Page 1

Valid for serial no. 803--xxx--xxxx0457 680 001 011107

OCF 2

OCF 2L, OCF 2D,

OCF 2M, OCF 2A

112101103105107109111102021110025108024042106023061104022041100020040060001

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Instruction manual

Betriebsanweisung

Manuel d’instructions

Gebruiksaanwijzing

Instrucciones de uso

Istruzioni per l’uso

Manual de instruções

ПдзгЯет чсЮуещт

Instrukcja obs³ugi

Page 2

-- 2 --

Rätt till ändring av specifikationer utan avisering förbehålles.

Ret til ændring af specifikationer uden varsel forbeholdes.

Rett til å endre spesifikasjoner uten varsel forbeholdes.

Oikeudet muutoksiin pidätetään.

Rights reserved to alter specifications without notice.

Änderungen vorbehalten.

Sous réserve de modifications sans avis préalable.

Recht op wijzigingen zonder voorafgaande mededeling voorbehouden.

Reservado el derecho de cambiar las especificaciones sin previo aviso.

Ci riserviamo il diritto di variare le specifiche senza preavviso.

Reservamo--nos o direito de alterar as especificações sem aviso prévio.

ДйбфзсеЯфбй фп дйкбЯщмб фспрпрпЯзузт рспдйбгсбцюн ЧщсЯт рспейдпрпЯзуз.

Zastrzegamy sobie prawo do wprowadzenia zmian.

SVENSKA 3..............................................

DANSK 12................................................

NORSK 21................................................

SUOMI 30................................................

ENGLISH 39..............................................

DEUTSCH 48.............................................

FRANÇAIS 57.............................................

NEDERLANDS 66.........................................

ESPAÑOL 75..............................................

ITALIANO 84..............................................

PORTUGUÊS 93..........................................

ЕЛЛЗНЙКБ 102.............................................

POLSKI 111.................................................

Page 3

ENGLISH

-- 3 9 --

TOCe

1 DIRECTIVE 40........................................................

2SAFETY 40...........................................................

3 INTRODUCTION 41...................................................

3.1 Equipment 41................................................................

4 TECHNICAL DATA 41.................................................

5 INSTALLATION 42....................................................

5.1 Unpacking and siting 42.......................................................

6 OPERATION 46.......................................................

6.1 Flow monitor 46..............................................................

7 MAINTENANCE 47....................................................

7.1 Inspection and cleaning 47....................................................

8 TROUBLESHOOTING 47..............................................

9 ORDERING SPARE PARTS 47..........................................

DIAGRAM 120............................................................

SPARE PARTS LIST 121...................................................

Page 4

-- 4 0 --

bk02d13e

1 DIRECTIVE

DECLARATION OF CONFORMITY

Esab Welding Equipment AB, 695 81 Laxå, Sweden, declares that cooling unit OCF

2 from serial number 803 onwards, conforms to standard EN 60204--1, in accordance with the requirements of directive (73/23/EEC) and appendix (93/68/EEC) and

standard EN 50199 in accordance with the requirements of directive (89/336/EEC)

and appendix (93/68/EEC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Paul Karlsson

Managing Director

Esab Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 12336

Laxå 98--01--09

2SAFETY

WARNING

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to take fumes and gases away from your breathing zone

and the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use earmuffs or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

PROTECT YOURSELF AND OTHERS!

GB

Page 5

-- 4 1 --

bk02d13e

3 INTRODUCTION

The OCF 2 cooling unit comes in four versions, designed for use with LTN/LTR

160/200/255, DTE 200/255, LTS160/250, and semi--automated power sources.

3.1 Equipment

Check the coolant level before use.

If necessary, top up with water and glycol.

S OCF 2L and OCF 2D are equipped with a transformer which is fed by the

welding power source.

Can be supplied with a flow monitor ( 0467 118 001).

S OCF 2M has relays to allow supply via the welding power source.

S OCF 2A is fitted with an earthed plug complying with Swedish regulations.

Can be stood on edge if it is fitted with feet (4 off. 0467 695 001).

4 TECHNICAL DATA

Model OCF 2L OCF 2D*) OCF 2M OCF 2A

Voltag e 400 V 400 V 230 V 230 V

Power consumption 250 W 250 W 250 W 250 W

Cooling effect 2000 W 2000 W 2000 W 2000 W

Power source LTN/LTR

200,255

DTE 200/255 LTS 160/250 L TN/LTR 160,

Automated.

Drive Internal from

welding power

source

Internal from

welding power

source

Internal from

welding power

source

Internal from

power supply

Coolant Water/Glycol Water/Glycol Water/Glycol Water/Glycol

Coolant capacity 5L 5L 5L 5L

Max. pressure 3 bar 3 bar 3 bar 3 bar

Max. water flow 4l/min 4l/min 4l/min 4l/min

Air flow 200 m3/h 200 m3/h 200 m3/h 200 m3/h

Fuse, slow 1.25 A 1.25 A

Enclosure class IP 23 IP 23 IP 23 IP 23

Weight 22 kg 25 kg 19,5 kg 19,5 kg

Dimensions 470x260x190 500x290x190 470x260x190 470x260x190

*) OCF 2D is a special version with larger external dimensions, but otherwise the same as OCF 2L.

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water. Equipment marked IP 23 is designed for indoor and outdoor use.

GB

Page 6

-- 4 2 --

bk02d13e

5 INSTALLATION

WARNING!

This product is intended for industrial use. In a domestic environment this product may cause radio

interference. It is the user’s responsibility to take adequate precautions.

S OCF 2L/OCF 2D To be installed by an electrician.

S OCF 2M/OCF 2A Maybeinstalledbyuser.

The only tool that is required for installation is a cross--head screwdriver.

5.1 Unpacking and siting

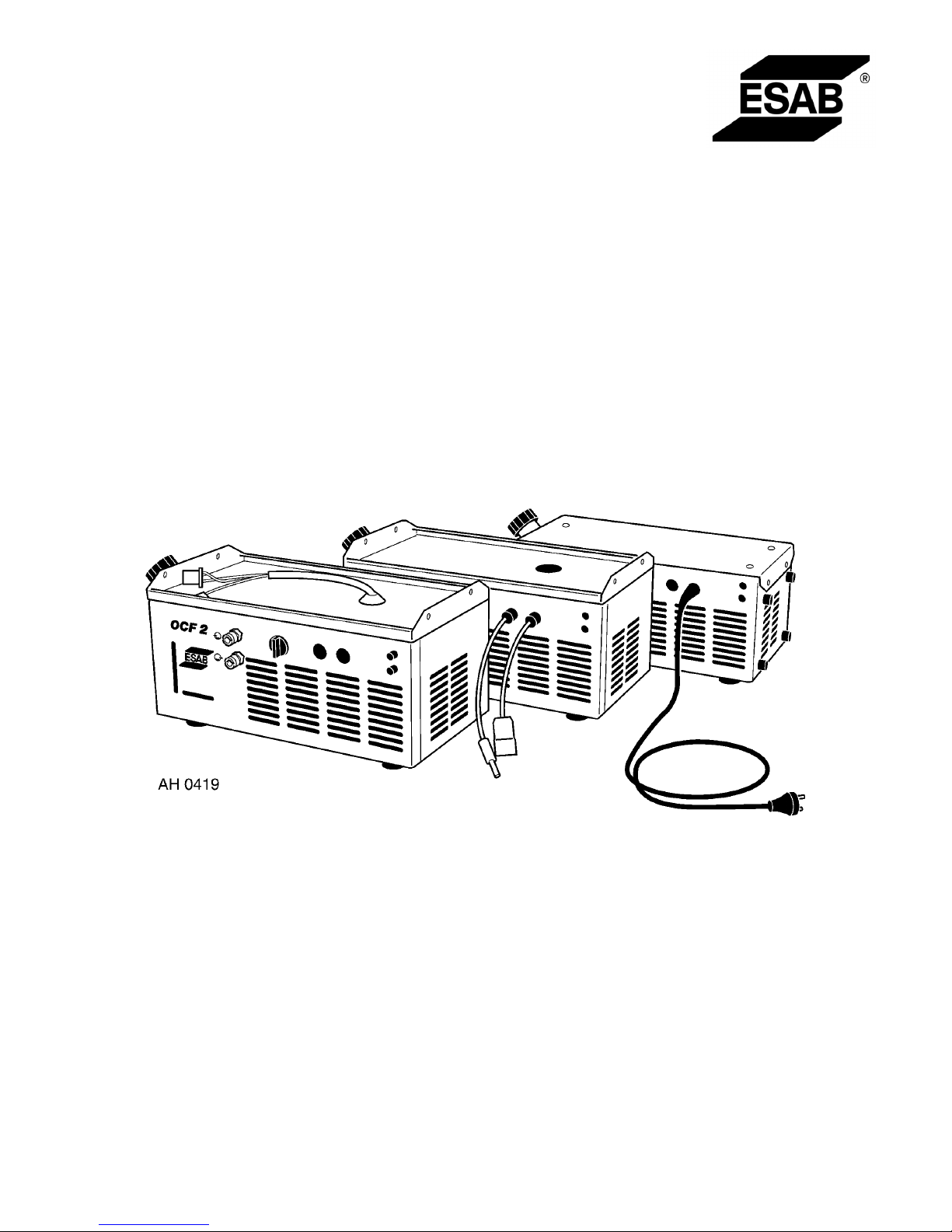

OCF 2 with a LTS 160/250 on top, with another free--standing, upright.

GB

Page 7

-- 4 3 --

bk02d13e

5.1.1 Connection

OCF 2L to LTN/LTR 200,255, NOT FITTED with connecting cable for cooling unit.

1. Unplug if necessary.

2. Remove the lower screws from the sides of the power source.

3. Remove the rear panel from the power source.

4. Hole D=38 to be drilled in base plate, see fig.1.

fig.1

5. NOTE! Clean any metal swarf from the welding power source.

6. Remove the front panel from the welding power source.

7. Connect the connecting cable for the cooling unit to the welding power source,

see fig.2.

fig.2

066-- to X02 (5--pin connector) according to drawing for relevant machine.

067-- to X02 (5--pin connector) according to drawing for relevant machine

905-- to earth terminal according to drawing for relevant machine

LTR 200/255

B4--to cable B4 from circuit board AP01 acc. to drawing for relevant machine

LTN 200/255

B4--to K2 on circuit board AP01 according to drawing for relevant machine

057-- to ST01 thermal cut--out according to drawing for relevant machine

XS24

XS25

065

B4

057

8. Place the power source on the cooling unit and raise the rear edge.

9. Feed the connectors from the cooling unit through the hole in the bottom panel.

10. Remove the clamp from the terminal inside the power source and join the

connectors see fig.3.

11. Refit the rear panel.

12. Tighten the screws in the bottom through the cover on the cooling unit.

13. Connect the water--cooled torch and do a test run.

fig.3

GB

Page 8

-- 4 4 --

bk02d13e

OCF 2L to LTN/LTR 200,255, and OCF 2D to DTE. FITTED with connecting cable

for cooling unit.

1. Unplug if necessary.

2. Remove the lower screws from the sides of the power source.

3. Remove the rear panel from the power source.

4. Remove the spring washer from the bottom panel (only applies to DTE):

5. Place the power source on the cooling unit and raise the rear edge.

6. Feed the connectors from the cooling unit through the hole in the bottom panel.

7. Remove the clamp from the terminal inside the power source and join the

connectors see fig.3.

8. Refit the rear panel.

9. Tighten the screws in the bottom through the cover on the cooling unit.

10. Connect the water--cooled torch and do a test run.

fig.3

OCF 2M to LTS 160/250.

1. Unplug if necessary.

2. Remove the lower cross --head screws from the sides of the power source.

3. Place the power source on the cooling unit.

4. Tighten the knobs (M5) at the sides through the cover of the cooling unit.

5. Connect the power cable and the flow monitor to the power source.

6. Connect the water--cooled torch and do a test run.

GB

Page 9

-- 4 5 --

bk02d13e

OCF 2A to LTN/LT R 160.

1. Remove the lower cross --head screws from the sides of the power source.

2. Place the power source on the cooling unit.

3. Tighten the screws in the bottom through the cover on the cooling unit.

4. Plug the power cable into an earthed wall socket 230 V, 6 A.

5. Connect the water--cooled torch and do a test run.

OCF 2A free-- standing

1. If the cooling unit is to stand upright, fit the feet to the right side panel.

2. Turn the cover upside down to provide a flat surface and screw it in place with

M5 screws.

3. Place the cooling unit on its side or stand it upright, secure with M5 screws.

4. Fit an earthed plug. (the existing plug complies with Swedish regulations)

5. Plug the power cable into an earthed wall socket 230 V, 6 A.

6. Connect the water--cooled torch and do a test run.

GB

Page 10

-- 4 6 --

bk02d13e

6 OPERATION

Glycol

The cooling unit contains poisonous glycol which must not be drunk or poured down

the drain or into the soil or water. Regularly top up the tank to a level 1 cm below the

top if water is lost during hose changes.

Avoid using glycol if the conditions are not cold enough to warrant it.

Pure water gives the b est cooling effect.

6.1 Flow monitor

Applies to OCF 2M and options.

The flow monitor is connected in series with

the thermal cut--out inside the power source.

If the water flow is restricted or stopped this

will trigger the flow monitor and prevent

further welding.

GB

Page 11

-- 4 7 --

bk02d13e

7 MAINTENANCE

Note:

All warranty undertakings given by the supplier cease to apply if the customer

attempts to rectify any faults on the machine during the warranty period.

7.1 Inspection and cleaning

The flow of air through the cooling unit carries small particles that stick to the cooling

element, especially in a dirty working environment. This can reduce cooling

performance. You should therefore clean the element regularly using compressed

air.

Replace the coolant about once a year. Refill with glycol mixture if the cooling unit is

to be used or stored in freezing conditions.

8 TROUBLESHOOTING

In case of major faults, contact your nearest ESAB authorised service workshop or

dealer.

Fault Action

Thermal cut--out lamp on power source comesonS Check cooling unit is running.

S Check that safety plug is fitted.

S If water is flowing, the flow monitor may be

faulty, counts as major fault, see above.

Pump or fan not working S Check both fuses

Pump not working S Major fault, see above.

Fan not working S Major fault, see above.

No water flow S Raise left panel.

Switch off, disconnect blue coupling, blow

through coolant hose to empty system.

Poor cooling effect S Clean cooling element with compressed air

9 ORDERING SPARE PARTS

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as designation and spare part number as shown in the spare parts list.

This will simplify dispatch and ensure you get the right part.

GB

Loading...

Loading...