Page 1

ESAB PAPR System

Respiratory protective device

Instruction manual

ESAB PAPR System GB 20180614

Page 2

ESAB AB

Lindholmsallén 9

Box 8004

402 77 Gothenburg

Sweden

Phone +46 (0) 31 50 90 00

www.esab.com

Page 3

TABLE OF CONTENTS

1

SAFETY ....................................................................................................... 4

1.1 Meaning of symbols ............................................................................... 4

1.2 Safety precautions ................................................................................. 4

2

INTRODUCTION.......................................................................................... 6

2.1 Overview ................................................................................................. 6

2.2 Equipment ............................................................................................... 6

2.3 Prerequisites........................................................................................... 6

3

TECHNICAL DATA ...................................................................................... 8

3.1 System overview .................................................................................... 8

3.2 Technical data......................................................................................... 8

3.3 Warranty.................................................................................................. 9

4

OPERATION ................................................................................................ 10

4.1 Assembly ................................................................................................ 10

4.1.1 Belt adjustment..................................................................................... 10

4.1.2 Particle filter.......................................................................................... 11

4.1.3 Removing the filter ............................................................................... 11

4.1.4 Inserting a new filter ............................................................................. 12

4.1.5 Changing the pre-filter .......................................................................... 12

4.1.6 Attaching the hose to the blower unit ................................................... 12

4.1.7 Donning the welding helmet ................................................................. 12

4.2 Usage....................................................................................................... 13

4.3 Inspection before use ............................................................................ 13

4.3.1 Alarm test ............................................................................................. 13

4.3.2 Air flow test ........................................................................................... 14

4.3.3 Batteries ............................................................................................... 14

4.3.3.1 Charging the battery .......................................................................... 14

4.3.3.2 Replacing the battery ........................................................................ 15

5

MAINTENANCE........................................................................................... 16

5.1 Cleaning .................................................................................................. 16

5.2 Storage and transportation ................................................................... 16

6

TROUBLESHOOTING ................................................................................. 17

CERTIFIED HELMETS ........................................................................................ 18

ORDERING SPARE PARTS................................................................................ 19

ORDERING NUMBERS AND SPARE PARTS LIST ........................................... 20

ESAB PAPR System.................................................................................................. 20

Sentinel A50 Air ......................................................................................................... 21

Warrior Tech Air......................................................................................................... 21

F20 and F20 Air.......................................................................................................... 22

G30 and G30 Air ........................................................................................................ 23

G40, G50, G40 Air and G50 Air ................................................................................. 24

Rights reserved to alter specifications without notice.

ESAB PAPR System © ESAB AB 2018

Page 4

1 SAFETY

1 SAFETY

1.1 Meaning of symbols

As used throughout this manual: Means Attention! Be Alert!

DANGER!

Means immediate hazards which, if not avoided, will result in immediate,

serious personal injury or loss of life.

WARNING!

Means potential hazards which could result in personal injury or loss of

life.

CAUTION!

Means hazards which could result in minor personal injury.

WARNING!

Before use, read and understand the instruction manual

and follow all labels, employer´s safety practices and Safety

Data Sheets (SDSs).

1.2 Safety precautions

WARNING!

Failing to follow these instructions may result in risk of fire, electric shock or

personal injury.

• Only charge the correct type of rechargeable battery to reduce the risk of

explosion, personal injury or other damages.

• Do not open the charger. Any repairs should be done by the

manufacturer or authorized service personnel.

• Do not attempt to take the unit apart, this action voids the warranty. Do

not disassemble the unit when it is plugged into the mains electric supply

to avoid the risk of electric shock or fire.

• Do not use the charger if it is visibly damaged.

Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who

works on or near the equipment observes all the relevant safety precautions. Safety

precautions must meet the requirements that apply to this type of equipment. The following

recommendations should be observed in addition to the standard regulations that apply to

the workplace.

All work must be carried out by trained personnel well-acquainted with the operation of the

equipment. Incorrect operation of the equipment may lead to hazardous situations which can

result in injury to the operator and damage to the equipment.

ESAB PAPR System

- 4 -

© ESAB AB 2018

Page 5

1 SAFETY

1. Anyone who uses the equipment must be familiar with:

○ its operation

○ location of emergency stops

○ its function

○ relevant safety precautions

○ welding and cutting or other applicable operation of the equipment

2. The operator must ensure that:

○ no unauthorised person is stationed within the working area of the equipment

when it is started up

○ no-one is unprotected when the arc is struck or work is started with the

equipment

3. The workplace must:

○ be suitable for the purpose

○ be free from drafts

4. Personal safety equipment:

○ Always wear recommended personal safety equipment, such as safety glasses,

flame-proof clothing, safety gloves

○ Do not wear loose-fitting items, such as scarves, bracelets, rings, etc., which

could become trapped or cause burns

5. General precautions:

○ Make sure the return cable is connected securely

○ Work on high voltage equipment may only be carried out by a qualified

electrician

○ Appropriate fire extinguishing equipment must be clearly marked and close at

hand

○ Lubrication and maintenance must not be carried out on the equipment during

operation

NOTE!

Dispose of electronic equipment at the recycling

facility!

In observance of European Directive 2012/19/EC on Waste

Electrical and Electronic Equipment and its implementation

in accordance with national law, electrical and/or electronic

equipment that has reached the end of its life must be

disposed of at a recycling facility.

As the person responsible for the equipment, it is your

responsibility to obtain information on approved collection

stations.

For further information contact the nearest ESAB dealer.

ESAB has an assortment of welding accessories and personal protection equipment

for purchase. For ordering information contact your local ESAB dealer or visit us on

our website.

ESAB PAPR System

- 5 -

© ESAB AB 2018

Page 6

2 INTRODUCTION

2 INTRODUCTION

These user instructions must be followed when using and operating the ESAB PAPR

System. Failure to follow these instructions may void the warranty of the product(s). Refer to

the terms of your purchase contract in respect of the product(s) for the specific details of the

warranty.

2.1 Overview

The ESAB PAPR System is a respiratory protective system that circulates over-pressured air

in the hood. The belt-mounted blower unit delivers air through a filter and via an air hose into

the headpiece. The supply of filtered air creates positive pressure inside of the headpiece,

which prevents the external contaminated air from entering the breathing zone.

2.2 Equipment

The ESAB PAPR System is supplied with:

• Blower unit including battery, PRSL particle filter and pre-filter

• Belt

• Air hose

• Air flow indicator

• Battery charger

• Instructions manual

2.3 Prerequisites

Use the ESAB PAPR System during welding in unconfined spaces, strictly in accordance

with this Instruction manual and the instructions supplied with the corresponding helmets.

Do not use the unit:

• When the blower unit is switched off. When the blower unit is switched off, little or no

respiratory protection is to be expected. Rapid buildup of carbon dioxide and depletion

of oxygen may occur in the head unit.

• In an atmosphere that poses an immediate health or hygiene hazard and/or has less

than 19.5% oxygen content, or contains unknown substances.

• In confined spaces or unventilated areas such as tanks, pipes and canals.

• Near flames and/or sparks.

• In areas with danger of explosion.

• In areas with high winds.

• If the blower unit malfunctions.

Make sure moving parts are not blocked in their movement.

Do not modify or alter the unit or the particle filter in any way.

Protect the unit from ingress of water or other liquids, in particular the motor and fan, the filter

and the battery.

Make sure that the headpiece fits perfectly. The efficiency of the system is only sufficient in

this case. The protective factor of the complete system is reduced if the seal of the

headpiece is not fitted properly, for example if long hair or facial hair is extending into the seal

line.

Correct respiratory protection will not be provided if any part of the equipment is modified in

any way.

Position the blower unit in a way that minimises the risk of the head unit hose becoming

caught up during use. Filters must be attached to the blower unit, and not directly to the

headpiece.

ESAB PAPR System

- 6 -

© ESAB AB 2018

Page 7

2 INTRODUCTION

During elevated inhalation flow the pressure in the device may become negative.

Leave the contaminated area immediately and if needed seek medical advice if:

• The Manufacturer’s Minimum Design Flow (MMDF) warning alarm sounds.

• Breathing becomes difficult.

• Dizziness or distress occurs.

• Any part of the system becomes damaged.

• Airflow into the head unit decreases or stops.

• Contaminant can be smelt or tasted inside the head unit.

• In the unlikely event of an allergic reaction to the material of the headpiece.

ESAB PAPR System

- 7 -

© ESAB AB 2018

Page 8

3 TECHNICAL DATA

3 TECHNICAL DATA

3.1 System overview

The ESAB PAPR System is a belt mounted powered respirator with a replaceable,

disposable high efficiency particle filter. The system is certified with the helmets covered in

the “Certified helmets” section.

The unit has a removable and rechargeable Lithium-ion battery. Battery life varies depending

on the air quality and particle concentration of the work area.

The unit has visual alarm for indicating low battery and a multifunctional alarm for indicating

filter blockage. Do not use the unit when it alarms.

The particle filter is designed for the unit. Check the particle filter for any damage or

deformation that could lead to contaminated air getting into the unit. In a dusty environment

the filter needs to be replaced frequently. The particle filter must be disposed if it is damaged

or clogged, and is triggering the alarm.

The unit warns with an audible alarm and flashing LEDs if the MMDF of 170l/min is not

achieved. Leave the contaminated area immediately if the warning alarm sounds.

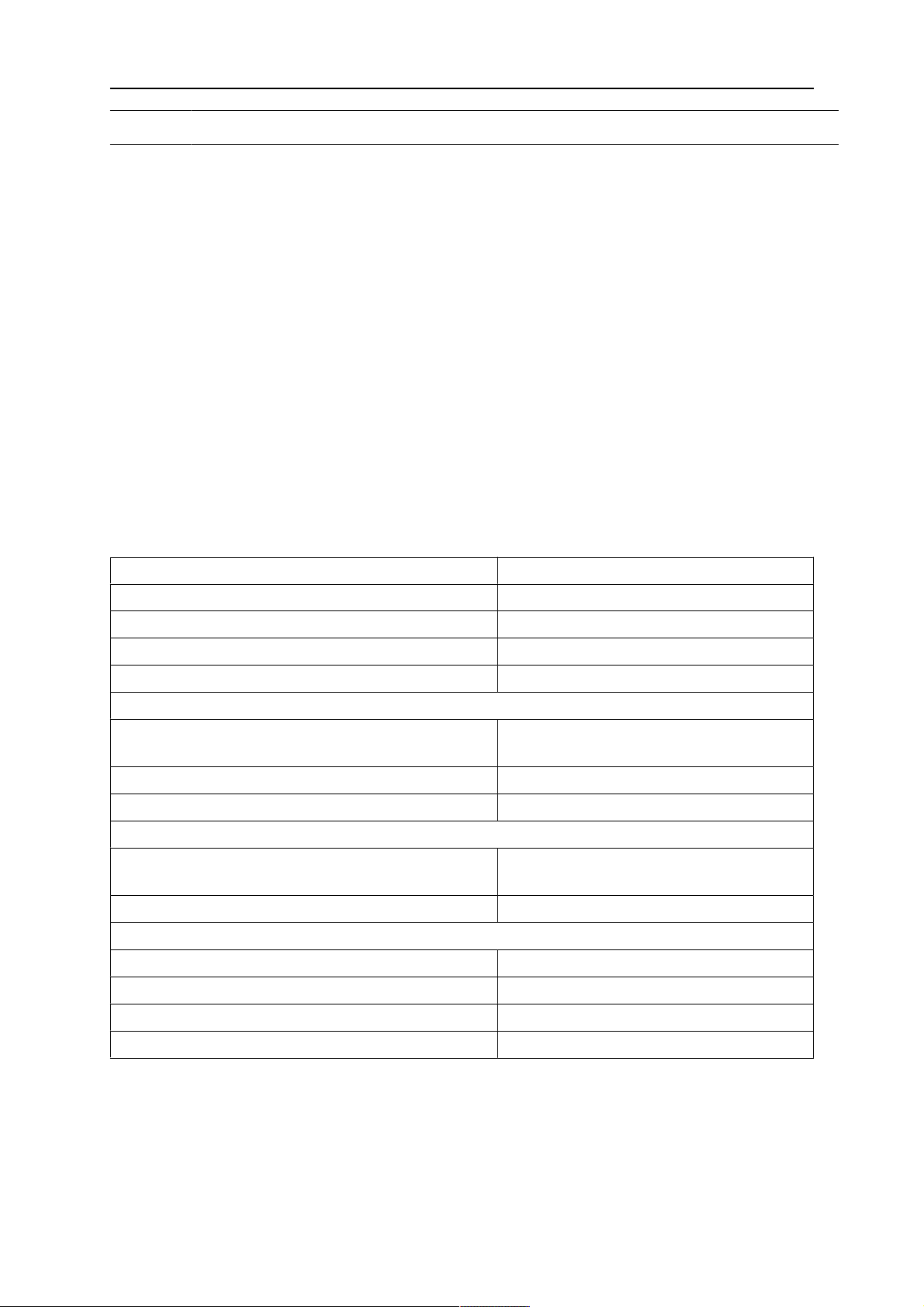

3.2 Technical data

Air flow

General 180–220l/min

Minimum 170l/min

Weight with particle filter 870g (1.9 lb)

Operating temperature 0–40°C (32–104°F)

Operating time

Minimum flow rate, fully charged battery, clean

environment >8hours

Maximum flow rate 6hours

Type of particle filter PRSL

Battery

Replaceable and rechargeable Li-ion

Type

Charging cycles >350

Alarms

Low battery Visual alarm

Insufficient flow rate (below 170 L/min) Visual, audible, vibration alarms

Actual Protection Factor (APF) 20/50

7.4V5200mAh

Noise level 65dBA

ESAB PAPR System

- 8 -

© ESAB AB 2018

Page 9

3 TECHNICAL DATA

Symbols

Refer to the manufacturer’s Instruction Manual

Store between 0-40°C (32–104°F)

Best before YYYY/MM

Maximum storage humidity <75%

Filter symbols:

R = The filter is reusable for more than one shift.

S = The filter protects against solid particles.

L = The filter protects against liquid particles.

3.3 Warranty

ESAB verifies that each product is free from defects of material and workmanship at the time

of delivery and is functioning according to its intended use.

ESAB provides warranty on defects of material and workmanship according to legal

requirements. Consumables are exempt from this warranty.

ESAB provides warranty on the ESAB Blower unit for a period of 12 months from the date of

purchase against mechanical or electrical defects.

ESAB provides warranty on the ESAB battery for a period of 12 months from the date of

manufacture.

The warranty does not cover any damages or functional deficiencies resulting from

• overloading, abusing or non-intended use of the product

• collisions or accidents

• non compliance with indications stated in these operating instructions

• improper installation or assembly

• insufficient maintenance

• modifying the product from its original state

• chemical influences

• normal wear and tear during proper operation

ESAB assumes no liability other than for replacement or repair of faulty parts.

NOTE!

In the event of a claim, contact the retailer from which the unit was purchased.

ESAB PAPR System

- 9 -

© ESAB AB 2018

Page 10

4 OPERATION

4 OPERATION

4.1 Assembly

Attach the respiratory unit onto the belt. Pass the strap through loops and the buckle.

Fit the battery to the blower unit:

Make sure that the battery is the indicated way up.

Make sure that the battery is snapped into position.

4.1.1 Belt adjustment

Fasten the belt using the adjusters to achieve a comfortable and secure fit. Secure any

excess belt.

ESAB PAPR System

- 10 -

© ESAB AB 2018

Page 11

4 OPERATION

Loosen Tighten

4.1.2 Particle filter

Use only particle filters supplied by ESAB.

WARNING!

Using any other filter voids the warranty and/or poses a serious risk to the health

of the operator.

Make sure to use correct kind of filter to acheive suitable protection from the hazard. The

respiratory power unit is equipped with a high efficiency particle filter of class PRSL.

At warning alarm, replace or check the pre-filter. In very dusty areas this is necessary on a

frequent basis.

Check and replace the filters regularly, see "Air flow test" section. Do not try to clean and

reuse filter.

Make sure the new filter is within the expiry date, unused and not damaged. The maximum

lifecycle of a filter is 2 weeks or 90 hours, whichever is reached first. Do not exceed the

timeframe.

4.1.3 Removing the filter

Pull up the cover from the right side of the blower to open the filter cover.

NOTE!

Do not use any tools to open the filter cover.

To remove the filter, pull it out of the unit. Clean the unit from dust ensuring no dust enters

the air inlet.

ESAB PAPR System

- 11 -

© ESAB AB 2018

Page 12

4 OPERATION

4.1.4 Inserting a new filter

To insert a new filter, put the filter back into position. Gently push until it fits well.

Snap the cover properly into the blower to close the filter cover. Do not use the blower unit

without the cover fitted correctly.

4.1.5 Changing the pre-filter

The pre-filter is a sleeve, fitted over the main

filter. To remove or replace simply pull off the

old filter and stretch the new one into

position. Make sure that the main filter is

completely covered by the pre-filter.

4.1.6 Attaching the hose to the blower unit

Align the pins of the hose bayonet connector with the slots in the air outlet of the blower.

Push the bayonet connector into the blower until it reaches the bottom of the hole and then

twist it clockwise until the locating pins clip into place.

Fit the hose to the hoods using the same method.

4.1.7 Donning the welding helmet

Set the rake of the welding helmet. Adjust the

welding filter to suit, see the helmet

Instruction manual.

Lift the helmet to its upper position.

Place over the head. Adjust the headgear

ratchet wheel by pushing it in and twisting

until a satisfactory tightness is achieved.

Pull the elasticated chin guard downwards

and at the same time pull the helmet down.

Ensure the elasticated chin guard fits

comfortably under the chin.

The welding helmet is now ready for use.

ESAB PAPR System

- 12 -

© ESAB AB 2018

Page 13

4 OPERATION

4.2 Usage

Switch on the unit by pressing the ON/OFF

button on the control panel. The airflow can

be adjusted by pressing the + / - buttons from

180l/min up to 220l/min in six speeds.

The green LED diodes show the actual

airflow level.

To prevent accidental changes, press and

hold the buttons for 2 seconds for the action

to occur.

The unit ensures constant supply of air. The microprocessor regulates the motor speed. If the

microprocessor cannot keep the adjusted airflow, a beeping alarm sounds. Check the blower

unit at this point. If possible, the microprocessor will reduce the airflow to the next lower level.

If it fails, the alarm continues to sound. When the airflow falls below the minimum safe

operating level, a second audible alarm joins the first. Leave the working environment and

reach a safe area to change the filter, or recharge or replace the battery.

Normal function is achieved with a fully charged battery.

At startup, the battery LED will flash red on the control panel. If the LED stays red the battery

level is low and must be charged.

If the problem persists, see "Troubleshooting" section.

4.3 Inspection before use

• Check that all components are in good condition with no visible damage.

Check the air hose, seals and the face piece. Replace any damaged or worn out parts.

• Make sure there is a good connection between the air hose, the headpiece and the

blower unit.

• Check that there is sufficient air flow, see "Air flow test" section.

• Check that the air is supplied through the whole respiratory system from the blower to

the hood.

• Check that the battery has sufficient charge, see "Batteries" section.

• Ensure the alarms are working correctly, see "Alarm test" section.

4.3.1 Alarm test

Block the air outlet with the palm of a hand or other suitable means.

The motor will try to compensate by increasing the speed until the alarm sounds.

ESAB PAPR System

- 13 -

© ESAB AB 2018

Page 14

4 OPERATION

4.3.2 Air flow test

1. Disconnect the air hose from the

blower unit.

2. Insert the airflow indicator into the

air hose connector and keep the

hose in vertical position at about eye

level.

3. Switch the power unit on. The

airflow is sufficient only if the ball

indicator reaches the minimum flow

rate level. If the indicator is below

the minimum flow rate level,

recharge or replace the battery or

change the filter. If the problem

persists, see "Troubleshooting"

section.

4.3.3 Batteries

WARNING!

Use only ESAB original battery charger delivered with the product. Using any

other battery charger voids the warranty and poses a serious risk of fire or

explosion to the health of the operator.

NOTE!

Batteries are delivered partially charged. All batteries must be fully charged

before first use. The battery can be charged separately or in the blower unit.

Do not use the charger for any other purpose than for which it was manufactured.

Do not charge the battery in a potentially explosive atmosphere.

The battery charger is intended for indoor use and it must be protected from moisture.

The battery charger controls the charging automatically. When the battery has been charged,

the charger switches to the trickle charging regime and keeps the battery fully charged. The

charging time is 4 to 6 hours.

4.3.3.1 Charging the battery

1. Check that the voltage of the electrical power supply is correct.

2. Plug the charger into the socket, either direct into the blower when the battery is fitted

or into the battery directly.

3. Connect the battery to the charger. The socket of the battery is positioned on the back

side. The charging state is indicated by a red LED.

4. After charging has been completed, the trickle charging regime is activated. The red

LED goes out and the green LED illuminates during trickle charging.

5. Disconnect the charger from the power supply. Do not leave the battery charger in

the power supply if not in use!

ESAB PAPR System

- 14 -

© ESAB AB 2018

Page 15

4 OPERATION

4.3.3.2 Replacing the battery

Remove the battery

Locate the battery catch. Pull back the battery catch and remove the battery by lifting it

upwards.

Insert the battery

Make sure the battery is facing the correct direction, see "Assembly" section. Slide it into the

blower until the battery catch engages.

Make sure that the battery catch is fully locked.

ESAB PAPR System

- 15 -

© ESAB AB 2018

Page 16

5 MAINTENANCE

5 MAINTENANCE

5.1 Cleaning

Clean the blower unit, filter housing and head unit regularly.

For single users, the units can be cleaned with a cloth moistened with lukewarm water and

soap.

For multiple users, disinfect when passed from one user to another.

Do not allow liquid to enter the workings of the blower unit or get on to the element of the

filter.

Allow the parts to air dry. Do not use solvents or abrasive cleaning agents. Do not dry the unit

using hot air or radiant heat.

The unit provides protection to the designed specification for 2 to 3 years, when maintained

in accordance with these instructions. Prior to each use check that the unit is free from

defects as cracks, split filters and hoses, cracked visors and helmet components.

5.2 Storage and transportation

Store or transport the blower and head units in the container in which they were provided, or

in similar container.

Protect it from direct sunlight, solvents and physical damage.

Store between 0-40°C and below 75%RH.

ESAB PAPR System

- 16 -

© ESAB AB 2018

Page 17

6 TROUBLESHOOTING

6 TROUBLESHOOTING

If there is a sudden change in air supply while using the system, check:

• the battery and its connector.

• that all parts of the air-supply system are assembled properly.

• that the charger is not faulty or malfunctioning (diodes off).

• if the filters are clogged and need to be replaced.

• that there is no hole in the air hose.

• that the hood seal is not damaged.

• that the working time after a full recharge of the battery has not decreased (if so,

replace the battery).

Fault Probable reason Recommendation

The blower unit does not work

at all.

Entirely depleted battery:

Check if the blower unit works

with another charged battery.

Faulty motor, circuit board or

Charge the battery. If the

problem persists, check the

battery.

Contact supplier.

connector.

Low airflow. Blocked air hose or airduct. Remove possible blockage.

Leakage. Check seals, connectors and

air hose. Make sure that air

cannot leak through holes or

tears.

Battery is not charged

enough.

Charge the battery. If the

problem persists, check the

battery.

Blocked filter or pre-filter. Change the pre-filter. If the

problem persists change the

main filter.

Short operating time. Clogged filter. Change filter.

Battery is not charged

properly.

Charge the battery. If the

problem persists, check the

battery.

Battery cannot be charged. Battery contact is damaged. Check the battery contact.

Charger is faulty. Contact supplier.

Battery cannot be charged

Battery is worn out. Install a new battery.

sufficiently.

ESAB PAPR System

- 17 -

© ESAB AB 2018

Page 18

CERTIFIED HELMETS

CERTIFIED HELMETS

Helmets certified together with the PAPR system:

A20

A30

SENTINEL A50™

Warrior™ Tech

F20

G30

G40

G50

ESAB PAPR System

- 18 -

© ESAB AB 2018

Page 19

ORDERING SPARE PARTS

ORDERING SPARE PARTS

CAUTION!

Repair and electrical work should be performed by an authorised ESAB service

technician. Use only ESAB original spare and wear parts.

The ESAB PAPR System is designed and manufactured in accordance with the

international and European standard EN12941:1998+A1:2003+A2:2008 as a TH2 / + P R

SL device offering an Assigned Protection Factor of 20 / 50 according to BS4275. Certified

by APAVE SUDEUROPE SAS Notified Body 0082. The ESAB PAPR System can provide

this level of protection when used with filters provided by the manufacturer marked ESAB

and EN12941:1998 TH2/3P R SL. Welding helmets are certified to EN 175B. This PPE

device complies with the following applicable EU standards: EN166B:2001 EN379:2003 +

A1:2009 EN175B. The ESAB PAPR System is manufactured under ISO 9001:2000 Quality

System. On completion of service or repair work, it is the responsibility of the person(s)

performing the work to ensure that the product still complies with the requirements of the

above standards.

Spare parts and wear parts can be ordered through your nearest ESAB dealer, see

esab.com. When ordering, please state product type, serial number, designation and spare

part number in accordance with the spare parts list. This facilitates dispatch and ensures

correct delivery.

ESAB PAPR System

- 19 -

© ESAB AB 2018

Page 20

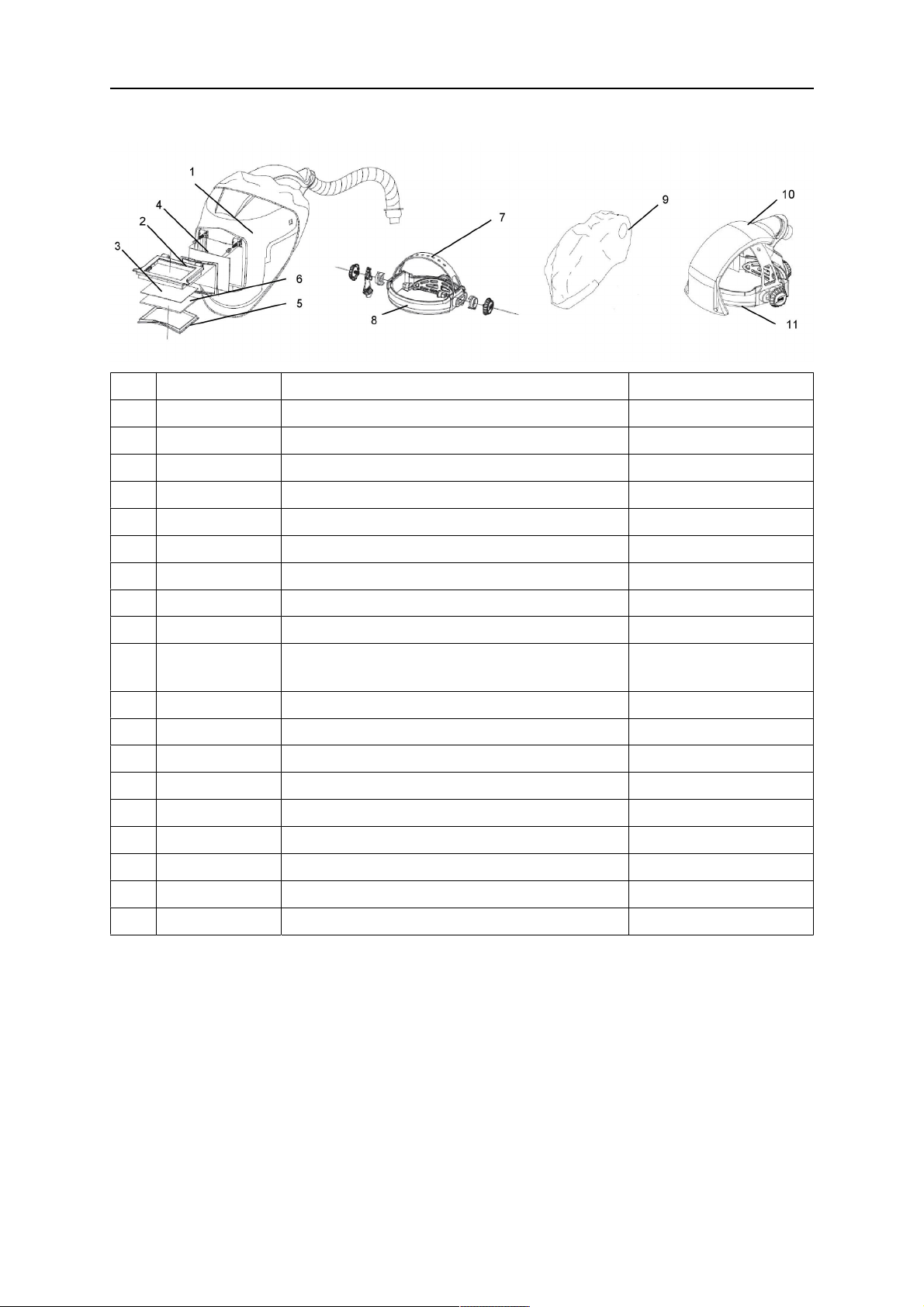

ORDERING NUMBERS AND SPARE PARTS LIST

ORDERING NUMBERS AND SPARE PARTS LIST

ESAB PAPR System

Item Ordering no. Denomination Notes

0700 002 303 Proban hose cover 1000 mm

0700 002 304 Proban hose cover 850 mm

0700 002 305 Air hose standard 850 mm

0700 002 306 Air hose long 1000 mm

0700 002 314 Flexi hose

0700 002 307 Comfort belt

0700 002 308 Motor unit

0700 002 309 P3 filter

0700 002 310 Pre-filter Pk 5

0700 002 311 Intelligent charger

0700 002 312 Battery

0700 002 313 Battery HD

ESAB PAPR System

- 20 -

© ESAB AB 2018

Page 21

ORDERING NUMBERS AND SPARE PARTS LIST

Sentinel A50 Air

Item Ordering no. Denomination Notes

1 0700 000 802 Front cover lens Clear

1 0700 000 803 Front cover lens Amber

2 0700 000 813 Sentinel A50 Air shell with air duct

3 0700 000 806 Auto-darkening filter Including 2 × CR2450

lithium battery

4 0700 000 807 2 × CR2450 lithium battery

5 0700 000 808 Inside cover lens 100 × 64 mm

6 0700 000 805 Headgear for A50 Air Including sweatbands

7 0700 000 810 Front sweat band

8 0700 000 812 Rear sweat band

9 0700 000 814 Face seal for A50 Air

Warrior Tech Air

Item Ordering no. Denomination Notes

2 0700 000 010 Front lens

4 0700 000 419 Warrior lens retainer

5 0700 000 420 Headgear and airduct

6 0700 000 421 Warrior face seal

ESAB PAPR System

- 21 -

© ESAB AB 2018

Page 22

ORDERING NUMBERS AND SPARE PARTS LIST

F20 and F20 Air

Item Ordering no. Denomination Notes

0700 000 426 F20, complete 60 × 110 mm

0700 000 427 F20, complete 90 × 110 mm

0700 000 428 F20 Air, complete 60 × 110 mm

0700 000 429 F20 Air, complete 90 × 110 mm

1 0700 000 509 Main shell F20

2 0700 000 510 Visor flip F20 60 × 110 mm

2 0700 000 511 Visor flip F20 90 × 110 mm

3 0160 307 001 Front cover lens F20 60 × 110 mm

3 0160 307 004 Front cover lens F20 90 × 110 mm

4 0160 307 004 Inside cover lens F20 90×110mm and

60×110mm

5 0700 000 256 Lens buckle 90 × 110 mm

5 0700 000 255 Lens buckle 60 × 110 mm

6 0760 031 633 Mineral glass 90 × 110 mm

6 0160 292 003 Mineral glass 60 × 110 mm

7 0700 000 415 Headgear

8 0700 000 414 Sweatband

9 0700 000 522 Head and face seal F20

10 0700 000 420 Headgear including airduct

11 0700 000 274 Sweatband for air

ESAB PAPR System

- 22 -

© ESAB AB 2018

Page 23

ORDERING NUMBERS AND SPARE PARTS LIST

G30 and G30 Air

Item Ordering no. Denomination Notes

0700 000 430 G30 DIN 10, complete

0700 000 431 G30 DIN 11, complete

0700 000 433 G30 Air DIN 10, complete

0700 000 434 G30 Air DIN 11, complete

1 0700 000 515 Main shell G30, G40 and G50

2 0700 000 415 Headgear

3 0700 000 414 Sweatband

4 0700 000 508 Flip up frame G30, Including screws

5 0700 000 501 Large inner visor Clear, G30, G40 and

G50

5 0700 000 502 Large inner visor G30 DIN 2

5 0700 000 503 Large inner visor G30 DIN 3

5 0700 000 504 Large inner visor G30 DIN 5

6 0700 000 505 Outer flip visor G30 DIN 5

6 0700 000 506 Outer flip visor G30 DIN 8

6 0700 000 507 Outer flip visor G30 DIN 10

7 0700 000 420 Headgear including air duct

8 0700 000 512 Head and face seal G30, G40 and G50

9 0700 000 274 Sweatband for air

ESAB PAPR System

- 23 -

© ESAB AB 2018

Page 24

ORDERING NUMBERS AND SPARE PARTS LIST

G40, G50, G40 Air and G50 Air

Item Ordering no. Denomination Notes

0700 000 436 G40, complete 60 × 110 mm

0700 000 437 G40, complete 90 × 110 mm

0700 000 438 G50 9-13, complete

0700 000 439 G40 Air, complete 60 × 110 mm

0700 000 440 G40 Air, complete 90 × 110 mm

0700 000 441 G50 Air 9-13, complete

1 0700 000 515 Main shell G30, G40 and G50

2 0700 000 501 Large inner visor Clear, G30, G40 and

G50

3 0700 000 517 Front cover lens G40 and G50

4 0160 292 003 Mineral glass G40 60 × 110 mm

4 0760 031 633 Mineral glass G40 90 × 110 mm

5 0700 000 518 Lens retainer G40 and G50

6 0700 000 523 ADF G50

7 0700 000 519 Cradle G40 90 × 110 mm and

G50

7 0700 000 520 Cradle G40 60 × 110 mm

8 0700 000 521 Gasket for mineral glass G40 60×110mm and

90×110mm

9 0700 000 415 Headgear

10 0700 000 420 Headgear including air duct

11 0700 000 951 Head and face seal G30, G40 and G50

0700 000 274 Sweatband for air

ESAB PAPR System

- 24 -

© ESAB AB 2018

Page 25

ORDERING NUMBERS AND SPARE PARTS LIST

ESAB PAPR System

- 25 -

© ESAB AB 2018

Page 26

ESAB AB, Lindholmsallén 9, Box 8004, 402 77 Gothenburg, Sweden, Phone +46 (0) 31 50 90 00

http://manuals.esab.com

For contact information visit esab.com

Loading...

Loading...