HW-17 HW-26 HW-18

ТехниЧескаЯ характеристика

Instruction manual

| РУССКИЙ | З |

|---|---|

| ENGLISH1 | 2 |

Оставляем за собой право изменять спецификацию без предупреждения. Rights reserved to alter specifications without notice.

СОДЕРЖАНИЕ

| ТЕХНИКА БЕЗОПАСНОСТИ | 4 |

|---|---|

| ТЕХНИЧЕСКАЯ ХАРАКТЕРИСТИКА | 6 |

| ЭЛЕКТРОДЫ | |

| СПИСОК ЗАПАСНЫХ ЧАСТЕЙ |

ТЕХНИЧЕСКАЯ ХАРАКТЕРИСТИКА

| ТИП ГОРЕЛКИ | HW-17 | HW-17V | HW-17R | HW-17RV | HW-17F | Ед. |

|---|---|---|---|---|---|---|

| Макс.ток при 50%ПВ | 150 | 150 | 150 | 150 | 150 | А, пост./перем. |

| Охлаждение | Возд. | Возд. | Возд. | Возд. | Возд. | |

| Длина горелки | 206 | 206 | 206 | 206 | 206 | mm |

| Диаметр рукоятки | 19 | 19 | 19 | 19 | 19 | mm |

| Головка: | ||||||

| длина с коротким колпачком | 97 | 97 | 97 | 97 | 97 | mm |

| длина с длинным колпачком | 189 | 189 | 189 | 189 | 189 | mm |

| Диаметр | 20 | 20 | 20 | 20 | 20 | mm |

| Угол | 60 | 60 | 60 | 60 | Измен. | ο |

| Масса(без кабеля) | 137 | 137 | 137 | 137 | 221 | Г |

| ТИП ГОРЕЛКИ | ТИП РУКОЯТКИ | ДЛИНА КАБЕЛЯ | РАЗЪЕ М | Артикул № |

|---|---|---|---|---|

| HW-17 OKC | Жесткая, с кнопкой | 3,8 m | OKC 50 mm | 588 000-716 |

| HW-17 OKC | Жесткая, с кнопкой | 7,6 m | OKC 50 mm | 588 000-717 |

| HW-17 CC | Жесткая, с кнопкой | 3,8 m | Евро | 588 000-718 |

| HW-17 CC | Жесткая, с кнопкой | 7,6 m | Евро | 588 000-719 |

| HW-17V OKC | Жесткая, с кнопкой | 3,8 m | OKC 50 mm | 588 000-720 |

| HW-17V OKC | Жесткая, с кнопкой | 7,6 m | OKC 50 mm | 588 000-721 |

| HW-17R OKC | Резин.чехол, с кнопкой | 3,8 m | OKC 50 mm | 588 000-722 |

| HW-17R OKC | Резин.чехол, с кнопкой | 7,6 m | OKC 50 mm | 588 000-723 |

| HW-17R CC | Резин.чехол, с кнопкой | 3,8 m | Евро | 588 000-724 |

| HW-17R CC | Резин.чехол, с кнопкой | 7,6 m | Евро | 588 000-725 |

| HW-17RV OKC | Резин.чехол, с клапаном | 3,8 m | OKC 50 mm | 588 000-726 |

| HW-17RV OKC | Резин.чехол, с клапаном | 7,6 m | OKC 50 mm | 588 000-727 |

| HW-17F OKC | Гибкая с кнопкой | 3,8 m | OKC 50 mm | 588 000-728 |

| HW-17F OKC | Гибкая с кнопкой | 7,6 m | OKC 50 mm | 588 000-729 |

| HW-17F CC | Гибкая с кнопкой | 3,8 m | Евро | 588 000-730 |

| HW-17F CC | Гибкая с кнопкой | 7,6 m | Евро | 588 000-731 |

ТЕХНИЧЕСКАЯ ХАРАКТЕРИСТИКА

HW-26F

| ТИП ГОРЕЛКИ | HW-26 | HW-26V | HW-26R | HW- 26RV | HW-26F | HW-18 | Ед. |

|---|---|---|---|---|---|---|---|

| Макс.ток при 50%ПВ | 220 | 220 | 220 | 220 | 220 | 400 | А, пост./перем. |

| Охлаждение | Возд. | Возд. | Возд. | Возд. | Возд. | Водян. | |

| Длина горелки | 248 | 248 | 248 | 248 | 248 | 267 | mm |

| Диаметр рукоятки | 27 | 27 | 27 | 27 | 27 | 27 | mm |

| Головка: | |||||||

| длина с коротким колпачком | 95 | 95 | 95 | 95 | 95 | 81 | mm |

| длина с длинным колпачком | 187 | 187 | 187 | 187 | 187 | 189 | mm |

| Диаметр | 23 | 23 | 23 | 23 | 23 | 23 | mm |

| Угол | 75 | 75 | 75 | 75 | Измен. | 60 | ۰ |

| Масса(без кабеля) | 221 | 221 | 221 | 221 | 221 | 200 | Г |

| ТИП ГОРЕЛКИ | ТИП РУКОЯТКИ | ДЛИНА КАБЕЛЯ | РАЗЪЕМ | Артикул № |

|---|---|---|---|---|

| HW-26 OKC | Жесткая, с кнопкой | 3,8 m | OKC 50 mm | 588 000-732 |

| HW-26 OKC | Жесткая, с кнопкой | 7,6 m | OKC 50 mm | 588 000-733 |

| HW-26 CC | Жесткая, с кнопкой | 3,8 m | Евро | 588 000-734 |

| HW-26 CC | Жесткая, с кнопкой | 7,6 m | Евро | 588 000-735 |

| HW-26V OKC | Жесткая, с кнопкой | 3,8 m | OKC 50 mm | 588 000-736 |

| HW-26V OKC | Жесткая, с кнопкой | 7,6 m | OKC 50 mm | 588 000-737 |

| HW-26R OKC | Резин.чехол, с кнопкой | 3,8 m | OKC 50 mm | 588 000-738 |

| HW-26R OKC | Резин.чехол, с кнопкой | 7,6 m | OKC 50 mm | 588 000-739 |

| HW-26R CC | Резин.чехол, с кнопкой | 3,8 m | Евро | 588 000-740 |

| HW-26R CC | Резин.чехол, с кнопкой | 7,6 m | Евро | 588 000-741 |

| HW-26RV OKC | Резин.чехол, с клапаном | 3,8 m | OKC 50 mm | 588 000-742 |

| HW-26RV OKC | Резин.чехол, с клапаном | 7,6 m | OKC 50 mm | 588 000-743 |

| HW-26F OKC | Гибкая с кнопкой | 3,8 m | OKC 50 mm | 588 000-774 |

| HW-26F CC | Гибкая с кнопкой | 7,6 m | Евро | 588 000-775 |

| HW-18 OKC | Жесткая, с кнопкой | 3,8 m | OKC 50 mm | 588 000-748 |

| HW-18 OKC | Жесткая, с кнопкой | 7,6 m | OKC 50 mm | 588 000-749 |

| HW-18 CC | Жесткая, с кнопкой | 3,8 m | Евро | 588 000-750 |

| HW-18 CC | Жесткая, с кнопкой | 7,6 m | Евро | 588 000-751 |

ВОЛЬФРАМОВЫЕ ЭЛЕКТРОДЫ

Чистый вольфрам

Этот электрод сделан из читого вольврама и его температура плавления равна 3400°С. Он используется для сварки алюминиевых сплавов на переменном токе. Конец электрода должен быть закруглен.

Торированный вольфрам

Этот тип электродов обычно используется для сварки на постоянном токе углеродистых и нержавеющих сталей, меди, титана и подобных металлов. Конец электрода должен быть заострён. Температура плавления равна 4000°С.

Цирконированный вольфрам

Эти электроды предназначены для сварки на переменном токе, но могут быть использованы и для сварки на постоянном токе. Такие электроды наиболее подходят для сварки легких металлов - алюминия, магния и т.п. Температура плавления равна 3800°С.

Лантанированный вольфрам

Эти электроды предназначены для сварки как на переменном токе, так и на постоянном токе. Температура плавления равна 4200°С

Заточка конца электрода

Конец электрода должен быть заточен по длине, см. рисунок ниже. Если электрод заточен неправильным образом, это можен привести к нестабильности сварочной дуги. На рисунке показан электрод, заточенный под углом 40°, который рекомендуется для сварки на малых токах. С увеличением сварочного тока угол заточки должен быть также увеличен. Рекомендуемые углы заточки приведены в таблице ниже.

При сварке на переменном токе конец электрода должен быть слегка закруглен. Заточка электрода необязательна. Достачно слегка подточить конец и элетрод сам приобретет необходимую форму, если его аккуратно перегрузить. Если конец электрода приобретает сферическую форму при сварке на переменном токе, это означает, что уровень тока слишком высокий для данного диаметра электрода.

Рекомедуемые углы заточки электроды для вольфрамового электрода:

| Сварочный ток, А | Угол заточки |

|---|---|

| 20 | 30° |

| 20 - 100 | 60 - 90° |

| 100 - 200 | 90 - 120° |

| >200 | 120° |

Газовая линза

является дополнительной принадлежностью ко всем сварочным горелкам HW. Преимуществами газовой линзы являются улучшенная газовая защита, низкий расход газа и повышенная несущая способность горелки по току.

Улучшенная газовая защита также позволяет использовать больший вылет вольфрамового электрода, что в свою очередь улучшает обзор сварочной ванны.

| Рекомендации по выбору электрода и сопла | ||||||||

|---|---|---|---|---|---|---|---|---|

| Ø электрода | Ø сопла, | Чистый | Цирконирован | Торированный | Лантанированн | Лантанированн | ||

| ММ | мм | вольфрам | ный | = ток, А | ый | ый | ||

| ≈ ток, А | ≈ ток, А | ≈ ток, А | = ток, А | |||||

| 0,5 | 6,4/8,0 | 5 - 15 | 5 - 20 | 5 - 20 | 5 - 30 | 5 - 30 | ||

| 1,0 | 6,4/8,0 | 10 - 60 | 15 - 80 | 20 - 80 | 15 - 100 | 20 - 100 | ||

| 1,6 | 6,4/8,0/9,8 | 50 - 100 | 70 - 150 | 80 - 150 | 70 - 160 | 80 - 160 | ||

| 2,4 | 9,8/11,2/12,7 | 100 - 160 | 110 - 180 | 120 - 220 | 110 - 200 | 120 - 230 | ||

| 3,2 | 11,2/12,7 | 130 - 180 | 150 - 200 | 200 - 300 | 150 - 205 | 200 - 305 | ||

| 4.0 | 12.7 | 180 - 230 | 180 - 250 | 250 - 400 | 180 - 270 | 250 - 420 | ||

CONTENTS

| SAFETY | 13 |

|---|---|

| TECHNICAL DESCRIPTION | 14 |

| ELECTRODES | 18 |

| SPARE PARTS | 20 |

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER'S SAFETY PRACTICES WHICH SHOULD BE BASED ON MANUFACTURER'S HAZARD DATA.

ELECTRIC SHOCK - Can kill

- Install and earth the welding unit in accordance with applicable standards.

- Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

- Insulate yourself from earth and the workpiece.

- Ensure your working stance is safe.

FUMES AND GASES - Can be dangerous to health

- Keep your head out of the fumes.

- Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and the general area.

ARC RAYS - Can injure eyes and burn skin

- Protect your eyes and body. Use the correct welding screen and filter lens and wear protective clothing.

- Protect bystanders with suitable screens or curtains.

FIRE HAZARD

• Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE - Excessive noise can damage hearing

- Protect your ears. Use ear defenders or other hearing protection.

- Warn bystanders of the risk.

MALFUNCTION

• Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE OPERATING MANUAL BEFORE INSTALLING AND OPERATING

PROTECT YOURSELF AND OTHERS!

TECHNICAL DESCRIPTION

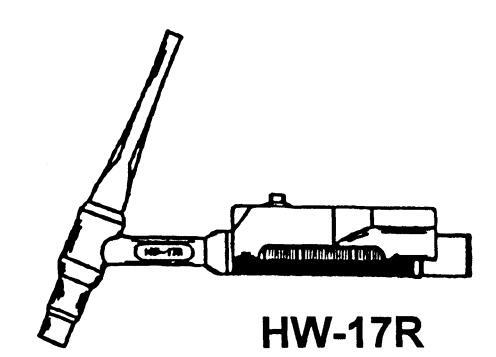

| TORCH TYPE | HW-17 | HW-17V | HW-17R | HW-17RV | HW-17F | Unit |

|---|---|---|---|---|---|---|

| Max. current 50% duty cycle | 150 | 150 | 150 | 150 | 150 | Amp. AC/DC, |

| Cooling method | Air | Air | Air | Air | Air | |

| Torch length | 206 | 206 | 206 | 206 | 206 | mm |

| Torch handle diameter | 19 | 19 | 19 | 19 | 19 | mm |

| Welding head: | ||||||

| length with short cap | 97 | 97 | 97 | 97 | 97 | mm |

| length with long cap | 189 | 189 | 189 | 189 | 189 | mm |

| diameter | 20 | 20 | 20 | 20 | 20 | mm |

| angle | 60 | 60 | 60 | 60 | Variable | degrees |

| Weight (without cable) | 137 | 137 | 137 | 137 | 221 | gram |

| ТҮРЕ | TORCHE HANDLE TYPE | CABLE LENGTH | CONNECTOR | Order no. |

|---|---|---|---|---|

| HW-17 OKC | Hard, with switch | 3,8 m | OKC 50 mm | 588 000-716 |

| HW-17 OKC | Hard, with switch | 7,6 m | OKC 50 mm | 588 000-717 |

| HW-17 CC | Hard, with switch | 3,8 m | Central | 588 000-718 |

| HW-17 CC | Hard, with switch | 7,6 m | Central | 588 000-719 |

| HW-17V OKC | Hard, with switch | 3,8 m | OKC 50 mm | 588 000-720 |

| HW-17V OKC | Hard, with switch | 7,6 m | OKC 50 mm | 588 000-721 |

| HW-17R OKC | Rubber, with switch | 3,8 m | OKC 50 mm | 588 000-722 |

| HW-17R OKC | Rubber, with switch | 7,6 m | OKC 50 mm | 588 000-723 |

| HW-17R CC | Rubber, with switch | 3,8 m | Central | 588 000-724 |

| HW-17R CC | Rubber, with switch | 7,6 m | Central | 588 000-725 |

| HW-17RV OKC | Rubber, with valve | 3,8 m | OKC 50 mm | 588 000-726 |

| HW-17RV OKC | Rubber, with valve | 7,6 m | OKC 50 mm | 588 000-727 |

| HW-17F OKC | Flexible with switch | 3,8 m | OKC 50 mm | 588 000-728 |

| HW-17F OKC | Flexible with switch | 7,6 m | OKC 50 mm | 588 000-729 |

| HW-17F CC | Flexible with switch | 3,8 m | Central | 588 000-730 |

| HW-17F CC | Flexible with switch | 7,6 m | Central | 588 000-731 |

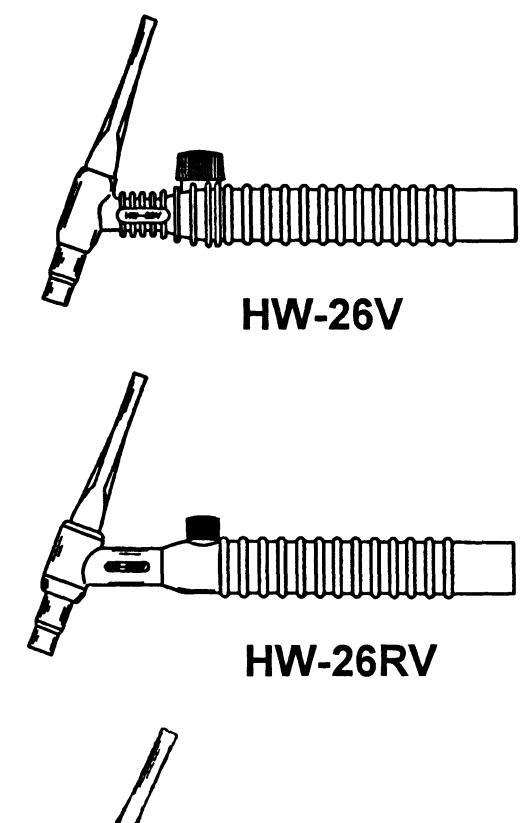

TECHNICAL DESCRIPTION

HW-26F

HW-26RV

| TORCH TYPE | HW-26 | HW-26V | HW-26R | HW- 26RV | HW-26F | HW-18 | Unit |

|---|---|---|---|---|---|---|---|

| Max. current 50% duty cycle | 220 | 220 | 220 | 220 | 220 | 400 | Amp. AC/DC, |

| Cooling method | Air | Air | Air | Air | Air | Water | |

| Torch length | 248 | 248 | 248 | 248 | 248 | 267 | mm |

| Torch handle diameter | 27 | 27 | 27 | 27 | 27 | 27 | mm |

| Welding head: | |||||||

| length with short cap | 95 | 95 | 95 | 95 | 95 | 81 | mm |

| length with long cap | 187 | 187 | 187 | 187 | 187 | 189 | mm |

| diameter | 23 | 23 | 23 | 23 | 23 | 23 | mm |

| angle | 75 | 75 | 75 | 75 | Variable | 60 | degrees |

| Weight (without cable) | 221 | 221 | 221 | 221 | 221 | 200 | gram |

| TYPE | TORCHE HANDLE TYPE | CABLE LENGTH | CONNECTOR | Order no. |

|---|---|---|---|---|

| HW-26 OKC | Hard, with switch | 3,8 m | OKC 50 mm | 588 000-732 |

| HW-26 OKC | Hard, with switch | 7,6 m | OKC 50 mm | 588 000-733 |

| HW-26 CC | Hard, with switch | 3,8 m | Central | 588 000-734 |

| HW-26 CC | Hard, with switch | 7,6 m | Central | 588 000-735 |

| HW-26V OKC | Hard, with switch | 3,8 m | OKC 50 mm | 588 000-736 |

| HW-26V OKC | Hard, with switch | 7,6 m | OKC 50 mm | 588 000-737 |

| HW-26R OKC | Rubber, with switch | 3,8 m | OKC 50 mm | 588 000-738 |

| HW-26R OKC | Rubber, with switch | 7,6 m | OKC 50 mm | 588 000-739 |

| HW-26R CC | Rubber, with switch | 3,8 m | Central | 588 000-740 |

| HW-26R CC | Rubber, with switch | 7,6 m | Central | 588 000-741 |

| HW-26RV OKC | Rubber, with valve | 3,8 m | OKC 50 mm | 588 000-742 |

| HW-26RV OKC | Rubber, with valve | 7,6 m | OKC 50 mm | 588 000-743 |

| HW-26F OKC | Flexible with switch | 3,8 m | OKC 50 mm | 588 000-774 |

| HW-26F CC | Flexible with switch | 7,6 m | Central | 588 000-775 |

| HW-18 OKC | Hard, with switch | 3,8 m | OKC 50 mm | 588 000-748 |

| HW-18 OKC | Hard, with switch | 7,6 m | OKC 50 mm | 588 000-749 |

| HW-18 CC | Hard, with switch | 3,8 m | Central | 588 000-750 |

| HW-18 CC | Hard, with switch | 7,6 m | Central | 588 000-751 |

TUNGSTEN ELECTRODES FOR TIG WELDING

Pure tungsten

This electrode is made of pure tungsten and has a fusing point of 3400°C. It is used for A.C. welding in aluminium alloys and the tip of the electrode must be round.

Thoriated tungsten

This type of electrode is generally used for D.C. welding of stainless steel, carbon steel, copper, titanium and similar metals. The tip should be pointed. The fusing point of thoriated tungsten is around 4000°C.

Zirconiated tungsten

This type of electrode is made particularly for A.C. welding but is also suitable for D.C. welding. Types of material which are particularly suited to welding with zirconiated tungsten include light metals such as aluminium, magnesium etc. Its fusing point is around 3800°C.

Lanthaniated tungsten

This type of electrode is suitable both for A.C. and D.C. welding. Its fusing point is around 4200°C.

Grinding the electrode tip

The electrode tip is to be ground lengthwise, see illustration below. If it is ground the wrong way the result will be instability in the arc. The illustration shows an electrode ground to a 40° angle, which is recommended for low welding currents. As the current is increased the electrode angle must be increased, too. Recommended angles for the electrode tip are shown in the table.

When welding with alternating current the tip of the electrode should be slightly rounded. Grinding the electrode is not necessary. It is enough to bevel the edge slightly as the electrode will shape itself if it is carefully overloaded. If the tip becomes spherical when welding with alternating current, it indicates that the current is too high for the electrode diameter concerned.

Recommended tip angle for a tungsten electrode:

| lelding current, ampere | Electrode angle |

|---|---|

| 20 | 30° |

| 20-100 | 60-90° |

| 100-200 | 90-120° |

| >200 | 120° |

Gas lens

w

available as an accessory for all HW torches.

The advantages of the gas lens include better and longer gas shielding, lower gas consumption and higher torch capacity. The longer gas shielding range also means that a longer tungsten electrode stick-out can be used, this giving improved viewing of the molten pool.

| Recommended electrode and cup selection | ||||||

|---|---|---|---|---|---|---|

| Electrode | Gas cup | Alt. current | AC | DC | AC | DC |

| diameter | diameter | (AC) | Zirconiated | Thoriated | Lanthaniated | Lanthaniated |

| mm | mm | Ampere | Ampere | Ampere | Ampere | Ampere |

| 0,5 | 6,4/8,0 | 5 - 15 | 5 - 20 | 5 - 20 | 5 - 30 | 5 - 30 |

| 1,0 | 6,4/8,0 | 10 - 60 | 15 - 80 | 20 - 80 | 15 - 100 | 20 - 100 |

| 1,6 | 6,4/8,0/9,8 | 50 - 100 | 70 - 150 | 80 - 150 | 70 - 160 | 80 - 160 |

| 2,4 | 9,8/11,2/12,7 | 100 - 160 | 110 - 180 | 120 - 220 | 110 - 200 | 120 - 230 |

| 3,2 | 11,2/12,7 | 130 - 180 | 150 - 200 | 200 - 300 | 150 - 205 | 200 - 305 |

| 4.0 | 12,7 | 180 - 230 | 180 - 250 | 250 - 400 | 180 - 270 | 250 - 420 |

RU

Список запасных Частей / Spare parts list HW-17 / HW-17V / HW-17R / HW-17RV / HV-17F

| Pos. | Article No. | Description | |

|---|---|---|---|

| 1 | 588 000-533 | Torch body | HW-17.OKC & CC |

| 2 | 588 000-535 | Torch body with valve | HW-17V.OKC |

| 3 | 366 960-043 | Valve stem with O-ring | |

| 366 960-045 | Valve stem, O-ring only | ||

| 4 | 157 123-029 | Long back cap with O-ring | |

| 5 | 157 123-028 | Short back cap with O-ring | |

| 366 960-070 | Back cap O-ring only | ||

| 6 | 157 123-009 | Collet | D=.020" 0,5 mm |

| 157 123-010 | D=.040" 1,0 mm | ||

| 157 123-011 | D=1/16 1,6 mm | ||

| 157 123-012 | D=3/32° 2,4 mm | ||

| 157 123-013 | D=1/8° 3,2 mm | ||

| 7 | 157 123-080 | Collet body | D=.020" 0,5 mm |

| 157 123-015 | D=.040° 1,0 mm | ||

| 157 123-016 | D=1/16 1,6 mm | ||

| 157 123-017 | D=3/32" 2,4 mm | ||

| 157 123-018 | D=1/8 3,2 mm | ||

| 8 | 157 123-052 | Nr 4 6,4 mm | |

| 15/ 123-053 | Nr 5 6,0 mm | ||

| 15/ 123-054 | Nr 6 9,8 mm | ||

| 15/123-055 | Nr 9 12 7 mm | ||

| 599 000 442 | Nr 10 15 9 mm | ||

| 588 000-442 | Nr 12 19 0 mm | ||

| 0 | 366 960-021 | l arge diameter gas lens insulator | |

| 3 | 500 500-021 | ||

| 10 | 157 123-085 | Large diameter gas lens, | D=3/32" 2,4 mm |

| 157 123-086 | D=1/8° 3,2 mm | ||

| 11 | 157 123-088 | Aluminium large diameter gas lens nozzle | Nr 6 9.8 mm |

| 157 123-089 | Nr 8 12,7 mm | ||

| 588 000-438 | Nr 10 15,9 mm | ||

| 10 | 15/123-098 | Nr 12 19,0 mm | |

| 12 | 366 960-020 | D- 00010 5 mm | |

| 13 | 157 123-020 | cias iens | D= 040" 1 0 mm |

| 157 123-021 | D=1/16"1.6 mm | ||

| 157 123-023 | D=3/32" 2 4 mm | ||

| 157 123-025 | D=5/32" 4.0 mm | ||

| 14 | 157 123-057 | Gas lens nozzle, aluminium | Nr 4 6.4 mm |

| 157 123-058 | Nr 5 8.0 mm | ||

| 157 123-059 | Nr 6 9,8 mm | ||

| 157 123-060 | Nr 7 11,2 mm | ||

| 157 123-061 | Nr 8 12,7 mm | ||

| 15 | 588 000-698 | Micro switch | |

| 16 | 588 000-699 | Switch clamp | |

| 17 | 588 000-595 | Torch handle | |

| 18 | 588 000-710 | Flex support | |

| 19 | 588 000-554 | Power cable 3.8 m | OKC |

| 588 000-555 | Power cable 7.6 m | ОКС | |

| 20 | 588 000-752 | Power cable 3.8 m | CC |

| 588 000-753 | Power cable 7.6 m | cc | |

| 21 | 588 000-758 | OKC connector | |

| 22 | 588 000-756 | Central connector | |

| 23 | 538 501-102 | Pin plug | |

| 24 | 588 000-759 | Cable cover, 3.8 m | |

| 588 000-760 | Cable cover, 7.6 m | ||

| 25 | 588 000-537 | Torch body with valve | HW-17RV.OKC |

| 26 | 588 000-539 | Torch body, includes cup gasket | HW-17F.OKC & CC |

| 27 | 588 000-536 | Torch body, includes cup gasket | HW-17R.OKC & CC |

| 28 | 366 960-016 | Cup gasket |

(RU)

Список запасных Частей / Spare parts list HW-26 / HW-26V / HW-26R / HW-26RV / HV-26F

| Pos. | No. | Description | |

|---|---|---|---|

| 1 | 588 000-541 | Torch body | HW-26.OKC & CC |

| 2 | 588 000-542 | Torch body with valve | HW-26V.OKC |

| 3 |

588 000-609

366 960-045 |

Valve stem with

|

|

| 4 | 157 123-029 | Long back cap with O-ring | |

| 5 | 157 123-028 | Short back cap with O-ring | |

| 366 960-070 | Back cap O-ring only | ||

| 6 | 157 123-009 | Collet | D=.020" 0,5 mm |

| 157 123-010 | D=.040" 1,0 mm | ||

| 157 123-011 | D=3/32" 2.4 mm | ||

| 157 123-013 | D=1/8" 3,2 mm | ||

| 157 123-014 | D=5/32" 4,0 mm | ||

| 7 | 157 123-080 | Collet body | D=.020" 0,5 mm |

| 15/ 123-015 | D=1/16" 1.6 mm | ||

| 157 123-017 | D=3/32" 2.4 mm | ||

| 157 123-018 | D=1/8" 3,2 mm | ||

| 8 | 157 123-052 | Aluminia nozzle | Nr 4 6,4 mm |

| 157 123-053 | Nr 5 8,0 mm | ||

| 15/ 123-054 | Nr 0 9,8 MM | ||

| 157 123-055 | Nr 8 12.7 mm | ||

| 588 000-442 | Nr 10 15,9 mm | ||

| 588 000-441 | Nr 12 19,0 mm | ||

| 9 | 366 960-021 | Large diameter gas lens insulator | |

| 10 | 157 123-085 | Large diameter gas lens | D=3/32" 2,4 mm0 |

| 157 123-087 | D=5/32" 4.0 mm | ||

| 11 | 157 123-088 | Aluminium large diameter gas lens nozzle | Nr 6 9,8 mm |

| 157 123-089 | Nr 8 12,7 mm | ||

| 588 000-438 | Nr 10 15,9 mm | ||

| 12 | 366 960-020 | Gas lons insulator | Nr 12 19,0 mm |

| 13 | 157 123-020 | Gas lens | D=.020" 0.5 mm |

| 157 123-021 | D=.040" 1,0 mm | ||

| 157 123-022 | D=1/16" 1,6 mm | ||

| 157 123-023 | D=3/32" 2,4 mm | ||

| 157 123-024 | D=5/32" 4.0 mm | ||

| 14 | 157 123-057 | Gas lens nozzle, aluminium | Nr 4 6,4 mm |

| 157 123-058 | Nr 5 8,0 mm | ||

| 157 123-059 | Nr 6 9,8 mm | ||

| l | 157 123-000 | Nr 8 12.7 mm | |

| 15 | 588 000-698 | Micro switch | |

| 16 | 588 000-700 | Switch clamp | |

| 17 | 588 000-443 | Torch handle | HW-26 HW-26R |

| 18 | 588 000-597 | Torch handle | HW-26F |

| 19 | 588 000-711 | | Flex support | |

| 20 | 588 000 697 | Power cable 3.6 m | |

| 21 | 588 000-761 | Power cable 3.8 m | |

| 588 000-762 | Power cable 7.6 m | ||

| 22 | 588 000-758 | OKC connector | |

| 23 | 588 000-756 | Central connector | |

| 24 | 538 501-102 | Pin plug | |

| 25 | 588 000-759 | Cable cover, 3.8 m | |

| 588 000-760 | Cable cover, 7.6 m | ||

| 26 | 588 000-601 | Torch handle | |

| 21 | 588 000-544 | ||

| 29 | 588 000-543 | Torch body, includes cup casket | HW-26R.OKC & CC |

| 30 | 588 000-546 | Torch body, includes cup gasket | HW-26F.OKC & CC |

| 31 | 366 960-016 | Cup gasket |

Список запасных Частей / Spare parts list HW-18

| Pos. | No. | Description | |

|---|---|---|---|

| 1 | 588 000-549 | Torch body | HW-18 OKC & CC |

| 2 | 157 123-029 | Long back cap with O-ring | |

| 3 | 157 123-028 | Short back cap with O-ring | |

| 366 960-070 | Back cap O-ring only | ||

| 4 | 157 123-009 | Collet | D=.020" 0,5 mm |

| 157 123-010 | D=.040" 1,0 mm | ||

| 157 123-011 | D=1/16" 1,6 mm | ||

| 157 123-012 | D=3/32 2,4 mm | ||

| 157 123-013 | D=5/32" 4.0 mm | ||

| 5 | 157 123-014 | Collet body | D= 020" 0.5 mm |

| Ŭ | 157 123-015 | D=.040" 1.0 mm | |

| 157 123-016 | D=1/16" 1.6 mm | ||

| 157 123-017 | D=3/32" 2,4 mm | ||

| 157 123-018 | D=1/8" 3,2 mm | ||

| 157 123-019 | D=5/32" 4,0 mm | ||

| 6 | 157 123-052 | Aluminium nozzle | Nr 4 6.4 mm |

| 157 123-053 | Nr 5 8.0 mm | ||

| 15/ 123-054 | Nr 6 9.8 mm | ||

| 157 123-055 | Nr 8 12 7 mm | ||

| 588 000-442 | Nr 10 15 9 mm | ||

| 588 000-441 | Nr 12 19.0 mm | ||

| 7 | 366 960-021 | Large diameter gas lens insulator | |

| 8 | 157 123-085 | Large diameter gas lens | D=3/32" 2,4 mm |

| - | 157 123-086 | D=1/8" 3,2 mm | |

| 157 123-087 | D=5/32" 4,0 mm | ||

| 9 | 157 123-088 | Aluminium large diameter gas lens nozzle | Nr 6 9,8 mm |

| 157 123-089 | Nr 8 12,7 mm | ||

| 588 000-438 | Nr 10 15,9 mm | ||

| 157 123-098 | Nr 12 19,0 mm | ||

| 366 960-020 | Gas lens insulator | ||

| 11 | 15/ 123-020 | Gasiens | D=.020 0,5 mm |

| 157 123-021 | D=1/16" 1.6 mm | ||

| 157 123-023 | D=3/32" 2.4 mm | ||

| 157 123-024 | D=1/8" 3.2 mm | ||

| 157 123-025 | D=5/32" 4,0 mm | ||

| 12 | 157 123-057 | Aluminium gas lens nozzle | Nr 4 6,4 mm |

| 157 123-058 | Nr 5 8,0 mm | ||

| 157 123-059 | Nr 6 9,8 mm | ||

| 157 123-060 | Nr 7 11,2 mm | ||

| 15/ 123-001 | Miero guitab | 1 NI 0 12,7 mm | |

| 599 000 700 | |||

| 14 | 588 000 507 | ||

| 15 | 588 000-597 | ||

| 17 | 588 000-675 | Power cable 3.8 m | |

| | | 588 000-676 | Power cable 7.6 m | OKC/CC |

| 18 | 588 000-770 | Water hose, 3.8 m | |

| | | 588 000-771 | Water hose, 7.6 m | - CC |

| 19 | 588 000-445 | Gas hose kit, 3.8 m | l cc |

| 588 000-444 | Gas hose kit, 7.6 m | СС | |

| 20 | 588 000-757 | Central connector | |

| 21 | 588 000-679 | Water hose, 3.8 m | OKC |

| 588 000-681 | Water hose, 7.6 m | OKC | |

| 22 | 588 000-772 | Gas hose, 3.8 m | OKC |

| 588 000-773 | Gas hose, 7.6 m | OKC | |

| 23 | 588 000-769 | OKC connector | |

| 24 | 538 501-102 | Pin plug | |

| 25 | 588 000-759 | Cable cover, 3.8 m | |

| 1 | 588 000-760 | Cable cover 7.6 m |

ESAB subsidiaries and representative offices

Europe

AUSTRIA ESAB Ges.m.b.H Vienna-Liesing Tel: +43 1 888 25 11 Fax: +43 1 888 25 11 85

BELGIUM S.A. ESAB N.V. Brussels Tel: +32 2 745 11 00 Fax: +32 2 726 80 05

THE CZECH REPUBLIC ESAB VAMBERK s.r.o. Prague Tel: +420 2 819 40 885 Fax: +420 2 819 40 120

DENMARK Aktieselskabet ESAB Copenhagen-Valby Tel: +45 36 30 01 11 Fax: +45 36 30 40 03

FINLAND ESAB Oy Helsinki Tel: +358 9 547 761 Fax: +358 9 547 77 71

FRANCE ESAB France S.A. Cergy Pontoise Tel: +33 1 30 75 55 00 Fax: +33 1 30 75 55 24

GERMANY ESAB GmbH Solingen Tel: +49 212 298 0 Fax: +49 212 298 204

GREAT BRITAIN ESAB Group (UK) Ltd Waltham Cross Tel: +44 1992 76 85 15 Fax: +44 1992 71 58 03

ESAB Automation Ltd Andover Tel: +44 1264 33 22 33 Fax: +44 1264 33 20 74

HUNGARY ESAB Kft Budapest Tel: +36 1 20 44 182 Fax: +36 1 20 44 186

ITALY ESAB Saldatura S.p.A. Mesero (Mi) Tel: +39 02 97 96 81 Fax: +39 02 97 28 91 81

THE NETHERLANDS ESAB Nederland B.V. Utrecht Tel: +31 30 248 59 22 Fax: +31 30 248 52 60

NORWAY AS ESAB Larvik Tel: +47 33 12 10 00 Fax: +47 33 11 52 03

POLAND ESAB Sp.z.o.o

Warszaw Tel: +48 22 813 99 63 Fax: +48 22 813 98 8

PORTUGAL ESAB Lda Lisbon Tel: +351 1 837 1527 Fax: +351 1 859 1277

SLOVAKIA ESAB Slovakia s.r.o. Bratislava Tel: +421 7 44 88 24 26 Fax: +421 7 44 88 87 41

SPAIN ESAB Ibérica S.A. Alcobendas (Madrid) Tel: +34 91 623 11 00 Fax: +34 91 661 51 83

SWEDEN ESAB Sverige AB Gothenburg Tel: +46 31 50 95 00

ESAB International AB Gothenburg Tel: +46 31 50 90 00 Fax: +46 31 50 93 60

Fax: +46 31 50 93 60 SWITZERLAND ESAB AG

ESAB AG Dietikon Tel: +41 1 741 25 25 Fax: +41 1 740 30 55

North and South America ARGENTINA CONARCO Buenos Aires Tel: +54 11 4 753 4039 Fax: +54 11 4 753 6313

BRAZIL ESAB S.A. Contagem-MG Tel: +55 31 333 43 33 Fax: +55 31 361 31 51

CANADA ESAB Group Canada Inc. Missisauga, Ontario Tel: +1 905 670 02 20 Fax: +1 905 670 48 79

MEXICO ESAB Mexico S.A. Monterrey Tel: +52 8 350 5959 Fax: +52 8 350 7554

USA ESAB Welding & Cutting Products Florence, SC Tel: +1 843 669 44 11 Fax: +1 843 664 44 58

Asia/Pacific AUSTRALIA

ESAB Australia Pty Ltd Ermington Tel: +61 2 9647 1232 Fax: +61 2 9748 1685

CHINA Shanghai ESAB A/P Shanghai Tel: +86 21 6539 7124 Fax: +86 21 6543 6622

INDIA ESAB India Ltd Calcutta Tel: +91 33 478 45 17 Fax: +91 33 468 18 80

INDONESIA P.T. Esabindo Pratama Jakarta Tel: +62 21 460 01 88 Fax: +62 21 461 29 29

MALAYSIA ESAB (Malaysia) Snd Bhd Selangor Tel: +60 3 703 36 15 Fax: +60 3 703 35 52

SINGAPORE ESAB Singapore Pte Ltd Singapore Tel: +65 861 43 22 Fax: +65 861 31 95

ESAB Asia/Pacific Pte Ltd Singapore Tel: +65 861 74 42 Fax: +65 863 08 39

SOUTH KOREA ESAB SeAH Corporation Kyung-Nam Tel: +82 551 289 81 11 Fax: +82 551 289 88 63

THAILAND ESAB (Thailand) Ltd Samutprakarn Tel: +66 2 393 60 62 Fax: +66 2 748 71 11

UNITED ARAB EMIRATES ESAB Middle East Dubai Tel: +971 4 338 88 29 Fax: +971 4 338 87 29

Representative offices BULGARIA ESAB Representative Office Sofia Tel/Fax: +359 2 974 42 88

EGYPT ESAB Egypt Dokki-Cairo Tel: +20 2 390 96 69 Fax: +20 2 393 32 13

ROMANIA ESAB Representative Office Bucharest Tel/Fax: +40 1 322 36 74

RUSSIA-CIS ESAB Representative Office Moscow Tel: +7 095 937 98 20 Fax: +7 095 937 95 80

ESAB Representative Office St Petersburg Tel: +7 812 325 43 62 Fax: +7 812 325 66 85

Distributors

For addresses and phone numbers to our distributors in other countries, please visit our home page

www.esab.com

ESAB Welding Equipment AB SE-695 81 LAXÅ SWEDEN Phone +46 584 81 000 Fax +46 584 123 08

/ww.esab.com

Loading...

Loading...