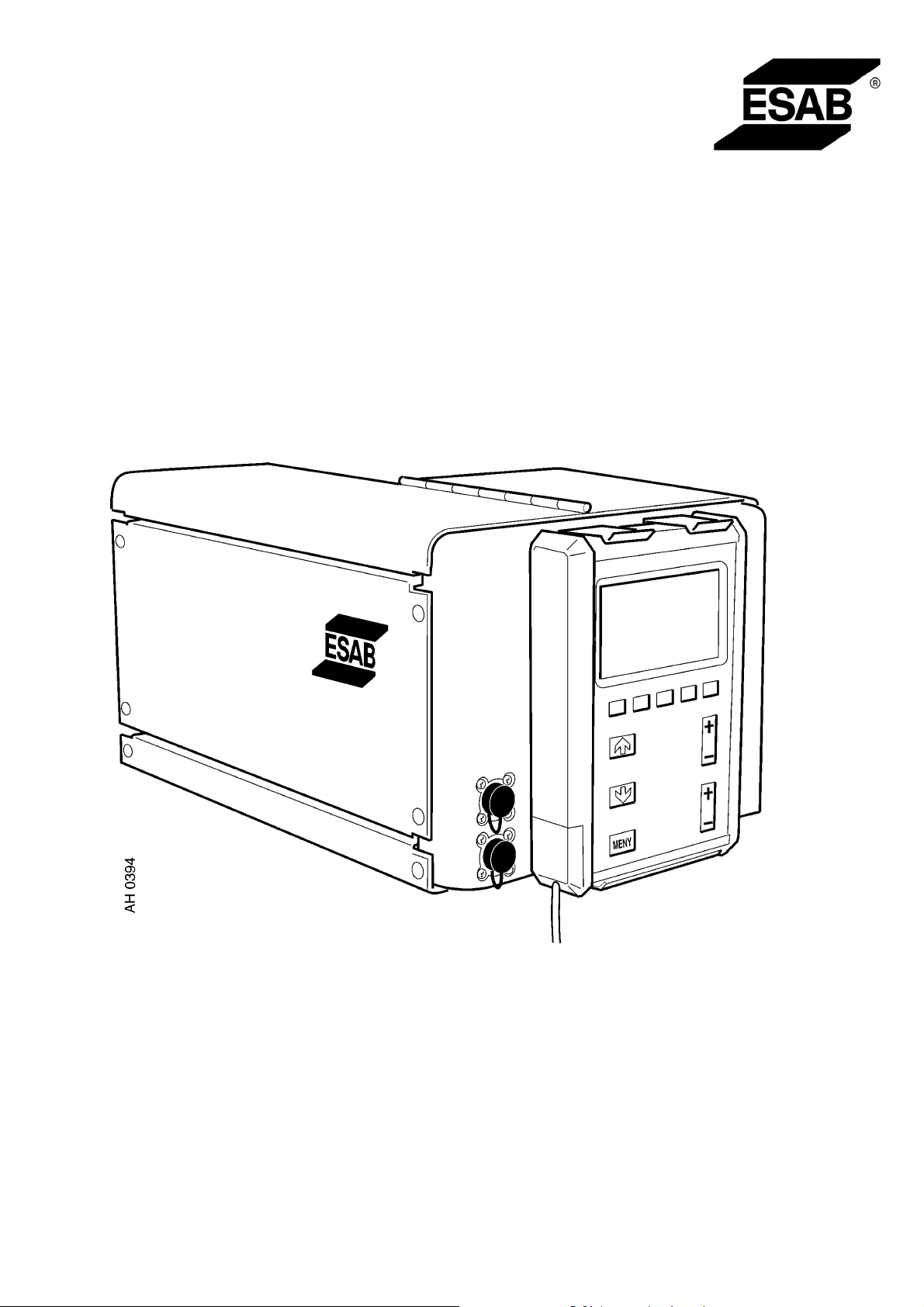

MLC 30C

101103105107109 111102021110025108024042106023061104022041100020040060001

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Instruction manual

Betriebsanweisung

Manuel d’instructions

Gebruiksaanwijzing

Instrucciones de uso

Istruzioni per l’uso

Manual de instruções

ПдзгЯет чсЮуещт

Valid for Serial NO 942 XXX--XXXX0457 038 001 010312

SVENSKA 3..............................................

DANSK 12................................................

NORSK 21................................................

SUOMI 30................................................

ENGLISH 39..............................................

DEUTSCH 48.............................................

FRANÇAIS 58.............................................

NEDERLANDS 68.........................................

ESPAÑOL 77..............................................

ITALIANO 87..............................................

PORTUGUÊS 97..........................................

ЕЛЛЗНЙКБ 107.............................................

Rätt ti ll ändring av specifikationer utan avisering förbehålles.

Ret til ændring af specifikationer uden varsel forbeholdes.

Rett til å endre spesifikasjoner uten varsel forbeholdes.

Oikeudet muutoksiin pidätetään.

Rights reserved to alter specifications without notice.

Änderungen vorbehalten.

Sous réserve de modifications sans avis préalable.

Recht op wijzigingen zonder voorafgaande mededeling voorbehouden.

Reservado el derecho de cambiar las especificaciones sin previo aviso.

Ci riserviamo il diritto di variare le specifiche senza preavviso.

Reservamo--nos o direito de alterar as especificações sem aviso prévio.

ДйбфзсеЯфбй фп дйкбЯщмб фспрпрпЯзузт рспдйбгсбцюн ЧщсЯт рспейдпрпЯзуз.

-- 2 --

ENGLISH

1 DIRECTIVE 40........................................................

2SAFETY 40...........................................................

3 INTRODUCTION 41...................................................

3.1 Technical specification 41.....................................................

3.2 Delivery contents 41..........................................................

4 INSTALLATION 42....................................................

4.1 Connection 42...............................................................

4.2 Termination resistance 43.....................................................

5 OPERATION 43.......................................................

5.1 Settings 43..................................................................

5.2 Changing the wire 44.........................................................

5.3 Welding 46..................................................................

6 MAINTENANCE 47....................................................

6.1 Cleaning 47.................................................................

7 ACCESSORIES 47....................................................

8 ORDERING SPARE PARTS 47..........................................

DIAGRAM 118............................................................

LIST OF COMPONENTS 119...............................................

SPARE PARTS LIST 121...................................................

TOCe

-- 3 9 --

4

GB

1 DIRECTIVE

DECLARATION OF CONFORMITY

Esab Welding Equipment AB, S--695 81 Laxå, Sweden, declares that Wire feed unit

MLC 30C from serial number 911 onwards, conforms to standard EN 60974--1, in

accordance with the requirements of directive (73/23/EEC) and appendix

(93/68/EEC) and standard EN 50199 in accordance with the requirements of directive (89/336/EEC) and appendix (93/68/EEC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -------Laxå 1999 05 10

Anders Birgersson

Managing Director

Esab Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 41192

2SAFETY

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and

the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use ear defenders or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

bm28d12e

-- 4 0 --

GB

3 INTRODUCTION

The MLC 30C wire feed unit is a part of ESAB’s Aristo 2000 system. The wire feed

unit pushes the wire through the welding hose to the welding torch and the

pneumatically--operated motor in the torch piston draws the wire to the contact tip.

This ensures smooth and even wire feeding, excellent for welding with soft wires

(e.g. aluminium) and fine wire dimensions.

The welding wire is isolated from the wire feed unit’s outer casing.

The wire feed unit can be placed in different positions. Equipped with a turning piece,

the MLC 30 C can be placed so that it pivots above the power source pilot. It can

also be fitted with a suspension unit so that it can be suspended above the

workplace, or it can be complemented with a set of wheels (trolley) so that it can be

maneuvered on the floor or on a workbench.

3.1 Technical specification

Mains supply 42 V 50/60 Hz

Power requirement 70 VA

Gas connection Hose nipple for 6 mm hose

Air connection Connector for 1/4“ hose

2

Air pressure Min. 500 kPa (5 kg/cm

Wire feed speed 1.5 -- 18 m/min

Wire diameter 0.8 - 1.6 mm

Welding torch PKB, hose lengths up to 16 m

Welding current Max 400 A at 60% intermittence

Inlet nozzle Hole diameter 2.7 mm

Outlet nozzle Hole diameter 1.5 mm

Remove the outlet nozzle when welding with 1.6 mm wire.

Brake hub intended for

reel with:

Max. outer diameter 300 mm

Hub hole, diameter 51.1 mm

Hub length 100 mm

Dimensions (l x w x h) 493 x 336 x 268 mm

Class of enclosures IP 21

Continuous A--weighted

acoustic pressure value

Weight 22 kg

58 dB

)

3.2 Delivery contents

The wire feed unit is delivered with the following accessories:

Inlet nozzles for the PKB welding torch

Nozzles for 0.8, 1.0, 1.2 and 1.6 mm Ss and Fe wire.

Nozzle for 0.8 -- 1.2 mm aluminium wire.

Feed rollers

For 0.6 -- 1.0 mm and 1.0 -- 1.6 mm wire.

bm28d12e

-- 4 1 --

GB

4 INSTALLATION

WARNING

This product is intended for industrial use. In a domestic environment this

product may cause radio interference. It is the user’s responsibility to take

adequate precautions.

4.1 Connection

4.1.1 Connections and control panel

5. Nipple for gas connection.

6. Connection for control cable from power source.

7. Connection for welding current from power source.

8. Connection for controller, optional connection. Only controller PUA 1 or

termination resistance can be connected here.

9. Connection for welding torch.

10. Controller.

S Connect compressed air to the hose on the back of the wire feed unit.

4.1.2 Connecting welding hose

1. Press the inlet nozzle (a) (selected according to

the size of the electrode) into the welding hose.

2. Open the wire feed unit on the side where the

feeder mechanism is located. Undo locking

screw in the connection plate.

3. Connect the welding hose (b) to the wire feed

unit and tighten the locking screw in the

connection plate.

4. Remove the plastic cover on the welding torch

housing. Undo locking screw (e) press the other

end of the hose into the torch. Tighten the

locking screw and replace the plastic cover.

bm28d12e

-- 4 2 --

GB

4.1.3 Connecting welding current

Connect the welding cable from the power source’s positive pole to the current

connection on the back of the wire feed unit.

4.1.4 Connecting compressed air

Connect compressed air (at least 500 kPa) to the hose that sticks out of the back of

the wire feed unit.

The air goes to a filter regulator that is pre--set at 500 kPa. The regulator drains itself

when the compressed air is turned off.

Note! Check regularly that the r egulator’s draining function is working properly.

Water present in the compressed air entering the welding torch will result in

operating problems.

4.2 Termination resistance

The termination r esistance must be located in the ends of the CAN--bus in order to

avoid communication problems. The controller has a built--in resistance, the power

source and wire feed unit lack built--in resistance. The termination resistance is sup plied with the power source.

Depending on the connection case, the resistance is connected as follows:

Termination resistance

Termination resistance

Controller connected to wire feed unit

Connect the termination resistance to the

back of the power source. Connected in this

way upon delivery

Controller connected to the power source

Connect the termination resistance to the

front of the wire feed unit.

5OPERATION

5.1 Settings

The wire feed unit does not have a control panel. Settings are made using the

controller, which can be connected to the wire feed unit or the power source. A

programming handbook that describes how the controller should be handled

accompanies the controller.

bm28d12e

-- 4 3 --

GB

5.1.1 Brake hub

The electrode reel is located on a brake hub, it is

adjusted upon delivery. If you need to make a follow--up

adjustment, follow the instructions below .

The brake action can be adjusted using the two screws S

(the springs) that are located inside the hub. Turn the

screws clockwise to reduce the brake action. Adjust the

hub so that the wire is somewhat slack when feeding

stops.

5.1.2 Cold wire feed

If you start the wire feed, the power source produces a voltage and the gas valve

opens. If the wire does not come into contact with the workpiece, the voltage and

gas are shut off after approx. three seconds. The wire feed continues until you

release the trigger.

5.1.3 Wire feed p ressure

The wire feed unit has a driving feed roller and a free--wheeling pressure roller. The

pressure roller is located in an axle mounted in bearings. The pressure on the wire

can be changed by means of a spring attached to the shaft, which can be adjusted

to different positions.

WARNING!

Rotating parts can cause injury, take great care.

5.2 Changing the wire

The wire liner is made of plastic and is sensitive to sharp objects. File away sharp

burrs and edges on the wire tip before the new welding wire is inserted into the wire

liner.

1. Loosen the pressure roller’s spring in the wire feed unit and torch.

2. Retract the remaining wire out of the wire liner. Remove the reel.

3. Insert the new reel.

4. Straighten out 5--10 cm of the wire and file away the burrs on the tip of the wire.

5. Check that the following components have the right dimensions: feed roller,

outlet nozzle, the welding hose inlet nozzle and the welding torch contact tip.

6. Insert the wire into the wire feed unit. Make sure that it sits correctly in the feed

roller’s groove and in the outlet nozzle. When welding with 1.6 mm welding wire

the outlet nozzle must first be removed. Insert the wire approx. 10 cm into the

welding hose.

7. Set the pressure roller’s spring to position 1, see the picture

on the right.

Set the pressure on the welding torch’s pressure roller in

accordance with the table below.

Place the welding hose as straight as possible.

8. Start the power source. Select motor power 1 A for the feed

motor if the wire diameter is 0.8 -- 1 mm. For thicker wires,

bm28d12e

-- 4 4 --

GB

select the m otor power as indicated in the table below. (Th e

following motor power settings are available 1.0 - 1.25 - 1.5

and 1.75 A)

Use the controller to set the motor power. Start from the m ain

menu and select the following functions:

AUXLIARY FUNCTIONS, CONFIGURATION, MIG/MAG DEFAULTS, MLC 30C,

MOTOR POWER.

9. Press in the torch trigger as far as it will go, let the wire feed thr ough the welding

hose and out through the contact tip.

If the motor does not have the capacity to feed the wire, increase the motor

power one step.

10. Set the correct feed pressure and motor power in accordance with the table

below.

11. Check that the brake hub is correctly adjusted, see 5.1.1 on the previous page.

IMPORTANT!

To prevent the reel sliding off the hub: Lock the reel in place

by turning the red knob as shown on the warning label atta-

ched next to the hub.

Mark and select the desired motor power.

5.2.1 Recommended settin gs

This table applies to PKB welding torches with 5, 10 and 16 metre hose length.

Wire type

∅ (mm)

AIMg ∅ 0.8--1.0 Plastic 0.8/0.3 0258 002 585 3 min 1.25

AIMg ∅ 1.2 Plastic 0.8/0.3 0258 002 585 4 mean 1.25--1.5

AISi ∅ 1.0 Plastic 0.8/0.3 0258 002 585 3 min 1.25

AISi ∅ 1.2 Plastic 0.8/0.3 0258 002 585 4 min 1.25

Fe ∅ 0.8 Steel 0.8/0.3 0258 005 581 5 mean 1.25--1.5

Fe ∅ 0.9--1.0 Steel 1.0/0.4 0258 002 582 5 mean 1.25--1.5

Fe ∅ 1.2 Steel 1.2/0.5 0258 002 583 4 mean 1.5

Fe ∅ 1.4--1.6 Steel 1.6/0.6 0258 002 584 5 mean 1.5

Ss ∅ 0.8 Steel 0.8/0.3 0258 002 581 5 mean 1.25--1.5

Ss ∅ 1.0 Steel 1.0/0.4 0258 002 582 5 mean 1.25--1.5

Ss ∅ 1.2 Steel 1.2/0.5 0258 002 583 5 mean 1.5

Lining Marking Ordering no.

PKB inlet nozzle

Wire pressure

MLC PKB

Motor power

MLC (A)

bm28d12e

-- 4 5 --

GB

5.3 Welding

For best welding results, you should use the synergic mode. It is also possible to use

independent settings (manual settings). The description below is applicable for the

synergic mode.

Set and adjust the wire feed unit for the particular wire that you will use, see 5.2

above. Then make the following settings:

1. Set the stop wire speed. This is the wire feed speed when the power source is

shut off (and the feed motor stops). If you have selected a stop speed that is too

low, the wire burns up in the contact tip. If the speed is too high, you end up with

too long “stick out“ and/or involuntary welding stoppage.

The controller is used to set the stop speed. Start in the main menu and select

the following functions:

AUXILIARY FUNCTIONS, CONFIGURATION, MIG/MAG DEFAULTS, MLC 30C, STOP

WIRE SPEED.

The stop speed can be set between 0.7 and 10 metres per minute.

Example: If the wire feed speed is 13 m/min or more, the stop speed should be

approx. 10 m/min. If the feed is 3 to 4 m/min, the stop speed should be approx. 1

m/min.

2. Set the start data. When you start welding, the power source needs information

about the wire feed speed to be able to provide the appropriate current. The

power source takes the relevant speed data from the wire feed unit approx 1.3

seconds after the start of welding. To obtain a good start, it is important that the

start data does not deviate too much from the actual speed. There are four ways

to set the start data:

a. Select MEASURE from the main menu and cold wire feed for at least 2

seconds. The wire feed speed that is shown last is stored as start data.

b. Select MEASURE from the main menu and set the wire speed using the

controller.

c. Select SET from the main menu and set the wire speed using the controller.

d. Recall your start data from a memory position where you have previously

stored them.

If you do not change the start data, then the last used start data will apply to the

next welding start.

3. Start welding.

a. First, press in the welding torch trigger for approx. one second so that air

starts to flow. This produces gas pre--flow and activates the power source.

Do not press the trigger so much so that the wire starts to be fed out.

b. Thereafter, press harder so that the wire feed starts and welding is begun.

c. Once welding has started, the power source detects the wire speed and

regulates the voltage accordingly.

d. If you want to use the crater filling function when you stop welding, you

reduce the wire speed gradually before the end of welding. In this case, you

have to set the stop speed somewhat lower than that stated in point 1.

above.

e. Once welding has stopped, the power source restarts after 0.4 seconds. It is

then activated for approx. 2 seconds. This function ensures that you can

quickly r estart, e.g. when spot--welding.

4. Do not change settings or the controller menu display during welding or wire

feeding. This can cause interruptions in welding, in which case the controller will

display error code 23.

In the welding torch’s instructions for use, you will find more information about how

you can regulate the wire speed with the torch.

bm28d12e

-- 4 6 --

GB

6 MAINTENANCE

Note:

All warranty undertakings given by the supplier cease to apply if the customer

attempts to rectify any faults on the machine during the warranty period.

6.1 Cleaning

Regular maintenance is important for reliability and safe operation.

6.1.1 Wire feed u nit

Keep clean and replace the feed mechanism’s wear parts at regular intervals.

Note that if the pressure on the pressure rollers is too great, this can cause abnormal

wear and tear on the pressure roller, feed roller and wire liner.

6.1.2 Welding to rch

Blow clean the wire liner regularly and clean the gas nozzle.

6.1.3 Dismantling when cleaning:

1. Detach the screw in the connection block using an Allen key. Remove the welding hose.

2. Detach the two stop screws that hold the inlet and outlet nozzles in place and remove them.

3. Refit in the reverse order.

7 ACCESSORIES

Connection kits: power source - wire feed u n it

Order no. Designation

0456 528 880 Connection kit, 1.7 metres

0456 528 881 Connection kit, 8 metres

0456 528 882 Connection kit, 16 metres

0456 528 883 Connection kit, 25 metres

0456 528 884 Connection kit, 35 metres

Other accessories

Listed in the list of spare parts.

8 ORDERING SPARE PARTS

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as designation and spare part number as shown in the spare parts list.

This will simplify dispatch and ensure you get the right part.

bm28d12e

-- 4 7 --

Loading...

Loading...