Page 1

7

1

PAB Device Profile

FIELDBUS

LAF/TAF and Aristo 1000

Page 2

7

2

1 GENERAL ............................................................................................................ 8

2 REFERENCES ..................................................................................................... 9

3 ABBREVIATIONS AND DEFINITIONS ................................................................ 9

4 REVISION HISTORY ............................................................................................ 9

5 FIELDBUS INTRODUCTION ............................................................................. 10

5.1 Profibus ......................................................................................................................... 10

5.1.1 Introduction to Profibus DP ..................................................................................... 10

5.1.2 Network overview ................................................................................................... 10

5.1.3 Technical features for Profibus DP / DPV1 ............................................................ 11

5.1.4 Mechanical Overview .............................................................................................. 12

5.1.5 Protocol and Supported Functions ........................................................................... 12

5.1.6 Physical Interface .................................................................................................... 12

5.1.7 Configuration and Indications ................................................................................. 12

5.1.8 Fieldbus Connectors ................................................................................................ 12

5.1.9 Configuration ........................................................................................................... 13

5.1.10 Indications ............................................................................................................ 14

5.2 Profinet .......................................................................................................................... 16

5.2.1 Introduction to PROFINET ..................................................................................... 16

5.2.2 Network overview ................................................................................................... 16

5.2.3 Technical features for PROFINET .......................................................................... 16

5.2.4 Mechanical Overview .............................................................................................. 16

5.2.5 Protocol and Supported Functions ........................................................................... 16

5.2.6 Physical Interface .................................................................................................... 16

5.2.7 Configuration and Indications ................................................................................. 17

5.2.8 Fieldbus Connectors ................................................................................................ 17

5.2.9 Configuration ........................................................................................................... 17

5.2.10 Indications ............................................................................................................ 18

6 USB MEMORY ................................................................................................... 19

6.1 Configuration File ........................................................................................................ 19

6.2 Web Interface ............................................................................................................... 20

6.3 Fieldbus information .................................................................................................... 20

6.4 Import and Export Directory (external USB) ........................................................... 21

7 BASIC SETUP ................................................................................................... 22

7.1 Motor Configuration .................................................................................................... 22

7.2 Unit of Length ............................................................................................................... 23

Page 3

7

3

8 FUNCTIONAL I/O DATA MAP ........................................................................... 24

8.1 In I/O from Controller to Welding Equipment ......................................................... 24

8.1.1 Mapping of the command bytes .............................................................................. 26

Command LSB .................................................................................................. 26

Command MSB ................................................................................................ 27

Command 2 LSB ............................................................................................... 27

Command 2 MSB ............................................................................................. 27

8.1.2 Mapping of the set values ........................................................................................ 28

Method and Regulation ..................................................................................... 29

Voltage .............................................................................................................. 29

Current .............................................................................................................. 29

AC Frequency ................................................................................................... 30

AC Balance ....................................................................................................... 30

AC Offset .......................................................................................................... 30

AC Phase Shift .................................................................................................. 30

Start Adjust ....................................................................................................... 31

Regulation Dynamics ........................................................................................ 31

Regulation Inductance ...................................................................................... 31

8.2 Out I/O from Welding Equipment to Controller ...................................................... 32

8.2.2 Mapping of the status bytes ..................................................................................... 34

Status LSB: ....................................................................................................... 34

Status MSB: ...................................................................................................... 35

Status 2 LSB: .................................................................................................... 35

Status 2 MSB: ................................................................................................... 36

8.2.3 Mapping of the output values .................................................................................. 37

Number of Errors/Events .................................................................................. 38

Measured Voltage ............................................................................................. 38

Measured Current .............................................................................................. 38

Measured Heat Input ......................................................................................... 38

Set Method and Regulation ............................................................................... 39

Set AC Frequency ............................................................................................. 39

Set AC Balance ................................................................................................. 40

Set Voltage ........................................................................................................ 40

Set Current ........................................................................................................ 40

Set AC Offset .................................................................................................... 40

Set AC Phase Shift ............................................................................................ 40

Error Record ...................................................................................................... 41

Heart Beat Value ............................................................................................... 41

Set Start Adjust ................................................................................................. 41

Set Regulation Dynamics .................................................................................. 41

Set Regulation Inductance ................................................................................ 42

9 ASYNCHRONOUS COMMUNICATION ............................................................. 43

9.1 Asynchronous Communication Sequences ................................................................ 43

9.1.1 Read Sequence ......................................................................................................... 43

9.1.2 Write Sequence ........................................................................................................ 43

9.1.3 Error Codes .............................................................................................................. 43

Page 4

7

4

Profibus ............................................................................................................. 44

Profinet .............................................................................................................. 44

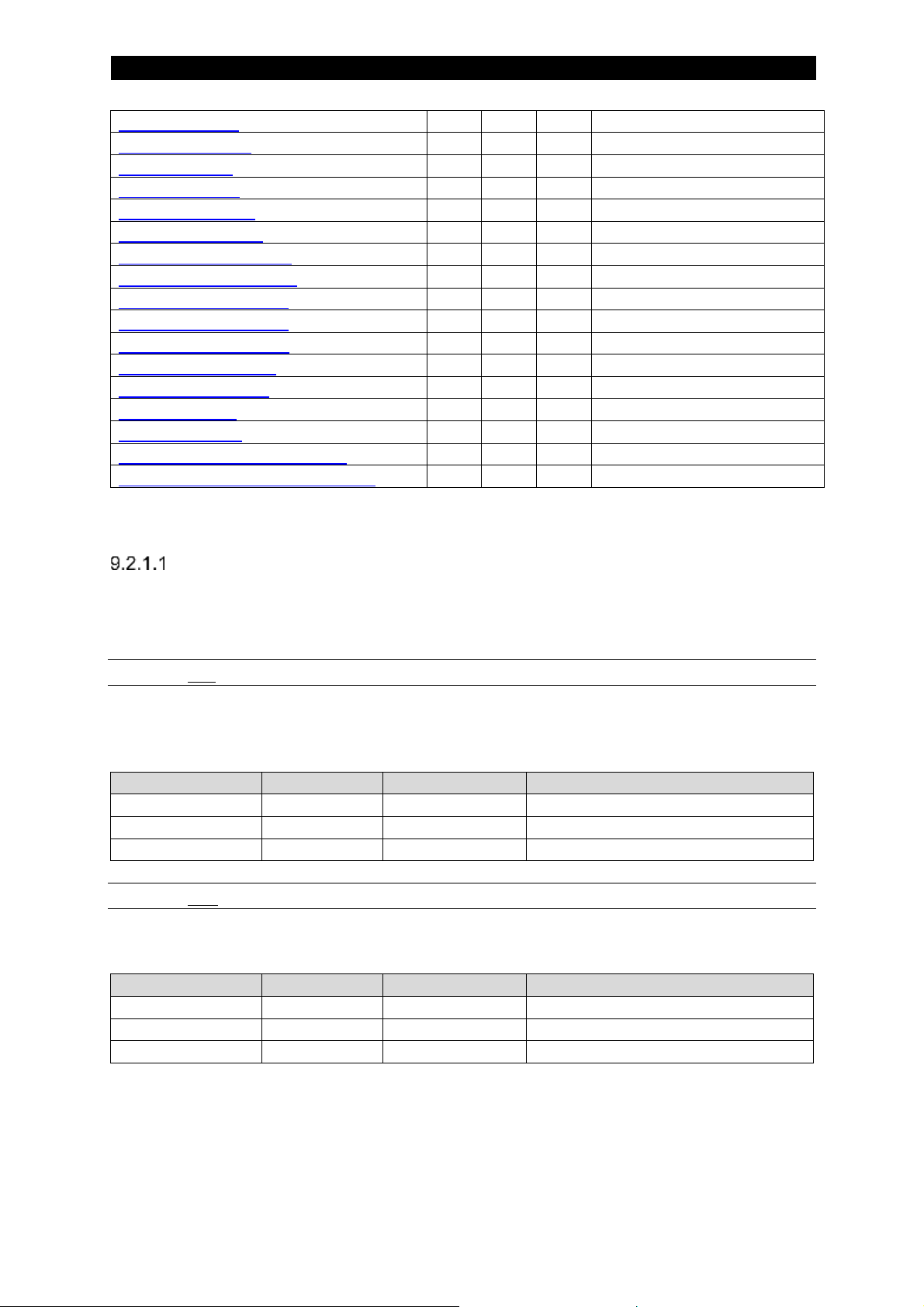

9.2 Functional Description of Asynchronous Communication ...................................... 45

9.2.1 Mapping of functions ............................................................................................... 46

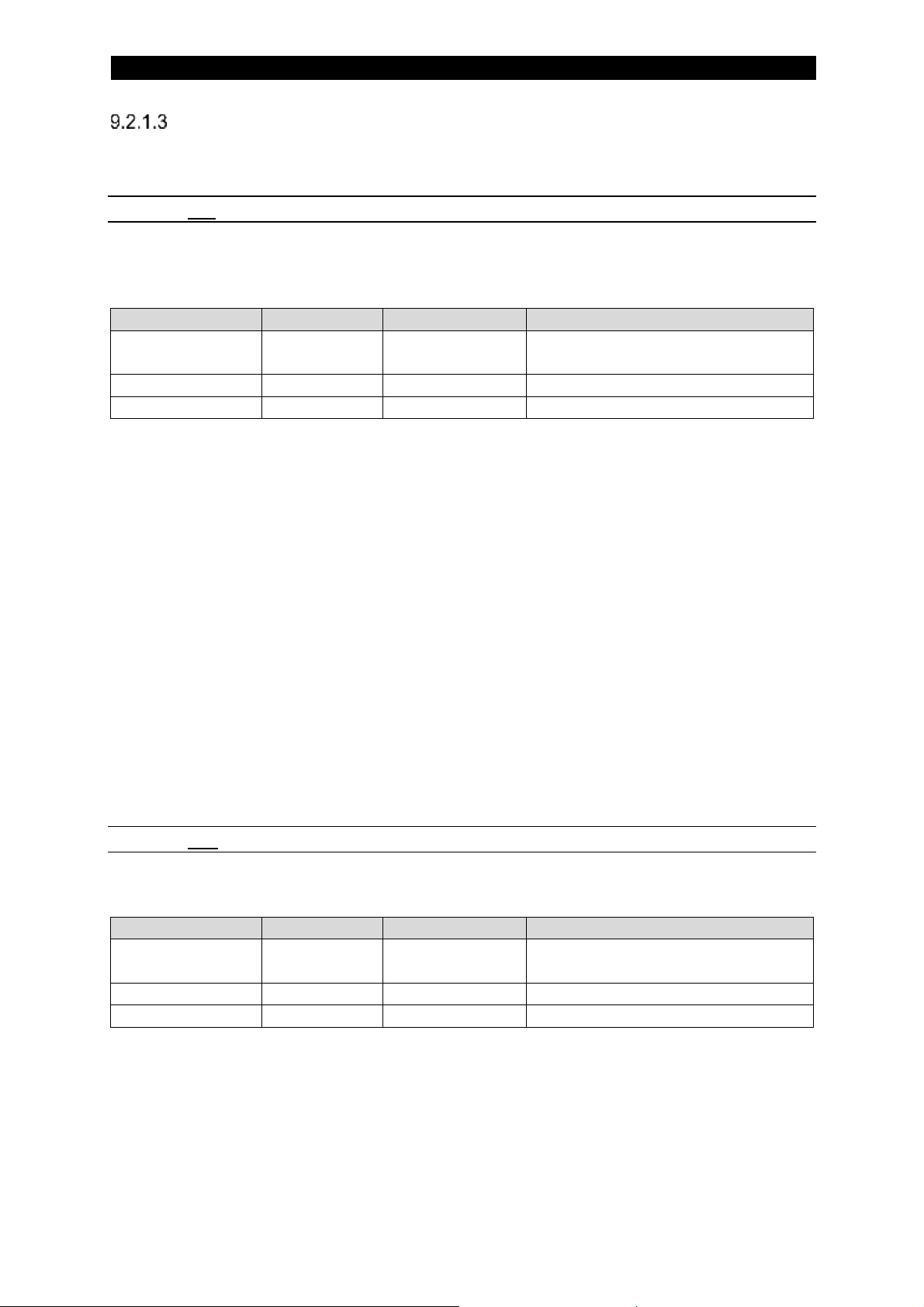

Weld Process ..................................................................................................... 47

Method .............................................................................................................. 48

Regulation Type ................................................................................................ 49

Wire Type ......................................................................................................... 50

Wire Dimension ................................................................................................ 50

Voltage .............................................................................................................. 51

Current .............................................................................................................. 51

Start Type .......................................................................................................... 52

Crater Fill Time ................................................................................................. 52

Burn Back Time ................................................................................................ 53

Regulation Dynamics ........................................................................................ 53

Regulation Inductance ...................................................................................... 54

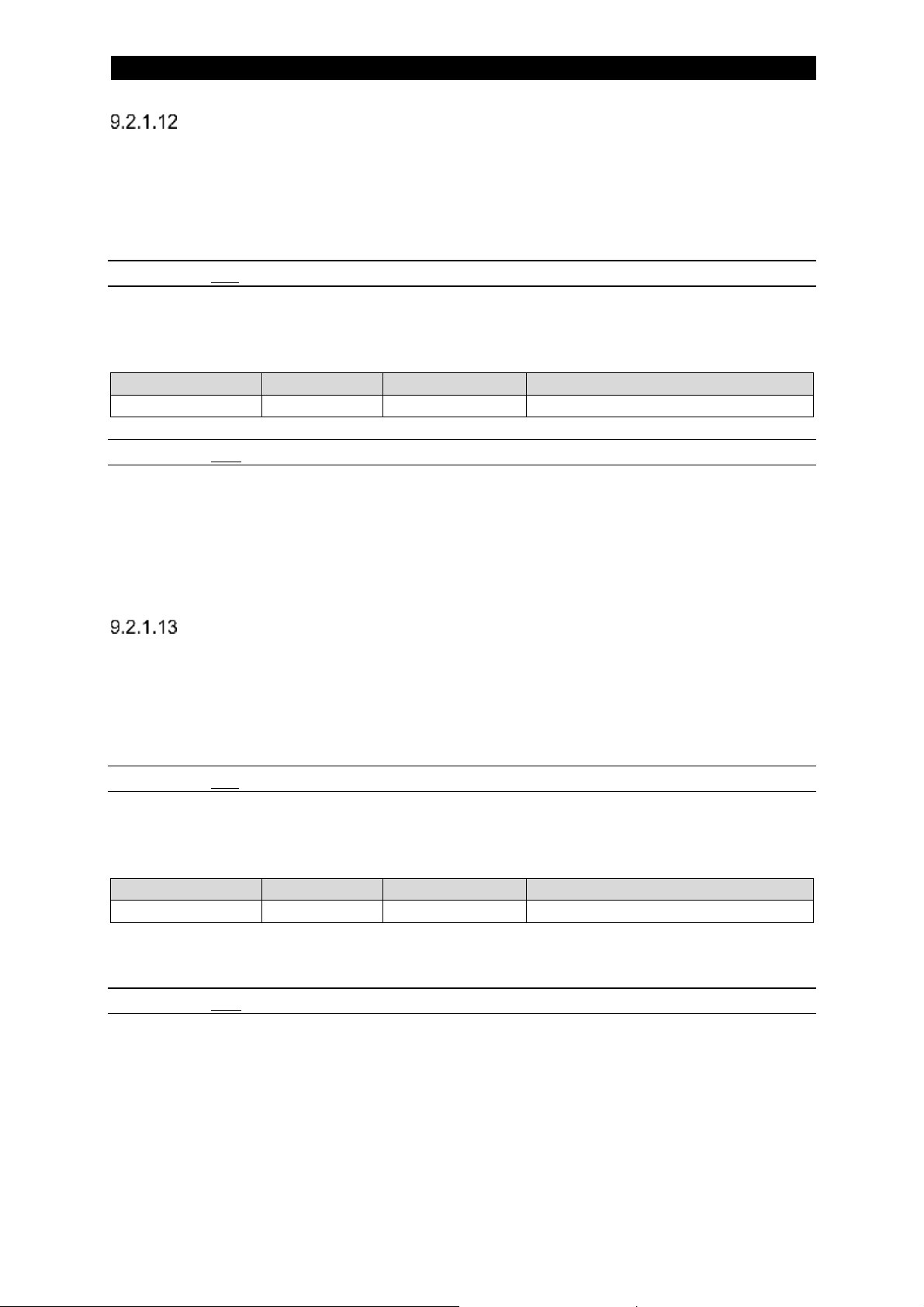

AC Frequency ................................................................................................... 54

AC Balance ....................................................................................................... 55

AC Offset .......................................................................................................... 55

AC Phase Shift .................................................................................................. 56

Start Adjust ....................................................................................................... 57

Cable Area ........................................................................................................ 57

Cable Length ..................................................................................................... 58

Get Wire Dimensions ........................................................................................ 58

Get Wire Types ................................................................................................. 60

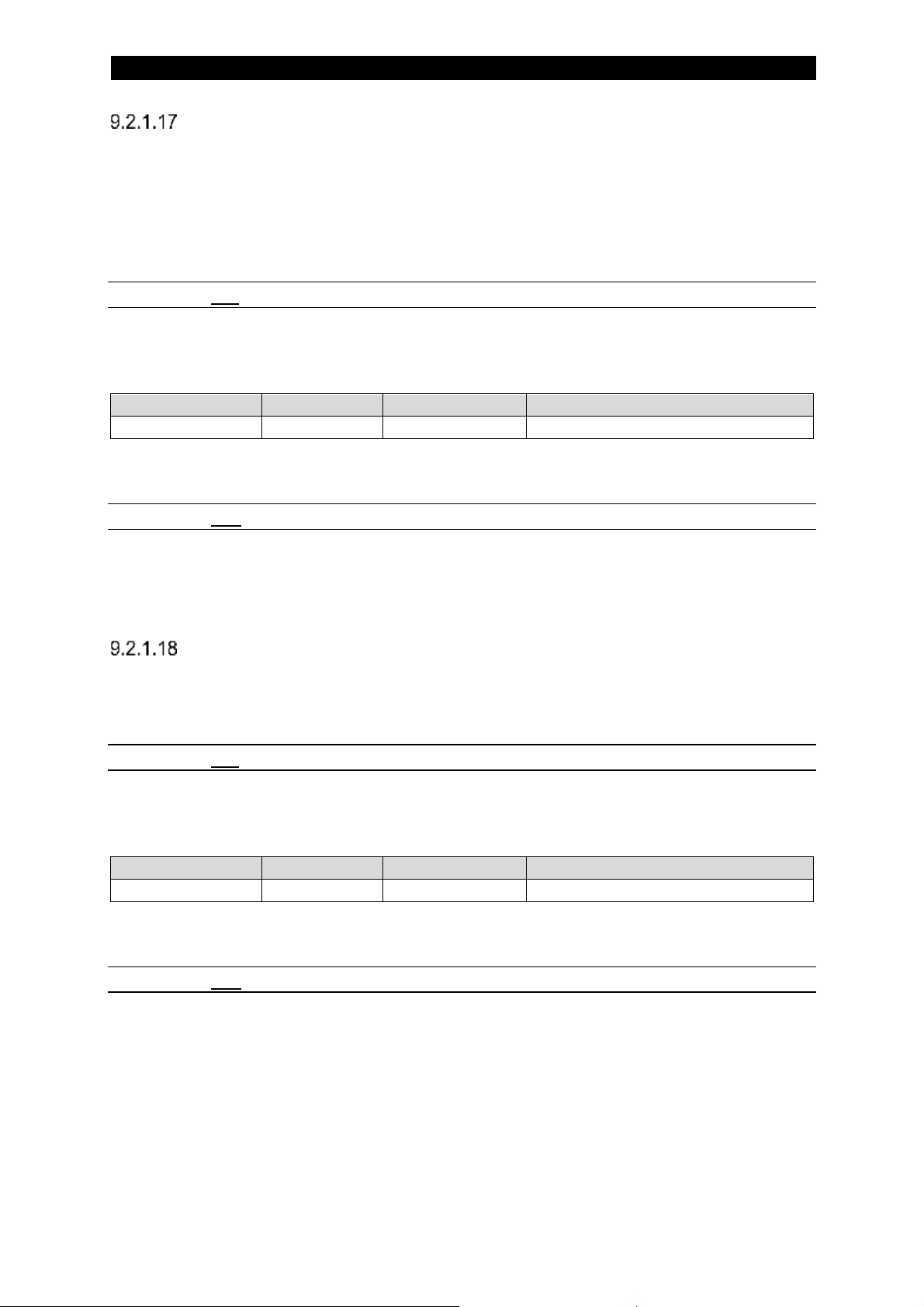

Measure Value Frequency ................................................................................ 60

Max OCV .......................................................................................................... 61

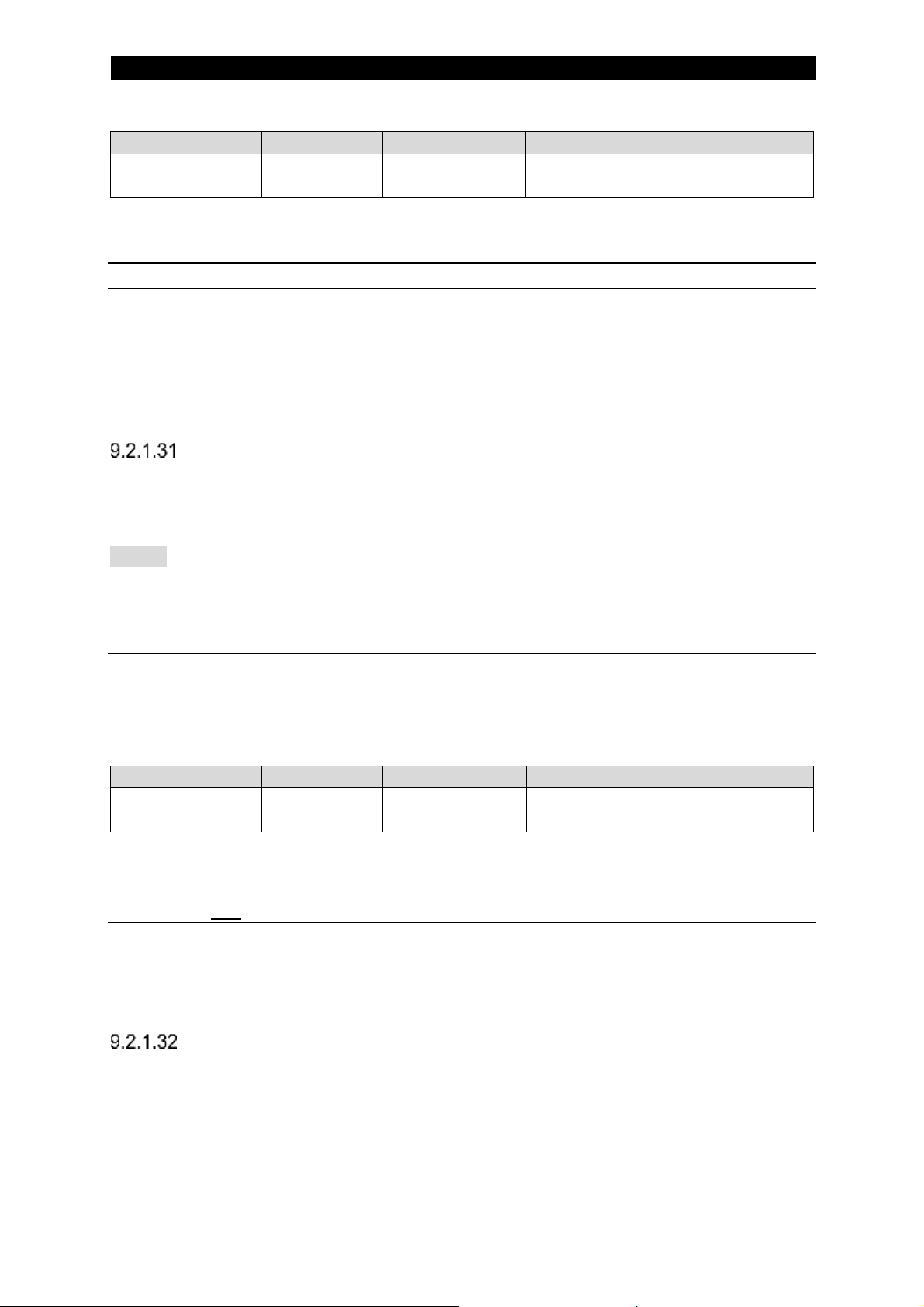

Parallel Power Sources ..................................................................................... 61

Number of units in parallel ............................................................................... 62

AC Sync Master ................................................................................................ 62

Couple ID .......................................................................................................... 63

Pair Parallel Couple .......................................................................................... 63

Measure Value Filter ......................................................................................... 64

Tandem Role ..................................................................................................... 64

Unit of Length ................................................................................................... 65

Language selection ............................................................................................ 65

Calendar Year ................................................................................................... 66

Calendar Month ................................................................................................ 67

Calendar Day .................................................................................................... 67

Calendar Hour ................................................................................................... 68

Calendar Minute ................................................................................................ 68

Calendar Second ............................................................................................... 68

Get Connected Units ......................................................................................... 69

Get Node Information ....................................................................................... 70

Get Welding System ......................................................................................... 70

Import Settings/Data ......................................................................................... 71

Export Settings/Data ......................................................................................... 71

Get Error Message ............................................................................................ 72

Error device type ............................................................................................... 72

Page 5

7

5

Get Error Text ................................................................................................... 73

CAN2 Node ID ................................................................................................. 74

Get Connected Units CAN2 .............................................................................. 74

Get Node Information CAN2 ............................................................................ 74

10 ADVANCED USE ............................................................................................ 76

10.1 Weld data handling ................................................................................................... 76

10.1.1 Input Area Switching ........................................................................................... 76

Input Weld Data Area ....................................................................................... 76

Output Weld Data Area..................................................................................... 77

10.1.2 Weld Data Set ....................................................................................................... 78

Input Weld Data Set Data ................................................................................. 78

Output Weld Data Set Data ............................................................................... 79

10.1.3 Asynchronous Weld Data Set Functions .............................................................. 79

Weld Data Set Recall ........................................................................................ 79

Weld Data Set Save .......................................................................................... 80

Weld Data Set Delete ........................................................................................ 80

10.2 Motor Handling ......................................................................................................... 81

10.2.1 Input Motor Data .................................................................................................. 81

Command LSB .................................................................................................. 81

Command MSB ................................................................................................ 82

Set values .......................................................................................................... 83

10.2.2 Output Motor Data ............................................................................................... 84

Status LSB ........................................................................................................ 84

Status MSB ....................................................................................................... 85

Set values .......................................................................................................... 86

Measure values .................................................................................................. 87

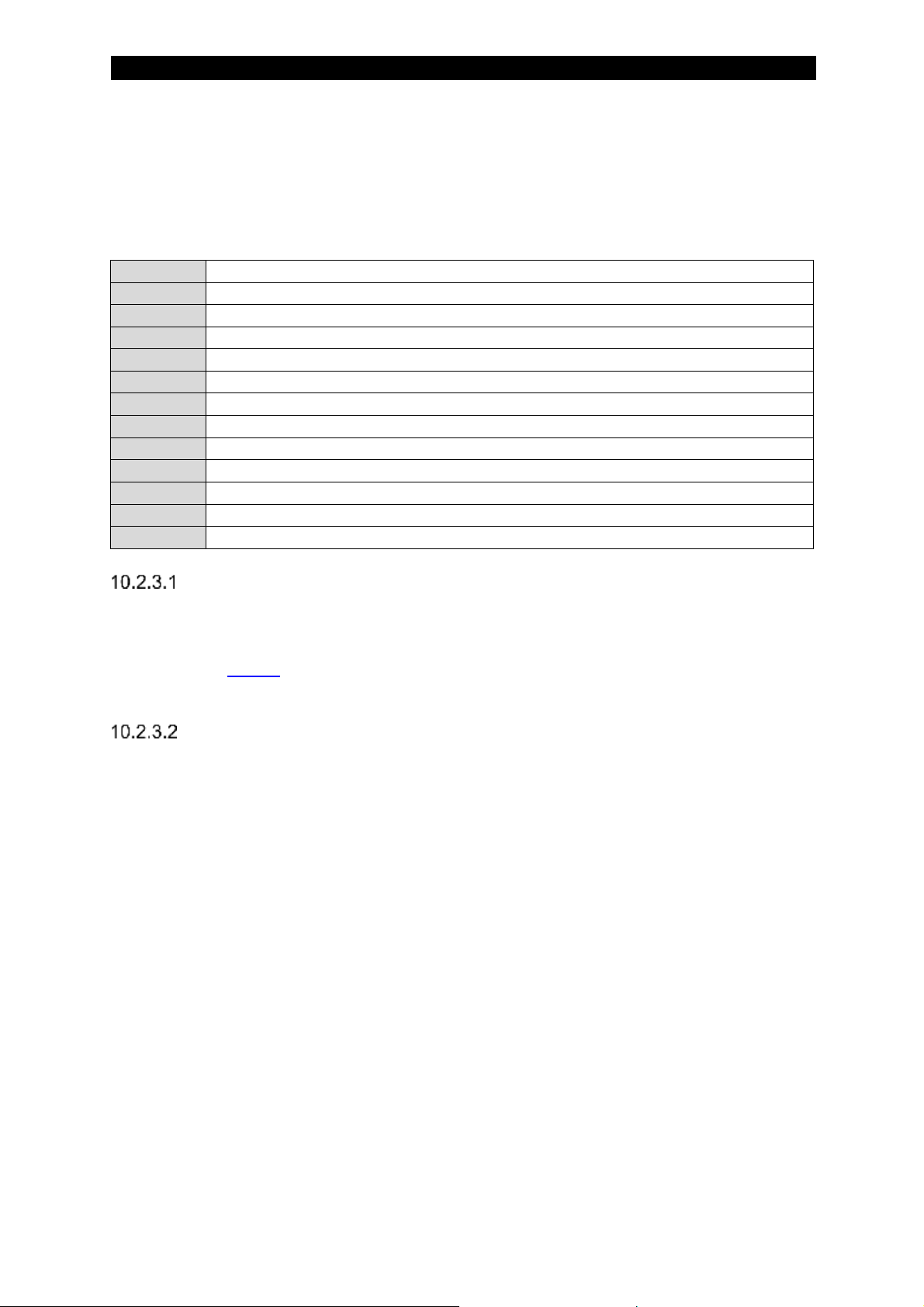

10.2.3 Mapping of external motor data ........................................................................... 88

Requested Travel Speed .................................................................................... 88

Requested Wire Speed ...................................................................................... 88

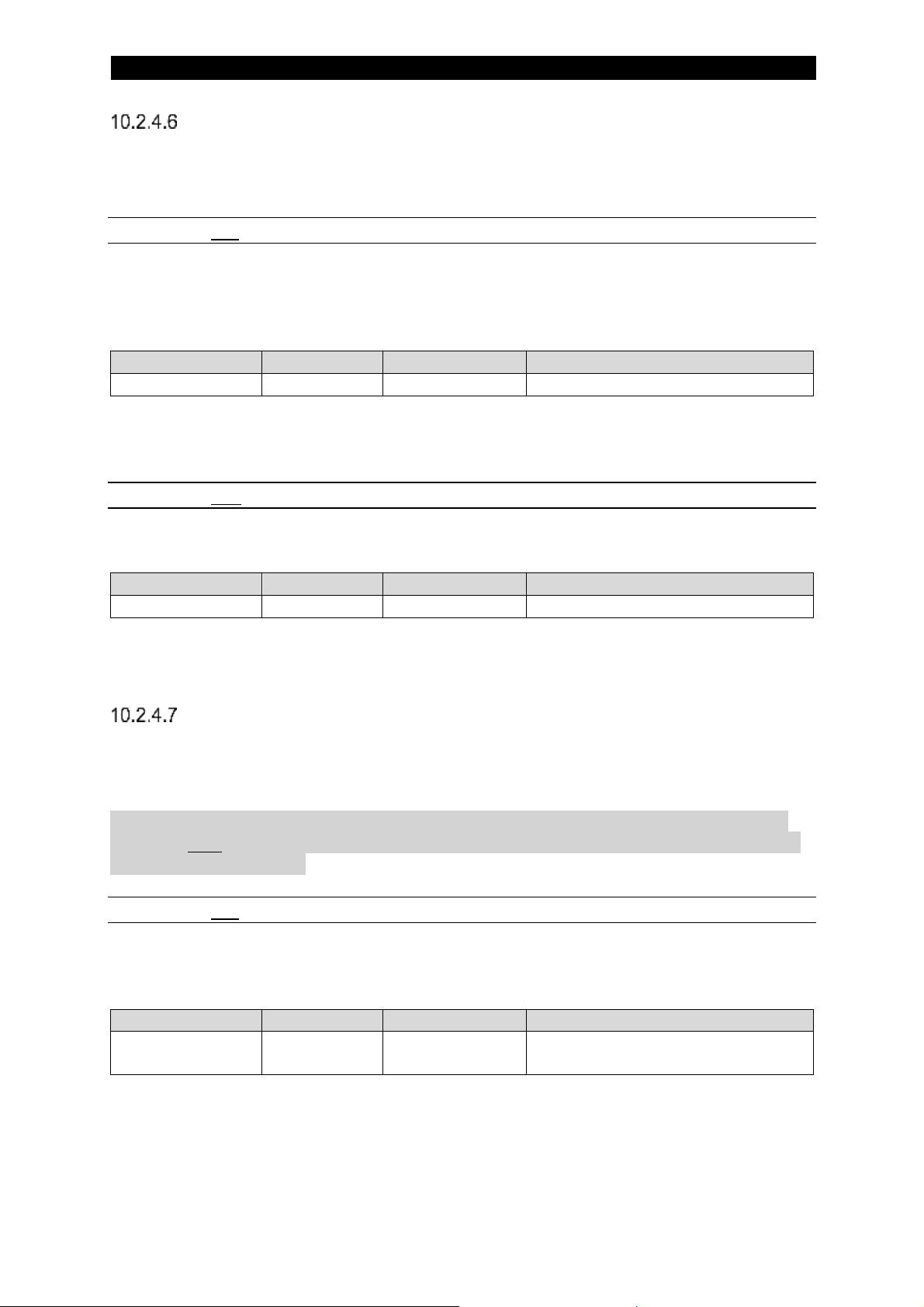

10.2.4 Asynchronous Motor Functions ........................................................................... 89

Wire Speed ........................................................................................................ 89

Travel Speed ..................................................................................................... 90

Travel Direction ................................................................................................ 90

Creep Start ........................................................................................................ 91

Creep Speed ...................................................................................................... 91

Max Travel Speed ............................................................................................. 92

Travel Control (Aristo 1000 only) .................................................................... 92

Travel Motor Drive ........................................................................................... 93

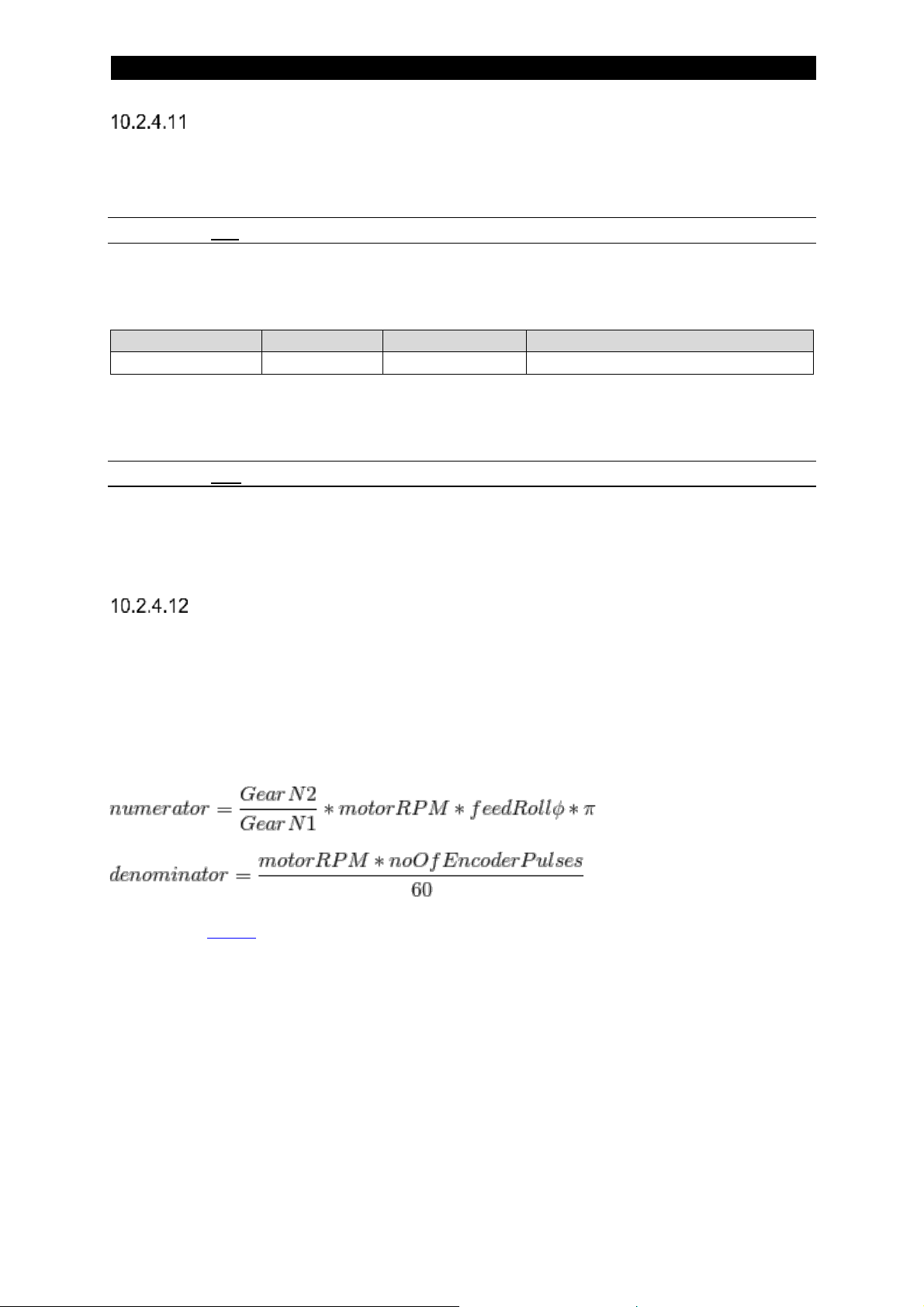

Wire Feed Motor Scale Factors ........................................................................ 93

Jog Wire Feed Low Speed .............................................................................. 94

Jog Wire Feed High Speed.............................................................................. 95

Travel Motor Scale Factors ............................................................................. 95

Jog Travel High Speed .................................................................................... 96

10.2.5 Scale Factors for ESAB motors ........................................................................... 97

Wire Feed Motors ............................................................................................. 97

Travel Motors .................................................................................................... 97

Page 6

7

6

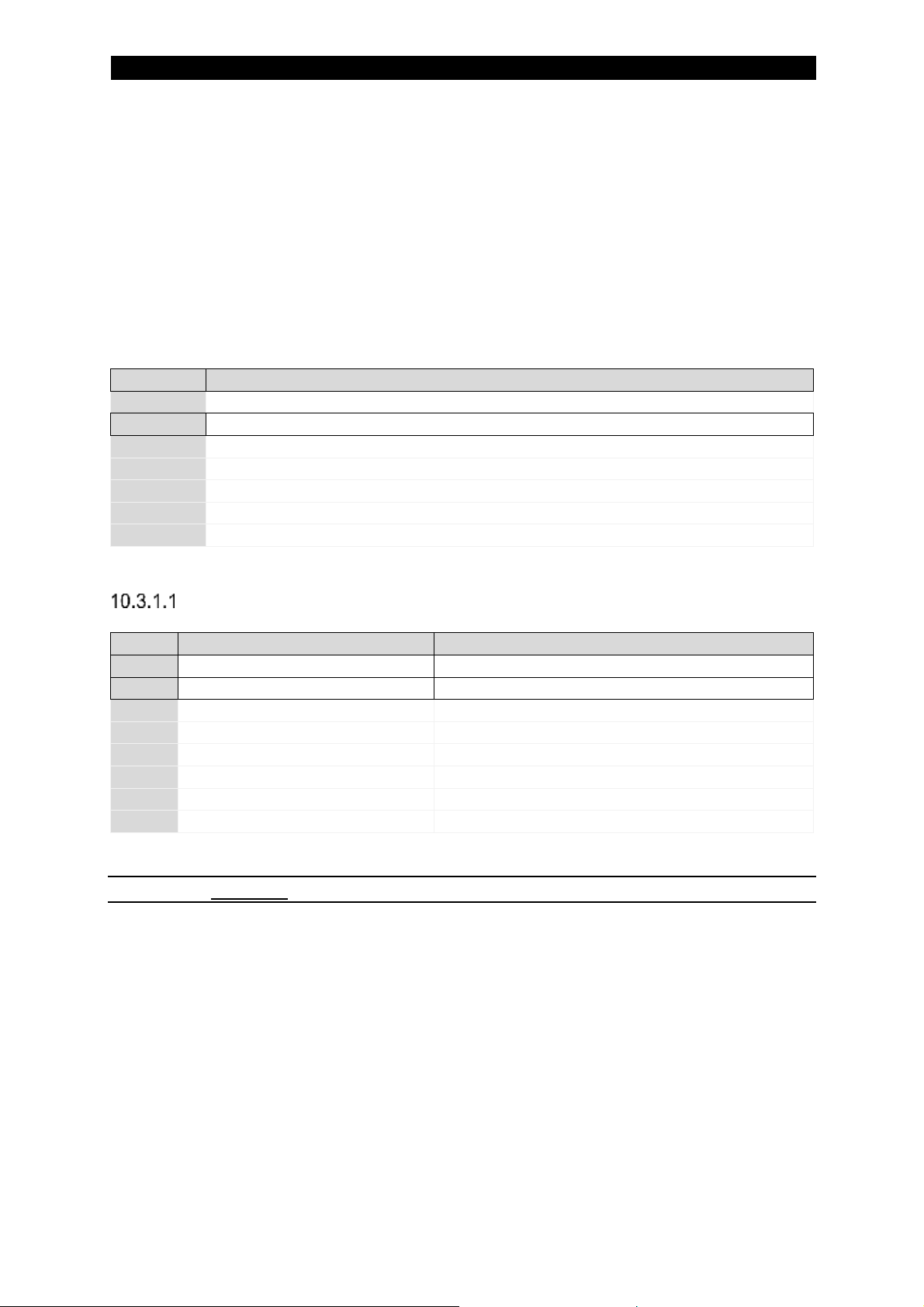

10.3 ICE Handling ............................................................................................................ 98

10.3.1 Input ICE data ...................................................................................................... 98

Command MSB ................................................................................................ 98

Set values .......................................................................................................... 99

10.3.2 Output ICE data .................................................................................................... 99

Status MSB ..................................................................................................... 100

Status 2 LSB ................................................................................................... 100

Status 2 MSB .................................................................................................. 101

Set values ........................................................................................................ 101

Measure values ................................................................................................ 101

10.3.3 Mapping of external ICE motor data .................................................................. 102

Requested ICE Wire Speed ............................................................................. 102

10.3.4 Asyncronous ICE Functions ............................................................................... 103

ICE Wire Speed Percentage ............................................................................ 103

ICE Active ...................................................................................................... 104

ICE Start Delay ............................................................................................... 104

ICE Wire Feed Motor Scale Factors ............................................................... 105

Jog ICE Wire Feed Low Speed ....................................................................... 106

Jog ICE Wire Feed High Speed ...................................................................... 106

ICE License remaining time ........................................................................... 107

11 TROUBLESHOOTING .................................................................................. 108

11.1 General ..................................................................................................................... 108

11.2 PAB ........................................................................................................................... 108

11.2.1 Fieldbus indications ............................................................................................ 108

11.2.2 Application program indications ........................................................................ 108

11.2.3 USB indications .................................................................................................. 110

11.2.4 Ethernet indications ............................................................................................ 111

11.3 Communication ....................................................................................................... 112

11.3.1 CAN bus ............................................................................................................. 112

11.3.2 Fieldbus .............................................................................................................. 113

11.4 PLC ........................................................................................................................... 115

11.4.1 Installation .......................................................................................................... 115

12 APPLICATION EXAMPLES .......................................................................... 116

12.1 Wire selection .......................................................................................................... 116

12.2 Motor Control ......................................................................................................... 117

12.2.1 FAA used for motor control ............................................................................... 117

12.2.2 External motor control ....................................................................................... 117

12.3 Single power source ................................................................................................ 118

12.4 Parallel power sources (single wire) ...................................................................... 119

12.5 Tandem power sources (two wires) ....................................................................... 120

Page 7

7

7

13 WEB INTERFACE ......................................................................................... 121

13.1 Weld Data Parameters ........................................................................................... 123

13.1.1 Main ................................................................................................................... 123

13.1.2 Start Data ............................................................................................................ 124

13.1.3 Stop Data ............................................................................................................ 125

13.1.4 Regulation Parameters ........................................................................................ 126

13.2 Configuration .......................................................................................................... 127

13.2.1 Main ................................................................................................................... 127

13.3 Machine Configuration .......................................................................................... 129

13.3.1 Wire Feed Axis ................................................................................................... 129

13.3.2 ICE Wire Feed Axis ........................................................................................... 130

13.3.3 Travel Axis ......................................................................................................... 131

13.3.4 Parallel PS .......................................................................................................... 132

13.3.5 Tandem ............................................................................................................... 133

13.4 Maintenance ............................................................................................................ 134

13.4.1 Unit Information ................................................................................................. 134

13.4.2 Event Handling ................................................................................................... 135

13.4.3 Export/Import Files ............................................................................................ 136

13.4.4 Calendar ............................................................................................................. 137

13.4.5 Memory .............................................................................................................. 138

13.4.6 Service Functions ............................................................................................... 139

14 ERRORS AND EVENTS ............................................................................... 140

Page 8

7

8

1 General

The PAB is a unit that acts as an interface between an external controller and ESAB

welding equipment. This document will describe the different ways to do this both

with set-up of the system and during welding.

In the tables you will sometimes see greyed-out areas, information about these can

be found in Advanced use.

In this document the terms cyclical data, asynchronous data and web interface will be

used and here the terms means the following:

• Cyclical data, this is the data that can be updated in the external controller’s

communication loop (hence cyclical). Typically this data is process oriented;

data that affects the weld directly (e.g. voltage, current etcetera)

• Asynchronous data, this is data that usually is changed when the welding is off

and can be for process settings or set-up of the system

• Web interface, this is typically set-up data, both for configuration of the system

but also for creation and handling of weld data sets

There exists a certain overlap between the different communication protocols. This is

necessary but could cause some confusion. Therefore it is important to understand

when to use the different protocols and to what end.

In general we can divide this into two scenarios: what you do during welding and

what you do to set up the system.

During welding it is possible to change individual parameters, like voltage and

current, to trim the welding process. This is typically done by the operator in ‘real

time’ and will give an instant feedback.

Still, you might want to change between two (or more) different weld cases, e.g.

switch from DC welding to AC welding on-the-fly. In that case you may want to

change more than a single parameter. This can be done by two different methods;

either use the double cyclical input area or use weld data sets. When either of these

two methods are used all changed parameters will take effect at the same time on a

switch command. Please note that when switching between weld data sets the input

area (from the PAB’s point of view) will not contain updated values. The reason for

this is that the input area is a read-only area for the PAB due to the master-slave

concept of the fieldbus and is the responsibility of the controlling unit, e.g. PLC. The

output area with the set values will, however, be updated.

NOTE: In previous versions of the Profinet/-bus profiles PAB tandem handling has

been an option. With this release the tandem handling has been removed and is left

for the integrator to implement in the controlling unit (e.g. PLC).This will simplify the

set-up of the system and give the integrator a better control of the sequence. The

same goes for start and stop phases.

Page 9

7

9

2 References

Number

Version

Document

Comment

1

2.00

A2, A6 PEK Control Panel

Instruction Manual, 0460 949 174 GB

2

1.00

DESCRIPTION OF EVENT

CODES GENERATED IN

STANDARD AUTOMATION UNITS

See USB stick, Documents folder

3 Abbreviations and Definitions

Abbreviation

Definition

PLC

Programmable Logic Controller, in this document used as the application

controller independent on the actual hardware involved.

TBD

To Be Defined

4 Revision History

Version

Date

Changes

1.0

2020-11-24

First Draft

1.1

2020-12-08

Corrected information about USB memory and FTP area

1.2

2021-02-26

Error in header information. Added handling of more than one slave

in parallel connection

1.3

2021-06-15

Mapping of ICE cyclical data in error in ICE section (10.3.1.2,

10.3.2.4, 10.3.2.5 and 10.3.3).

Start adjust example outside range (8.2.3.14).

Get wire types number of bits was wrong, now 32 bits (9.1.2.21).

1.4

2022-03-21

Corrected error in 9.2.1.44.2 (96 bits/12 bytes)

Page 10

7

10

5 Fieldbus Introduction

This document describes the features of the PAB fieldbus interface. Specific

information pertaining to the implementation solutions is documented in separate

paragraphs for the specific implementations.

5.1 Profibus

5.1.1 Introduction to Profibus DP

Profibus has an international user organisation called Profibus International, PI, and

local national organisations, PNO. Technical questions regarding the fieldbus should

be addressed to your local Profibus User Group in the instance. Address list is

available on the Profibus Internet Site; http://www.profibus.com.

For general help on Profibus, contact Profibus international on e-mail;

info@profibus.com. Profibus-DP is normally used in industrial automation, to transfer

fast data for motor controllers, MMI, I/O units and other industrial equipment.

5.1.2 Network overview

The media for the fieldbus is a shielded copper cable consisting of a twisted pair.

The baud rate for the bus is between 9.6 kbaud to max 12 Mbaud. The Profibus-DP

network is able to carry 126 nodes and the total amount of data for Profibus-DP is

244 Byte per module.

PLEASE NOTE: Node number 126 is only for commissioning purposes and should

not be used to exchange user data.

The figure below gives an overview of a Profibus-DP network.

Page 11

7

11

5.1.3 Technical features for Profibus DP / DPV1

The table below gives a summary of the technical features.

Summary of technical features of Profibus DP

Transmission technique:

PROFIBUS DIN 19245 Part 1

• EIA RS 485 twisted pair cable of fiber optic

• 9.6 kbit/s up to 12 Mbit/s, max distance 200m at

1.5 Mbit/s extendible with repeaters

Medium Access: hybrid medium access

protocol according to DIN 19245 Part 1

• Mono – Master or Multi – Master systems

supported

• Master and Slave Devices, max 126 stations

possible

Communications: Peer – to – Peer ( user

data transfer ) or Multicast (synchronisation)

• Cyclic Master – Slave transfer and acyclic

Master – Master data transfer

Operation Modes:

• Operate: cyclic transfer of input and output data

• Clear: inputs are read and outputs are cleared

• Stop: only Master – Master functions are

possible

Synchronisation: enables synchronisation of

the input and/or outputs of all DP-Slaves

• Sync – Mode: Outputs are synchronised

• Freeze – Mode: Inputs are synchronised

Functionality:

• Cyclic user data transfer between DP-Master(s)

and DP-Slaves

• Activation or deactivation of individual DPSlaves

• Checking of the configuration of the DP-Slaves

• Powerful diagnostics mechanisms, 3 hierarchical

levels of the diagnosis messages

• Synchronization of inputs and/or outputs

• Address assignments for the DP-Slaves over the

bus with Master Class 2

• Configuration of the DP-Master (DPM1) over the

bus

• Max 244 bytes input and output data per DPSlave, typical 32 bytes.

Security and protection mechanisms:

• All messages are transmitted with Hamming

Distance HD=4

• Watchdog timer at the DP-Slaves

• Access protection for the inputs/outputs at the

DP – Slaves

• Data transfer monitoring with configurable timer

DP–Master (DPM1)

Cabling and Installation:

• Connecting or disconnecting of stations without

affection of other stations

Page 12

7

12

Added for Profibus DPV1

Communication:

• Acyclic Master – Slave communication

5.1.4 Mechanical Overview

The PAB is a slave node that can be read and written to, from a Profibus-DP master.

The PAB will not initiate communication to other nodes, it will only respond to

incoming commands.

5.1.5 Protocol and Supported Functions

• Fieldbus type: PROFIBUS-DP EN 50 170 (IEC 61158)

• Protocol stack supplier: SIEMENS

• Extended functions supported: Diagnostics and User Parameter data

accessed via mailbox telegram.

• Auto baudrate detection supported. Baudrate range: 9.6 kbit – 12 Mbit.

5.1.6 Physical Interface

• Transmission media: Profibus bus line, type A or B specified in EN50170

• Topology: Master – Slave communication

• Fieldbus connectors: 9 pin female DSUB as standard

• Cable: Shielded copper cable, Twisted pair

• Isolation: The bus is galvanically separated from the other electronics with an

on board DC/DC converter. Bus signals (A-line and B-line) are isolated via

opto couplers.

• Profibus-DP communication ASIC: NP30 chip from HMS.

5.1.7 Configuration and Indications

• Address range: 1-99

• Cyclic I/O data size: up to 244 bytes, configurable

• Bus termination switch on board

• LED indicators: ON-line, OFF-line, Fieldbus related diagnostics

• I/O data transmission: The module supports cyclic I/O data transmission.

• Acyclic data transmission: The module supports acyclic data transmission.

5.1.8 Fieldbus Connectors

The Profibus-DP standard EN 50170 (IEC 61158) recommend the use of a 9 pin

female D-sub connector. Depending on the protection class and type of application,

other connector designs are also allowed.

Guideline: If the module should be used with larger data transfer rates than 1500

kbit/s, the D-sub connector is recommended to use.

Page 13

7

13

D-sub

Screw Terminal

Name

Housing

Shield

Connected to PE

1

Not connected

2 Not connected

3

B-line

Positive RxD/TxD according to RS-485

specification

4

RTS

Request To Send*

5

GND

Isolated GND from RS-485 side*

6

+5V Bus

Isolated +5V from RS-485 side*

7

Not connected

8

A-line

Negative RxD/TxD according to RS-485

specification

9

Not connected

* +5V Bus and GND are used for bus termination, please note that in this application

the bus termination is handled by a switch on the Anybus card. Some devices, like

optical transceivers (RS-485 to fiber optics) might require external power supply from

these pins. PTS is used in some equipment to determine the direction of

transmission. In this application only A-line, B-line and Shield are used.

5.1.9 Configuration

Baudrate

The baudrate on a Profibus-DP network is set during configuration of the master and

only one baudrate is possible in a Profibus-DP installation. The PAB has an auto

baudrate detection function and the user does not have to configure the baudrate on

the module.

Baudrates (in kbps) supported by the PAB are:

9.6

19.2

93.75

187.5

500

1500

3000

6000

12000

Termination

The end node in a Profibus-DP network has to be terminated to avoid reflections on

the bus line. The circuit board inside the PAB is equipped with a termination switch to

accomplish this in an easy way.

The PAB shall not be terminated using this switch, if termination is needed this has to

be handled by an external termination connector.

Page 14

7

14

PLEASE NOTE: Make sure that the switch is in the OFF position.

Node Address

The PAB is equipped with two rotary switches on the module inside, this enables

address settings from 1 – 99 in decimal format. Please note that the address is set by

the application program inside the PAB and that the switches therefore will not have

any impact on the address.

PLEASE NOTE: The node address is not read from the switches.

GSD file

Each device on a Profibus-DPV1 network is associated with a GSD file, containing all

necessary information about the device. This file is used by the network configuration

program during configuration of the network.

The latest version of this file can be received by contacting ESAB.

5.1.10 Indications

The circuit board is equipped with four LED’s mounted at the front and one LED on

the board, used for debugging purposes. The function of the LED’s are described in

the table and figure below.

LED no

State

Description

1

Green

DPV1 request currently being executed

Off

No DPV1 request is currently being executed (or no power)

2

Green

Bus online, data exchange possible

Green, flashing

Clear mode

Red

Application stopped

Off

Bus not online (or no power)

3

Red

Bus offline

Off

Bus not offline (or no power)

4

Off

No diagnostics present (or no power)

Red, flashing (1Hz)

Error in Configuration Data

Red, flashing (2Hz)

Error in Parameter Data

Red, flashing (4Hz)

Error in initialisation of the PROFIBUS communication ASIC

Page 15

7

15

LED

Designation

1

Acyclic Traffic

2

Fieldbus Online

3

Fieldbus Offline

4

Fieldbus Diagnostics

There is also one additional Bicolour Watchdog LED on the main circuit board inside

the PAB. This LED is for internal use only.

Page 16

7

16

5.2 Profinet

5.2.1 Introduction to PROFINET

Profibus has an international user organisation called Profibus & Profinet

International, PI, and local national organisations, PNO. Technical questions

regarding the fieldbus should be addressed to your local Profibus User Group in the

instance. Address list is available on the Profinet Internet Site;

http://www.profinet.com. For general help on Profinet, contact Profibus & Profinet

international on e-mail; info@profibus.com. Profinet is normally used in industrial

automation, to transfer fast data for motor controllers, MMI, I/O units and other

industrial equipment.

5.2.2 Network overview

PROFINET IO is very similar to Profibus but on Ethernet. While Profibus uses cyclic

communications to exchange data with Programmable Controllers at a maximum

speed of 12 Mbaud over a twisted copper pair (or fibre optics), PROFINET IO uses

cyclic data transfer to exchange data with Programmable Controllers over Ethernet.

As with Profibus, a Programmable Controller and a device must both have a prior

understanding of the data structure and meaning. In both systems data is organized

as slots containing modules with the total number of I/O points for a system the sum

of the I/O points for the individual modules.

5.2.3 Technical features for PROFINET

TBD

5.2.4 Mechanical Overview

The PAB is a slave node that can be read and written to, from a PROFINET master.

The PAB will not initiate communication to other nodes, it will only respond to

incoming commands.

5.2.5 Protocol and Supported Functions

• ROFINET IO- Up to 64 slots / 1 subslot

• Up to 1024 bytes cyclical I/O (512 input & 512 output)

• 2ms cycle time

5.2.6 Physical Interface

Mainly full-duplex with 100 MBit/s electrical (100BASE-TX) or optical (100BASE-FX)

according to IEEE 802.3 are recommended as device connections. Autocrossover is

mandatory for all connections so that the use of crossover cables can be avoided.

From IEEE 802.1Q the VLAN with priority tagging is used. All real-time data are thus

given the highest possible priority 6 and are therefore forwarded by a switch with a

minimum delay.

Page 17

7

17

The Profinet protocol can be recorded and displayed with any Ethernet analysis tool.

Wireshark also decodes the Profinet telegrams in the current version.

The Link Layer Discovery Protocol (LLDP) has been extended with additional

parameters, so that in addition to the detection of neighbours, the propagation time of

the signals on the connection lines can be communicated.

5.2.7 Configuration and Indications

• LED indicators: ON-line, OFF-line, Fieldbus related diagnostics

• I/O data transmission: The module supports cyclic I/O data transmission.

• Acyclic data transmission: The module supports acyclic data transmission.

5.2.8 Fieldbus Connectors

Ethernet, auto-crossover is supported.

5.2.9 Configuration

Node Address

User defined.

GSD file

Each device on a PROFINET network is associated with a GSD file, containing all

necessary information about the device. This file is used by the network configuration

program during configuration of the network.

The latest version of this file can be received by contacting ESAB.

Page 18

7

18

5.2.10 Indications

The circuit board is equipped with four LED’s mounted at the front and one LED on

the board, used for debugging purposes. The function of the LED’s are described in

the table and figure below.

LED no

State

Description

1

Link/Activity

Green

Link established

Green, flashing

Receiving/Transmitting data

Off

No link or power off

2

Communication

Status

Green

On line, RUN

- Connection with the IO Controller established

- IO Controller is in RUN state

Green, 1 flash

On line, STOP

- Connection with the IO Controller established

- IO Controller is in STOP state

Off

Off line

- No connection with IO Controller

3

Module Status

Green

Initialised, no error

Green, 1 flash

Diagnostic data available

Green, 2 flashes

Blink. Used by the engineering tool to identify the

Anybus module

Red, 1 flash

Configuration Error

- Too many modules/submodules

- I/O size derived from IO Controller configuration

is too large

- Configuration mismatch (no module/wrong

module)

Red, 3 flashes

No station name or no IP address assigned

Red, 4 flashes

Internal error

Off

No power or not initialised

4

-

-

There is also one additional Bicolour Watchdog LED on the main circuit board inside

the PAB. This LED is for internal use only.

Page 19

7

19

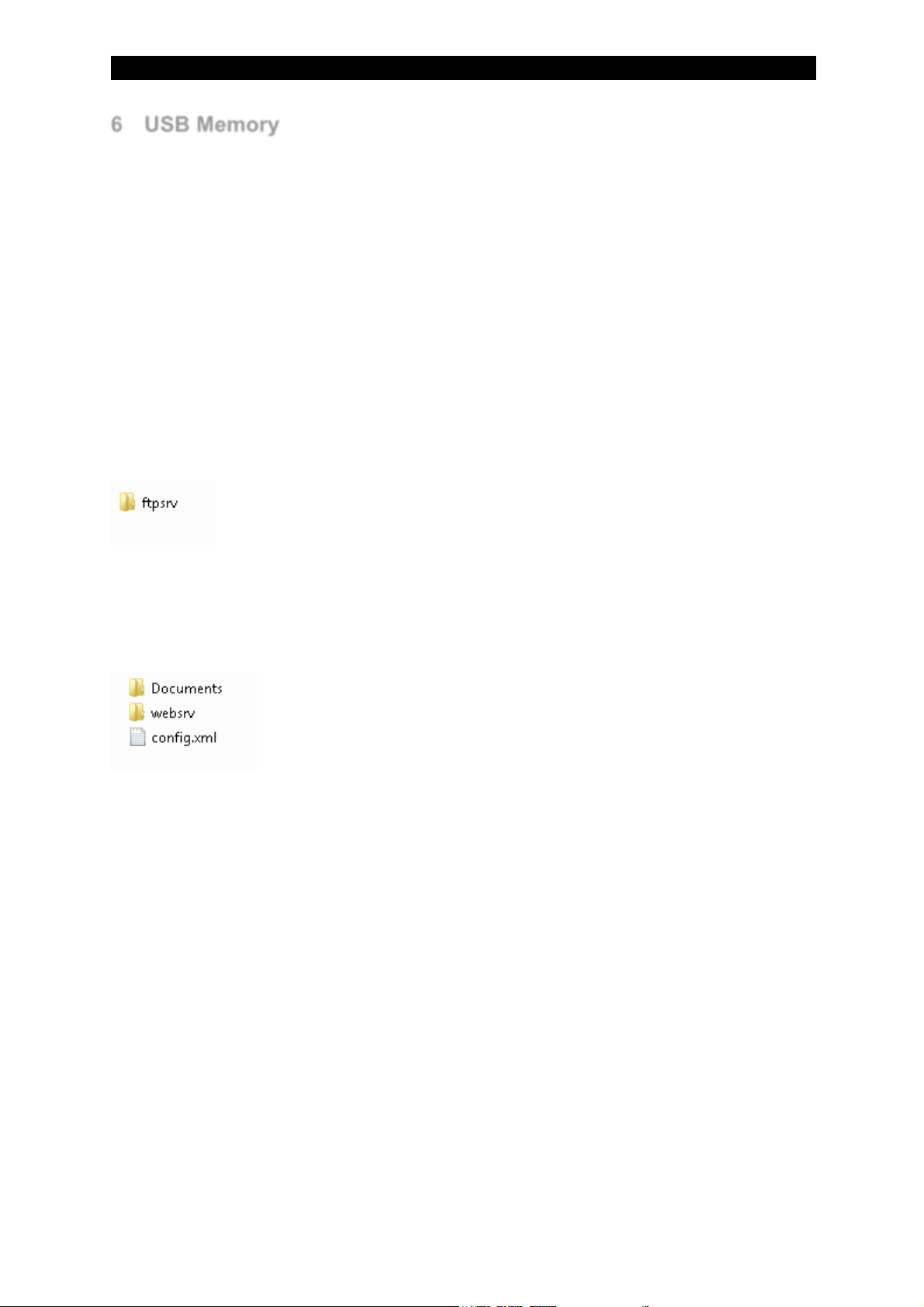

6 USB Memory

The PAB is delivered with a USB memory stick attached.

Please note that this USB memory stick has to be attached at start up and also

when using the web interface. Recommended is to keep it mounted at all times and

to read/write files through the FTP client. If necessary the USB memory can be

removed to allow for backing up of data or updating the web interface, just make sure

it is present during start up and regular usage.

There is also a possibility to add an external USB memory stick in addition to the one

mentioned above and this external memory is mirrored by the software to an FTP

area.

Exported data is put in a folder named ftpsrv on the external USB memory and if you

want to import files they also have to reside in that folder.

If you connect to the FTP area you will see the above directory. Connection to the

FTP area can be via a web browser or an FTP program.

There are several files and folders on the internal USB memory and they will be

described below.

6.1 Configuration File

This file is used for set-up of items necessary for the PAB prior to communication

with the controlling unit (e.g. PLC).

The file contains:

Page 20

7

20

NodeAddress is the PAB’s Profibus address (for Profinet users, the value does not

matter) and has to be set to different values in each PAB if more than one PAB is

present in the network.

EthernetAdress is the address where you can reach the web page and FTP server.

The connection for this is on the PAB motherboard (for Profinet users the Profinet

connector is on the small daughterboard).

To start the webserver you just need to connect with your computer to the PAB and

type in the Ethernet address specified in the config.xml file and you will get to the

home page. Please note that you have to set up your computer with a fixed IP

address (different from the one in the config.xml file) in the same range as the PAB;

in this case 192.168.0.X, where X cannot be “5”.

The same goes for the FTP server, just open a browser window and type in

ftp://192... (the above specified address) and you will get a file view of the FTP area.

You can also use a FTP client like Filezilla or similar to connect.

UseMotorCard if you have an ESAB FAA connected for motor control then set this

to “1”, as in the example. If you have your own motor control then set this to “0”. See

Motor Configuration for more information.

MeasureFrequency it is possible to set the output frequency of the measurement

values from the welding equipment to a value between 1 and 10 Hz. Default is 1 Hz.

6.2 Web Interface

The files used by the web interface are located in the “websrv” folder. Please see

Web Interface for more information on how to use this functionality.

6.3 Fieldbus information

This fieldbus profile as well as the GSD files for PLC adaptation are also found in the

directory “Documents” of the USB memory stick.

Page 21

7

21

6.4 Import and Export Directory (external USB)

The directory “ftpsrv” is the source and destination for files imported and exported to

and from the PAB. Please see Import Settings/Data and Export Settings/Data for

more information. If you want to import files and the directory is missing then please

just create a directory with the name “ftpsrv” in the root area of the external USB and

put the files to be imported there.

Page 22

7

22

7 Basic Setup

There are some settings which have to be set up in every application. This chapter

will try to list these settings and explain why they have to be defined.

7.1 Motor Configuration

For the specific application the integrator has to decide what motor drive to use.

Basically there are two options: ESAB FAA or external controller.

ESAB FAA is a two motor controller and is standard for our automation range.

Different motors can be chosen to cater for different needs (travel, wire). The FAA

can be used for wire control only if desired, see below.

External controller is an integrator supplied controller that is driven by the PLC. The

set values are still supplied by the PAB and should be forwarded to the external

controller. If this is not done for the wire control then the CA and CC modes will not

work, and if not used for travel control then the issues would be scratch start and

measure data for heat input. There could be other effects as well. The

recommendation, therefore, is to use the requested speed values output by the PAB.

For FAA usage the settings are:

• The “UseMotorCard” in the config.xml file has to be set to “1”

• Chose FAA or external drive for the travel movement (Travel Motor Drive):

o FAA: set this to “on”

o External: set this to “off”

For external controller the settings are:

• The “UseMotorCard” in the config.xml file has to be set to “0”

• External drive has to be chosen for the travel movement (Travel Motor Drive):

o set this to “off”

All motor settings can be found in the chapter Motor Handling. You will also find the

in- and output area information in said chapter, you will need this information

regardless of chosen motor drive.

Please also see Application Examples for additional information.

Page 23

7

23

7.2 Unit of Length

Note: for all parameters based on length (like speed) you need to make sure you

have the correct setting for what you want to use, cm or inch. If this setting is

incorrect with regards to the values you set then the system will not work as

intended. Make sure to check that you have this set up correctly.

Page 24

7

24

8 Functional I/O Data Map

The data in this section is generally process data. The communication is controlled

by the external bus master and is cyclical. The master writes to and reads from

memory areas in the slave. The speed and refresh rate on the bus is set by the

master.

8.1 In I/O from Controller to Welding Equipment

This data area is 64 byte long.

The input area is divided into two 28 byte long sub areas and one common area. This

division is used with one area being the active area and the other one being the

passive area. Which area that is active and passive is selected via a switch in the

command area. Please note that the common area is not included in the switch and

will remain active for both input areas.

The status information in the output area will show which area is active and which is

passive. Any data updated in the passive area will just be stored and no action will be

taken at that moment. When the areas are switched all data in the previously passive

area will be engaged at the same moment thus minimizing the effect of the transition.

Please see Input Area Switching for more information.

Common Input Area

Byte

Function

0

Command LSB

1

Command MSB

2

Command 2 LSB

3

Command 2 MSB

4

Weld Data Set

5 - 6 - 7 -

Input Area #1

8

Method and Regulation LSB

9

Method and Regulation MSB

10

Voltage LSB

11

Voltage MSB

12

Wire Speed LSB

13

Wire Speed MSB

14

Current LSB

15

Current MSB

16

Travel Speed LSB

17

Travel Speed MSB

Page 25

7

25

18

AC Frequency LSB

19

AC Frequency MSB

20

AC Balance LSB

21

AC Balance MSB

22

AC Offset LSB

23

AC Offset MSB

24

AC Phase Shift LSB

25

AC Phase Shift MSB

26

Start Adjust LSB

27

Start Adjust MSB

28

Regulation Dynamics LSB

29

Regulation Dynamics MSB

30

Regulation Inductance LSB

31

Regulation Inductance MSB

32 33 34

ICE wire speed percentage LSB

35

ICE wire speed percentage MSB

Input Area #2

36

Method and Regulation LSB

37

Method and Regulation MSB

38

Voltage LSB

39

Voltage MSB

40

Wire Speed LSB

41

Wire Speed MSB

42

Current LSB

43

Current MSB

44

Travel Speed LSB

45

Travel Speed MSB

46

AC Frequency LSB

47

AC Frequency MSB

48

AC Balance LSB

49

AC Balance MSB

50

AC Offset LSB

51

AC Offset MSB

52

AC Phase Shift LSB

53

AC Phase Shift MSB

54

Start Adjust LSB

55

Start Adjust MSB

56

Regulation Dynamics LSB

57

Regulation Dynamics MSB

58

Regulation Inductance LSB

59

Regulation Inductance MSB

60 61 62

ICE wire speed percentage LSB

63

ICE wire speed percentage MSB

Page 26

7

26

8.1.1 Mapping of the command bytes

The command area is used to control the process flow and settings that are directly

coupled to weld handling. The mapping of the command bytes are described below.

Byte

Function

0

Command LSB

1

Command MSB

2

Command 2 LSB

3

Command 2 MSB

4

Weld Data Set

… 63

-

Command LSB

Bit

Function

Comment

0

Weld On

1 Quick Stop

2 -

Not in use

3 - Not in use

4

Jog M1 +

Wire Motor

5

Jog M1 -

6 Jog M2 +

Travel Motor

7

Jog M2 -

8.1.1.1.1 Weld On

Weld On starts the weld when set to one (‘1’). If the weld doesn’t start, please check

error status.

To stop the weld set this bit to zero (‘0’).

8.1.1.1.2 Quick Stop

This bit, when set to one (‘1’), performs a Quick Stop if the Equipment is in a welding

procedure. Quick Stop means that the Welding Equipment will do a normal stop

procedure without a craterfill.

This function is used when a fast stop is required but it will handle burnback the

normal way to avoid that the wire get stuck in the weld pool. This bit will also block a

start command.

Page 27

7

27

Command MSB

Bit

Function

Comment

0

Jog M3 +

ICE Wire Motor

1

Jog M3 -

2 High Speed

For jogging

3 - Not in use

4 - Not in use

5 - Not in use

6 - Not in use

7 - Not in use

Command 2 LSB

Bit

Function

Comment

0 - Not in use

1 - Not in use

2 - Not in use

3 - Not in use

4 - Not in use

5 - Not in use

6 - Not in use

7 - Not in use

Command 2 MSB

Bit

Function

Comment

0 - Not in use

1 - Not in use

2

Input Area Switch

Toggles: 0->to area #1, 1->to area #2

3 - Not in use

4 - Not in use

5 - Not in use

6 - Not in use

7 - Not in use

Page 28

7

28

8.1.2 Mapping of the set values

If you need to change the parameters of the weld, especially during welding, the set

values area is used.

Please note that the set value area is divided into two separate areas. Since they are

identical except for the addresses only the first will be shown below.

Greyed-out areas below can be found in Advanced use.

8

Method and Regulation LSB

9

Method and Regulation MSB

10

Voltage LSB

11

Voltage MSB

12

Wire Speed LSB

13

Wire Speed MSB

14

Current LSB

15

Current MSB

16

Travel Speed LSB

17

Travel Speed MSB

18

AC Frequency LSB

19

AC Frequency MSB

20

AC Balance LSB

21

AC Balance MSB

22

AC Offset LSB

23

AC Offset MSB

24

AC Phase Shift LSB

25

AC Phase Shift MSB

26

Start Adjust LSB

27

Start Adjust MSB

28

Regulation Dynamics LSB

29

Regulation Dynamics MSB

30

Regulation Inductance LSB

31

Regulation Inductance MSB

32 33 34

ICE wire speed percentage LSB

35

ICE wire speed percentage MSB

Page 29

7

29

Method and Regulation

This will set the method and regulation type to use for the weld.

Argument

Type

Value

Comment

Composite

USHORT

Bit 0-7 is Method:

Value 0: DC+

Value 1: AC

Value 2: DC-

Bit 8-15 is Regulation Type:

Value 0: CA

Value 1: CW

Value 2: CC

8.1.2.1.1 CA

CA stands for Constant Amperage. In the CA mode the power source regulates both

the voltage and the current. The current is regulated with help of the wire drive. In

this mode the wire speed will vary to keep the current level.

8.1.2.1.2 CW

CW stands for Constant Wire. In the CW mode the power source regulates the

voltage. The wire speed is held constant and thus the current will be allowed to vary.

8.1.2.1.3 CC

CC stands for Constant Current. In the CC mode the power source regulates both

the voltage and the current. The voltage is regulated with help of the wire drive. In

this mode the wire speed will vary to keep the voltage level.

Aristo 1000 only.

Voltage

The voltage parameter is a 16 bit unsigned number with the resolution of 0.1V. To set

a voltage of 25V this parameter has to be set to 250.

Current

The current parameter is a 16 bit unsigned number with the resolution of 1A. To set a

current of 500A this parameter has to be set to 500.

Page 30

7

30

AC Frequency

AC Frequency is a 16 bit unsigned number with a resolution of 1Hz. To set an AC

Frequency of 50 Hz, this parameter has to be set to 50.

When running several AC power sources in tandem the frequency set for the leading

AC power source will be set also for the trailing AC power sources.

This setting is for Aristo 1000 only.

AC Balance

AC balance is a 16 bit unsigned number with a resolution of 1%. To set an AC

balance of 70%, this parameter has to be set to 70.

The percentage value is the positive period’s part of the total period.

This setting is for Aristo 1000 only.

AC Offset

AC offset is a 16 bit unsigned number with a resolution of 0.1V. The AC Offset can

be either positive or negative. When negative, two’s complement is used.

To set an offset voltage of -2.5V this argument has to be set to 65511 (i.e. 65536 –

25).

This setting is for Aristo 1000 only.

AC Phase Shift

When welding with more than one AC power source in tandem the possibility to

introduce phase shift between the leading AC power source and the trailing power

source(s) may prove beneficial. This setting will allow the user to set the phase shift

between the leading AC power source and this power source.

AC Phase Shift is a 16 bit unsigned number with a resolution of 1°. To set an AC

Phase Shift of 90° this argument has to be set to 90.

This setting is for Aristo 1000 only.

Page 31

7

31

Start Adjust

Start Adjust is a 16 bit unsigned number with a resolution of 1%. This value can be

updated at all times. Start adjust will adjust the start table result with the percentage

set. This can help getting better start result when there are variations in the

conditions that the power source does not have any information about.

To set a Start Adjust of 150% this argument has to be set to 150. Note that the

default value for this setting is 100% and that you can set this between 50 and 200%

Regulation Dynamics

Regulation Dynamics is a 16 bit unsigned number with the resolution of 1. To set the

regulation dynamics to 50 this parameter has to be set to 50.

Ranges for the settable spectrum when it comes to Regulation Dynamics differ

between Aristo 1000 and LAF/TAF systems. Please see reference [1] for more

information on this setting.

Regulation Inductance

Regulation Inductance is a 16 bit unsigned number with the resolution of 1. To set

the regulation inductance to 40 this parameter has to be set to 40.

This parameter is only valid for the Aristo 1000. Please see reference [1] for more

information on this setting.

Page 32

7

32

8.2 Out I/O from Welding Equipment to Controller

This area is 64 byte long. This area will contain both set values and measured data.

Byte

Function

0

Status LSB

1

Status MSB

2

Status 2 LSB

3

Status 2 MSB

4

Number of Errors/Events

5 - 6

Requested Travel Speed LSB**

7

Requested Travel Speed MSB

8

Measured Voltage LSB

9

Measured Voltage MSB

10

Measured Current LSB

11

Measured Current MSB

12

Measured Heat Input LSB

13

Measured Heat Input MSB

14

Measured Wire Speed LSB

15

Measured Wire Speed MSB

16

Measured Travel Speed LSB

17

Measured Travel Speed MSB

18

Set Method and Regulation LSB

19

Set Method and Regulation MSB

20

Set AC Frequency LSB

21

Set AC Frequency MSB

22

Set AC Balance LSB

23

Set AC Balance MSB

24

Set Voltage LSB

25

Set Voltage MSB

26

Set Current LSB

27

Set Current MSB

28

Set Wire Speed LSB

29

Set Wire Speed MSB

30

Set Travel Speed LSB

31

Set Travel Speed MSB

32

Set AC Offset LSB

33

Set AC Offset MSB

34

Set Weld Data Set

35 - 36

Set AC Phase Shift LSB

37

Set AC Phase Shift MSB

38

Requested Wire Speed LSB**

39

Requested Wire Speed MSB

40

Error/Event Code LSB*

41

Error/Event Code MSB

42

Error/Event Sub Code

43

Error/Event Node ID

Page 33

7

33

44

Error/Event Device Type

45

Error/Event Sub Unit

46

Heart Beat Value LSB

47

Heart Beat Value MSB

48

Set Start Adjust LSB

49

Set Start Adjust MSB

50

Set Regulation Dynamics LSB

51

Set Regulation Dynamics MSB

52

Set Regulation Inductance LSB

53

Set Regulation Inductance MSB

54 55 56 57 58

Measured ICE wire speed LSB

59

Measured ICE wire speed MSB

60

Set ICE wire speed percentage LSB

61

Set ICE wire speed percentage MSB

62

Requested ICE Wire Speed LSB**

63

Requested ICE Wire Speed MSB

* Latest error/event message received

** For external motor

Page 34

7

34

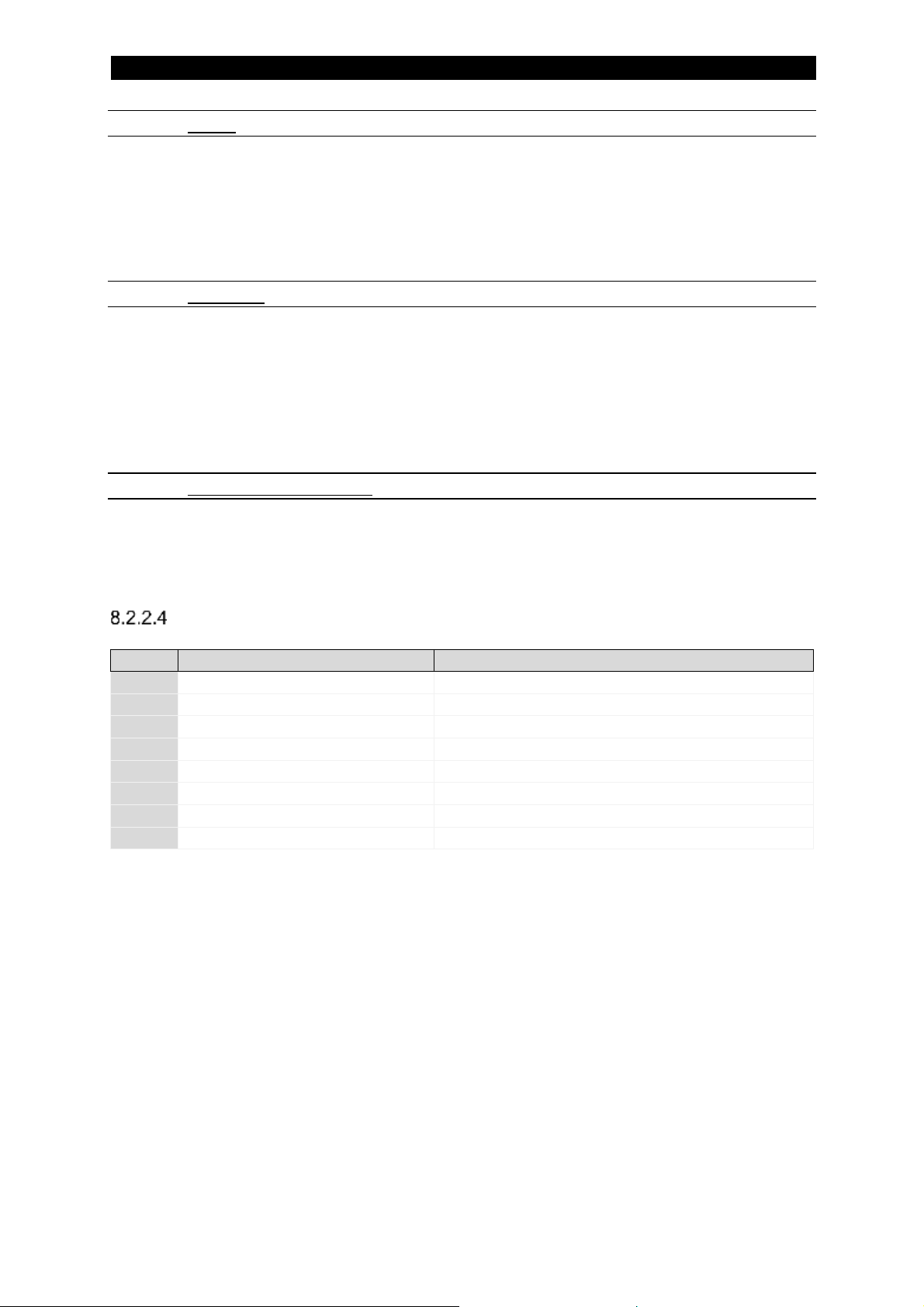

8.2.2 Mapping of the status bytes

The status area is used to present the process flow and settings that are directly

coupled to weld handling. The mapping of the status bytes are described below.

Byte

Function

0

Status LSB

1

Status MSB

2

Status 2 LSB

3

Status 2 MSB

4

Number of Errors/Events

… 63

-

Status LSB:

Bit

Function

Comment

0

Weld Started

1 Welding

2 Weld Finished

Only applicable in LAF/TAF

3

Error

Set when error is active

4

Jog M1 +

Wire Motor

5

Jog M1 -

6 Jog M2 +

Travel Motor

7

Jog M2 -

8.2.2.1.1 Weld Started

This bit indicates that the Weld On command has been received. In practice this bit

follows the Weld On bit.

8.2.2.1.2 Welding

As soon as the welding requirements are met, this bit is set. Usually this means that

the current is above a specific threshold for a specific amount of time. This status bit

is sometimes also named ‘Current flow’.

8.2.2.1.3 Weld Finished

This bit indicates that the weld is finished. It is set to zero (‘0’) when the contactor is

closed and set to one (‘1’) when the burn back time and crater fill has been

completed.

Only for LAF/TAF applications.

Page 35

7

35

8.2.2.1.4 Error

If an error is active, this bit is set to one (‘1’). Cleared when all errors that prohibit

start are cleared.

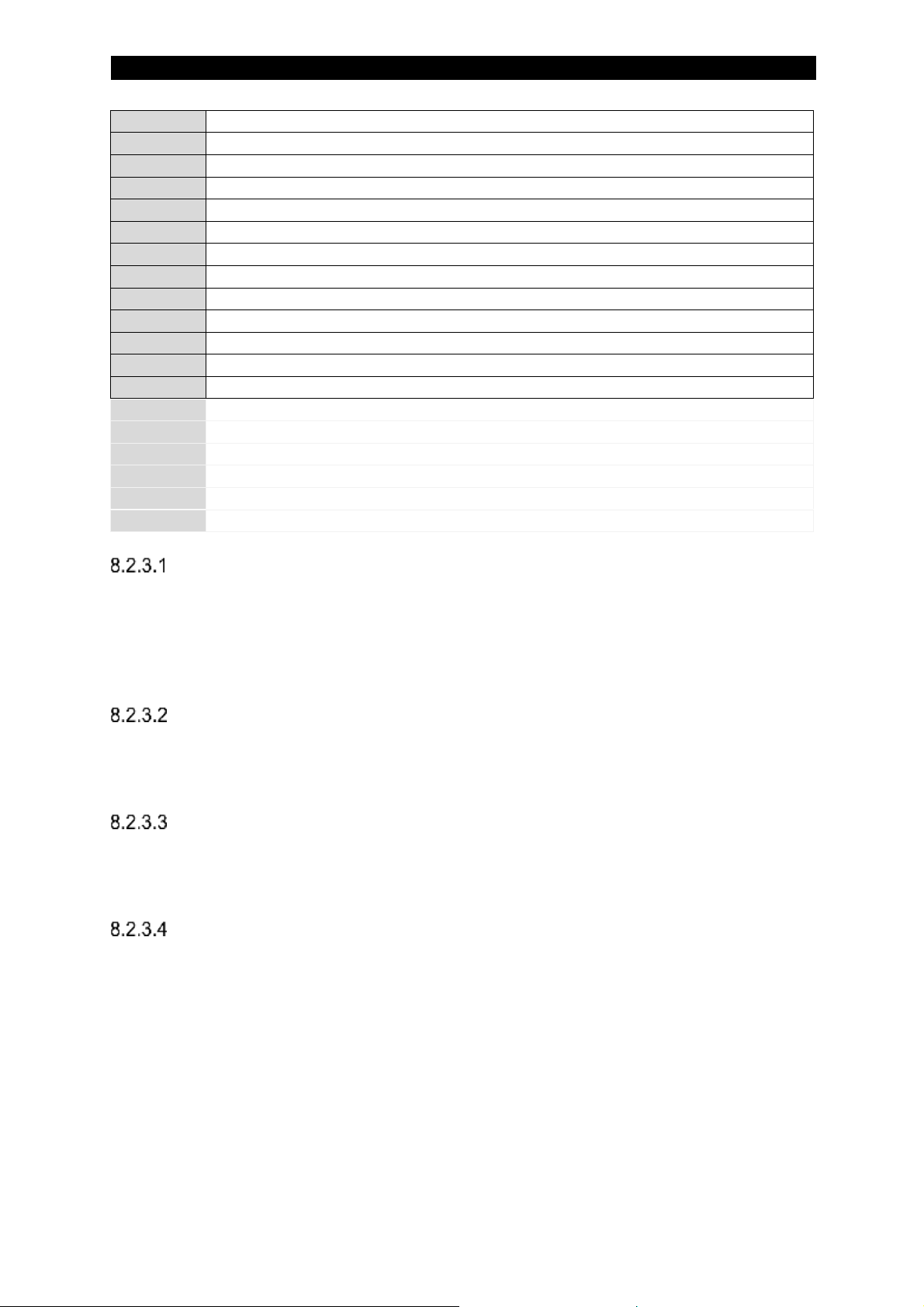

Status MSB:

Bit

Function

Comment

0

Jog M3 +

ICE Wire Motor

1

Jog M3 -

2 High Speed

For jogging

3

Ready to start

Set when possible to start

4

Travel Direction

0: square, 1: triangle

5

Travel Motor Drive

0: deactivated, 1: activated

6

Limit Switch Square

7 Limit Switch Triangle

8.2.2.2.1 Ready to start

When this bit is set to one (‘1’) it is possible to start a weld. If it is set to zero (‘0’) then

at least one requirement/condition to allow start is not fulfilled.

Status 2 LSB:

Bit

Function

Comment

0 - Not in use

1 - Not in use

2

Method

0: DC, 1: AC

3

ICE Active

0: off, 1: on

4

Event

Set when event information is available

5

File Busy

Set when import or export function active

6 - Not in use

7

Parallel Couple Status

0: -, 1: Coupled

8.2.2.3.1 Method

This flag show if the method chosen is AC or DC. The bit is set if AC is selected.

Only for Aristo 1000.

Page 36

7

36

8.2.2.3.2 Event

If an event has occurred, this bit is set to one (‘1’). Information about the event is

available the error/event information segment of the PAB output area.

This flag will be active for about five seconds and then reset.

8.2.2.3.3 File Busy

If this flag is set (“1”) then this indicates that an import or export function has been

activated and that the PAB is busy either saving or reading data. When this flag is active

it will not be possible to initiate another save or read of data.

Please note that this flag does not indicate success or failure of the file activity.

8.2.2.3.4 Parallel Couple Status

This flag show the status of the parallel coupling. If this flag is set then the power

source is set as parallel master and has found its parallel slave(s).

Status 2 MSB:

Bit

Function

Comment

0

ICE License activated

0: no, 1: yes

1

ICE License expires

0: no, 1: yes

2

Selected Input Area

‘0’ denotes area #1 and ‘1’ area #2

3 - Not in use

4 - Not in use

5 - Not in use

6 - Not in use

7 - Not in use

Page 37

7

37

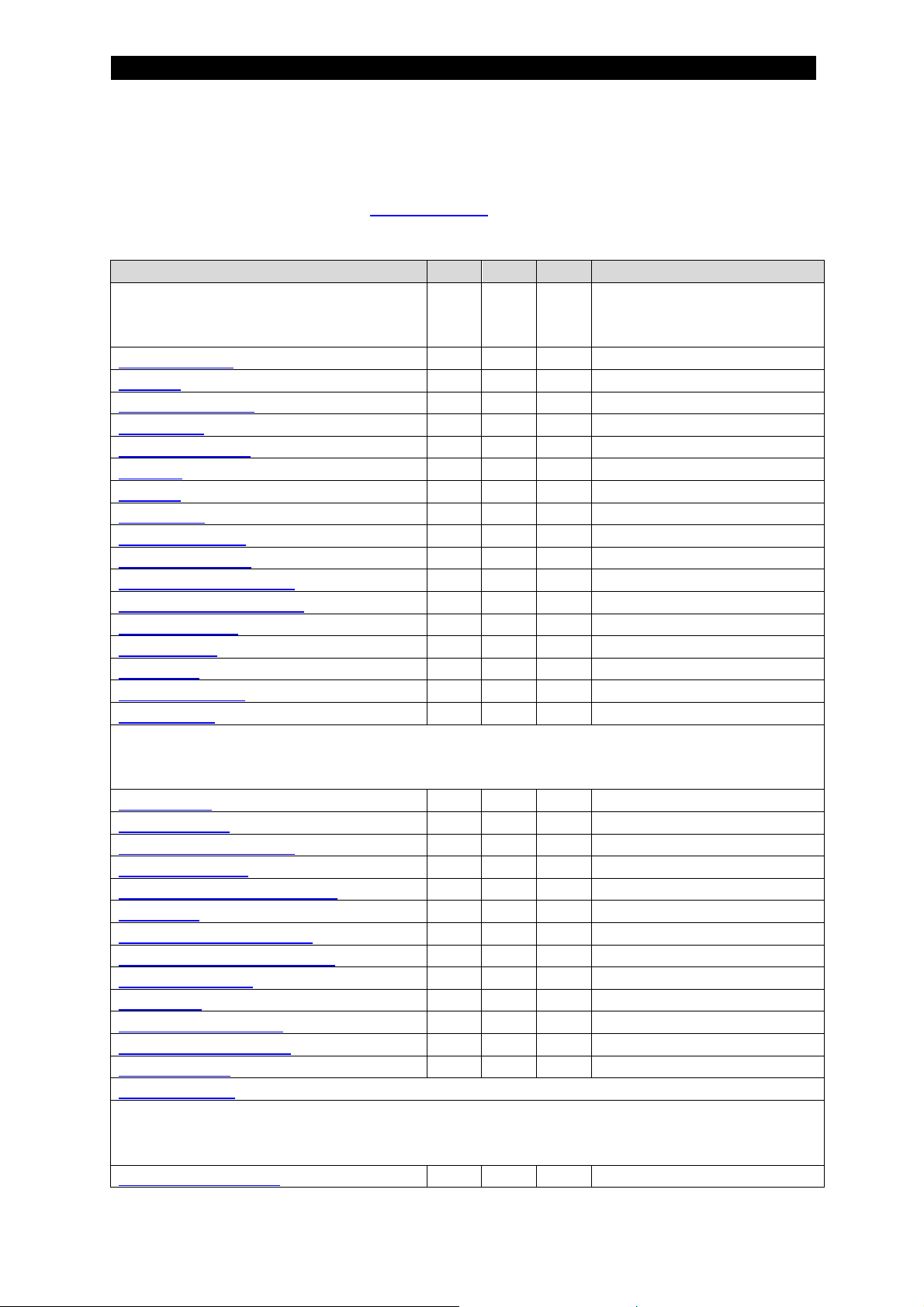

8.2.3 Mapping of the output values

This area is used by the PAB to communicate settings and measure values to the

controlling system.

Greyed-out areas below can be found in Advanced use.

4

Number of Errors/Events

5 - 6

Requested Travel Speed LSB

7

Requested Travel Speed MSB

8

Measured Voltage LSB

9

Measured Voltage MSB

10

Measured Current LSB

11

Measured Current MSB

12

Measured Heat Input LSB

13

Measured Heat Input MSB

14

Measured Wire Speed LSB

15

Measured Wire Speed MSB

16

Measured Travel Speed LSB

17

Measured Travel Speed MSB

18

Set Method and Regulation LSB

19

Set Method and Regulation MSB

20

Set AC Frequency LSB

21

Set AC Frequency MSB

22

Set AC Balance LSB

23

Set AC Balance MSB

24

Set Voltage LSB

25

Set Voltage MSB

26

Set Current LSB

27

Set Current MSB

28

Set Wire Speed LSB

29

Set Wire Speed MSB

30

Set Travel Speed LSB

31

Set Travel Speed MSB

32

Set AC Offset LSB

33

Set AC Offset MSB

34

Set Weld Data Set

35 - 36

Set AC Phase Shift LSB

37

Set AC Phase Shift MSB

38

Requested Wire Speed LSB

39

Requested Wire Speed MSB

40

Error/Event Code LSB

41

Error/Event Code MSB

42

Error/Event Sub Code

43

Error/Event Node ID

44

Error/Event Device Type

Page 38

7

38

45

Error/Event Sub Unit

46

Heart Beat Value LSB

47

Heart Beat Value MSB

48

Set Start Adjust LSB

49

Set Start Adjust MSB

50

Set Regulation Dynamics LSB

51

Set Regulation Dynamics MSB

52

Set Regulation Inductance LSB

53

Set Regulation Inductance MSB

54 55 56 57 58

Measured ICE wire speed LSB

59

Measured ICE wire speed MSB

60

Set ICE wire speed percentage LSB

61

Set ICE wire speed percentage MSB

62

Requested ICE Wire Speed LSB

63

Requested ICE Wire Speed MSB

Number of Errors/Events

This value represents the total number of errors/events detected. This is the same as

the number of the last post in the error/event log.

This is an eight (8) bit unsigned number.

Measured Voltage

This value is measured by the welding equipment. This is a 16 bit number with the

resolution of 0.1V. A presented value of 402 shall thus be interpreted as 40.2V.

Measured Current

This value is measured by the welding equipment. This is a 16 bit number with the

resolution of 1A. A presented value of 655 shall thus be interpreted as 655A.

Measured Heat Input

The heat input is the energy per unit of distance added to the material, this is a 16 bit

value with the resolution of 0.1 kJ/cm. A presented value of 100 shall thus be

interpreted as 10.0 kJ/cm.

Please note that when the travel speed is set to zero (0) then this parameter will

instead report the power with a resolution of 10W.

Page 39

7

39

Set Method and Regulation

This value will reflect the regulation type set for the weld.

Argument

Type

Value

Comment

Composite

USHORT

Bit 0-7 is Method:

Value 0: DC+

Value 1: AC

Value 2: DC-

Bit 8-15 is Regulation Type:

Value 0: CA

Value 1: CW

Value 2: CC

8.2.3.5.1 CA

CA stands for Constant Amperage. In the CA mode the power source regulates both

the voltage and the current. The current is regulated with help of the wire drive. In

this mode the wire speed will vary to keep the current level.

8.2.3.5.2 CW

CW stands for Constant Wire. In the CW mode the power source regulates the

voltage. The wire speed is held constant and thus the current will be allowed to vary.

8.2.3.5.3 CC

CC stands for Constant Current. In the CC mode the power source regulates both

the voltage and the current. The voltage is regulated with help of the wire drive. In

this mode the wire speed will vary to keep the voltage level.

Aristo 1000 only.

Set AC Frequency

This value reflects the set AC Frequency to the unit, see AC Frequency. This is a 16

bit unsigned number with the resolution of 1Hz. At a set AC Frequency of 10Hz, this

parameter will have the value 10.

Aristo 1000 only.

Page 40

7

40

Set AC Balance

This value reflects the set AC Balance to the unit, see AC Balance. This is a 16 bit

unsigned number with the resolution of 1%. At a set AC Balance of 23%, this

parameter will have the value 23.

The percentage value is the positive period’s part of the total period.

Aristo 1000 only.

Set Voltage

This value reflects the set voltage to the unit, see Voltage. This is a 16 bit unsigned

number with the resolution of 0.1V. At a set voltage of 25V, this parameter will have

the value 250.

Set Current

This value reflects the set current to the unit, see Current. This is a 16 bit unsigned

number with the resolution of 1A. At a set current of 500A, this parameter will have

the value 500.

Set AC Offset

This value reflects the set AC Offset to the unit, see AC Offset. This is a 16 bit

unsigned number with a resolution of 0.1V. The Set AC Offset can be either positive

or negative. When negative, two’s complement is used.

At a set AC Offset voltage of -2.5V this parameter will have the value 65511 (i.e.

65536 – 25).

Aristo 1000 only.

Set AC Phase Shift

This value reflects the set AC Phase Shift to the unit, see AC Phase Shift. This is a

16 bit unsigned number with the resolution of 1°. At a set AC Phase Shift of 60°, this

parameter will have the value 60.

Aristo 1000 only.

Page 41

7

41

Error Record

This is the last of the errors in the error list, i.e. latest error reported. The format is:

Name

No of bits

Comment

Error Code

16 Error Sub Code

8 Error Node

8

Value between 1 – 31

Error Device Type

8 Error Sub Unit

8

When requesting this information via the asynchronous interface the following data is

added:

Name

No of bits

Comment

Error Date

24

Bit 23 - 16

Year

Bit 15 - 8

Month

Bit 7 - 0

Day

Error Time

24

Bit 23 - 16

Hours

Bit 15 - 8

Minutes

Bit 7 - 0

Seconds

Heart Beat Value