November, 2002

Installation, Operation and Maintenance Manual for the

PCM-875A Plasmarc Mechanized

Cutting System

F-15-753

Cutting Systems

411 South Ebenezer Road

Florence, South Carolina, U.S.A

.

The equipment described in this manual is

potentially hazardous. Use caution when installing,

operating and maintaining this equipment.

Purchaser is solely responsible for the safe

operation and use of all products purchased,

including compliance with OSHA and other

government standards. ESAB Cutting

Systems has no liability for personal injury or

other damage arising out of the use of any

product manufactured or sold be ESAB. See

standard ESAB terms and conditions of sale

for a specific statement of ESAB’s

responsibilities and limitations on its liabilit y.

ESAB Cutting Systems first priority is total

customer satisfaction. We constantly look for

ways to improve our products, service and

documentation. As a result, we make

enhancements and/or design changes as

required. ESAB makes every possible effort to

ensure our documentation is current. We

cannot guarantee that each piece of

documentation received by our customers

reflects the latest design enhancements.

Therefore, the information contained in this

document is subject to change without notice.

This manual is ESAB Part Number F15753

This manual is for the convenience and use of the

cutting machine purchaser. It is not a contract or

other obligation on the part of ESAB Cutting

Systems.

Printed in U.S.A.

© ESAB Cutting Systems, 2002

PCM-875A System Table of Contents

Section 1 Safety Page 1-(_)

1.1 Introduction ................................................................................................... 1

1.2 Safety Notations And Symbols ....................................................................... 2

1.3 General Safety Information ............................................................................. 3-4

1.4 Installation Precautions................................................................................... 4

1.5 Electrical Grounding ....................................................................................... 5

1.6 Operating A Plasma Cutting Machine ............................................................. 5-8

1.7 Service Precautions........................................................................................ 9-10

1.8 Safety References.......................................................................................... 11-16

1.8.1 National Standards................................................................................. 11

1.8.2 International Standards........................................................................... 12-16

Section 2 Description Page 2-(_)

2.1 General........................................................................................................... 1

2.2 PCM-875A Power Console ............................................................................ 1

2.2.1 Technical Specifications – PCM-875A..................................................... 1

2.2.2 Dimensions and Weight.......................................................................... 2

2.3 Remote Arc Starter (RAS2)............................................................................. 3

2.3.1 Technical Specifications ......................................................................... 3

2.3.2 Dimensions and Weight.......................................................................... 3

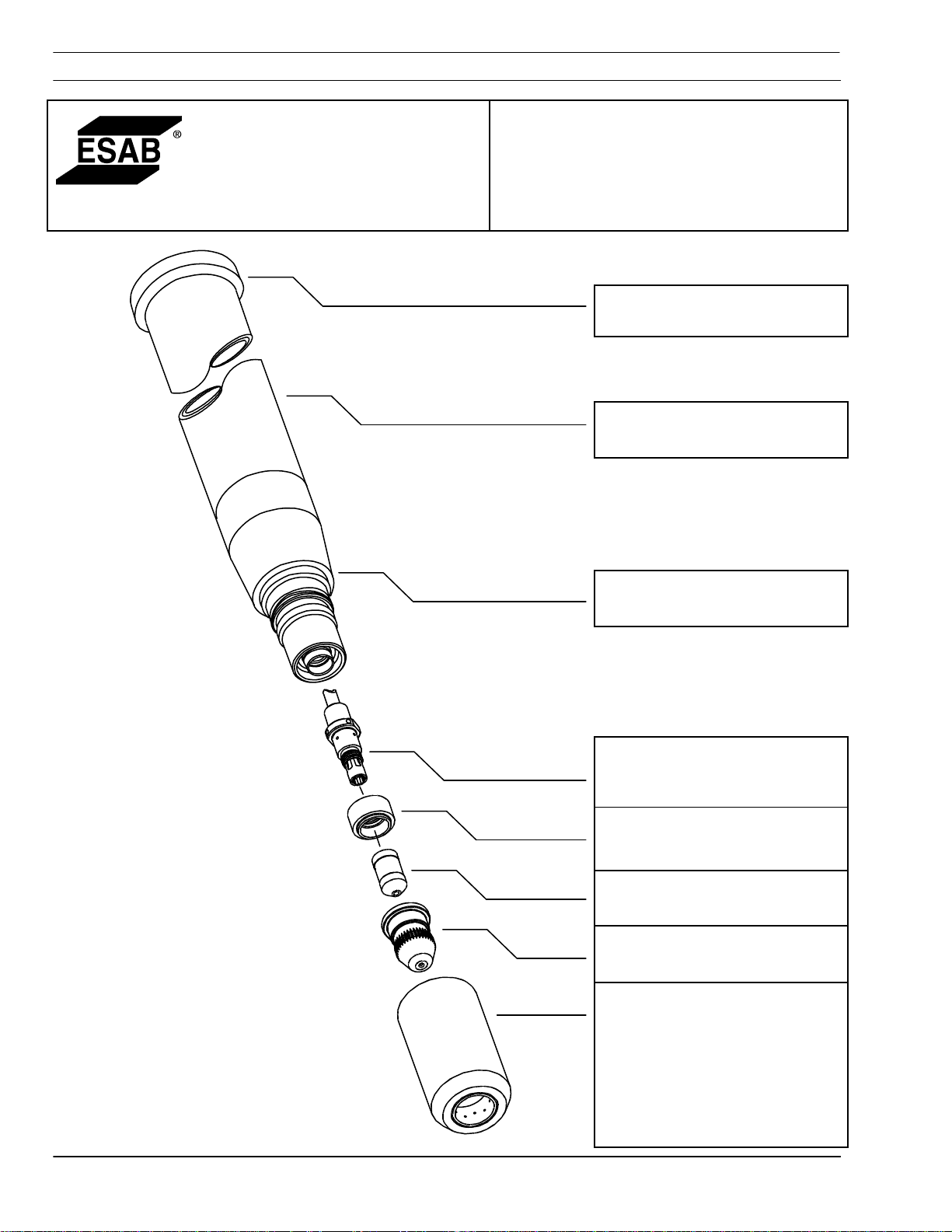

2.4 PT-20AMX Torch ........................................................................................... 4

2.4.1 Technical Specifications ......................................................................... 4

2.4.2 Dimensions and Weight.......................................................................... 5

2.4.3 Torch Spare Parts Kit ............................................................................. 6

i

PCM-875A System Table of Contents

Section 3 Installation Page 3-(_)

3.1 General .......................................................................................................... 1

3.2 Installation of power console........................................................................... 1

3.2.1 Requirements ......................................................................................... 1

3.2.2 Location ................................................................................................. 2

3.2.3 Inspection before installation ................................................................... 2

3.2.4 Primary Electrical Input Connections........................................................ 3

3.2.5 Connection of Plasma Console to CNC Interface..................................... 4

3.2.6 Secondary (Output) Connection .............................................................. 5-8

3.3 Connection of Remote Arc Starter (RAS2)....................................................... 9

3.3.1 Mounting ............................................................................................... 9

3.3.2 Connecting Service Lines (Input).............................................................. 10

3.3.3 Setting Spark Gap .................................................................................. 11

3.3.4 RAS2 Output Connections...................................................................... 12

3.3.5 Termination of Torch Shield Braid............................................................ 13-14

3.4 Installing Front-end torch Parts ........................................................................ 15-17

3.5 Interconnecting Diagram................................................................................. 18-19

Section 4 Operation Page 4-(_)

4.1 PCM-875A Console Operation -- General ....................................................... 1

4.2 Console Controls............................................................................................ 2-3

4.3 RAS2 ............................................................................................................. 3

4.4 PT-20AMX Plasma Torch................................................................................ 4

4.5 Cut Quality ..................................................................................................... 5

4.5.1 Introduction ............................................................................................ 5

4.5.2 Cut Angle ............................................................................................... 6

4.5.3 Cut Flatness ........................................................................................... 7

4.5.4 Surface Finish (Roughness) ..................................................................... 8

4.5.5 Dross ..................................................................................................... 9-10

4.5.6 Dimensional Accuracy............................................................................. 10-11

4.6 Process Data................................................................................................... 11-23

ii

PCM-875A System Table of Contents

Section 5 Maintenance Page 5-(_)

5.1 PCM-875A Console ....................................................................................... 1

5.1.1 General.................................................................................................. 1

5.1.2 Inspection and Cleaning ......................................................................... 2-3

5.1.3 Flow Switch 4

5.2 RAS2 (Remote Arc Starter)............................................................................. 5

5.2.1 General.................................................................................................. 5

5.2.2 Spark Gap Procedure............................................................................. 5

5.3 PT-20AMX Plasmarc Torch ............................................................................ 6

5.3.1 General.................................................................................................. 6

5.3.2 Dirt or Contamination ............................................................................. 7

5.3.3 Loose Consumables............................................................................... 7

5.3.4 Damage Caused by Loose Parts or Overheating ..................................... 8

5.3.5 Consumables- Remove and Replace..................................................... 8-10

5.3.6 Measuring Torch Gas Flows ................................................................... 10

5.3.7 Removal and Replacement of the Torch Body......................................... 11

iii

PCM-875A System Table of Contents

Section 6 Troubleshooting Page 6-(_)

6.1 Troubleshooting PCM-875A Plasmarc System ................................................ 1

6.2 Console ......................................................................................................... 2-8

6.2.1 Power Light (PL1) does not come on....................................................... 2

6.2.2 No Air Flow............................................................................................. 2

6.2.3 Power Light is on but nothing happens when signal is given to fire with

no fault light .........................................................................................

6.2.4 Fault light activates when torch fire signal is given.................................... 4-5

6.2.5 Air is on but nothing happens when torch fire signal is given .................... 6

6.2.6 High Frequency and Pilot Arc are on but no main arc transfer.................. 7

6.2.7 Poor Cutting Performance....................................................................... 7

6.2.8 Air does not shut off................................................................................ 7

6.2.9 Main arc difficult to start.......................................................................... 8

6.3 Reference Voltage Checks.............................................................................. 9

6.4 PT-20AMX Torch Troubleshooting10 .............................................................. 10-11

6.4.1 Insufficient Penetration............................................................................ 10

3

6.4.2 Main Arc Extinguishes............................................................................. 10

6.4.3 Dross Formation ..................................................................................... 10

6.4.4 Double Arcing......................................................................................... 11

6.4.5 Uneven Arc............................................................................................. 11

6.4.6 Unstable Cutting Conditions.................................................................... 11

6.4.7 Main Arc Does Not Strike........................................................................ 11

6.4.8 Poor Consumable Life............................................................................. 11

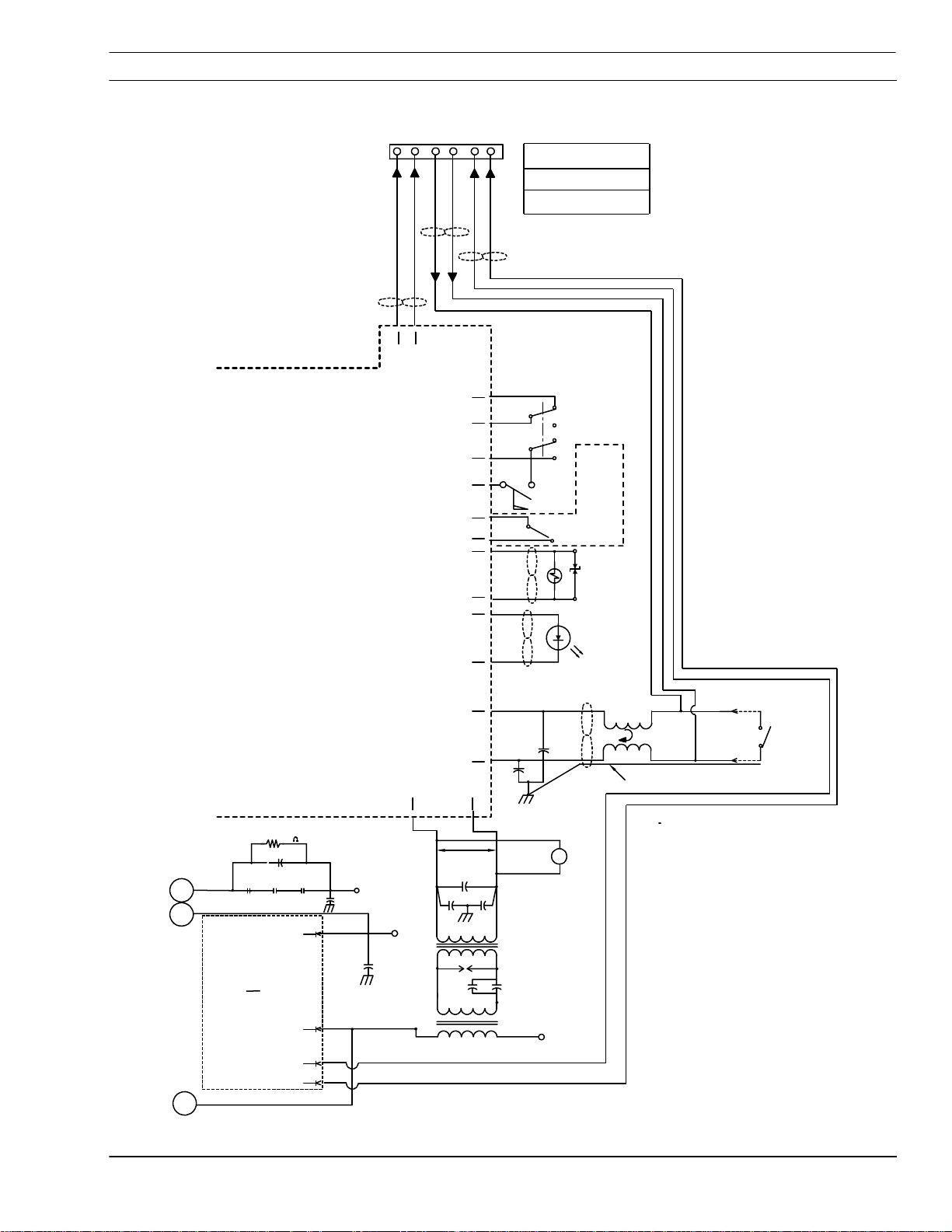

6.5 230V Power Console Electrical Drawings ........................................................ 12-17

6.5.1 Schematic .............................................................................................. 12-13

6.5.2 Wiring Diagrams ..................................................................................... 14-17

6.6 400V Power Console Electrical Drawings ........................................................ 18-23

6.6.1 Schematic .............................................................................................. 18-19

6.6.2 Wiring Diagrams ..................................................................................... 20-23

6.7 Remote Arc Starter Schematic........................................................................ 24

Section 7 Replacement Parts Page 7-(_)

7.1 General .......................................................................................................... 1

7.2 Ordering......................................................................................................... 1

7.3 PCM875A Power Console – 230V .................................................................. 2-9

7.4 PCM-875A Power Console – 400V ................................................................. 10-18

7.5 Remote Arc Starter......................................................................................... 19-21

7.6 PT-20AMX Plasmarc Cutting Torch................................................................. 22-25

Back Manual

Customer/Technical Information

iv

Cover

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

1.1 Introduction

The process of cutting metals with plasma

equipment provides industry with a valuable and

versatile tool. ESAB cutting machines are

designed to provide both operation safety and

efficiency. However, as with any machine tool,

sensible attention to operating procedures,

precautions, and safe practices is necessary to

achieve a full measure of usefulness. Whether an

individual is involved with operation, servicing, or

as an observer, compliance with established

precautions and safe practices must be

accomplished. Failure to observe certain

precautions could result in serious personnel injury

or severe equipment damage. The following

precautions are general guidelines applicable when

working with cutting machines. More explicit

precautions pertaining to the basic machine and

accessories are found in the instruction literature.

For a wide scope of safety information on the field

of cutting and welding apparatus, obtain and read

the publications listed in the Recommended

References.

1-1

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

1.2 Safety Notations And Symbols

!

DANGER

!

The following words and symbols are used

throughout this manual. They indicate different

levels of required safety involvement.

ALERT or ATTENTION. Your safety is

involved or potential equipment failure exists.

Used with other symbols and information.

Used to call attention to immediate hazards

which, if not avoided, will result in serious

personal injury o r lo ss o f life.

WARNING

!

CAUTION

!

CAUTION

NOTICE

Used to call attention to potential hazards that

could result in personal injury or loss of life.

Used to call attention to hazards that could

result in minor personal injury or equipment

damage.

Used to call attention to minor hazards to

equipment.

Used to call attention to important

installation, operation or maintenance

information not directly related to safety

hazards.

1-2

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

1.3 General Safety Information

NOTICE

Some subjects listed are not related specifically to

the type of equipment covered in this manual.

However, the safety principles still apply. They are

offered as a reminder that this equipment or

related apparatus should be operated with

alertness and understanding. Safety of operators,

technicians, maintenance workers and observers

should not be taken for granted.

Machinery may start automatically.

WARNING

!

WARNING

!

Equipment positioning mechanized plasma torch

moves in various directions and speeds.

· Moving machinery can crush.

· Only qualified personnel should operate or

service this power source.

· Keep all personnel, materials, and equipment

not involved in production process clear of

entire system area.

· Fence off entire work cell to prevent personnel

from passing through area or standing in the

working envelope of the equipment.

· Post appropriate WARNING signs at every

work cell entrance.

· Follow lockout procedure before servicing any

equipment.

Failure to follow operating instructions

could result in death or serious injury.

Read and understand this operator’s manual

before using machine.

· Read entire procedure before operating or

performing any system maintenance.

· Special attention must be given to all hazard

warnings that provide essential information

regarding personnel safety and/or possible

equipment damage.

· All safety precautions relevant to electrical

equipment and process operations must be

strictly observed by all having system

responsibility or access.

· Read all safety publications made available by

your company.

1-3

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

Failure to follow safety warning label

WARNING

!

1.4 Installation Precautions

instructions could result in death or

serious injury.

Read and understand all safety warning labels on

machine.

Refer to operator’s manual for additional safety

information.

WARNING

!

Improperly Installed Equipment Can

Cause Injury Or Death.

Follow these guidelines while installing machine:

· Contact your ESAB representative before

installation. He can suggest certain

precautions regarding piping installation and

machine lifting, etc. to ensure maximum

security.

· Never attempt any machine modifications or

apparatus additions without first consulting a

qualified ESAB representative.

· Observe machine clearance requirements for

proper operation and personnel safety.

· Always have qualified personnel perform

installation, troubleshooting and maintenance

of this equipment.

· Provide a wall mounted disconnect switch with

proper fuse sizes close to the power supply.

1-4

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

1.5 Electrical Grounding

Electrical grounding is imperative for proper

machine operation and SAFETY. Refer to this

manual’s Installation section for detailed grounding

instructions.

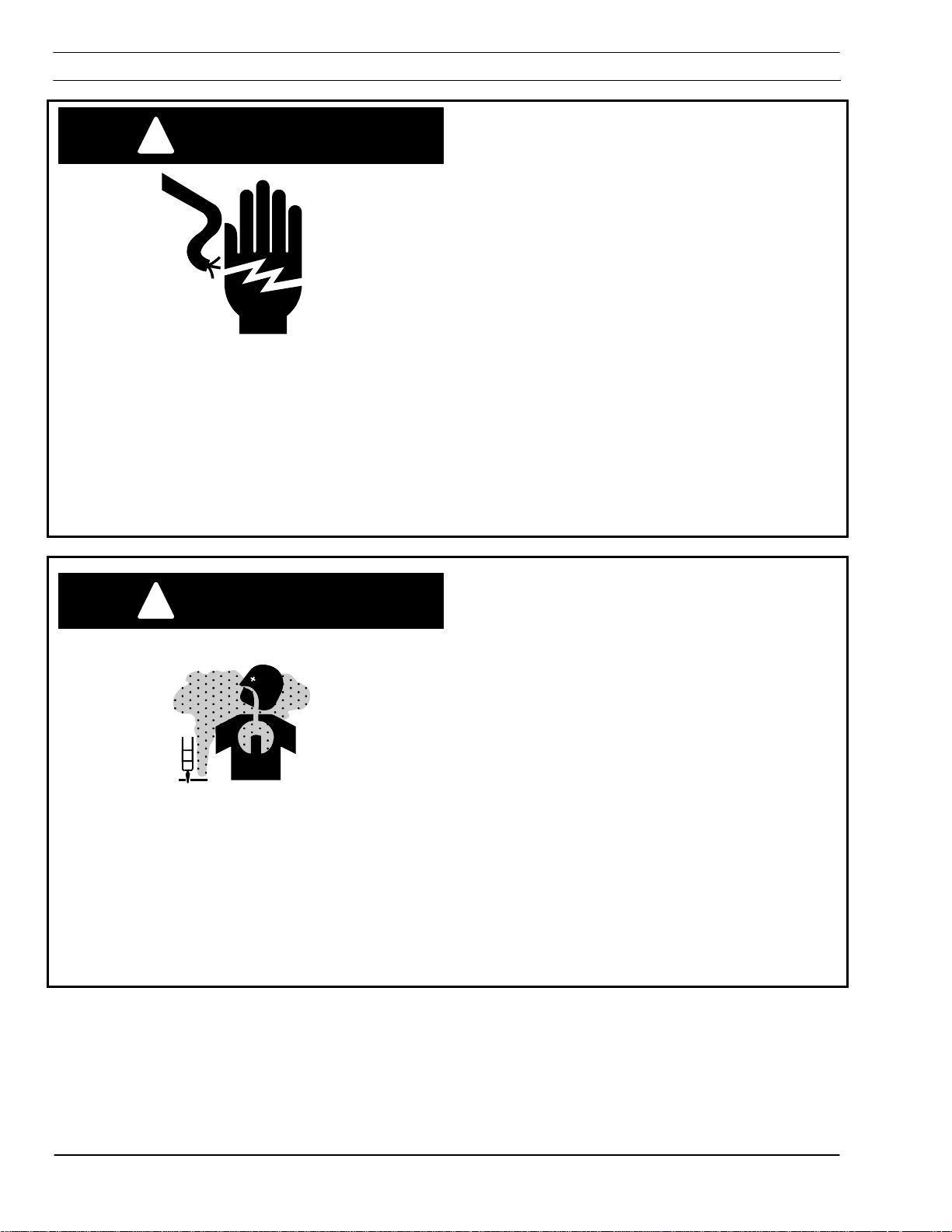

Electric shock hazard.

WARNING

!

1.6 Operating A Plasma Cutting Machine

Improper grounding can cause severe injury or

death.

Machine must be properly grounded before put

into service.

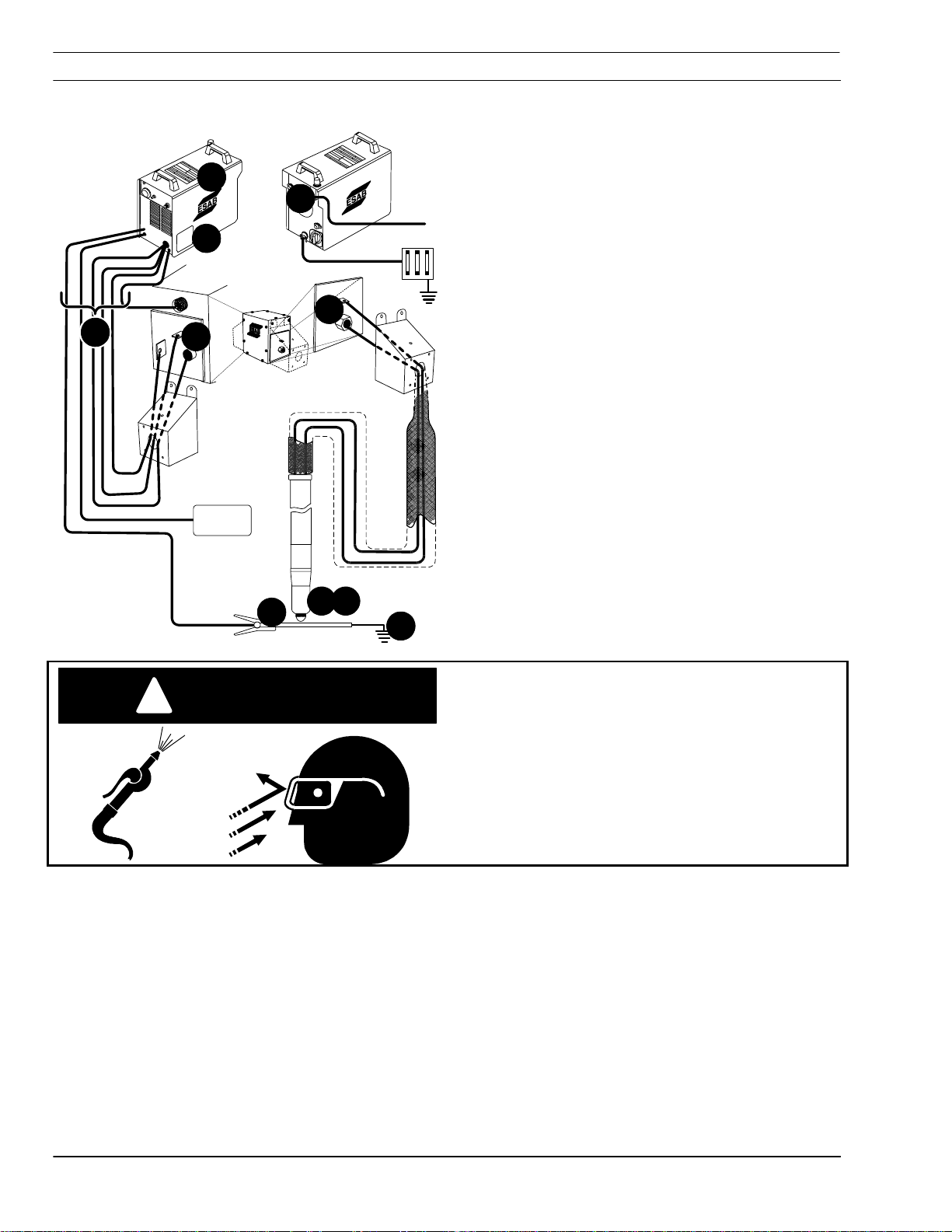

Flying debris and loud noise

WARNING

!

hazards.

· Hot spatter can burn and injure eyes. Wear

goggles to protect eyes from burns and flying

debris generated during operation.

· Chipped slag may be hot and fly far.

Bystanders should also wear goggles and

safety glasses.

· Noise from plasma arc can damage hearing.

Wear correct ear protection when cutting

above water.

Burn hazard.

WARNING

!

Hot metal can burn.

· Do not touch metal plate or parts immediately

after cutting. Allow metal time to cool, or douse

with water.

· Do not touch plasma torch immediately after

cutting. Allow torch time to cool.

1-5

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

Hazardous voltages. Electric shock

WARNING

!

can kill.

· Do NOT touch plasma torch, cutting table or

cable connections during plasma cutting process.

· Always turn power off to plasma power

supplies before touching or servicing plasma torch.

· Always turn power off to plasma power

supplies before servicing any system component.

· Do not touch live electrical parts.

· Keep all panels and covers in place when

machine is connected to power source.

· Wear insulating gloves, shoes and clothing to

insulate yourself from workpiece and electrical

ground.

· Keep gloves, shoes, clothing, work area, and

equipment dry.

· Replace worn or damaged cables.

Fume hazard.

WARNING

!

Fumes and gases generated by the plasma cutting

process can be hazardous to your health.

· Do NOT breathe fumes.

· Do not operate plasma torch without fume

removal system operating properly.

· Use additional ventilation to remove fumes if

necessary.

· Use approved respirator if ventilation is not

adequate.

· Provide positive mechanical ventilation when

cutting galvanized steel, stainless steel, copper,

zinc, beryllium, or cadmium. Do not breathe these

fumes.

·

operations. Heat or arc rays can react with

chlorinated hydrocarbon vapors to form phosgene,

a highly toxic gas and other irritant gases.

Do not operate near degreasing and spraying

1-6

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

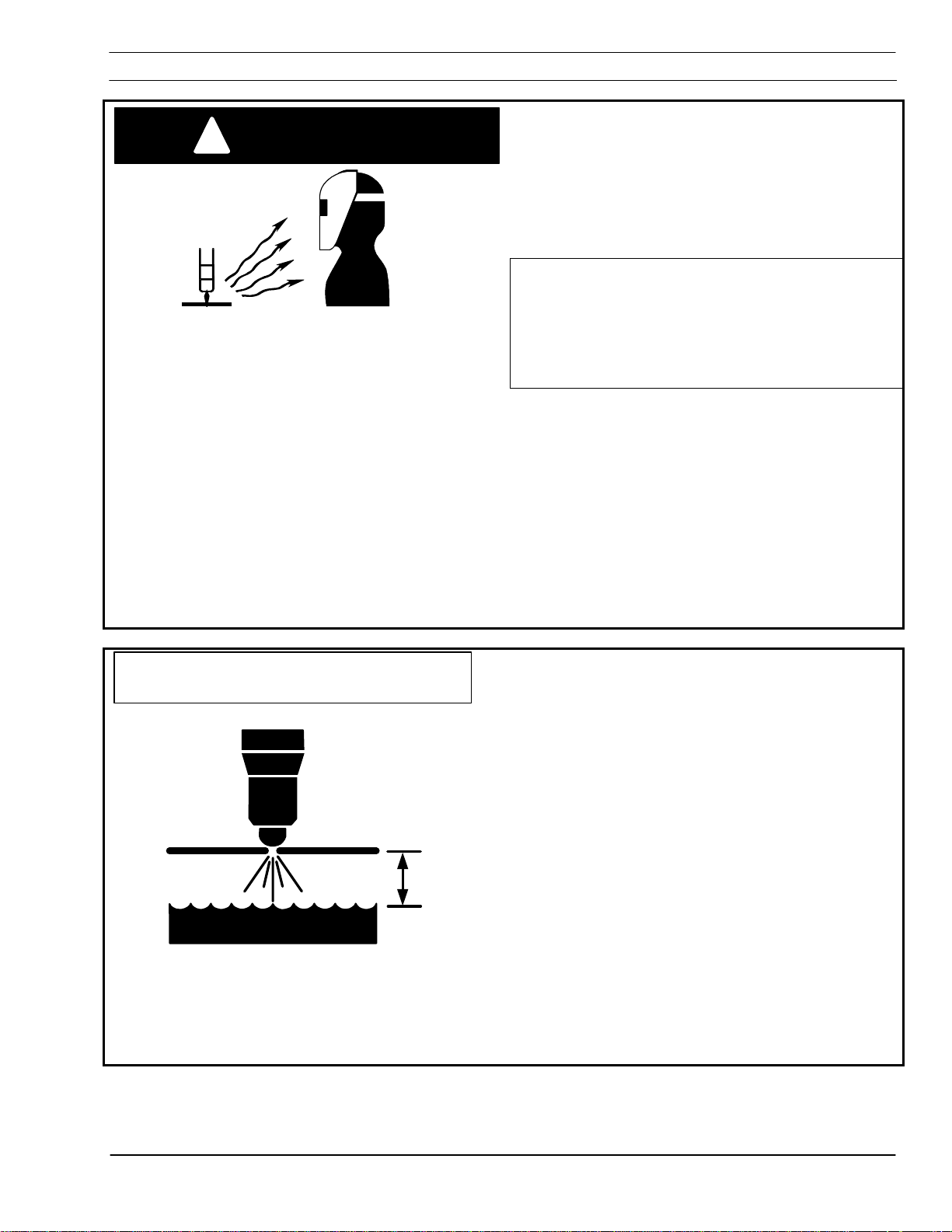

Radiation hazard.

WARNING

!

Arc rays can injure eyes and burn skin.

· Wear correct eye and body protection.

· Wear dark safety glasses or goggles with side

shields. Refer to following chart for recommended

lens shades for plasma cutting:

Arc Current Lens Shade

Up to 100 Amps Shade No. 8

100-200 Amps Shade No. 10

200-400 Amps Shade No. 12

Over 400 Amps Shade No. 14

· Replace glasses/goggles when lenses are

pitted or broken

· Warn others in area not to look directly at the

arc unless wearing appropriate safety glasses.

· Prepare cutting area to reduce reflection and

transmission of ultraviolet light.

§ Use special paint on walls to absorb UV

light.

§ Install protective screens or curtains to

reduce ultraviolet transmission.

CAUTION

Do Not Use this Torch Under Water.

The PT-20AMX is designed to be a dry

cutting process.

Cutting under water may result in:

· reduced consumable life

· degradation of cut quality

· possible damaged torch

Cutting under water may result in poor cutting

performance. Water vapor created when hot material

or sparks contact liquid may cause arcing inside torch.

When cutting on a water table, reduce the water level

to provide maximum clearance between water and

material.

1-7

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

Burn Hazard.

WARNING

!

Heat, spatter, and sparks cause fire and burns.

· Do not cut near combustible material.

· Do not have on your person any combustibles

(e.g. butane lighter).

· Pilot arc can cause burns. Keep torch nozzle

away from yourself and others when activating

plasma process.

· Wear correct eye and body protection.

· Wear gauntlet gloves, safety shoes and hat.

· Wear flame-retardant clothing covering all

exposed areas.

· Wear cuffless trousers to prevent entry of

sparks and slag.

· Have fire extinguishing equipment available for

use.

Explosion hazard.

WARNING

!

· Certain molten aluminum-lithium (Al-Li) alloys

can cause explosions when plasma cut OVER

water.

§ These alloys should only be dry cut on a

dry table.

§ DO NOT dry cut over water.

§ Contact your aluminum supplier for

additional safety information regarding

hazards associated with these alloys

Do not cut in atmospheres containing

·

explosive dust or vapors.

·

Do not carry any combustibles on your person

(e.g. butane lighter)

· Do not cut containers that have held

combustibles.

.

1-8

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

1.7 Service Precautions

Hazardous voltages. Electric shock

WARNING

!

can kill.

· Do NOT touch plasma torch, cutting table or

cable connections during plasma cutting process.

· Always turn power off to plasma power

supplies before touching or servicing plasma torch.

· Always turn power off to plasma power

supplies before removing covers or panels to

service any system component.

· Do not touch live electrical parts.

· Keep all panels and covers in place when

machine is connected to power source.

· Keep gloves, shoes, clothing, work area, and

equipment dry.

· Inspect power and ground leads cables for

wear or cracking. Replace worn or damaged

cables. Do not use if damaged.

WARNING

!

· Never bypass safety interlocks.

· Follow lock-out procedures.

Hot Torch can cause skin burns.

Allow torch to cool before servicing.

1-9

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

Danger of Electric Shock.

DANGER

!

CAUTION

CAUTION

!

Torch may be electrically active.

Turn off Plasma Power Console before

servicing torch.

Establish and adhere to preventive maintenance.

A composite program can be established from

recommended schedules.

Avoid leaving test equipment or hand tools on

machine. Severe electrical or mechanical damage

could occur to equipment or machine.

Extreme caution should be used when probing

circuitry with an oscilloscope or voltmeter.

Integrated circuits are susceptible to over voltage

damage. Power off before using test probes to

prevent accidental shorting of components.

All circuit boards securely seated in sockets, all

cables properly connected, all cabinets closed and

locked, all guards and covers replaced before

power is turned on.

1-10

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

1.8 Safety References -- Regulations, Standards, Guidelines

1.8.1 USA

The following recognized publications on safety in welding and cutting

operations are recommended. These publications have been prepared

to protect persons from injury or illness and to protect property from

damage, which could result from unsafe practices. Although some of

these publications are not related specifically to this type of industrial

cutting apparatus, the principles of safety apply equally.

· “Precautions and Safe Practices in Welding and Cutting with

Oxygen-Fuel Gas Equipment,” Form 2035. ESAB Cutting

Systems.

· “Precautions and Safe Practices for Electric Welding and Cutting,”

Form 52-529. ESAB Cutting Systems.

· “Safety in Welding and Cutting” - ANSI Z 49.1, American Welding

Society, 2501 NW 7th Street, Miami, Florida, 33125.

· “Recommended Safe Practices for Shielded Gases for Welding and

Plasma Arc Cutting” - AWS C5.10-94, American Welding Society.

· “Recommended Practices for Plasma Arc Welding” - AWS C5.1,

American Welding Society.

· “Recommended Practices for Arc Cutting” - AWS C5.2, American

Welding Society.

· “Safe Practices” - AWS SP, American Welding Society.

· “Standard for Fire Protection in Use of Cutting and Welding

Procedures” - NFPA 51B, National Fire Protection Association, 60

Batterymarch Street, Boston, Massachusetts, 02110.

· “Standard for Installation and Operation of Oxygen - Fuel Gas

Systems for Welding and Cutting” - NFPA 51, National Fire

Protection Association.

· “Safety Precautions for Oxygen, Nitrogen, Argon, Helium, Carbon

Dioxide, Hydrogen, and Acetylene,” Form 3499. ESAB Cutting

Systems. Obtainable through your ESAB representative or local

distributor.

· "Design and Installation of Oxygen Piping Systems," Form 5110.

ESAB Cutting Systems.

· “Precautions for Safe Handling of Compressed Gases in

Cylinders”, CGA Standard P-1, Compressed Gas Association.

Literature applicable to safe practices in welding and cutting with

gaseous materials is also available from the Compressed Gas

Association, Inc., 500 Fifth Ave., New York, NY 10036.

1-11

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

1.8.2 International

Accident Prevention

VBG- Unfallverhütungsvorshriften

General Provisions

VBG 1

Allgemeine Unfallverhütungsvorshriften

Electrical Equipment and operating Equipment

VBG 4

Elektrische Anlagen

Welding, Cutting and related working methods

VBG 15

Schweißen un Schneiden un verwandte Verfahren

Shot Blasting Works

VBG 48

Strahlarbeiten

Gases

VBG 61

Gase

Oxygen

VBG 62

Sauerstoff

Operating liquid jet cutting machines

VBG 87

Arbeiten mit Flüssigkeitsstrahlem

VBG 93

Laser beams, accident prevention and Electrotechnology

Laserstrahlung, Unfallverhütungs-vorschriften für

Feinmechnik und Elektrotechnik

Noise

VBG 121

Lärm

1-12

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

VDE Regulations

VDE - Vorschriften

VDE 0100

Erection of power installations with normal voltages up to

1000 volts

Bestimmungen für das Errichten von Stakstromanlagen

mit Nennspannungen bis 1000 Volt

Electrical equipment of industrial machines

VDE0113

VDE 0837

VDE 0837-

50

Elektrishe Ausrüstung von Industriemaschinen

Radiation safety of laser products; users guide (DIN EN

60825)

Strahlungssicherheit von Lasereinrichtungen und

Benutzungsrichtlinen (DIN EN 60825)

Specification for laser guards

Anforderung an Lasershcutzwänden

TRAC Technical Rules for Acetylene and Carbide Stores

TRAC- Techische Regein für Azetylenanlagen und Calciumcargidlager

Acetylene lines

TRAC-204

Azetylenleitungen

Acetylene cylinder battery systems

TRAC-206

Azetylenflaschenbatterieanlagen

Safety devices

TRAC-207

Sicherheitseinrichtungen

TRG Technical Rules for Pressure gases

TRG – Technische Regein für Druckgase

TRG 100

TRG 101

TRG 102

TRG 104

General regulations for pressure gases

Allgemeine Bestimmungen für Druckgase

Pressure gases

Druckgase

Technical gas mixtures

Technishe Gasgemische

Pressure gases; alterative use of compressed gas tanks

Druckgase, wahlweise Verwendung von

Druckgasbehältem

1-13

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

TRGS – Technische Richtlinien für Gefahrstoffe

TRGS-102 Techn. Richtkonzentration (TRK) für gefährliche Stoffe

DIN Standards

DIN-Normen

TRGS-402

TRGS-900 Grenzwerte in der Luft am Arbeitsplatz (Luftgrenzwerte)

TA TA-Luft un TA-Lärm (BLm SchV)

DIN 2310

Part 1

Teil 1

DIN 2310

Part 2

Teil 2

DIN 2310

Part 4

Teil 4

DIN 2310

Part 5

Teil 5

DIN 2310

Part 6

Ermittlung u. Beurteilung der Konzentration gefährlicher

Stoffe in der Luft im Arbeitsbereich

Thermal cutting; terminology and nomenclature

Thermsiches Schneiden, Allgemeine Begriffe und

Bennungen

Thermal cutting; determination of quality of cut faces

Thermsiches Schneiden, Ermittein der Güte von

Schnittflächen

Thermal cutting; arc plasma cutting; process principles,

quality, dimensional tolerances

Thermsiches Schneiden, Plasmaschneiden,

Verfahrensgrundlagen, Güte, Maßtoleranzen

Thermal cutting; laser beam cutting of metallic materials;

process principles

Laserstrahlschneiden von metallischen Werkstoffen,

Verfahrensgrundlagen, Güte, Maßtoleranzen

Thermal cutting; Classification, processes

1-14

Teil 6 Einführung, Verfahren

DIN 4844

Part 1

Teil 1 Sicherheitskennzeichen (Siehe EN 7287)

Safety markings (DIN EN 7287)

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

DIN EN ISO Harmonized Standards

DIN EN ISO-Harmonisierte Normen

DIN EN

292/1 and 2

DIN EN 559

DIN EN 560

DIN EN 561

DIN EN

626-1

DIN EN

848-1

Safety of machinery

Sicherheit von Maschinen, Geräten und Anlagen

Hoses for welding, cutting and allied processes

Schläuche für Schweißen, Schneiden und verwandte

Verfahren

Hose connections and hose couplings for equipment for

welding, cutting and allied processes

Schlauchanschlüsse und Schlauchverbindungen für

Geräte zum Schweißen, Schneiden und verwandte

Verfahren

Gas welding equipment hose couplings

Gasschweißgeräte, Kupplungen

Safety of machines, reduction of risks to health

Sichereit von Maschinen, Reduzierung des

Gesundheitsrisikos

Single spindle vertical milling machines

Fräsmaschine für einseitige Bearbeitung mit drehendem

Werkzeug

DIN EN

1829

DIN EN

9013

DIN EN

12584

DIN EN

12626

DIN EN

28206

DIN EN

31252

High pressure water jet machines

Hochdruckwasserstrahlschneidmaschine

Thermal cutting, oxygen cutting, process principles,

dimensional tolerances

Thermisches Schneiden, Autogenes Brennschneiden,

Verfahrensgrundlagen, Güte, Maßtoleranzen

Imperfections in oxy/fuel flame cuts, laser beam cuts and

plasma

Unregeimäßigkeiten an Brennschnitten, Laserstrahl- und

Plasmaschnitten

Laser processing machines

Laserbearbeitungsmaschinen

Acceptance testing for oxygen cutting machines

Abnahmeprüfung für Brennschneidmaschinen

Laser Equipment

Lasergeräte

1-15

SECTION 1 PCM-875A Mechanized Plasma Cutting System SAFETY

VDI Guidelines

DIN EN

31553

DIN EN

60204-1

DIN EN

60825

DIN EN 999

VDI 2906

VDI 2084

Laser and laser related equipment

Laser und Laseranlagen

Electrical equipment of machines

Elekrische Ausrüstung von Maschinen

Radiation safety of laser products

Strahlensicherheit von Laseranlagen

Arrangement of protection devices

Anordnung von Schutzeinrichtungen

Quality of cut faces on metallic workpieces; abrasive

water jet cutting and arc plasma cutting

Schnittflächenqualität beim Schneiden von Werkstücken

aus Metall, Abrasiv- Wasserstrahischneiden und

Plasmastrahischneiden

Room air; Technical systems for welding workshops

Raumluft techn. Anlagen für Schweißwerkstätten

1-16

SECTION 2 PCM-875A Mechanized Plasma Cutting System Description

2.1 General

The PCM-875A Mechanized Plasma Cutting

2.2 PCM-875A Power Console

2.2.1 Technical Specifications: PCM-875A

230V 50Hz, 3 Phase

Options

1 phase 3 phase

System is a compact 60 ampere package

consisting of plasma power console, remote arc

starter, and PT-20AMX plasma torch. Simple

bulkhead connections allow easy system assembly.

Connect to input power and a source of clean, dry,

compressed air (5,18 to 5,87 bar) and you can

begin cutting up to 13 mm thick material.

There are 2 power console options available:

230 V 50 Hz, 1 or 3 phase P/N 0558003356

400 V 50 Hz, 3 phase P/N 0558003357

400V 50Hz, 3 phase

P/N 0558003356

P/N 0558003357

60% Duty Cycle 60 A at 120 VDC

Rated Output

100 % Duty Cycle 50 A at 120 VDC

Output Current Range 10 to 60 A/phase

Open Circuit Voltage 275 VDC

Rated Primary Input at 7,2 kW Maximum

Output Power, 60 A at 120 VDC

Power Factor at 60 Amperes Output

55/49 A

(230V, 1

phase)

74% (230 V,

1 phase)

26/24 A per

phase

(230V, 3

phase)

90% (230 V, 3

phase)

13 A/phase

92% (400 V, 3 phase)

Efficiency at 60 Amperes Output 90% typical

Current Capacity 60 A DCSP

Air Requirements 153,4 l/minute at 5,2 bars

Power Cord Length Provided 1,8m 3,1m

2-1

SECTION 2 PCM-875A Mechanized Plasma Cutting System Description

2.2.2 Dimensions and Weight: PCM-875A Power Console

465 mm

Weight = 39,5 kg

516 mm

275 mm

2-2

SECTION 2 PCM-875A Mechanized Plasma Cutting System Description

2.3 Remote Arc Starter (RAS-2)

The remote arc starter (RAS-2) is placed inline

between power console and torch. The RAS is the

source of high frequency energy used to start the

plasma cutting process.

RAS-2 with 15,2 m leads

RAS-2 with 30,4 m leads

Technical Specifications

P/N 0558003601

P/N 0558003602

Input: 110 VAC, 50/60 Hz. Control power provided by

PCM-875A console.

Spark Gap: 1mm

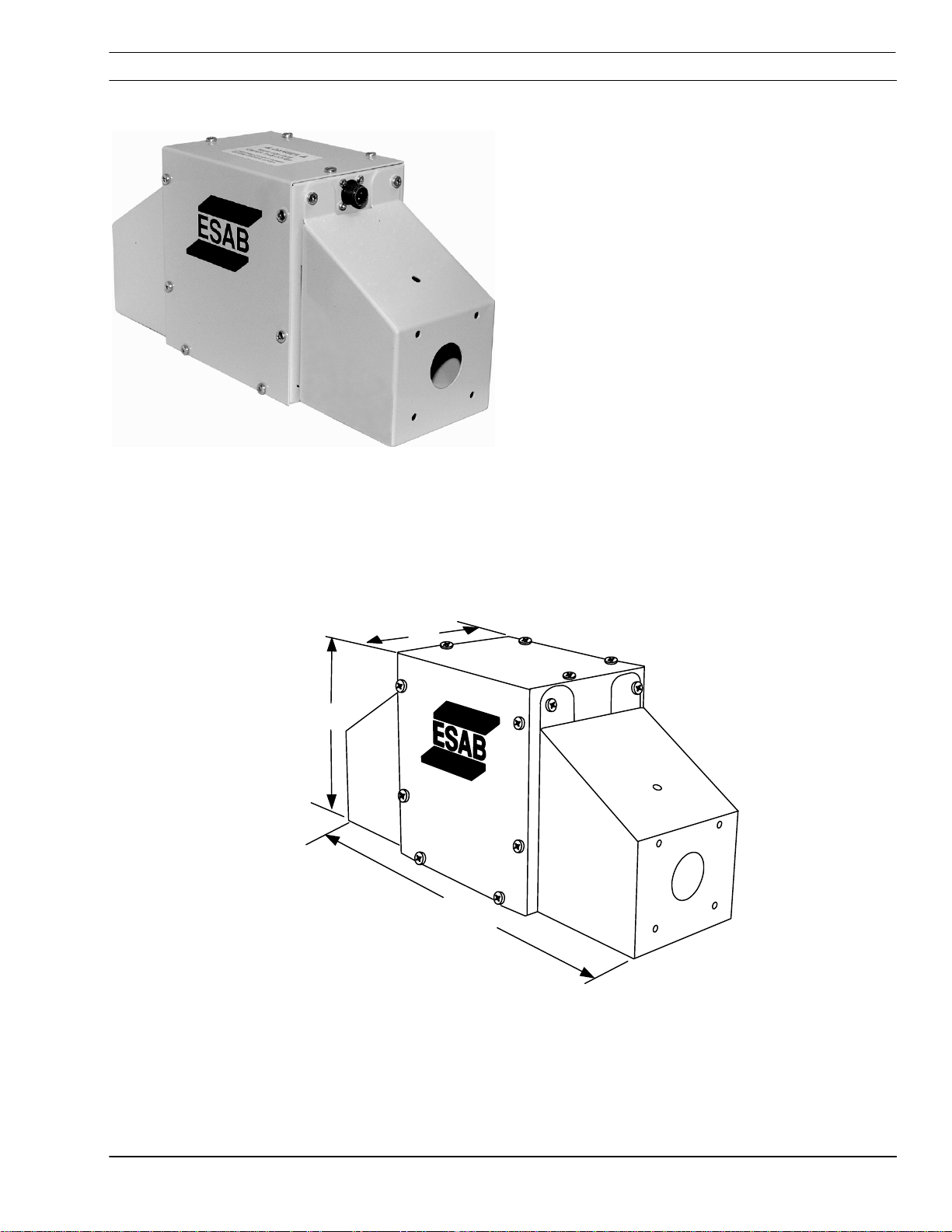

Dimensions and Weight

123,8mm

184,2mm

374mm

Weight = 3,4kg

2-3

SECTION 2 PCM-875A Mechanized Plasma Cutting System Description

2.4 PT-20AMX

The patented PT-20AMX is a 100 amp capacity,

pilot-arc mechanized torch available in 3 different

torch lead length packages.

The torch uses clean, dry air as the cut gas for

cutting carbon steel, aluminum, or stainless steel.

PT-20AMX Torch with 1,2 m lead P/N 0558002632

PT-20AMX Torch with 5,7 m lead P/N 0558002633

PT-20AMX Torch with 7,6 m lead P/N 0558003381

DO NOT use oxygen with this torch!

WARNING

!

2.4.1 Technical Specifications

Type: Air Cooled, single gas at 9,9 kl/hr

A hazardous fire may result.

Rating: 100 Amperes at 100% Duty Cycle

Gas Purity: Air: Needs to be clean, dry and free of all particulate matter.

Nitrogen: 99.995% clean

Gs Type: Air, nitrogen

2-4

SECTION 2 PCM-875A Mechanized Plasma Cutting System Description

2.4.2 Dimensions

34,9 mm

435 mm

2-5

SECTION 2 PCM-875A Mechanized Plasma Cutting System Description

2.4.3 Torch Spare Part Kit

PT-20AMX Torch Spare Parts Kit is available for

maintaining the PT-20AMX torch with minimum

downtime.

P/N 0558002319

Description

Heat Shield (70/100 A)

Cutting Nozzle (50 A)

Cutting Nozzle (70 A)

Electrode 50Hz 0558001617 5

Electrode Insulator 21373 1

Electrode Holder Assembly 21332 1

Baffle Tube 21374 1

Pilot Arc Adaptor 19497 1

O-ring 488157 5

Lubricant (1 oz.) 17672 1

Seat/Baffle Wrench 21375 1

1/16: Hex-Key Wrench 93750006 1

NOTICE

P/Number Quantity

21326 3

21330 5

23129 5

The description of the heat shield (P/N

21326) listed above indicates a range of 70

to 100 amperes. Testing has proven

satisfactory results when used at 60 amps

and lower.

2-6

NOTICE

The 50A cutting nozzle can be used at 50

amperes and lower.

The 70A cutting nozzle can be used at 50

to 70 cutting amperes.

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.1 General

Proper installation is important for satisfactory and

trouble free operation. Follow these instructions

carefully.

Failure to follow these directions

WARNING

!

carefully may lead to injury or death.

Read this entire manual before

proceeding.

Damage to property or equipment may occur.

3.2 Installation of the PCM-875A Power Console

3.2.1 Equipment Required

A source of clean dry air at 153,4 liters/minute at

5,2 to 5,9 bar. The maximum inlet pressure of the

air filter-regulator is 10,4 bar and should not be

exceeded.

3-1

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.2.2 Location

Console

Adequate ventilation is necessary to provide proper

cooling of the PCM-875A.

Exposure to dirt, dust and excessive heat should be

minimized.

There should be a minimum of 305 mm clearance

between the power console and any wall or other

obstruction for free air movement.

Restricting airflow into the power console through

CAUTION

the louvers will cause overheating. Do not install

any type of air filtering device on to the power

console cooling air passages. Warranty will be

voided if such a device is used.

3.2.3 Inspection of Power Console Before installation

A. Remove equipment from the shipping

containers.

B. Remove all packing material and inspect for

evidence of concealed damage, which may

not have been initially apparent. Notify the

shipping carrier of any damage at once.

C. Check container for any loose parts prior to

disposing of shipping materials.

D. Check air louvers and all other openings to

ensure that any obstruction is removed.

3-2

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.2.4 Primary electrical Input Connections

Electric Shock Can Kill!

WARNING

!

CAUTION

!

The PCM-875A Power Console is equipped with a

Ensure all power is off by opening the line

(wall) disconnect switch and power cord is

disconnected before attempting to make any

connections inside the power console.

Ensure that the power source is properly

configured for your input power supply. DO

NOT connect a power console configured for

230V to a 460V input power. Damage to

machine will occur.

3 m 4 conductor power cable for 3- phase

connection. If single-phase 230V is required, tape

back red wire on the input power cable.

A line (wall) disconnect switch with fuses or circuit

breakers should be provided at the main power

panel.

Input Requirements

Volts Phase Amps

230 1 49 16 80

230 3 24 16 50

400 3 13 6 25

Input and

Ground

Conductor

(mm

2

)

Fuse Size

(A)

3-3

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

Failure to connect chassis to an

WARNING

!

approved electrical ground may

result in electrical shock, severe

burns or death.

The chassis must be connected to an

approved electrical ground.

The PCM-875A power console is internally wired for

connecting to an external power source.

Console Power Lead

3.2.5 Connection of Plasma Console To CNC Interface

The CNC interface (TB4) is mounted on the

front left corner of the console base.

· Arc On Signal – This signal originates in the

plasma console. It is a normally open contact,

which closes on main arc transfer. Used to

activate machine motion and arc voltage

control.

1234567

Relay

Signal

Arc On

Start

Closing

Signal

Relay

Closing

20:1 (+)

Divider

Voltage

Not Used

· Start Signal – Signal is derived from CNC

machine. It is a normally open contact, which

closes starting the plasma sequence. The

system is off when this contact closure is

removed.

· 20:1 (+) Voltage Divider – The voltage divider

provides a signal ouput, which is proportional to

the cutting voltage. Signal reduction is 20 to 1

and controls whether the torch is raised or

lowered in reference to the work piece. This is

referred to torch to work distance. This

distance is adjustable by varying arc voltage

reference voltage.

· Not Used

3-4

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.2.6 Secondary (Output) Connections to Power Console

Electric Shock Can Kill!

WARNING

!

Ensure all power is off by opening the line

(wall) disconnect switch and power cord is

disconnected before attempting to make

any connections inside the power console.

Remove outside cover

Insert power cable, pilot arc, and air hose through

power cable bushing.

Power Cable Bushing TB1

3-5

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

1

Pilot Arc

2

Cut Gas

3

Arc Current

NOTICE

Bolt pilot arc cable ring connection to the copper

1

terminal.

Connect air hose to air/power connector (left hand

2

threads).

Connect power cable to air/power connector using

3

#10 screw

The console cover does not have to be removed to

make the three connections above. Remove

access panel if replacing cables or checking

connections.

3-6

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

115VAC RAS Cable

Insert115VAC Pilot Arc Cable

TB1

Insert 115VAC RAS cable through strain relief

located in the lower right corner of the front panel.

Rout 115VAC RAS cable along inside edge in

notches in insulating material to TB1.

2 conductor

115VAC cable

routed through

notch

3-7

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

Remove connection for internal arc start from TB1

TB1

CAUTION

!

Replace cover if next step is not required.

Plug terminal connectors into 2 available lugs on

TB1.

Cable Terminals to TB1 should be

insulated to prevent possible damage due

to internal arcing in the power console.

The above illustration shows the terminals

un-insulated for clarity of wire positions.

3-8

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.3 Connecting the Remote Arc Starter

3.3.1 Mounting RAS2

Mounting location of RAS unit is restricted by the

length of torch leads, 1,2 m -- 5,4 m or 7,6 m.

228,6mm

203,2mm

12,7mm

13,5mm

82,6mm

8mm

55,9mm

3-9

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.3.2 Connecting Service Lines to Remote Arc Starter 2

Remove end covers on RAS2 box.

Arc Start

Cable

Pilot Arc

Cable

115 VAC Arc Start Cable

Connector

Pilot Arc Lug

Air Connection

Power Cable Lug

Power

Cable

Air Hose

· Connect arc start cable to RAS2 box.

· Connect pilot arc cable to pilot arc lug using

#10 screw and nut with lock washers.

· Connect power cable to power cable lug using

¼” screw with washers and nut.

· Connect air hose fitting (left hand threads).

Note that this hose has the same fittings on both

ends and orientation does not matter.

3-10

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.3.3 Setting the Spark Gap in the RAS2

1 mm

Factory set to 1mm.

Adjustment procedure:

1. Loosen screw “a” using a 1/8” (0.125”)

internal hex wrench.

2. Insert 1mm feeler gage between the

tungsten electrodes.

3. Slide electrodes till slight pressure is felt on

the gage.

4. Tighten locking screws on spark gap

assembly.

”a”

3-11

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.3.4 RAS2 Output Connections to Torch

· Pilot Arc – Connect pilot arc cable in torch

bundle to pilot arc output lug using #10 screw,

lock washers and nut.

· Torch – left hand threads connect the torch

gas (air) and plasma arc current. (Cable inside gas

hose conducts the plasma cutting current)

Torch Lead Pilot Arc

Connector

Torch Lead

Voltage/Gas Hose

3-12

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.3.5 Terminating Shield Braid at RAS2

1. Insert Braid and hose bundle through RAS

cover hole.

Insert bundle

Flair Braid

2. Flare braid by bending it back at 90 degrees

about 25 mm from the end.

3-13

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3. Insert ground plate over torch leads.

Insert Ground Plate

Fasten Ground Plate

4. Fasten ground plate with 4 screws inserted

from the outside. Trim braid strands if desired.

3-14

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3.4.1 Installing Torch Front End Parts

WARNING

!

Seat

Make sure power switch on console is in

OFF position and primary input power is

de-energized.

1. The seat comes assembled to the front end

of the torch. IF the seat becomes damaged, the

torch body must be replaced. DO NOT attempt

to remove the seat from torch body.

Electrode Holder Assembly

Wrench

21375

Baffle Tube

2. Electrode holder assembly (21332) includes

the baffle tube (21374). If baffle tube becomes

damaged, it can be replaced by un-threading the

damaged tube out of the holder. Use small hex

end of the wrench (21375) in hex broach on the

tube. Tighten tube securely but do not overtighten.

3-15

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

3. Install the electrode insulator (21373) onto

electrode holder assembly (21332) and then thread

electrode (21150) onto the electrode holder

assembly. Assemble electrode firmly by hand. Do

not use wrenches or pliers. These three parts

combined are the electrode assembly.

21332

21373

21150

4. Install nozzle onto the electrode assembly by

inserting small shoulder on electrode insulator into

nozzle’s rear opening. Place nozzle and electrode

assembly into the heat shield as shown in page 6.

If front end of the torch is facing down as normal in

a setup, the nozzle and electrode assembly can be

stacked in the heat shield and then assembled to

the torch. Be sure to use proper heat shield and

nozzle combination as noted in page 18.

O-ring (488157)

5. Apply a thin film of lubricant (17672) to O-ring

(488157).

17672

3-16

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

6.Tighten heat shield fully to hold the parts in firm

contact with each other and to the torch head.

“Fully” means at least 5mm rotation after electrode

seat contacts electrode holder.

7. After retainer/heat shield is tightened, try to

rotate the nozzle with your finger tips. If it rotates,

the sealing of components is not tight enough and

NOTICE

CAUTION

!

will likely leak gas.

See “Section 6 – Maintenance” for torch

lead installation or replacement.

IMPORTANT: See Maintenance section.

Follow all instructions in the booklet

packed with your unit. DO NOT install or

attempt to operate this torch without

following these instructions.

3-17

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

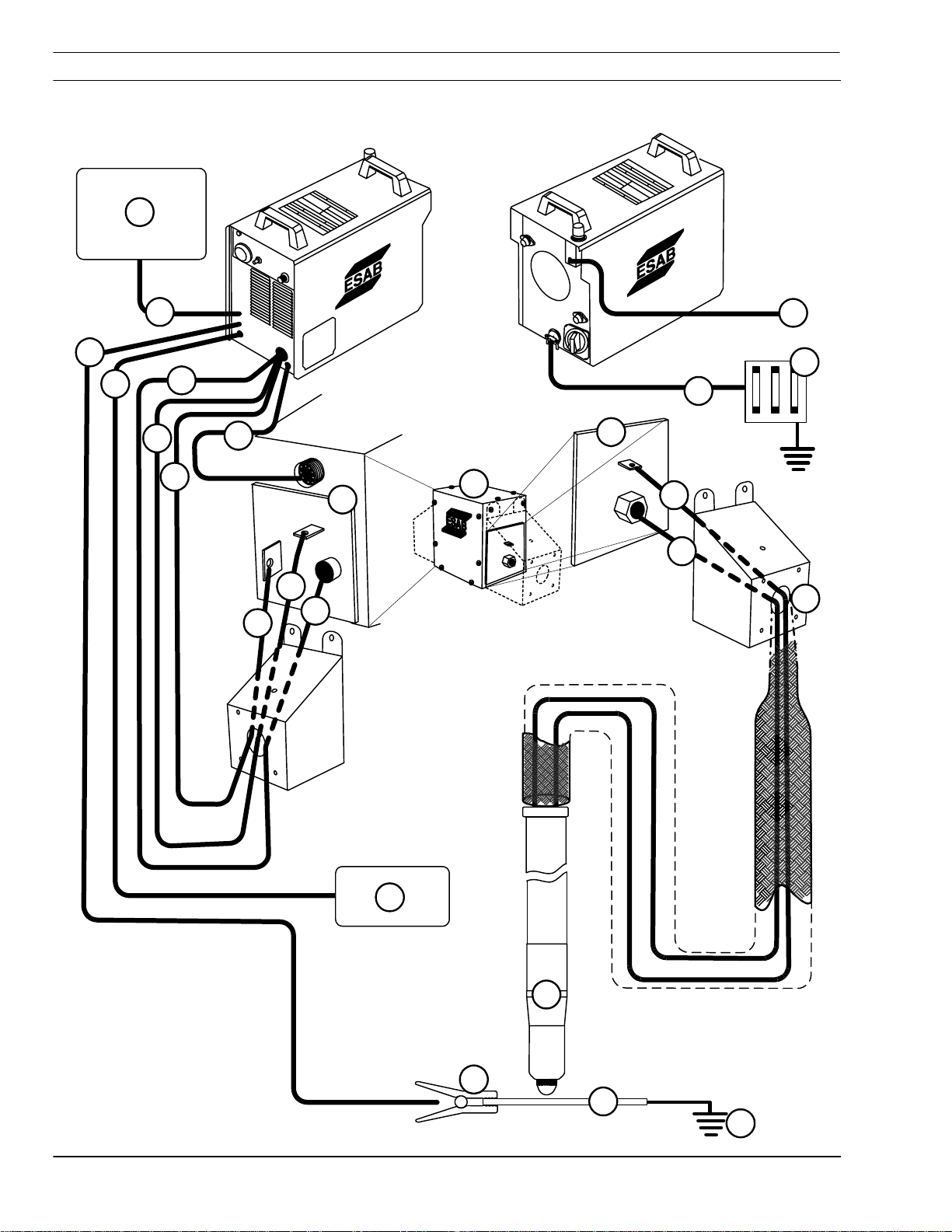

3.5 Interconnecting Diagram

19

20

4

21

5

6

7

8

10

9

6

7

5

11

3

12

13

1

2

14

3-18

22

15

16

17

18

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

1 Air Supply

2 Wall Disconnect Switch (Grounded)

3 PCM-875A Power Supply Cable

4 Work Cable (Negative)

5 Pilot Arc Cable

6 Gas Connection

7 Power Supply Cable

8 115 V High Frequency Start Cable

9 RAS Input Bulkhead

10 Remote Arc Starter

11 RAS Output Bulkhead

12 Pilot Arc Cable

13 Power/Gas Hose

14 Torch Lead Bundle Shield Ground

15 PT-20 AMX Plasmarc Torch

16 Work Cable Clamp

17 Work Piece

18 Earth Ground

19 ATAS Start/Stop CSR

20 CSR Cable

21 Height Control Cable (Voltage Divider)

22 Voltage Divider (Height Control)

3-19

SECTION 3 PCM-875A Mechanized Plasma Cutting System Installation

This page intentionally left blank.

3-20

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.1 PCM-875A Console Operation -- General

Electric Shock Can Kill!

WARNING

!

· Do not operate the console with the

cover removed.

· Do not apply power to the unit while

holding or carrying the console.

· Do not touch the torch while console

power switch is on.

· Plasma Arc Emi t s Haza rdous UV

WARNING

!

and Visible Radiation.

· Damage to skin and eyes is possible.

· Do not ever look directly at a plasma

arc. Blindness could result.

· Wear Safety Approved eye protection.

· Comply to all local and national

regulations for safety equipment.

Noise Levels May Exceed Safe

WARNING

!

Limits.

Sparks and Slag May Be Hazardous.

· Wear Safety Approved Hearing

Protection.

· Wear Safety Approved Eye Protection.

Possible Damage to Console from

CAUTION

Sparks and Slag.

Position PCM-875A at least 3 meters form

the Cutting Area.

4-1

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.2 PCM-875A Plasma Console Controls

Power Switch -- Rear Panel

· Located on the rear panel.

· On Position – Front panel green pilot light will

glow indication control circuit is energized and

cooling fan will run.

· Off Position – No Power to the control circuit.

Power Switch White Pilot Light

Output Current Control – Front Panel

· Adjustable from 10 to 60 Amperes

Current Output Control

Air Test Switch – Front Panel

· Test Position

Air filter-regulator can be adjusted to

desired pressure 4,6 to 5,3 kgf/cm

to 75 PSI). Allow a few minutes for air to

flow to remove an accumulated

condensation.

2

(65

4-2

Air Test Switch

· Operate Position

Place the toggle switch in this position

for normal operation.

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

Fault Light – Operations are stopped.

Will illuminate amber under the following conditions:

· Light mostly ON but will blink off 1/10 of a

second every second. Indicates airflow is low.

· Light is mostly Off but will blink on for 1/10 of

a second every second. Indicates over

temperature and duty cycle has been exceeded.

Allow power console to cool before returning to

operation.

· Light will blink off and on 5 times a second.

Fault Light

NOTICE

4.3 RAS Operation

Indicates the input voltage is outside the plus or

minus 15% range of input rating.

· Light will be on continuously. Indicates input

current has been exceeded. Over Current.

All fault lights will remain on for a

minimum of 10 seconds. If fault is

resolved, all will reset automatically except

for over current. To clear over current,

power must be shut off for 5 seconds and

turned back on.

The RAS is a self-contained unit and requires no

operator intervention to function.

4-3

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.4 PT-20AMX Plasma Torch.

Electric Shock Can Kill!

WARNING

!

Plasma incorporates high voltages at

dangerous amperage.

Do not touch the;

· Plasma torch

· Torch lead

· RAS

· RAS supply lines

· Console

while power is applied to console.

Electric shock Can Kill!

WARNING

!

Do not service torch or otherwise touch

the plasma torch unless the power source

has been disconnected or turned off.

Hot Torch May Burn Skin.

CAUTION

!

Allow torch to cool before servicing.

4-4

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.5 Cut Quality

4.5.1 Introduction

NOTICE

Causes affecting cut quality are interdependent.

Changing one variable affects all others. Determining a

solution may be difficult. The following guide offers

possible solutions to undesirable cutting results. To

begin select the most prominent condition:

§ 4.5.2 Cut angle, negative or positive

§ 4.5.3 Cut not flat, rounded or undercut

§ 4.5.4 Surface roughness

§ 4.5.5 Dross

§ 4.5.6 Dimensional Accuracy

§ Process Data

Usually the recommended cutting parameters will give

optimal cut quality. Occasionally conditions may vary

and slight adjustments will be required. If so:

· Make small incremental adjustments when making

corrections.

· Adjust arc voltage in one volt increments, up or

down as required.

Adjust cutting speed 5% or less as required, until

conditions improve.

Before attempting ANY corrections, check cutting

variables with the factory recommended

settings/consumable part numbers listed in Process

Data.

4-5

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.5.2 Cut Angle

Part

Negative Cut Angle

Top dimension is greater than the bottom.

· Misaligned torch

· Bent or warped material

· Worn or damaged consumables

· Standoff low (arc voltage)

Drop Part

Part

· Cutting speed slow (machine travel rate)

Positive Cut Angle

Top dimension is less than the bottom dimension.

· Misaligned torch

· Bent or warped material

· Worn or damaged consumables

Drop

4-6

Part

· High standoff high (arc voltage)

· Cutting speed fast

· Current high or low. (See process data for

recommended current level for specific nozzles).

· Wrong secondary gas flow.

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.5.3 Cut Flatness

Top And Bottom Rounded

Condition usually occurs when material is 0.25" thick (6,4mm)

or less.

· High current for given material thickness (See

process data for proper settings).

Drop

Drop

Part

Top Edge Undercut

Standoff low (arc voltage)

Part

4-7

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.5.4 Surface Finish

Process

Induced

Roughness

Top View

Or Machine

Induced

Roughness

Cut Face

Process Induced Roughness

Cut face is consistently rough and may be confined to

one axis.

· Worn or damaged consumables

Machine Induced Roughness

Can be difficult to distinguish from process induced

roughness and is often confined to one axis.

Roughness is inconsistent.

· Dirty rails, wheels and/or drive rack/pinion. (Refer to

maintenance section in machine owner’s manual).

· Carriage wheel adjustment

4-8

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.5.5 Dross

Cut Face

Lag Lines

Dross is a by-product of the cutting process. It is the

undesirable material that remains attached to the part.

In most cases, dross can be reduced or eliminated

with proper torch and cutting parameter setup. Refer

to Process Data.

Roll Over

Side View

Cut Face

Lag Lines

High Speed Dross

Material weld or rollover on bottom surface along kerf.

Difficult to remove. May require grinding or chipping.

“S” shaped lag lines.

· Standoff high (arc voltage)

· Cutting speed fast

Side View

Slow Speed Dross

Forms as globules on bottom along kerf. Removes

easily.

Globules

· Cutting speed slow

4-9

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

Side View Splatter

Cut Face

Top Dross

Appears as splatter on top of material. Usually

removes easily.

· Cutting speed fast

· Standoff high (arc voltage).

Intermittent Dross

Appears on top or bottom along kerf.

Non-continuous. Can appear as any kind of dross

· Possible worn consumables

Other Factors Affecting Dross:

· Material temperature

· Heavy mill scale or rust

· High carbon alloys

· Gas Purity

4-10

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

4.5.6 Dimensional Accuracy

Generally, using the slowest possible speed (within

approved levels) will optimize part accuracy. Most

material thickness overlap for different voltages.

Select consumables to allow a lower arc voltage

and slower cutting speed.

4.6 Process Data

NOTICE

Recommended cutting speed and arc voltage will

give optimal cutting performance.

Small incremental adjustments may be needed due

to material quality, material temperature and specific

alloy. The operator should remember that all

cutting variables are interdependent. Changing one

setting affects all others and cut quality could

deteriorate. Always start at the recommended

settings.

Before attempting ANY corrections, check cutting

variables with the factory recommended settings/

consumable part numbers listed in the process

data.

4-11

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

Material:

Mild Steel

PT-20AMX

Plasmarc Torch

Amperes:

Gas:

Lock Ring P/N 57N70

Handle with

Torch Body P/N 21359

40

Air

Sleeve

P/N

05508003419

Electrode

Holder

Assembly

Electrode

Insulator

Electrode

50Hz

Nozzle 50A P/N 21330

Heat Shield –

Blue

P/N 21332

P/N 21373

P/N

0558001617

P/N 21326

4-12

Note: Heat shield rated at 70 to

100A is used for this application

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

PT-20AMX

40

Amperes

Process Data

Material Thickness

mm

2,0 3,0

Air Pressure

Bar

5 5

Height Readings

Initial Height

Arc Voltage (Stand-off)

mm

Travel Speed

3,0 3,0

110 110

Mild Steel

mm per minute

Kerf Width

Millimeters

3810 2540

1,1 1,1

4-13

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

Material:

Mild Steel

PT-20AMX

Plasmarc Torch

Amperes:

Gas:

Lock Ring P/N 57N70

Handle with

Torch Body P/N 21359

50

Air

Sleeve

P/N

05508003419

Electrode

Holder

Assembly

Electrode

Insulator

Electrode

50Hz

Nozzle 50A P/N 21330

Heat Shield –

Blue

P/N 21332

P/N 21373

P/N

0558001617

P/N 21326

4-14

Note: Heat shield rated at 70 to

100A is used for this application

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

PT-20AMX

50

Amperes

Process Data

Material Thickness

mm

5,0 6,0 10,0 13,0

Air Pressure

Bar

6,0 6,0 6,0 6,0

Height Readings

Initial Height

Arc Voltage (Stand-off)

mm

Travel Speed

3,0 5,0 6,0 8,0

110 120 130 150

Mild Steel

mm per minute

Kerf Width

Millimeters

2540 1651 1016 457

1,6 1,9 3,2 4,0

4-15

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

Material:

Aluminum

PT-20AMX

Plasmarc Torch

Amperes:

Gas:

Lock Ring P/N 57N70

Handle with

Torch Body P/N 21359

40

Air

Sleeve

P/N

05508003419

Electrode

Holder

Assembly

Electrode

Insulator

Electrode

50Hz

Nozzle 50A P/N 21330

Heat Shield –

Blue

P/N 21332

P/N 21373

P/N

0558001617

P/N 21326

4-16

Note: Heat shield rated at 70 to

100A is used for this application

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

PT-20AMX

40

Amperes

Process Data

Material Thickness

mm

2,0 3,0

Air Pressure

Bar

5 5

Height Readings

Initial Height

Arc Voltage (Stand-off)

mm

Travel Speed

3,0 3,0

110 110

Aluminum

mm per minute

Kerf Width

Millimeters

3810 2667

1,57 1,57

4-17

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

Material:

Aluminum

PT-20AMX

Plasmarc Torch

Amperes:

Gas:

Lock Ring P/N 57N70

Handle with

Torch Body P/N 21359

50

Air

Sleeve

P/N

05508003419

Electrode

Holder

Assembly

Electrode

Insulator

Electrode

50Hz

Nozzle 50A P/N 21330

Heat Shield –

Blue

P/N 21332

P/N 21373

P/N

0558001617

P/N 21326

4-18

Note: Heat shield rated at 70 to

100A is used for this application

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

PT-20AMX

50

Amperes

Process Data

Material Thickness

mm

5,0 6,0 10,0 13,0

Air Pressure

Bar

6,0 6,0 6,0 6,0

Height Readings

Initial Height

Arc Voltage (Stand-off)

mm

Travel Speed

3,0 5,0 6,0 8,0

110 120 130 150

Aluminum

mm per minute

Kerf Width

Millimeters

2286 1905 762 203

Not

Available

3,2 4,7 4,7

4-19

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

Material: Stainless Steel

PT-20AMX

Plasmarc Torch

Amperes:

Gas:

Lock Ring P/N 57N70

Handle with

Torch Body P/N 21359

40

Air

Sleeve

P/N

05508003419

Electrode

Holder

Assembly

Electrode

Insulator

Electrode

50Hz

Nozzle 50A P/N 21330

Heat Shield –

Blue

P/N 21332

P/N 21373

P/N

0558001617

P/N 21326

4-20

Note: Heat shield rated at 70 to

100A is used for this application

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

PT-20AMX

40

Amperes

Process Data

Material Thickness

mm

2,0 3,0

Air Pressure

Bar

5 5

Height Readings

Initial Height

Arc Voltage (Stand-off)

mm

Travel Speed

3,0 3,0

110 110

Stainless Steel

mm per minute

Kerf Width

Millimeters

3302 1905

Not

Available

1,6

4-21

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

Material: Stainless Steel

PT-20AMX

Plasmarc Torch

Amperes:

Gas:

Lock Ring P/N 57N70

Handle with

Torch Body P/N 21359

50

Air

Sleeve

P/N

05508003419

Electrode

Holder

Assembly

Electrode

Insulator

Electrode

50Hz

Nozzle 50A P/N 21330

Heat Shield –

Blue

P/N 21332

P/N 21373

P/N

0558001617

P/N 21326

4-22

Note: Heat shield rated at 70 to

100A is used for this application

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

PT-20AMX

50

Amperes

Process Data

Material Thickness

mm

5,0 6,0 10,0 13,0

Air Pressure

Bar

6,0 6,0 6,0 6,0

Height Readings

Initial Height

Arc Voltage (Stand-off)

mm

Travel Speed

3,0 5,0 6,0 8,0

110 120 130 150

Stainless Steel

mm per minute

Kerf Width

Millimeters

1270 762 203 152

Not

available

3,2 4,7 4,7

4-23

SECTION 4 PCM-875A Mechanized Plasma Cutting System Operation

This page intentionally left blank.

4-24

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

5.1 PCM-875A Console

5.1.1 General

CAUTION

!

CAUTION

!

NOTICE

Stop work immediately if this equipment

does not operate properly. Equipment

damage or personal injury may result.

Do not permit untrained persons to

inspect, clean, or repair this equipment.

Maintenance must be performed by

specially trained personnel.

Use of replacement parts other than ESAB

replacement parts may void warranty.

Electric Shock Can Kill!

WARNING

!

Disconnect wall switch before inspection

and maintenance of the power console.

5-1

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

5.1.2 Inspection and Cleaning

F

F

F

EE

F

F

Frequent inspection and cleaning of the PCM 875A

system is recommended for safe and proper

operation.

A. Check work cable for secure connection to

workpiece.

B. Check safety earth ground at workpiece and

at power console chassis.

C. Check heat torch heat shield. Replace if

damaged.

D. Check torch electrode and cutting nozzle for

wear at least once per 8 hours operation.

E. Ensure cable and hoses are not damaged

or kinked.

F. Ensure all plugs, fittings and ground

connections are tight.

A

CBD

Wear safety eye protection when

WARNING

!

using compressed air.

Serious eye injury may result.

5-2

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

Water and oil may accumulate in

CAUTION

compressed air lines. Direct the first air

blast away from equipment to avoid

possible damage.

G. With all input power disconnected, wearing

proper eye and face protection, blow out

the inside of the console using low-pressure

dry compressed air.

H. Periodically drain water from the filter

beneath the air-filter regulator.

5-3

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

5.1.3 Flow Switch

The Flow Switch (P/N 951202) may need to be

cleaned if excessive contamination is found in the

air supply.

1

Flow Switch Location

1

Solenoid Location

2

Piston Plug

Spring

A

2

View A-A

A

Note: The flow switch can be disassembled and

cleaned without extraction from the power supply.

1) Turn Off power supply

2) Remove piston plug

3) Remove the spring. Use care when handling

spring to prevent distortion.

Piston

5-4

Flow Switch Body

4) Remove the piston.

5) Clean all parts with warm water and a mild

detergent. Allow parts to dry thoroughly before

reassembly.

6) Reassemble switch in reverse order.

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

5.2. Remote Arc Starter

5.2.1 General

Check input and output bulkhead connections for

5.2.2 Spark Gap

1 mm

tightness.

Factory set to 1mm.

Adjustment procedure:

1. Loosen screw “a” using a 1/8” (0.125”)

internal hex wrench.

2. Insert 1mm feeler gage between the

tungsten electrodes.

3. Slide electrodes till slight pressure is felt on

the gage.

4. Tighten locking screws on spark gap

assembly.

”a”

5-5

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

5.3 PT-20AMX Plasmarc Torch

WARNING

!

Before any maintenance is attempted on

this torch, make sure the POWER SWITCH

on the console is in the OFF position and

the PRIMARY INPUT POWER is

DE-ENERGIZED.

5.3.1 General

1. Periodically check heat shield, electrode holder

assembly, electrode nozzle seat, and electrode

insulator. Replace if worn or damaged.

2. Apply a thin film of lubricant 17672 (supplied in

spare parts kit) to O-ring. Check O-ring for damage

whenever shield is removed. Replace if necessary.

3. Power and pilot arc cables should be inspected

periodically. If cuts through protective sheath or if

gas leaks are noted, replace damaged component.

5-6

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

5.3.2 Dirt or Contamination

Dirt or other contamination in the torch and loose

consumable parts can cause premature failure of

the PT-20AM Torch through internal arcing. To

avoid this, users are instructed to do the following:

1. Ensure that clean, dry, or oil-free air is being

used.

2. Avoid excessive use of the silicone o-ring

grease used to lubricate the torch o-ring. A thin

film is sufficient.

3. Wipe the torch body insulator clean with a

cloth before installing each fresh set of

consumables. The ability of the insulator to resist

arc tracking over its surface is reduced when dirt

or other contamination is allowed to collect there.

5.3.3 Loose Consumables

Tests have shown that with proper use of the torch

within rated operating conditions (especially arc

current and gas flow rate), the torch consumable

parts do not become loose if they are firmly

installed in the first place.

1. Tighten heat shield fully at each consumable

change or inspection. “Fully” means at least 5

mm of rotation after electrode seat contacts

electrode holder.

NOTE: trying to rotate the portion of the nozzle

extending outside heat shield can check

consumable tightness.

2. Check consumable tightness at beginning of

each work shift, even if everything was working

normally at the end of the previous shift.

3. Ensure that the torch electrode seat and

electrode holder are clean and free of dust or dirt

Debris may prevent mating surfaces from having

solid contact.

5-7

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

The torch requires good electrical contact

CAUTION

5.3.4 Damage Caused by Loose Parts and Torch Overheating.

between the electrode seat and electrode

holder. If good contact is not maintained,

then the resulting potential difference

causes internal arcing and possible torch

damage.

Electrode Insulator (21373)

Deformation at this edge indicates

torch overheating. Check gas

pressure, gas flow rate and current

setting. Deformation leads to loose

parts and internal arcing. Do not

operate torch with a deformed

insulator.

5.3.5 Consumables- Remove and Replace

1. Bring torch to a position where it is easily

Arc tracking indicates loose parts. Make sure heat

shield is tightened fully, at least 5mm of rotation

after electrode seat contacts electrode holder.

Check tightness again after a few minutes of use.

Parts damaged by arcing will cause destruction of

torch. Parts damaged by arcing must be replaced.

accessed by machine operator, in its normal

vertical position and at least 6 inches above the

workpiece or the edge of the water table.

Make sure that the power source has been

WARNING

!

turned off and that the power cable has

been unplugged at the wall receptacle

before proceeding.

5-8

2. Unscrew the heat shield and lower it away

from the torch, allowing nozzle and electrode

assembly to remain with shield.

SECTION 5 PCM-875A Plasmarc Cutting System Maintenance

3. Remove the nozzle and electrode assembly

from the shield and inspect for wear. The nozzle

orifice should be round at both the entrance and

the exit. If the nozzle orifice is worn in an oval

shape or shows other signs of damage at either

end, it should be replaced. The inside of the nozzle

may have light gray deposits from the electrode.

These may be removed with steel wool but care

must be taken to remove all traces of the steel

wool afterward.

1,5 mm

If the electrode has a pit that is more than 1.5mm

deep at its center, replace it. Grasp the electrode

holder with the fingers using the two flats and

grasp the electrode between the thumb and finger

of the other hand and twist.

Inspect electrode insulator and electrode holder

assembly for signs of damage such as arc tracking

or cracking and replace them if any are found.

Insure that the baffle tube is securely threaded into

the electrode holder, but do not over tighten. Use

the small hex end of the plastic wrench in the

spare parts kit.

After installing the electrode insulator onto the

electrode holder assembly, install electrode by