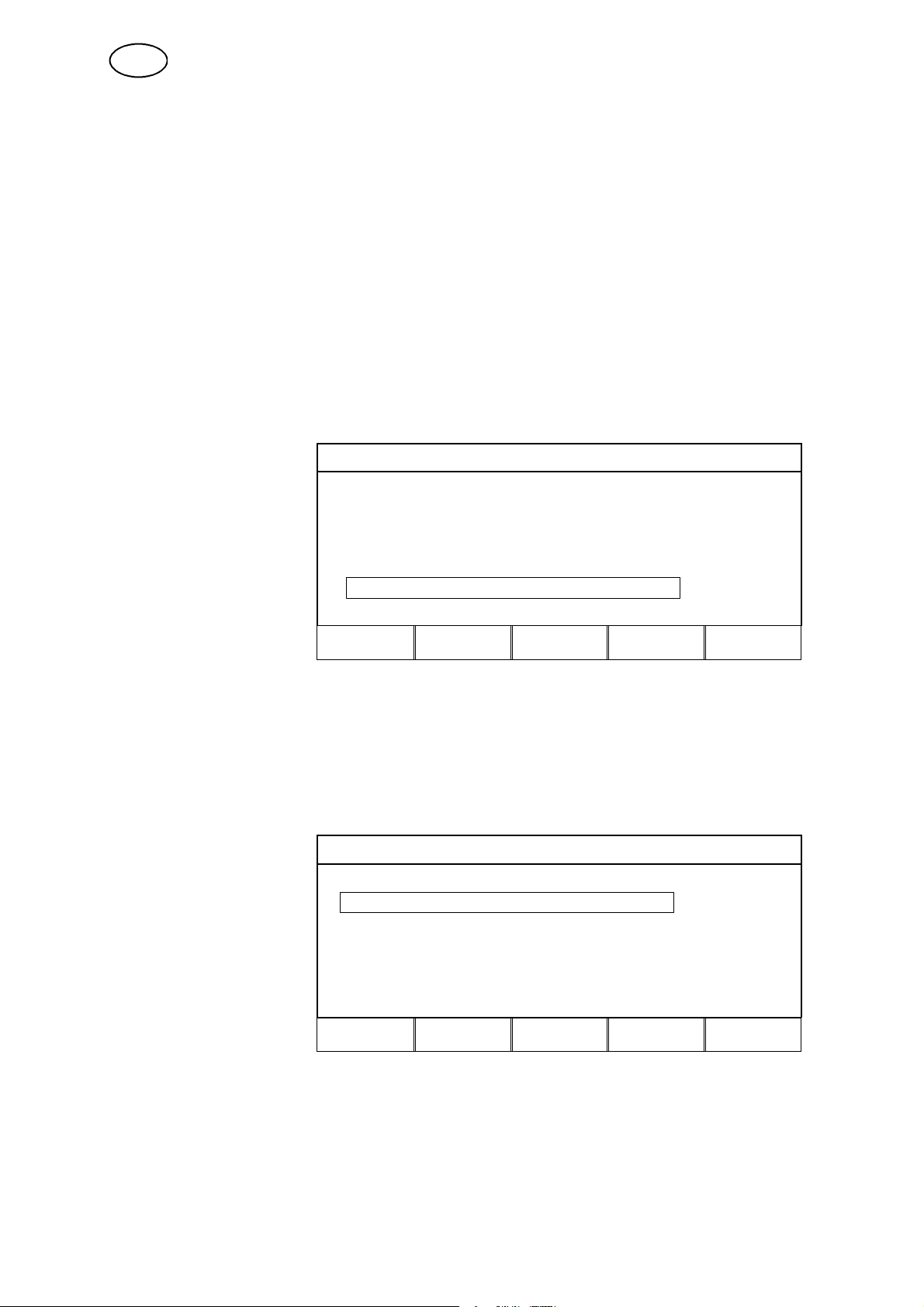

Process

ESAB LUD 450

The first setting is

the type of welding

process. Use the

arrow keys to select

the line for

PROCESS. Press

ENTER to display

the list of options.

PROCESS: MIG/MAG

METHOD: PULSE

WIRE TYPE: AlSi

SHIELDING GAS: Ar+20%CO2

WIRE DIMENSION: 1.0 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

Position the cursor on the line for MIG/MAG in the

list and press ENTER again. Now we have set

PROCESS = MIG/MAG.

FAST

MODE

MIG/MAG

MMA

TIG

CARBON, ArcAir

ENTER

bu14d01e

-- 1 6 --

Page 17

GB

Method

Position the cursor

on the line for

METHOD. Press

ENTER to display

the list of options.

ESAB LUD 450

PROCESS: MIG/MAG

METHOD: PULSE

WIRE TYPE: AlSi

SHIELDING GAS: Ar+20%CO2

WIRE DIMENSION: 1.0 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

Position the cursor on the line for DIP/SPRAY

in the list and press ENTER. We have now set the

METHOD = DIP/SPRAY.

Wire type

ESAB LUD 450

Position the cursor

on the line for WIRE

TYPE. Press ENTER

to display the list of

options.

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: AlSi

SHIELDING GAS: Ar+20%CO2

WIRE DIMENSION: 1.0 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

FAST

MODE

DIP/SPRAY

PULSE

FAST

MODE

ENTER

ENTER

Here is an example of a list that has so many options

that they cannot all be displayed at the same time.

The arrow in the bottom right cordown of the list

indicates that more options will become visible as you

scroll down the list.

Now position the cursor on the line for Fe and press

ENTER.

We have now set the WIRE TYPE = Fe.

-- 1 7 --

bu14d01e

Fe

Ss (Stainless)

Ss duplex

AlMg

AlSi

Metal cored Fe

Rutile FC Fe

Page 18

GB

Shielding gas

Position the cursor

on the line for

SHIELDING GAS.

Press ENTER to

display the list of

options.

ESAB LUD 450

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: Fe

SHIELDING GAS: Ar + 20% CO

WIRE DIMENSION: 1.0 mm

AUXILIARY FUNCTIONS

2

SET MEASURE MEMORY

Position the cursor on the line for Ar+8%CO2 and

press ENTER. We have now set the

SHIELDING GAS = Ar+8%CO2.

Wire dimension

ESAB LUD 450

Position the cursor

on the line for WIRE

DIMENSION. Press

ENTER to display

the list of options.

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: Fe

SHIELDING GAS: Ar8%CO2

WIRE DIMENSION: 1.0 mm

AUXILIARY FUNCTIONS

FAST

MODE

CO2

Ar+20 % CO2

Ar+2 % O2

Ar+5 % O2+5 % CO2

Ar+8 % CO2

Ar+23 % CO2

Ar+15%CO2+5%O2

ENTER

SET MEASURE MEMORY

Position the cursor on the line for 1.2 mm and press

ENTER. We have now set the WIRE DIMENSION =

1.2 mm.

-- 1 8 --

bu14d01e

FAST

MODE

0.8 mm

1.0 mm

1.2 mm

1.6 mm

ENTER

Page 19

GB

The next line in the main menu is AUXILIARY FUNCTIONS. You can read more

about these functions in the section “AUXILIARY FUNCTIONS“ see step 9.

ESAB LUD 450

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: Fe

SHIELDING GAS: Ar8%CO2

WIRE DIMENSION: 1.2 mm

AUXILIARY FUNCTIONS

"

SET MEASURE MEMORY

FAST

MODE

ENTER

2.8.2 Weld data settings

You can use the settings menu to set the values of various welding parameters, such

as voltage and wire feed speed. If you switch to synergic mode the microprocessor

will take care of several of these settings.

To start, we call up the main menu by pressing the MENU key. Then select the

settings menu by pressing the SET key. We will now make the following settings:

S WIRE FEED SPEED = 10.0 m/min

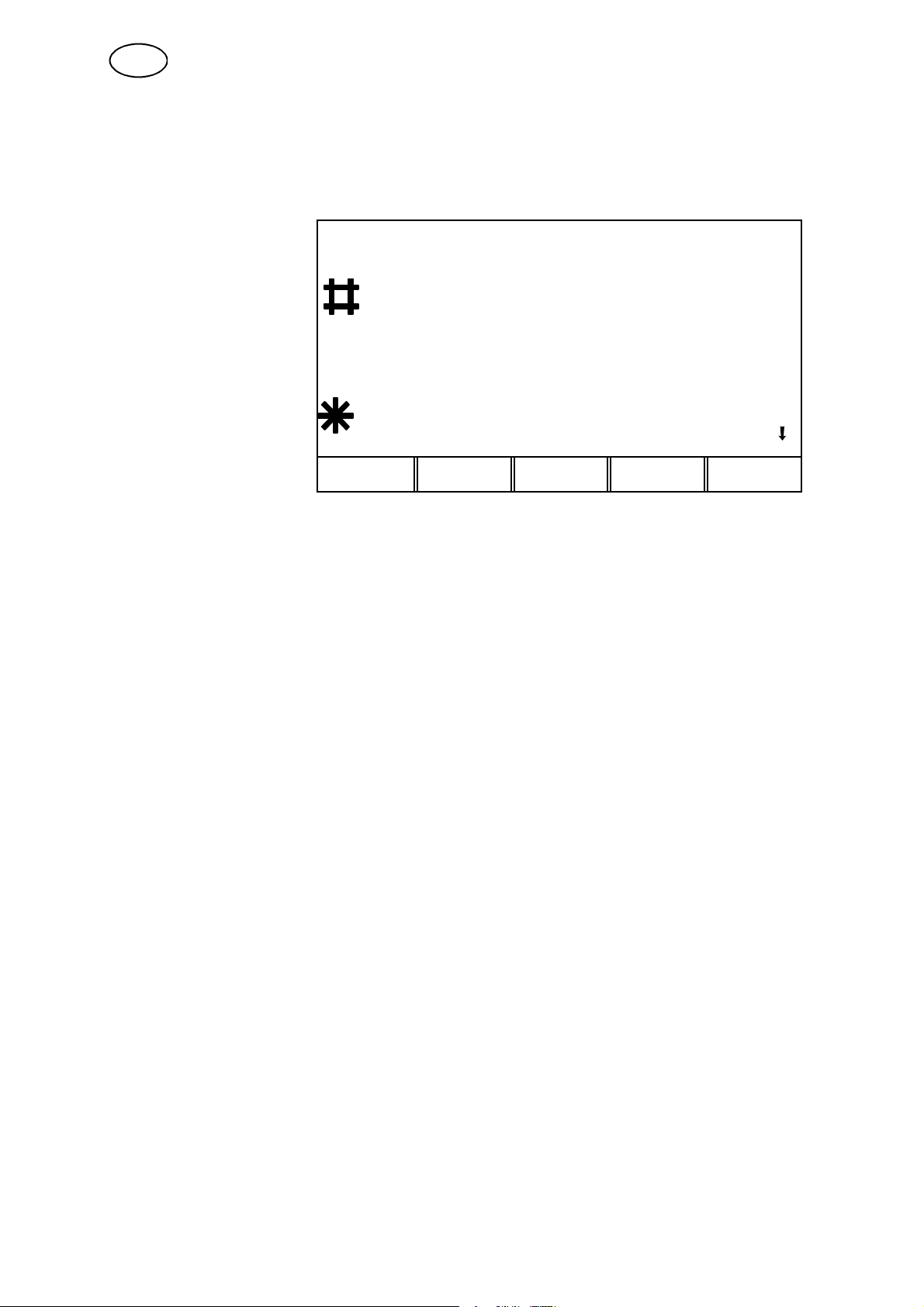

Wire feed speed

WELD DATA SETTING

Position the cursor

on the line

WIRE SPEED.

Setitto10.0m/min

using:

VOLTAGE: # 29.0 (+0.0) V

WIRE SPEED:

INDUCTANCE: 85 %

SYNERGIC MODE ON

START DATA . . .

STOPDATA ....

10.0 m/min

*

CRATR

FILL

HOT

START

4-STROKE

QUIT

In the settings menu you can now also see the values that the microprocessor has

chosen for voltage and inductance.

The voltage parameter may also be adjusted if required.

bu14d01e

-- 1 9 --

Page 20

GB

2.8.3 Start data settings

Using the start data menu you can adjust the settings that affect the starting

sequence during MIG/MAG welding. We will set the following:

S GAS PRE--FLOW = 0.8 s

S CREEP START = YES

S HOT START = YES

S HOT START time = 1.0 s

S HOT START wire feed speed = +2.5 m/min

Start by opening the main menu, by pressing the MENU key.

Then go to the settings menu by pressing the SET key.

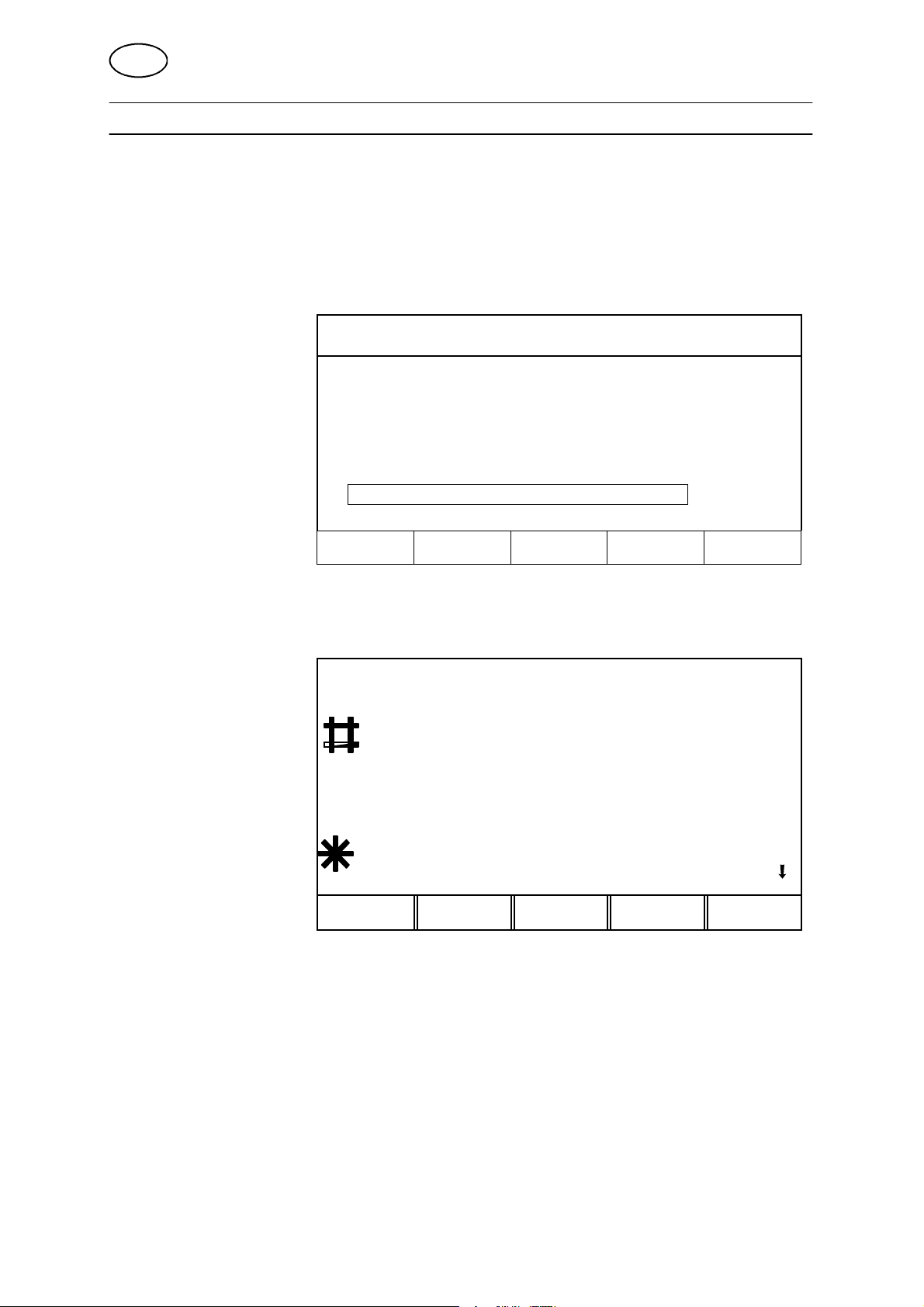

WELD DATA SETTING

Position the cursor

on the line START

DATA and press

ENTER.

VOLTAGE: # 29.0 (+0.0) V

WIRE SPEED:

INDUCTANCE: 70 %

SYNERGIC MODE ON

START DATA ..

STOPDATA ....

CRATR

FILL

HOT

START

4-STROKE

10.0 m/min

*

QUIT

Gas pre--flow time

Here you enter the length of time you want the shielding gas to flow before welding

begins.

START DATA, SYNERGIC MODE

Position the cursor

on the line for GAS

PREFLOW. Set it to

0.8 s using one of

the plus/minus keys

GASPREFLOW: 0.8 s

CREEPSTART: YES

HOTSTART: NO

CRATR

FILL

HOT

START

4-STROKE

QUIT

bu14d01e

-- 2 0 --

Page 21

GB

Creep start

Here you simply choose whether you want to use the creep start function or not, i.e.

YES or NO. Wire feed speed and creep start are preset and cannot be changed.

START DATA, SYNERGIC MODE

Position the cursor

on the line CREEP

START. Press

ENTER to display

the list of

options.Set it to

YES press ENTER

GASPREFLOW: 0.8 s

CREEPSTART: YES

HOT START: NO

CRATR

FILL

HOT

START

4-STROKE

QUIT ENTER

Hot start

To begin with you choose whether you want to use the hot start function or not. If you

decide to use the hot start function, you should then enter the hot start time and any

increase in the wire feed speed.

START DATA, SYNERGIC MODE

Position the cursor

on the line HOT

START. Press

ENTER to display

the list of

options.Set it to

GASPREFLOW: 0.8 s

CREEPSTART: YES

HOT START: YES

HOT START TIME: 1.5 s

WIRE SP: 2.0 m/min

YES press ENTER

CRATR

FILL

HOT D

START

4-STROKE QUIT ENTER

Position the cursor

on the line HOT

START TIME. Set

it to 1.0 s using one

of the plus/minus

keys.

bu14d01e

START DATA, SYNERGIC MODE

GASPREFLOW: 0.8 s

CREEPSTART: YES

HOTSTART: YES

HOT START TIME: 1.0 s

WIRE SP: 2.0 m/min

CRATR

FILL

HOT D

START

-- 2 1 --

4-STROKE

QUIT

Page 22

GB

Position the cursor

on the line

WIRE SP.

Setitto2.5m/min.

START DATA, SYNERGIC MODE

GASPREFLOW: 0.8 s

CREEPSTART: YES

HOTSTART: YES

HOT START TIME: 1.0 s

WIRE SP: 2.5 m/min

CRATR

FILL

HOT D

START

4-STROKE

QUIT

All the start settings have now been made.

Return to the settings menu by pressing QUIT.

2.8.4 Stop data settings

The stop data menu is used to make the settings that affect the stop sequence

during MIG/MAG welding.

We will enter the following stop data:

S CRATER FILL = YES

S CRATER FILL TIME =1.5 s

S FINAL WIRE FEED SPEED = 3.0 m/min

S BURNBACK TIME =0.11 s

S GAS POST--FLOW =2.0 s

Position the cursor

on the line STOP

DATA and press

ENTER.

bu14d01e

WELD DATA SETTING

VOLTAGE: # 29.0 (+0.0) V

WIRE SPEED:

INDUCTANCE: 70 %

SYNERGIC MODE ON

START DATA . . .

STOP DATA . . .

CRATR

FILL

HOT D

START

-- 2 2 --

4-STROKE

10.0 m/min

*

QUIT ENTER

Page 23

GB

Crater fill

Begin by choosing whether you want to use the crater fill function or not. If you

choose to use crater fill you will then also have to set the crater fill time and wire feed

speed.

STOP DATA SYNERGIC MODE

Move the cursor on

the line CRATER

FILL and press

ENTER to display

the list of options.

Select YES.

CRATERFILL YES

TIME : 1.5 s

FIN. WIRE SPEED: 2.8 m/min

BURNBACKTIME: 0.12 s

GASPOSTFLOW: 0.5 s

CRATR D

FILL

HOT D

START

4-STROKE

QUIT ENTER

Crater fill time

STOP DATA SYNERGIC MODE

Position the cursor

on the line TIME.

Setitto1.5susing

one of the

plus/minus keys

CRATERFILL YES

TIME: 1.5 s

FINAL WIRE SPEED: 2.8 m/min

BURNBACKTIME: 0.12 s

GASPOSTFLOW: 0.5 s

CRATR D

FILL

HOT D

START

4-STROKE QUIT

Final wire feed speed

This is used to set the wire feed speed that will be used when crater fill is complete.

Position the cursor

on the line FINAL

WIRE SPEED.

Setitto3.0m/min

using one of the

plus/minus keys.

bu14d01e

STOP DATA SYNERGIC MODE

CRATERFILL YES

TIME: 3.0 s

FINAL WIRE SPEED: 3.0 m/min

BURNBACKTIME: 0.12 s

GASPOSTFLOW: 0.5 s

CRATR D

FILL

HOT D

START

-- 2 3 --

4-STROKE

QUIT

Page 24

GB

Burnback time

Position the cursor

on the line

BURNBACK TIME.

Setitto0.11susing

one of the

plus/minus keys.

STOP DATA SYNERGIC MODE

CRATERFILL YES

TIME: 3.0 s

FINAL WIRE SPEED: 4.0 m/min

BURNBACKTIME: 0.11 s

GASPOSTFLOW: 0.5 s

CRATR D

FILL

HOT D

START

4-STROKE

QUIT

Gas post--flow

Use this to set the time for which the gas continues to flow after welding is complete.

STOP DATA SYNERGIC MODE

Position the cursor

on the line GAS

POST--FLOW. Set

it to 2.0 s using one

of the plus/minus

keys.

CRATERFILL YES

TIME: 1.5 s

FINAL WIRE SPEED: 3.0 m/min

BURNBACKTIME: 0.11 s

GASPOSTFLOW: 2.0 s

CRATR D

FILL

HOT D

START

4-STROKE

QUIT

This completes the stop data settings and means that all the weld data settings for

MIG/MAG welding have been entered.

bu14d01e

-- 2 4 --

Page 25

GB

3 MMA welding

3.1 Synergic mode

The welding power source also has a synergic mode for MMA welding.

This means that the welding power source automatically optimises the welding

characteristics to suit the type and size of electrode you have chosen.

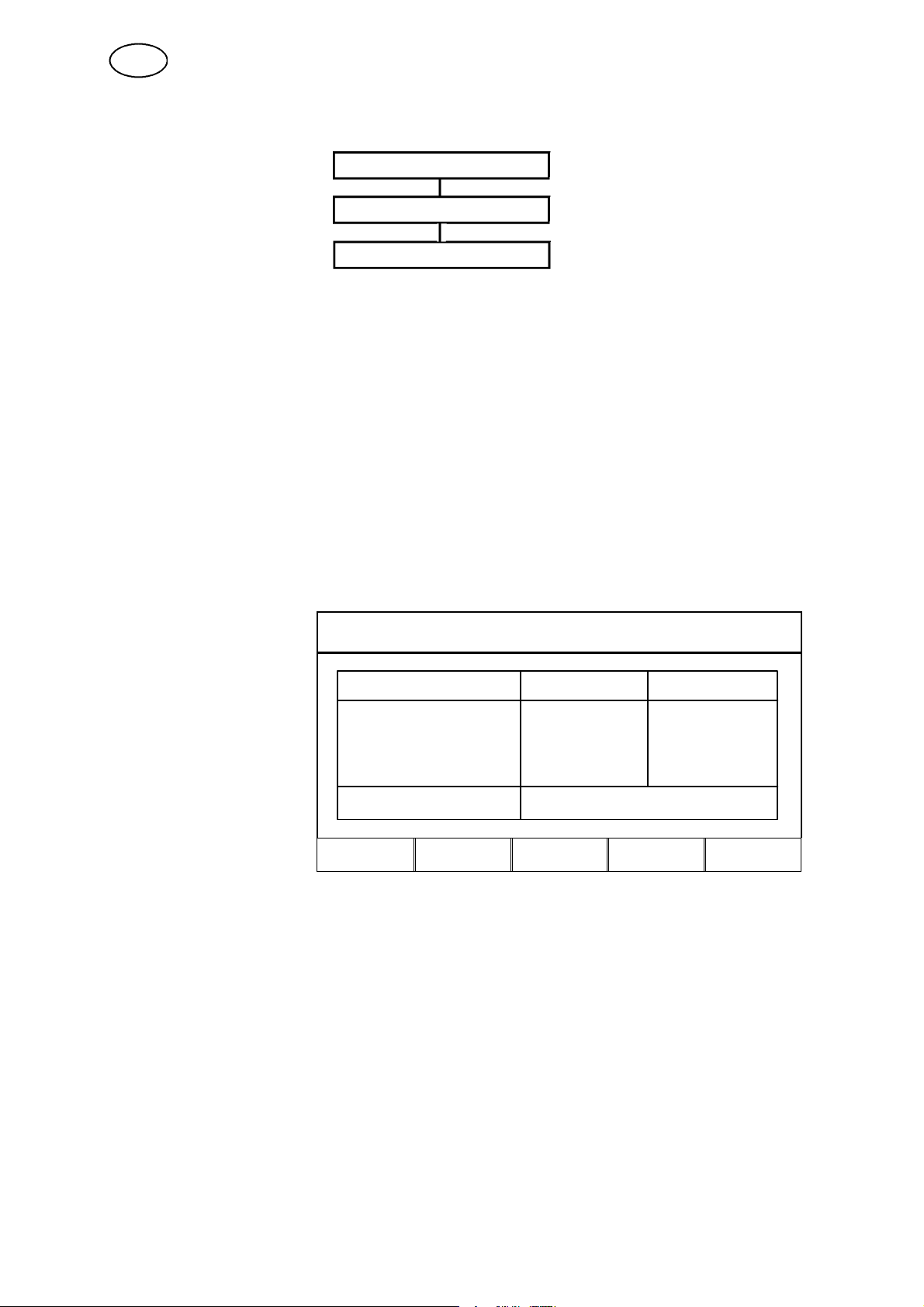

3.2 Basic settings

The basic settings for MMA welding are entered using the controller’s main menu.

1. Welding process = MMA

2. Electrode type

Three different types of electrode can be chosen if you want to weld in synergic

mode.

S Basic

S Rutile

S Cellulosic

3. Electrode diameter

The table below shows the electrode diameters that can be selected when the power

source is in synergic mode.

Electrode type Electrode diameter (mm)

Basic 1.62.02.53.24.04,55.05,66.0

Rutile 1.62.02.53.24.04,55.05,66.0

Cellulosic 2.5 3.2

bu14d01e

-- 2 5 --

Page 26

GB

3.3 Welding data

If you stay in synergic mode you only need to set the welding current.

The welding current can also be adjusted during welding by using the +/-- keys.

When you adjust the welding current the arc force is automatically adjusted to

compensate if the welding power source is in synergic mode.

In the settings menu you can see what value has been chosen for the parameter

welding current.

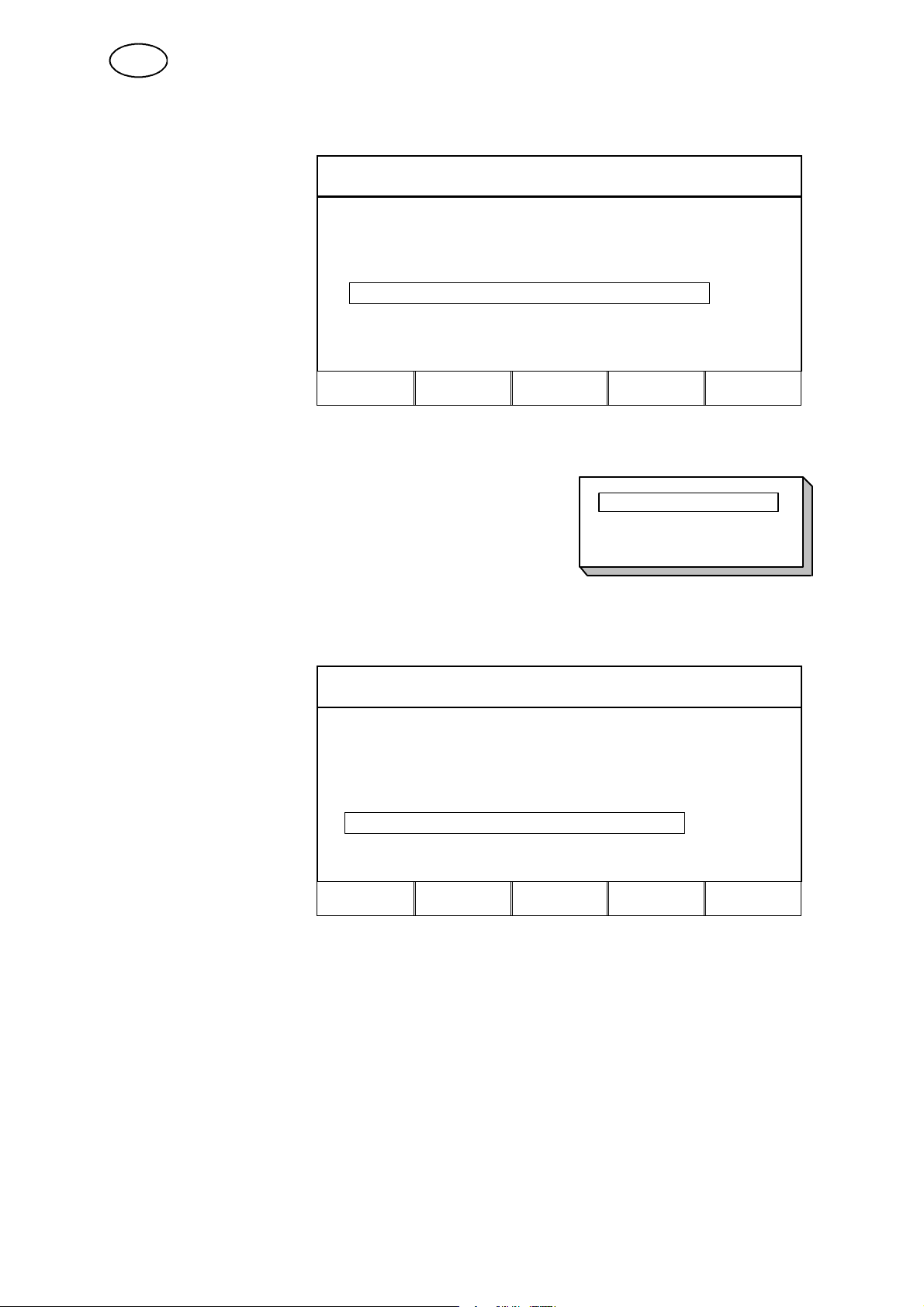

ESAB LUD 450

Display the SETUP

menu by pressing

the SET key.

PROCESS: MMA

ELECTRODE TYPE: RUTILE

ELECTRODE DIAMETER: 2.5 mm

AUXILIARY FUNCTIONS

"

With our chosen

combination of

electrode type and

electrode diameter

the power source

has set the welding

current to 80 A.

SET MEASURE MEMORY

WELD DATA SETTING

CURRENT: 80 A

SYNERGIC MODE: ON

FAST

MODE

QUIT

ENTER

bu14d01e

-- 2 6 --

Page 27

GB

3.4 MMA--configuration

See step 9.2.6.

3.5 Setting--up example MMA

Here is an example of how to set up for MMA welding.

3.5.1 Basic settings

The main menu is used to make the settings that concern choice of electrode.

First we call up the main menu, if this has not already been done, by pressing the

MENU key.

We will make the following three settings:

S PROCESS = MMA

S ELECTRODE TYPE= RUTILE

S ELECTRODE DIAMETER = 2.5 mm

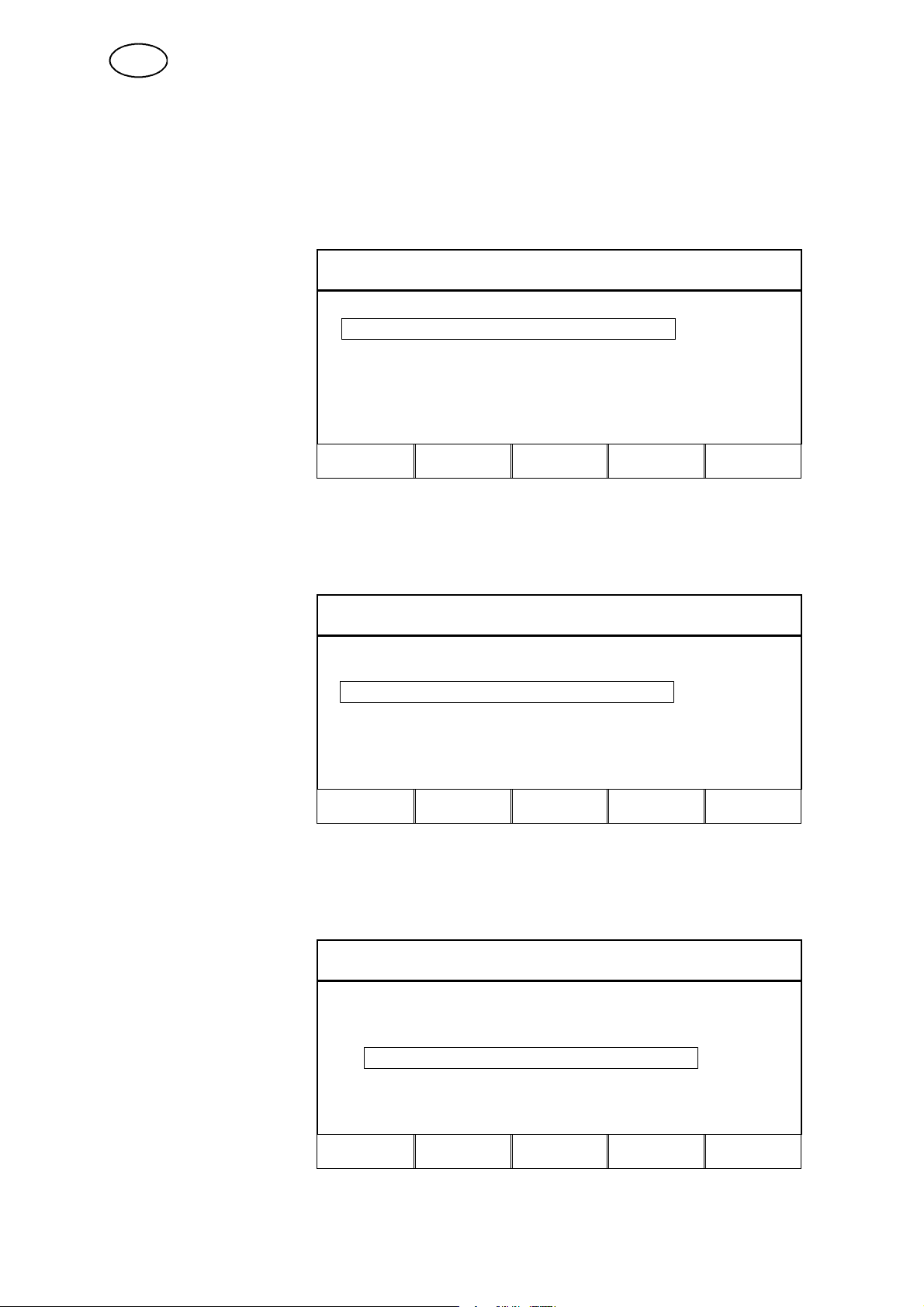

Process

ESAB LUD 450

Use the arrow keys

to select

PROCESS. Press

ENTER to display

the list of options.

PROCESS: MMA

ELECTRODE TYPE: BASIC

ELECTRODE DIAMETER: 6 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

Position the cursor over the MMA option in the list and

press ENTER. We have now set the PROCESS = MMA.

Electrode type

ESAB LUD 450

FAST

MODE

MIG/MAG

MMA

TIG

CARBON, ArcAir

ENTER

Use the arrow keys

to select

ELECTRODE TYPE.

Press ENTER to

display the list of

PROCESS: MMA

ELECTRODE TYPE: BASIC

ELECTRODE DIAMETER: 6 mm

AUXILIARY FUNCTIONS

options.

SET MEASURE MEMORY

Position the cursor over the RUTILE option in the list

and press ENTER. We have now set the ELECTRODE

TYPE = RUTILE.

bu14d01e

-- 2 7 --

FAST

MODE

BASIC

RUTILE

CELLULOSA

ENTER

Page 28

GB

Electrode diameter

Use the arrow keys

to select

ELECTRODE

DIAMETER. Press

ENTER to display

the list of options.

ESAB LUD 450

PROCESS: MMA

ELECTRODE TYPE: RUTILE

ELECTRODE DIAMETER: 6 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

Position the cursor over the value 2.5 mm in the list

and press ENTER. We have now set the ELECTRODE

DIAMETER = 2.5 mm.

ESAB LUD 450

PROCESS: MMA

ELECTRODE TYPE: RUTILE

ELECTRODE DIAMETER: 2.5 mm

AUXILIARY FUNCTIONS

"

FAST

MODE

1.6 mm

2mm

2.5 mm

3.2 mm

4mm

4,5 mm

5mm

ENTER

FAST

SET MEASURE MEMORY

MODE ENTER

The next line in the menu is AUXILIARY FUNCTIONS. You can read more about

these functions in the section “AUXILIARY FUNCTIONS“ See step 9.

We have now completed the settings for MMA welding.

bu14d01e

-- 2 8 --

Page 29

GB

4 TIG welding

4.1 Basic settings

The basic settings for TIG welding are made in the main menu.

1. Welding process = TIG

2. Welding method

With TIG welding you have a choice of two different welding methods.

S Constant current

S Pulse

3. Start method

There is also a choice of two start methods.

S Liftarc

S HF--START

With Liftarc start you touch the electrode to the workpiece to strike the arc, then

raise it slightly. With HF start the arc is struck by a high frequency spark that is

produced when the electrode is a certain distance from the workpiece.

4. Gun trigger mode

In TIG welding you can choose whether you want the TIG torch to operate with

the trigger latch off or on. The main difference is that with the trigger latch off you

have to hold the trigger in during welding, but when it is on you can release the

trigger during welding. The difference between having the trigger latch off or on

is illustrated in the following diagrams, along with the other functions in the

start/stop cycle.

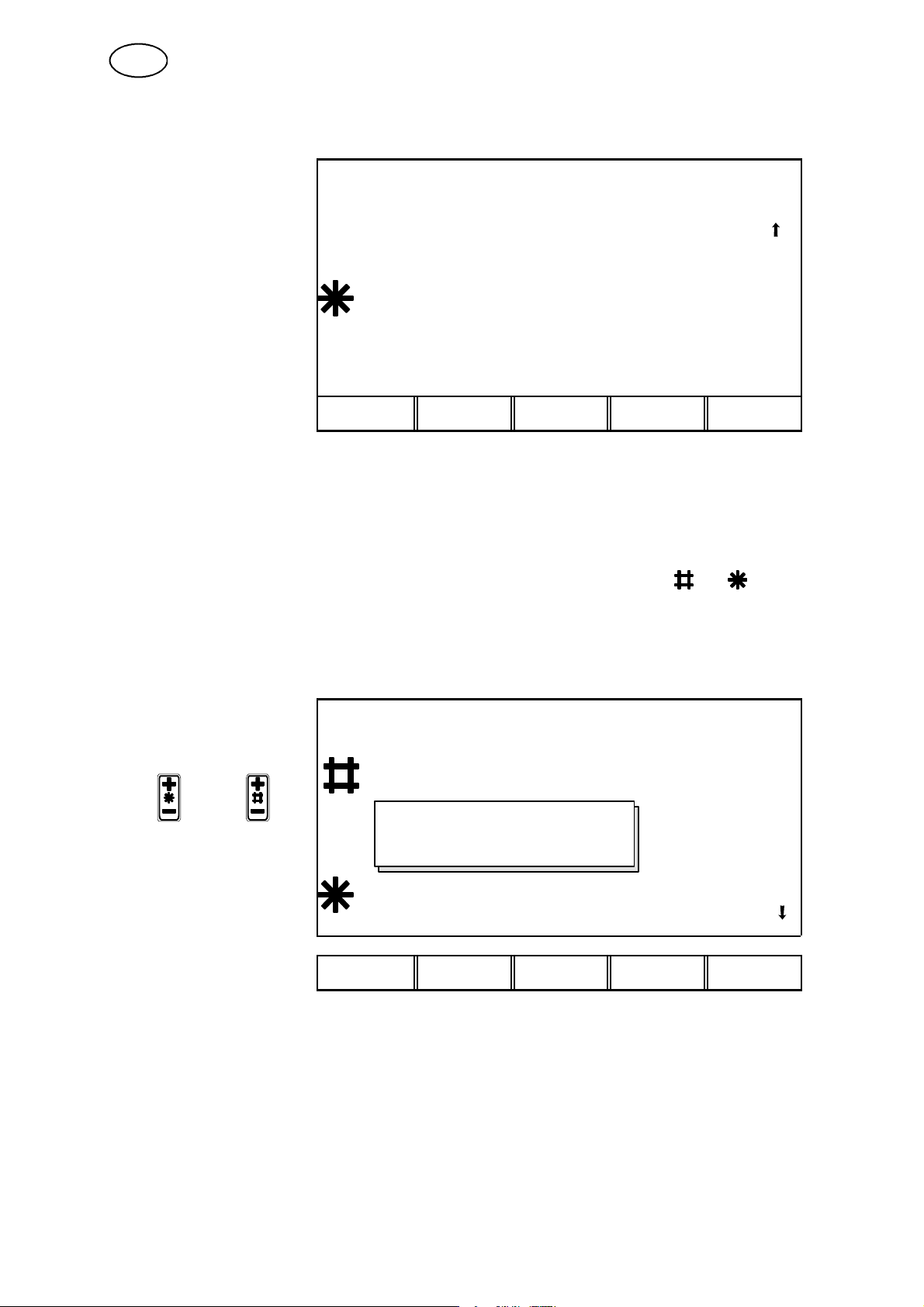

Trigger latch off

2

1

Slope

down

Gas

post--flow

Gas pre--flow

Slope

up

With the trigger latch off, gas pre--flow begins when the TIG gun trigger is pressed

(1). The current then rises to the pilot level (a couple of amperes) and the arc ignites.

The current then rises to the set value (following the Slope--up slope if applicable).

When the trigger is released (2) the current falls back to the pilot level (following the

Slope--down slope if applicable) and the arc is extinguished. The gas continues to

flow for the post--flow period, if applicable.

bu14d01e

-- 2 9 --

Page 30

GB

Trigger latch on

3

1

Gas pre--flow

2

Slope

up

Slope

down

4

Gas

post--flow

With the trigger latch on, gas pre--flow begins when the TIG gun trigger is pressed

(1). When the gas pre--flow period has elapsed the current rises to the pilot level (a

couple of amperes) and the arc ignites.

When the trigger is released (2) the current rises to the set value (following the

Slope--up slope if applicable).

When the trigger is pressed again (3) the current again rises to the pilot

level(following the Slope--down slope if applicable).

When the trigger is released again (4) the arc is extinguished and the gas post--flow

period begins (if applicable).

When you are in the weld data settings menu or the measure menu you can switch

the trigger latch off or on using one of the soft keys.

4.2 Welding data settings

The values of the welding parameters are set using the settings menu. Certain

parameters are specific to the chosen method and certain are common to both TIG

methods. The following parameters can be set for TIG welding.

See the APPENDIX step 10. for details of parameter setting ranges.

Method CONSTANT CURRENT Method PULSE

S Current S Pulse current

S Slope--up S Background current

S Slope--down S Pulse time

S Gas pre--flow S Background time

S Gas post--flow S Slope--up

S Slope--down

S Gas pre--flow

S Gas post--flow

bu14d01e

-- 3 0 --

Page 31

GB

Current

The term current refers here to the welding current when welding with constant

current.

Pulse current and background current

When using pulsed current you have to set several parameters that are linked to the

welding current. Pulse current and background current indicate the uper and lower

limits of the current, see the diagram below.

Current

PULSE TIME

BACKGROUND TIME

PULSE CURRENT

BACKGROUND CURRENT

Time

Pulse time and background time

The pulse time sets the duration of the current pulses.

The background time sets the time between pulses.

For welding with pulse current, see the above diagram. The adjustment range for

pulse time and background time is 0.001--5.000 s.

Gas pre--flow and gas post--flow

The parameters gas pre--flow and gas post--flow are used to set how long you want

the gas to flow before and after welding.

Slope--up and Slope--down

The Slope parameters govern the gradual rise and fall of the we lding current over a

given time.

bu14d01e

-- 3 1 --

Page 32

GB

4.3 TIG--configuration

See step 9.2.6.

4.4 Setting--up example TIG

The following explains how to set up for TIG welding using the constant current

method. The setting--up procedure is similar for pulse welding.

4.4.1 Basic settings

We start by displaying the main menu, if this has not already been done, by pressing

the MENU key.

We will make the following four settings:

S PROCESS = TIG

S METHOD = CONSTANT CURRENT

S START METHOD = LIFT ARC

S GUN TRIGGER MODE= 2--STROKE

Process

ESAB LUD 450

Use the arrow keys

to select

PROCESS. Press

ENTER to display

the list of options.

PROCESS: MMA

ELECTRODE TYPE: RUTILE

ELECTRODE DIAMETER: 2.5 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

Position the cursor on the TIG option in the list and

press ENTER. We have now set the PROCESS =

TIG.

FAST

MODE ENTER

MIG/MAG

MMA

TIG

CARBON, ArcAir

bu14d01e

-- 3 2 --

Page 33

GB

Method

Position the cursor

on the line

METHOD. Press

ENTER to display

the list of options.

ESAB LUD 450

PROCESS: TIG

METHOD: PULSED I

START METHOD: LIFTARC

GUN TRIGGER MODE: 4--STROKE

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

Position the cursor on the line for CONSTANT I

in the list and press ENTER.

We have now set the METHOD = CONSTANT

CURRENT.

Start method

Position the cursor

on the line START

METHOD. Press

ENTER to display

the list of options.

PROCESS: TIG

METHOD: CONSTANT I

START METHOD: LIFTARC

GUN TRIGGER MODE: 4--STROKE

AUXILIARY FUNCTIONS

ESAB LUD 450

FAST

MODE

CONSTANT I

PULSED I

ENTER

SET MEASURE MEMORY

Position the cursor on the line for LIFTARC in the

list and press ENTER. We have now set the

START METHOD = LIFTARC.

-- 3 3 --

bu14d01e

FAST

MODE

LIFTARC

HF--START

ENTER

Page 34

GB

Gun trigger mode

Position the cursor

on the line GUN

TRIGGER MODE.

Press ENTER to

display a list of

options.

ESAB LUD 450

PROCESS: TIG

METHOD: CONSTANT I

START METHOD: LIFTARC

GUN TRIGGER MODE: 4--STROKE

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

Position the cursor on the line for 2--STROKE in

the list and press ENTER. We have now set the

GUN TRIGGER MODE = 2--STROKE.

PROCESS: TIG

METHOD: CONSTANT I

START METHOD : LIFTARC

GUN TRIGGER MODE: 2--STROKE

AUXILIARY FUNCTIONS

ESAB LUD 450

"

FAST

MODE

2--STROKE

4--STROKE

ENTER

SET MEASURE MEMORY

FAST

MODE

ENTER

The next line in the menu is AUXILIARY FUNCTIONS. See the section “AUXILIARY

FUNCTIONS“ See step 9. for more information.

bu14d01e

-- 3 4 --

Page 35

GB

4.4.2 Weld data settings

Use the settings menu to set the values of the various welding parameters.

We will make the following settings:

S CURRENT = 200 A

S SLOPE--UP TIME = 2.0 s

S SLOPE--DOWN TIME = 1.4 s

S GAS PRE--FLOW = 3.0 s

S GAS POST--FLOW = 5.0 s

Press MENU key, call up the settings menu by pressing the SET key.

Current

WELD DATA SETTING

Position the cursor

on the line for

CURRENT.

Set the value to

200 A using one of

the plus/minus

CURRENT: 200 A

SLOPEUPTIME: 4,0s

SLOPE DOWN TIME: 6,0 s

GASPREFLOW: 2.5 s

GASPOSTFLOW: 3.3 s

keys.

GAS

PURGE

4

STROKE

QUIT

Slope--up and Slope--down

The Slope--up and Slope--down parameters are each linked to the plus and minus

keys respectively. To set the Slope--up time use the uper key, and to set the

Slope--down time use the lower key.

WELD DATA SETTING

Move the cursor to the

line for SLOPE UP and

SLOPE DOWN TIME.

Set the

SLOPEUPTIMEto

2.0 s by stepping with

the upper

key.

plus/minus

CURRENT: 200 A

SLOPEUPTIME:#2.0s

SLOPE DOWN TIME:

GAS PRE--FLOW: 2.5 s

GAS POST--FLOW: 3.3 s

6.0 s

*

bu14d01e

GAS

PURGE

4

STROKE

-- 3 5 --

QUIT

Page 36

GB

Set the SLOPE DOWN

TIME to 1.4 s by

stepping with the lower

plus/minus-- key.

WELD DATA SETTING

CURRENT: 200 A

SLOPEUPTIME: #2.0s

SLOPE DOWN TIME:

GASPREFLOW: 2.5 s

GASPOSTFLOW: 3.3 s

1.4 s

*

GAS

PURGE

4

STROKE

QUIT

Gas pre--flow and gas post--flow

The parameters gas pre--flow and gas post--flow are each linked to their own specific

plus/minus key in the same way as the Slope parameters above. The uper

plus/minus key is used to set the gas pre--flow and the lower one is used to set the

gas post--flow.

WELD DATA SETTING

Move the cursor to the

line for GAS

PRE--FLOW and GAS

POST--FLOW.

Set the GAS

PRE--FLOW to 3.0 s by

stepping with the upper

plus/minus key.

CURRENT: 200 A

SLOPEUPTIME: 2.0s

SLOPE DOWN TIME: 1.4 s

GASPREFLOW: #3.0s

GASPOSTFLOW:

GAS

PURGE

4

STROKE

3.3 s

*

QUIT

WELD DATA SETTING

Set the GAS

PRE--FLOW to 5.0 s by

stepping with the lower

plus/minus key.

CURRENT: 200 A

SLOPE UP: 2.0 s

SLOPE DOWN: 1.4 s

GASPREFLOW: #3.0

GASPOSTFLOW:

GAS

PURGE

4

STROKE

5.0

*

QUIT

We have now completed the set--up procedure for TIG welding.

bu14d01e

-- 3 6 --

Page 37

GB

5 Arc air gouging

5.1 Synergic mode

The power source has a synergic mode for arc air gouging.

This means that the power source automatically selects a suitable value for the

voltage on the basis of the chosen electrode diameter.

It is possible to use electrodes with a different diameter to those displayed on the

controller, but this means that the user must make the necessary settings for certain

parameters.

5.2 Basic settings

The basic settings for arc air gouging are made in the controller’s main menu.

1. Welding process = ARC AIR GOUGING (Carbon, ArcAir)

2. Electrode diameter

The table below shows the electrode diameters that can be used when the power

source is in synergic mode.

Electrode diameter

4 mm (3/16 in)

5mm

6mm(1/4in)

8mm

5.3 Welding data

If you use the power source in synergic mode there is actually no need to set any of

the welding parameters. The voltage parameter can however be adjusted if wished.

The parameters shown in italics are constant, i.e. they are unaffected by any change

in voltage.

Welding parameters for arc air gouging

S Voltage

S Inductance

S Control type

See the “APPENDIX“ See step 10. for a table giving the full range of parameter

settings.

bu14d01e

-- 3 7 --

Page 38

GB

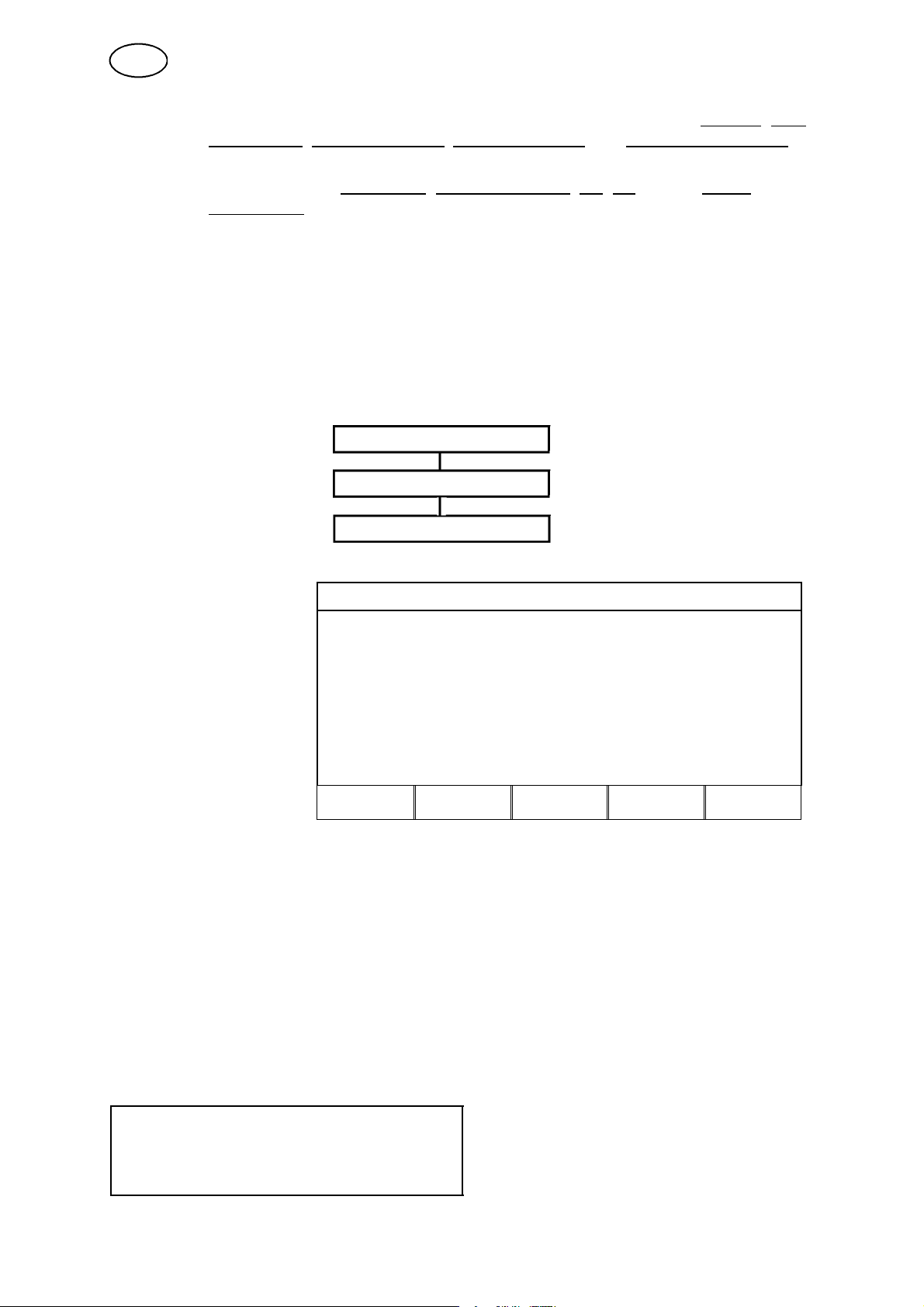

5.4 Setting--up example for arc air gouging

5.4.1 Basic settings

Use the main menu to set the electrode diameter.

To start, call up the main menu by pressing the MENU key.

We will make the following two settings:

S PROCESS = ARC AIR GOUGING (Carbon, ArcAir)

S ELECTRODE DIAMETER = 8 mm

Process

ESAB LUD 450

Use the arrow keys

to select the

PROCESS line.

Press ENTER to

display the list of

options.

PROCESS: MMA

ELECTRODE TYPE: BASIC

ELECTRODE DIAMETER: 6 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

Position the cursor on the line CARBON ArcAir in

the list and press ENTER. We have now set the

PROCESS = ARC AIR GOUGING.

Electrode diameter

Use the arrow keys

to select the line

ELECTRODE

DIAMETER.

PROCESS: CARBON, ArcAir

ELECTRODE DIAMETER: 6 mm

AUXILIARY FUNCTIONS

Press ENTER to

display the list of

options.

SET MEASURE MEMORY

Position the cursor on the line 8 mm and press

ENTER. The setting ELECTRODE DIAMETER =

8mm is now complete.

ESAB LUD 450

FAST

MODE

MIG/MAG

MMA

TIG

CARBON, ArcAir

FAST

MODE

4mm

5mm

6mm

8mm

ENTER

ENTER

The set--up procedure for arc air gouging is now complete.

bu14d01e

-- 3 8 --

Page 39

GB

5.4.2 Welding data

In the settings menu you can see what value has been selected for the voltage

parameter. If necessary you can also adjust the voltage setting.

ESAB LUD 450

Go to the settings

menu by pressing

the SET key.

PROCESS: CARBON, ArcAir

ELECTRODE DIAMETER: 8 mm

AUXILIARY FUNCTIONS

On the basis of our

electrode diameter

setting the power

source has set the

voltage to 43 V.

SET MEASURE MEMORY

WELD DATA SETTING

VOLTAGE: 43.0 V

SYNERGIC MODE: ON

FAST

MODE

QUIT

ENTER

bu14d01e

-- 3 9 --

Page 40

GB

6 MEASURED VALUE DISPLAY

6.1 Description of measured value display

The measured value display lets you see the measured values of various welding

parameters during welding. Which parameters are displayed depends on which

welding process you have selected.

The example below shows a measured value display for MIG/MAG.

TIP!

In pulse welding you can choose whether the voltage is displayed as the overall

average or the pulse average.

This setting can be made under MIG/MAG basic settings. See section 9.2.4.3.

If you want to see the measured value display; first make sure the main menu is

displayed. Press the MEASURE key.

ESAB LUD 450

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: Fe

SHIELDING GAS: Ar+8%CO2

WIRE DIMENSION: 1.2 mm

AUXILIARY FUNCTIONS

SET MEASURE MEMORY

The measured value display could look like this. The arrow at the bottom right of the

display indicates that there is more information than can be displayed.

DIP/SPRAY, Fe, Ar+8%CO2, 1.2 mm

Scroll down using

the arrow down

key.

22,5 Volt

FAST

MODE

ENTER

bu14d01e

134 Amp

6,0 m/min

REM QUIT

-- 4 0 --

Page 41

GB

A fourth value is visible in the display.

134 Amp

6,0 m/min

3,01 kW

6.2 Changing set values

DIP/SPRAY, Fe, Ar+8%CO2, 1.2 mm

REM QUIT

You can change the value of certain parameters in the measured value display.

Which parameters can be changed depends on which welding process is selected.

The parameter values that can be changed are always identified by or .

DIP/SPRAY, Fe, Ar+8%CO2, 1.2 mm

Change by pressing

or

The window that

pops up will

disappear after 1.5 s

if neither of the

buttons are used.

22,5 Volt

VOLTAGE: 22,5 (+3,5) V

134 Amp

6,0 m/min

REM QUIT

bu14d01e

-- 4 1 --

Page 42

GB

7MEMORY

The controller can store up to 99 sets of weld data. Each of these sets is given a

number from 1 to 99. If the weld data memory is full, i.e. if 99 sets of data are

already stored and you want to save an additional set of data, then the oldest set of

weld data is automatically deleted.

You can also delete and copy sets of weld data and recall a set of weld data to the

working memory.

Here is an example showing how to store, recall, copy and delete data.

7.1 Store

When you want to store a set of data, first make sure the main menu is displayed.

Press the MEMORY key. If the weld data memory is empty the display will appear as

follows.

MEMORY FUNCTIONS -- STORED DATA SETS

:

NO STORED DATA SETS

STORE QUIT

:

Example

We will now store a set of weld data. We will store it in memory location 10. Press

the STORE key. The display will appear as follows.

STORE IN DATA NR. 1

If you press

ENTER now the

set of data will be

saved as number

1, as indicated by

thetoplineofthe

display.

QUIT ENTER

You can use the plus/minus keys to select the memory location you want to store the

set of data in. This is shown in the top line of the display.

bu14d01e

-- 4 2 --

Page 43

GB

The number shown in the top line of the display is the first empty position found in

the memory.

STORE IN DATA NR. 10

Select number 10

using the

plus/minus

keys. Press

ENTER.

QUIT ENTER

The set of data is now stored as number 10. At the bottom of the display you can

see part of the contents of data set 10.

STORE IN DATA NR. 10

10

" DIP/SPRAY, Fe, CO2, 1.2 mm

QUIT ENTER

To return to the memory menu press the QUIT key.

Tip!

If the display indicates STOREINDATANR.1,you can go directly to set 99 by

pressing the minus on either

or

.

bu14d01e

-- 4 3 --

Page 44

GB

7.2 Delete

In the memory menu you can delete one or more sets of weld data.

Example

We will now delete the set of data we stored in the earlier example. Press the

DELETE key.

MEMORY FUNCTIONS -- STORED DATA SETS

10 50

DIP/SPRAY, Fe, Ar+20% CO2, 1.2 mm

STORE DELETE RECALL COPY QUIT

The last stored set of data is marked automatically. If more than one set of data has

been stored you can move the cursor between them using the arrow left and arrow

right keys.

DELETE WELD DATA NR. 10

Press ENTER to

confirm you want to

10

delete data set

number 10.

" DIP/SPRAY, Fe, Ar+20% CO2, 1.2 mm

QUIT ENTER

bu14d01e

-- 4 4 --

Page 45

GB

7.3 Recall

To recall a previously stored set of data; first check that the memory menu is

displayed. Press the RECALL key.

MEMORY FUNCTIONS -- STORED DATA SETS

10

STORE DELETE RECALL COPY QUIT

Example

The last stored set of data is marked automatically. If there is more than one set of

data you can move the cursor between them using the arrow left and arrow right

keys.

RECALL WELD DATA NR. 10

Press ENTER to

confirm that you

10

want to recall data

set number 10.

" DIP/SPRAY, Fe, Ar+20% CO2, 1.2 mm

QUIT ENTER

Return to the memory menu by pressing the QUIT key.

7.4 Copy

You can copy the contents of a previously stored set of data into another memory

location. Start by pressing the COPY key.

MEMORY FUNCTIONS -- STORED DATA SETS

10

bu14d01e

DIP/SPRAY, Fe, Ar+20% CO2, 1.2 mm

STORE DELETE RECALL COPY QUIT

-- 4 5 --

Page 46

GB

Example

The last stored set of data is marked automatically. If more than one set of data has

been stored you can move the cursor between them using the arrow left and arrow

right keys. We will now copy the contents of memory location 10 into location 50.

Use either of the plus/minus keys to mark the memory location you want to copy to.

COPY WELD DATA NR. 10 TILL NR. 50

Scroll forward to

number 50 using

the plus key and

ENTER.

10

" DIP/SPRAY,Fe, Ar+20% CO2, 1.2 mm

QUIT ENTER

STORE OVER EXISTING WELD DATA ?

10

" DIP/SPRAY,Fe, Ar+20% CO2, 1.2 mm

NO YES

The weld data in location 10 has now been copied to memory location 50.

If memory location 50 was already occupied a message appears in the display.

COPY WELD DATA NR. 10 TILL NR. 50

10 50

" DIP/SPRAY,Fe, Ar+20% CO2, 1.2 mm

Press the QUIT key to return to the memory menu.

-- 4 6 --

bu14d01e

QUIT ENTER

Page 47

GB

7.5 Remote control

To start, we call up the main menu by pressing the MENU key. Then select the

measure menu by pressing the MEASURE key.

DIP/SPRAY, Fe, Ar+8%CO2, 1.2 mm

From the measure

menu you can switch to

operating the

equipment by remote

control by pressing the

“Remote“ key.

There are four different

remote control devices:

22,5 Volt

134 Amp

6,0 m/min

REM

Digital remote control

The digital remote control is used when you want to recall weld data settings from

the weld data memory without using the standard controller.

S Aristo Control 5--program.

This remote control lets you recall 5 different sets of weld data settings from

memory. You save them in memories 1--5.

You can also adjust the voltage for the welding program you have recalled.

Analogue remote control

With an analogue remote control you can control the primary parameters of the

welding process from a unit other than the standard controller.

S Aristo Control Synergic PAE 2.

With this remote control you can increase/decrease the wire feed speed and

voltage either side of the synergic line you have chosen.

S Esab PSF welding torch with 2 knobs.

This welding torch has 2 knobs that allow you to increase/decrease the wire feed

speed and voltage either side of the synergic line you have chosen. It is also

possible to adjust these during welding.

S Esab PSF welding torch with 3 programs.

This welding torch has a three position key.

The key lets you recall 3 different sets of weld data settings from memory, for

example for root beads and filler beads. It is also possible to change welding

program during welding.

7.5.1 Configuring a remote control

See step 9.2.3.

bu14d01e

-- 4 7 --

Page 48

GB

8FASTMODE

8.1 Description of fast mode

If you have stored one or more sets of weld data in the weld data memory you can

make one or more of them (maximum of four) available through the FAST MODE

key in the main menu.

ESAB LUD 450

PROCESS: MIG/MAG

METHOD: DIP/SPRAY

WIRE TYPE: Fe

SHIELDING GAS: Ar+8%CO2

WIRE DIMENSION: 1.2 mm

AUXILIARY FUNCTIONS

"

SET MEASURE MEMORY

When you press the fast mode key the display may appear like this.

DIP/SPRAY, Fe,Ar+20% CO2, 1.2 mm

FAST

MODE

ENTER

22,5 Volt

134 Amp

6,0 m/min

WELD

DATA 1

Four of the soft buttons can thus be ”linked” to a weld--data setting of their own in the

weld--data memory. See soft button function under section 9.2.4.2.

The fifth soft button’s 2nd function is used to shift functions for the four soft buttons.

You can shift the four soft buttons from having weld--data settings to having those

functions available in measure mode (gas purge, hot start, wire inching, trigger

mode, crater fill, creep start, etc.)

WELD

DATA 2

WELD

DATA 3

WELD

DATA 4

2ND

FUNCT

8.2 Configuring the fast mode keys

See step 9.2.8.1.

bu14d01e

-- 4 8 --

Page 49

GB

9 AUXILIARY FUNCTIONS

9.1 Memory card operations

In order to use the memory card functions you must

first install the PC card.

1. Turn off the power to the welding machine

2. Insert the PC card

3. Turn on the power

4. Press auxiliary functions, ENTER

5. Press memory card operation, ENTER

The following display appears:

Insert PC-card here

MEMORY CARD OPERATIONS

WELD DATA SETS

STORE DELETE RECALL QUIT

STORE

This is used to save weld data settings (in memory locations 1--99) to the PC card

using the controller.

If the same weld data is already stored on the card it will be written over by the data

in the controller’s own memory.

Exempel

PC cardSetting control

The weld data

settings in the

controller are.

123101250

The PC

card

is empty

Press STORE.

The weld data settings from the controller are now

stored on the PC card

-- 4 9 --

bu14d01e

PC card

123101250

Page 50

GB

DELETE

Use this if you want to delete the contents of the PC card memory (all weld data

settings).

Example

PC--card

The weld data settings on the PC card are:

123101250

PC--card

Press DELETE. The PC card’s memory is

now empty.

RECALL

This is used to copy weld data settings from the PC card to the controller.

If a weld data setting is already stored in the controller’s own memory it will be

written over by the settings stored on the PC card.

Example

PC--cardSetting control

Press RECALL.

123101250 23456

Setting control

The controller now has 3 new sets of weld data

settings (4, 5, 6) and sets 2 and 3 have been

updated with the settings that were stored on the

123456

10 12 50

PC card.

Error codes

If the controller detects an error in the PC card you will see an error code that briefly

describes the error in question.

Check the following:

S That the PC card is properly installed.

S That the PC card is not of an unknown or unapproved make.

S That the data stored on the card is compatible with the software in the controller.

S That the PC card has the correct version number and is using the correct format.

bu14d01e

-- 5 0 --

Page 51

GB

9.2 Configuration

9.2.1 Language and Unit of length

See step 1.3.

9.2.2 Lock function

MAIN MENU

AUXILIARY FUNCTIONS

CONFIGURATION

LOCK FUNCTION

Sometimes you may want to restrict access to certain controller functions to prevent

someone else from changing important parameters or settings.

When the password function is active and the measure, (remote control) or fast

mode menus are selected, a password is requested whenever you try to return to

the main menu by pressing the QUIT or MENU keys.

Normally the equipment starts up in one of these three menus when you first switch

it on, and the only way to exit in order to go to other memories is to give the right

password.

LOCK FUNCTION

LOCK STATUS OFF

SET/CHANGE LOCK CODE

QUIT

ENTER

In PASSWORD MODE the password function can be switched off without deleting

the existing password. If you try to switch on the password function when no

password is stored, the display shows a computer--like “keyboard“ which you can

use to enter a new password.

When you activate the password a small icon of a key appears on the first line of the

display to show that the password function is activated. You can then move freely

between the menus until you go into the measure menu or fast mode menu, which

trigger the password function and prevent the user from exiting these menus without

first entering the password.

In ENTER/CHANGE PASSWORD you can edit the existing password or enter a new

one.

The password can consist of up to any10 letters or numbers.

bu14d01e

-- 5 1 --

Page 52

GB

Deactivating password function

When you are in the measure menu or fast mode menu with the password function

deactivated, you can exit these menus at any time by pressing QUIT or the MENU

key to get back to the main menu.

If the lock function is active and you try to exit, the following message will be

displayed to warn the user about the password protection.

PRESS ENTER TO

LOCK CODE

From here you can choose QUIT if you change your mind and want to go back to the

previous menu, or continue by pressing ENTER to input the password.

This will take you to the keyboard display so that you can type in the password and

confirm it by pressing the enter key on the keyboard.

If the password is incorrect, you will see an error message that gives the user the

option of trying again or going back to the original menu, i.e. the measure menu or

fast mode menu.

If the password is correct, all restrictions on moving to another menu will be lifted,

but the password function will still remain active, this means that you can leave the

measure/fast mode menus temporarily, but when you go back to them the password

will be activated again.

If you want to make changes outside the measure/fast mode menus (e.g. change

settings, deactivate password function, etc.) you can return to them and password

mode and reactivate the password to restrict the user to the measure/fast mode

menus again.

bu14d01e

-- 5 2 --

Page 53

GB

9.2.3 Remote controls

MAIN MENU

AUXILIARY FUNCTIONS

CONFIGURATION

REMOTE CONTROLS

All remote control configurations apply to any wire feed unit that is connected.

If you deselect ANALOG1 this will affect both wire feed units if you are using twin

wire feed units.

MIG/MAG--REMOTE CONTROLS

FORGET OVERRIDE ENABLED

DIGITAL OP: 5--PROG

ANALOG 1: NONE

ANALOG 2: NONE

QUIT ENTER

Move the cursor to the line FORGET CHANGE, and press ENTER to display a list of

options.

The forget change function in “on“ mode means you always have access to the

original weld data in the selected memory location when you come to the end of a

weld.

In other words, if you have made a change to a synergic line, for example increased

the voltage by 2 V, when you finish the current weld that change will be cancelled

and the original data will be recalled.

This is useful when testing new welding parameters, for example.

Configuring a digital remote control

When using a digital remote control you must specify the type of device that is used;

a 5--program device or 32--program device (BINARY CODED).

If you position the cursor on the line DIGITAL OP and press ENTER you will see a

list of the available options.

BINARY CODED

5--PROG

bu14d01e

-- 5 3 --

Page 54

GB

Configuring an analogue remote control

When you use an analogue remote control you should use the controller to specify

which potentiometer(s) you want to use (maximum of two).

The controller designates the potentiometers ANALOG 1 and ANALOG 2 and

assigns specific welding parameters to each, depending on the welding process, e.g.

voltage (ANALOG 1) and wire feed speed (ANALOG 2) for MIG/MAG.

If you position the cursor on the line ANALOGUE 1

and press ENTER you will see a list.

You can now choose whether the potentiometer

ANALOG 1 is to be used (VOLTAGE) or not

(NONE).

Select the line VOLTAGE from the list and press ENTER.

MIG/MAG -- REMOTE CONTROLS

The following

display apppears

FORGET OVERRIDE ENABLED

DIGITAL OP: 5--PROG

ANALOG 1: VOLTAGE

ANALOG 2: NONE

RANGE ON INPUTS:

ANALOG 1, DIG +/-- MIN: # 8.0 V

MAX

If you position the cursor on the line ANALOGUE 2

and press ENTER you will see a list.

You can now choose whether the potentiometer

ANALOG 2 is to be used (WIRE SPEED) or not

(NONE).

NONE

VOLTAGE

50,0 V

*

QUIT ENTER

NONE

WIRE SPEED

Select the line WIRE SPEED from the list and press ENTER.

MIG/MAG -- REMOTE CONTROLS

The following

display apppears

FORGET OVERRIDE ENABLED

DIGITAL OP: 5--PROG

ANALOG 1: VOLTAGE

ANALOG 2: WIRE SPEED

RANGE ON ANALOG INPUTS:

ANALOG 1, DIG +/-- MIN: # 8.0 V

MAX:

ANALOG 2 MIN: # 1.5 m/min

MAX:

QUIT ENTER

60 V

*

25 m/min

*

You should also set the control range for the potentiometer(s) you will use. You do

this by using the plus/minus keys on the controller to specify a minimum and

maximum value.

This only applies to non--synergic mode. In synergic mode you set ANALOG1 to +-10 V in relation to the chosen synergic line, while ANALOG 2 wire feed is set to

non--synergic.

bu14d01e

-- 5 4 --

Page 55

GB

9.2.4 MIG/MAG defaults

9.2.4.1 Trigger functions

Use the arrow keys

to select the line

GUN TRIGGER

MODE.

Press ENTER to

display the list of

options.

MAIN MENU

AUXILIARY FUNCTIONS

CONFIGURATION

MIG/MAG DEFAULTS

CONFIGURATION--MIG/MAG DEFAULTS

GUN TRIGGER MODE: 4--STROKE

SOFT KEYS SETUP:

VOLT. MEASURE IN PULSED: AVERAGE

Position the cursor on the line for 2--STROKE

in the list and press ENTER. We have now set the

GUN TRIGGER MODE = 2--STROKE.

CONFIGURATION--MIG/MAG DEFAULTS

GUN TRIGGER MODE: 2--STROKE

SOFT KEYS SETUP:

VOLT. MEASURE IN PULSED: AVERAGE

QUIT ENTER

2--STROKE

4--STROKE

bu14d01e

QUIT ENTER

-- 5 5 --

Page 56

GB

9.2.4.2 Soft key functions

MAIN MENU

AUXILIARY FUNCTIONS

CONFIGURATION

MIG/MAG DEFAULTS

SOFT KEYS

We have already mentioned the five “soft keys“ on the controller. During MIG/MAG

welding the user has the opportunity to select the functions of these keys from

several options.

Ofthefivesoftkeysthethreeontheleftcanbeassignedachosenfunction.

You can choose from the following options:

S Gas purge

S Wire inching

S Trigger mode (2/4)

S Crater fill ON/OFF

S Creep start ON/OFF

S Hot start ON/OFF

S Trigg weld--data switch ON/OFF

A soft key is assigned to one of these functions as follows.

The following appears in the character display. The display has two columns; one for

function and another for key number. The figures 1, 2 and 3 each represent a key,

i.e. the key on the far left is number 1, and so on.

In the following example we will assign key number 1 the function CRATER FILL

ON/OFF.

ASSOCIATE FUNCTIONS TO SOFT KEYS

Position the cursor

on the line

CRATER FILL

ON/OFF. Press

key number 1, i.e.

the key on the far

left.

Function Soft key

NONE 1, 2,3

GAS PURGE

WIRE INCHING

TRIGGER MODE (2/4)

CRATERFILL ON/OFF

CREEPSTART ON/OFF

HOT START ON/OFF

TRIGG WELD DATA SWITCH ON/OFF

bu14d01e

NONE NONE NONE QUIT

-- 5 6 --

Page 57

GB

The display shows that key number 1 has now been assigned the function CRATER

FILL ON/OFF. The number 1 has moved down to the line CRATER FILL ON/OFF

and at the bottom of the display you can see the key caption CRATERFILL for the

left hand key.

ASSOCIATE FUNCTIONS TO SOFT KEYS

Function Soft key

NONE 2,3

GAS PURGE

WIRE INCHING

TRIGGER MODE (2/4)

CRATERFILL ON/OFF 1

CREEPSTART ON/OFF

HOT START ON/OFF

TRIGG WELD DATA SWITCH ON/OFF

CRATR

FILL

NONE NONE QUIT

The other two keys can each be assigned a function in the same way by matching

one of the functions in the left column with a key number in the right column.