PROTIG 450

LTP 450

104

Programming manual

Valid for program version 2.10B and 2.11A0456 638 104 981110

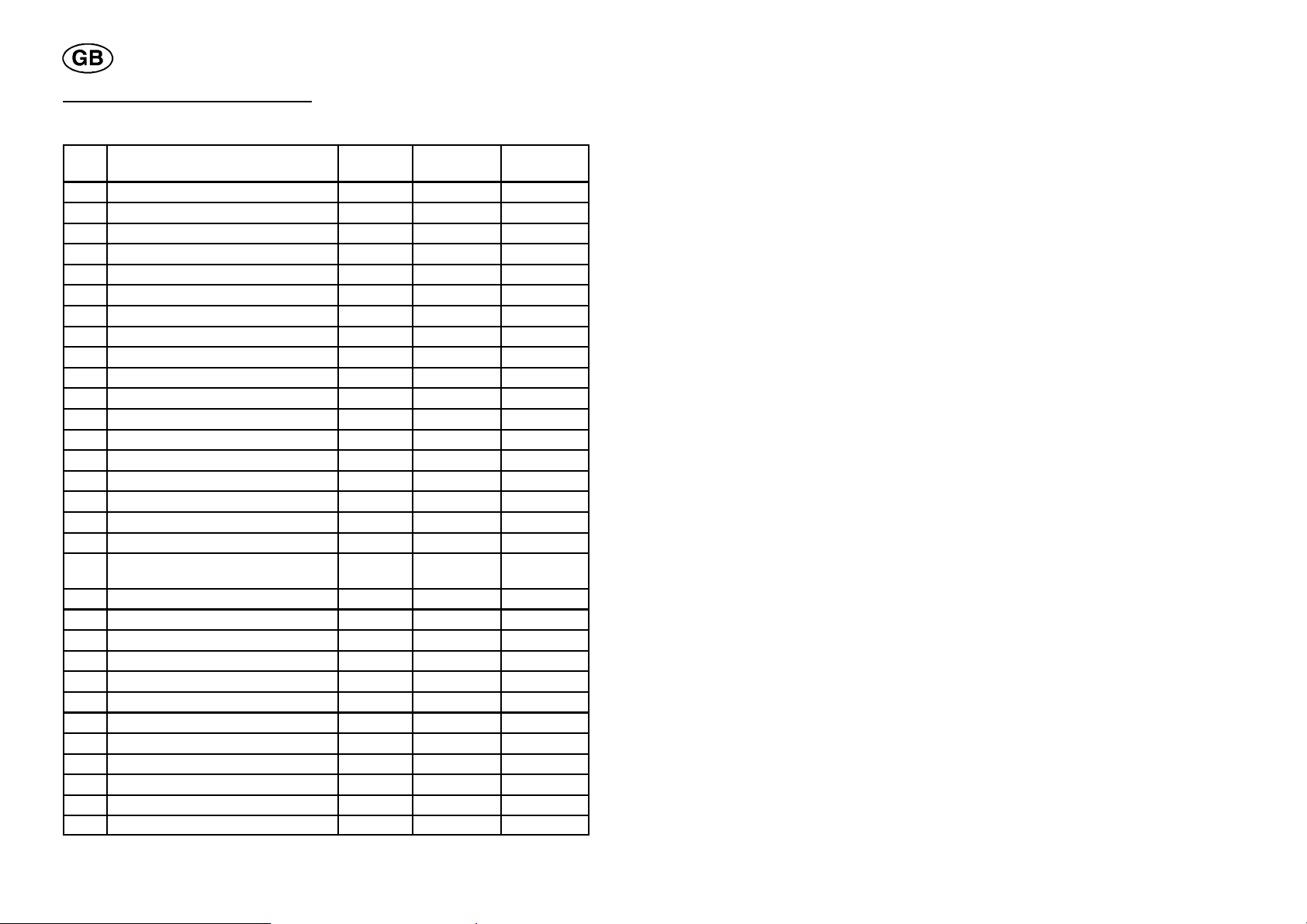

1 INTRODUCTION 4........................................................

1.1 Mode of operation -- Control box 4.......................................

1.2 Sectors 4............................................................

1.3 Display and keyset 6..................................................

2 WELDING PARAMETERS 12................................................

2.1 Welding current 12.....................................................

2.2 Gas 14...............................................................

2.3 Wire feed speed 15....................................................

2.4 Preheating time 15.....................................................

2.5 Rotation speed 16.....................................................

2.6 Arc voltage control (AVC) 16............................................

2.7 Weaving 18..........................................................

3 START AND STOP 19......................................................

3.1 Start 19...............................................................

3.2 Stop 19...............................................................

3.3 Restart 19............................................................

4 TO GET STARTED 20......................................................

4.1 General 20............................................................

4.2 How to indicate a tool code 20............................................

4.3 How to change languages 22.............................................

5 PROGRAM EDITING 23.....................................................

5.1 Entering a parameter value 23............................................

5.2 Increasing/decreasing a parameter value 23................................

5.3 Creating a new sector 24................................................

5.4 Changing the breakpoint of a sector 24....................................

5.5 Creating a transport sector 25............................................

5.6 Finding the home position 26.............................................

5.7 Entering a slope 26.....................................................

5.8 Moving within a program 27..............................................

5.9 Deleting in a program 28................................................

5.10Changing weld data during welding 29.....................................

5.11Zeroing the control box 30...............................................

6 PROGRAMMING EXAMPLES 31.............................................

6.1 Example 1a: 31........................................................

6.2 Example 1b: 35........................................................

6.3 Example 1c: 38........................................................

6.4 Example 1d: 42........................................................

6.5 Example 1e: 48........................................................

7 THE LIBRARY 53..........................................................

7.1 Storing a program 53...................................................

7.2 Recalling a program 53..................................................

7.3 Viewing the tool code 54.................................................

7.4 Deleting a program 55..................................................

8 MANUAL MODE 56........................................................

8.1 Field of application 56...................................................

8.2 Editing a parameter 56..................................................

TOCe

-- 2 --

9 PC--CARD 59.............................................................

9.1 Field of application 59...................................................

9.2 How to install the card 59................................................

9.3 How to recall a program 59..............................................

9.4 How to store a program 60...............................................

9.5 How to delete a program 61..............................................

9.6 How to take out the PC--card 62..........................................

10 ERROR CODES 62.........................................................

10.1 Error handling 62.......................................................

10.2 Incorrect editing codes 71...............................................

11 SHOW CURRENT PARAMETER VALUES 72..................................

11.1 Field of application 72...................................................

11.2 How to view actual parameter values 73...................................

12 SOFTWARE UPGRADE 73..................................................

12.1 Application field 73.....................................................

12.2 Menu explanation 74....................................................

12.3 How to upgrade 75.....................................................

12.4 Measures to be taken when the upgrading of the power source units failed 78....

12.5 Measures to be taken when the upgrading of the control box failed 79...........

13 SOFWARE KEY 80.........................................................

13.1 General 80............................................................

13.2 Locking the control box 80...............................................

13.3 Unlocking the control box 81.............................................

13.4 Changing the code 82...................................................

14 NOTEBOOK 83............................................................

14.1 Field of application 83...................................................

14.2 How to enter data in the notebook 83......................................

14.3 Example 2a: 84........................................................

15 MANUAL WELDING 94.....................................................

15.1 Field of application 94...................................................

15.2 How to create a welding program 94.......................................

15.3 Example 3a: 94........................................................

15.4 How to weld 100........................................................

16 APPENDIX 100.............................................................

16.1 Tool codes 100..........................................................

16.2 Symbols 101...........................................................

16.3 Setting ranges -- welding parameters 102....................................

17 TECHNICAL TERMS 103.....................................................

TOCe

-- 3 --

1 INTRODUCTION

1.1 Mode of operation -- Control box

The control box consists of four memory units, the working area, the

library, the notebook and the auxiliary function.

S In the working area the welding program is created.

S In the library the program can be stored.

During welding it is always the contents of the working area that control

the welding process. Thus it is also possible to call in a welding program

from the library to the working area.

S In the notebook you can make your own notes about special welding

parameters, for example.

S In the auxiliary function you can:

S change languages

S view all existing error messages

S show actual parameter values

S software upgrade

S sofware key

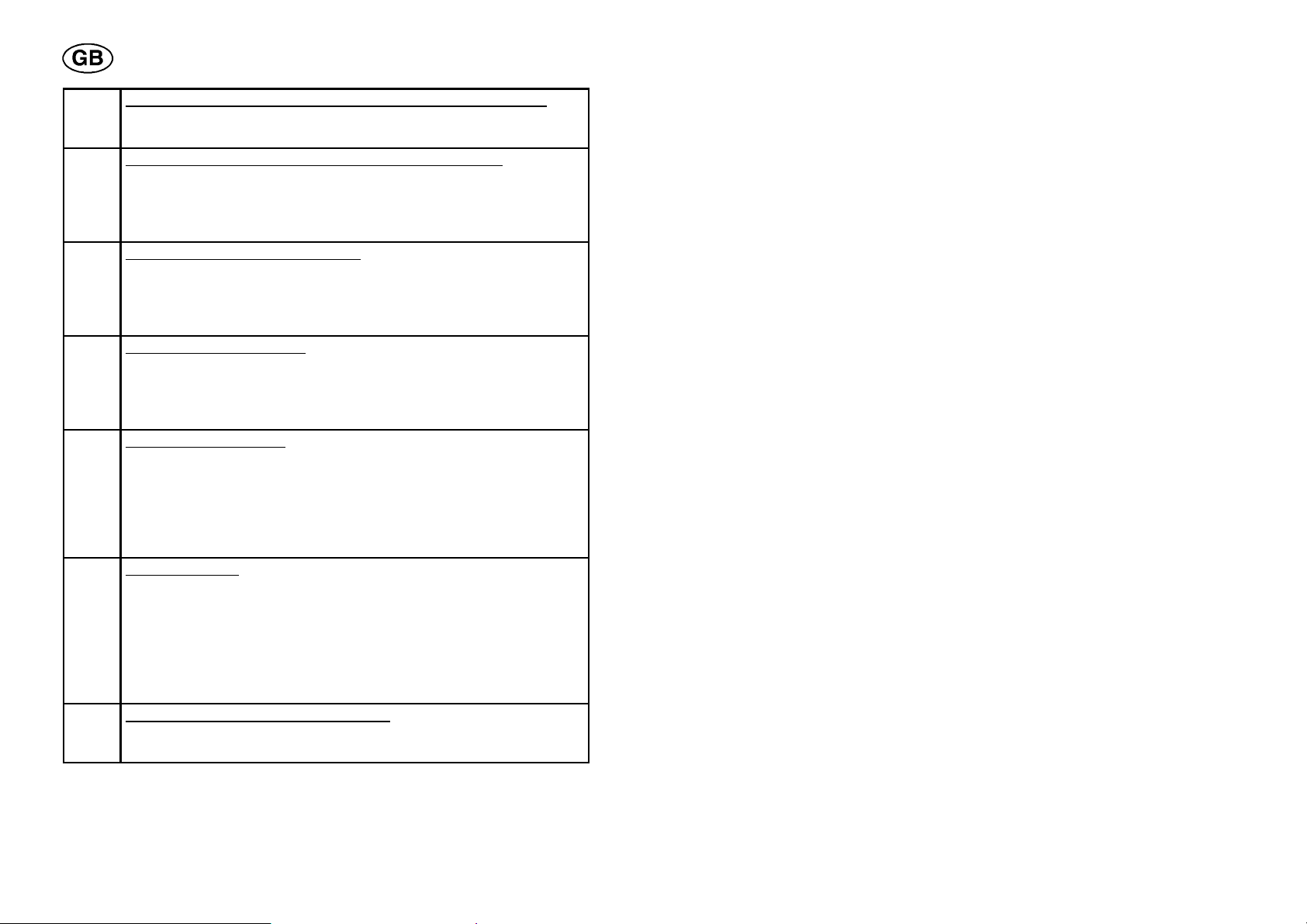

1.2 Sectors

A welding program for welding of tubes can be divided into different parts or

sectors. Each sector corresponds to a special part of the circumference of

the tube. Max. number of sectors for one program is one hundred (100).

Sector 4

Sector 3

A sector can be assigned its own set of values for different welding

parameters, such as current, rotation speed, wire feed speed, etc. In this

way the welding can be performed using different parameter settings for

different parts of the joint of the tube.

dpa8d1ea

Sector 1

Sector 2

-- 4 --

The division into sectors is done by indicating different breakpoints along

the circumference of the tube. Each such breakpoint constitutes the

starting point of a new sector. In the figure below, the breakpoint 0.000 is

the starting point of sector 1, breakpoint 0.250 the starting point of sector 2,

etc.

Breakpoint 0,000

Sector 4

Breakpoint 0,750

Sector 1

Breakpoint 0,250

Sector 3

Sector 2

Breakpoint 0,500

L TP 450 allows welding of up to 10 turns in the same welding joint, i.e. the

welding tool can be rotated 10 times round the tube.

The breakpoints in the previous figure all start with the integer 0 which

means that they form the breakpoints of turn 1. The breakpoints of turn 2

(if there is one) always start with the integer 1,etc.

S Turn 1 = breakpoints 0.000 -- 0.999

S Turn 2 = breakpoints 1.000 -- 1.999

S Turn 3 = breakpoints 2.000 -- 2.999

S Turn 4 = breakpoints 3.000 -- 3.999

S Turn 5 = breakpoints 4.000 -- 4.999

S Turn 6 = breakpoints 5.000 -- 5.999

S Turn 7 = breakpoints 6.000 -- 6.999

S Turn 8 = breakpoints 7.000 -- 7.999

S Turn 9 = breakpoints 8.000 -- 8.999

S Turn 10 = breakpoints 9.000 -- 9.999

To terminate a welding program a so--called end sector is indicated.

For a sector to be counted as an end sector the following two conditions

must be fulfilled:

S There is no sector following.

S The welding current value of the sector = 0 ampere.

dpa8d1ea

-- 5 --

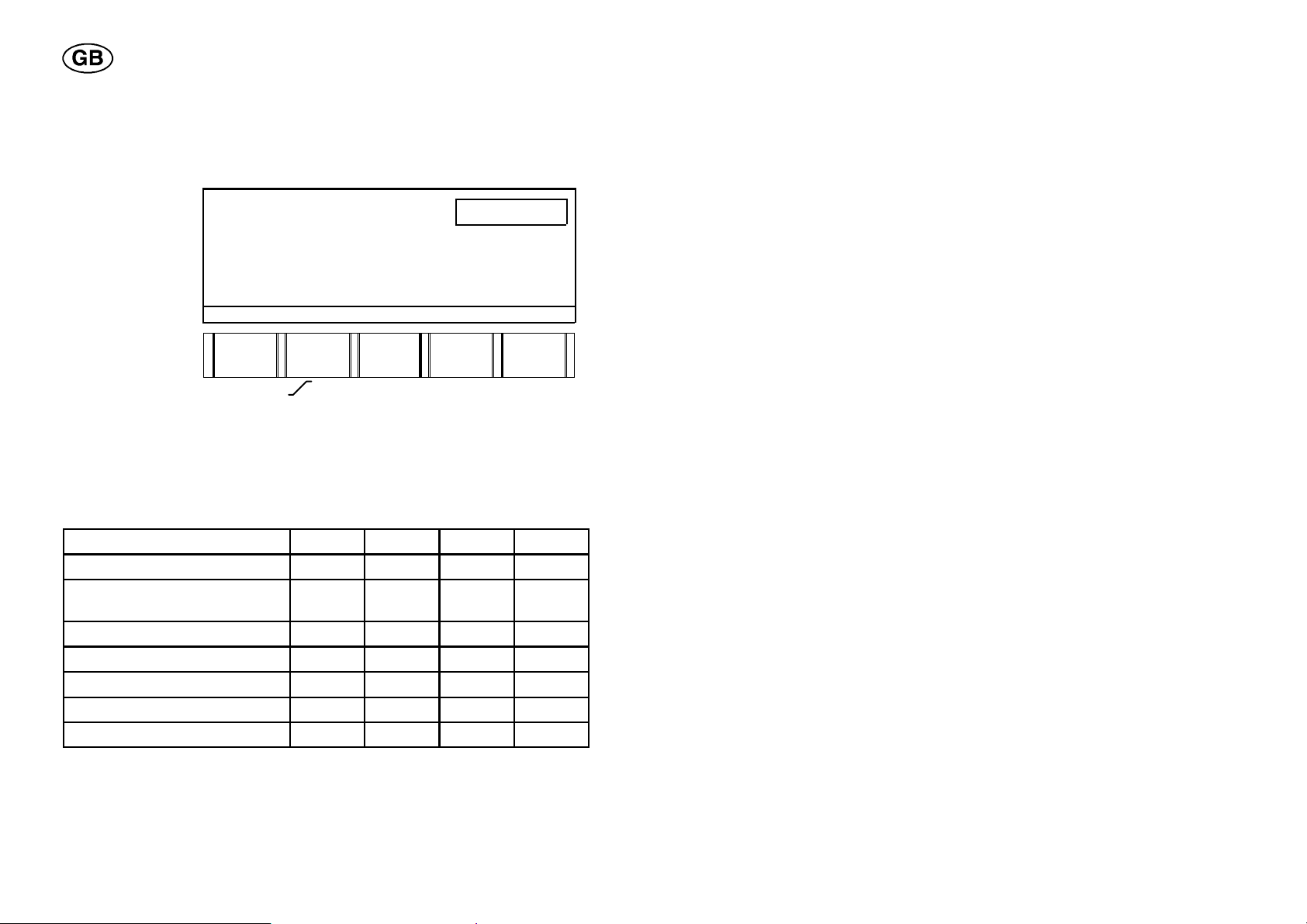

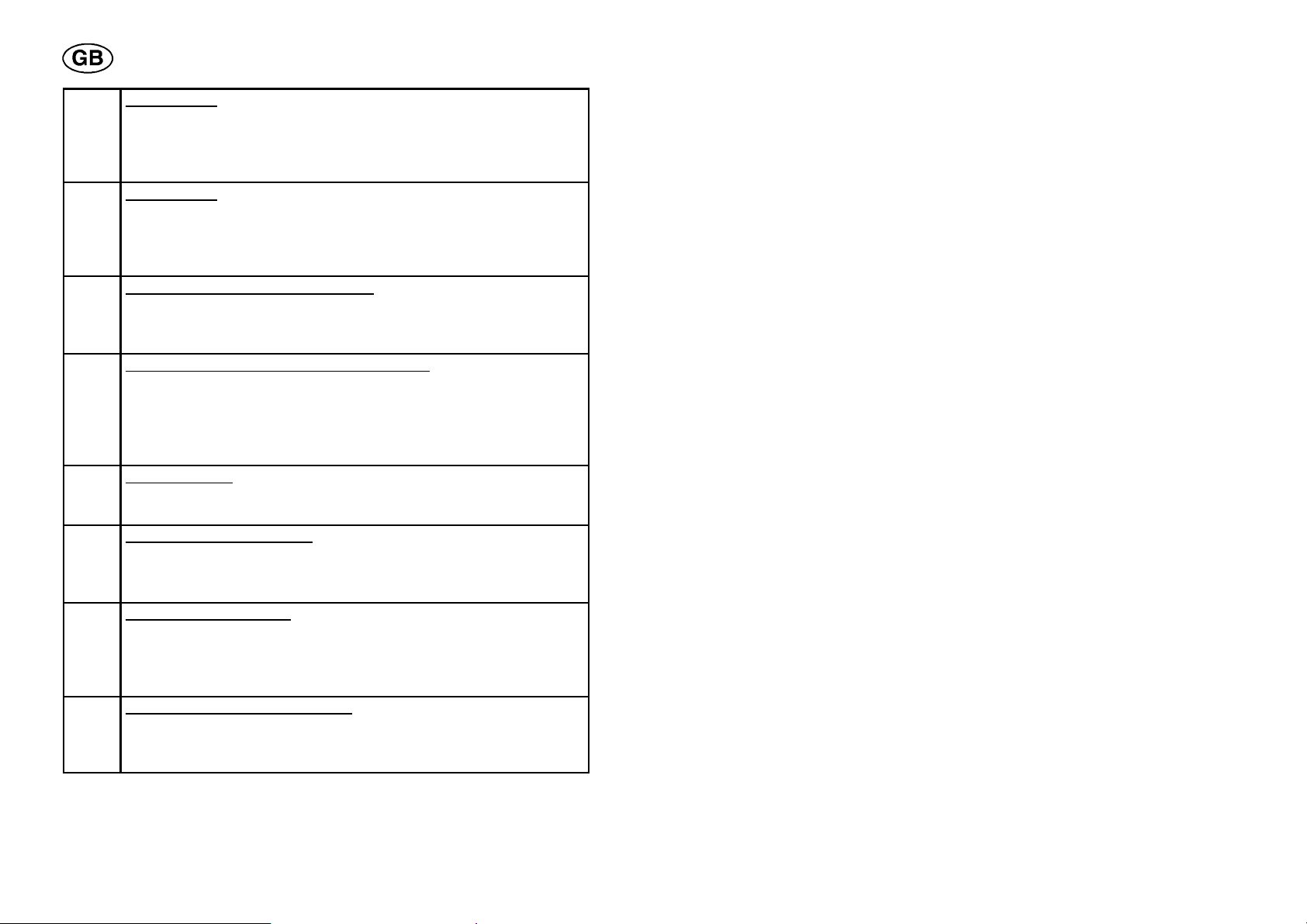

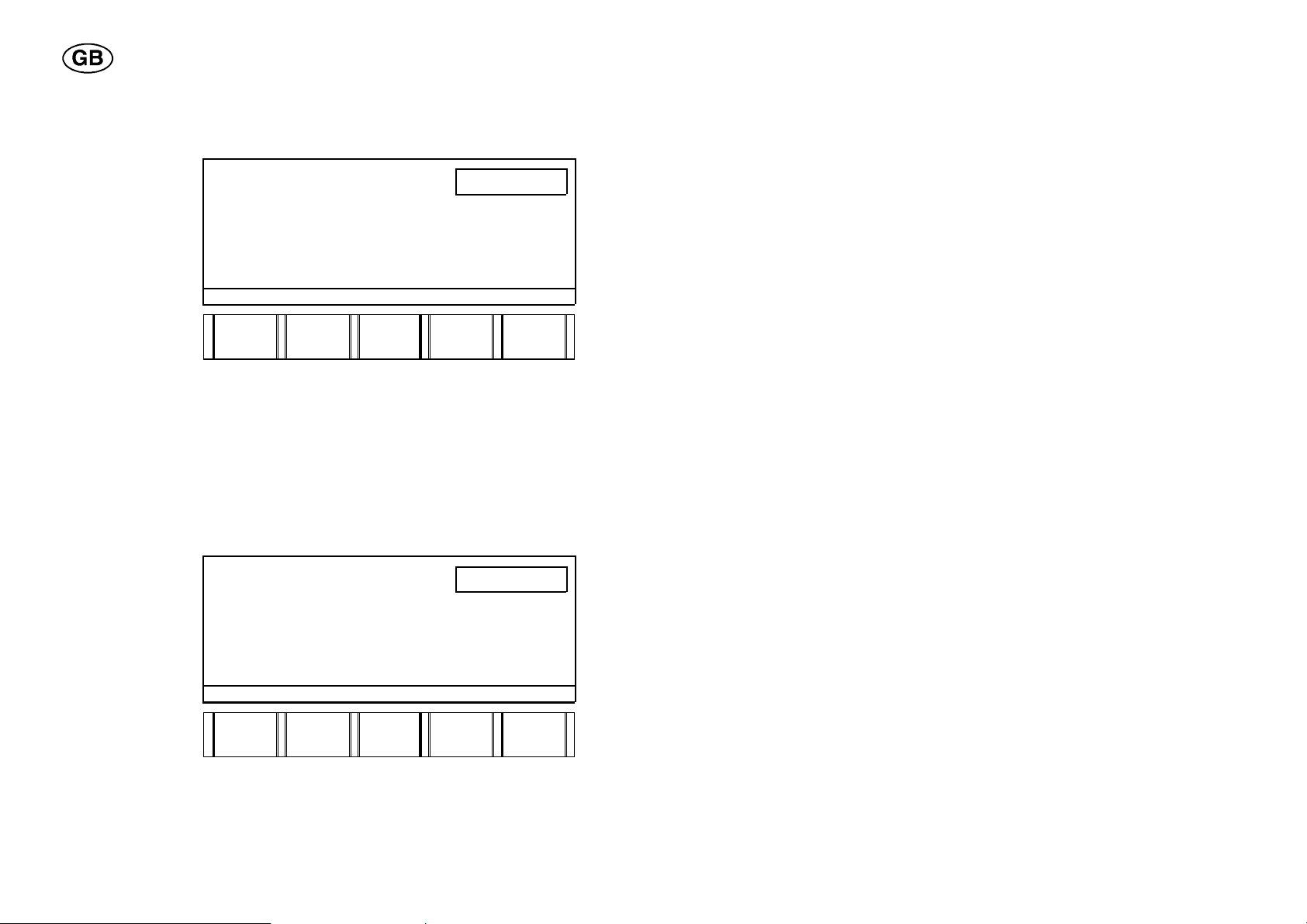

1.3 Display and keyset

A Display

B Soft keys

C Function keys

dpa8d1ea

-- 6 --

Display

a

SECTOR 2(4)

WELD GAS

15

ROOT GAS

e

START GAS

0.500

s

s

s

c

b

5

g

d

h

WELD

GAS

ROOT

GAS

START

GAS

f

The following information is shown in the display.

a The program sector at present involved.

b The number of sectors in the current program.

c The breakpoint of the sector (sector 2 in this example).

d The digit box shows the numerical value entered and different

numerical characters. For further information, see page 101.

e Showing that the indicated value has been borrowed from a previous

sector (in this example from sector 1).

g 5 text boxes describing the function of the so--called soft keys (f).

h Message line describing the actual state.

WELDING = a welding sequence is going on.

END = a welding sequence is completed.

TRANSPORT = transfer without welding.

STOP = the welding sequence was interrupted due to activation

of the stop key.

dpa8d1ea

-- 7 --

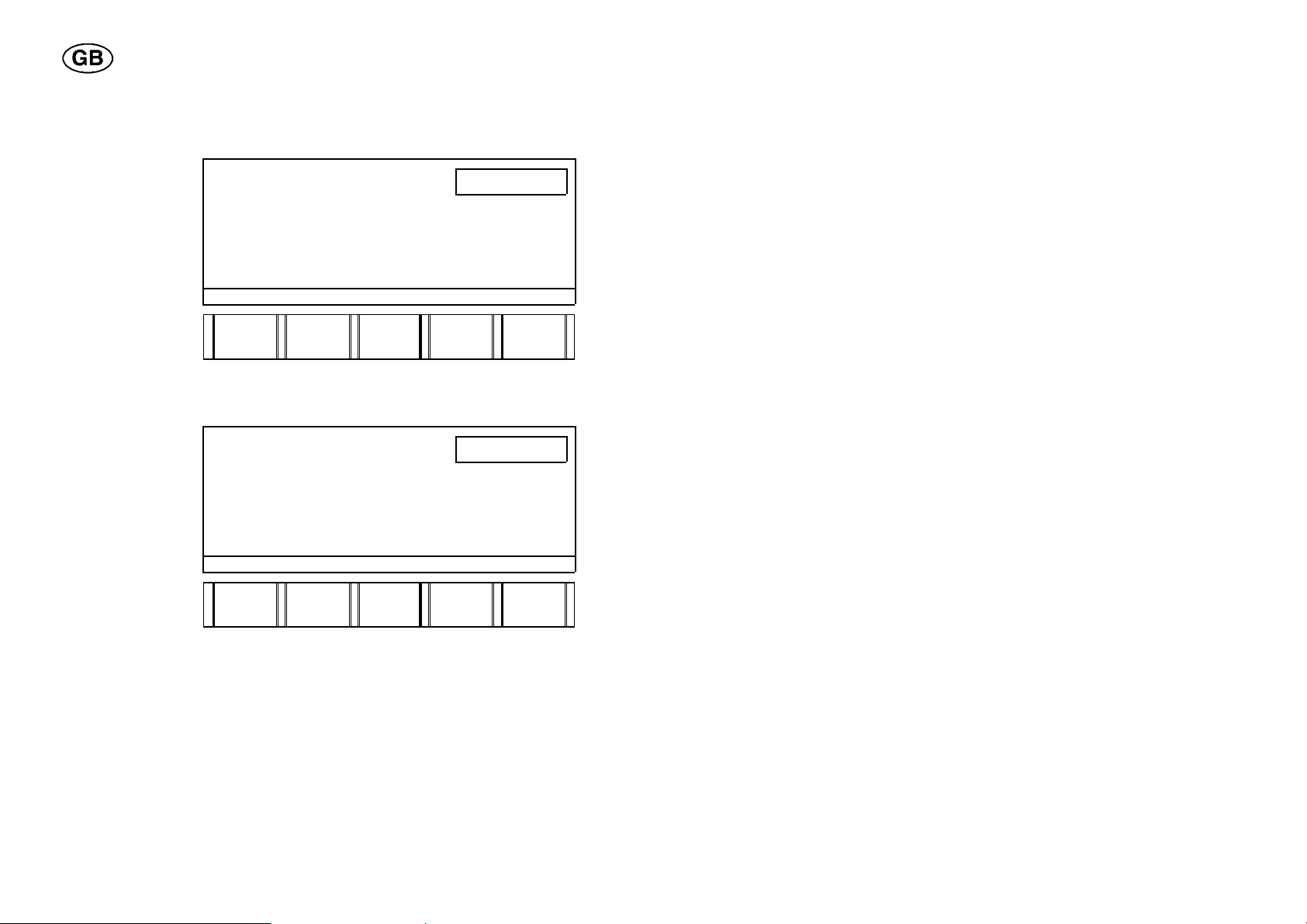

Soft keys

By way of the soft keys (a) the functions connected with the respective

display (in this case the GAS parameter display), the significance of which is

indicated in the text boxes (b). Depending on the display selected, up to five

soft keys can be activated.

Function

keys

Parameter keys

The welding parameters are divided into seven different groups, each group

represented by one ordinary key and a set of soft keys.

Welding current Gas

Rotation speed Wire feed speed

Arc voltage control (AVC) Weaving

Preheating time

dpa8d1ea

-- 8 --

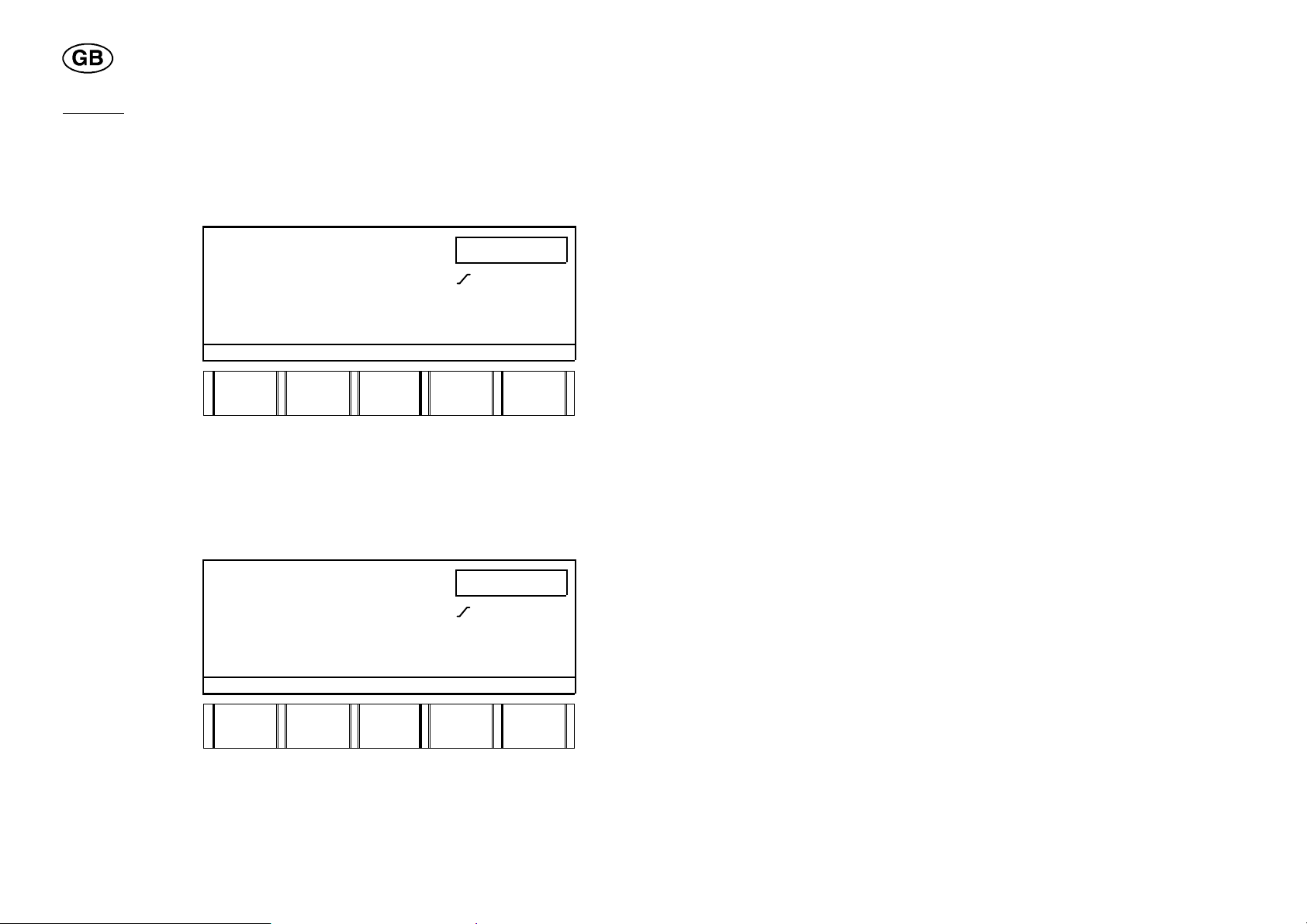

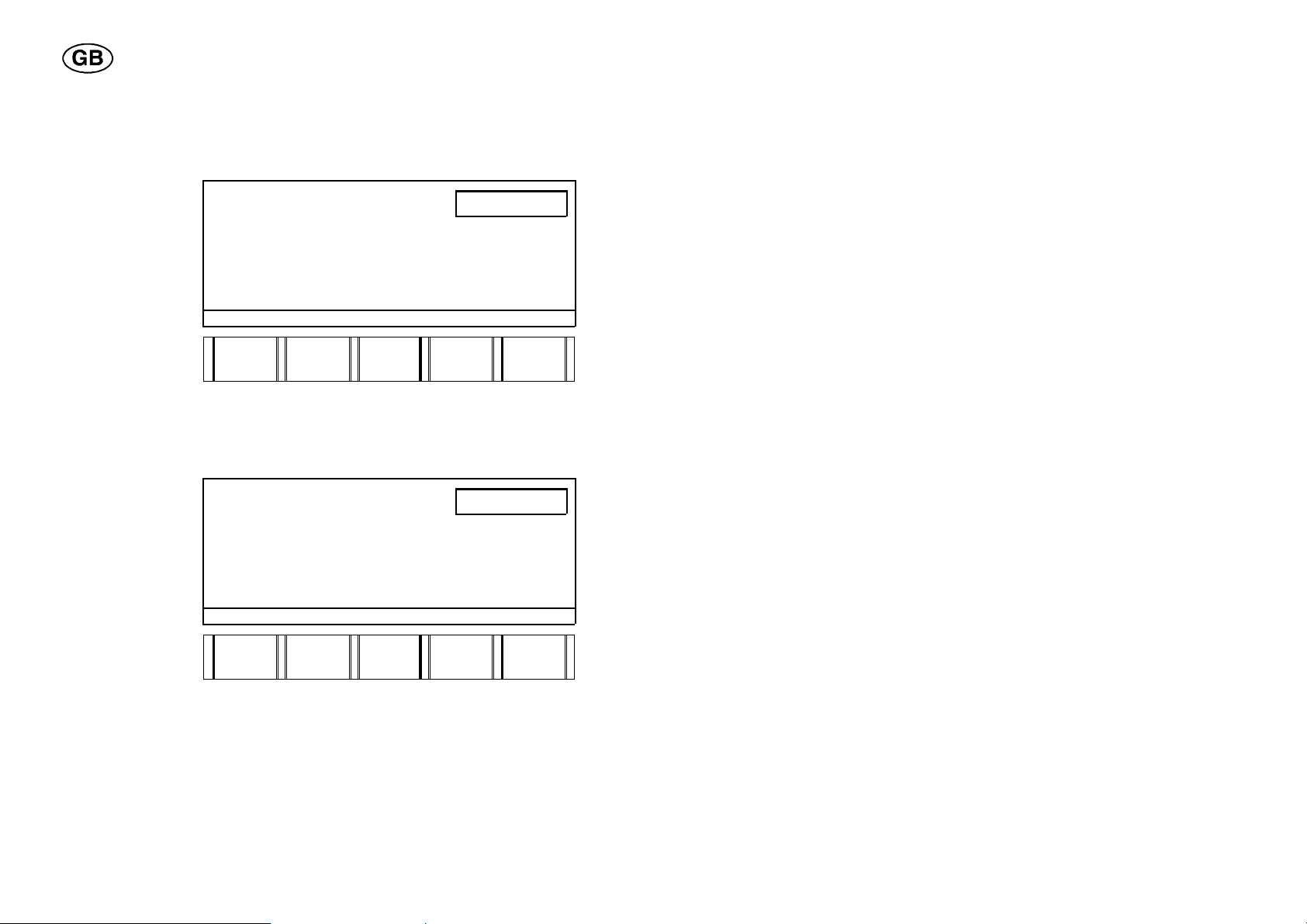

SHIFT key

This key is used for changing the significance of other keys on the

keyboard.

PLUS/MINUS keys

These keys are used for increasing/decreasing set values.

Numerical keys

These keys are used for entering the digits 0--9 and decimal point.

Other keys

SLOPE

This key is used when you want to add a slope function to a parameter and

is indicated in the following way in the display

.

By slope is meant a gradual change of a set value.

Slope up = gradual increase

Slope down = gradual decrease

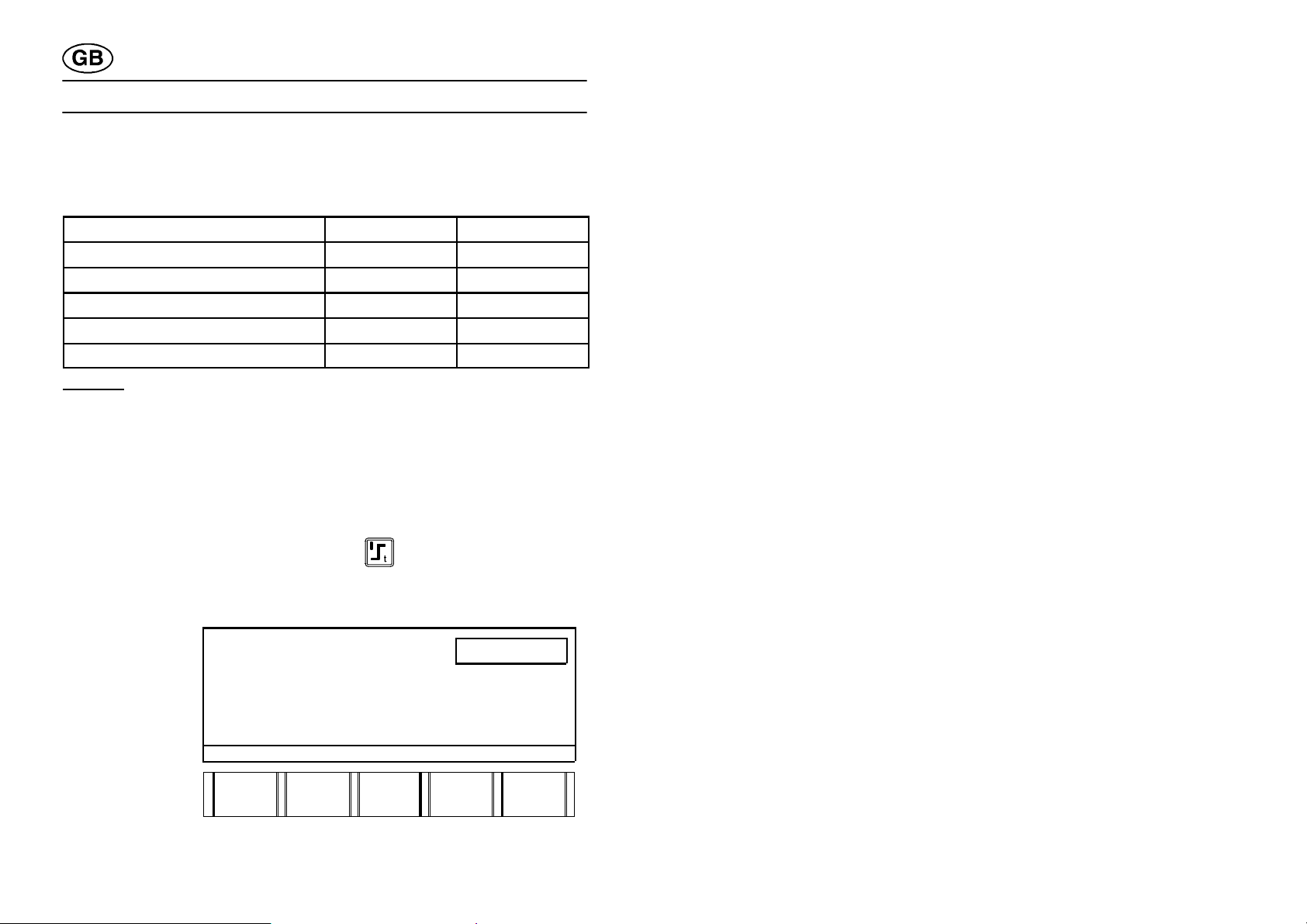

The following parameters can be assigned a slope function:

dpa8d1ea

-- 9 --

Current (both peak and background current) when pulsed current is used,

rotation, arc length control, wire feed speed , weaving amplitude.

A slope can be time--controlled by indicating that it shall go on for a certain

number of seconds. It can also be sector--controlled, making it a so--called

sector slope, by indicating between which two breakpoints it shall be

located.

SECTOR

This key indicates the breakpoint of a program and moving to indicated

sector.

STEP

This key is used for stepping forward in the program.

DELETE

This key is used for deleting the whole program, part of a program in the

working area, or just the figures in the digit box.

MANUAL MODE

This key is used for positioning the electrode before welding, and for making

sure that the program in the working area functions as desired.

MEMORY (library)

This key is used for entering or leaving the library and for storing a program,

or for recalling a program from the library to the working area.

CORRECT

This key is used for correcting the position of the electrode in connection

with weaving (centre line adjustment).

MODE (auxiliary functions)

This key is used for getting to the different auxiliary functions, such as

language, error log, show actual parameter values and software upgrading.

NEXT

This key is not used.

dpa8d1ea

-- 1 0 --

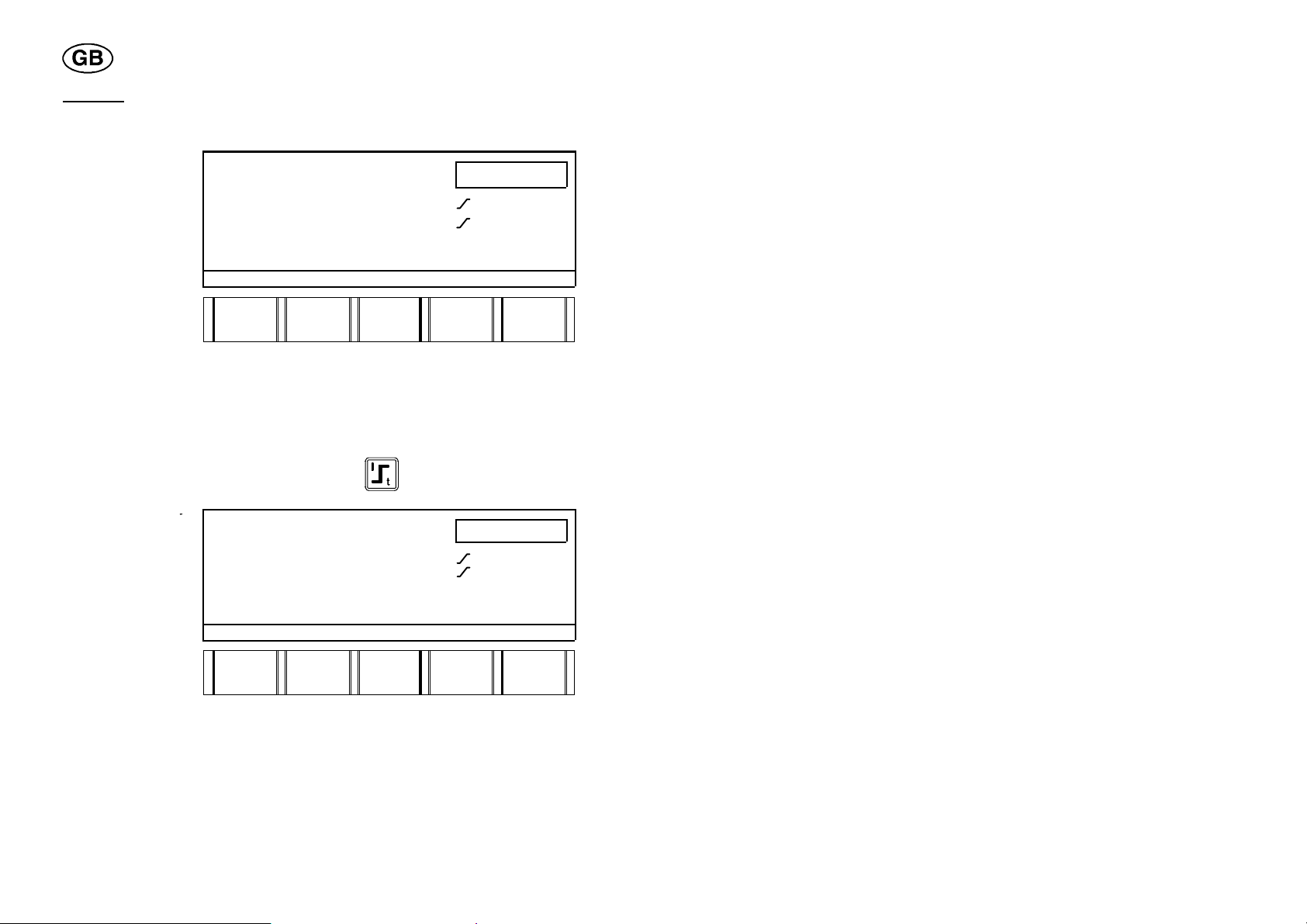

NOTEBOOK

These keys are used if you want to make notes on a welding sequence.

TOOL CODE

These keys are used if you want to view the code of the connected tool.

RESTART

These keys are used for restarting a welding sequence.

SECTOR SLOPE

These keys are used if you want to create a sector slope.

DIRECT STOP

Pressing this key will lead to direct stop of the welding. The gas postflow

takes place according to settings in the end sector.

START

This key is used for starting a welding sequence.

STOP

This key is used for stopping a welding sequence. The welding sequence is

terminated according to the settings in the end sector.

dpa8d1ea

-- 1 1 --

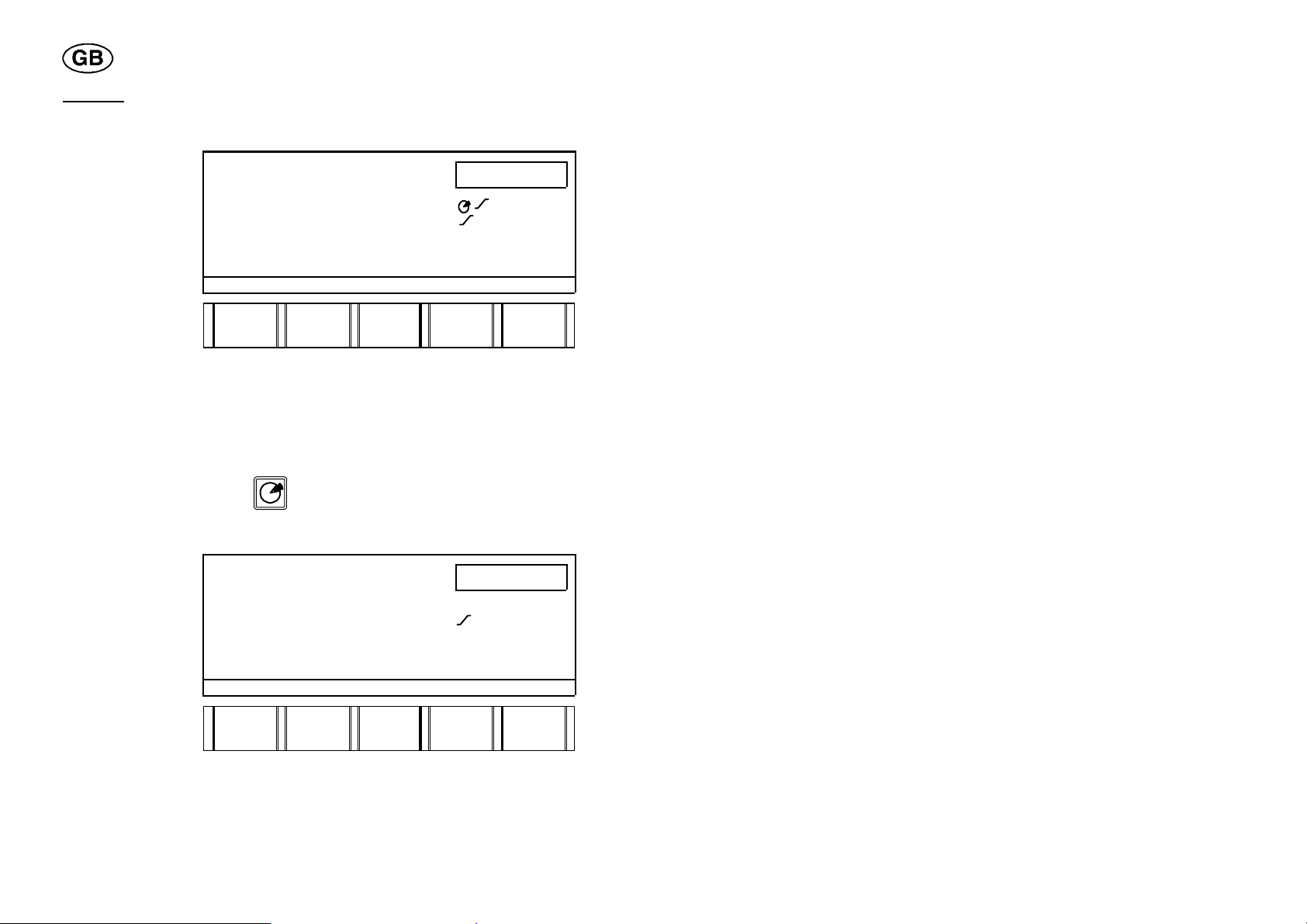

2 WELDING PARAMETERS

Setting ranges for the welding parameters can be found in the APPENDIX

on page 102.

2.1 Welding current

There are four different parameters for welding current:

S PEAK CURRENT

S BACKGROUND CURRENT

S PEAK TIME (1 s)

S BACKGROUND TIME (1 s)

The values in brackets are preset values.

Peak time

Background time

current

Peak

Background current

The welding current can be either pulsed or continuous (not pulsed).

If you want to weld using pulse current a value must be entered for all four

parameters. When welding with continuous current, however, you only need

to enter the value for peak current. Entering a value also for background

current will result in pulsed current with preset pulse and background

times. Of course, the pulse and background times can also be changed.

The weaving motion can be synchronised with the welding current (pulsed

current) so that the peak current sets in at the same time as the electrode is

in an end position. This is also called special pulsing.

dpa8d1ea

-- 1 2 --

Special pulsing

By special pulsing is meant that the welding current is synchronised with the

weaving motion, i.e. you get peak current when the electrode is in an end

position of the weaving motion. Thus the peak current time is determined by

the dwell time of the respective dwell position.

Special pulsing can be used in combination with both continuous and pulsed

rotation. Special pulsing with pulsed rotation -- also called square--wave

pulsing -- means that the gear ring rotates when the electrode is in an end

position of the weaving motion.

Special pulsing with

continuous rotation

Rotation direction

Special pulsing with

pulsed rotation

Rotation direction

A = background current B = peak current

As to special pulsing, the wire feed can be either continuous or pulsed. As

to pulsed wire feed, the synchronisation with the welding current takes place

in the way described above, see the section “Wire Feed Speed“ on page 15.

dpa8d1ea

-- 1 3 --

SECTOR 1(4)

PEAK CURRENT

BACKGR. CURRENT

PEAK TIME

BACKGR. TIME

0.000

A

A

s

s

CONT/

PEAK

CURR

BACKGR

CURR

PEAK

TIME

BACKGR

TIME

SPEC.

PULS

To activate the function special pulsing, press the marked soft key in the

display for welding parameters.

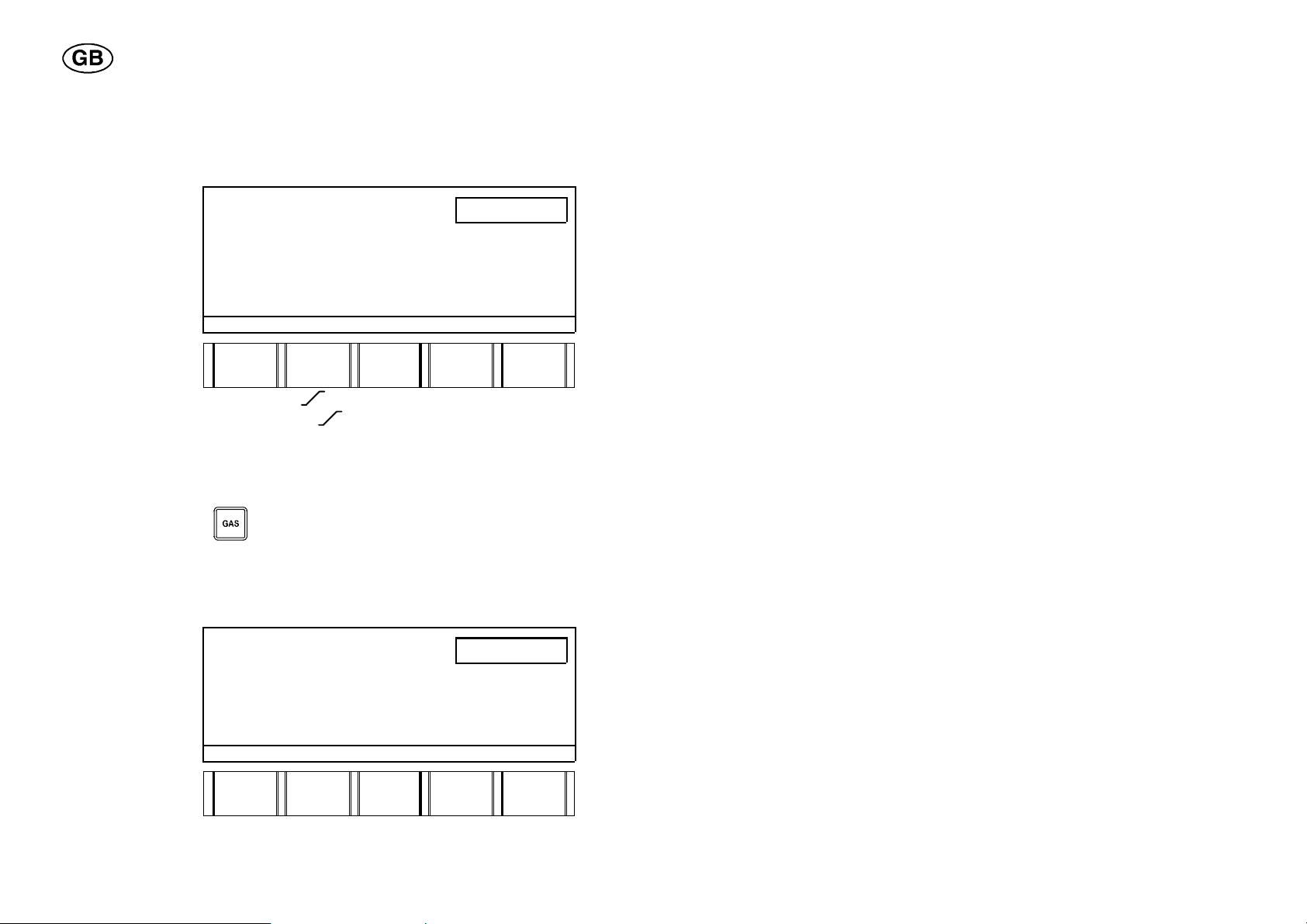

2.2 Gas

In the Shielding Gas parameter group three parameters are represented:

S WELD GAS

S ROOT GAS

S START GAS

By weld gas is meant the shielding gas on the upper side of the joint. The

weld gas parameter indicates the time the shielding gas is to flow on the

upper side of the joint before and after welding.

The values of the weld gas parameter are preset. The following values for

preflow and postflow of the weld gas apply at the start if nothing else has

been indicated:

S Weld gas preflow = 2 s

S Weld gas postflow = 4 s

By root gas is meant the shielding gas on the underside of the joint. The

root gas parameter indicates the time the shielding gas is to flow on the

underside of the joint before and after welding.

dpa8d1ea

-- 1 4 --

Some shielding gases, for example helium (He), can cause difficulty with

regard to striking the arc. If such a shielding gas is to be used as weld gas,

it could be advisable to use another gas mixture at the start moment -- a

so--called start gas.

If one value is entered for weld gas in sector 1 and one for start gas, only

the start gas is going to flow. The weld gas starts flowing when the arc is

struck.

2.3 Wire feed speed

This parameter is used to indicate the desired feed speed of the filler wire in

cm/min.

The wire feed speed can be pulsed or continuous (not pulsed).

In the Wire Feed Speed parameter group two parameters are represented:

S PEAK WIRE FEED SPEED

S BACKGROUND WIRE FEED SPEED

For welding with continuous (not pulsed) wire feed speed, only the peak

wire feed parameter shall be entered.

For welding with pulsed wire feed speed, both the peak wire feed speed

and the background wire feed speed parameters shall be entered.

The pulsed wire feed speed is always automatically synchronised with the

welding current. The wire feed speed is high using pulse current and low

using background current.

2.4 Preheating t ime

Preheating is used for heating the workpiece at the starting point in order to

obtain correct penetration of the molten pool. The preheating time is defined

as the time elapsing between arc strike and start of the rotary motion. If no

value has been entered for the preheating parameter, the arc will strike at

the same time as rotation is started.

NOTE! In the Welding Current parameter group you cannot indicate a

sector slope when preheating is involved.

dpa8d1ea

-- 1 5 --

2.5 Rotation speed

This parameter indicates the rotation speed of the electrode round the

workpiece. It is indicated in per mill (thousandths) of the max. rotation speed

of the welding tool used.

Just like welding current and wire feed speed, the rotation speed can be

pulsed or continuous (not pulsed).

In the Rotation Speed parameter group four parameters are represented:

S ROTATION FORWARDS

S ROTATION BACKWARDS

S PULSED ROTATION FORWARDS

S PULSED ROTATION BACKWARDS

The pulse rotation is always automatically synchronised with the welding

current. The welding tool rotates when peak current is used, and stands still

when background current is used.

2.6 Arc voltage control (AVC)

This parameter is used for automatic control of the arc when welding with a

tool fitted with an AVC unit.

Arc voltage control (AVC) means that the arc voltage, and by that the length

of the arc (i.e. the distance between the tip of the electrode and the

workpiece), is automatically controlled in the course of welding.

In the Arc Voltage Control (AVC) parameter group three parameters are

represented:

S PEAK VOLTAGE (Arc voltage when using peak current)

S BACKGROUND VOLTAGE (Arc voltage when using background

current)

S DELA Y TIME

dpa8d1ea

-- 1 6 --

With the parameters peak voltage and background voltage you set the

reference value for arc voltage control when using peak current and

background current. When using continuous current only the peak voltage

parameter shall be entered.

If no value is entered for peak voltage a value measured right after the

welding start is used as reference value.

If no value is entered for background voltage and pulsed welding current

has been selected, no arc voltage control takes place when background

current is used.

NOTE! A time slope cannot be indicated in sector 1 for peak voltage and

background voltage.

In order to stabilise the arc before starting the arc voltage control, a delay

time can be entered. During the delay time the AVC unit is locked.

If no delay time is entered the following applies:

S The delay time will be equally long (at least 5 seconds) as the slope--up

time (if any) for the welding current.

If the slope--up time is shorter than 5 seconds, the AVC unit can start

controlling when the slope time has elapsed, but only by increasing the

arc voltage (arc length).

S If no slope--up time has been entered for the welding current, a fixed

delay time of 5 seconds applies. The AVC unit is not completely locked -the arc voltage (arc length) can be increased.

dpa8d1ea

-- 1 7 --

2.7 Weaving

Weaving is used if you want to oscillate the electrode laterally when welding

with welding tools fitted with a weaving unit.

In the Weaving parameter group four parameters are represented:

S WEAVE AMPLITUDE (5 mm)

S WEAVE SPEED (5 mm/s)

S DWELL TIME RIGHT (1 s)

S DWELL TIME LEFT (1 s)

amplitude (mm)

left

dwell time (s)

right

dwell time (s)

Weave speed (mm/s)

The values in brackets are preset values. If one of the parameter values is

indicated in the display, the preset values will come up automatically.

The weaving motion can be synchronised with the welding current (pulse

current) so that the pulse current sets in at the same time as the electrode is

in dwell position. This is also called special pulsing and is described in the

section Special Pulsing on page 13.

dpa8d1ea

-- 1 8 --

3 START AND STOP

3.1 Start

To start the welding, use the START key .

It is impossible to start a welding program if another tool code has been

indicated than the one used in the program in question.

3.2 Stop

A requested welding stop over the STOP key means that the program

jumps to the following end sector, no matter which sector you are in at the

moment. The welding is terminated according to the settings of the end

sector.

A requested welding stop over the DIRECT STOP key

immediate stop of the welding. The gas postflow takes place according to

the time set in the end sector.

leads to

3.3 Restart

If the welding was interrupted it is restarted with the SHIFT and START

keys

Irrespective of whether the welding was stopped over the STOP

or the DIRECT STOP key , the start parameters of the preceding

start sector are used. The program then continues from the position in the

welding program where it was interrupted.

dpa8d1ea

.

-- 1 9 --

4 TO GET STARTED

4.1 General

Some of the factors controlling the welding process are specific to each one

of the welding tools, for example the rotation speed. Therefore, every

welding program must be connected to a tool code, associated with the

tool that the program was made up for.

4.2 How to indicate a tool code

S Turn the mains switch on the welding power source to position 1.

S The following display comes up:

CHOOSE CONNECTED TOOL

PRB , PRC "

PRH

PRD

POC 12--60 mm

TIG HAND TORCH

A25

NEXT

ENTER

Example: You have connected PRC 33--90

S Move the marking to the line for PRB, PRC using the soft key NEXT.

Choose the desired tool and press ENTER.

A window comes up, showing available tool sizes.

S Move the marking to the size of the tool you have connected (in this

example 33--90 mm) using the soft key NEXT and press ENTER.

dpa8d1ea

-- 2 0 --

CHOOSE CONNECTED TOOL

Pressthesof

t

g

p

existingpro

g

TOOLTYPEMISMATC

H

gra

m

PRB, PRC " 8--17 mm

PRH 17-- 49 mm

PRD 33-- 90 mm

POC 12--60 mm 60--170 mm

TIG HAND TORCH

A25

NEXT

QUIT ENTER

Result: The new tool code is accepted and the following text is displayed:

CONNECTED TOOL: PRB, PRC 33--90 mm.

NOTE! In the event a program with another tool code should already be

stored in the working area this must first be deleted. (If you want to keep the

old program that was stored in the working area, you must store it in the

library.)

The following information is displayed in the display:

S

key delete

existin

ram.

.

ro-

WARNING!

TOOLTYPE MISMATCH

PROGRAM MADE FOR: PRB, PRC 17-- 49 mm

CONNECTED TOOL: PRB, PRC 33-- 90 mm

DELETE

PROG.

Result: The new tool code is accepted and the display displays:

CONNECTED TOOL: PRB, PRC 33--90 mm.

dpa8d1ea

-- 2 1 --

4.3 How to change languages

Pressthesof

t

Pressthesof

t

l

The different texts displayed on the control box are available in the following

four languages:

S English, German, Swedish, Norwegian.

On delivery and after resetting the box, all texts displayed are in English.

Language

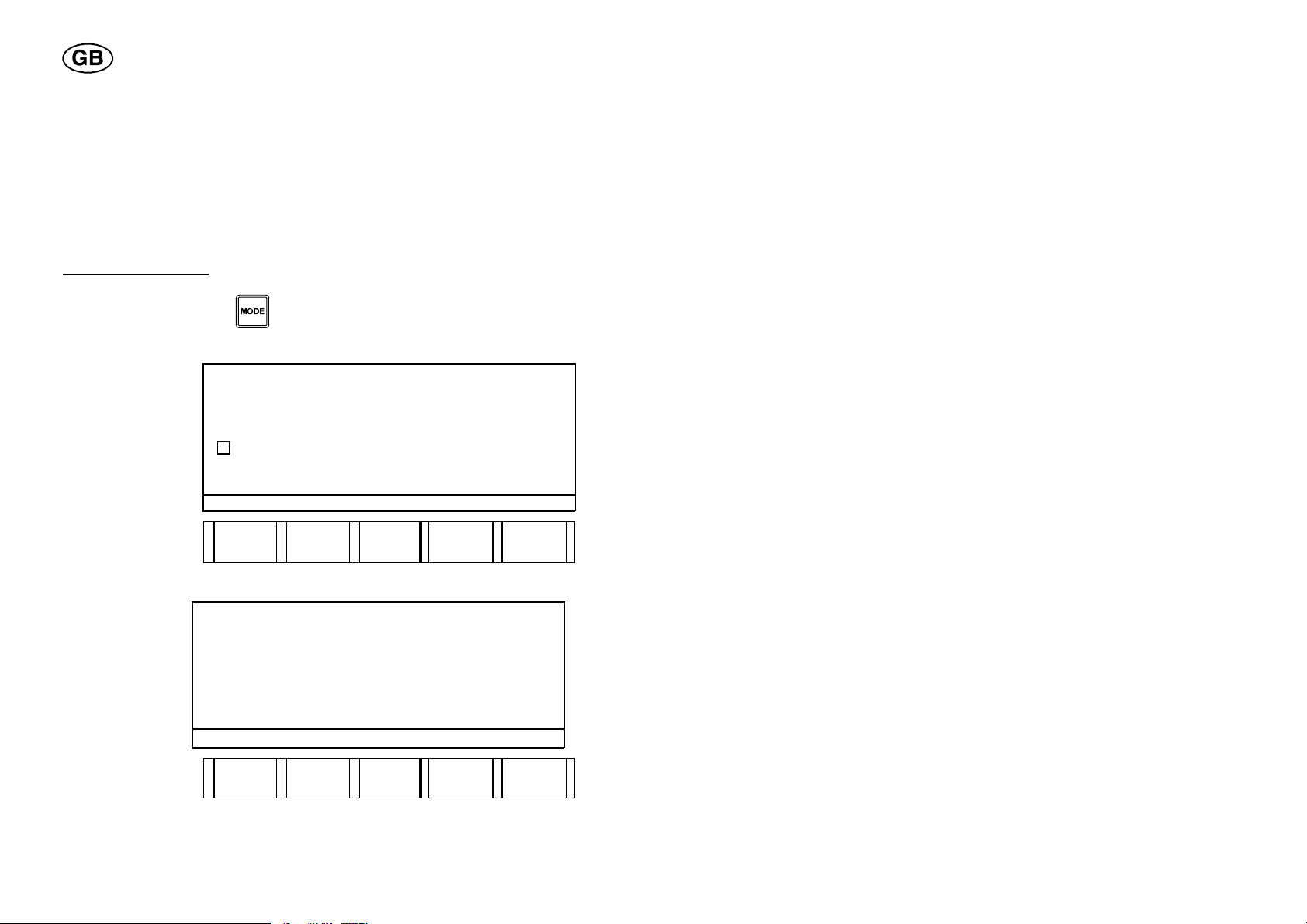

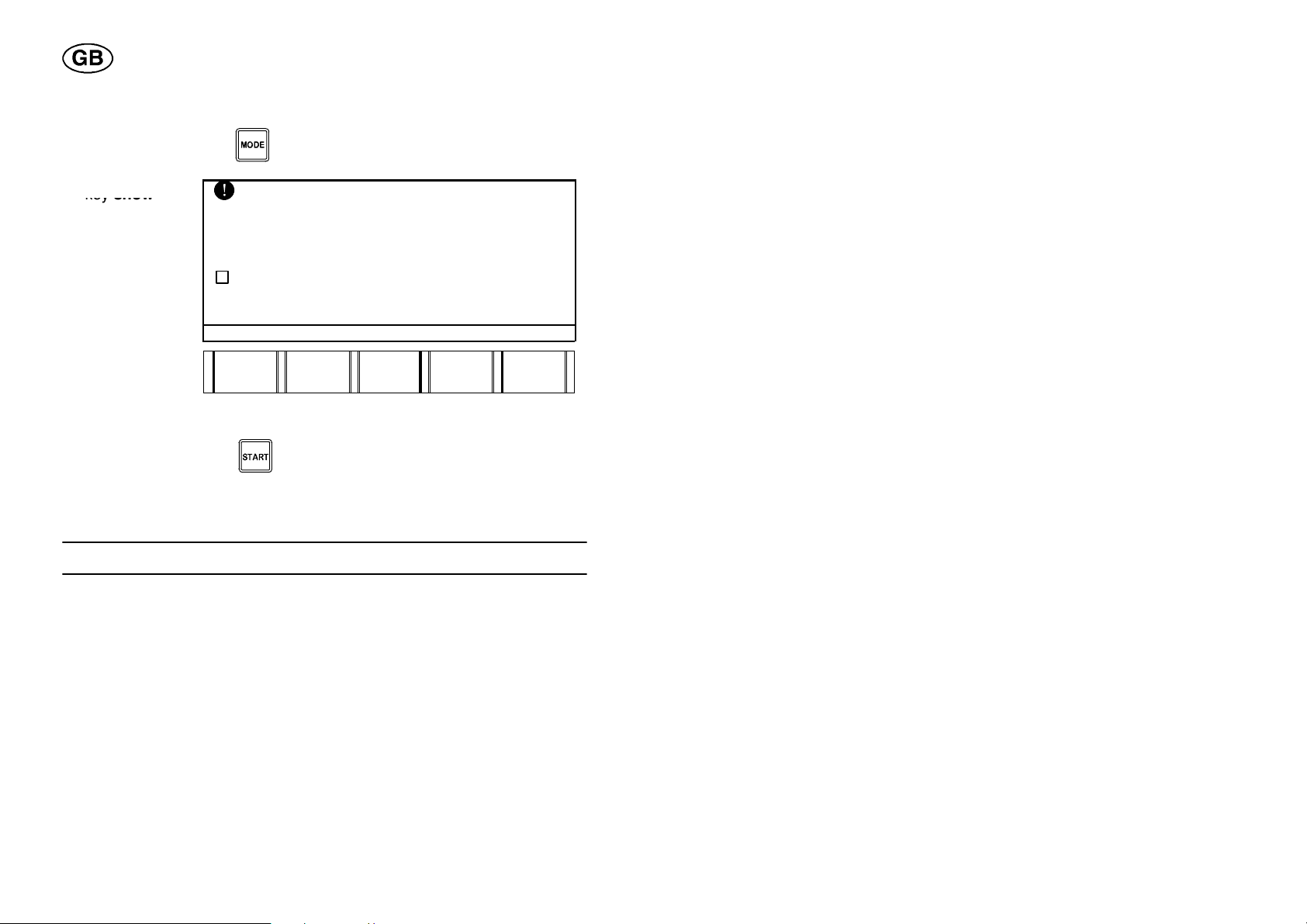

S Press the MODE key

selection

to get to the auxiliary functions, and the

following display comes up:

S

key language.

LANGUAGE "

ERROR LOG "

SHOW ACTUAL PARAMETER VALUES

SOFTWARE UPGRADE "

SOFTWARE KEY "

LAN-GUAGE

AUXILIARY FUNCTIONS

ERROR

LOG

SHOW

PARA- METER

SOFT--.

WARE

UPGR.

SOFT-WARE

KEY

S Press the soft key next language and step to the desired language.

S

key change

CHOSEN LANGUAGE: ENGLISH

anguage.

AVAILABLE LANGUAGES

ENGLISH NORSK

DEUTSCH

SVENSKA

NEXT

LANG

CHANGE

LANG

QUIT

Result: All texts will from now on be in the new language (in this example

Swedish).

dpa8d1ea

-- 2 2 --

S

Terminate

byy

ftk

pressing the

so

bryt.

ey av-

VALT SPRÅK: SVENSKA

TILLGÄNGLIGA SPRÅK

ENGLISH NORSK

DEUTSCH

SVENSKA

NÄSTA

SPRÅK

BYT

SPRÅK

AVBRYT

S Press the MODE key to return to the working area.

5 PROGRAM EDITING

5.1 Entering a parameter value

S Make sure the right group of parameters is displayed in the display by

pressing one of the seven parameter keys.

S Enter a value in the digit box.

S Press the soft key of the desired parameter.

Note that the parameters always inherit the value from the previous

sector if no new value is entered.

5.2 Increasing/decreasing a parameter value

The parameter value to be altered must be shown in the digit box.

S Mark the desired parameter using one of the soft keys. The set value

comes up in the box.

S Press the PLUS

dpa8d1ea

or the MINUS key .

-- 2 3 --

5.3 Creating a new sector

A new sector is created by entering a new breakpoint into an existing sector.

S Enter a new value for the breakpoint of the new sector.

S Press the SECTOR key

In doing this, a new sector is created which is a copy of the original sector,

but with another breakpoint and another sector number. The new sector is

automatically positioned in the right place in the program. This is determined

by the value of the new breakpoint.

Creating a new sector during welding

Proceed as follows to create a new sector during the welding:

S Enter a value into one of the following parameter groups using the

numerical keys:

S Press the corresponding soft key.

A new sector is now automatically created.

.

5.4 Changing the breakpoint of a sector

Make sure the existing breakpoint value of the sector is displayed in the digit

box.

S Press the SECTOR key

The breakpoint value is now shown in the digit box.

S Enter the new breakpoint value.

.

S Press the SECTOR key

or

S Change the breakpoint value using the PLUS key

key

dpa8d1ea

.

-- 2 4 --

or the MINUS

5.5 Creating a transport secto r

If you want to rotate the welding tool without welding within a sector, you

can create a transport sector. Sector 1 cannot function as a transport

sector -- it can only function as a delayed start.

Transport sector

S Enter a value for the breakpoint of the new sector using the numerical

keys.

S Press the SECTOR key

S Set the WELDING CURRENT

.

(the peak current) to 0.

NOTE! If the welding current value is inherited, the welding current value of

the following sector will also be 0. Don’t forget to change them to the right

value.

All the other parameter values can remain.

Delayed start

Change the breakpoint of sector 1 in the following way in order to delay the

start:

S Press the STEP key

S Press the SECTOR key

and go to sector 1.

.

S Enter the breakpoint, for example 0.100 instead of 0.000, using the

numerical keys.

S Press the SECTOR key

again.

dpa8d1ea

-- 2 5 --

5.6 Finding the home position

When the tube welding tools PRH and POC are used, it can sometimes be

necessary to return to the home position (start position), for example in the

event of a welding stop.

S Rotate the tool manually till it is within a tenth of a rotation to the left or

right of the home position. See also under the section “Manual Mode” on

page 56.

S Press the START key

Once this is done, the welding tool automatically starts rotating to the home

position, and a welding sequence starts.

.

5.7 Entering a slope

A time slope or a sector slope can be indicated for the following parameter

groups:

Welding current Rotation speed

Arc voltage control (AVC) Weaving

Wire feed speed

Time slope

S Press the key for the parameter group in question.

S Mark the desired parameter using one of the soft keys.

S Enter the desired slope time value.

S Press the SLOPE key

dpa8d1ea

.

-- 2 6 --

Sector slope

To create a sector slope no time value is to be entered. A sector slope

always goes on from one breakpoint to the next one.

NOTE! In the Welding Current parameter group you cannot indicate a

sector slope when preheating is involved.

S Press the key for the parameter group in question.

S Mark the desired parameter using one of the soft keys.

S Press the SHIFT key

and the SLOPE key simultaneously,

and a sector slope is created.

Whatisaslope?

A slope is a linear change between two parameter values, based on time or

position (breakpoint).

A time--based slope (time slope) is active during the time indicated.

A position--based slope (sector slope) is active between two adjacent

breakpoints.

5.8 Moving within a program

Move to the next parameter group

Using the STEP key

When using the STEP function, only the parameter groups that have been

assigned a value are displayed.

When stepping through the end sector, you will automatically jump to the

tool code.

Move between

sectors

By entering a sector number in the digit box in the display and then pressing

you can step through the whole welding program.

the SECTOR key

it is possible to jump between the different sectors of

the program. When jumping to a new sector you always end up in the same

group of parameters as the one you left.

dpa8d1ea

-- 2 7 --

5.9 Deleting in a program

Delete a parameter value

You can delete a parameter value if it has not been borrowed from a

previous sector. For the value to be deleted, it must be displayed in the digit

box.

S Press the DELETE key

. The digit box asks DEL?

S Press the soft key of the parameter to confirm.

Delete a

sector

You can only delete the sector in which you are at the moment. It can be

done in two different ways:

Alternative 1

S Press the DELETE key

and then the SECTOR key .

Alternative 2

S Press the SECTOR key

. The breakpoint of the sector comes up in

the digit box.

S Press the DELETE key

S Press the SECTOR key

. The digit box asks DEL?

to confirm.

dpa8d1ea

-- 2 8 --

Delete the contents of the working area

The working area always contains the welding program last used. Maybe

you want to clear the working area completely, for example to change the

tool code.

Delete a program in the working area in the following way:

S Press the DELETE key

and then the MEMORY key .

5.10 Changing weld data during welding

To change welding data in the course of welding, a value must be displayed

in the digit box.

S Mark the parameter in question using one of the soft keys. The set value

now comes up in the digit box.

S Enter the new value using the numerical keys, or increase/decrease the

value using the PLUS

NOTE! When a value is changed in the working area, the old value will be

overwritten and the new one applies. If the value is inherited, the value in

the following sector will also be changed.

/ MINUS keys.

dpa8d1ea

-- 2 9 --

5.11 Zeroing the control box

In the event the control box should get blocked, i.e. it does not react when

the keys are activated, it is necessary to reset the box. This is done in the

following way:

S Set the mains voltage switch on the power source to 0.

S Hold down the mid one of the five soft keys on the control box, and turn

the mains voltage switch to position 1.

dpa8d1ea

-- 3 0 --

6 PROGRAMMING EXAMPLES

Pressthesof

t

ouspeak

6.1 Example 1a:

The first example is a simple welding program, consisting of two sectors,

sector 2 being a stop sector. The program contains four parameters:

welding current, rotation, weld gas preflow and weld gas postflow.

Sector 1 Sector 2

Breakpoint 0.000 1.010

Welding current (continuous) (A) 200 0

Rotation (continuous) (‰) 250 250

Gas preflow (weld gas) (s) 5

Gas postflow (weld gas) (s) 7

Sector 1

Breakpoint

Sector 1 automatically is assigned the breakpoint 0.000, if nothing else is

indicated.

Welding current

Pulse current = 200 A

S Press the key for WELDING CURRENT

. The picture for welding

current settings comes up in the display.

S Enter the value 200 using the numerical keys.

S

key continu-

pulse current.

SECTOR 1(1) 0.000

PEAK CURRENT A

BACKG. CURRENT A

PEAK TIME s

BACKGR.TIME s

CONT/

PEAK

CURR.

BACKGR.

CURR.

PEAK

TIME

200

BACKGR

TIME

SPEC.

PULS

Result: PEAK CURRENT = 200 A in sector 1.

dpa8d1eb

-- 3 1 --

Rotation speed

Pressthesof

t

forward

Pressthesof

t

Continuous rotation forward = 250 ‰ of the max. rotation speed.

S Press the key for ROTATION SPEED

.

S Enter the value 250 using the numerical keys.

S

key rotation

.

SECTOR 1(1) 0.000

ROTATION FORWARD

ROTATION BACKW.

PULSE ROT. FORW.

PULSE ROT. BACKW.

ROTA

TION

FORW

ROTA-TION

BACKW

PULSE

ROT.

FORW

250

PULSE

ROT.

BACKW.

Result: ROTATION FORWARD = 250 in sector 1.

Gas

Preflow of weld gas = 5sin sector 1.

S Press the key for gas

.

S Enter the value 5 using the numerical keys.

The gas preflow has a preset value of 2 s, which applies if no other value

is entered and displayed in the display at the start.

S

key weld gas.

SECTOR 1(1) 0.000

5

WELD GAS s

ROOT GAS s

START GAS s

WELD

GAS

ROOT

GAS

START-GAS

Result: WELD GAS = 5 s in sector 1.

dpa8d1eb

-- 3 2 --

Sector 2

Pressth

e

Pressthesof

t

ouspeak

Breakpoint

S Enter the value of the new breakpoint 1.010 using the numerical keys.

S

SECTOR key.

SECTOR 1(1) 0.000

1 WELD GAS 5 s

ROOT GAS s

START GAS s

1.010

WELD

GAS

ROOT

GAS

START

GAS

Result: Sector 2 out of 2 sectors in all.

Welding current

Peak current = 0A

As sector 2 is to be a stop sector, the welding current must be assigned the

value of 0 amperes. Note that the parameter (peak current) has been

assigned the value 200 as the value was inherited from the preceding

sector.

S Press the key for WELDING CURRENT

.

S Enter the value 0 using the numerical keys.

S

key continu-

current.

SECTOR 2(2) 1.010

1 PEAK CURRENT 200 A

BACKGR. CURRENT A

PEAK TIME s

BACKGR. TIME s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

0

BACKGR

TIME

SPEC.

PULS

Result: PEAK CURRENT = 0 A in sector 2 (end sector).

dpa8d1eb

-- 3 3 --

Rotation speed

Pressthesof

t

As this is the last sector of the program and the welding current is set to 0,

the sector will be interpreted as a stop sector, irrespective of the rotation

value. In other words, we can keep the rotation value that was borrowed

from the previous sector.

S Press the key for ROTATION SPEED

SECTOR 2(2) 1.010

1 ROTATION FORWARD 250

ROTATION BACKW.

PULSE ROT. FORW.

PULSE ROT. BACKW.

ROTA

TION

FORW.

ROTA-TION

BACKW.

to view the result.

PULSE

ROT.

FORW.

PULSE

ROT.

BACKW.

Result: ROTATION FORWARD = 250 ‰ in sector 2 (borrowed value)

Gas

The weld gas preflow of = 7s.

S Press the key for gas

.

S Enter the value 7 using the numerical keys. The gas postflow has a

preset value of 4 s, which applies if no other value is entered and

displayed in the display at the start.

S

key weld gas.

SECTOR 2(2) 1.010

7

1WELDGAS s

ROOT GAS s

START GAS s

WELD

GAS

ROOT

GAS

START

GAS

Result: WELD GAS = 7 s in sector 2.

dpa8d1eb

-- 3 4 --

6.2 Example 1b:

Pressth

e

We now want to extend the previous program by adding a slope up and

slope down time to the welding current. We also add a new sector to the

program, which is to be placed between the other two sectors.

Sector 1 Sector 2 Sector 3

Breakpoint 0.000 0.500 1.010

Welding current (continuous) (A) 200 150 0

Slope up (s) 2 -- -Slope down (s) -- -- 4

Rotation, continuous (‰) 250 250 250

Gas preflow (weld gas) (s) 5 -- -Gas postflow (weld gas) (s) -- -- 7

Sector 1

Go back to sector 1.

S Enter the value 1 using the numerical keys.

S

SECTOR key.

SECTOR 2(2) 1.010

1

2 WELD GAS 7 s

ROOT GAS s

START GAS s

WELD

GAS

ROOT

GAS

START

GAS

Result: Return to sector 1 with the breakpoint 0.000.

dpa8d1eb

-- 3 5 --

Slope

Enterth

eva

lue

Enterth

eva

lue

The slope--up time = 2sfor the peak current of sector 1.

When a slope function is to be added, first make sure the corresponding

picture is displayed in the display.

S Press the key for WELDING CURRENT

.

S Press the soft key for continuous peak current.

S

2.

S Press the

SLOPE key.

SECTOR 1(2) 0.000

1 PEAK CURRENT 200 A

BACKGR. CURRENT A

PEAK TIME s

BACKGR. TIME s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

2

BACKGR

TIME

SPEC.

PULS

Result: PEAK CURRENT = 200 A, 2.0 s in sector 1.

Sector

2

New breakpoint = 0.500

We are now going to add a sector to the program. The breakpoint of the

new sector is to be 0.500, and the sector will automatically be placed

between the two sectors already existing.

S

0.5.

S Press the

SECTOR key.

SECTOR 1(2) 0.000

1 PEAK CURRENT 200 A

BACKGR. CURRENT A

PEAK TIME s

BACKGR. TIME s

0.5

2.0 s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

SPEC.

PULS

Result: Breakpoint 0.500 is placed as sector no. 2 (borrowed value).

dpa8d1eb

-- 3 6 --

Welding current

Pressthesof

t

ouspeak

Enterth

eva

lue

numericalkeys

Peak current = 150 A

S Press the key for WELDING CURRENT

S Enter the value 150 using the numerical keys.

S

key continu-

current.

SECTOR 2(3) 0.500

1 PEAK CURRENT 200 A

BACKGR CURRENT A

PEAK TIME s

BACKGR. TIME s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

Result: PEAK CURRENT = 150 A in sector 2.

Sector

3

Go to sector 3.

S

3 using the

SECTOR 2(3) 0.500

.

S Press the

SECTOR key.

2 PEAK CURRENT 150 A

BACKGR. CURRENT A

PEAK TIME s

BACKGR. TIME s

.

150

2.0 s

BACKGR

TIME

SPEC.

PULS

3

CONT/

PEAK

CURR

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

SPEC.

PULS

Result: You have moved to sector 3 with the breakpoint 1.010.

dpa8d1eb

-- 3 7 --

Slope

Enterth

eva

lue

Slope down = 4sfor the peak current of sector 3.

S Press the soft key for continuous peak current.

S

4.

S Press the

SLOPE key.

SECTOR 3(3) 1.010

3 PEAK CURRENT 0 A

BACKGR CURRENT A

PEAK TIME s

BACKGR. TIME s

4

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

SPEC.

PULS

Result: PEAK CURRENT = 0 A, 4.0 s in sector 3 (stop sector).

6.3 Example 1c:

We now extend the previous program by changing the welding current of

sector 1 from 200 A to 180 A. We also add a new sector to the program,

which will automatically be placed between sector 1 and sector 2.

Sector 1 Sector 2 Sector 3 Sector 4

Breakpoint 0.000 0.250 0.500 1.010

Welding current (continuous)

(A)

Slope up (s) 2 -- -- -Slope down (s) -- 4 -- 4

Rotation, continuous (‰) 250 250 250 250

Gas preflow (weld gas) (s) 5 -- -- -Gas postflow (weld gas) (s) -- -- -- 7

180 170 150 0

dpa8d1eb

-- 3 8 --

Sector 1

Enterth

eva

lue

numericalkeys

Pressthesof

t

ouspeak

Go back to sector 1.

S

1 using the

.

S Press the

SECTOR key.

SECTOR 3(3) 1.010

3 PEAK CURRENT 0 A

BACKGR CURRENT A

PEAK TIME s

BACKGR. TIME s

1

4.0 s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

Result: Return to sector 1 with the breakpoint 0.000.

Welding current

Peak current = changed from 200 A to 180 A.

S Enter the value 180 using the numerical keys.

S

key continu-

current.

SECTOR 1(3) 0.000

1 PEAK CURRENT 200 A

BACKGR CURRENT A

PEAK TIME s

BACKGR. TIME s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

Result: PEAK CURRENT = 180 A, 2.0 s in sector 1.

180

2.0 s

SPEC.

PULS

SPEC.

PULS

dpa8d1eb

-- 3 9 --

Sector 2

Enterth

eva

lue

Pressthesof

t

ouspeak

New breakpoint = 0.250

We are now going to add a sector to the program. The new sector is to have

the breakpoint 0.250 and will automatically be placed in the right position

between sector 1 and sector 2.

S

0.25.

S Press the

SECTOR key.

SECTOR 1(3) 0.000

1 PEAK CURRENT 180 A

BACKGR. CURRENT A

PEAK TIME s

BACKGR. TIME s

0.25

2.0 s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

SPEC.

PULS

Result: SECTOR 0.250 is placed as sector 2 in the program (values

borrowed from sector 1).

Welding current

Peak current = 170 A.

S Enter the value 170 using the numerical keys.

S

key continu-

current.

SECTOR 2(4) 0.250

1 PEAK CURRENT 180 A

BACKGR. CURRENT A

PEAK TIME s

BACKGR. TIME s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

170

BACKGR

TIME

2.0 s

SPEC.

PULS

Result: PEAK CURRENT = 170 A in sector 2.

dpa8d1eb

-- 4 0 --

Slope

Enterth

eva

lue

numericalkeys

Slope down = 4sfor the peak current in sector 2.

S Press the soft key for continuous peak current .

S

4 using the

SECTOR 2(4) 0.250

.

2 PEAK CURRENT 170 A

S Press the

SLOPE key.

BACKGR. CURRENT A

PEAK TIME s

BACKGR. TIME s

4

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

Result: PEAK CURRENT = 170 A, 4.0 s in sector 2.

SPEC

PULS

dpa8d1eb

-- 4 1 --

6.4 Example 1d:

We now extend the program further by adding some new welding

parameters.

Sector 1 Sector 2 Sector 3 Sector 4

Breakpoint 0.000 0.250 0.500 1.010

Welding current (continuous)

(A)

Welding current (background current) (A)

Welding current (pulse time)

(s)

Welding current (Background time) (s)

Slope up (s) 2 -- -- -Slope down (s) -- 3 -- 4

Preheating (s) 2 2 2 2

Rotation, (cont. forward) (‰) 250 250 250 250

Gas preflow (weld gas) (s) 5 -- -- -Gas postflow (weld gas) (s) -- -- -- 7

Wire feed (continuous)

(cm/min)

A VC, (pulse voltage) (V) 11.2 11.2 11.2 11.2

AVC,

(background voltage) (V)

Weaving, (weaving ampl.)

(mm)

Weaving, (weaving speed)

(mm/s)

Weaving, (dwell time right)

(s)

Weaving, (dwell time left) (s) 1.0 1.0 1.0 1.0

180 170 150 0

100 100 100 100

0.5 0.5 0.5 0.5

1.0 1.0 1.0 1.0

110 110 110 110

10.9 10.9 10.9 10.9

5.0 5.0 5.0 5.0

8.0 8.0 8.0 8.0

1.0 1.0 1.0 1.0

dpa8d1eb

-- 4 2 --

Sector 1

Enterth

eva

lue

numericalkeys

Pressthesof

t

groundcur

Go back to sector 1.

S

1 using the

.

S Press the

SECTOR key.

SECTOR 2(4) 0.250

2 PEAK CURRENT 170 A

BACKGR CURRENT A

PEAK TIME s

BACKGR TIME s

1

4.0 s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

SPEC.

PULS

Result: Return to sector 1 with the breakpoint 0.000.

Welding current

Background current = 100 A.

S Press the key for WELDING CURRENT

.

S Enter the value 100 using the numerical keys.

S

key back--

rent.

-

-

SECTOR 1(4) 0.000

1 PEAK CURRENT 180 A

BACKGR. CURRENT A

PEAK TIME s

BACKGR. TIME s

CONT/

PEAK

CURR

BACKGR

CURR.

PEAK

TIME

100

BACKGR

TIME

2.0 s

SPEC.

PULS

Result: BACKGR. CURRENT = 100 A. 2.0 s in sector 1 and

PULSE TIME = 1.00 s and BACKGR. TIME = 1.00 s (preset values)

dpa8d1eb

-- 4 3 --

Pulse time = 0.5 s instead of 1.0.

Pressthesof

t

Pressthesof

t

S Enter the value 0.5 using the numerical keys.

S

key peak time.

SECTOR 1(4) 0.000

0.5

1 PEAK CURRENT 180 A

BACKGR. CURRENT 100 A

PEAK TIME 1.00 s

BACKGR.TIME 1.00 s

CONT/

PULSE

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

Result: PEAK TIME = 0.50 s instead of 1.00 s in sector 1.

Preheating time

The preheating time = 2s

S Press the key for PREHEATING TIME

.

S Enter the value 2.0 using the numerical keys.

S

key preheat.

SECTOR 1(4) 0.000

PREHEAT s

2,0

2.0 s

2.0 s

SPEC.

PULS

PRE-HEAT.

Result: PREHEAT = 2.0 in sector 1.

dpa8d1eb

-- 4 4 --

Wire feed speed

Pressthesof

t

ouspeakwire

Pressthesof

t

ous/pea

k

We are now going to use filler wire. As we intend to weld using continuous

wire feed (not pulsed) only the pulsed wire parameter need to be entered.

Pulsed wire = 110 cm/min

S Press the key for WIRE FEED SPEED

.

S Enter the value 110 using the numerical keys

S

key continu-

feed.

SECTOR 1(4) 0.000

PEAK WIRE. cm/m in

BACKGR WIRE. cm/min

CONT/

PEAK

WIRE

BACKGR

WIRE

Result: PEAK WIRE FEED = 110 cm/min in sector 1.

Arc voltage control (AVC)

The peak voltage = 11.2 V

S Press the key for ARC VOLTAGE CONTROL, (AVC)

S Enter the value 11.2 using the numerical keys.

S

key continu-

voltage.

SECTOR 1(4 ) 0.000

PEAK VOLTAGE V

BACKGR. VOLTAGE V

DELAY TIME s

110

.

11.2

CONT/

PULSE

VOLT.

BACKGR

VOLT.

DELAY

TIME

Result: PEAK VOLTAGE = 11.2 V in sector 1.

dpa8d1eb

-- 4 5 --

Background voltage = 10.9 V

Pressthesof

t

groundvol

t

Pressthesof

t

speed

S Enter the value 10.9 using the numerical keys.

S

key back-

age.

-

-

SECTOR 1(4 ) 0.000

1 PEAK VOLTAGE 11,2 V

BACKGR. VOLTAGE V

DELAY TIME s

10.9

CONT/

PULSE

VOLT.

BACKGR

VOLT.

DELAY.

TIME

Result: BACKGR VOLTAGE = 10.9 V in sector 1.

Weaving

We are now going to add values for weaving. Some of the values are

preset. See preset values, page 18 .

Weaving speed = 8.0 mm

S Press the key for WEAVING

.

S Enter the value 8.0 using the numerical keys.

S

key weaving

.

SECTOR 1 (4 ) 0.000

WEAVE AMPL. mm

WEAVE. SPEED. mm/s

DWELL RIGHT s

DWELL LEFT s

WEAVE.

AMPL

WEAVE

SPEED

DWELL

RIGHT

8.0

DWELL

LEFT

Result: WEAVING SPEED = 8.0 mm/s. The preset values are also shown

(sector 1).

dpa8d1eb

-- 4 6 --

Sector 2

Enterth

eva

lue

numericalkeys

Enterth

eva

lue

numericalkeys

Go to sector 2.

S

2 using the

S Press the

SECTOR key.

SECTOR 1(4) 1.010

.

1 WEAVE. AMPL 5.0 mm

1 WEAVE SPEED 8.0 mm/s

1DWELLRIGHT 1.0s

1 DWELL LEFT 1.0 s

2

WEAVE

AMPL

WEAVE

SPEED

DWELL

RIGHT

DWELL

LEFT

Result: You have moved to sector 2(4) with the breakpoint 0.250.

Slope

We are now going to change the slope--down time in sector 2. Make sure

the corresponding parameter picture is shown in the display.

S Slope down = 3sinstead of 4 s.

Press the key for WELDING CURRENT

.

Press the soft key for continuous peak current .

S

3 using the

S Press the

SLOPE key.

SECTOR 2(4) 0.250

.

2 PEAK CURRENT 170 A

1 BACKGR. CURRENT 100 A

1 PEAK TIME 0,50 s

1 BACKGR. TIME 1,00 s

CONT/

PULSE

CURR.

BACKGR

CURR.

PEAK

TIME

3

BACKGR

TIME

4.0 s

2.0 s

SPEC.

PULS

Result: PEAK CURRENT = 170 A 3.0 s SLOPE in sector 2.

dpa8d1eb

-- 4 7 --

6.5 Example 1e:

We now want to make changes in the program by moving the breakpoint in

sector 3 from 0.500 to 0.750 and adding special pulsingand a sector

slope in sector 2 and sector 3.

Sector 1 Sector 2 Sector 3 Sector 4

Breakpoint 0.000 0.250 0.750 1.010

Welding current (continuous)

(A)

Welding current (background

current) (A)

Welding current (pulse time)

(s)

Welding current (background

time) (s)

Special pulsing -- -- --

Slope up (s) 2 -- -- -Slope down (s) -- Sector

Preheating (s) 2 2 2 2

Rotation, (cont. forward) (‰) 250 250 250 250

Gas preflow (weld gas) (s) 5 -- -- -Gas postflow (weld gas) (s) -- -- -- 7

Wire feed (continuous)

(cm/min)

AVC, (pulse voltage) (V) 11.2 11. 2 11.2 11.2

AVC, (background voltage) (V) 10.9 10.9 10.9 10.9

Weav. (weaving ampl) (mm) 5.0 5.0 5.0 5.0

Weav. (weaving speed) (mm/s) 8.0 8.0 8.0 8.0

Weaving (dwell time right) (s) 1.0 1.0 1.0 1.0

Weaving (dwell time left) (s) 1.0 1.0 1.0 1.0

180 170 150 0

100 100 100 100

0.5 0.5 0.5 0.5

1.0 1.0 1.0 1.0

slope

Sector

slope

4

110 110 110 110

dpa8d1eb

-- 4 8 --

Sector 1

Enterth

eva

lue

numericalkeys

Pressthesoftk

eyy

f

pulsing

Go back to sector 1.

S

1 using the

.

S Press the

SECTOR key.

SECTOR 2(4) 0.250

2 PEAK CURRENT 170 A

1 BACKGR. CURRENT 100 A

1 PEAK TIME 0,50 s

1 BACKGR. TIME 1,00 s

1

3.0 s

3.0 s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

BACKGR

TIME

SPEC.

PULS

Result: Return to sector 1 with the breakpoint 0.000.

Special pulsing (welding current)

We are now going to add special pulsing. Make sure the corresponding

picture is shown in the display.

PEAK

TIME

.

2.0 s

2.0 s

BACKGR

TIME

SPEC.

PULS

S Press the key for WELDING CURRENT

or special

.

SECTOR 1(4) 0.000

1 PEAK CURRENT 180 A

1 BACKGR CURRENT 100 A

1 PEAK TIME 0,50 s

1 BACKGR. TIME 1,00 s

CONT/

PEAK

CURR.

BACKGR

CURR.

Result: SPECIAL PULSING = takes place throughout the program.

dpa8d1eb

-- 4 9 --

Sector 2

Enterth

eva

lue

numericalkeys

Go to sector 2.

S

2 using the

S Press the

SECTOR key.

SECTOR 1(4) 0.000

.

1 PEAK CURRENT 180 A

1 BACKGR. CURRENT 100 A

1 SPECIAL PULSING

2

2.0 s

2.0 s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

Result: You have moved to sector 2.

Sector slope

We want to add a sector slope in sector 2.

S Press the soft key for continuous peak current .

S Press the keys SHIFT

2 PEAK CURRENT 170 A

1 BACKGR. CURRENT 100 A

2 SPECIAL PULSING

CONT/

PEAK

CURR.

SECTOR 2(4) 0.250

and SLOPE .

BACKGR

CURR.

PEAK

TIME

Result: PEAK CURRENT = 170 A in sector 2.

BACKGR

TIME

BACKGR

TIME

2.0 s

SPEC.

PULS

SPEC.

PULS

dpa8d1eb

-- 5 0 --

Sector 3

Enterth

eva

lue

numericalkeys

Pressth

e

again

Go to sector 3.

S

3 using the

S Press the

SECTOR key.

SECTOR 2(4) 0.250

.

2 PEAK CURRENT 170 A

1 BACKGR CURRENT 100 A

2 SPECIAL PULSING

3

2.0 s

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

Result: You have moved to sector 3.

Breakpoint

The breakpoint = 0.750 instead of 0.500.

To change the breakpoint, proceed as follows:

S Press the SECTOR key

. The digit box now shows 0.500.

S Enter the value 0.75 using the numerical keys.

S

SECTOR key

SECTOR 3(4) 0.500

.

3 PEAK CURRENT 150 A

1 BACKGR. CURRENT 100 A

3 SPECIAL PULSING

CONT/

PEAK

CURR.

BACKGR

CURR.

PEAK

TIME

Result: The new breakpoint = 0.750 in sector 3.

BACKGR

TIME

0.75

BACKGR

TIME

3.0 s

SPEC.

PULS

SPEC.

PULS

dpa8d1eb

-- 5 1 --

Sector slope

We now want to add a sector slope to sector 3.

S Press the soft key continuous peak current.

S Press the keys SHIFT

3 PEAK CURRENT 150 A

1 BACKGR. CURRENT 100 A

3 SPECIAL PULSING

CONT/

PEAK

CURR.

SECTOR 3(4) 0.750

and SLOPE .

BACKGR

CURR.

Result: PEAK CURRENT = 150 A .

PEAK

TIME

BACKGR

TIME

2.0 s

SPEC.

PULS

dpa8d1eb

-- 5 2 --

7 THE LIBRARY

Pressthesof

t

Welding programs created in the working area are stored in the library. Up

to 250 different programs can be stored here, depending on the size of the

programs. (See the section PC--CARDS, page 59.)

7.1 Storing a program

S Make up a program in the working area.

S Press the MEMORY key

.

S Enter the position no. of the program (for example 3) using the numerical

keys.

S

key store.

LIBRARY Page 1 (1)

(NEXT)

PAGE

STORE RECALL PC--

CARD

3

DELETE

PROG.

STO flashes in the digit box.

Result: The program is to be found under program position 3 in the library.

S Leave the library and use the MEMORY key

to return to the

working area.

7.2 Recalling a program

Note! When recalling a program from the library, the working area must be

empty.

S Press the MEMORY key

dpa8d1ec

.

-- 5 3 --

S Select a program position (for example 3) using the numerical keys.

Pressthesof

t

Pressth

e

MEMkeysat

S

key recall.

LIBRARY Page 1 (1)

3

3

(NEXT)

PAGE

STORE

RECALL

PC-CARD

DELETE

PROG.

RCL flashes in the digit box.

S Press the MEMORY key

to get back to the working area.

Result: You have recalled a copy of program no. 3 from the library to the

working area.

7.3 Viewing the tool code

In the library you can also view the tool code that is connected with a

particular program position.

S Press the MEMORY key

S Select a program position (for example 3) using the numerical keys.

S

SHIFT and

thesametime.

LIBRARY Page 1 (1)

3

.

3

(NEXT)

PAGE

STORE

RECALL

PC-CARD

DELETE

PROG.

Result: The display shows the tool code (PRB , PRC 33--90 mm) connected

with program position no. 3.

dpa8d1ec

-- 5 4 --

S Press the MEMORY key to get back to the working area.

Pressthesof

t

program

Pressthesof

t

7.4 Deleting a program

S Press the MEMORY key .

S Select a program position (for example 3) using the numerical keys

S

key delete

.

LIBRARY Page 1 (1)

3

3

(NEXT)

PAGE

STORE RECALL PC--

CARD

The following display comes up:

S

key yes.

Library Page 1 (1)

3

DEL?

NO YES

Result: You have deleted program position no. 3 in the library.

S Press the MEMORY key

to get back to the working area.

DELETE

PROG.

dpa8d1ec

-- 5 5 --

8 MANUAL MODE

8.1 Field of application

Manual mode is used for correct positioning of the tungsten electrode

before the welding, and for making sure that the program in the working

area functions as desired.

The following welding parameters can be modified:

S

S

S

S

S

NOTE! When pressing START in any of the manual menus (except the gas

menu), the program will be run in the working area without arc.

Gas

Wire feed speed

Rotation speed

Arc voltage control (AVC)

Weaving

8.2 Editing a parameter

S Press the MANUAL MODE key .

Change rotation speed forward

S Press the ROTATION SPEED key

.

dpa8d1ec

-- 5 6 --

MANUAL

ROTATION FORWARD

ROTATION BACKW:

ROTA-TION

FORW.

ROTA-TION

BACKW.

S Press the soft key rotation forward and run the motor by pressing the

PLUS key

or the MINUS key .

NOTE! If the soft key for rotation backward and the PLUS key

are pressed, the result will be rotation forwards,

or

S Enter a value using the numerical keys and press the soft key rotation

forward (the rotation stops after 1 turn).

When you return to the working area, the program will start from the

adjusted position.

MANUAL

ROTATION FORW

ROTATION BACKW.

ROTA-TION

FORW.

ROTA-TION

BACKW.

Result: The program will start without the arc (i.e. the value of the welding

current parameter = 0).

The same procedure is used for changing the value of the parameters for

wire feed speed, arc voltage and weaving.

dpa8d1ec

-- 5 7 --

The following applies with regard to the gas parameter:

Themessagelineg

S Press the soft key weld gas to open the gas valve,

S Press the soft key weld gas once again to close the gas valve.

From this position the welding (with arc) is started in the following way:

S Press the START key

displays welding.

WELDING

WELD

GAS

MANUAL

.

ROOT

GAS

START

GAS

S Press the MANUAL MODE key to return to the working area.

dpa8d1ec

-- 5 8 --

9 PC--CARD

Pressthesof

t

9.1 Field of application

The PC--card is used for storing all the welding programs in the library.

It also makes it possible to copy welding programs between different control

boxes.

9.2 How to install the card

S Open the door on the left side panel of the

control box.

S Insert the PC--card into the card reader so

that the lock catches.

S Close the door.

9.3 How to recall a program

S Press the MEM key .

Note! When a program is recalled from the PC--card, all the

programs in the library are automatically deleted. If you want to keep the

library programs, you must first store them on another PC--card.

S Press the soft key PC--card.

S

key recall.

PC-- CARD

STORE

RECALL

QUIT

DELETE

CARD

After a couple of seconds a pop --up menu confirms the action.

dpa8d1ec

-- 5 9 --

PC-- CARD

Pressthesof

t

RECALLED WELD DATA

SET FROM PC--CARD

STORE RECALL QUIT

DELETE

CARD

Result: All the programs previously stored on the PC--card have now been

copied and stored in the library.

S Press the soft key quit to return to the library.

9.4 How to store a program

S Press the MEMORY key

S Press the soft key PC--card.

Note! When a program is stored on the PC- card, all other

programs on the card will automatically be deleted.

S

key store.

PC-- CARD

STORE RECALL QUIT

DELETE

CARD

After a couple of seconds a pop --up menu confirms the action.

dpa8d1ec

-- 6 0 --

PC-- CARD

Pressthesof

t

STORED WELD DATA

SET IN PC--CARD

STORE RECALL QUIT

DELETE

CARD

Result: All programs stored in the library have now been copied and stored

on the PC--card.

S Press the soft key quit to return to the library.

9.5 How to delete a program

S Press the MEM key .

S Press the soft key PC--card.

S

key delete

card.

After a couple of seconds a pop --up menu confirms the action.

PC-- CARD

STORE RECALL QUIT

DELETE

CARD

dpa8d1ec

-- 6 1 --

PC-- CARD

DELETEDWELDDATA

SET IN PC--CARD

STORE RECALL QUIT

DELETE

PROG

Result: You have deleted all the programs on the PC--card.

S Press the soft key quit to return to the library,

9.6 How to take out the PC --card

S Open the door on the left side panel of the control box.

S Press the small black button to the right of the PC--card.

S Draw the PC--card out of the card reader.

S Close the door.

10 ERROR CODES

10.1 Error h andling

Error codes are used to indicate that an error has occurred in the welding

process. The code is shown in the display by way of a pop--up menu,

displayed for 2,5 seconds. After that an exclamation mark

the top left corner of the display.

All error codes are stored in an error list and can be studied later on.

is shown in

dpa8d1ec

-- 6 2 --

SECTOR 3(4) 0.500

Pressthesof

t

keyerrorlog

.

ERROR 12

IN WELD DATA UNIT

3 SPECIALPULSN

CONT/

PEAK

CURR.

BACKGR

CURR

PEAK

TIME

BACKGR

TIME

Result: An error has occurred in the weld data unit (control box).

Howtoviewtheerror

S Press the MODE key

log:

.

S

keyerror log.

AUXILIARY FUNCTIONS

LANGUAGE "

ERROR LOG "

SHOW ACTUAL PARAMETER VALUES

SOFTWARE UPGRADE "

SOFTWARE KEY "

LAN-GUAGE

ERROR

LOG

SHOW

PARA- METER

SOFT--.

WARE

UPGR.

Result: You get into the error log codes.

This can be viewed on the display:

1. The queue number of the error.

2. When the error occurred (Date and time).

3. Where the error occurred.

4. The error code number.

For further information about what is wrong, proceed as follows:

SPEC.

PULS

SOFT--.

WARE

KEY

NOTE!

dpa8d1ec

disappears from the display as soon as you enter this menu.

-- 6 3 --

S Enter for example error no. 2, using the numerical keys.

Pressthesof

t

Pressthesof

t

S

key view error

ERROR LOG Page 1(2 ) 2

number.

Error No" Date Tim Unit Error

1 " 971007 13:07.03 PSOURCE 1

2 " 971007 13:07.50 CBOX 18

3 " 971007 14:56.07 ROT/WIRE 2

(NEXT)

PAGE

PREV

PAG E

VIEW

ERROR

NO.

QUIT DELETE

ALL

Result: Information about error code 18 is shown, CBOX (the weld data unit

in the control box) has lost contact with the welding power source.

A more detailed description of the error and measures to be taken are

shown in the table over Error Codes Resulting from Incorrect Editing on

page 66.

How to delete an error

log

S

key delete

ERROR LOG -- VIEW MESSAGE 1

error.

Error 18:

" Lost contact with power source

Unit: CBOX

Date: 971007

Time: 13:07.50

QUIT DELETE

ERROR

Result: The error code disappears from the display.

If you want full control over errors occurring over a period you need not

delete the errors. Up to 100 error numbers can be stored in the control box.

dpa8d1ec

-- 6 4 --

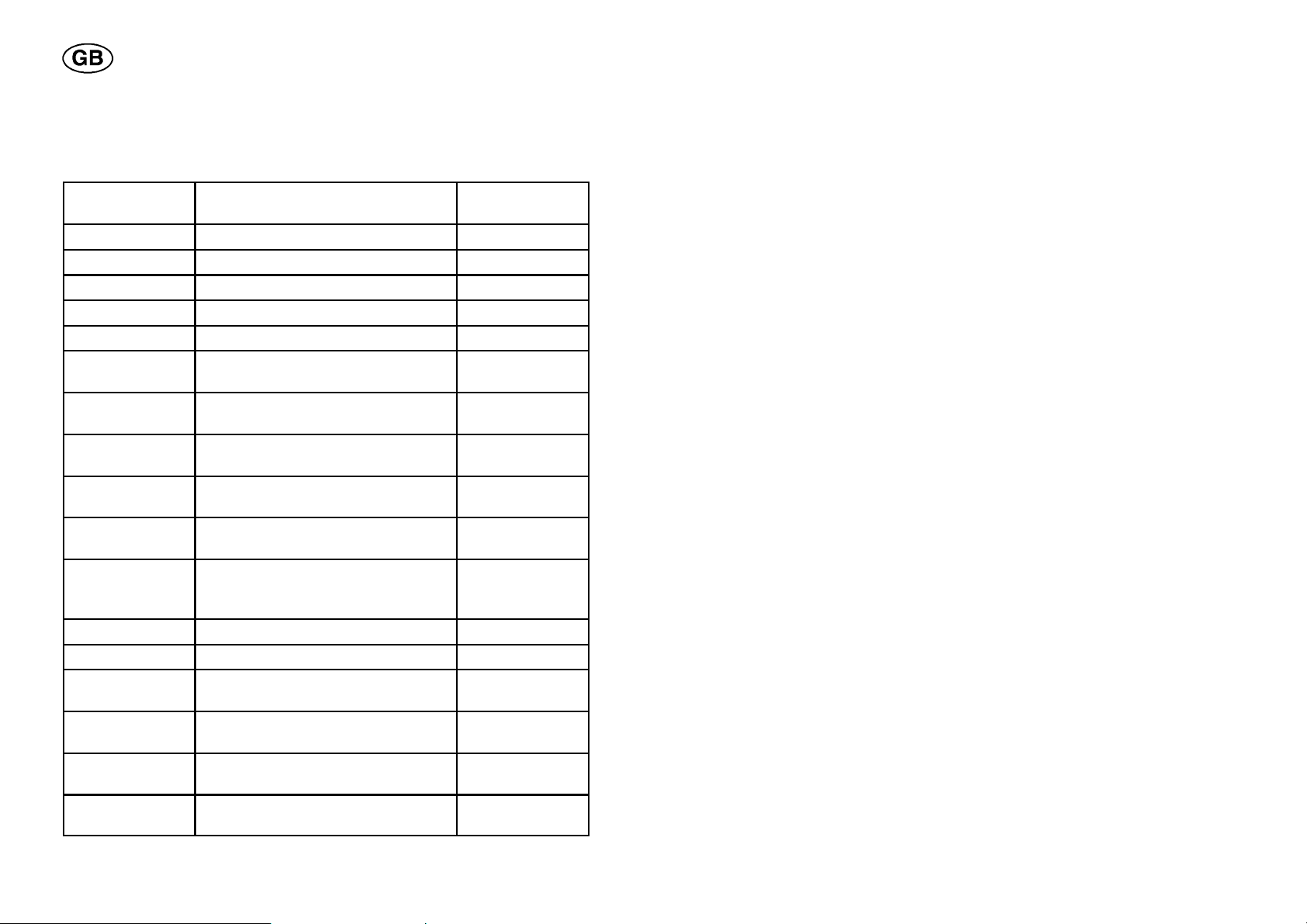

Overview of error handling codes

Code Description CBOX ROOT/WIRE

WEAVE/AVC

1 EPROM x x x

2 RAM x x x

3 External RAM (write, read) x x

4 Supply voltage 5V x

5 High + DC voltage x

6 High temperature x

7 High primary current x

8 Supply voltage 1* x x x

9 Supply voltage 2* x x

10 Supply voltage 3* x

11 Current servo/Wire speed servo x

12 Communication error (warning) x x x

13 Servo 1 x

14 Communications error (bus off) x

15 Lost messages x x x

16 Servo 2 x

17 Contact lost with the motor unit x

18 Contact lost with weld. power source x

19 Memory error in battery-- fed computer

memory

20 Prohibited setting values x

21 Current limit 1 x

22 Spill in buffer transmitter x

23 Spill in buffer receiver x

25 Incompatible weld data format x

26 Watch dog x x

27 Current limit 2 x

28 Spill in stack x x x

29 No water flow x

30 Contact lost with TIG card x

31 No response from display unit x

32 No gas flow x

x

PSOURCE

dpa8d1ec

-- 6 5 --

Unit

CBOX +3V

ROOT/WIRE

WEAVE/AVC

PSOURCE +15VC --15V +15VB

Supply voltage

1*

+ 15V + 60V

Supply voltage

2*

Supply voltage

3*

CBOX = Weld Data card, control box

ROOT/WIRE = Motor card for controlling the rotation and wire feed motors.

WEAVE/AVC = Motor card for controlling the weaving and AVC motors.

PSOURCE = Circuit card for controlling the welding power source.

Error handling codes

Code Description

1 Program memory error (EPROM)

Cause: The program memory has lost a value. I.e the value in a

particular memory position no longer agrees with the original value. No functions are blocked through this error.

Measure: Voltage disconnection necessary for resetting. If the

error remains, call in a service technician.

2 Error in the microprocessor RAM

Cause: The microprocessor cannot write/read a certain memory

position in its own internal memory.

No functions are blocked through this error.

Measure: Voltage disconnection necessary for resetting. If the

error remains, call in a service technician.

3 Error in external RAM

Cause: The microprocessor cannot write/read a certain memory

position in its own external memory.

No functions are blocked through this error.

Measure: Voltage disconnection necessary for resetting. If the

error remains, call in a service technician.

4 Voltage drop in the 5 V supply voltage

Cause: Supply voltage too high.

All normal microprocessor activities cease, waiting for switch--off.

Measure: Voltage disconnection necessary for resetting. If the

error remains, call in a service technician.

dpa8d1ec

-- 6 6 --

5 High + DC voltage outside limit value

Cause: Voltage too high or too low. Too high a voltage can be due

to powerful transients on the mains supply or to a weak supply

system (high inductance on the mains)

The welding power source is automatically switched off.

Measure: Voltage disconnection necessary for resetting. If the

error remains, call in a service technician.

6 High temperature

Cause: The thermal cut--out has tripped.

The welding power source is automatically switched off and cannot be switched on again until the temperature has gone down

and the cut--out is reset.

Measure: Check that the cooling air intake/outlet are not blocked

or dirty. Check that the work cycle does not exceed the ratings.

7 High primary current

Cause: Current too high in the welding power source.

The welding power source is automatically switched off and permanently blocked.

Measure: Voltage disconnection necessary for resetting. If the

error remains, call in a service technician.

8 Low battery voltage, weld data card (control box)

Cause: Battery voltage too low.

No functions are blocked through this error.

Measure: Make a backup on a PC--card. Call in a service technician.

8 Supply voltage +15 VC, PC--card (welding power source)

Cause: Voltage too high or too low.

Measure: Call in a service technician.

8 Supply voltage +15 V, motor card (rotation/wire) (weaving/

AVC)

Cause: Voltage too low.

Measure: Call in a service technician.

9 Supply voltage --15V, PC--card (welding power source)

Cause: The voltage is either too high or too low.

Measure: Call in a service technician.

9 Supply voltage +60 V, motor card (rotation/wire)(weaving/

AVC)

Cause: Current too low.

Measure: Call in a service technician.

dpa8d1ec

-- 6 7 --

10 Supply voltage +15 VB, PC--card (welding power source)

Cause: Voltage too high or too low.

Measure: Call in a service technician.

11 Incorrect current, PC--card (welding power source)

Cause: The welding power source failed in supplying the current

determined by the processor.

No functions are blocked through this error.

Measure: Call in a service technician.

12 Communication error (warning)

Cause: The CAN circuit error counter shows too high value.

The contact with the control box can be broken. This can result

from occasional overload.

Measure: Check the handling of the program during welding.

13 Incorrect rotation speed

Cause: Cannot keep up the speed determined by the processor.

The welding is interrupted

Measure: Check the cabling. If the error remains, call in a service

technician.

14 Communication error

Cause: The CAN circuit error counter shows too high value.

The welding process is stopped. This can result from occasional

overload.

Measure: Check the handling of the program during welding. Voltage disconnection necessary for resetting. If the error remains,

call in a service technician.

15 Lost messages

Cause: A message has been overwritten by another message. A

too frequent use of the pushbuttons on the control box, during

welding, may cause this fault.

The welding process is stopped.

Measure: Check the handling of the program during welding. Voltage disconnection necessary for resetting. If the error remains,

call in a service technician.

16 Incorrect wire feed / weaving speed

Cause: Cannot keep up the speed determined by the processor.

Measure: Check the cabling.

dpa8d1ec

-- 6 8 --

17 Contact lost

Cause: The control box has lost contact with one or both the mo-

tor units. Activities in progress are disabled.

Measure: Check the cabling. If the error remains, call in a service

technician.

18 Contact lost

Cause: The control box has lost contact with the power source.

Activities in progress are disabled.

Measure: Check the cabling. If the error remains, call in a service

technician.

19 Error in computer memory (RAM)

Cause: Can result from program upgrading.

Measure: Switch on the mains voltage, and automatic resetting is

effected.

20 Unpermitted setting values stored (RAM)