INSTRUCTIONS for

SOLID/CORED WIRE FEEDER

F-12-786-M

March, 2001

MIG-35

P/N 953552 W/2-ROLL DRIVE

P/N 677634 W/4-ROLL DRIVE*

(*See Supplement F-12-821)

NOTE: For design changes in MIG-35 units, refer to page 23.

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation and safe

practices for arc welding equipment, we urge you to read our booklet, Precautions and Safe Practices for Arc Welding,

Cutting and Gouging, Form 52-529. Do NOT permit untrained persons to Install, operate, or maintain this equipment. Do

NOT attempt to install or operate this equipment until you have read and fully understand these instructions. If you do not

fully understand these instructions, contact your supplier for further information. Be sure to read the Safety Precautions on

page 3 before installing or operating this equipment.

Be sure this information reaches the operator.

You can get extra copies through your supplier.

USER RESPONSIBILITY

This equipment will perform in conformity with the description thereof contained in this manual and accompanying

labels and/or inserts when installed, operated, maintained and repaired in accordance with the instructions provided.

This equipment must be checked periodically. Malfunctioning equipment should not be used. Parts that are broken,

missing, worn, distorted or contaminated should be replaced immediately. Should such repair or replacement become

necessary, the manufacturer recommends that a telephone or written request for service advice be made to the

Authorized Distributor from whom purchased.

This equipment or any of its parts should not be altered without the prior written approval of the manufacturer. The

user of this equipment shall have the sole responsibility for any malfunction which results from improper use, faulty

maintenance, damage, improper repair or alteration by anyone other than the manufacturer or a service facility

designated by the manufacturer.

2

SAFETY PRECAUTIONS

WARNING: These Safety Precautions are for

your protection. They summarize precautionary information from the references listed in

Additional Safety Information section. Before

performing any installation or operating procedures, be

sure to read and follow the safety precautions listed below

as well as all other manuals, material safety data sheets,

labels, etc. Failure to observe Safety Precautions can result

in injury or death.

PROTECT YOURSELF AND OTHERS

Some welding, cutting, and gouging

processes are noisy and require ear

protection. The arc, like the sun, emits

ultraviolet (UV) and other radiation and

can injure skin and eyes. Hot metal can cause burns.

Training in the proper use of the processes and equipment is essential to prevent accidents. Therefore:

1. Always wear safety glasses with side shields in any work

area, even if welding helmets, face shields, and goggles

are also required.

2. Use a face shield fitted with the correct filter and cover

plates to protect your eyes, face, neck, and ears from

sparks and rays of the arc when operating or observing

operations. Warn bystanders not to watch the arc and

not to expose themselves to the rays of the electric-arc

or hot metal.

3. Wear flameproof gauntlet type gloves, heavy long-sleeve

shirt, cuffless trousers, high-topped shoes, and a welding helmet or cap for hair protection, to protect against

arc rays and hot sparks or hot metal. A flameproof apron

may also be desirable as protection against radiated

heat and sparks.

4. Hot sparks or metal can lodge in rolled up sleeves,

trouser cuffs, or pockets. Sleeves and collars should be

kept buttoned, and open pockets eliminated from the

front of clothing

5. Protect other personnel from arc rays and hot sparks

with a suitable non-flammable partition or curtains.

6. Use goggles over safety glasses when chipping slag or

grinding. Chipped slag may be hot and can fly far.

Bystanders should also wear goggles over safety glasses.

FIRES AND EXPLOSIONS -- Heat from

flames and arcs can start fires. Hot slag

or sparks can also cause fires and explosions. Therefore:

1. Remove all combustible materials well away from the

work area or cover the materials with a protective nonflammable covering. Combustible materials include wood,

cloth, sawdust, liquid and gas fuels, solvents, paints and

coatings, paper, etc.

2. Hot sparks or hot metal can fall through cracks or

crevices in floors or wall openings and cause a hidden

smoldering fire or fires on the floor below. Make certain

that such openings are protected from hot sparks and

metal.“

3. Do not weld, cut or perform other hot work until the

workpiece has been completely cleaned so that there

are no substances on the workpiece which might produce flammable or toxic vapors. Do not do hot work on

closed containers. They may explode.

4. Have fire extinguishing equipment handy for instant use,

such as a garden hose, water pail, sand bucket, or

portable fire extinguisher. Be sure you are trained in its

use.

5. Do not use equipment beyond its ratings. For example,

overloaded welding cable can overheat and create a fire

hazard.

6. After completing operations, inspect the work area to

make certain there are no hot sparks or hot metal which

could cause a later fire. Use fire watchers when necessary.

7. For additional information, refer to NFPA Standard 51B,

"Fire Prevention in Use of Cutting and Welding Pro-

--

cesses", available from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL SHOCK -- Contact with live

electrical parts and ground can cause

severe injury or death. DO NOT use AC

welding current in damp areas, if movement is confined, or if there is danger of

falling.

1. Be sure the power source frame (chassis) is connected

to the ground system of the input power.

2. Connect the workpiece to a good electrical ground.

3. Connect the work cable to the workpiece. A poor or

missing connection can expose you or others to a fatal

shock.

4. Use well-maintained equipment. Replace worn or damaged cables.

5. Keep everything dry, including clothing, work area, cables,

torch/electrode holder, and power source.

6. Make sure that all parts of your body are insulated from

work and from ground.

7. Do not stand directly on metal or the earth while working

in tight quarters or a damp area; stand on dry boards or

an insulating platform and wear rubber-soled shoes.

8. Put on dry, hole-free gloves before turning on the power.

9. Turn off the power before removing your gloves.

10. Refer to ANSI/ASC Standard Z49.1 (listed on next page)

for specific grounding recommendations. Do not mistake

the work lead for a ground cable.

ELECTRIC AND MAGNETIC FIELDS —

May be dangerous. Electric current flowing through any conductor causes localized Electric and Magnetic Fields

(EMF). Welding and cutting current creates EMF around welding cables and

welding machines. Therefore:

1. Welders having pacemakers should consult their physician before welding. EMF may interfere with some pacemakers.

2. Exposure to EMF may have other health effects which are

unknown.

3. Welders should use the following procedures to minimize

exposure to EMF:

A. Route the electrode and work cables together. Secure

them with tape when possible.

B. Never coil the torch or work cable around your body.

C. Do not place your body between the torch and work

cables. Route cables on the same side of your body.

D. Connect the work cable to the workpiece as close as

possible to the area being welded.

E. Keep welding power source and cables as far away

from your body as possible.

10/98

FUMES AND GASES -- Fumes and

gases, can cause discomfort or harm,

particularly in confined spaces. Do

not breathe fumes and gases. Shielding gases can cause asphyxiation.

Therefore:

1. Always provide adequate ventilation in the work area by

natural or mechanical means. Do not weld, cut, or gouge

on materials such as galvanized steel, stainless steel,

copper, zinc, lead, beryllium, or cadmium unless positive

mechanical ventilation is provided. Do not breathe fumes

from these materials.

2. Do not operate near degreasing and spraying operations. The heat or arc rays can react with chlorinated

hydrocarbon vapors to form phosgene, a highly toxic

gas, and other irritant gases.

3. If you develop momentary eye, nose, or throat irritation

while operating, this is an indication that ventilation is not

adequate. Stop work and take necessary steps to improve ventilation in the work area. Do not continue to

operate if physical discomfort persists.

4. Refer to ANSI/ASC Standard Z49.1 (see listing below)

for specific ventilation recommendations.

5. WARNING: This product, when used for welding or

cutting, produces fumes or gases which

contain chemicals known to the State of

California to cause birth defects and, in

some cases, cancer. (California Health &

Safety Code

CYLINDER HANDLING -- Cylinders, if

mishandled, can rupture and violently

release gas. Sudden rupture of cylinder, valve, or relief device can injure or

kill. Therefore:

1. Use the proper gas for the process and use the proper

pressure reducing regulator designed to operate from

the compressed gas cylinder. Do not use adaptors.

Maintain hoses and fittings in good condition. Follow

manufacturer's operating instructions for mounting regulator to a compressed gas cylinder.

2. Always secure cylinders in an upright position by chain

or strap to suitable hand trucks, undercarriages, benches,

walls, post, or racks. Never secure cylinders to work

tables or fixtures where they may become part of an

electrical circuit.

3. When not in use, keep cylinder valves closed. Have

valve protection cap in place if regulator is not connected. Secure and move cylinders by using suitable

hand trucks. Avoid rough handling of cylinders.

4. Locate cylinders away from heat, sparks, and flames.

Never strike an arc on a cylinder.

5. For additional information, refer to CGA Standard P-1,

"Precautions for Safe Handling of Compressed Gases in

Cylinders", which is available from Compressed Gas

Association, 1235 Jefferson Davis Highway, Arlington,

VA 22202.

§25249.5 et seq.)

EQUIPMENT MAINTENANCE -- Faulty or

improperly maintained equipment can

cause injury or death. Therefore:

1. Always have qualified personnel perform the installation, troubleshooting, and maintenance work. Do not

perform any electrical work unless you are qualified to

perform such work.

2. Before performing any maintenance work inside a power

source, disconnect the power source from the incoming

electrical power.

3. Maintain cables, grounding wire, connections, power

cord, and power supply in safe working order. Do not

operate any equipment in faulty condition.

4. Do not abuse any equipment or accessories. Keep

equipment away from heat sources such as furnaces,

wet conditions such as water puddles, oil or grease,

corrosive atmospheres and inclement weather.

5. Keep all safety devices and cabinet covers in position

and in good repair.

6. Use equipment only for its intended purpose. Do not

modify it in any manner.

ADDITIONAL SAFETY INFORMATION -- For

more information on safe practices for electric arc welding and cutting equipment, ask

your supplier for a copy of "Precautions and

Safe Practices for Arc Welding, Cutting and

Gouging", Form 52-529.

The following publications, which are available from the

American Welding Society, 550 N.W. LeJuene Road, Miami, FL 33126, are recommended to you:

1. ANSI/ASC Z49.1 - "Safety in Welding and Cutting"

2. AWS C5.1 - "Recommended Practices for Plasma Arc

Welding"

3. AWS C5.2 - "Recommended Practices for Plasma Arc

Cutting"

4. AWS C5.3 - "Recommended Practices for Air Carbon

Arc Gouging and Cutting"

5. AWS C5.5 - "Recommended Practices for Gas Tungsten

Arc Welding“

6. AWS C5.6 - "Recommended Practices for Gas Metal Arc

Welding"“

7. AWS SP - "Safe Practices" - Reprint, Welding Handbook.

8. ANSI/AWS F4.1, "Recommended Safe Practices for

Welding and Cutting of Containers That Have Held

Hazardous Substances."

MEANING OF SYMBOLS - As used throughout this manual: Means Attention! Be Alert!

Your safety is involved.

Means immediate hazards which, if

not avoided, will result in immediate,

serious personal injury or loss of life.

Means potential hazards which could

result in personal injury or loss of life.

Means hazards which could result in

minor personal injury.

4

SP98-10

PRÉCAUTIONS DE SÉCURITÉ

AVERTISSEMENT: Ces règles de sécurité ont pour

objet d assurer votre protection. Veillez à lire et à

observer les précautions énoncées ci-dessous avant de

monter l équipement ou de commercer à lutiliser. Tout

défaut dobservation de ces précautions risque

dentraîner des blessures graves ou mortelles.

1. PROTECTION INDIVIDUELLE-- Les brûlures de la

peau et des yeux dues au rayonnement de larc

électrique ou du métal incandescent, lors du soudage

au plasma ou à lélectrode ou lors du gougeage à

larc, peuvent savérer plus graves que celles

résultant dune exposition prolongée au soleil. Aussi

convient-il dobserver les précautions suivantes:

a. Portez un écran facial adéquat muni des plaques

protectrices et des verres filtrants appropriés afin de

vous protéger les yeux, le visage, le cou et les

oreilles des étincelles et du rayonnement de larc

électrique lorsque vous effectuez des soudures ou

des coupes ou lorsque vous en observez lexécution.

AVERTISSEZ les personnes se trouvant à proximité

de façon à ce quelles ne regardent pas larc et à ce

quelles ne sexposent pas à son rayonnement, ni à

celui du métal incandescent.

b. Portez des gants ignifugés à crispins, une tunique

épaisse à manches longues, des pantalons sans

rebord, des chaussures à embout dacier et un

casque de soudage ou une calotte de protection,

afin déviter dexposer la peau au rayonnement de

larc électrique ou du métal incandescent. ll est

également souhaitable dutiliser un tablier

ininflammable de façon à se protéger des étincelles

et du rayonnement thermique.

c. Les étincelles ou les projections de métal incandes-

cent risquent de se loger dans des manches

retroussées, des bords relevés de pantalons ou

dans des poches. Aussi convient-il de garder

boutonnés le col et les manches et de porter des

vêtements sans poches à lavant.

d. Protégez des étincelles et du rayonnement de larc

électrique les autres personnes travaillant à proximité

à laide dun écran ininflammable adéquat.

e. Ne jamais omettre de porter des lunettes de sécurité

lorsque vous vous trouvez dans un secteur où lon

effectue des opérations de soudage ou de coupage

à larc. Utilisez des lunettes de sécurité à écrans ou

verres latéraux pour piquer ou meûler le laitier. Les

piquetures incandescentes de laitier peuvent être

projetées à des distances considérables. Les

personnes se trouvant à proximité doivent également

porter des lunettes de protection.

f. Le gougeage à larc et le soudage à larc au plasma

produisent un niveau de bruit extrêmement élevé

(de 100 à 114 dB) et exigent par conséquent

lemploi de dispositifs appropriés de protection auditive.

2. PRÉVENTION DES INCENDES-- Les projections de

laitier incandescent ou détincelles peuvent

provoquer de graves incendies au contact de

matériaux combustibles solides, liquides ou gazeux.

Aussi faut-il observer les précautions suivantes:

a. Éloigner suffisamment tous les matériaux combus-

tibles du secteur où lon exécute des soudures ou

des coupes à larc, à moins de les recouvrir

complètement dune bâche non-inflammable. Ce

type de matériaux comprend notamment le bois, les

vêtements, la sciure, lessence, le kérosène, les

peintures, les solvants, le gaz naturel, lacétylène, le

propane et autres substances combustibles

semblables.

b. Les étincelles ou les projections de métal incandes-

cent peuvent tomber dans des fissures du plancher

ou dans des ouvertures des murs et y déclencher

une ignition lente cachée. Veiller à protéger ces

ouvertures des étincelles et des projections de

métal.

c. Nexécutez pas de soudures, de coupes, dopérations

de gougeage ou autres travaux à chaud à la surface

de barils, bidons, réservoirs ou autres contenants

usagés, avant de les avoir nettoyés de toute trace

de substance susceptible de produire des vapeurs

inflammables ou toxiques.

d. En vue dassurer la prévention des incendies, il

convient de disposer dun matériel dextinction prêt

à servir immédiatement, tel quun tuyau darrosage,

un seau à eau, un seau de sable ou un extincteur

portatif.

e. Une fois le travail à larc terminé, inspectez le

secteur de façon à vous assurer quaucune étincelle

ou projection de métal incandescent ne risque de

provoquer ultérieurement un feu.

3. CHOC ÉLECTRIQUE-- Le gougeage à larc et à larc

au plasma exige lemploi de tensions à vide

relativement importantes; or, celles-ci risquent de

causer des dommages corporels graves et même

mortels en cas dutilisation inadéquate. La gravité

du choc électrique reçu dépend du chemin suivi par

le courant à travers le corps humain et de son

intensité.

a. Ne laissez jamais de surfaces métalliques sous

tension venir au contact direct de la peau ou de

vêtements humides. Veillez à porter des gants bien

secs.

b. Si vous devez effectuer un travail sur une surface

métallique ou dans un secteur humide, veillez à

assu-rer votre isolation corporelle en portant des

gants secs et des chaussures à semelles de caoutchouc et en vous tenant sur une planche ou une

plate-forme sèche.

c. Mettez toujours à la terre le poste de soudage/

coupage en le reliant par un câble à une bonne prise

de terre.

d. Nutilisez jamais de câbles usés ou endommagés.

Ne surchargez jamais le câble. Utilisez toujours un

équipement correctement entretenu.

e. Mettez léquipement hors tension lorsquil nest pas

en service. une mise à la masse accidentelle peut

en effet provoquer une surchauffe de léquipement

et un danger dincendie. Ne pas enrouler ou passer

5

9/97

levage, des câbles de grue ou divers chemins

électriques.

g. Empêchez lapparition de toute humidité, notamment

sur vos vêtements, à la surface de lemplacement de

travail, des câbles, du porte-électrode et du poste de

soudage/coupage. Réparez immédiatement toute fuite

deau.

4. VENTILATION-- La respiration prolongée des fumées

résultant des opérations de soudage/coupage, à

lintérieur, dun local clos, peut provoquer des malaises et des dommages corporels. Aussi convient-il

dobserver les précautions suivantes:

a. Assurez en permanence une aération adéquate de

lemplacement de travail en maintenant une ventilation naturelle ou à laide de moyens mécaniques.

Neffectuez jamais de travaux de soudage ou de

coupage sur des matériaux de zinc, de plomb, de

beryllium ou de cadmium en labsence de moyens

mécaniques de ventilation capables dempêcher

linhalation des fumées dégagées par ces matériaux.

b. Neffectuez jamais de travaux de soudage ou de

coupage à proximité de vapeurs dhydrocarbure chloré

résultant dopérations voisines de dégraissage ou de

pulvérisation. La chaleur dégagée ou le rayonnement

de larc peut déclencher la formation de phosgène -gaz particulièrement toxique -- et dautres gaz irritants, à partir des vapeurs de solvant.

c. Une irritation momentanée des yeux, du nez ou de la

gorge constatée au cours de lutilisation de

léquipement dénote un défaut de ventilation. Arrêtezvous de travailler afin de prendre les mesures nécessaires à lamélioration de la ventilation. Ne poursuivez

pas lopération entreprise si le malaise persiste.

d. Certaines commandes comportent des canalisations

où circule de lhydrogène. Larmoire de commande est

munie dun ventilateur destiné à empêcher la formation de poches dhydrogène, lesquelles présentent un

danger dexplosion; ce ventilateur ne fonctionne que

si linterrupteur correspondant du panneau avant se

trouve placé en position ON (Marche). Veillez à

manuvrer cette commande en vérifiant si le couvercle

est bien en place, de façon à assurer lefficacité de la

ventilation ainsi réalisée. Ne jamais débrancher le

ventilateur.

e. Les fumées produites par lopération de soudage ou

de coupage peuvent savérer toxiques. Aussi est-il

nécessaire de disposer en permanence dun dispositif

adéquat de ventilation de type aspirant, afin déliminer du voisinage de lopérateur tout dégagement de

fumée visible.

f. Consultez les recommandations particulières en matière

de ventilation indiquées à lalinéa 6 de la norme Z49.1

de lAWS.

5. ENTRETIEN DE LÉQUIPEMENT-- Un équipement

entretenu de façon défectueuse ou inadéquate risque

non seulement de réaliser un travail de mauvaise

qualité mais, chose plus grave encore, dentraîner

des dommages corporels graves, voire mortels en

déclenchant des incendies ou des chocs électriques.

Observez par conséquent les précautions suivantes:

a. Efforcez-vous de toujours confier à un personnel qua-

lifié linstallation, le dépannage et lentretien du poste

de soudage et de coupage. Neffectuez aucune

réparation électrique sur léquipement à moins dêtre

qua-lifié à cet effet.

b. Ne procédez jamais à une tâche dentretien

quelconque à lintérieur du poste de soudage/

coupage, avant davoir débranché lalimentation

électrique.

c. Maintenez en bon état de fonctionnement les câbles,

le câble de masse, les branchements, le cordon

dalimentation et le poste de soudage/coupage.

Nutilisez jamais le poste ou léquipement sil présente

une défectuosité quelconque.

d. Prenez soin du poste de soudage et de coupage et

des équipements accessoires. Gardez-les à lécart

des sources de charleur, notamment des fours, de

lhumidité, des flaques deau maintenez-les à labri

des traces dhuile ou de graisse, des atmosphères

corrosives et des intempéries.

e. Laissez en place tous les dispositifs de sécurité et

tous les panneaux de larmoire de commande en

veillant à les garder en bon état.

f. Utilisez le poste de soudage/coupage conformément

à son usage prévu et neffectuez aucune modification.

6. INFORMATIONS COMPLÉMENTAIRES RELATIVES

À LA SÉCURITÉ--

Pour obtenir des informations complémentaires sur

les règles de sécurité à observer pour le montage et

lutilisation déquipements de soudage et de coupage

électriques et sur les méthodes de travail

recommandées, demandez un exemplaire du livret

N° 52529 Precautions and Safe Practices for Arc

Welding, Cutting and Gouging publié par ESAB.

Nous conseillons également de consulter les publications sui-vantes, tenues à votre disposition par

lAmerican Welding Society, 550 N.W. LeJuene Road,

Miami, FL 32126:

a. Safety in Welding and Cutting AWS Z49.1

b. Recommended Safe Practices for Gas-Shielded Arc

Welding AWS A6. 1.

c. Safe Practices for Welding and Cutting Containers

That Have Held Combustibles AWS-A6.0.

d. Recommended Safe Practices for Plasma Arc Cut-

ting AWS-A6. 3.

e. Recommended Safe Practices for Plasma Arc Weld-

ing AWS-C5. 1.

f. Recommended Safe Practices for Air Carbon Arc

Gouging and Cutting AWS-C5. 3.

g. Code For Safety in Welding and Cutting

CSA-Standard W117. 2.

6

9/97

SECTION 1 DESCRIPTION AND SPECIFICATIONS

I. DESCRIPTION AND SPECIFICATIONS

The MIG-35 Wire Feeder covered in this literature is designed for short arc, spray arc mig or cored wire welding

with a constant potential (CP) welding power source. In

short arc welding, relatively low voltages and small- diameter wires are used. Wire speed is set so that the

low-voltage arc actually shorts out to the weld puddle

50-200 times a second. The result is a small weld puddle,

with minimum melting of base metal and minimum transfer of heat into the work. Short arc welding can be done

in any position, and used to weld sheet as thin as 1/16-in.

In spray arc welding, heavier wires and higher voltages

are used, and there is no shorting out of the arc. Metal

is transferred in a stream of droplets through the arc. The

weld puddle is larger and out-of-position welding is somewhat more difficult, but higher rates of metal deposition

are possible.

SPECIFICATIONS

Input Power Required ...115 volts, 60 hz, single phase

Wire Feed Speed Range .... 0- 1000 in./min. (0-423

mm/sec)

Wire Sizes Accommodated:

Hard/Soft . . . ..... . 023 thru 1/8-in.(.6 thru 3.2 min)

Flux Cored .... 045-in. thru 1/8-in.(1.2 thru 3.2 mm)

Length ....................................... 18.5-in. (470 mm)

Width ............................................13-in. (330 min)

Height .........................................16.5-in (419 min)

Weight (less wire) ........................43-lbs. (19.5 kg)

The MIG-35 uses a heavy duty EH-10A wire drive motor

designed to feed wires from .023-in. to 1/8-in. in diameter. Rate of wire feed (0-1000 inches per minute) is precisely controlled by a solid-state governor printed circuit

board housed in the control assembly. For operator safety,

the torch switch is energized by 12 volts supplied by the

control. All interconnecting cable and hose are quickly

detachable to provide maximum portability of the wire

feeder.

A water kit may be purchased (as an optional accessory)

for use with the MIG-35 when used with water cooled

torches.

FEATURES:

Permanent-magnet motor with high starting torque:

6000 rpm at full load with 40:1 gear reduction.

Quick release pressure roll assembly; no readjust-

ment of pressure required when loading fresh spool

of wire.

All control circuits incorporated on two solid-state

printed boards, mounted for easy access and removal.

Gas purge pushbutton switch to actuate gas sole-

noid only, permit purging of hose and torch.

Inch switch for inching wire without energizing

power source contactor.

Anti-stick circuit for precise adjustment of amount

of wire burnback after wire feed stops, to eliminate

freezing of wire in weld puddle.

Low voltage circuit (12v) for torch switch, to as-

sure operator safety.

All cable and hose connections quickly detachable.

Ground Fault Interrupt Circuit.

CONTROLS:

On front panel: Wire Speed potentiometer, wire speed

range switch, wire inch switch, gas purge pushbutton,

ground fault indicator lamp.

On rear panel: Main power switch, anti-stick potentiometer.

CONNECTIONS:

On front panel: Torch switch cable receptacle.

On rear panel: Power source control cable receptacle.

On machine base: Shielding gas hose, welding power

cable, torch wire conduit, provision for optional water

connections.

7

SECTION 2 EQUIPMENT

WIRE SPEED

EH-10 MOTOR-GEAR UNIT

WIRE SPEED

RANGE SW.

ACCY. SUPPORT

ASSEMBLY

TORCH SWITCH

RECEPTACLE

POTENTIOMETER

WIRE INCH

SWITCH

POWER CABLE

ADAPTABLE BLOCK

GAS PURGE

PUSHBUTTON

TORCH GAS

CONNECTION

Fig. 1 - MIG-35 Wire Feeder (front and rear view)

II. REQUIRED COMPANION EQUIPMENT AND AC-

CESSORIES

A. Constant potential power source, such as:

SVI-450i, 452cv, 652cvcc, etc.

B. Control cable assembly. For connection of the

MIG 35 to ESAB power sources with a 19-pin Amp

receptacle, the following control cable assemblies

are available:

6-foot/(1.8m), P/N 31829

30-foot/(9. I m), P/N 31830

60-foot/(18.3m), P/N 31831

C. Mig welding torch, with contact tip, wire conduit

and outlet guide for wire size/type to be employed.

A suitable air or water cooled torch may be used

with the MIG-35.

When using a water-cooled torch it will be necessary to connect the torch water hose to a continuous water supply or to the wire feeder base by using an optional water kit (see Section I I I -D/E).

With the mig torch, you must have a wire feed accessory kit appropriate to the size and type of wire to be

used. The kit will normally include the feed roll (see

Section II-E).

D. Feed Roll: See Table 1. The MIG-35 comes

equipped with a pressure roll but NOT feed roll.

Select the proper feed roll and Outlet Guide from

Table I for the wire size and type to be used.

MAIN LINE SWITCH

ANTI-STICK

POTENTIOMETER

CONTROL

GAS SOLENOID

VALV E

(Ref.) OPENING FOR POWER

SOURCE LIFTING RING

CABLE RECEPTACLE

Table I

Wire Size/ Two Roll Drive Four RollDrive Outlet***

Type In. Feed Roll Feed Roll Kit* Guide

Hard

.023 17998 (V) 999745n

.030 2075300(V) 999325(V) 993860(a)

.035 2075303(V) 999326(V) 993860(a)

.045 2075302(V) 999327(V) 39N15(b)

.052 2075330(V) 999328(V) 39N15(b)

1/16 2075299(V) 999329(V) 39N15(b)

Cored/Hard

.035 19761 (Serr.) 993860(a)

.045 19761 Serr.) 999330 (Serr.) 39N15(b)

.052 2075261 (Serr.) 999331 (Serr.) 39N15(b)

1/16 2075261 (Serr.) 999332 (Serr.) 39N15(b)

5/64 2075261 (Serr.) 999333 (Serr.) 62N17(c)

3/32 2075257 (Serr.) 999334 (Serr.) 62N17(c)

7/64 2075257 (Serr.) 999335 (Serr.) 39N16

1/8 2075255 (Serr.) 999336 (Serr.) 39N17

Soft

.030 2075304(U) 999320(U) 29N13**

.035 2075304(U) 999321(U) 29N13**

3/64 2075301(U) 999322(U) 29N13**

1/16 2075298(U) 999323(U) 29N13**

3/32 2075297(U) 999324(U) 29N13**

n Requires Guide Bushing, P/N 17997.

* Includes a center wire guide and 2 upper and 2 lower feed rolls.

** Required outlet insert as follows: For .030/.035 wire use 993902, For 3/64 wire

use 05N57, For 1/16 wire use 12N75, For 3/32 wire use 05N58.

*** Outlet Guides must be ordered separately.

Recommended U-Groove Pressure Roll 2075346 be used.

(a) Includes replaceable sleeve (995651).

(b) Includes replaceable sleeve (995692).

(c) Includes replaceable sleeve (995693).

SPINDLE ASSY.

CIRCUIT

BREAKER

POWER SOURCE

8

SECTION 2 EQUIPMENT

E. Shielding Gas Regulator/Flowmeter and fitted

hose to bring gas from flowmeter to wire feeder.

Such as:

Regulator/Flowmeters:

R-5007 Argon/Helium/Nitrogen, P/N 998124.

R-5008 CO2 P/N 998125.

Gas Hoses:

Argon/Helium, Nitrogen, P/N 40V77 (12-1/2-ft.) or

P/N 34V38 (25-ft.)

Heavy Duty, P/N 19416 (12-1/2-ft.)* or P/N 19415

(25ft.)*

* Must be used for CO2 and can also be used for Argon/Helium/

Nitrogen.

III. OPTIONAL ACCESSORIES

*A. Lock-In Circuit Kit (P/N 996959). Allows opera-

tor to release torch switch after arc has been struck.

Includes small circuit board, mounting bracket, and

pre-lugged leads. Instructions (F- 12-336) supplied

with kit. (Circuit connections are shown on schematic diagram in this booklet.)

*B. Preflow/Postflow Kit (P/N 994853). Provides

timed preflow and postflow of shielding gas. Includes printed circuit board, miniature pots for setting the preflow and postflow intervals (from 0. 1 to

3 sec.), mounting brackets, pre-lugged leads. Supplied with instructions for mounting and wiring

(F-12-508).

*NOTE: Lock-in and preflow/postflow may be used to-

gether after a capacitor is removed from the

lock-in printed circuit board. For installation,

refer to the lock-in kit instruction literature

(Form 12- 336).

D. Water Kit (P/N 994466).

Permits the convenient connection of a

water-cooled torch and continuous water supply

to the wire feeder. The kit consists of a coupling,

two adaptors and a fitting. A dependable cooling

water supply, delivery and return water hoses (P/N

40V76, 2 required) will also be required. Note that

Fig. 2 illustrates the use of power cable adaptor

P/N 634693, in addition to the kit. If adaptor

(634693) is not used, adaptor (45VII supplied with

kit) can be connected to the output terminal of the

power source. Install the kit in accordance with Fig.

9 and Sec. IV-F. Connect the water-cooled torch

as shown in Fig. 2.

E. Lifting Bracket (P/N 634287; see Fig. 1). Mounts

on the wire feeder spool support between the support and the spindle assembly. Enables you to

mount the wire feeder overhead on a boom.

F. Spool Enclosure Kit (P/N 600240). Provides pro-

tection of spool of wire against dust and dirt. For

installation instructions refer to Form 12-824.

G. Reel Assembly (P/N 995570). Reel slips over

spindle to allow use of coiled wire.

H. Wire Straightener (P/N 34V74). Reduces wire cast

to improve feedability and increase service life of

torch liners and contact tips (see Fig. 7). Mounts

to the EH-10 accessory support inlet guide, P/N

11N53. This Guide is required to complete the installation on the wire inlet side of the straightener.

I. Wire Spool Spacer (P/N 17511). Enables the use

of a 8-in. diameter spool of welding wire with spindle

assembly on the MIG-35 wire feeder.

J. Four Roll Drive Accessory Support Assembly

(P/N 600216). Refer to booklet F- 12-821 for de-

scription.

K. Wire Feeder Rotary Turntable, P/N 678940. Al-

lows rotation of feeder as operator changes work

positions. This reduces strain and bending of torch

cables - see F- 12-984.

L. Wire Feeder Mobile Undercarriage Kit, P/N

680005. This kit includes a mounting plate and

caster type wheels to provide complete mobility for

wire feeder (see F-14322).

9

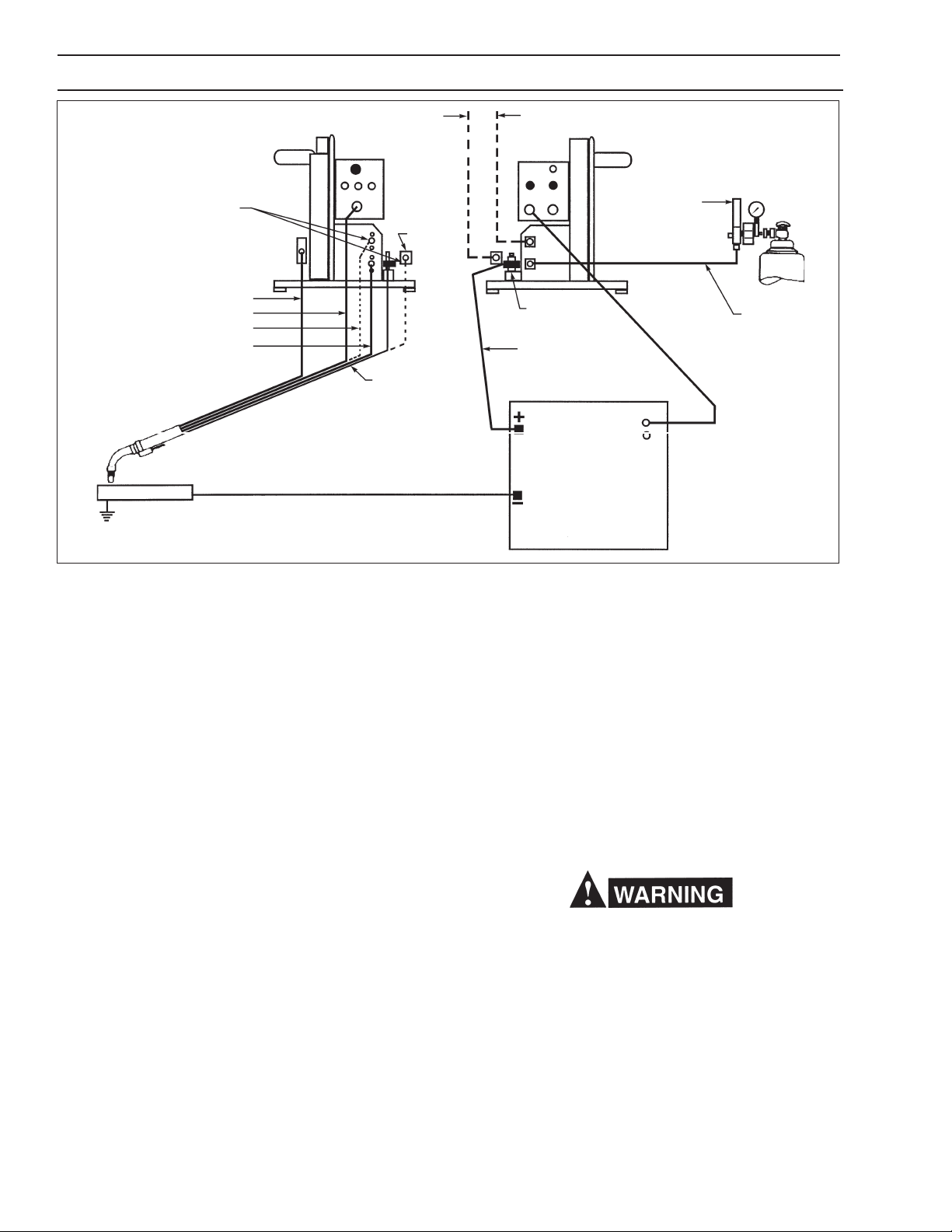

SECTION 4 INSTALLATION

*WATER KIT -994466

TORCH CONDUIT

TORCH SWITCH

*TORCH WATER HOSE

TORCH GAS HOSE

WORK

GROUND

*WATER DRAIN HOSE - 40V76 (12-1/2 Ft.)

FRONT VIEW

*ADAPTOR

- 45V11

TORCH

POWER

CABLE

WELDING WORK CABLE

(4/O, Customer Supplied)

*WATER IN HOSE - 40V76 (12-1/2 Ft.)

REAR VIEW

REGULATOR/

FLOWMETER

POWER

CABLE

ADAPTOR - 634693

ELECTRODE WELDING

CABLE

(4/O, Customer Supplied)

C.P. POWER SOURCE

*Parts required when

using a Water Kit & Water

Cooled Torch.

Fig. 2 - Interconnection Diagram

IV. INSTALLATION

After checking to be sure you have all required components and accessories (see Section 11), proceed as

follows (with reference to Fig. 2, Interconnection Diagram):

A. HOSE AND ELECTRICAL CONNECTIONS

Connect shielding gas supply hose. Connect control cable to rear panel of unit and to power supply.

(If power supply is not new, check to make certain

that no wiring changes have been made which permit actuation of contactor by some means other

than power received through the welding control

cable receptacle. Any such modifications must be

removed before attaching control cable to power

supply.)

NOTE: When using a water-cooled torch, the water

connections shown in Figure 2 must also be

made.

B. TORCH CONNECTIONS

Attach torch gas hose to connection. Plug in torch

switch cable and lock by twisting. After inserting conduit liner (if used) and attaching wire outlet guide of

correct size, connect wire feed conduit to welding head

clamp and lock in place. Connect torch power cable to

power cable adaptor (with a second cable from that

stud to the power source).

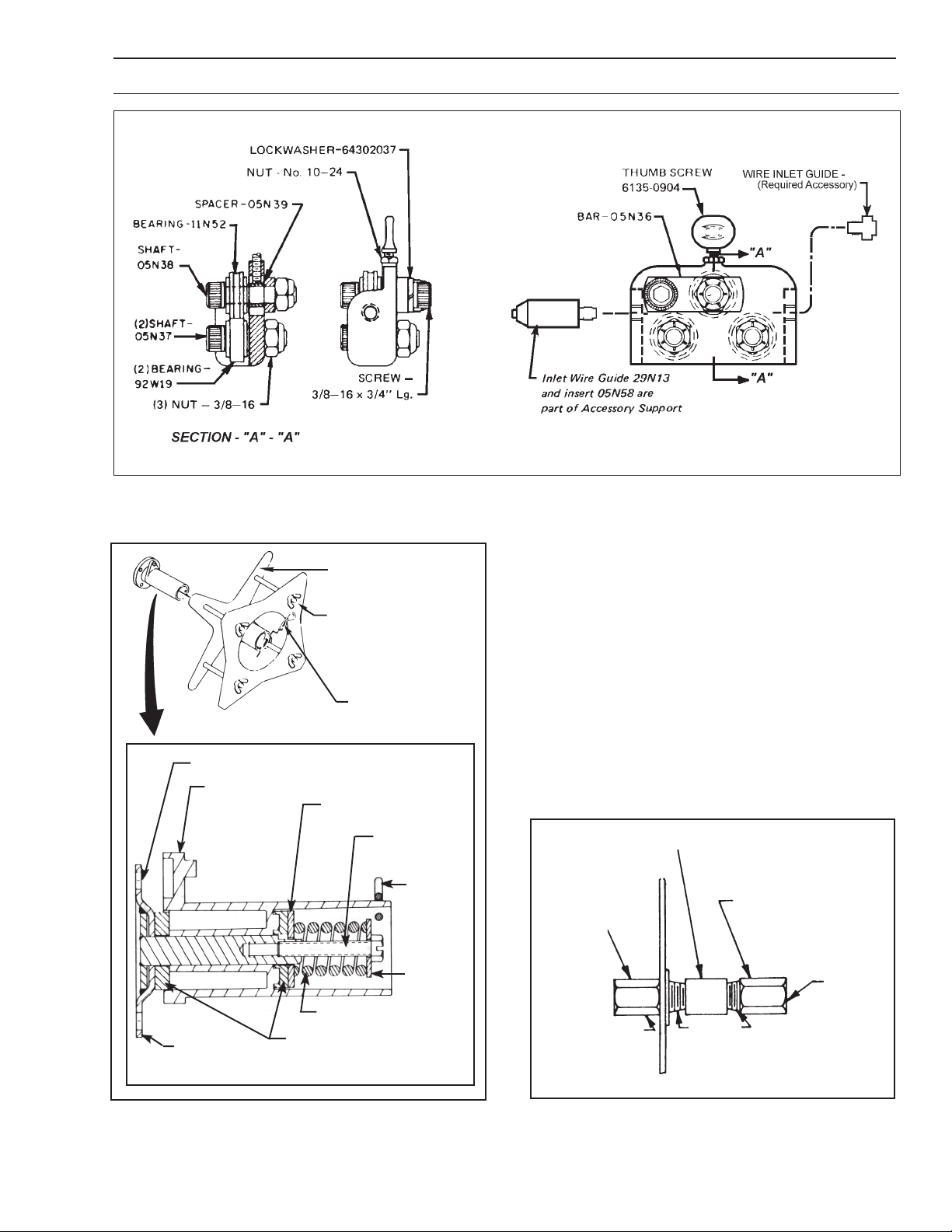

C. INSTALLING FEED ROLL

1. Release the clapper on the accessory support assembly (Figure 6) by disengaging the retainer from

the clapper fork.

2. Remove thumbscrew, bell washer and flat washer

from the feed roll shaft.

3. Slip the feed roll on the shaft, engaging the key.

Be sure to observe the THIS SIDE OUT marking

on the feed roll.

4. Replace flat washer, bell washer and thumbscrew,

tightening screw sufficiently to eliminate all end play

from the feed roll.

D. INSTALLING SPOOL OF WIRE

Make sure safety glasses with side shields are worn

when handling or changing wire, or clipping wire

off at the spool or at the end of the torch-serious

eye injury can result due to the springiness of the

wire which quickly unravels, or a cut wire end which

may shoot across the room.

1. Remove hairpin clip from spindle.

2. Position the spool of wire so that when it is placed

on the spindle, wire will be drawn to the feed roll

from the bottom of the spool. The spool should be

held so that the index hole on the back will engage

the lug on the spindle.

10

SECTION 4 INSTALLATION

3. Slide the spool onto the spindle until it engages

the lug. Lock in place with the hairpin clip.

4. Loosen the brake screw in the center of the spindle

hub, then tighten it just enough to prevent coasting of the spool when wire is drawn from it. Too

much pressure will load the wire feed motor unnecessarily. Too little pressure will permit the spool

to overrun, causing the wire to kink and tangle.

5. Thread wire to torch as follows:

a. Round off the free end of the welding wire with

a file.

b. Raise the clapper to relieve pressure on the

feed roll.

c. Thread the wire through the inlet guide, over

the groove in the feed roll, and into the outlet

guide.

d. Replace the pressure roll clapper.

e. Remove nozzle and contact tip from torch. Inch

the wire until it emerges from the front end of

torch. Slide the contact tube over the end of

the wire and secure it in place. Replace torch

nozzle.

6. When wire coils are to be used instead of spools,

mount wire reel on spindle as though it were a spool

(see 1 and 3 above). Remove thumbnuts and cover

plate from reel. Remove coil from its package, but

do not remove its binding wires. Slide coil onto reel

so that wire will be drawn from bottom of coil (starting end for a coil is always the outer end). Replace

reel cover plate and thumbnuts. Cut off coil tie wires

and any kinked wire. Then adjust brake screw and

thread wire to torch as covered in 4 and 5 above.

E. ADJUSTING THE PRESSURE ROLL ASSEMBLY

When a new wire size or type is to be used, set the

pressure roll adjustment as follows:

1. Release the clapper and unscrew the pressure adjusting knob until the pressure spring is free.

2. Thread the wire through the inlet and outlet guides

of the accessory support.

3. Engage the clapper making sure the wire is held in

the feed roll groove.

4. Alternately press and release the torch switch (see

Caution note in Para. D above) while slowly tightening the pressure adjusting knob until the wire

begins to feed without slipping. The spring pressure applied should be the minimum required to

provide positive, nonslip wire feed. Too little pressure will result in wire slippage while excessive

pressure will scar and deform the wire. Note that a

light spring (1 82W55) is installed on the accessory support for use with soft and small diameter

hard wire. For large diameter hard wire, replace

this spring with a heavy spring (182W54) supplied

with the unit.

F. WATER KITS (Optional see Fig. 9)

Mount bulkhead adaptor (58V75) behind opening provided in vertical base plate, above gas connection, and

secure with screws (No. 8-32 x 3/8-in.) and lockwashers

provided. Attach coupling and adaptor (11N16) behind

bulkhead adaptor. Mount torch cable adaptor (45V11)

on welding power stud. Connect water drain hose to

this adaptor, and water inlet hose to adaptor 11N16.

Power source contactor becomes energized the

moment the torch trigger is depressed. Arcing can

occur if the wire is brought to a ground. Keep the

torch awayfrom ground until welding is to begin.

11

SECTION 5 OPERATIONS

V. ADJUSTMENTS AND OPERATION.

A. CONTROL SETTINGS

1. Turn the Main Power Switch on the rear control

panel to the ON position.

2. Set the dual Range wire speed switch to the High

or Low range desired. The Low range provides wire

speeds from 0-500 ipm, and the High range allows speeds from 400 through Maximum ipm.

3. Set the wire feed rate by adjusting the WIRE

SPEED control knob on the front panel. The wire

feed rate, in turn, controls the current furnished by

the CP power source.

IMPORTANT

If the factory-set acceleration time feature

does not satisfy your welding requirements, a

trim pot on the logic board can be adjusted to

provide the exact acceleration (time) characteristics you desire, as follows:

(1) If stumbling arc starts occur, the accel-

eration time may be too short and the trim

pot (R23) should be adjusted counterclockwise to increase the time.

(2) If burnbacks or near burnbacks occur, the

acceleration time may be too long and the

trim pot (R23) should be adjusted clockwise to decrease the time.

4. Set the ANTI-STICK control on the rear panel to

the desired setting depending on the amount of

burnback desired. The higher the setting, the

greater the amount of time that the contactor is

held in to allow the wire to burnback out of the

puddle, after releasing the torch switch.

B. FEEDING WIRE

If wire has been threaded through torch and contact tip

as directed in Sec. IV-D-5, simply operate the inch

switch or cut off wire, as required, so that the wire extends about 1/2 in. beyond the end of the torch nozzle.

C. SHIELDING GAS FLOW RATE

Hold gas purge pushbutton in and set desired gas

flow rate at the shielding gas regulator-flowmeter. Hold

push-button in at least 15 seconds to insure adequate

purging of gas hose and torch.

If preflow/postflow kit has been installed (inside the

control box) set its potentiometer for the desired preflow

and postflow intervals (range: 0. 1 to 3 seconds).

D. MAKING THE WELD

Start to weld by pressing the torch switch lever to actuate the torch switch. This closes the welding contactor,

and starts wire feed and gas flow. Then touch the end

of the welding wire to the workpiece to establish the

arc. The switch lever must be depressed for the duration of the weld. Welding action will be stopped and all

services discontinued when the lever is released and

returns to its original position. If the torch is withdrawn

from the workpiece during welding, the arc will be interrupted, but shielding gas flow and welding wire feed

will continue until the switch lever is released.

Do not allow metal-to-metal contact between the

wire feeder chassis and a metal surface connected

in any way to a welding ground. With such contact, a poor welding ground connection may create a difference in potential that sends part of the

welding current through the safety ground wiring

in the control cable and wire feeder, resulting in

burnout of that wiring and/or damage to wire feeder

circuitry. If the safety ground burns out, the operator may be exposed to 115V. shock hazard.

NOTE: If lock-in circuit (optional) has been installed,

switch lever can be released as soon as arc

has been struck. When weld is complete, services are discontinued by closing torch switch

again.

12

SECTION 6 OPERATIONS

VI. OPERATING SEQUENCE

NORMAL

1 . Close torch switch.

Gas solenoid opens, weld contactor closes,

wire feed motor runs.

2. Release torch switch.

Wire feed motor deenergized, brake circuit ef-

fective.

Anti-stick circuit energized.

3. Anti-stick circuit times out (delay determined

by setting of anti-stick potentiometer).

Weld contactor opens.

4. Release torch switch.

Gas solenoid valve closes.

PREFLOW/POSTFLOW

Same as NORMAL except that when torch switch is

closed, only gas solenoid valve is immediately energized. Contactor and wire feed motor are energized

only after interval established by setting of preflow potentiometer. When torch switch is opened, gas solenoid valve remains energized until interval established

by setting of postflow potentiometer has elapsed.

LOCK-IN

Same as NORMAL except that closing of torch switch

energizes a parallel switch in lock-in circuit, so torch

switch lever can be released immediately. At end of

weld, momentary closing of the torch switch initiates

the sequence that normally follows opening of that

switch.

NOTE: Lock-in and preflow1postflow may be used to-

gether after a capacitor is removed from the

lock-in printed circuit board. For installation, refer to the lock-in kit instruction literature (form

12-335).

13

SECTION 7 TROUBLESHOOTING

VII. TROUBLESHOOTING

Listed below are a number of trouble symptoms,

each followed by the checks or action suggested

to determine the cause. Listing of checks and/or

actions is inmost probable order, but is not necessarily 100% exhaustive. Always follow this general rule. Do not replace a printed circuit (PC) board

until you have made all the preceding checks. Always put the main power switch in OFFposition

before removing or installing a PC board. To avoid

damage, take great care not to grasp or pull on

components when removing a PC board. If a

printed circuit (PC) board is determined to be the

problem, check with your ESAB supplier for a

trade-in on a new PC board. Supply the distributor

with the part number of the PC board as well as

the serial number of the wire feeder Do not attempt

to repair the PC board yourself. Warranty on a PC

board will be null and void if repaired by customer

or an unauthorized repair shop.

A. SYMPTOM: Wire Feeder totally inoperative.

1. Check for 110-115 VAC between black and

white wires on main line switch (rear panel). If

not present, trouble lies in power input source.

2. If power is present at main line switch, check

for 110-115 VAC between P4-15 and P4-16. If

not present, reset circuit breaker.

B. SYMPTOM: Circuit breaker blows repeatedly as

soon as main line switch is turned ON.

1. Check wiring for short.

2. If no short can be found, replace J Governor

board.

C. SYMPTOM: Circuit breaker blows when torch

switch is closed.

1. Check for jammed or defective wire feed motor/drive unit.

2. If motor/drive unit is OK, replace logic board.

D. SYMPTOM: With torch switch closed, wire feed

motor runs, and weld contactor closes, but gas

solenoid is not energized.

1 . Check for missing (or loose) jumper between

TB1-5 and TB1-6.

2

. Check solenoid for defect.

3. Check for defective contact (NC) on gas

pushbutton switch.

E. SYMPTOM: With torch switch closed, weld

contactor closes and gas solenoid is energized,

but wire feed motor does not run.

1. Check for defect in cable to wire feed motor.

2. Check for excessively-worn motor brushes, or

other motor defect.

3. Check DC voltage across C7 on J Governor

board and turn WFS from min. to max. Volt-

age should adjust 0 to 10V. If voltage is there

but motor still does not run, replace J Governor board. If no voltage, replace J Governor or

logic board.

F. SYMPTOM: Wire feed motor does not run

when wire inch switch is activated.

1. Check switch for defect.

2. Check wiring beyond switch for break.

3. Replace J governor board.

4. Replace logic board.

G. SYMPTOM: No control over motor speed by

wire feed speed potentiometer.

1. Check wire speed potentiometer circuit across

P1 pins 9 and 10 with an ohmmeter. Resistance should range from 150 K to 50 K ohms

(max. to min.) in the High range, and from 110

K to 10 K ohms (max. to min.) in the Low range.

Replace potentiometer if defective.

2. Replace J governor board.

H. SYMPTOM: No control over anti-stick time.

1. Check anti-stick potentiometer with ohmmeter. Resistance should range from 0- 100 K

ohms. Replace potentiometer if defective.

2. Replace logic board.

I. SYMPTOM: Erratic or pulsing wire feed rate.

1. Replace J governor board.

J. SYMPTOM: Brake resistor (R2) burns out.

1. Replace resistor.

2. Replace logic board if R2 bums out again.

K. SYMPTOM: Motor runs as soon as main line

switch is closed.

1. If contactor and solenoid are also energized:

a. Check for defective torch switch or short

in switch cable.

b. Replace logic board.

2. If contactor and solenoid are not simultaneously energized:

a. Replace J governor board.

b. Replace logic board.

L. SYMPTOM: With torch switch closed, wire

feed motor runs, but welding contactor and

gas solenoid are not activated.

1. Check for break in wiring.

2. Check for blown fuse on logic board.

3. Replace logic board.

M. SYMPTOM: Ground Fault Light is ON and

torch trigger does not activate feeder.

1. Check or contact between the welding circuit

and the feeder chassis and clear any short

circuits.

2. Turn power OFF and back ON and

ground fault should reset.

3. Replace logic board.

4. Replace ground fault detector (sensor).

14

SECTION 8 MAINTENANCE

VIll. MAINTENANCE

If this equipment does not operate properly, stop

work immediately and investigate the cause of the

malfunction. Maintenance work must be performed

by an experienced person, and electrical work by

a trained electrician. Do not permit untrained persons to inspect, clean, or repair this equipment.

Use only recommended replacement parts.

A. GENERAL MAINTENANCE

Little maintenance is required to keep the wire feeder

in top operating condition. It is important, however, that

moving parts such as feed and pressure rolls, wire feed

motor, etc., be kept clean and free of dust or dirt. Cleaning is best accomplished by regularly blowing off these

parts with dry compressed air. This should be done

once for every eight hours of operating time, more often if necessary.

B. LUBRICATION OF MOTOR-GEAR UNIT

The EH-10A motor-gear unit is lubricated with a heavy

duty grease when assembled at the factory and should

not require further lubrication unless disassembled. If

disassembled, relubricate with Texaco Multifak grease.

C. CHECKING OR REPLACEMENT OF MOTOR

BRUSHES

Motor brushes should be checked periodically. If a

brush is broken, or worn down to less than 3/8-in.

length, it must be replaced. Brushes can be inspected

by unscrewing the brushholder plug and withdrawing

the brush assembly. Never remove a brush without

matchmarking it and its holder, so that it can be replaced in the same holder in its original position.

15

SECTION 9 REPLACEMENT PARTS

IX. REPLACEMENT PARTS DATA

1. All replacement parts are keyed on the illustrations which follow. Order replacement parts by part number and

part name, as shown on illustrations.

2. Many of the parts on the illustrations, particularly electronic parts, are vendor items. This means that they are

standard commercial parts made by and purchased from other manufacturers. If you order from these outside

sources, use the manufacturers part number or designation as shown in the Electrical Parts List.

3. Always state the series or serial number of the machine on which the parts are to be used. The serial number is

stamped on the unit nameplate.

ELECTRICAL PARTS LIST

Symbol Part No. Description and Vendor

ASP 92W64 Potentiometer 100K ohm, 2W - Allen Bradley No. J5054OD-J

WSP

C1 993716 Capacitor - I mfd. 600V

C2, C3 672348 Capacitor - .0 1 mfd. 1000V

GS 951125 Switch - Pushbutton - Switchcraft, No. 203 Littleswitch

GSV 2062305 Solenoid Valve - ASCO, P/N JS82611 0

IS 97W10 Switch - DPDT, Cutler Hammer 8906K1453

MLS, SWS 97W64 Switch - DPST 15A/125V, (Cutler Hammer No. 7560K5)

P3 182W64 Connector 2 POLE/2 Wire - Pass and Seymour No. 7468

P4 674569 Connector P/C - AMP Incorp. P/N 583617-3

P5 634772 Receptacle - Amphenol No. MS-3102A-18-12P

R2 17240003 Resistor - 3 Ohm, 25W, Ohmite Type 270-25. No. L25J3RO

TB-1 95W12 Terminal Block - Cinch - Jones No. 8-140

TB-2 92W11 Terminal Block - Jones No. 354-11-04-001

TR1 994303 Transformer, Prim. 117, 50-60 Cy. - Stancor No. P8362

SPINDLE ASSY.

948259 (See Fig. 8)

SPEED RANGE (H/LS)

SWITCH - 950629

(P3) RECEPTACLE - 182W64

EH-10A MOTOR-GEAR UNIT

ASSY. - 679773 (See Fig. 5)

ACCESSORY SUPPORT

(ASSY. - 49V51

See Fig. 6)

Not Illustrated

INSULATOR RING60N90

KEY - 28N33

THUMBSCREW61351087

FLAT WASHER - 64309431

BELL WASHER - 950783

n RECOMMENDED SPARE PARTS

GAS CONNECTION 58V58

(GSV) GAS SOLENOID

VALVE - 2062305n

INLET CONNECTION

74S76

POWER CABLE ADAPTOR BLOCK

ASSY. - 674156

WARNING DECAL - 954440*

CONTROL ASSY. - 37911

(See Fig. 4)

(WSP) - See Fig. 4

(GS) PUSHBUTTON PURGE SW. 951125

(IS) - INCH SWITCH - 97W10

WARNING DECAL - 995204

GROUND FAULT INDICATOR LAMP

(Ref.) OPENING FOR ESAB

POWER SOURCE LIFTING RING

BASE/FRAME

2075554

(2) SKID - 999629**

* Replace Decal if it Becomes Exces-

sively Worn or Lost

** Earlier wire feeder bases only con-

tained 2-skid mfg. holes. To install 3hole skids, use skid as a template and

redrill new holes in wire feeder base.

Fig. 3 - MIG-35 Wire Feeder, P/N 953552

16

SECTION 9 REPLACEMENT PARTS

WARNING LABEL 995164

(WSP)

KNOB 13730611

(R2) RESISTOR 17240003

WARNING LABEL

- 954440

SIDE PANEL - 37912YL

SWITCH, TOGGLE 97W64

SWITCH, TOGGLE 97W10

PC BOARD BRACKET - 37914

CHASSIS - 32305GY

FILTER

NETWORK

- 996918

POTENTIOMETER

- - 92W64

TERMINAL BLOCK

6 POS 20 AMP- 93W21

TERMINAL BLOCK 8 POS 15 AMP- 93W21

(WSP) POTENTIOMETER - 92W64

SWITCH, TOGGLE - 634518

PC BOARD ASSY.

LOGIC (P2) - 38178

COVER - 994309YL

WARNING LABEL

- 995204 (Electrical Shock)

PC BOARD ASSY. (P1)

J GOV. - 994236

SWITCH SEAL, BLACK

- 951474

CIRCUIT

BREAKER

- 2062161

STRAIN

RELIEF

- 96W85

KNOB - 951502

(P5) RECEPTACLE - 634722

Fig. 4 - Control Assembly, P/N 37911

8 - 32 UNC 2B

.25 DEEP - 2 PLCS

8 - 32 UNC 2B

.60 DEEP ON

ARMATURE SHAFT

(4) HEX, HD. SCREWS 5/16 - 18x3/4

(4) FLAT WASHER 5/16

(4) LOCKWASHER 5/16

5/16 - 18 UNC 2B

.63 MIN. DEPTH

(11 full threads)

VIEW A-A

Do not use old existing hardware to mount the motor. Only use the

5/16 hardware supplied.

.19 STRIP

LENGTH

Fig. 5 - EH-10A Motor-Gear Unit Assembly (40:1, 0-1000 ipm) P/N 679773

17

SECTION 9 REPLACEMENT PARTS

OUTPUT SHAFT ASSY.

(Part of 19734 OUTPUT GEAR CASE

OUTPUT GEAR CASE

19734 - (Includes

Output Shaft Assy.

Shown Above)

FEED ROLL LOCATING

COLLAR -599877

GEAR ASSY. B - 20293

OUTPUT SHAFT SEALl

GEAR ASSY. A - 20292

MAGNET ASSY. - 19730

ARMATURE SHAFT SEALl

OUTPUT GEAR CASE GASKET*

llBRUSH END BELL - 19732

(Includes TWO-BRUSH

HOLDER ASSYS.)

ARMATURE & BEARINGS 19726

Includes:

ARMATURE BEARING - 20288

MOTOR CORD LEAD - 19731

BRUSH HOLDERll

BRUSH

CAP

(2) CARBON BRUSH

REPLACEMENT KIT - 679784

Includes:

(2) BRUSH CAP

(2) CARBON BRUSH

SCREW 10-24 X 1/2

Fig. 5A - EH-10A Motor-Gear Unit Parts Breakdown

CLAPPER - 60N98

ROLL PIN 1/4 x 1-3/4 LG

INLET

INLET WIRE GUIDE

29N13

INLET GUIDE INSERT

05N58

SETSCREW #6-32 x 1/4 LG

(2) LOCKING HANDLE

BOLT 1/4 x 1-5/8 LG

SUPPLIED

HEAVY SPRING - 182W54 (FOR LARGE DIA. HARD WIRE)

(61330849)

ASSEM. - 49V44

(Includes)

SPACER - 60N79

PRESSURE ROLL

28V52

NUT - 5/16-18

SHAFT - 60N65

KNOB - 60N68

LIGHT SPRING - 182W55 (FOR SOFT &

SMALL DIA. HARD WIRE)

RETAINER - 58N24

FORK - 49V43

WIRE OUTLET GUIDE/INSERT*

(SEE TABLE 1)

CONDUIT

OUTLET

WIRE OUTLET*

GUIDE

CLAMP - 61N02

ROLLPIN - 3/16 x 1-3/4 LG

SCREW - 5/16 - 18 x 2 LG

* Outlet Guide Not Included in Assembly Part No.

49V51.

Fig. 6 - Accessory Support Assembly, P/N 49V51 - 2 Roll Drive

(4 Roll Drive - See Supplement F-12-821)

18

SECTION 9 REPLACEMENT PARTS

11N53

Fig. 7 - Optional Wire Straightener, P/N 34V74

WIRE REEL - 995570

Includes:

REEL - 995568

COVER - 995569

(4) WING NUT, 1/213

63398183

REEL

(4) .359 DIA. HOLE ON 3 DIA. D.C.

SPINDLE - 948258

SUPPORT 948257

(2) BRAKE PAD - 948255

(Ref. Hair Pin Clip)

D TYPE WASHER 948254

SPRING - 948253

SCREW

5/1618 x 2

HAIR PIN

CLIP

634347

WASHER 948256

WATER

CONNECTION

58V75

(OUTLET)

5/8 - LH

COUPLING - 68121075

ADAPTOR - 11N16

(INLET)

5/8 - 18LH

1/4N.P.T.

Fig. 8 - Spindle Assembly, P/N 948259,

Optional Wire Reel, P/N 995570

Fig. 9 - Water Kit, 994466

19

Fig. 11 - Schematic Diagram

20

Fig. 12 - Wiring Diagram

21

NOTES

22

DESIGN CHANGES

The E edition of this booklet include the following:

1. Changed control fuse (F1) from 5 to 6-1/4 amps.

2. Changed logic board from 994239 to 675473.

3. Changed mother board from 994281 to 675475.

4. Add information on page 16 regarding interchangeability of logic/mother boards.

The F edition of this booklet includes the following:

1. Corrected J Gov. p.c. P/N from 999741 to 994236.

2. Corrected Spotweld Kit P/N from 994396 to 999741.

3. Added information to Table 1.

4. Added note regarding bypassing WSV if installed when water recirculator is used.

The G edition of this booklet includes the following: 1. Added parts breakdown for EH- 10A motor.

2. Added optional Dual Range Wire Speed Kit & related information.

The H edition includes the following for serial numbered units beginning with M89P - - - - - (for P/N

953552) and M89N - - - - - (for P/N 677634):

1. Added wire speed Range (Hi-Low) Switch to front panel.

2. Revised front panel component locations.

3. Changed resistor R2 from 50W, 5 ohm to 25W, 3 ohm.

4. Changed fuse (F1, 6-1/4 amps.) to circuit breaker (CB, 7 amps.)

The J edition covers part number change of Gas Purge switch (GS) 994925 to 951125.

The K edition covers change in control cables for connecting wire feeder to latest power sources and to delete the

discontinued water kit with solenoid valve (2075760) and wire wiper accessories.

The L edition covers changes in controls, optional accessories, operating sequences and troubleshooting.

The L edition was edited to change the part number for the Control Assembly from 953549 which was incorrect to

37911. The date was updated, but there was not a revision change.

The M edition updates Table 1, removes information on the Wire Wiper Holder which is no longer used and

updates call outs and/or part numbers on Fig. 3, Fig. 4, Fig. 5A, Fig. 6 and Fig. 7.

23

ESAB Welding & Cutting Products, Florence, SC Welding Equipment

COMMUNICATION GUIDE - CUSTOMER SERVICES

A. CUSTOMER SERVICE QUESTIONS:

Order Entry Product Availability Pricing Delivery

Order Changes Saleable Goods Returns Shipping Information

Telephone: (800)362-7080 / Fax: (800) 634-7548

Telephone: (800)783-5360 / Fax: (800) 783-5362

Telephone: (800) 235-4012/ Fax: (888) 586-4670

B. ENGINEERING SERVICE: Telephone: (843) 664-4416 / Fax : (800) 446-5693

Welding Equipment Troubleshooting Hours: 7:30 AM to 5:00 PM EST

Warranty Returns Authorized Repair Stations

C. TECHNICAL SERVICE: Telephone: (800) ESAB-123/ Fax: (843) 664-4452

Part Numbers Technical Applications Hours: 8:00 AM to 5:00 PM EST

Performance Features Technical Specifications Equipment Recommendations

D. LITERATURE REQUESTS: Telephone: (843) 664-5562 / Fax: (843) 664-5548

E. WELDING EQUIPMENT REPAIRS: Telephone: (843) 664-4487 / Fax: (843) 664-5557

Repair Estimates Repair Status Hours: 7:30 AM to 3:30 PM EST

F. WELDING EQUIPMENT TRAINING:

Telephone: (843)664-4428 / Fax: (843) 679-5864

Training School Information and Registrations Hours: 7:30 AM to 4:00 PM EST

G. WELDING PROCESS ASSISTANCE:

Telephone: (800) ESAB-123 / Fax: (843) 664-4454 Hours: 7:30 AM to 4:00 PM EST

H. TECHNICAL ASST. CONSUMABLES:

Telephone : (800) 933-7070 Hours: 7:30 AM to 5:00 PM EST

Eastern Distribution Center

Central Distribution Center

Western Distribution Center

Hours: 7:30 AM to 4:00 PM EST

IF YOU DO NOT KNOW WHOM TO CALL

Telephone: (800) ESAB-123/ Fax: (843) 664-4452/ Web:http://www.esab.com

F-12-786-M 3/2001 Printed in U.S.A.

Hours: 7:30 AM to 5:00 PM EST

Loading...

Loading...