ESAB Precision Plasmarc System with Electronic Flow Control Installation manual / Instruction manual

Page 1

F-15-480-D

October, 2000

Installation, Operation and Maintenance Manual for the

PRECISION PLASMARC SYSTEM

with Electronic Flow Control

CUTTING SYSTEMS

411 s. Ebenezer Road

Florence, SC 29501-0545

Page 2

The equipment described in this manual is

potentially hazardous. Use caution when installing,

operating and maintaining this equipment.

Purchaser is solely responsible for the safe

operation and use of all products purchased,

including compliance with OSHA and other

government standards. ESAB Cutting

Systems has no liability for personal injury or

other damage arising out of the use of any

product manufactured or sold be ESAB. See

standard ESAB terms and conditions of sale

for a specific statement of ESAB’s

responsibilities and limitations on its liability.

Every effort was made to ensure the accuracy

and completeness of this manual. Information

in this document is subject to change without

notice.

This manual is ESAB Part Number F15480

This manual is ESAB Part Number F15480

This manual is ESAB Part Number F15480This manual is ESAB Part Number F15480

This manual is for the convenience and use of the

cutting machine purchaser. It is not a contract or

other obligation on the part of ESAB Cutting

Systems.

©©©© ESAB Cutting Systems, 2000

Printed in U.S.A.

Page 3

Precision Plasma Electronic Flow Control Table of Contents

Page

Section 1 Safety

1.1 Introduction 1

1.2 Safety Notations And Symbols 1

1.3 General Safety Information 2

1.4 Installation Precautions 3

1.5 Electrical Grounding 4

1.6 Operating A Plasma Cutting Machine 4

1.7 Service Precautions 8

1.8 Safety References 9

Section 2 Description

2.1 General 1

2.2 Scope 1

2.3 Package Options Available 1

2.4 Technical Specifications

2.4.1 Precision Plasma System 2

2.4.2 Plasma Gas 3

2.4.3 Start Gas 3

2.4.4 Secondary Gas 3

2.4.5 PT-24 Torch 3

Section 3 Installation

3.1 General 1

3.2 Equipment Required 1

3.3 Location 1

3.4 Primary Electrical Input Connect ion s 2

3.5 Interconnecting Lines 4

Precision Plasmarc Component Interconnecting Diagram 8

3.6 Torch Mounting 10

3.7 Torch Coolant 11

3.8 Inspection of Gas and Coolant Lines 11

3.9 Replacement o f EPROM in the Plasmarc P o w er Source

Programmable Logic Controller (PLC)

i

12

Page 4

Precision Plasma Electronic Flow Control Table of Contents

Section 4 Operation

4.1 Power Supply Controls

4.1.1 Main Power Switch 1

4.1.2 Pilot Arc Switch 1

4.1.3 Fault Indicator Lights 2

4.1.4 Meters 2

4.1.5 Current Control Switch 2

4.2 Cut Quality

4.2.1 Introduction 3

4.2.2 Cut Angle 3

4.2.3 Cut Flatness 4

4.2.4 Surface Finish 5

4.2.5 Dross 6

4.2.6 Dimensional Accuracy 8

4.3 Influence of Gas Options on Cut Quality

4.3.1 Introduction 9

4.3.2 Aluminum 9

4.3.3 Carbon Steel 10

4.3.4 Stainless Steel 11

4.4 Process Data

4.4.1 Introduction 13

4.4.2 Process Data Settings 14

Plasma Marking Data 54

4.4.3 Relationship of Kerf Width to Amperes and Material Thickness 76

4.4.3.1 Aluminum Kerf Values 76

4.4.3.2 Carbon Steel Kerf Values 78

4.4.3.3 Stainless Steel Kerf Values O2/N2/O

2

4.4.3.4 Stainless Steel Kerf Values Air/Air/CH

4.4.3.5 Stainless Steel Kerf Values N2/N2/CH

4

4

81

82

83

4.4.3.6 Stainless Steel Kerf Values N2/N

2

84

4.4.3.7 Stainless Steel Kerf Values Air/Air 86

ii

Page 5

Precision Plasma Electronic Flow Control Table of Contents

Section 5 Maintenance

5.1 General 1

5.2 Inspection and Cleaning 1

5.3 PT-24 Torch Description 2

5.4 Torch Maintenance 5

5.5 PT-24 Consumable Disassembly and Inspection 7

5.6 PT-24 Torch Re-Assembly 9

Section 6 Troubleshooting

6.1 General Safety 1

6.2 Programmable Logic Controller (PLC) 1

6.2.1 PLC LED Introduction 2

6.2.2 PLC LED Functions 2

6.3 Troubleshooting Guide

6.3.1 Reduced Consumable Life 3

6.3.2 Poor Cut Quality 4

6.3.3 No Pilot Arc 4

6.3.4 No Arc Transfer 4

6.3.5 No Preflow 4

6.3.6 Torch Fails to Fire 4

6.3.7 Nozzle Life Extremely Short 5

6.3.8 Short Electrode Life 5

6.3.9 Short Electrode AND Nozzle Life 5

6.4 Flow Control Schematic 6

6.5 Gas Flow Schematic 7

6.6 Junction Box Wiring Diagram 8

6.7 Junction Box Schematic 9

6.8 Precision Plasma Power Module Wiring Diagram 10-11

6.9 Power Module Schematic 12

6.10 Power Source Wiring Diagrams 13-17

6-11 Power Source Schematic 18-19

iii

Page 6

Precision Plasma Electronic Flow Control Table of Contents

6.12 Technical Guide to Using/Understanding the Operation of the EFC 20

6.12.1 Precision Process Timers 21

6.12.2 Process Timer Values 22

6.12.3 Process Window Key Functions 23

6.12.4 Proportional Valve Analog Values for PARAM.CUT

PARAM.CUT and DEF.TEC

PARAM.CUTPARAM.CUT

DEF.TEC 24

DEF.TECDEF.TEC

6.12.5 Process Gas Selection Requirements 25

6.12.6 EFC Process Gas Flow Chart 26

6.12.7 Station On, Flush/Pressurize Cycle Timers 27

6.12.8 Solenoid/Proportional Valve Requirements and

Gas Error Monitoring

Carbon Steel PG-O2, SG-O

Carbon Steel PG-O2, SG-N2/O

Carbon Steel PG-O2, Sg-O

Stainless Steel PG-N2, SG-N

2

2

2

2

Stainless Steel PG-N2, SG-N2/CH

4

28

30

32

34

36

Stainless Steel PG-Air, SG-Air 38

Stainless Steel PG-Air, SG-Air/CH

Aluminum PG-N2, SG- N

Aluminum PG-N2, SG-N2/CH

2

4

4

40

42

44

Marking PG-Argon, SG-Air 46

Section 7 Replacement Parts

7.1 General 1

7.2 Ordering 2

7.3 Plasmarc Power Source – Exterior Components 3

7.4 Plasmarc Power Source – Internal Components 8

7.5 Power Source Module 18

7.6 EFC Junction Box 26

7.7 Electronic Flow Control Box 32

7.8 PT-24 Torch Assembly EFC Series A/M 36

7.9 T Gas Shut-off Valve Assembly - Series A/M Torch 38

7.10 PT-24 Torch Assembly – Version 1 40

7.11 Solenoid Assembly - EFC Torch – Version 1 42

Customer/Technical Information Back Manual Cover

iv

Page 7

SECTION 1 SAFETY

1.1 Introduction

The process of cutting metals with plasma equipment

provides industry with a valuable and versatile tool.

ESAB cutting machines are designed to provide both

operation safety and efficiency. However, as with any

machine tool, sensible attention to operating

procedures, precautions, and safe practices is

necessary to achieve a full measure of usefulness.

Whether an individual is involved with operation,

servicing, or as an observer, compliance with

established precautions and safe practices must be

accomplished. Failure to observe certain precautions

could result in serious personnel injury or severe

equipment damage. The following precautions are

general guidelines applicable when working with

cutting machines. More explicit precautions pertaining

to the basic machine and accessories are found in the

instruction literature. For a wide scope of safety

information on the field of cutting and welding

apparatus, obtain and read the publications listed in

the Recommended References.

1.2 Safety Notations And Symbols

!

DANGER

!

WARNING

!

CAUTION

!

CAUTION

The following words and symbols are used throughout

this manual. They indicate different levels of required

safety involvement.

ALERT or ATTENTION. Your safety is involved

or potential equipment failure exists. Used in

concurrence with other symbols and information.

Used to call attention to immediate hazards

which, if not avoided, will result in serious

personal injury or loss of life.

Used to call attention to potential hazards

that could result in personal injury or loss of

life.

Used to call attention to hazards that could

result in minor personal injury or equipment

damage.

Used to call attention to minor hazards to

equipment.

NOTICE

Used to call attention to important

installation, operation or maintenance

information not directly related to safety

hazards.

1-1

Page 8

SECTION 1 SAFETY

1.3 General Safety Information

Machine starts automatically.

WARNING

!

This equipment moves in various directions and

This equipment moves in various directions and

This equipment moves in various directions andThis equipment moves in various directions and

speeds.

speeds.

speeds.speeds.

• Moving machinery can crus h .

Moving machinery can crus h .

Moving machinery can crus h .Moving machinery can crus h .

• Only qualified personnel should operate or service

Only qualified personnel should operate or service

Only qualified personnel should operate or serviceOnly qualified personnel should operate or service

equipment.

equipment.

equipment.equipment.

• Keep all personnel, materials , an d equ ipment not

Keep all personnel, materials , an d equ ipment not

Keep all personnel, materials , an d equ ipment notKeep all personnel, materials , an d equ ipment not

involved in production process clear of entire

involved in production process clear of entire

involved in production process clear of entireinvolved in production process clear of entire

system area.

system area.

system area.system area.

• Keep gear racks and rails clear of debris or

Keep gear racks and rails clear of debris or

Keep gear racks and rails clear of debris orKeep gear racks and rails clear of debris or

obstructions, such as tools or clothing.

obstructions, such as tools or clothing.

obstructions, such as tools or clothing.obstructions, such as tools or clothing.

• Fence off entire work cell to prevent personn el

Fence off entire work cell to prevent personn el

Fence off entire work cell to prevent personn elFence off entire work cell to prevent personn el

from passing through area or standing in the

from passing through area or standing in the

from passing through area or standing in thefrom passing through area or standing in the

working envelope of the equipment.

working envelope of the equipment.

working envelope of the equipment.working envelope of the equipment.

WARNING

!

• Post appropriate WARNING signs at every work

Post appropriate WARNING signs at every work

Post appropriate WARNING signs at every workPost appropriate WARNING signs at every work

cell entrance.

cell entrance.

cell entrance.cell entrance.

• Follow lockout procedure before servicing.

Follow lockout procedure before servicing.

Follow lockout procedure before servicing.Follow lockout procedure before servicing.

Failure to follow operating instructions

could result in death or serious injury.

Read and understand this operator’s manual before

Read and understand this operator’s manual before

Read and understand this operator’s manual beforeRead and understand this operator’s manual before

using machine.

using machine.

using machine.using machine.

• Read entire procedure before operating or

Read entire procedure before operating or

Read entire procedure before operating orRead entire procedure before operating or

performing any system maintenance.

performing any system maintenance.

performing any system maintenance.performing any system maintenance.

• Special attention must be given to all hazard

Special attention must be given to all hazard

Special attention must be given to all hazardSpecial attention must be given to all hazard

warnings that provide essential information

warnings that provide essential information

warnings that provide essential informationwarnings that provide essential information

regarding personnel safety and/or possible

regarding personnel safety and/or possible

regarding personnel safety and/or possibleregarding personnel safety and/or possible

equipment damage.

equipment damage.

equipment damage.equipment damage.

• All safety precautions relevant to electrical

All safety precautions relevant to electrical

All safety precautions relevant to electricalAll safety precautions relevant to electrical

equipment and process operations must be

equipment and process operations must be

equipment and process operations must beequipment and process operations must be

strictly observed by all having system

strictly observed by all having system

strictly observed by all having systemstrictly observed by all having system

responsibility or access.

responsibility or access.

responsibility or access.responsibility or access.

• Read all safety publications made available by

Read all safety publications made available by

Read all safety publications made available byRead all safety publications made available by

your company.

your company.

your company.your company.

1-2

Page 9

SECTION 1 SAFETY

Failure to follow safety warning label

WARNING

!

1.4 Installation Precautions

instructions could result in death or

serious injury.

Read and understand all safety warning labels on

Read and understand all safety warning labels on

Read and understand all safety warning labels onRead and understand all safety warning labels on

machine.

machine.

machine.machine.

Refer to operator’s manual for additional safety

Refer to operator’s manual for additional safety

Refer to operator’s manual for additional safetyRefer to operator’s manual for additional safety

information.

information.

information.information.

WARNING

!

Improperly installed equipment can cause

injury or death.

Follow these guidelines while installing machine:

Follow these guidelines while installing machine:

Follow these guidelines while installing machine:Follow these guidelines while installing machine:

Do not connect a cylinder directly to mach in e inlet. An

Do not connect a cylinder directly to mach in e inlet. An

Do not connect a cylinder directly to mach in e inlet. AnDo not connect a cylinder directly to mach in e inlet. An

appropriate cylinder regulator must be installed on a

appropriate cylinder regulator must be installed on a

appropriate cylinder regulator must be installed on aappropriate cylinder regulator must be installed on a

fuel gas cylinder to reduce pressure to a reasonable

fuel gas cylinder to reduce pressure to a reasonable

fuel gas cylinder to reduce pressure to a reasonablefuel gas cylinder to reduce pressure to a reasonable

inlet supply pressure. Machine regulator is then used

inlet supply pressure. Machine regulator is then used

inlet supply pressure. Machine regulator is then usedinlet supply pressure. Machine regulator is then used

to obtain pressure required by torches.

to obtain pressure required by torches.

to obtain pressure required by torches.to obtain pressure required by torches.

Contact your ESAB representative before installation.

Contact your ESAB representative before installation.

Contact your ESAB representative before installation.Contact your ESAB representative before installation.

He can suggest certain precautions regarding piping

He can suggest certain precautions regarding piping

He can suggest certain precautions regarding pipingHe can suggest certain precautions regarding piping

installation and machine lifting, etc. to ensure

installation and machine lifting, etc. to ensure

installation and machine lifting, etc. to ensureinstallation and machine lifting, etc. to ensure

maximum security.

maximum security.

maximum security.maximum security.

Never attempt any machine modifications or apparatus

Never attempt any machine modifications or apparatus

Never attempt any machine modifications or apparatusNever attempt any machine modifications or apparatus

additions without first consulting a qualified ESAB

additions without first consulting a qualified ESAB

additions without first consulting a qualified ESABadditions without first consulting a qualified ESAB

representative.

representative.

representative.representative.

Observe machine clearance requ irements for proper

Observe machine clearance requ irements for proper

Observe machine clearance requ irements for properObserve machine clearance requirements for proper

operation and personnel safety.

operation and personnel safety.

operation and personnel safety.operation and personnel safety.

1-3

Page 10

SECTION 1 SAFETY

1.5 Electrical Grounding

Electrical grounding is imperative for proper machine

operation and SAFETY. Refer to this manual’s

Installation section for detailed grounding instructions.

Electric shock hazard.

WARNING

!

Improper grounding can cause severe injury or deat h.

Improper grounding can cause severe injury or deat h.

Improper grounding can cause severe injury or deat h.Improper grounding can ca use seve re injury or de a t h.

Machine must be properly grounded before put into

Machine must be properly grounded before put into

Machine must be properly grounded before put intoMachine must be properly grounded before put into

service.

service.

service.service.

Improper grounding can damage machine

WARNING

!

and electrical components.

• Machine must be properly grounded before put

Machine must be properly grounded before put

Machine must be properly grounded before putMachine must be properly grounded before put

into service.

into service.

into service.into service.

1.6 Operating A Plasma Cutting Machine

WARNING

!

WARNING

!

• Cutting table must be properly grounded to

Cutting table must be properly grounded to a good

Cutting table must be properly grounded toCutting table must be properly grounded to

Earth ground rod.

Earth ground rod.

Earth ground rod.Earth ground rod.

a good

a gooda good

Flying debris and loud noise hazards.

• Hot spatter can burn and injure eyes. Wear

Hot spatter can burn and injure eyes. Wear

Hot spatter can burn and injure eyes. WearHot spatter can burn and injure eyes. Wear

goggles to protect eyes from burns and flying

goggles to protect eyes from burns and flying

goggles to protect eyes from burns and flyinggoggles to protect eyes from burns and flying

debris generated during operation.

debris generated during operation.

debris generated during operation.debris generated during operation.

• Chipped slag may be hot and fly far. Bystanders

Chipped slag may be hot and fly far. Bystanders

Chipped slag may be hot and fly far. BystandersChipped slag may be hot and fly far. Bystanders

should also wear goggles and safety glasses.

should also wear goggles and safety glasses.

should also wear goggles and safety glasses.should also wear goggles and safety glasses.

• From plasma arc can damage hearing. Wear

From plasma arc can damage hearing. Wear

From plasma arc can damage hearing. WearFrom plasma arc can damage hearing. Wear

correct ear protection when cutting above water.

correct ear protection when cutting above water.

correct ear protection when cutting above water.correct ear protection when cutting above water.

Burn hazard.

Hot metal can burn.

Hot metal can burn.

Hot metal can burn.Hot metal can burn.

• Do not touch metal plate or parts immediately after

Do not touch metal plate or parts immediately after

Do not touch metal plate or parts immediately afterDo not touch metal plate or parts immediately after

cutting. Allow metal time to cool, or douse with

cutting. Allow metal time to cool, or douse with

cutting. Allow metal time to cool, or douse withcutting. Allow metal time to cool, or douse with

water.

water.

water.water.

• Do not touch plasma torch immediately after

Do not touch plasma torch immediately after

Do not touch plasma torch immediately afterDo not touch plasma torch immediately after

cutting. Allow torch time to cool.

cutting. Allow torch time to cool.

cutting. Allow torch time to cool.cutting. Allow torch time to cool.

1-4

Page 11

SECTION 1 SAFETY

WARNING

!

Hazardous voltages. Electric shock

can kill.

• Do NOT touch plasma torch, cutting table or cable

Do NOT touch plasma torch, cutting table or cable

Do NOT touch plasma torch, cutting table or cableDo NOT touch plasma torch, cutting table or cable

connections during plasma cutting process.

connections during plasma cutting process.

connections during plasma cutting process.connections during plasma cutting process.

• Always turn power off to plasma power supplies

Always turn power off to plasma power supplies

Always turn power off to plasma power suppliesAlways turn power off to plasma power supplies

before touching or servicing plasma torch.

before touching or servicing plasma torch.

before touching or servicing plasma torch.before touching or servicing plasma torch.

• Always turn power off to plasma power supplies

Always turn power off to plasma power supplies

Always turn power off to plasma power suppliesAlways turn power off to plasma power supplies

before opening or servicing plasma plumbing or

before opening or servicing plasma plumbing or

before opening or servicing plasma plumbing orbefore opening or servicing plasma plumbing or

flow control box.

flow control box.

flow control box.flow control box.

• Do not touch live electrical parts.

Do not touch live electrical parts.

Do not touch live electrical parts.Do not touch live electrical parts.

• Keep all panels and covers in place when machine

Keep all panels and covers in place when machine

Keep all panels and covers in place when machineKeep all panels and covers in place when machine

is connected to power source.

is connected to power source.

is connected to power source.is connected to power source.

• Insulate yourself from

Insulate yourself from workpiece and electrical

Insulate yourself from Insulate yourself from

ground: wear insulating gloves, shoes and

ground: wear insulating gloves, shoes and

ground: wear insulating gloves, shoes andground: wear insulating gloves, shoes and

clothing.

clothing.

clothing.clothing.

• Keep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, andKeep gloves, shoes, clothing, work area, and

equipment dry.

equipment dry.

equipment dry.equipment dry.

workpiece and electrical

workpiece and electricalworkpiece and electrical

WARNING

!

WARNING

!

Pinch hazard.

Moving vertical slides can crush or pinch.

Moving vertical slides can crush or pinch.

Moving vertical slides can crush or pinch.Moving vertical slides can crush or pinch.

Keep hands clear of torch and slide during operation.

Keep hands clear of torch and slide during operation.

Keep hands clear of torch and slide during operation.Keep hands clear of torch and slide during operation.

Fume hazard.

Fumes and gases generated by the plasma cutting

Fumes and gases generated by the plasma cutting

Fumes and gases generated by the plasma cuttingFumes and gases generated by the plasma cutting

process can be hazardous to your health.

process can be hazardous to your health.

process can be hazardous to your health.process can be hazardous to your health.

• Do NOT breathe fumes.

Do NOT breathe fumes.

Do NOT breathe fumes.Do NOT breathe fumes.

• Do not operate plasma torch without fume removal

Do not operate plasma torch without fume removal

Do not operate plasma torch without fume removalDo not operate plasma torch without fume removal

system operating properly.

system operating properly.

system operating properly.system operating properly.

• Use additional ventilation to remove fumes if

Use additional ventilation to remove fumes if

Use additional ventilation to remove fumes ifUse additional ventilation to remove fumes if

necessary.

necessary.

necessary.necessary.

• Use approved respirator if ventilation is not

Use approved respirator if ventilation is not

Use approved respirator if ventilation is notUse approved respirator if ventilation is not

adequate.

adequate.

adequate.adequate.

1-5

Page 12

SECTION 1 SAFETY

WARNING

!

Radiation hazard.

Arc rays can injure eyes and burn

Arc rays can injure eyes and burn skin.

Arc rays can injure eyes and burn Arc rays can injure eyes and burn

• Wear correct eye and body protection .

Wear correct eye and body protection .

Wear correct eye and body protection .Wear correct eye and body protection.

• Wear dark safety glasses or goggles with

Wear dark safety glasses or goggles with side

Wear dark safety glasses or goggles with Wear dark safety glasses or goggles with

shields. Refer to following chart for recommended

shields. Refer to following chart for recommended

shields. Refer to following chart for recommendedshields. Refer to following chart for recommended

lens shades for plasma cutting:

lens shades for plasma cutting:

lens shades for plasma cutting:lens shades for plasma cutting:

Arc Current

Arc Current Le

Arc CurrentArc Current

Up to 100 Amps

Up to 100 Amps Shade No. 8

Up to 100 AmpsUp to 100 Amps

100-200 Amps

100-200 AmpsShade No. 10

100-200 Amps100-200 Amps

200-400 Amps

200-400 AmpsShade No. 12

200-400 Amps200-400 Amps

Over 400 Amps

Over 400 Amps Shade No. 14

Over 400 AmpsOver 400 Amps

• Replace glasses/goggles when lenses are pitted or

Replace glasses/goggles when lenses are pitted or

Replace glasses/goggles when lenses are pitted orReplace glasses/goggles when lenses are pitted or

broken

broken

brokenbroken

• Warn others in area not to look directly at the arc

Warn others in area not to look directly at the arc

Warn others in area not to look directly at the arcWarn others in area not to look directly at the arc

unless wearing appropriate safety glasses.

unless wearing appropriate safety glasses.

unless wearing appropriate safety glasses.unless wearing appropriate safety glasses.

• Prepare cutting area to reduce reflection and

Prepare cutting area to reduce reflection and

Prepare cutting area to reduce reflection andPrepare cutting area to reduce reflection and

transmission of ultraviolet light.

transmission of ultraviolet light.

transmission of ultraviolet light.transmission of ultraviolet light.

• Paint walls and other surfaces with dark colors to

Paint walls and other surfaces with dark colors to

Paint walls and other surfaces with dark colors toPaint walls and other surfaces with dark colors to

reduce reflections.

reduce reflections.

reduce reflections.reduce reflections.

Lens Shade

Le Le

Shade No. 10

Shade No. 10Shade No. 10

Shade No. 12

Shade No. 12Shade No. 12

skin.

skin.skin.

ns Shade

ns Shadens Shade

Shade No. 8

Shade No. 8Shade No. 8

Shade No. 14

Shade No. 14Shade No. 14

side

sideside

WARNING

!

• Install protective screens or curtains to reduce

Install protective screens or curtains to reduce

Install protective screens or curtains to reduceInstall protective screens or curtains to reduce

ultraviolet transmission.

ultraviolet transmission.

ultraviolet transmission.ultraviolet transmission.

Ruptured Gas Cylinders Can Kill

Mishandling gas cylinders can ruptu re an d viol en tly

Mishandling gas cylinders can ruptu re an d viol en tly

Mishandling gas cylinders can ruptu re an d viol en tlyMishandling gas cylinders can rupture and violently

release gas.

release gas.

release gas.release gas.

• Avoid rough handling of cylinders.

Avoid rough handling of cylinders.

Avoid rough handling of cylinders.Avoid rough handling of cylinders.

• Keep cylinder valves closed when not in use.

Keep cylinder valves closed when not in use.

Keep cylinder valves closed when not in use.Keep cylinder valves closed when not in use.

• Maintain hoses and fittings in good condition.

Maintain hoses and fittings in good condition.

Maintain hoses and fittings in good condition.Maintain hoses and fittings in good condition.

• Always secure cylinders in an upright position by

Always secure cylinders in an upright position by

Always secure cylinders in an upright position byAlways secure cylinders in an upright position by

chain or strap to a suitable stable object not part of

chain or strap to a suitable stable object not part of

chain or strap to a suitable stable object not part ofchain or strap to a suitable stable object not part of

an electrical circuit.

an electrical circuit.

an electrical circuit.an electrical circuit.

• Locate cylinders away from heat, sparks and

Locate cylinders away from heat, sparks and

Locate cylinders away from heat, sparks andLocate cylinders away from heat, sparks and

flames. Never strike an arc on a cylinder.

flames. Never strike an arc on a cylinder.

flames. Never strike an arc on a cylinder.flames. Never strike an arc on a cylinder.

• Refer to CGA Standard P-1, “Precautions for Safe

Refer to CGA Standard P-1, “Precautions for Safe

Refer to CGA Standard P-1, “Precautions for SafeRefer to CGA Standard P-1, “Precautions for Safe

Handling of Compressed Gases in Cylinders”,

Handling of Compressed Gases in Cylinders”,

Handling of Compressed Gases in Cylinders”,Handling of Compressed Gases in Cylinders”,

available from Compressed Gas Association.

available from Compressed Gas Association.

available from Compressed Gas Association.available from Compressed Gas Association.

1-6

Page 13

SECTION 1 SAFETY

WARNING

!

Spark hazard.

Heat, spatter, and sparks cause fire and burns.

Heat, spatter, and sparks cause fire and burns.

Heat, spatter, and sparks cause fire and burns.Heat, spatter, and sparks cause fire and burns.

• Do not cut near combustible material.

Do not cut near combustible material.

Do not cut near combustible material.Do not cut near combustible material.

• Do not cut containers that have held combustibles.

Do not cut containers that have held combustibles.

Do not cut containers that have held combustibles.Do not cut containers that have held combustibles.

• Do not have on your person any combustibles (e.g.

Do not have on your person any combustibles (e.g.

Do not have on your person any combustibles (e.g.Do not have on your person any combustibles (e.g.

butane lighter).

butane lighter).

butane lighter).butane lighter).

• Pilot arc can cause burns. Keep torch nozzle

Pilot arc can cause burns. Keep torch nozzle

Pilot arc can cause burns. Keep torch nozzlePilot arc can cause burns. Keep torch nozzle

away from yourself and others when activating

away from yourself and others when activating

away from yourself and others when activatingaway from yourself and others when activating

plasma process.

plasma process.

plasma process.plasma process.

• Wear correct eye and body protection .

Wear correct eye and body protection .

Wear correct eye and body protection .Wear correct eye and body protection.

• Wear gauntlet gloves, safety shoes and hat.

Wear gauntlet gloves, safety shoes and hat.

Wear gauntlet gloves, safety shoes and hat.Wear gauntlet gloves, safety shoes and hat.

• Wear flame-retardant clothing that covers all

Wear flame-retardant clothing that covers all

Wear flame-retardant clothing that covers allWear flame-retardant clothing that covers all

exposed areas.

exposed areas.

exposed areas.exposed areas.

• Wear

Wear cuffless trousers to prevent entry of sparks

cuffless trousers to prevent entry of sparks

Wear Wear

cuffless trousers to prevent entry of sparkscuffless trousers to prevent entry of sparks

and slag.

and slag.

and slag.and slag.

CAUTION

POOR PERFORMANCE WILL RESULT

WHEN CUTTING ABOVE WATER.

The PT-24 is designed to be a dry cutting

process.

Cutting above water may result in:

Cutting above water may result in:

Cutting above water may result in:Cutting above water may result in:

• reduced consumable life

reduced consumable life

reduced consumable lifereduced consumable life

• degradation of cut quality

degradation of cut quality

degradation of cut qualitydegradation of cut quality

Cutting above water may result in poor cutting

Cutting above water may result in poor cutting

Cutting above water may result in poor cuttingCutting above water may result in poor cutting

performance. Water vapor created when hot material

performance. Water vapor created when hot material

performance. Water vapor created when hot materialperformance. Water vapor created when hot material

or sparks contact liquid may cause arcing inside torch.

or sparks contact liquid may cause arcing inside torch.

or sparks contact liquid may cause arcing inside torch.or sparks contact liquid may cause arcing inside torch.

When cutting on a water table, reduce the water level

When cutting on a water table, reduce the water level

When cutting on a water table, reduce the water levelWhen cutting on a water table, reduce the water level

to provide maximum clearance between water and

to provide maximum clearance between water and

to provide maximum clearance between water andto provide maximum clearance between water and

material.

material.

material.material.

1-7

Page 14

SECTION 1 SAFETY

WARNING

!

1.7 Service Precautions

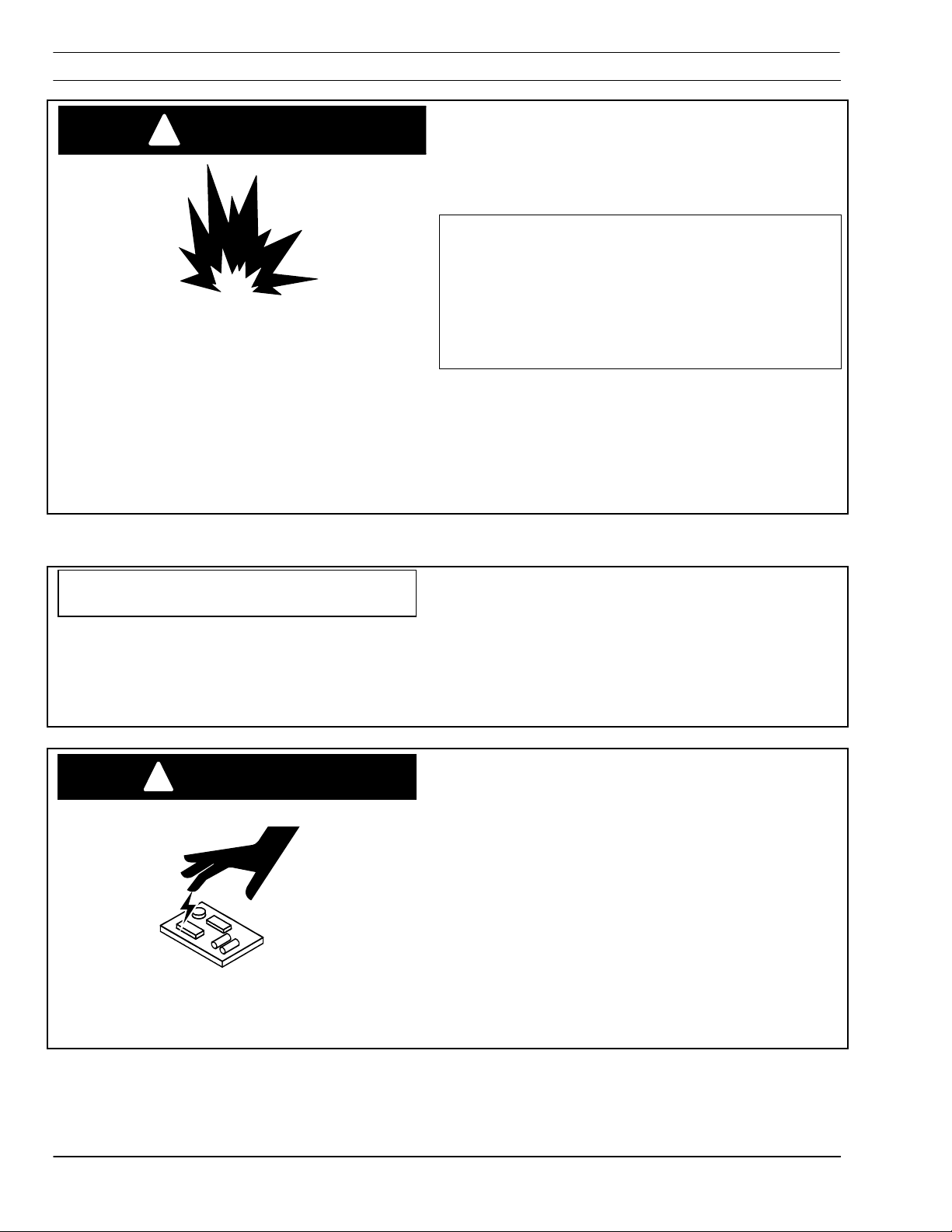

Explosion hazard.

Certain molten aluminum-lithium (Al-

Certain molten aluminum-lithium (Al-Li) alloys can

Certain molten aluminum-lithium (Al-Certain molten aluminum-lithium (Alcause explosions when plasma cut OVER water.

cause explosions when plasma cut OVER water.

cause explosions when plasma cut OVER water.cause explosions when plasma cut OVER water.

Do not plasma cut the following Al-

Do not plasma cut the following Al-Li alloys with

Do not plasma cut the following Al-Do not plasma cut the following Alwater:

water:

water:water:

Alithlite (Alcoa)

Alithlite (Alcoa) X8192 (Alcoa)

Alithlite (Alcoa)Alithlite (Alcoa)

Alithally (Alcoa)

Alithally (Alcoa) Navalite (US Navy)

Alithally (Alcoa)Alithally (Alcoa)

2090 Alloy (Alcoa)

2090 Alloy (Alcoa) Lockalite (Lockheed)

2090 Alloy (Alcoa)2090 Alloy (Alcoa)

X8090A (Alcoa)

X8090A (Alcoa) Kalite (Kaiser)

X8090A (Alcoa)X8090A (Alcoa)

X8092 (Alcoa)

X8092 (Alcoa) 8091 (

X8092 (Alcoa)X8092 (Alcoa)

• These alloys should only be dry cut on a dry table.

These alloys should only be dry cut on a dry table.

These alloys should only be dry cut on a dry table.These alloys should only be dry cut on a dry table.

• DO NOT d ry cut ove r water.

DO NOT d ry cut ove r water.

DO NOT d ry cut ove r water.DO NOT d ry cut ove r water.

• Contact your aluminum supplier for additional

Contact your aluminum supplier for additional

Contact your aluminum supplier for additionalContact your aluminum supplier for additional

safety information regarding hazards associated

safety information regarding hazards associated

safety information regarding hazards associatedsafety information regarding hazards associated

with these alloys

with these alloys

with these alloyswith these alloys

X8192 (Alcoa)

X8192 (Alcoa)X8192 (Alcoa)

Navalite (US Na vy)

Navalite (US Na vy)Navalite (US Navy)

Lockalite (Lo ckheed)

Lockalite (Lo ckheed)Lockalite (Lo ckheed)

Kalite (Kaiser)

Kalite (Kaiser)Kalite (Kaiser)

8091 (Alcan)

8091 (8091 (

.

Li) alloys can

Li) alloys canLi) alloys can

Li alloys with

Li alloys withLi alloys with

Alcan)

Alcan)Alcan)

CAUTION

CAUTION

!

Establish and adhere to preventive maintenance. A

Establish and adhere to preventive maintenance. A

Establish and adhere to preventive maintenance. AEstablish and adhere to preventive maintenance. A

composite program can be established from

composite program can be established from

composite program can be established fromcomposite program can be established from

recommended schedules in the instruction literature.

recommended schedules in the instruction literature.

recommended schedules in the instruction literature.recommended schedules in the instruction literature.

Avoid leaving test equipment or hand tools on

Avoid leaving test equipment or hand tools on

Avoid leaving test equipment or hand tools onAvoid leaving test equipment or hand tools on

machine. Severe electrical or mechanical damage

machine. Severe electrical or mechanical damage

machine. Severe electrical or mechanical damagemachine. Severe electrical or mechanical damage

could occur to equipment or machine.

could occur to equipment or machine.

could occur to equipment or machine.could occur to equipment or machine.

Extreme caution should b e us ed when probing

Extreme caution should b e us ed when probing

Extreme caution should b e us ed when probingExtreme caution should b e us ed when probing

circuitry with an oscilloscope or voltmeter. Integrated

circuitry with an oscilloscope or voltmeter. Integrated

circuitry with an oscilloscope or voltmeter. Integratedcircuitry with an oscilloscope or voltmeter. Integrated

circuits are susceptible to over voltage damage.

circuits are susceptible to over voltage damage.

circuits are susceptible to over voltage damage.circuits are susceptible to over voltage damage.

Power off before using test probes to prevent

Power off before using test probes to prevent

Power off before using test probes to preventPower off before using test probes to prevent

accidental shorting of components.

accidental shorting of components.

accidental shorting of components.accidental shorting of components.

All circuit boards securely seated in sockets, all cables

All circuit boards securely seated in sockets, all cables

All circuit boards securely seated in sockets, all cablesAll circuit boards securely seated in sockets, all cables

properly connected, all cabinets closed and locked, all

properly connected, all cabinets closed and locked, all

properly connected, all cabinets closed and locked, allproperly connected, all cabinets closed and locked, all

guards and covers replaced before power is turned

guards and covers replaced before power is turned

guards and covers replaced before power is turnedguards and covers replaced before powe r is turned

on.

on.

on.on.

Never plug or unplug a printed circuit board while

Never plug or unplug a printed circuit board while

Never plug or unplug a printed circuit board whileNever plug or unplug a printed circuit board while

machine power is on. Instantaneous surges of voltage

machine power is on. Instantaneous surges of voltage

machine power is on. Instantaneous surges of voltagemachine power is on. Instantaneous surges of voltage

and current can damage electron ic components.

and current can damage electron ic components.

and current can damage electron ic components.and current can damage electronic compon en t s .

1-8

Page 15

SECTION 1 SAFETY

1.8 Safety References

The following nationally recognized publications on safety in welding

and cutting operations are recommended. These publications have

been prepared to protect persons from injury or illness and to protect

property from damage, which could result from unsafe practices.

Although some of these publications are not related specifically to this

type of industrial cutting apparatus, the principles of safety apply

equally.

• “Precautions and Safe Practices in Welding and Cutting with

Oxygen-Fuel Gas Equipment,” Form 2035. ESAB Cutting

Systems.

• “Precautions and Safe Practices for Electric Welding and Cutting,”

Form 52-529. ESAB Cutting Systems.

• “Safety in Welding and Cutting” - ANSI Z 49.1, Am erican Welding

Society, 2501 NW 7th Street, Miami, Florida, 33125.

• “Recommended Safe Practices for Shielded Gases for Welding and

Plasma Arc Cutting” - AWS C5.10-94, American Welding Society.

• “Recommended Practices for Plasma Arc Welding” - AWS C5.1,

American Welding Society.

• “Recommended Practices for Arc Cutting” - AWS C5.2, American

Welding Society.

• “Safe Practices” - AWS SP, American Welding Society.

• “Standard for Fire Protection in Use of Cutting and Welding

Procedures” - NFPA 51B, National Fire Protection Association, 60

Batterymarch Street, Boston, Massachusetts, 02110.

• “Standard for Installation and Operation of Oxygen - Fuel Gas

Systems for Welding and Cutting” - NFPA 51, National Fire

Protection Association.

• “Safety Precautions for Oxygen, Nitrogen, Argon, Helium, Carbon

Dioxide, Hydrogen, and Acetylene,” Form 3499. ESAB Cutting

Systems. Obtainable through your ESAB representative or local

distributor.

• "Design and Installation of Oxygen Piping Systems," Form 5110.

ESAB Cutting Systems.

• “Precautions for Safe Handling of Compressed Gases in

Cylinders”, CGA Standard P-1, Compressed Gas Association.

Literature applicable to safe practices in welding and cutting with

gaseous materials is also available from the Compressed Gas

Association, Inc., 500 Fifth Ave., New York, NY 10036.

1-9

Page 16

SECTION 1 SAFETY

This page intentionally left blank.

1-10

Page 17

SECTION 2 DESCRIPTION

2.1 General

2.2 Scope

The Precision Plasmarc System consists of four

separate components. The power source, the

junction box, the flow control box, and the PT-24

torch. The power source provides power and

coolant to the PT-24 torch via the junction box.

The purpose of this manual is to provide the

operator with all the information required to install

and operate the Precision Plasmarc System.

Technical reference material is also provided to

assist in troubleshooting the cutting package.

2.3 Package Options Available

Precision Plasmarc package options available through your ESAB dealer

Precision Plasmarc Power Source (

Hz (required)

Electronic Flow Control Box (required) P/N 22406

Junction Box (required) P/N 22407

Power Bundle (one required)

Gas Line Bundle (one required)

Control Lead Flow Console to Junction Box

(one required)

Torch Coolant (one gallon (3.8 l) containers. four gallons (15 l) required) P/N 156F05

NOTES:

200/230/380/415/460/575) 3-phase 50/60

4.5 ft. (1.4 m) P/N 0558001463

12 ft. (4.4 m) P/N 0558001877PT-24 Torch Electronic Flow Series A/M (one required)

17 ft. (5.2 m) P/N 0558001464

12 ft. (3.6 m) P/N 22428

25 ft. (7.6 m) P/N 21905

40 ft. (12.2 m) P/N 22504

60 ft. (18 m) P/N 21906

80 ft. (24.4 m) P/N 22505

100 ft. (30 m) P/N 21907

10 ft. (3 m) P/N 37533

20 ft. (6 m) P/N 37534

30 ft. (9 m) P/N 37535

60 ft. (18 m) P/N 37536

100 ft. (30 m) P/N 37537

10 ft. (3 m) P/N 21917

20 ft. (6 m) P/N 21918

30 ft. (9 m) P/N 21919

60 ft. (18 m) P/N 21920

100 ft. (30 m) P/N 21921

P/N 37357

• Control lead from the power source to customer CNC is supplied based on customer order.

• Gas supply, hoses, work lead and input primary cable are all supplied by the customer.

• See Process Data Sheets for a list of torch consumabl e par ts.

2-1

Page 18

SECTION 2 DESCRIPTION

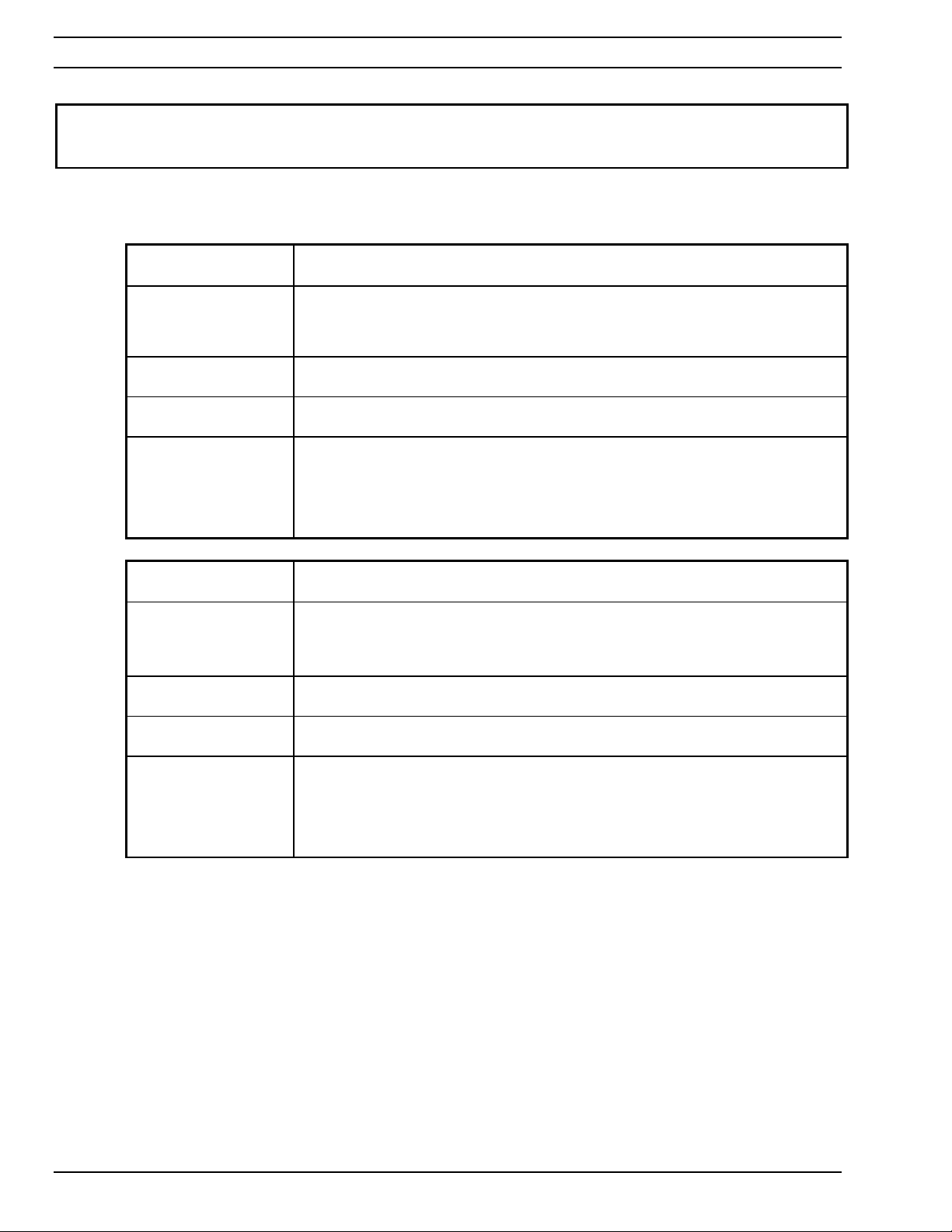

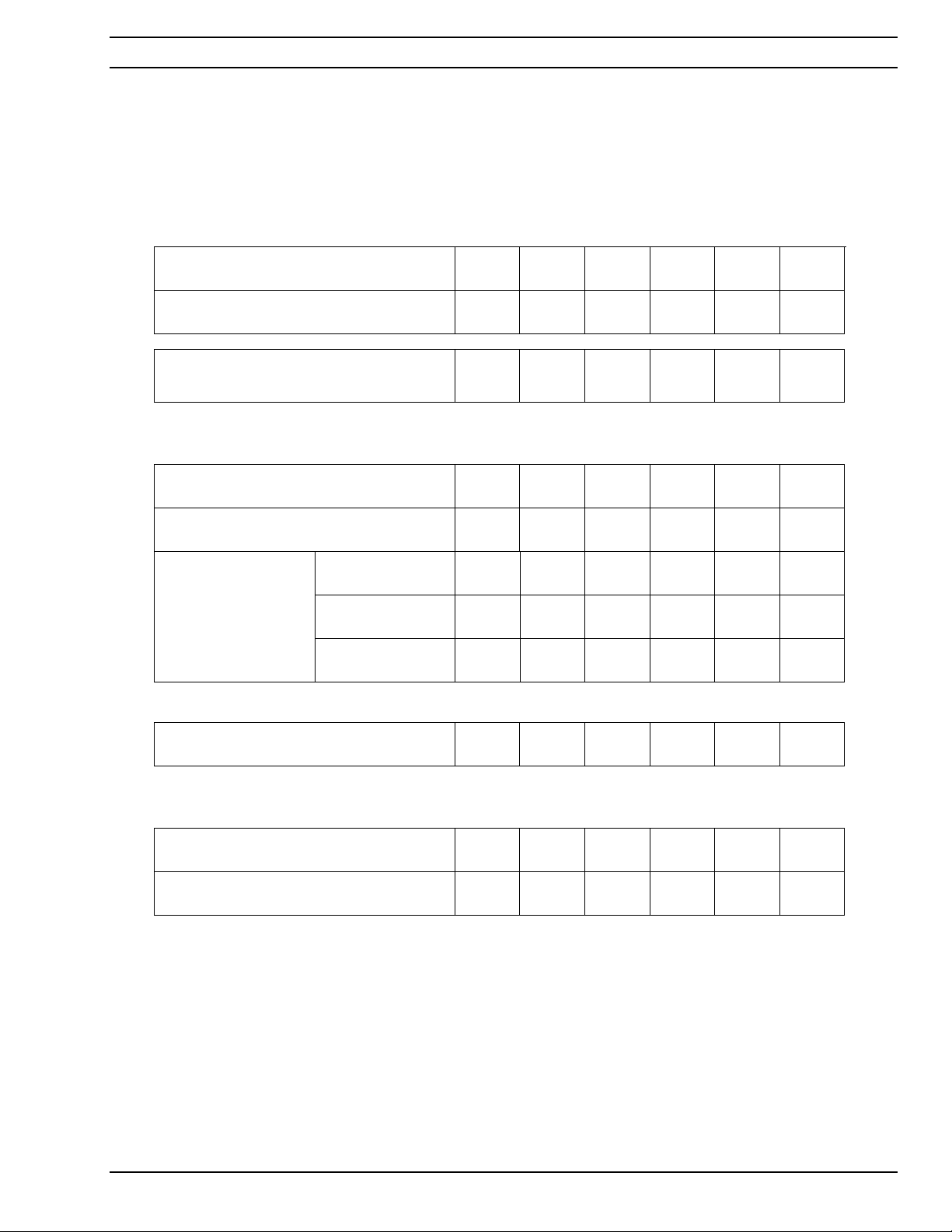

2.4 Precision Plasma Technical Specifications

2.4.1 System

Input Voltage 200/230/380/415/460/575 V 3 phase 50/60 Hz

Input Current 65/60/50/40/30/25 amps per phase

Power Factor 0.95

Output Current Range 15-100 amps dc

Output Load Voltage 120 V dc

Duty Cycle 100%

Open Circuit Voltage 315 V dc

JUNCTION BOX

JUNCTION BOX

JUNCTION BOXJUNCTION BOX

42" (1067mm)

WEIGHT = 560 lbs. (254 kg)

WEIGHT = 560 lbs. (254 kg)

WEIGHT = 560 lbs. (254 kg)WEIGHT = 560 lb s. (254 kg)

POWER SUPPLY

POWER SUPPLY

POWER SUPPLYPOWER SUPPLY

L

O

R

T

N

O

C

T

N

E

R

R

U

C

L

P

N

O

I

S

I

C

E

R

22" (559mm)

6.75" (171mm)

T

O

L

I

P

C

R

A

R

E

W

O

P

19.75" (502mm)

C

R

A

M

S

A

WEIGHT = 26.5 lbs.(12 kg)

WEIGHT = 26.5 lbs.(12 kg)

WEIGHT = 26.5 lbs.(12 kg)WEIGHT = 26.5 lbs.(12 kg)

10.62" (270mm)

44" (1118mm)

ELECTRONIC FLOW CONTROL BOX

ELECTRONIC FLOW CONTROL BOX

ELECTRONIC FLOW CONTROL BOX ELECTRONIC FLOW CONTROL BOX

14.5" (1118mm)

H

T

E

M

5

-

3

H

2

N

2

N

2

O

I

2

R

A

O

2

N

R

I

12.25" (311mm)

A

G

A

M

S

A

L

P

.

2

S

A

O

G

N

A

M

S

A

L

P

N

.

1

E

G

Y

O

X

N

O

N

E

G

O

R

T

I

N

R

I

A

N

O

G

R

A

S

A

G

D

L

E

I

H

S

.

2

S

O

A

N

G

D

L

E

I

H

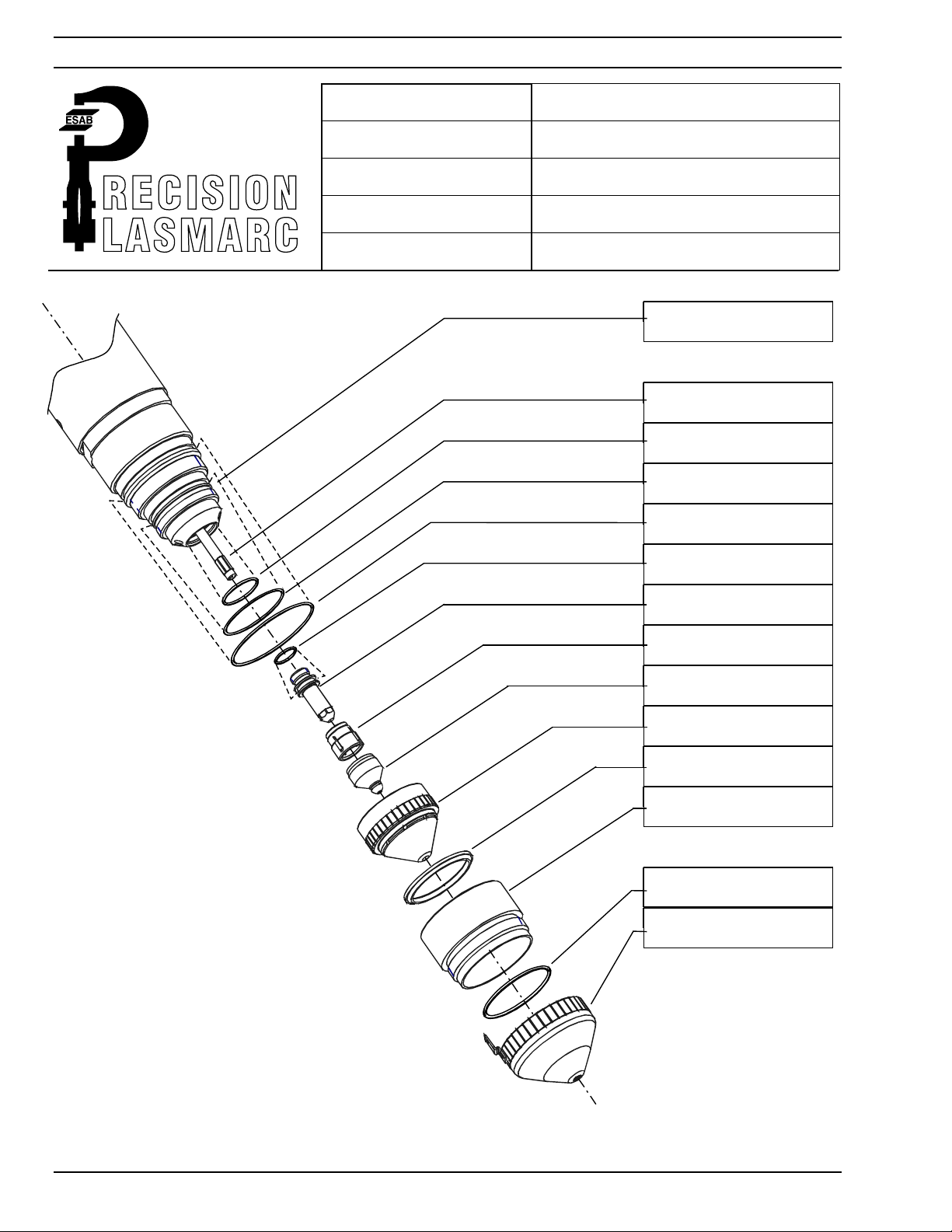

S

.

1

N

E

S

O

G

O

A

N

R

T

I

N

N

E

G

O

R

T

I

N

E

N

A

T

H

E

M

N

E

G

Y

X

O

N

E

G

O

R

D

Y

H

R

I

A

12" (305mm)

2-2

WEIGHT = 51 lbs. (23 kg)

WEIGHT = 51 lbs. (23 kg)

WEIGHT = 51 lbs. (23 kg)WEIGHT = 51 lbs. (23 kg)

Page 19

SECTION 2 DESCRIPTION

2.4.2 Plasma Gas Technical Specifications

Type O2, N2, Air

Pressure 125 psig (8.6 bars)

Flow

Purity Required*

Recommended Liquid Cylinder Service

Regulators

Recommended Cylinder 2-Stage

Regulators

Recommended Heavy –Duty Hi-flow

Station or Pipeline Regulators

Recommended High-capacity Station

or Pipeline Regulators

100 cfh (47 l/min) max. (varies with

application)

-99.995%

O

2

-99.995%

N

2

Air-clean, dry and oil free

Oxygen: R-76-150-540LC (P/N 19777)

Inert gas: R-76-150-580LC (P/N 19977)

Oxygen: R-77-150-540 (P/N 998337

Hydrogen/Methane:R-77-150-350 (P/N

998342)

Nitrogen: R-77-150-580 (P/N 998344)

Industrial Air: R-77150=590 (P/N

998348)

Oxygen: R-76-150-024 (P/N 19151)

R-6703 (P/N 22236)

Gas Filter Required 25 micron w/bowl guard (P/N 56998133)

2.4.3 Start Gas Technical Specifications

Type N2, Air

Pressure 125 psig (8.6 bar)

Flow

Minimum Purity Required 99.995%

2.4.4 Secondary Gas Technical Specifications

Type N2, O2, H-35, Methane, Air

Pressure

Flow

Minimum Purity Required 99.995%

2.4.5 Pt-24 Torch Technical Specifications

60 cfh (28 l/min) max (varies with

application)

100 psig (6.6 bar) H-35,

Methane; 125 psig (8.6 bar) N

O

, Air

2

,

2

60 cfh (28 l/min) max (varies with

application)

Type Water-Cooled, Dual Gas

Rating 100 amps @ 100 % duty cycle

Dimensions See Package Options (2.3)

2-3

Page 20

SECTION 2 DESCRIPTION

Page intentionally left blank.

2-4

Page 21

SECTION 3 INSTALLATION

3.1 General

Proper installation can contribute materially to the

NOTICE

satisfactory and trouble-free operation of the Precision

Plasmarc System. It is suggested that each step in

this section be studied and carefully followed.

3.2 Equipment Required

3.3 Location

• Gas Supply and Hoses. Gas supply may be from

a bulk source or from a bank of manifold cylinders

and regulated to supply 125 psig (8.6 bar) to the

Flow Control (gas flowing).

• Work Lead. No. 4 AWG cable is recommended for

connecting workpiece to power source.

• Primary Input Cable.

• 25 micron gas filters (or better) are required on the

supply side for the EFC to function properly.

• Ventilation is necessary to provide proper cooling

of the power supply.

• Minimize dirt, dust and exposure to external heat

sources.

• Allow a minimum of two feet clearance around the

power supply for free air movement.

CAUTION

!

Do Not Restrict Air Flow

Restricting intake air with any type of filter on or around

Restricting intake air with any type of filter on or around

Restricting intake air with any type of filter on or aroundRestricting intake air with any type of filter on or around

the power supply may void the warranty.

the power supply may void the warranty.

the power supply may void the warranty.the power supply may void the warranty.

3-1

Page 22

SECTION 3 INSTALLATION

3.4 Primary Electrical Input Connections

Electric Shock Can Kill!

DANGER

!

Provide maximum protection against electrical

shock.

Before any connections are made inside the

machine, open the line (wall) disconnect switch

and unplug the power cord.

Input Power Configuration

WARNING

!

Machine must be properly configured for your

input power.

The machine is shipped from the factory

configured for 575 V, 60 Hz input.

Do NOT connect a power source of any other

voltage unless machine is reconfigured. Damage

to the machine will occur.

Input Power Connection At Wall

A line (wall) disconnect switch with fuses or circuit

breakers should be provided at the main power panel.

Connect the input power cable of the power source

directly to the disconnect switch or a proper plug and

receptacle may be purchased from a local electrical

supplier. (S ee table on the next page for

recommended input conductors and fuses )

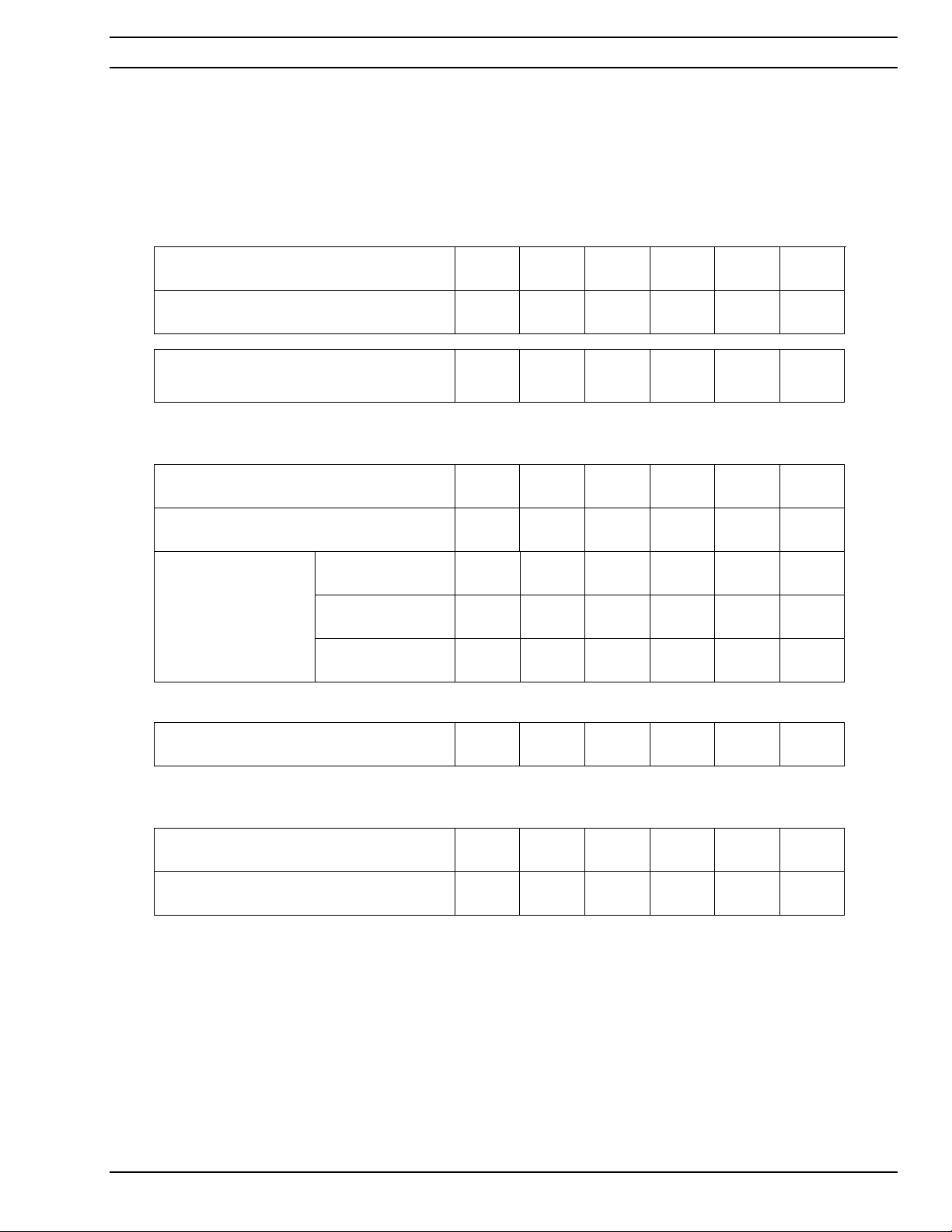

Recommended Sizes For Input Conductors And Line Fuses

Recommended Sizes For Input Conductors And Line Fuses

Recommended Sizes For Input Conductors And Line FusesRecommended Sizes For Input Conductors And Line Fuses

Input requirements

Volts Phase Amps

208 3 70 No. 4 25 100

230 3 60 No. 6 16 80

380 3 50 No. 8 10 80

415 3 40 No. 10 6 60

460 3 30 No. 10 6 50

575 3 25 No. 10 6 40

Input & ground

conductor,

cu/awg/mm

2

Fuse ratings /

phase, amps

3-2

Page 23

SECTION 3 INSTALLATION

The following procedure explains the proper installation

steps for connecting primary electrical power to the

power source.

1. Remove right si de panel.

2. Ensure input power cable is disconnected from all

electrical sources.

3. Route input power cable through the strain relief

located at the rear panel.

Ground Connection

TB2

200

230

380

415

460

575

PHASE 1

200

230

380

415

460

575

TB1

200

230

380

415

460

575

200

230

380

415

460

575

PHASE 2

PHASE 3

K1

Input Power Cable

(Customer supplied)

Main

Contactor

7 Position

Terminal Block

Auto

Transformer

Factory Wired

for 575 volts

4. Pull input power cable through the strain relief to

allow cable wires sufficient length to connect to the

main contactor. Tighten strain relief to ensure

input power cable is secured.

5. Connect input power cable ground wire to the

ground lug provided on the base of the power

source.

6. Connect three power leads of the input power

cable to the terminals located atop the main

contactor. Secure the leads by tightening each

screw.

7. Connect jumper power cables from the bottom of

the main contactor to the proper input voltage

marked on the auto transformer. The unit is

factory set for 575 V as shown to the left.

CAUTION

!

Input Power Jumper Connection

Input Power Jumper Connection

Input Power Jumper ConnectionInput Power Jumper Connection

Ensure each input power jumper cable is connected to

Ensure each input power jumper cable is connected to

Ensure each input power jumper cable is connected toEnsure each input power jumper cable is connected to

the correct input voltage on

the correct input voltage on auto transformer.

the correct input voltage on the correct input voltage on

Factory wired for 575 V.

Factory wired for 575 V.

Factory wired for 575 V.Factory wired for 575 V.

8. Connect jumper wire to the proper input voltage

auto transformer.

auto transformer.auto transformer.

connector located on the 7-position terminal block.

TB2

3-3

Page 24

SECTION 3 INSTALLATION

3.5 Interconnecting Lines

Black

Red/Orange

Yellow

Blue

Mounting Plate

Gas Line Bundle

Gas Bundle

Installation

1. All interconnecting service lines supplied are

numbered or color coded on each end with

corresponding numbers/colors marked on the

cabinets.

2. Connect all four lines in Gas Line Bundle to Flow

Control Box and Junction Box. Lines and

connections are color coded. In addition,

mounting plate hole spacing is asymmetrical to

prevent improper connection. Order of colors

should be: blue, yellow, red/orange, black

3-4

Page 25

SECTION 3 INSTALLATION

x

x

x

x

Power supply and EFC Connections to J-Bo

Power supply and EFC Connections to J-Bo

Power supply and EFC Connections to J-Bo

Power supply and EFC Connections to J-Bo

Power Supply Bundle

Power Supply Negative

Connection

Pilot Arc

Connection

#6 Hose Connection

(to power source)

#7 Hose

Connection

(from power

source)

Gas Bundle

Connections

Control Lead Connection

from EFC

3. Connect power and coolant lines in Power

Supply Bundle from power source to junction

box. Power bundle consists of #6 and # 7

coolant lines (with 5/8-18 L.H. fittings), power

cable (#3 AWG) and yellow pilot arc cable (#16

AWG). Both coolant lines are stamped with a 6

or 7 on the fitting to assist in identification.

3-5

Page 26

SECTION 3 INSTALLATION

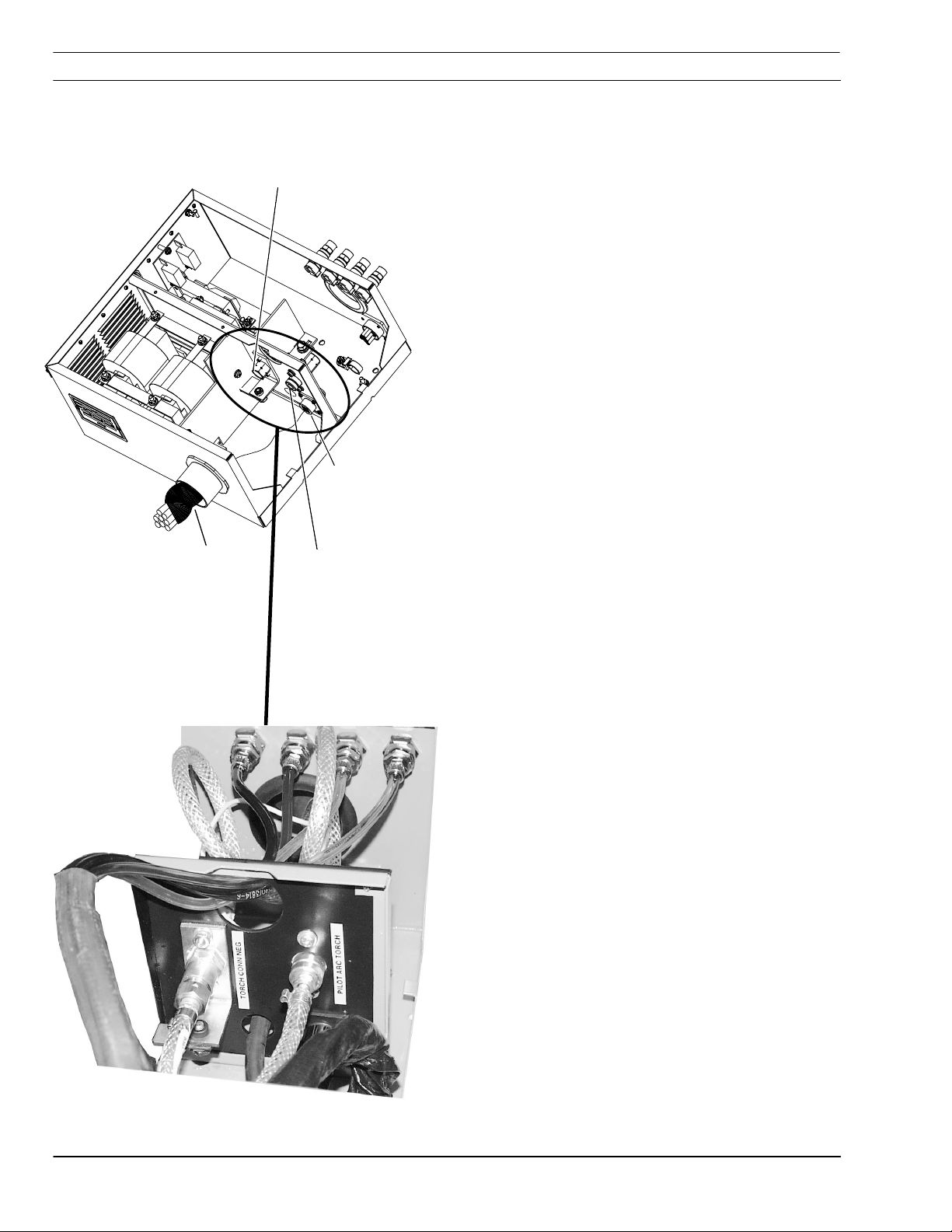

Junction Box to Torch Connections

Junction Box to Torch Connections

Junction Box to Torch ConnectionsJunction Box to Torch Connections

4. Connect Torch Bundle Leads/Hoses to

Junction box. (see Interconnecting Block

Diagram)

Torch Bundle

Torch Hose/Power

Cable Connection

Torch

Solenoid

Electrical

Connection

Torch Pilot Arc

Connection

3-6

Page 27

SECTION 3 INSTALLATION

Precision Plasmarc Component Interconnecting Diagram

25 micron Filters

EFC

Control Lead

EFC/Junction

Box

N

CNC

ASIOB

High

Frequency

120VAC

High Frequency 120VAC

Gas Line Bundle

O

2

2

AirCH

4

Ar

Ground Rod

Torch

Cutting Table

Junction

Power Bundle

Box

Work Lead

Control Lead

Power Supply to CNC

Primary Power Cable

3-7

Page 28

SECTION 3 INSTALLATION

r

r

Gas Line Contamination Will Damage

CAUTION

!

1/4 NPT

Proportional Valves

Purge Gas Lines

Before connecting gas delivery lines to the

Before connecting gas delivery lines to the

Before connecting gas delivery lines to theBefore connecting gas delivery lines to the

Electronic Flow Control, purge all lines thoroughly.

Electronic Flow Control, purge all lines thoroughly.

Electronic Flow Control, purge all lines thoroughly.Electronic Flow Control, purge all lines thoroughly.

Residue from the hose manufacturing process may

Residue from the hose manufacturing process may

Residue from the hose manufacturing process mayResidue from the hose manuf acturing process may

clog/damage the proportional valves in your EFC.

clog/damage the proportional valves in your EFC.

clog/damage the proportional valves in your EFC.clog/damage the proportional valves in your EFC.

5. Purge gas lines between supply and the EFC

before connecting. Proportional valves in the

EFC are very sensitive to dust and other foreign

particles.

25 micron Gas Filte

25 micron Gas Filter

25 micron Gas Filter25 micron Gas Filte

25µ Filters

N

O

2

6. Connect Gas Delivery lines to Electronic Flow

Control. Install 25 micron Gas filters in all

delivery lines between gas source and EFC.

2

AirCH

4

Ar

3-8

Page 29

SECTION 3 INSTALLATION

Power Source

Rating

Label

Pilot Arc

Work

Torch

600 amp

Bus Fuse

Remove Access Cover

Pilot Arc

Work

Torch

CNC Control Lead

Flow Control

Lead

7. Remove panel from rear of console and attach the

pilot-arc, torch and work lead.

Serial

Tag

8. Connect control lead between the console and the

Electronic Flow Control. Connect coolant lines of

the Power Bundle.

Coolant In from Torch

# 6 Connection

Coolant Out to Torch

CONTROL LEAD

3-9

Page 30

SECTION 3 INSTALLATION

3.6 Torch Mounting

CAUTION

1.812" (46mm)

Diameter Collar

" (51mm)

2.0

Diameter Sleeve

Vent Hole

Do Not Cover Vent Hole.

When mounting, do not to cover the small vent hole in

When mounting, do not to cover the small vent hole in

When mounting, do not to cover the small vent hole inWhen mounting, do not to cover the small vent hole in

the side of the sleeve. This hole allows coolant to

the side of the sleeve. This hole allows coolant to

the side of the sleeve. This hole allows coolant tothe side of the sleeve. This hole allows coolant to

drain from inside the sleeve should a leak occur in a

drain from inside the sleeve should a leak occur in a

drain from inside the sleeve should a leak occur in adrain from inside the sleeve should a leak occur in a

service line.

service line.

service line.service line.

Torch Mounting Options.

Torch Mounting Options.

Torch Mounting Options.Torch Mounting Options.

• The torch is normally mounted by the 2.0 inch

diameter (51mm) sleeve. Do not cover vent hole.

• For custom alternative mounting, the torch can be

mounted by the 1.812" (46 mm) dia collar shown.

This insulated collar and its shoulder are machined

relative to the nozzle retainer thread on the torch

body.

• Use only specified mounting surfaces

3-10

Page 31

SECTION 3 INSTALLATION

3.7 Torch Coolant

T

O

L

I

P

C

R

L

O

R

T

N

O

C

T

N

E

R

R

U

C

RECISION PLASMARC

A

R

E

W

O

P

• Remove coolant fill cap at front of console and fill

coolant tank with 4 gallons (15 liters) of plasma

coolant, P/N 156F05 (one gallon).

Coolant

Fill Cap

CAUTION

!

• Do not fill above maximum level

• Reinstall Cap.

Commercial Antifreeze Will Cause Torch To

Malfunction

Use Special Torch Coolant! P/N156F05

Due to high electrical conductivity, DO NOT use tap

Due to high electrical conductivity, DO NOT use tap

Due to high electrical conductivity, DO NOT use tapDue to high electrical conductivity, DO NOT use tap

water or commercial antifreeze for torch cooling. A

water or commercial antifreeze for torch cooling. A

water or commercial antifreeze for torch cooling. Awater or commercial antifreeze for torch cooling. A

specially formulated torch coolant is REQUIRED. This

specially formulated torch coolant is REQUIRED. This

specially formulated torch coolant is REQUIRED. Thisspecially formulated torch coolant is REQUIRED. This

coolant also protects for freezing to –34° C.

coolant also protects for freezing to –34° C.

coolant also protects for freezing to –34° C.coolant also protects for freezing to –34° C.

3.8 Inspection of Gas and Coolant Lines

Operating the unit without coolant will cause

Operating the unit without coolant will cause

Operating the unit without coolant will causeOperating the unit without coolant will cause

permanent damage to the coolan t pu mp.

permanent damage to the coolan t pu mp.

permanent damage to the coolan t pu mp.permanent damage to the coolant pump .

To complete installation, it is necessary to inspect

field assembled connections for leaks.

• Gas lines, use a standard soap solution.

Pressurize the system from the control (SDP file)

• Coolant- check connections for signs of

moisture at connections

3-11

Page 32

SECTION 3 INSTALLATION

3.9 Replacement of EPROM in the Plasmarc Power Source Programmable Logic

Controller (PLC)

The Precision Plasmarc System may be shipped

configured for a manual flow control (Series “A”). If

so, the EPROM in the Programmable Logic

Controller must be replaced with an EFC EPROM.

This EFC EPROM is shipped with the power source.

Using the Wrong EPROM Could Result In

CAUTION

!

CAUTION

!

Damaged System Components

The Series “A” and the EFC EPROMs are

programmed with different software. The EFC

EPROM ignores the process gas pressure

switch inputs and does not include the

process gas purge required for the Series “A”.

Mishandling Can Damage Electronic

Components.

CAUTION

!

WARNING

!

Handle electronic components with care.

• Do not drop

• Do not bend pins

• Do not touch circuit components- handle

along edges when possible

Electronic Components Are Subject To

Electro-Static-Discharge (ESD) Damage

Integrated Circuit parts are sensitive to over

voltages. The damage may not be seen

immediately but show up as a premature

failure.

The EFC EPROM is shipped in an anti-static

bag. Store EPROM in this bag.

Wear a protective ground strap when handling

sensitive electronic components.

Electric shock Can Kill!

Unplug power cable from wall to power source

before any connections or adjustments are

made inside power source.

3-12

Page 33

SECTION 3 INSTALLATION

T

O

I

P

L

C

R

A

R

E

W

O

P

C

R

A

M

S

A

L

P

N

O

I

S

I

1. Ensure the Plasmarc Power Source is

disconnected from electricity source.

2. Expose the PLC by removing the left side panel

of the Plasmarc Power Source.

3. Pop the EPROM cover on the PLC to expose

the EPROM.

PLC

Left Side Panel

L

O

R

T

N

O

C

N

T

E

R

R

U

C

C

E

R

EFC EPROM

Package Location

3-13

Page 34

SECTION 3 INSTALLATION

Using An EPROM Puller Tool May Damage

CAUTION

EPROM Locked In Place

Socket

Forcibly removing a clamped EPROM in the

PLC may cause the socket/EPROM to break.

Special Zero Force EPROM Socket is used to

eliminate the need for special tools.

4. Remove the EPROM from the socket. THIS

DOES NOT REQUIRE A PULLER. Release the

clamp locking the EPROM in place, lift the

Series “A” EPROM from the socket.

5. Remove the EFC EPROM from the packaging.

6. Carefully align the EFC EPROM pins with the

socket holes and insert.

7. Lock the EPROM by moving th e l eve r back

while holding the EPROM in place.

EPROM Lock Released

8. Replace the EPROM cover and the Power

Source left side panel.

EPPESA= Series “A” EPROM, manual flow control

P/N 99513607

EPPSEFC= EFC EPROM, electronic flow con t ro l

P/N 99513608

3-14

Page 35

SECTION 4 OPERATION

ARC

4.1 Power Supply Controls

4.1.1 Main Power Switch

LOW

EMERGENCY

STOP

DO NOT SWITCH

WHILE CUTTING

Main Power Switch

Controls the input power to the fan, water cooler and

the PC Board. Amber indicator light to the left of the

switch.

4.1.2 Pilot Arc Switch

EMERGENCY

STOP

CAUTION

Pilot Arc Switch

Used to select HIGH or LOW Start Pilot Arc depending

on cutting conditions. See Process Data for more

information on which conditions High and Low Start

are used.

POWER

ON

OFF

Adjusting Pilot Arc While in Operation Could

Damage Torch.

Do not adjust pilot arc switch while in operation.

Adjust before torch starts.

4-1

Page 36

SECTION 4 OPERATION

4.1.3 Fault Indicator Lights

Fault Indicator Lights

• Coolant flow will show low coolant flow. When

unit is turned on, the light will briefly show a fault

and then go out.

• Plasma Gas Pressure fault indicator -- low

Plasma Gas Pressure. Torch will not fire when

indicated. Not used for the E FC.

• Start Gas Pressure fault indicator -- low start gas

pressure. Torch will not fire when indicated. Not

used for the EFC.

used for the EFC.

used for the EFC.used for the EFC.

• P/S Temp fault indicator -- over temperature in the

inverter power source. Power source will shut

down.

• P/S Fault Indicator – fault in plasma control PCB

in the inverter power source. Power source will

shut down.

• Over-Under Voltage fault Indicator -- indicate

input voltage is above or below the tolerances of

the PCU console. Will latch until power is recycled

by main power switch.

• Emergency Stop fault indicator -- shows CNC

Interlock condition. Power Source will not work.

Not used for the EFC.

Not used for the EFC.Not used for the EFC.

Not

NotNot

4.1.4 Meters

4.1.5 Current Control Switch

• Cutting Cu rre nt Meter (A) -- Displays actual

cutting current in amperes.

• Cutting Vo ltage Meter (V) -- Displays actual

cutting voltage.

Control Remote/Panel Switch

• Panel Positi on – Output current is set by the

output current dial

• Out p ut Curr ent Dial – sets the cutting current

when current setting is made from the console

front panel. Dial reads 0 to 99.9 amps. 70.0 amps

shown.

• Remote Position – output current is set by the

CNC (or remote pot) with an analog dc signal

4-2

0-10 Vdc = 0-100 Adc

Page 37

SECTION 4 OPERATION

4.2 Cut Quality

4.2.1 Introduction

Causes affecting cut quality are interdependent.

Changing one variable affects all others. Determining a

solution may be difficult. The following guide offers

possible solutions to different undesirable cutting

results. To begin select the most prominent condition:

§ 4.2.2 Cut Angle, negative or positive

§ 4.2. 3 Cut not flat, rounded or undercut

§ 4.2.4 Surface roughness

§ 4.2.5 Dross

Usually the recommended cutting parameters will give

optimal cut quality, occasionally conditions may vary

enough that slight adjustments will be required. If so:

• Make small incremental adjustments when

making corrections.

• Adjust Arc Voltage in 5 volt increments, up or

down as required.

• Adjust cutting speed 5% or less as required

until conditions improve.

NOTICE

4.2.2 Cut Angle

Part

Before attempting ANY corrections, check cutting

variables with the factor y recommended

settings/consumable part numbers listed in

Process Data.

Negative Cut Angle

Top dimension is greater than the bottom.

• Misaligned torch

• Bent or warped material

• Worn or damaged consumables

• Standoff low (arc voltage)

• Cutting speed slow (machine travel rate)

Drop

Part

4-3

Page 38

SECTION 4 OPERATION

Positive Cut Angle

Part

Top dimension is less than the bottom dimension.

• Misaligned torch

• Bent or warped material

• Worn or damaged consumables

• High standoff High (arc voltage)

• Cutting speed fast

• Current high or low. (See Process Data for

PartDrop

recommended current level for specific nozzles).

4.2.3 Cut Flatness

Drop

Top And Bottom Rounded

Condition usually occurs when material is .25” thick

(6,4mm) or less.

• High current for given material thickness (See

Process Data for proper settings).

Part

4-4

Page 39

SECTION 4 OPERATION

Top Edge Undercut

• Standoff low (Arc Voltage)

Drop

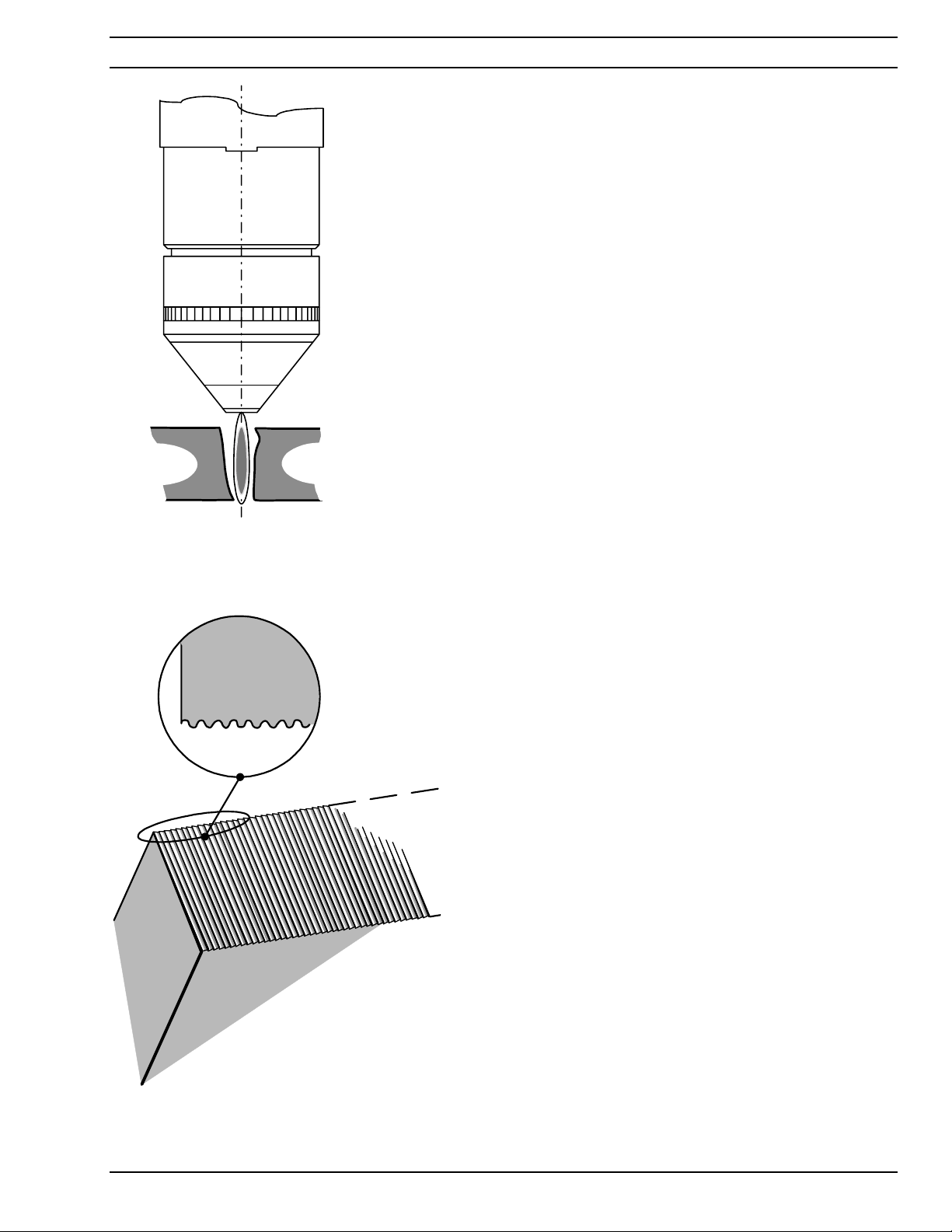

4.2.4 Surface Finish

Top View

Part

Process Induced Roughness

Cut face is consistently rough. May or may not be

confined to one axis.

• Incorrect Shield Gas mixture (See Process Data)

• Worn or damaged consumables

Cut Face

MMMMachine Induced Roughness

Can be difficult to distinguish from Process Induced

Roughness. Often confined to only one axis.

Roughness is inconsistent.

or

Process

Induced

Roughness

Machine

Induced

Roughness

• Dirty rails, wheels and/or drive rack/pinion. (Refer

to Maintenance Section in machine owners

manual).

• Carriage wheel adjustment

4-5

Page 40

SECTION 4 OPERATION

4.2.5 Dross

Dross is a by-product of the cutting process. It is the

undesirable material that remains attached to the part.

In most cases, dross can be reduced or eliminated

with proper torch and cutting parameter setup. Refer

to Process Data.

Cut

Lag

Lines

Face

High Speed Dross

Material weld or rollover on bottom surface along kerf.

Difficult to remove. May require grinding or chipping.

“S” shaped lag lines.

Rollover

• Standoff high (arc voltage)

Side View

Lag

Lines

• Cutting speed fast

Cut Face

Slow Speed Dross

Forms as globules on bottom along kerf. Removes

easily.

Globules

• Cutting speed slow

Side View

4-6

Page 41

SECTION 4 OPERATION

Side View

Splatter

Top Dross

Appears as splatter on top of material. Usually

removes easily.

• Cutting speed fast

• Standoff high (arc voltage).

Cut

Face

Intermittent Dross

Appears on top or bottom along kerf.

Non-continuous. Can appear as any kind of dross

• Possible worn consumables

Other Factors Affecting Dross;

• Material temperature

• Heavy mill scale or rust

• High carbon alloys

4-7

Page 42

SECTION 4 OPERATION

4.2.6 Dimensional Accuracy

Generally using the slowest possible speed (within

approved levels) will optimize part accuracy. Select

consumables to allow a lower arc voltage and slower

cutting speed.

NOTICE

NOTICE

Recommended cutting speed and arc voltage will

give optimal cutting performance in most cases.

Small incremental adjustments may be needed

due to material quality, material temperature and

specific alloy. The operator should remember

that all cutting variables are interdependent.

Changing one setting affects all others and cut

quality could deteriorate. Always start at the

recommended settings.

Before attempting ANY corrections, check

cutting variables with the factory recommended

settings/consumable part numbers listed in the

Process Data.

4-8

Page 43

SECTION 4 OPERATION

4.3 Influence of Gas Options on Cut Quality

4.3.1 Introduction

All gases are not suitable for all situations. Certain

gases assist in cutting specific materials and

thickness. The f ollowing explains w h y certain gases

are selected and their influence on the finished part.

Other influences such as arc voltage and gas

flow/pressure are covered in the Process Data.

NOTICE

4.3.2 Aluminum

Material Thickness:

Material Thickness:

Material Thickness:Material Thickness:

Cut Qualities:

Cut Qualities:

Cut Qualities:Cut Qualities:

Plasma Gas:

Plasma Gas: Nitrogen

Plasma Gas:Plasma Gas:

All thickness’ between .062" to .625" (1,6 mm to 15,9 mm)

• Smooth cut face

• Virtually no dross

Shield Gas:

Shield Gas: Nitrogen/Methane

Shield Gas:Shield Gas:

Discussion:

Discussion:

Discussion:Discussion:

Shield mixture is very important. Between 2 and 3 parts nitrogen, to 1

part methane ratio is desired. Incorrect ratio results in heavy dross.

Refer to Cutting Process Data in this section for

recommended flow/pressure settings.

4-9

Page 44

SECTION 4 OPERATION

Refer to Cutting Process Data in the PT24

NOTICE

4.3.3 Carbon Steel

Material Thickness:

Material Thickness:

Material Thickness:Material Thickness:

26 GA (.018") to 10 GA (.135") (0,5 mm to 3,4 mm)

Manual for recommended flow/pressure

settings.