PT-36 Integrated Gas Control Cutting Data

Cut Data Manual (EN)

0558010300 Version 4.5 released on 13May13

BE SURE THIS INFORMATION REACHES THE OPERATOR.

YOU CAN GET EXTRA COPIES THROUGH YOUR SUPPLIER.

CAUTION

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the

principles of operation and safe practices for arc welding and cutting equipment, we urge

you to read our booklet, “Precautions and Safe Practices for Arc Welding, Cutting, and

Gouging,” Form 52-529. Do NOT permit untrained persons to install, operate, or maintain

this equipment. Do NOT attempt to install or operate this equipment until you have read

and fully understand these instructions. If you do not fully understand these instructions,

contact your supplier for further information. Be sure to read the Safety Precautions before installing or operating this equipment.

USER RESPONSIBILITY

This equipment will perform in conformity with the description thereof contained in this manual and accompanying labels and/or inserts when installed, operated, maintained and repaired in accordance with the instructions provided. This equipment must be checked periodically. Malfunctioning or poorly maintained equipment

should not be used. Parts that are broken, missing, worn, distorted or contaminated should be replaced immediately. Should such repair or replacement become necessary, the manufacturer recommends that a telephone

or written request for service advice be made to the Authorized Distributor from whom it was purchased.

This equipment or any of its parts should not be altered without the prior written approval of the manufacturer.

The user of this equipment shall have the sole responsibility for any malfunction which results from improper

use, faulty maintenance, damage, improper repair or alteration by anyone other than the manufacturer or a service facility designated by the manufacturer.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

2

TABLE OF CONTENTS

SUBSECTION TITLE ............................................................................PAGE

Safety Precautions..........................................................................................5

Carbon Steel Quality.......................................................................................13

Aluminum Quality .........................................................................................33

Stainless Steel Quality......................................................................................37

Carbon Steel Production ...................................................................................51

Aluminum Production .....................................................................................67

Stainless Steel Production................................................................................. 79

Water Injection Aluminum Production.................................................................... 101

Water Injection Stainless Steel Production .................................................................111

Carbon Steel Air ......................................................................................... 125

Aluminum Air ........................................................................................... 139

Stainless Steel Air ........................................................................................145

3

TABLE OF CONTENTS

4

SAFETY PRECAUTIONS

Safety Precautions

WARNING: These Safety Precautions are for your

protection. They summarize precautionary information from the references

listed in Additional Safety Information

section. Before performing any installation or operating procedures, be sure to read and

follow the safety precautions listed below as well

as all other manuals, material safety data sheets,

labels, etc. Failure to observe Safety Precautions

can result in injury or death.

PROTECT YOURSELF AND OTHERS -Some welding, cutting, and gouging

processes are noisy and require ear

protection. The arc, like the sun, e mits

ultraviolet (UV) and other radiation

and can injure skin and eyes. Hot metal can cause

burns. Training in the proper use of the processes

and equipment is essential to prevent accidents.

Therefore:

1. Always wear safety glasses with side shields in

any work area, even if welding helmets, face

shields, and goggles are also required.

2. Use a face shield tted with the correct lter and

cover plates to protect your eyes, face, neck, and

ears from sparks and rays of the arc when operating or observing operations. Warn bystanders

not to watch the arc and not to expose themselves

to the rays of the electric-arc or hot metal.

3. Wear ameproof gauntlet type gloves, heavy

long-sleeve shirt, cuess trousers, high -topped

shoes, and a welding helmet or cap for hair

protection, to protect against arc rays and hot

sparks or hot metal. A ameproo f apron may also

be desirable as protection against radiated heat

and sparks.

4. Hot sparks or metal can lodge in rolled up sle eves,

trouser cus, or pockets. Sleeves and collars

should be kept buttoned, and open pockets

eliminated from the front of clothing.

5. Protect other personnel from arc rays and hot

sparks with a suitable non-ammable partition

or curtains.

6. Use goggles over safety glasses when chipping

slag or grinding. Chipped slag may be hot and

can y far. Bystanders should also wear goggles

over safety glasses.

Safety - English

FIRES AND EXPLOSIONS -- Heat from

ames and arcs can start res. Hot

slag or sparks can also cause res and

explosions. Therefore:

1. Remove all combustible materials well away from

the work area or cover the materials with a protective non-ammable covering. Combustible

materials include wood, cloth, sawdust, liquid

and gas fuels, solvents, paints and coatings,

paper, etc.

2. Hot sparks or hot metal can fall through cracks

or crevices in oors or wall openings and cause a

hidden smoldering re or res on the oor below.

Make certain that such openings are protected

from hot sparks and metal.“

3. Do not weld, cut or perform other hot work until

the work piece has been completely cleaned so

that there are no substances on the work piece

which might produce ammable or toxic vapors.

Do not do hot work on closed containers. They

may explode.

4. Have re extinguishing equipment handy for

instant use, such as a garden hose, water pail,

sand bucket, or portable re extinguisher. Be

sure you are trained in its use.

5. Do not use equipment beyond its ratings. For

example, overloaded welding cable can overheat

and create a re hazard.

6. After completing operations, inspect the work

area to make certain there are no hot sparks or

hot metal which could cause a later re. Use re

watchers when necessary.

7. For additional information, refer to NFPA Standard 51B, "Fire Prevention in Use of Cutting and

Welding Processes", available from the National

Fire Protection Association, Batter y march Park,

Quincy, MA 02269.

ELECTRICAL SHOCK -- Contact with

live electrical parts and ground can

cause severe injury or death. DO

NOT use AC welding current in damp

areas, if movement is conned, or if there is danger

of falling.

5

SAFETY PRECAUTIONS

1. Be sure the power source frame (chassis) is connected to the ground system of the input power.

2. Connect the work piece to a good electrical

ground.

3. Connect the work cable to the work piece. A poor

or missing connection can expose you or others

to a fatal shock.

4. Use well-maintained equipment. Replace worn or

damaged cables.

5. Keep everything dry, including clothing, work

area, cables, torch/electrode holder, and power

source.

6. Make sure that all parts of your body are insulated

from work and from ground.

7. Do not stand directly on metal or the earth while

working in tight quarters or a damp area; stand

on dry boards or an insulating platform and wear

rubber-soled shoes.

8. Put on dry, hole-free gloves before turning on the

power.

3. Welders should use the following procedures to

minimize exposure to EMF:

A. Route the electrode and work cables together.

Secure them with tape when possible.

B. Never coil the torch or work cable around your

body.

C. Do not place your body between the torch and

work cables. Route cables on the same side of

your body.

D. Connect the work cable to the work piece as close

as possible to the area being welded.

E. Keep welding power source and cables as far

away from your body as possible.

FUMES AND GASES -- Fumes and

gases, can cause discomfort or harm,

particularly in conned spaces. Do

not breathe fumes and gases. Shielding gases can cause asphyxiation.

Therefore:

9. Turn o the power before removing your gloves.

10. Refer to ANSI/ASC Standard Z49.1 (listed on

next page) for specic grounding recommendations. Do not mistake the work lead for a ground

cable.

ELECTRIC AND MAGNETIC FIELDS

— May be dangerous. Electric current owing through any conductor causes localized Electric and

Magnetic Fields (EMF). Welding and

cutting current creates EMF around welding cables

and welding machines. Therefore:

1. Welders having pacemakers should consult their

physician before welding. EMF may interfere with

some pacemakers.

2. Exposure to EMF may have other health eects which

are unknown.

1. Always provide adequate ventilation in the work area

by natural or mechanical means. Do not weld, cut, or

gouge on materials such as galvanized steel, stainless steel, copper, zinc, lead, beryllium, or cadmium

unless positive mechanical ventilation is provided.

Do not breathe fumes from these materials.

2. Do not operate near degreasing and spraying operations. The heat or arc rays can react with chlorinated

hydrocarbon vapors to form phosgene, a highly

toxic gas, and other irritant gases.

3. If you develop momentary eye, nose, or throat irritation while operating, this is an indication that

ventilation is not adequate. Stop work and take

necessary steps to improve ventilation in the work

area. Do not continue to operate if physical discomfort persists.

4. Refer to ANSI/ASC Standard Z49.1 (see listing below)

for specic ventilation recommendations.

6

SAFETY PRECAUTIONS

5. WARNING: This product, when used for welding

or cutting, produces fumes or gases

which contain chemicals known to

the State of California to cause birth

defects and, in some cases, cancer.

(California Health & Safety Code

§25249.5 et seq.)

CYLINDER HANDLING -- Cylinders,

if mishandled, can rupture and violently release gas. Sudden rupture

of cylinder, valve, or relief device can

injure or kill. Therefore:

1. Use the proper gas for the process and use the

proper pressure reducing regulator designed to

operate from the compressed gas cylinder. Do not

use adaptors. Maintain hoses and ttings in good

condition. Follow manufacturer's operating instructions for mounting regulator to a compressed gas

cylinder.

1. Always have qualied personnel perform the installation, troubleshooting, and maintenance work.

Do not perform any electrical work unless you are

qualied to perform such work.

2. Before performing any maintenance work inside a

power source, disconnect the power source from

the incoming electrical power.

3. Maintain cables, grounding wire, connections, power

cord, and power supply in safe working order. Do

not operate any equipment in faulty condition.

4. Do not abuse any equipment or accessories. Keep

equipment away from heat sources such as furnaces,

wet conditions such as water puddles, oil or grease,

corrosive atmospheres and inclement weather.

5. Keep all safety devices and cabinet covers in position

and in good repair.

6. Use equipment only for its intended purpose. Do

not modify it in any manner.

2. Always secure cylinders in an upright position by

chain or strap to suitable hand trucks, undercarriages, benches, walls, post, or racks. Never secure

cylinders to work tables or xtures where they may

become part of an electrical circuit.

3. When not in use, keep cylinder valves closed. Have

valve protection cap in place if regulator is not connected. Secure and move cylinders by using suitable

hand trucks. Avoid rough handling of cylinders.

4. Locate cylinders away from heat, sparks, and ames.

Never strike an arc on a cylinder.

5. For additional information, refer to CGA Standard P-1,

"Precautions for Safe Handling of Compressed Gases

in Cylinders", which is available from Compressed

Gas Association, 1235 Jeerson Davis Highway,

Arlington, VA 22202.

EQUIPMENT MAINTENANCE -- Faulty or

improperly maintained equipment can

cause injury or death. Therefore:

ADDITIONAL SAFETY INFORMATION -- For

more information on safe practices for

electric arc welding and cutting equipment, ask your supplier for a copy of

"Precautions and Safe Practices for Arc

Welding, Cutting and Gouging", Form

52-529.

The following publications, which are available from

the American Welding Society, 550 N.W. LeJuene Road,

Miami, FL 33126, are recommended to you:

1. ANSI/ASC Z49.1 - "Safety in Welding and Cutting"

2. AWS C5.1 - "Recommended Practices for Plasma Arc

Welding"

3. AWS C5.2 - "Recommended Practices for Plasma Arc

Cutting"

4. AWS C5.3 - "Recommended Practices for Air Carbon

Arc Gouging and Cutting"

7

SAFETY PRECAUTIONS

5. AWS C5.5 - "Recommended Practices for Gas Tungsten Arc Welding“

6. AWS C5.6 - "Recommended Practices for Gas Metal

Arc Welding"“

7. AWS SP - "Safe Practices" - Reprint, Welding Handbook.

8. ANSI/AWS F4.1, "Recommended Safe Practices for

Welding and Cutting of Containers That Have Held

Hazardous Substances."

MEANING OF SYMBOLS - As used

throughout this manual: Means Attention! Be Alert! Your safety is involved.

Means immediate hazards which,

if not avoided, will result in immediate, serious personal injury

or loss of life.

Means potential hazards which

could result in personal injury or

loss of life.

Means hazards which could result

in minor personal injury.

8

SAFETY PRECAUTIONS

Hydrogen explosion hazard! Read the following before attempting

DANGER

A hazard exists whenever a water table is used with plasma arc cutting. Severe explosions have resulted from the accumulation of hydrogen beneath the plate being cut. Thousands of dollars in property damage have been caused by

these explosions. Personal injury or death could result from such an explosion.

The best available information indicates that three possible sources of hydrogen exists in water tables:

1. Molten Metal Reaction

Most of the hydrogen is liberated by a fast reaction of molten metal from the kerf in the water to form metallic ox-

ides. This reaction explains why reactive metals with greater anity for oxygen, such as aluminum and magnesium,

release greater volumes of hydrogen during the cut than does iron or steel. Most of this hydrogen will come to the

surface immediately, but some will cling to small metallic particles. These particles will settle to the bottom of the

water table and the hydrogen will gradually bubble to the surface.

2. Slow Chemical Reaction

Hydrogen may also result from the slower chemical reactions of cold metal particles with the water, dissimilar metals,

or chemicals in the water. The hydrogen gradually bubbles to the surface.

to cut when using a water table.

3. Plasma & Shield Gas

Hydrogen or other fuel gases, such as Methane (CH4), may come from the plasma or shield gas. H-35 is a commonly

used plasma gas. This gas is 35% hydrogen by volume. When using H-35 at high currents, as much as 125 cfh of

hydrogen will be released.

Regardless of the source, the hydrogen gas can collect in pockets formed by the plate being cut and slats on the

table, or pockets from warped plate. There can also be accumulation of hydrogen under the slag tray or even in the

air reservoir, if these are part of the table design. The hydrogen, in the presence of oxygen or air, can then be ignited

by the plasma arc or a spark from any source.

4. Follow these practices to reduce hydrogen generation and accumulation:

A. Clean the slag (especially ne particles) from the bottom of the table frequently. Rell the table with clean water.

B. Do not leave plates on the table overnight or a weekend.

C. If a water table has been unused for several hours, vibrate it in some way before the rst plate is laid in position.

This will allow accumulated hydrogen in the refuse to break loose and dissipate before it is conned by a plate

on the table. This might be accomplished by laying the rst plate onto the table with a slight jolt, then raising

the plate to permit hydrogen to escape before it is nally set down for cutting.

D. If cutting above water, install fans to circulate air between the plate and the water surface.

E. If cutting underwater, agitate the water under the plate to prevent accumulation of hydrogen. This can be done

by aerating the water using compressed air.

F. If possible, change the level of the water between cuts to dissipate accumulated hydrogen.

G. Maintain pH level of the water near 7 (neutral). This reduces the rate of chemical reaction between water and

metals.

9

SAFETY PRECAUTIONS

Possible explosion hazard from plasma cutting aluminum-lithium alloys!

Aluminum-Lithium (Al-Li) alloys are used in the aerospace industry because of 10% weight

savings over conventional aluminum alloys. It has been reported that molten Al-Li alloys

can cause explosions when they come into contact with water. Therefore, plasma cutting

of these alloys should not be attempted in the presence of water. These alloys should only

be dry cut on a dry table. Alcoa has determined that "dry" cutting on a dry table is safe

and gives good cutting results. DO NOT dry cut over water. DO NOT water injection cut.

WARNING

The following are some of the Al-Li alloys currently available:

Alithlite (Alcoa) X8192 (Alcoa)

Alithally (Alcoa) Navalite (U. S. Navy)

2090 Alloy (Alcoa) Lockalite (Lockhead)

X8090A (Alcoa) Kalite (Kaiser)

X8092 (Alcoa) 8091 (Alcan)

For additional details and information on the safe use from the hazards associated with

these alloys, contact your aluminum supplier.

WARNING

WARNING

WARNING

Oil And Grease Can Burn Violently!

• Never use oil or grease on this torch.

• Handle torch clean hands only on clean surface.

• Use silicone lubricant only where directed.

• Oil and grease are easily ignited and burn violently in the presence of

oxygen under pressure.

Hydrogen explosion hazard.

Do Not Cut Underwater With H-35! Dangerous buildup of hydrogen gas is possible in

the water table. Hydrogen gas is extremely explosive. Reduce the water level to 4 inches minimum below the workpiece. Vibrate plate, stir air and water frequently to prevent

hydrogen gas buildup.

Spark hazard.

Heat, spatter, and sparks cause re and burns.

• Do not cut near combustible material.

• Do not cut containers that have held combustibles.

• Do not have on your person any combustibles (e.g. butane lighter).

• Pilot arc can cause burns. Keep torch nozzle away from yourself and

others when activating plasma process.

• Wear correct eye and body protection.

• Wear gauntlet gloves, safety shoes and hat.

• Wear ame-retardant clothing that covers all exposed areas.

• Wear cuess trousers to prevent entry of sparks and slag.

10

SAFETY PRECAUTIONS

Maximum Gas Flow Rates With PT-36 Torch

Gas &

Pressure

Air (85psi / 5.9bar)

Process

Air (85psi / 5.9bar)

Air Curtain

Argon

(125psi / 8.6bar)

CH-4

(75psi / 5.2bar)

H-35 / F5

(75psi / 5.2bar)

Nitrogen

(125psi / 8.6bar)

Oxygen

(125psi / 8.6bar)

Maximum Gas Flow Rates - CFH (CMH)

With PT-36 Torch

EPP-201 EPP-360 EPP-450 EPP-601

269

(7. 6)

1200

(34)

100

(2.8)

85

(2.4)

95

(2.7)

385

(10.9)

66

(1.9)

Note: No marking with the 600 ampere nozzle.

269

(7. 6)

1200

(34)

100

(2.8)

85

(2.4)

202

(5.7)

496

(14.0)

190

(5.4)

474

(13.4)

1200

(34)

100

(2.8)

85

(2.4)

202

(5.7)

496

(14.0)

295

(8.4)

474

(13.4)

1200

(34)

100

(2.8)

85

(2.4)

254

(7. 2)

496

(14.0)

295

(8.4)

Gas Purity

Clean, Dry, Oil Free

Filtered to 25 microns

Filtered to 25 microns

DIN Quality ISO 8573-1

Oil Quality mg/m3 = 0.1 Class 2

Particle Size 0.1µm Class 1

Temperature +3°C Class 4

99.995%, Filtered to 25 microns

93%, Filtered to 25 microns

99.995%, Filtered to 25 microns

99.99%, Filtered to 25 microns

99.5%, Filtered to 25 microns

11

12

Carbon Steel

Quality

13

14

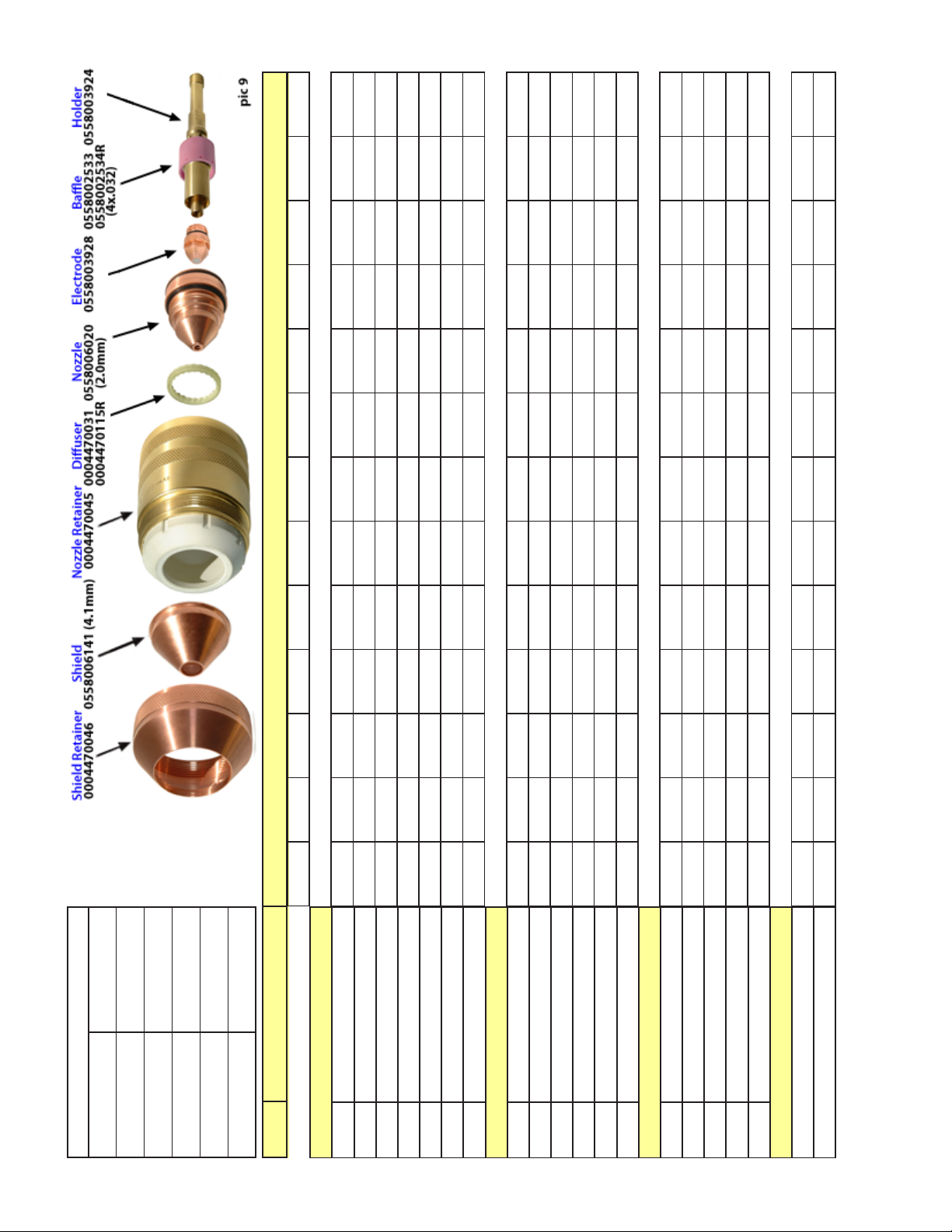

M MS 30A GS6 ncode109 pic36

MARKING

Material Carbon Steel

Gas Select 6

Amperes 30

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

5.2

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

5.2

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

15

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.100)

3

3(0.100)

3(0.100)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

70

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 30A GS1 ncode109 pic36

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 30 30

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

1(0.040) 2(0.080) 3(0.125)

Gas Parameters:

1 1 1

4.8 4.8 4.8

0.5 0.5 1.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

4.5 4.5 4.5

0.5 0.5 1.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

16

30 30 30

P6 Cut Current - Amps

30 30 30

P7 Start Current - Amps

Timers: (sec)

0.1 0.1 0.1

0.4 0.5 0.5

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0

T3 Thick Plate

0.1 0.1 0.1

1.0 1.0 1.0

(0.130) 3(0.130) 4(0.150)

3(0.130) 3(0.130) 4(0.150)

2(0.080) 2(0.080) 3(0.120)

3

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

1(0.040) 2(0.080) 3(0.125)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.10 0.10 0.10

T5 Gas O

Version 4.5 released on 13May13

110 110 11 2

H5 Arc Voltage - Volts

Machine Parameters:

1.7(0.065) 1.7(0.065) 1.7(0.065)

3810(150) 1400(55) 1140(45)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M MS 45A GS6 ncode101 pic17

MARKING

Material Carbon Steel

Gas Select 6

Amperes 45

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

5.2

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

5.2

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

17

14

P6 Cut Current - Amps

14

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

85

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 45A GS1 ncode101 pic17

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 45 45

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

1(0.040) 2(0.080) 3(0.125)

Gas Parameters:

1 1 1

3.5 3.5 3.5

0.0 0.0 0.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

4.5 4.0 4.0

0.0 0.0 0.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

18

45 45 45

P6 Cut Current - Amps

50 50 50

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6

0.2 0.3 0.3

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6

1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160)

4(0.160) 5(0.200) 5(0.200)

3(0.120) 3(0.125) 5(0.180)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

1(0.040) 2(0.080) 3(0.125)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

123 131 134

H5 Arc Voltage - Volts

Machine Parameters:

2.3(0.090) 3.0(0.120) 2.8(0.110)

3810(150) 1980(78) 1650(65)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M MS 55A GS6 ncode102 pic17

MARKING

Material Carbon Steel

Gas Select 6

Amperes 55

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

5.2

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

5.2

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

19

14

P6 Cut Current - Amps

14

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

85

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 55A GS1 ncode102 pic17

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 55 55

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

4(0.160) 5(0.188) 6(0.250)

Gas Parameters:

1 1 1

3.5 3.5 3.5

0.0 0.0 0.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

4.0 4.1 4.1

0.0 0.0 0.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

20

55 55 55

P6 Cut Current - Amps

50 50 50

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6

0.3 0.3 0.3

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6

1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160)

6(0.240) 5(0.200) 5(0.200)

6(0.240) 5(0.200) 5(0.200)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

4(0.160) 5(0.188) 6(0.250)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

127 132 137

H5 Arc Voltage - Volts

Machine Parameters:

2160(85) 1400(55) 1020(40)

2.5(0.100) 2.5(0.100) 3.0(0.120)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M MS 60A GS6 ncode110 pic37

MARKING

Material Carbon Steel

Gas Select 6

Amperes 60

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

5.2

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

5.2

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

21

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

3(0.100)

3(0.100)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

75

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 60A GS1 ncode110 pic37

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 60 60

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

3(0.125) 4(0.160) 5(0.188) 6(0.250)

Gas Parameters:

1 1 1 1

4.1 4.1 4.1 4.1

2.0 2.0 2.0 2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

4.5 4.5 4.5 4.5

2.0 2.0 2.0 2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

22

60 60 60 60

P6 Cut Current - Amps

45 45 45 45

P7 Start Current - Amps

Timers: (sec)

0.3 0.6 0.6 0.6

0.6 0.6 0.6 1.0

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0

T3 Thick Plate

0.1 0.1 0.1 0.1

1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160)

3(0.120) 4(0.160) 4(0.160) 4(0.160)

3(0.120) 3(0.110) 3(0.110) 4(0.140)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

3(0.125) 4(0.160) 5(0.188) 6(0.250)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.10 0.10 0.10 0.10

T5 Gas O

Version 4.5 released on 13May13

105 105 105 108

H5 Arc Voltage - Volts

Machine Parameters:

1.5(0.060) 1.5(0.060) 1.5(0.060) 1.7(0.065)

3810(150) 3050(120) 2030(80) 1900(75)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M MS 100A GS6 ncode103 pic2

MARKING

Material Carbon Steel

Gas Select 6

Amperes 10 0

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

3.6

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

3.6

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

23

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

90

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 100A GS1 ncode103 pic2

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 10 0 100

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

6(0.250) 10(0.375) 12(0.500)

Gas Parameters:

1 1 1

1.7 1.7 1.7

2.8 2.8 2.8

4.1 4.1 4.1

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

2.8 2.8 2.8

100 100 100

P5 Shield Cut - CMH

P6 Cut Current - Amps

24

50 50 50

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6

0.1 0.2 0.4

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6

1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160)

6(0.220) 6(0.250) 6(0.250)

3(0.125) 5(0.180) 6(0.240)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

6(0.250) 10(0.375) 12(0.500)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

142 149 156

H5 Arc Voltage - Volts

Machine Parameters:

2160(85) 1650(65) 1520(60)

2.0(0.080) 2.0(0.080) 2.3(0.090)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M MS 130A GS6 ncode104 pic29

MARKING

Material Carbon Steel

Gas Select 6

Amperes 13 0

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

3.6

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

3.6

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

25

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

80

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 130A GS1 ncode104 pic29

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 130 130

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

6(0.250) 10(0.375) 12(0.500) 16(0.625)

Gas Parameters:

1 1 1 1

1.7 1.7 1.7 1.7

3.4 3.4 4.5 4.5

3.5 3.5 3.5 3.5

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

3.4 3.4 4.5 4.5

130 130 130 130

P5 Shield Cut - CMH

P6 Cut Current - Amps

26

60 60 60 60

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6

0.5 0.5 0.5 0.5

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160)

6(0.250) 6(0.250) 6(0.250) 13(0.500)

3(0.130) 3(0.130) 5(0.200) 7(0.275)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

6(0.250) 10(0.375) 12(0.500) 16(0.625)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

125 133 142 152

H5 Arc Voltage - Volts

Machine Parameters:

2.4(0.095) 2.4(0.095) 2.4(0.095) 2.5(0.100)

2540(100) 2160(85) 1900(75) 1350(53)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M MS 200A GS6 ncode105 pic3

MARKING

Material Carbon Steel

Gas Select 6

Amperes 200

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

2.8

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

2.8

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

27

14

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

70

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 200A GS1 ncode105 pic3

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 200 200

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

16(0.625) 20(0.750) 25(1.000) 32(1.250)

Gas Parameters:

1 1 1 1

1.2 1.2 1.2 1.2

3.1 3.1 3.1 3.1

3.2 3.2 3.2 3.2

3.1 3.1 3.1 3.1

200 200 200 200

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

28

100 100 100 100

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6

0.4 0.5 1.0 1.0

T1 Ramp Up

T2 Pierce

0.0 0.5 1.0 1.0

T3 Thick Plate

0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160)

4(0.170) 5(0.180) 9(0.360) 7(0.260)

4(0.160) 5(0.180) 6(0.240) 7(0.260)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

16(0.625) 20(0.750) 25(1.000) 32(1.250)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

136 140 148 155

H5 Arc Voltage - Volts

Machine Parameters:

1900(75) 1650(65) 1140(45) 760(30)

3.0(0.120) 3.0(0.120) 3.0(0.120) 3.8(0.150)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M MS 280A GS6 ncode106 pic4

MARKING

Material Carbon Steel

Gas Select 6

Amperes 280

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

2.1

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

2.1

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

29

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

70

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 280A GS1 ncode106 pic4

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 280 280

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

16(0.625) 20(0.750) 25(1.000) 32(1.250) 35(1.375)

Gas Parameters:

1 1 1 1 1

1.7 1.7 1.7 1.7 1.7

4.7 4.7 4.7 4.7 4.7

3.6 3.6 3.6 3.6 3.6

4.7 4.7 4.7 4.7 4.7

280 280 280 280 280

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

30

150 150 150 150 150

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6 0.6

0.7 0.7 1.0 1.5 1.9

T1 Ramp Up

T2 Pierce

0.0 0.0 1.0 1.0 1.0

T3 Thick Plate

0.6 0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160)

5(0.200) 8(0.310) 12(0.470) 13(0.500) 14(0.563)

4

18(0.700) 13(0.500) 18(0.700) 19(0.750) 22(0.850)

16(0.625) 20(0.750) 25(1.000) 32(1.250) 35(1.375)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

140 150 160 165 175

H5 Arc Voltage - Volts

Machine Parameters:

2290(90) 2160(85) 1520(60) 1220(48) 890(35)

2.8(0.110) 2.9(0.115) 3.4(0.135) 3.0(0.120) 3.6(0.140)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M MS 360A GS6 ncode107 pic31

MARKING

Material Carbon Steel

Gas Select 6

Amperes 360

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

2.1

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

2.1

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

31

18

P6 Cut Current - Amps

18

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

62

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q MS 360A GS1 ncode107 pic31

QUALITY PRODUCTION

Material Carbon Steel Carbon Steel

Gas Select 1 1

Amperes 360 360

Cut Gas O2 O2

Start Gas N2 AIR

Shield Gas N2 AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

20(0.750) 25(1.000) 32(1.250) 35(1.375) 38(1.500)

Gas Parameters:

1 1 1 1 1

1.2 1.2 1.2 1.2 1.2

5.7 7.1 7.1 7.1 7.1

3.0 3.0 3.0 3.0 3.0

5.7 7.1 7.1 7.1 7.1

360 360 360 360 360

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

32

150 150 150 150 150

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6 0.6

1.3 1.7 2.0 2.0 2.0

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0 1.0

T3 Thick Plate

0.6 0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160)

6(0.250) 7(0.280) 10(0.410) 11 (0.430) 12(0.460)

4

13(0.500) 19(0.750) 19(0.750) 20(0.800) 25(1.000)

20(0.750) 25(1.000) 32(1.250) 35(1.375) 38(1.500)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

143 145 157 158 160

H5 Arc Voltage - Volts

Machine Parameters:

3.8(0.150) 4.1(0.160) 4.6(0.180) 5.0(0.195) 5.5(0.215)

2540(100) 2030(80) 1270(50) 1070(42) 890(35)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Aluminum

Quality

33

34

Q AL 360A GS5 ncode166 pic28

(NOTE: Piercing not recommended on thicknesses greater than 38 mm Pierce delay indicated for edge starts greater than 38 mm)

5 5 5 5 5 5

0.3 0.3 0.3 0.3 0.3 0.3

8.5 8.5 8.5 8.5 8.5 8.5

3.8 3.8 3.8 3.8 3.8 3.8

8.5 8.5 8.5 8.5 8.5 8.5

16(0.625) 20(0.750) 25(1.000) 32(1.250) 38(1.500) 45(1.750)

360 360 360 360 360 360

QUALITY

Material Aluminum

Gas Select 5

Amperes 360

Start Gas N2

Cut Gas H35

Shield Gas N2

Code Description Material Thickness - mm (inch)

Gas Parameters:

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

150 150 150 150 150 150

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6 0.6 0.6

0.2 0.2 0.2 0.3 0.4 0.5

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6 0.6 0.6

T4 Ramp Down

0.35 0.35 0.35 0.35 0.35 0.35

T5 Gas O

1.0 1.0 1.0 1.0 1.0 1.0

T6 Raise Lift

(inch)

Height Parameters: mm

(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.167)

4

H1 Ignition

18(0.700) 18(0.700) 18(0.700) 25(1.000) 32(1.250) 32(1.250)

H2 Pierce

14(0.540) 10(0.390) 10(0.410) 14(0.560) 18(0.700) 17(0.680)

H3 Cutting

16(0.625) 20(0.750) 25(1.000) 32(1.250) 38(1.500) 45(1.750)

H4 Thickness

177 180 190 205 215 220

H5 Arc Voltage - Volts

Machine Parameters:

4.8(0.190) 4.4(0.175) 4.8(0.190) 5.3(0.210) 6.9(0.270) 7.1(0.280)

2540(100) 2290(90) 1520(60) 1140(45) 840(33) 640(25)

(in/min)

Speed - mm/min

Kerf - mm (inch)

ESAB Welding and Cutting Products

35

Version 4.5 released on 13May13

Q AL 450A GS5 ncode167 pic45

(NOTE: Piercing not recommended on thicknesses greater than 38 mm Pierce delay indicated for edge starts greater than 38 mm)

5 5 5 5 5 5 5 5 5

0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3

5.7 5.7 5.7 5.7 5.7 5.7 5.7 5.7 5.7

2.8 2.8 2.8 2.8 2.8 2.8 2.8 2.8 2.8

5.7 5.7 5.7 5.7 5.7 5.7 5.7 5.7 5.7

20(0.750) 25(1.000) 32(1.250) 38(1.500) 45(1.750) 50(2.000) 55(2.250) 65(2.500) 75(3.000)

450 450 450 450 450 450 450 450 450

QUALITY

Material Aluminum

Gas Select 5

Amperes 450

Start Gas N2

Cut Gas H35

Shield Gas N2

Code Description Material Thickness - mm (inch)

Gas Parameters:

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

200 200 200 200 200 200 200 200 200

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6

1.0 1.2 1.2 1.5 2.0 2.0 2.2 2.5 3.0

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6

T4 Ramp Down

0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35

T5 Gas O

1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

T6 Raise Lift

(inch)

Height Parameters: mm

(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160)

4

H1 Ignition

13(0.500) 14(0.550) 18(0.700) 18(0.720) 19(0.740) 19(0.740) 19(0.760) 20(0.790) 21(0.820)

H2 Pierce

11(0.450) 14(0.550) 18(0.690) 18(0.720) 19(0.740) 19(0.740) 19(0.760) 20(0.790) 21(0.820)

H3 Cutting

20(0.750) 25(1.000) 32(1.250) 38(1.500) 45(1.750) 50(2.000) 55(2.250) 65(2.500) 75(3.000)

H4 Thickness

155 165 175 180 185 190 196 202 215

H5 Arc Voltage - Volts

Machine Parameters:

5.1(0.200) 5.6(0.220) 5.6(0.220) 6.1(0.240) 6.6(0.260) 7.2(0.285) 7.5(0.296) 7.8(0.307) 10.2(0.400)

2790(110) 2030(80) 1780(70) 1400(55) 1140(45) 840(33) 760(30) 610(24) 380(15)

(in/min)

Speed - mm/min

Kerf - mm (inch)

ESAB Welding and Cutting Products

36

Version 4.5 released on 13May13

Stainless Steel

Quality

37

38

M SS 60A GS6 ncode136 pic50

MARKING

Material Stainless Steel

Gas Select 6

Amperes 60

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

5.2

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

5.2

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

39

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

3(0.100)

3(0.100)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

75

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q SS 60A GS18 ncode136 pic50

QUALITY

Material Stainless Steel

Gas Select 5,18

Amperes 60

Start Gas N2

Cut Gas F5

Shield Gas N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

2(0.080) 3(0.125) 5(0.188) 6(0.250)

Gas Parameters:

18 18 18 18

P1 Gas Select

4.8 4.8 4.8 4.8

P2 Plasma Start - Bar

3.0 4.1 2.6 2.0

5.2 5.2 5.2 5.2

P3 Shield Start - CMH

P4 Plasma Cut - Bar

60 60 60 60

3.0 4.1 2.6 2.0

P5 Shield Cut - CMH

P6 Cut Current - Amps

40

45 45 45 45

P7 Start Current - Amps

Timers: (sec)

0.3 0.3 0.3 0.3

0.5 0.5 0.5 0.5

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0

T3 Thick Plate

0.1 0.1 0.1 0.1

1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160)

4(0.160) 4(0.160) 4(0.160) 4(0.160)

3(0.135) 3(0.135) 3(0.135) 4(0.140)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

2(0.080) 3(0.125) 5(0.188) 6(0.250)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.10 0.10 0.10 0.10

T5 Gas O

Version 4.5 released on 13May13

145 145 148 150

H5 Arc Voltage - Volts

Machine Parameters:

1.1(0.045) 1.1(0.045) 1.1(0.045) 1.1(0.045)

5330(210) 3560(140) 1400(55) 1140(45)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M SS 100A GS6 ncode137 pic8

MARKING

Material Stainless Steel

Gas Select 6

Amperes 10 0

Cut Gas ARG

Start Gas ARG

Shield Gas N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

3.6

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

3.6

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

41

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

90

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q SS 100A GS18 ncode137 pic8

NOTE: Thickness: 3mm and 5mm use N2 for cut gas.

18 18 18 18

1.0 1.0 1.0 1.0

5.7 5.7 5.7 5.7

3(0.125) 5(0.188) 6(0.250) 10(0.375)

3.8 3.8 3.8 3.1

QUALITY

Material Stainless Steel

Gas Select 18

Amperes 10 0

Start Gas N2

Cut Gas F5

Shield Gas N2

Code Description Material Thickness - mm (inch)

Gas Parameters:

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

5.7 5.7 5.7 5.7

100 100 100 100

P5 Shield Cut - CMH

P6 Cut Current - Amps

60 60 60 60

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6

0.4 0.4 0.4 0.6

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6

T4 Ramp Down

0.35 0.35 0.35 0.35

T5 Gas O

1.0 1.0 1.0 1.0

T6 Raise Lift

(inch)

Height Parameters: mm

(0.157) 4(0.157) 4(0.157) 4(0.157)

4

H1 Ignition

10(0.394) 10(0.394) 10(0.394) 10(0.394)

H2 Pierce

4(0.142) 4(0.146) 3(0.114) 3(0.130)

H3 Cutting

3(0.125) 5(0.188) 6(0.250) 10(0.375)

H4 Thickness

145 156 155 155

H5 Arc Voltage - Volts

Machine Parameters:

1.4(0.055) 1.8(0.071) 2.1(0.083) 2.5(0.098)

4191(165) 2159(85) 1651(65) 1143(45)

(in/min)

Speed - mm/min

Kerf - mm (inch)

ESAB Welding and Cutting Products

42

Version 4.5 released on 13May13

M SS 130A GS6 ncode131 pic9

MARKING

Material Stainless Steel

Gas Select 6

Amperes 13 0

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

3.6

4.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

3.6

4.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

43

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

2(0.062)

2(0.062)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

80

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q SS 130A GS5 ncode131 pic9

QUALITY

Material Stainless Steel

Gas Select 5

Amperes 130

Start Gas N2

Cut Gas H35

Shield Gas N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

10(0.375) 12(0.500) 20(0.750) 25(1.000)

Gas Parameters:

5 5 5 5

1.0 1.0 1.0 1.0

5.7 5.7 5.7 5.7

3.1 3.1 3.1 3.1

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

5.7 5.7 5.7 5.7

130 130 130 130

P5 Shield Cut - CMH

P6 Cut Current - Amps

44

60 60 60 60

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6

0.6 0.6 0.8 1.2

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160)

8(0.300) 8(0.310) 12(0.460) 12(0.470)

4

10(0.400) 10(0.400) 13(0.500) 15(0.600)

10(0.375) 12(0.500) 20(0.750) 25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

158 163 183 189

H5 Arc Voltage - Volts

Machine Parameters:

1020(40) 890(35) 510(20) 300(12)

3.4(0.135) 3.6(0.140) 4.1(0.160) 4.6(0.180)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M SS 200A GS6 ncode132 pic10

MARKING

Material Stainless Steel

Gas Select 6

Amperes 200

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

2.8

4.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

2.8

4.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

45

16

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

70

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q SS 200A GS5 ncode132 pic10

QUALITY

Material Stainless Steel

Gas Select 5

Amperes 200

Start Gas N2

Cut Gas H35

Shield Gas N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

10(0.375) 12(0.500) 20(0.750) 25(1.000) 32(1.250) 38(1.500)

Gas Parameters:

5 5 5 5 5 5

1.0 1.0 1.0 1.0 1.0 1.0

5.7 5.7 5.7 5.7 5.7 5.7

3.8 3.8 3.8 3.8 3.8 3.8

5.7 5.7 5.7 5.7 5.7 5.7

200 200 200 200 200 200

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

46

100 100 100 100 100 100

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6 0.6 0.6

0.6 0.6 0.6 1.0 1.5 1.8

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160)

9(0.350) 9(0.350) 10(0.400) 13(0.500) 18(0.700) 19(0.750)

7(0.270) 6(0.240) 9(0.340) 11(0.430) 12(0.490) 14(0.550)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

10(0.375) 12(0.500) 20(0.750) 25(1.000) 32(1.250) 38(1.500)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

169 160 180 192 200 210

H5 Arc Voltage - Volts

Machine Parameters:

1270(50) 1140(45) 760(30) 510(20) 360(14) 300(12)

3.8(0.150) 3.9(0.155) 4.1(0.160) 4.7(0.185) 5.3(0.210) 5.6(0.220)

(in/min)

Speed - mm/min

Kerf - mm (inch)

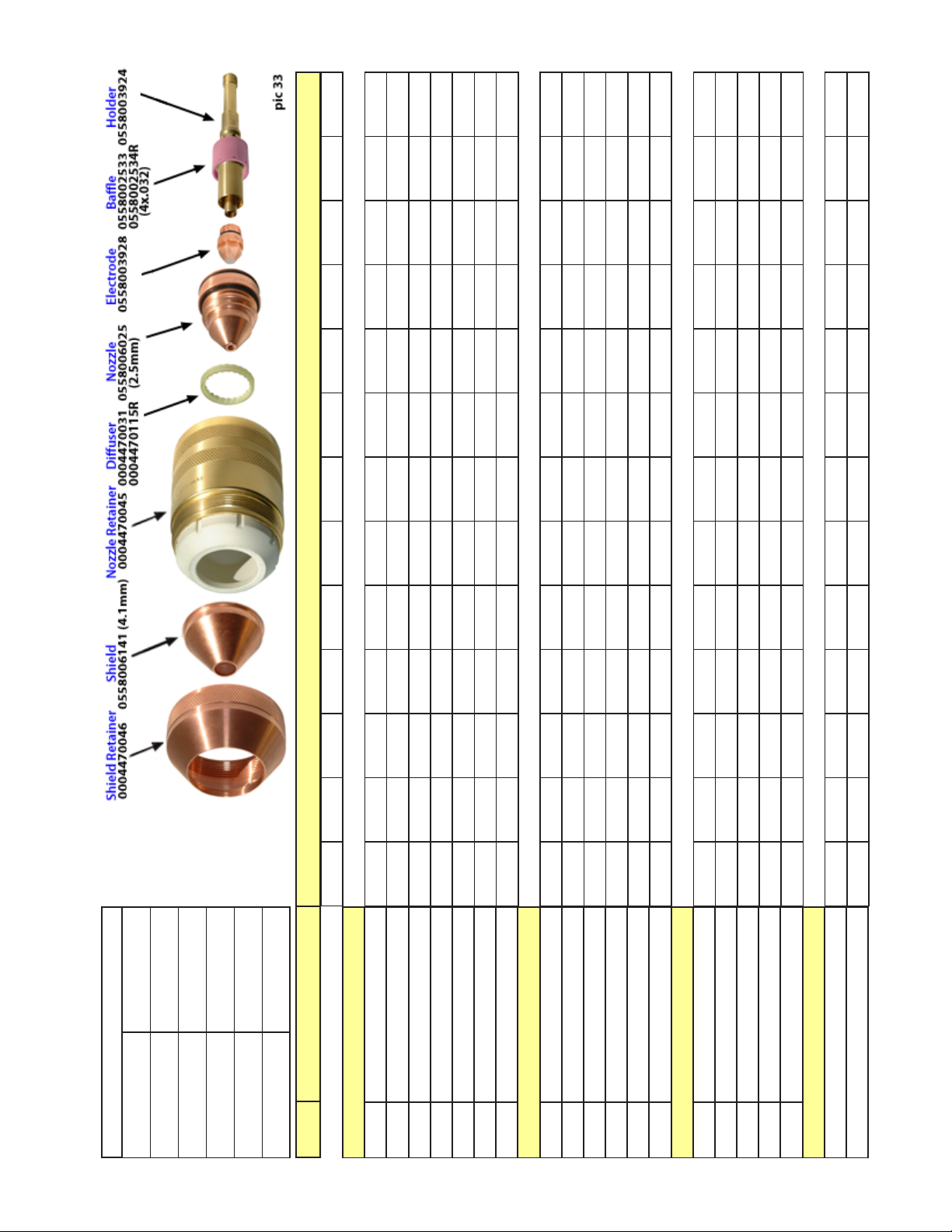

M SS 260A GS6 ncode133 pic33

MARKING

Material Stainless Steel

Gas Select 6

Amperes 260

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

2.1

4.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

2.1

4.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

47

25

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

5(0.180)

5(0.180)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

65

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q SS 260A GS5 ncode133 pic33

QUALITY

Material Stainless Steel

Gas Select 5

Amperes 260

Start Gas N2

Cut Gas H35

Shield Gas N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

10(0.375) 12(0.500) 20(0.750) 25(1.000) 32(1.250) 38(1.500)

Gas Parameters:

5 5 5 5 5 5

1.0 1.0 1.0 1.0 1.0 1.0

7.1 7.1 7.1 7.1 7.1 7.1

3.8 3.8 3.8 3.8 3.8 3.8

7.1 7.1 7.1 7.1 7.1 7.1

260 260 260 260 260 260

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

48

150 150 150 150 150 150

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6 0.6 0.6

0.3 0.3 0.6 1.0 1.3 1.9

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160)

6(0.220) 6(0.250) 10(0.395) 13(0.530) 14(0.550) 14(0.540)

4

10(0.375) 10(0.375) 15(0.600) 19(0.750) 19(0.750) 19(0.750)

10(0.375) 12(0.500) 20(0.750) 25(1.000) 32(1.250) 38(1.500)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

156 160 185 190 195 200

H5 Arc Voltage - Volts

Machine Parameters:

1780(70) 1400(55) 940(37) 640(25) 510(20) 380(15)

4.2(0.165) 4.2(0.165) 4.7(0.185) 5.3(0.210) 5.5(0.215) 6.1(0.240)

(in/min)

Speed - mm/min

Kerf - mm (inch)

M SS 360A GS6 ncode134 pic28

MARKING

Material Stainless Steel

Gas Select 6

Amperes 360

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

2.1

4.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

2.1

4.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

49

18

P6 Cut Current - Amps

18

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.161)

4

4(0.161)

4(0.161)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

62

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Q SS 360A GS5 ncode134 pic28

QUALITY

Material Stainless Steel

Gas Select 5

Amperes 360

Start Gas N2

Cut Gas H35

Shield Gas N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

20(0.750) 25(1.000) 32(1.250) 35(1.375) 38(1.500)

Gas Parameters:

5 5 5 5 5

0.3 0.3 0.3 0.3 0.3

8.5 8.5 7.1 7.1 7.1

3.6 3.6 3.6 3.6 3.6

8.5 8.5 7.1 7.1 7.1

360 360 360 360 360

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

50

150 150 150 150 150

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6 0.6

0.6 1.0 1.3 1.6 1.6

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160)

4

18(0.700) 25(1.000) 25(1.000) 25(1.000) 25(1.000)

13(0.500) 14(0.550) 18(0.690) 18(0.705) 19(0.730)

20(0.750) 25(1.000) 32(1.250) 35(1.375) 38(1.500)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

180 185 195 205 205

H5 Arc Voltage - Volts

Machine Parameters:

1140(45) 890(35) 760(30) 640(25) 510(20)

5.7(0.225) 6.1(0.240) 6.5(0.255) 6.9(0.270) 6.9(0.270)

(in/min)

Speed - mm/min

Kerf - mm (inch)

Carbon Steel

Production

51

52

M MS 100A GS6 ncode112 pic2

MARKING

Material Carbon Steel

Gas Select 6

Amperes 10 0

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

3.6

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

3.6

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

53

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

90

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

P MS 100A GS9 ncode112 pic2

PRODUCTION

Material Carbon Steel

Gas Select 9

Amperes 10 0

Cut Gas O2

Start Gas N2/AIR

Shield Gas N2 /AIR

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

3(0.125) 6(0.250) 10(0.375) 12(0.500)

Gas Parameters:

9 9 9 9

1.7 1.7 1.7 1.7

2.8 2.8 2.8 2.8

4.1 4.1 4.1 4.1

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

2.8 2.8 2.8 2.8

100 100 100 100

P5 Shield Cut - CMH

P6 Cut Current - Amps

54

50 50 50 50

P7 Start Current - Amps

Timers: (sec)

0.6 0.6 0.6 0.6

0.1 0.1 0.2 0.4

T1 Ramp Up

T2 Pierce

0.0 0.0 0.0 0.0

T3 Thick Plate

0.6 0.6 0.6 0.6

1.0 1.0 1.0 1.0

(0.160) 4(0.160) 4(0.160) 4(0.160)

6(0.250) 6(0.250) 6(0.250) 6(0.250)

3(0.125) 3(0.125) 3(0.125) 3(0.125)

4

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

3(0.125) 6(0.250) 10(0.375) 12(0.500)

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35 0.35 0.35 0.35

T5 Gas O

Version 4.5 released on 13May13

142 149 153 155

H5 Arc Voltage - Volts

Machine Parameters:

1.7(0.065) 2.0(0.080) 2.5(0.100) 2.5(0.100)

5720(225) 3560(140) 1900(75) 1520(60)

(in/min)

Speed - mm/min

Kerf - mm (inch)

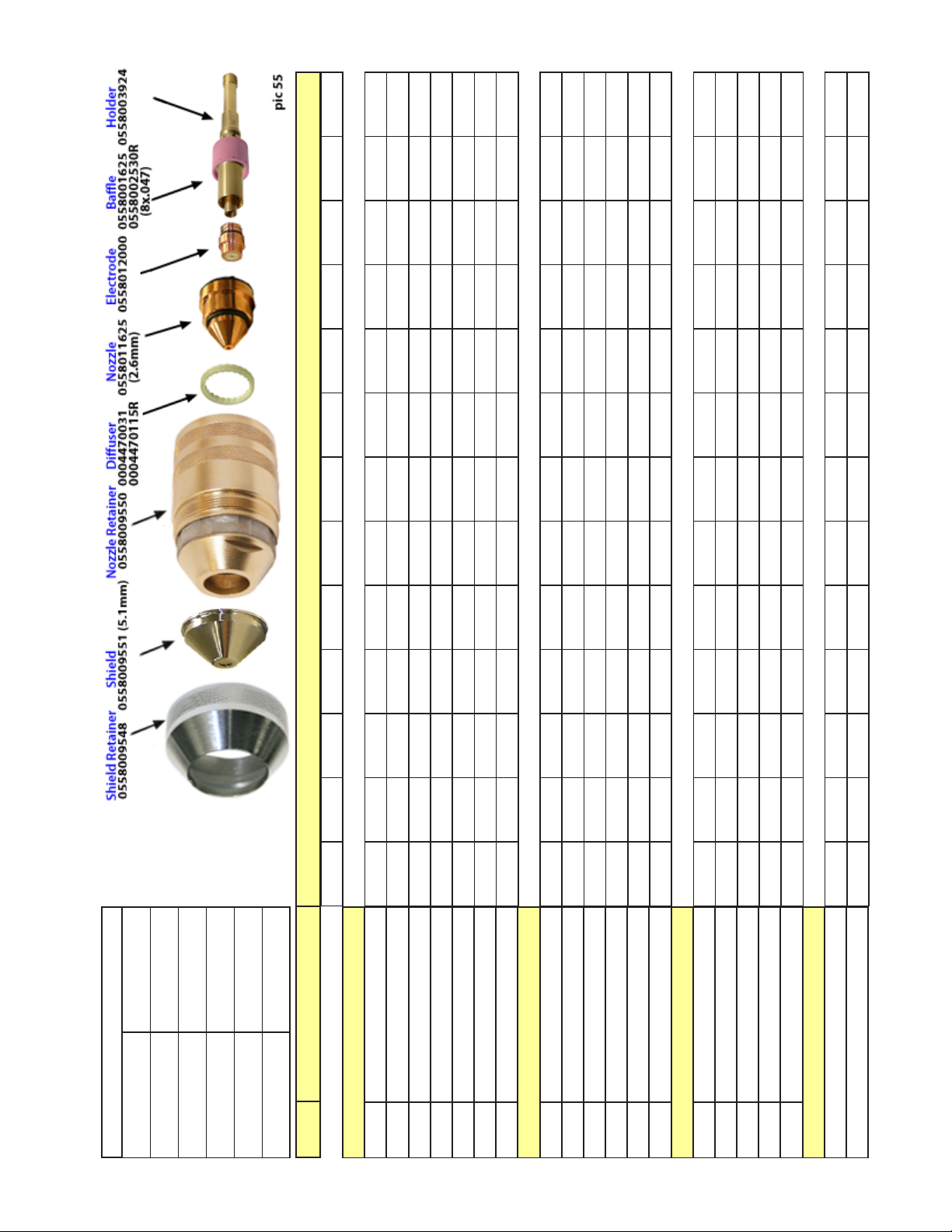

M MS 130A GS6 ncode113 pic29

MARKING

Material Carbon Steel

Gas Select 6

Amperes 13 0

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

3.6

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

3.6

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

55

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

80

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

P MS 130A GS2 ncode113 pic29

(NOTE: Piercing not recommended on thicknesses greater than 25 mm Pierce delay indicated for edge starts greater than 25 mm)

3(0.125) 6(0.250) 10(0.375) 12(0.500) 16(0.625) 20(0.750) 25(1.000) 32(1.250) 35(1.375) 38(1.500)

2 2 2 2 2 2 2 2 2 2

1.7 1.7 1.7 1.7 1.7 1.7 1.7 1.7 1.7 1.7

3.1 3.1 3.1 3.1 3.1 3.1 3.1 3.1 3.1 3.1

3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5

3.1 3.1 3.1 3.1 3.1 3.1 3.1 3.1 3.1 3.1

130 130 130 130 130 130 130 130 130 130

60 60 60 60 60 60 60 60 60 60

0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6

0.3 0.3 0.6 0.6 0.6 1.0 1.5 1.5 1.5 1.5

0.0 0.0 0.0 0.0 0.0 0.5 0.5 0.5 0.5 0.5

0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6

0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35 0.35

1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

(inch)

(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160) 4(0.160)

4

3(0.130) 3(0.130) 4(0.170) 7(0.260) 7(0.260) 7(0.260) 10(0.380) 10(0.380) 10(0.380) 10(0.380)

2(0.080) 3(0.100) 4(0.170) 6(0.240) 6(0.255) 5(0.214) 10(0.380) 9(0.340) 10(0.380) 10(0.380)

3(0.125) 6(0.250) 10(0.375) 12(0.500) 16(0.625) 20(0.750) 25(1.000) 32(1.250) 35(1.375) 38(1.500)

127 127 135 145 146 144 172 175 177 180

6100(240) 3810(150) 2790(110) 2030(80) 1520(60) 1400(55) 510(20) 380(15) 300(12) 250(10)

(in/min)

2.0(0.080) 2.0(0.080) 2.0(0.080) 2.0(0.080) 2.0(0.080) 2.8(0.110) 4.1(0.160) 4.6(0.180) 4.6(0.180) 4.6(0.180)

PRODUCTION

Material Carbon Steel

Gas Select 2

Amperes 130

Cut Gas O2

Start Gas AIR/N2

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

Gas Parameters:

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

P7 Start Current - Amps

Timers: (sec)

T1 Ramp Up

T2 Pierce

T3 Thick Plate

T4 Ramp Down

T5 Gas O

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

H5 Arc Voltage - Volts

Machine Parameters:

Speed - mm/min

Kerf - mm (inch)

ESAB Welding and Cutting Products

56

Version 4.5 released on 13May13

M MS 200A GS6 ncode114 pic56

MARKING

Material Carbon Steel

Gas Select 6

Amperes 200

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

2.8

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

2.8

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

57

14

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

70

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

P MS 200A GS2 ncode114 pic56

(NOTE: Piercing not recommended on thicknesses greater than 32 mm Pierce delay indicated for edge starts greater than 32 mm)

5(0.188) 6(0.250) 10(0.375) 12(0.500) 20(0.750) 22(0.875) 25(1.000) 32(1.250) 38(1.500) 45(1.750) 50(2.000)

2 2 2 2 2 2 2 2 2 2 2

1.7 1.7 1.7 1.7 1.7 1.7 1.7 1.7 1.7 1.7 1.7

5.2 5.2 5.2 5.7 5.7 5.7 5.7 5.7 5.7 5.7 5.7

4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1

5.2 5.2 5.2 5.7 5.7 5.7 5.7 5.7 5.7 5.7 5.7

200 200 200 200 200 200 200 200 200 200 200

75 75 75 75 75 75 75 75 75 75 75

0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6

0.3 0.3 0.3 0.3 0.7 0.8 1.0 1.3 1.3 1.3 1.5

0.0 0.0 0.0 0.0 0.5 0.8 1.0 1.0 1.0 1.0 1.0

0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6

0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

(inch)

(0.236) 6(0.236) 6(0.236) 6(0.236) 6(0.236) 6(0.236) 6(0.236) 6(0.236) 6(0.236) 6(0.236) 6(0.236)

6

13(0.512) 13(0.512) 13(0.512) 13(0.512) 19(0.748) 19(0.748) 19(0.748) 13(0.512) 13(0.512) 13(0.512) 19(0.748)

2(0.063) 2(0.091) 2(0.091) 3(0.102) 4(0.165) 5(0.209) 6(0.252) 7(0.283) 8(0.319) 7(0.291) 11 (0.449)

5(0.188) 6(0.250) 10(0.375) 12(0.500) 20(0.750) 22(0.875) 25(1.000) 32(1.250) 38(1.500) 45(1.750) 50(2.000)

130 140 138 143 145 152 158 160 170 173 187

6990(275) 5330(210) 3560(140) 3050(120) 2030(80) 1650(65) 1270(50) 970(38) 640(25) 430(17) 280(11)

(in/min)

2.1(0.081) 2.3(0.089) 2.8(0.109) 2.8(0.109) 3.2(0.125) 3.2(0.127) 3.3(0.128) 3.7(0.147) 4.6(0.180) 5.3(0.209) 5.7(0.225)

PRODUCTION

Material Carbon Steel

Gas Select 2

Amperes 200

Cut Gas O2

Start Gas AIR/N2

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

Gas Parameters:

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

P6 Cut Current - Amps

P7 Start Current - Amps

Timers: (sec)

T1 Ramp Up

T2 Pierce

T3 Thick Plate

T4 Ramp Down

T5 Gas O

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

H5 Arc Voltage - Volts

Machine Parameters:

Speed - mm/min

Kerf - mm (inch)

ESAB Welding and Cutting Products

58

Version 4.5 released on 13May13

M MS 260A GS6 ncode127 pic53

MARKING

Material Carbon Steel

Gas Select 6

Amperes 260

Cut Gas ARG

Start Gas ARG

Shield Gas AIR/N2

Code Description Material Thickness - mm (inch)

ESAB Welding and Cutting Products

25(1.000)

Gas Parameters:

6

2.1

2.0

P1 Gas Select

P2 Plasma Start - Bar

P3 Shield Start - CMH

2.1

2.0

P4 Plasma Cut - Bar

P5 Shield Cut - CMH

59

12

P6 Cut Current - Amps

12

P7 Start Current - Amps

Timers: (sec)

0.1

0.0

T1 Ramp Up

T2 Pierce

0.0

T3 Thick Plate

0.1

1.0

(0.160)

4

4(0.160)

4(0.160)

25(1.000)

(inch)

T6 Raise Lift

Height Parameters: mm

H1 Ignition

H2 Pierce

H3 Cutting

H4 Thickness

T4 Ramp Down

0.35

T5 Gas O

Version 4.5 released on 13May13

70

H5 Arc Voltage - Volts

Machine Parameters:

0.0(0.000)

2540(100)

(in/min)

Speed - mm/min

Kerf - mm (inch)

P MS 260A GS2 ncode127 pic53