Installation, Operation and Maintenance for the

®

EtchArc

-1125

PLASMA MARKING SYSTEM

F15-727

May, 2005

411 South Ebenezer Road

Florence, SC 29501-0545

The equipment described in this manual is

potentially hazardous. Use caution when installing,

operating and maintaining this equipment.

Purchaser is solely responsible for the safe

operation and use of all products purchased,

including compliance with OSHA and other

government standards. ESAB Cutting

Systems has no liability for personal injury or

other damage arising out of the use of any

product manufactured or sold be ESAB. See

standard ESAB terms and conditions of sale

for a specific statement of ESAB’s

responsibilities and limitations on its liability.

ESAB Cutting Systems first priority is total

customer satisfaction. We constantly look for

ways to improve our products, service and

documentation. As a result, we make

enhancements and/or design changes as

required. ESAB makes every possible effort to

ensure our documentation is current. We

cannot guarantee that each piece of

documentation received by our customers

reflects the latest design enhancements.

Therefore, the information contained in this

document is subject to change without notice.

This manual is ESAB Part Number F15727

This manual is ESAB Part Number F15727

This manual is ESAB Part Number F15727This manual is ESAB Part Number F15727

....

This manual is for the convenience and use of the

cutting machine purchaser. It is not a contract or

other obligation on the part of ESAB Cutting

Systems.

Printed in U.S.A.

©

© ESAB Cutting Systems, 2005

©©

EtchArc-1125 Table of Contents

Page

Section 1 Safety

1.1 Introduction.................................................................................................... 1

1.2 Safety Notations And Symbols........................................................................ 1

1.3 General Safety Information.............................................................................. 2

1.4 Installation Precautions................................................................................... 3

1.5 Electrical Grounding ....................................................................................... 4

1.6 Operating A Plasma Cutting Machine.............................................................. 4-7

1.7 Service Precautions........................................................................................ 8

1.8 Safety References .......................................................................................... 9

1.8.1 National Standards................................................................................. 9

1.8.2 International Standards........................................................................... 10-11

Section 2 Description

2.1 Introduction Overview...................................................................................... 1

2.1.1 Interconnection Diagram......................................................................... 2

2.2 System Description ........................................................................................ 3

2.2.1 EtchArc-1125 Systems........................................................................... 3

2.2.2 EtchArc-1125 Power Supply (only).......................................................... 3

2.2.3 PM60 Plasma Marker Torch.................................................................... 4

2.2.4 PM60 Torch Lead Assemblies ................................................................ 4

2.2.5 Options .................................................................................................. 4

Section 3 Installation

3.0 General .......................................................................................................... 1

3.1 Interface......................................................................................................... 2

3.2 Requirements................................................................................................. 3

3.3 Connecting the EtchArc.................................................................................. 4

3.3.1 Rear Panel.............................................................................................. 4

3.3.2 Converting a 230 VAC unit to a 208 VAC unit.......................................... 5

3.3.3 Torch Lead Connections, Front Panel ..................................................... 6-7

3.3.4 Torch Bundle (Leads) to PM60 Torch...................................................... 8-13

i

EtchArc-1125 Table of Contents

Page

Section 4 Operation

4.0 Set-up ............................................................................................................ 1

4.1 Power Supply ................................................................................................. 1

4.2 Gas Set-up..................................................................................................... 2

4.3 CNC Set-up.................................................................................................... 3

4.4 Process Data................................................................................................... 4-10

Section 5 Maintenance

5.0 General........................................................................................................... 1

5.1 Routine Maintenance ...................................................................................... 2

5.2 Flow Switch .................................................................................................... 3

Section 6 Troubleshooting

6.0 General........................................................................................................... 1

6.1 Troubleshooting Guide.................................................................................... 1-5

6.2 Power Supply Schematic, 208/230v (P/N 0588000967)................................. 6-7

6.3 Wiring Diagram, 208/230v............................................................................... 8-11

6.4 Power Supply Schematic, 460v (P/N 0588000949)........................................ 12-13

6.5 Wiring Diagram, 460v...................................................................................... 14-17

6.6 Power Supply Schematic, 575v (P/N 0588000966)........................................ 18-19

6.7 Wiring Diagram, 575v...................................................................................... 20-23

6.8 Plasma (CUT) Gas Circuit................................................................................ 24

ii

EtchArc-1125 Table of Contents

Page

Section 7 Replacement Parts

7.1 General .......................................................................................................... 1

7.2 Ordering......................................................................................................... 1

7.3 EtchArc-1125, Front and Rear Exterior, all models .......................................... 2-3

7.4 EtchArc-1125, Right interior view, 208/230V model......................................... 4-5

7.5 EtchArc-1125, Left interior view, 208/230v model ........................................... 6-7

7.6 EtchArc-1125, Top interior view with cover removed, 208/230v model ............ 8-9

7.7 EtchArc-1125, Top interior cross section view 1, 208/230v model................... 10-11

7.8 EtchArc-1125, Top interior cross section view 2, 208/230v model................... 12-13

7.9 EtchArc-1125, Right interior view, 460v and 575v models............................... 14-15

7.10 EtchArc-1125, Left interior view, 460v and 575v models ............................... 16-17

7.11 EtchArc-1125, Top interior view with cover removed, 460v and 575v models 18-19

7.12 EtchArc-1125, Top interior cross section view 1, 460v and 575v models....... 20-21

7.13 EtchArc-1125, Top interior cross section view 2, 460v and 575v models....... 22-23

7.14 TechArc-1125 Inside View, 460v and 575v models ....................................... 24-25

7.15 Argon Gas Circuit (Cut Gas).......................................................................... 26-27

7.16 PM60 Plasma Torch..................................................................................... 28-29

7.17 Torch Leads and Other System Parts............................................................ 30-31

7.18 PM-60 Plasma Marking Torch Starter Spare Parts Kit.................................... 32-33

Back Manual

Customer/Technical Information

Cover

iii

EtchArc-1125 Table of Contents

This page intentionally left blank

iv

SECTION 1 Safety

1.1 Introduction

The process of cutting metals with plasma equipment

1.2 Safety Notations And Symbols

!

DANGER

!

provides industry with a valuable and versatile tool.

ESAB cutting machines are designed to provide both

operation safety and efficiency. However, as with any

machine tool, sensible attention to operating

procedures, precautions, and safe practices is

necessary to achieve a full measure of usefulness.

Whether an individual is involved with operation,

servicing, or as an observer, compliance with

established precautions and safe practices must be

accomplished. Failure to observe certain precautions

could result in serious personnel injury or severe

equipment damage. The following precautions are

general guidelines applicable when working with

cutting machines. More explicit precautions pertaining

to the basic machine and accessories are found in the

instruction literature. For a wide scope of safety

information on the field of cutting and welding

apparatus, obtain and read the publications listed in

the Recommended References.

The following words and symbols are used throughout

this manual. They indicate different levels of required

safety involvement.

ALERT or ATTENTION. Your safety is involved

or potential equipment failure exists. Used with

other symbols and information.

Used to call attention to immediate hazards

which, if not avoided, will result in serious

personal injury or loss of life.

WARNING

!

CAUTION

!

CAUTION

NOTICE

EtchArc-1125 Power Source 1-1

Used to call attention to potential hazards that

could result in personal injury or loss of life.

Used to call attention to hazards that could result

in minor personal injury or equipment damage.

Used to call attention to minor hazards to

equipment.

Used to call attention to important installation,

operation or maintenance information not

directly related to safety hazards.

SECTION 1 Safety

1.3 General Safety Information

WARNING

!

Machinery often starts automatically.

This equipment moves in various directions and

This equipment moves in various directions and

This equipment moves in various directions and This equipment moves in various directions and

speeds.

speeds.

speeds.speeds.

• Moving machinery can crush.

Moving machinery can crush.

Moving machinery can crush.Moving machinery can crush.

• Only qualified personnel should operate or

Only qualified personnel should operate or

Only qualified personnel should operate or Only qualified personnel should operate or

service this power source.

service this power source.

service this power source.service this power source.

• Keep all personnel, materials, and equipment

Keep all personnel, materials, and equipment

Keep all personnel, materials, and equipment Keep all personnel, materials, and equipment

not involved in prod

not involved in production process clear of

not involved in prodnot involved in prod

entire system area.

entire system area.

entire system area.entire system area.

• Fence off entire work cell to prevent personnel

Fence off entire work cell to prevent personnel

Fence off entire work cell to prevent personnel Fence off entire work cell to prevent personnel

from passing through area or standing in the

from passing through area or standing in the

from passing through area or standing in the from passing through area or standing in the

working envelope of the equipment.

working envelope of the equipment.

working envelope of the equipment. working envelope of the equipment.

• Post appropriate WARNING signs at every work

Post appropriate WARNING signs at every work

Post appropriate WARNING signs at every work Post appropriate WARNING signs at every work

cell entrance.

cell entrance.

cell entrance. cell entrance.

• Follow lockout proced

Follow lockout procedure before servicing any

Follow lockout procedFollow lockout proced

equipment.

equipment.

equipment.equipment.

uction process clear of

uction process clear of uction process clear of

ure before servicing any

ure before servicing any ure before servicing any

Failure to follow operating instructions

WARNING

!

could result in death or serious injury.

Read and understand this operator’s manual before

Read and understand this operator’s manual before

Read and understand this operator’s manual before Read and understand this operator’s manual before

using machine.

using machine.

using machine.using machine.

• Read entire procedure before operating or

Read entire procedure before operating or

Read entire procedure before operating or Read entire procedure before operating or

performing any system maintenance.

performing any system maintenance.

performing any system maintenance. performing any system maintenance.

• Special attention must be given to all hazard

Special attention must be given to all hazard

Special attention must be given to all hazard Special attention must be given to all hazard

warnings that provide essential information

warnings that provide essential information

warnings that provide essential information warnings that provide essential information

re

regarding personnel safety and/or possible

garding personnel safety and/or possible

rere

garding personnel safety and/or possible garding personnel safety and/or possible

equipment damage.

equipment damage.

equipment damage.equipment damage.

• All safety precautions relevant to electrical

All safety precautions relevant to electrical

All safety precautions relevant to electrical All safety precautions relevant to electrical

equipment and process operations must be

equipment and process operations must be

equipment and process operations must be equipment and process operations must be

strictly observed by all having system

strictly observed by all having system

strictly observed by all having system strictly observed by all having system

responsibility or access.

responsibility or access.

responsibility or access. responsibility or access.

• Read all safety publications made available

Read all safety publications made available by

Read all safety publications made availableRead all safety publications made available

your company.

your company.

your company.your company.

by

by by

EtchArc-1125 Power Source 1-2

SECTION 1 Safety

Failure to follow safety warning label

WARNING

!

1.4 Installation Precautions

instructions could result in death or

serious injury.

Read and understand all safety warning labels on

Read and understand all safety warning labels on

Read and understand all safety warning labels on Read and understand all safety warning labels on

machine.

machine.

machine.machine.

Refer to operator’s manual for additiona

Refer to operator’s manual for additional safety

Refer to operator’s manual for additionaRefer to operator’s manual for additiona

information.

information.

information.information.

l safety

l safety l safety

WARNING

!

Improperly Installed Equipment Can Cause

Injury Or Death.

Follow these guidelines while installing machine:

Follow these guidelines while installing machine:

Follow these guidelines while installing machine:Follow these guidelines while installing machine:

• Contact your ESAB representative before

Contact your ESAB representative before

Contact your ESAB representative before Contact your ESAB representative before

installation. He can suggest certain precautio

installation. He can suggest certain precautions

installation. He can suggest certain precautioinstallation. He can suggest certain precautio

regarding piping installation and machine lifting,

regarding piping installation and machine lifting,

regarding piping installation and machine lifting, regarding piping installation and machine lifting,

etc. to ensure maximum security.

etc. to ensure maximum security.

etc. to ensure maximum security.etc. to ensure maximum security.

• Never attempt any machine modifications or

Never attempt any machine modifications or

Never attempt any machine modifications or Never attempt any machine modifications or

apparatus additions without first consulting a

apparatus additions without first consulting a

apparatus additions without first consulting a apparatus additions without first consulting a

qualified ESAB representative.

qualified ESAB representative.

qualified ESAB representative.qualified ESAB representative.

• Observe machine clearance requirements for

Observe machine clearance requirements for

Observe machine clearance requirements for Observe machine clearance requirements for

prope

proper operation and personnel safety.

r operation and personnel safety.

propeprope

r operation and personnel safety. r operation and personnel safety.

• Always have qualified personnel perform

Always have qualified personnel perform

Always have qualified personnel perform Always have qualified personnel perform

installation, troubleshooting and maintenance of

installation, troubleshooting and maintenance of

installation, troubleshooting and maintenance of installation, troubleshooting and maintenance of

this equipment.

this equipment.

this equipment.this equipment.

• Provide a wall mounted disconnect switch with

Provide a wall mounted disconnect switch with

Provide a wall mounted disconnect switch with Provide a wall mounted disconnect switch with

proper fuse sizes close to the power supply.

proper fuse sizes close to the power supply.

proper fuse sizes close to the power supply.proper fuse sizes close to the power supply.

ns

ns ns

EtchArc-1125 Power Source 1-3

SECTION 1 Safety

1.5 Electrical Grounding

Electrical grounding is imperative for proper

machine operation and SAFETY. Refer to this

manual’s Installation section for detailed grounding

instructions.

Electric shock hazard.

WARNING

!

1.6 Operating A Plasma Cutting Machine

Improper grounding can cause severe injury or

Improper grounding can cause severe injury or

Improper grounding can cause severe injury or Improper grounding can cause severe injury or

death.

death.

death.death.

Machine

Machine must be properly grounded before put into

MachineMachine

service.

service.

service.service.

must be properly grounded before put into

must be properly grounded before put into must be properly grounded before put into

Flying debris and loud noise

WARNING

!

hazards.

• Hot spatter can burn and injure eyes. Wear

Hot spatter can burn and injure eyes. Wear

Hot spatter can burn and injure eyes. Wear Hot spatter can burn and injure eyes. Wear

goggles to protect eyes from burns and flying

goggles to protect eyes from burns and flying

goggles to protect eyes from burns and flying goggles to protect eyes from burns and flying

debris generated during

debris generated during operation.

debris generated during debris generated during

operation.

operation.operation.

• Chipped slag may be hot and fly far.

Chipped slag may be hot and fly far.

Chipped slag may be hot and fly far. Chipped slag may be hot and fly far.

Bystanders should also wear goggles and

Bystanders should also wear goggles and

Bystanders should also wear goggles and Bystanders should also wear goggles and

safety glasses.

safety glasses.

safety glasses.safety glasses.

• Noise from plasma arc can damage hearing.

Noise from plasma arc can damage hearing.

Noise from plasma arc can damage hearing. Noise from plasma arc can damage hearing.

Wear correct ear protection when cutting above

Wear correct ear protection when cutting above

Wear correct ear protection when cutting above Wear correct ear protection when cutting above

water.

water.

water. water.

Burn hazard.

WARNING

!

Hot metal can burn.

Hot metal can burn.

Hot metal can burn.Hot metal can burn.

• Do not touch m

Do not touch metal plate or parts immediately

Do not touch mDo not touch m

after cutting. Allow metal time to cool, or douse

after cutting. Allow metal time to cool, or douse

after cutting. Allow metal time to cool, or douse after cutting. Allow metal time to cool, or douse

with water.

with water.

with water.with water.

• Do not touch plasma torch immediately after

Do not touch plasma torch immediately after

Do not touch plasma torch immediately after Do not touch plasma torch immediately after

cutting. Allow torch time to cool.

cutting. Allow torch time to cool.

cutting. Allow torch time to cool.cutting. Allow torch time to cool.

etal plate or parts immediately

etal plate or parts immediately etal plate or parts immediately

EtchArc-1125 Power Source 1-4

SECTION 1 Safety

g

!

can kill.

• Do NOT touch plasma torch, cutti

Do NOT touch plasma torch, cutting table or

Do NOT touch plasma torch, cuttiDo NOT touch plasma torch, cutti

cable connections during plasma cutting process.

cable connections during plasma cutting process.

cable connections during plasma cutting process.cable connections during plasma cutting process.

• Always turn power off to plasma power

Always turn power off to plasma power

Always turn power off to plasma power Always turn power off to plasma power

supplies before touching or servicing plasma torch.

supplies before touching or servicing plasma torch.

supplies before touchin

• Always turn power off to plasma power

Always turn power off to plasma power

Always turn power off to plasma power Always turn power off to plasma power

supplies before servicing any system component.

supplies before servicing any system component.

supplies before servicing any system component.supplies before servicing any system component.

• Do not touch live

Do not touch live electrical parts.

Do not touch liveDo not touch live

• Keep all panels and covers in place when

Keep all panels and covers in place when

Keep all panels and covers in place when Keep all panels and covers in place when

machine is connected to power source.

machine is connected to power source.

machine is connected to power source.machine is connected to power source.

• Wear insulating gloves, shoes and clothing to

Wear insulating gloves, shoes and clothing to

Wear insulating gloves, shoes and clothing to Wear insulating gloves, shoes and clothing to

insulate yourself from workpiece and electrical

insulate yourself from workpiece and electrical

insulate yourself from workpiece and electrical insulate yourself from workpiece and electrical

ground.

ground.

ground.ground.

• Keep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, and Keep gloves, shoes, clothing, work area, and

equipment d

equipment dry.

equipment dequipment d

• Replace worn or damaged cables.

Replace worn or damaged cables.

Replace worn or damaged cables.Replace worn or damaged cables.

ry.

ry.ry.

or servicing plasma torch. supplies before touching or servicing plasma torch.

electrical parts.

electrical parts. electrical parts.

ng table or

ng table or ng table or

WARNING

Hazardous voltages. Electric shock

WARNING

!

Fume hazard.

Fumes and gases generated by the plasma cutting

Fumes and gases generated by the plasma cutting

Fumes and gases generated by the plasma cutting Fumes and gases generated by the plasma cutting

process can be hazardous to your health.

process can be hazardous to your health.

process can be hazardous to your health.process can be hazardous to your health.

• Do NOT breathe fumes.

Do NOT breathe fumes.

Do NOT breathe fumes.Do NOT breathe fumes.

• Do not operate plasma torch without fume

Do not operate plasma torch without fume

Do not operate plasma torch without fume Do not operate plasma torch without fume

removal system operating properly.

removal system operating properly.

removal system operating properly. removal system operating properly.

• Use additional

Use additional ventilation to remove fumes if

Use additionalUse additional

necessary.

necessary.

necessary.necessary.

• Use approved respirator if ventilation is not

Use approved respirator if ventilation is not

Use approved respirator if ventilation is not Use approved respirator if ventilation is not

adequate.

adequate.

adequate.adequate.

• Provide positive mechanical ventilation when

Provide positive mechanical ventilation when

Provide positive mechanical ventilation when Provide positive mechanical ventilation when

cutting galvanized steel, stainless steel, copper,

cutting galvanized steel, stainless steel, copper,

cutting galvanized steel, stainless steel, copper, cutting galvanized steel, stainless steel, copper,

zinc, beryllium, or cadmium. Do not breathe these

zinc, beryllium, or cadmium. Do not breathe these

zinc, beryllium, or cadmium. Do not breathe these zinc, beryllium, or cadmium. Do not breathe these

fumes.

fumes.

fumes.fumes.

Do

Do not operate near degreasing and spraying

•

Do Do

operations. Heat or arc rays can react with

operations. Heat or arc rays can react with

operations. Heat or arc rays can react with operations. Heat or arc rays can react with

chlorinated hydrocarbon vapors to form phosgene,

chlorinated hydrocarbon vapors to form phosgene,

chlorinated hydrocarbon vapors to form phosgene, chlorinated hydrocarbon vapors to form phosgene,

a highly toxic gas and other irritant gases.

a highly toxic gas and other irritant gases.

a highly toxic gas and other irritant gases. a highly toxic gas and other irritant gases.

not operate near degreasing and spraying

not operate near degreasing and spraying not operate near degreasing and spraying

ventilation to remove fumes if

ventilation to remove fumes if ventilation to remove fumes if

EtchArc-1125 Power Source 1-5

SECTION 1 Safety

WARNING

!

Radiation hazard.

Arc rays can injure eyes and burn skin.

Arc rays can injure eyes and burn skin.

Arc rays can injure eyes and burn skin.Arc rays can injure eyes and burn skin.

• Wear corre

Wear correct eye and body protection.

Wear correWear corre

• Wear dark safety glasses or goggles with side

Wear dark safety glasses or goggles with side

Wear dark safety glasses or goggles with side Wear dark safety glasses or goggles with side

shields. Refer to following chart for recommended

shields. Refer to following chart for recommended

shields. Refer to following chart for recommended shields. Refer to following chart for recommended

lens shades for plasma cutting:

lens shades for plasma cutting:

lens shades for plasma cutting:lens shades for plasma cutting:

Arc Current

Up to 100 Amps

100

200

Over 400 Amps

• Replace glasses/goggles when lenses are

pitted or broken

pitted or broken

pitted or brokenpitted or broken

• Warn others in area not to look directly at the

arc unless wearing appropriate safety glasses.

arc unless wearing appropriate safety glasses.

arc unless wearing appropriate safety glasses.arc unless wearing appropriate safety glasses.

• Prepare cutting area to reduce reflection and

transmission

transmission of ultraviolet light.

transmissiontransmission

Arc Current Lens Shade

Arc CurrentArc Current

Up to 100 Amps Shade No. 8

Up to 100 AmpsUp to 100 Amps

100----200 Amps

100100

200----400

200200

Over 400 Amps Shade No. 14

Over 400 AmpsOver 400 Amps

Replace glasses/goggles when lenses are

Replace glasses/goggles when lenses are Replace glasses/goggles when lenses are

Warn others in area not to look directly at the

Warn others in area not to look directly at the Warn others in area not to look directly at the

Prepare cutting area to reduce reflection and

Prepare cutting area to reduce reflection and Prepare cutting area to reduce reflection and

§ Use special paint on walls to absorb UV

light.

light.

light.light.

ct eye and body protection.

ct eye and body protection.ct eye and body protection.

Lens Shade

Lens Shade Lens Shade

Shade No. 8

Shade No. 8Shade No. 8

200 Amps Shade No. 10

200 Amps200 Amps

400 Amps

400 400

of ultraviolet light.

of ultraviolet light. of ultraviolet light.

Use special paint on walls to absorb UV

Use special paint on walls to absorb UV Use special paint on walls to absorb UV

Shade No. 10

Shade No. 10Shade No. 10

Amps Shade No. 12

Shade No. 12

AmpsAmps

Shade No. 12Shade No. 12

Shade No. 14

Shade No. 14Shade No. 14

§ Install protective screens or curtains to

Install protective screens or curtains to

Install protective screens or curtains to Install protective screens or curtains to

reduce ultraviolet transmission.

reduce ultraviolet transmission.

reduce ultraviolet transmission.reduce ultraviolet transmission.

EtchArc-1125 Power Source 1-6

SECTION 1 Safety

!

WARNING

!

Heat, spatter, and sparks cause fire and burns.

Heat, spatter, and sparks cause fire and burns.

Heat, spatter, and sparks cause fire and burns. Heat, spatter, and sparks cause fire and burns.

• Do not cut near combustible material.

Do not cut near combustible material.

Do not cut near combustible material.Do not cut near combustible material.

• Do

Do not have on your person any combustibles

not have on your person any combustibles

DoDo

not have on your person any combustibles not have on your person any combustibles

(e.g. butane lighter).

(e.g. butane lighter).

(e.g. butane lighter).(e.g. butane lighter).

• Pilot arc can cause burns. Keep torch nozzle

Pilot arc can cause burns. Keep torch nozzle

Pilot arc can cause burns. Keep torch nozzle Pilot arc can cause burns. Keep torch nozzle

away from yourself and others when activating

away from yourself and others when activating

away from yourself and others when activating away from yourself and others when activating

plasma process.

plasma process.

plasma process.plasma process.

• Wear correct eye and body protection.

Wear correct eye and body protection.

Wear correct eye and body protection.Wear correct eye and body protection.

• Wear gauntlet gloves, safety shoes and hat.

Wear gauntlet gloves, safety shoes and hat.

Wear gauntlet gloves, safety shoes and hat.Wear gauntlet gloves, safety shoes and hat.

• WWWWear flame

ear flame----retardant clothing covering all

ear flameear flame

exposed areas.

exposed areas.

exposed areas.exposed areas.

• Wear cuffless trousers to prevent entry of

Wear cuffless trousers to prevent entry of

Wear cuffless trousers to prevent entry of Wear cuffless trousers to prevent entry of

sparks and slag.

sparks and slag.

sparks and slag.sparks and slag.

• Have fire extinguishing equipment available for

Have fire extinguishing equipment available for

Have fire extinguishing equipment available for Have fire extinguishing equipment available for

use.

use.

use.use.

retardant clothing covering all

retardant clothing covering all retardant clothing covering all

Explosion hazard.

• Certain molten aluminum

Certain molten aluminum----lithium (Al

Certain molten aluminumCertain molten aluminum

can cause explos

can cause explosions when plasma cut OVER

can cause exploscan cause explos

water.

water.

water. water.

§ These alloys should only be dry cut on a

These alloys should only be dry cut on a

These alloys should only be dry cut on a These alloys should only be dry cut on a

dry table.

dry table.

dry table.dry table.

§ DO NOT dry cut over water.

DO NOT dry cut over water.

DO NOT dry cut over water.DO NOT dry cut over water.

ions when plasma cut OVER

ions when plasma cut OVER ions when plasma cut OVER

lithium (Al----Li) alloys

lithium (Allithium (Al

Li) alloys

Li) alloys Li) alloys

WARNING

Burn Hazard.

§ Contact your aluminum supplier for

Contact your aluminum supplier for

Contact your aluminum supplier for Contact your aluminum supplier for

additional safety information regarding

additional safety information regarding

additional safety information regarding additional safety information regarding

hazards associated with these alloys

hazards associated with these alloys

hazards associated with these alloyshazards associated with these alloys

Do not cut in atmospheres con

Do not cut in atmospheres containing

•

Do not cut in atmospheres conDo not cut in atmospheres con

explosive dust or vapors.

explosive dust or vapors.

explosive dust or vapors.explosive dust or vapors.

•

Do not carry any combustibles on your person

Do not carry any combustibles on your person

Do not carry any combustibles on your person Do not carry any combustibles on your person

(e.g. butane lighter)

(e.g. butane lighter)

(e.g. butane lighter)(e.g. butane lighter)

• Do not cut containers that have held

Do not cut containers that have held

Do not cut containers that have held Do not cut containers that have held

combustibles.

combustibles.

combustibles.combustibles.

EtchArc-1125 Power Source 1-7

taining

taining taining

.

SECTION 1 Safety

g

1.7 Service Precautions

!

CAUTION

CAUTION

!

can kill.

• Do NOT touch plasma torch

Do NOT touch plasma torch, cutting table or

Do NOT touch plasma torchDo NOT touch plasma torch

cable connections during plasma cutting process.

cable connections during plasma cutting process.

cable connections during plasma cutting process.cable connections during plasma cutting process.

• Always turn power off to plasma power

Always turn power off to plasma power

Always turn power off to plasma power Always turn power off to plasma power

supplies before touching or servicing plasma torch.

supplies before touching or servicing plasma torch.

supplies before touchin

• Always turn power off to plasma power

Always turn power off to plasma power

Always turn power off to plasma power Always turn power off to plasma power

supplies before removing covers or panels to

supplies before removing covers or panels to

supplies before removing covers or panels to supplies before removing covers or panels to

service any s

service any system component.

service any sservice any s

• Do not touch live electrical parts.

Do not touch live electrical parts.

Do not touch live electrical parts.Do not touch live electrical parts.

• Keep all panels and covers in place when

Keep all panels and covers in place when

Keep all panels and covers in place when Keep all panels and covers in place when

machine is connected to power source.

machine is connected to power source.

machine is connected to power source.machine is connected to power source.

• Keep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, and Keep gloves, shoes, clothing, work area, and

equipment dry.

equipment dry.

equipment dry.equipment dry.

• Inspect power and ground leads cables for

Inspect power and ground leads cables for

Inspect power and ground leads cables for Inspect power and ground leads cables for

wear or cracking. Repl

wear or cracking. Replace worn or damaged

wear or cracking. Replwear or cracking. Repl

cables. Do not use if damaged.

cables. Do not use if damaged.

cables. Do not use if damaged.cables. Do not use if damaged.

• Never bypass safety interlocks.

Never bypass safety interlocks.

Never bypass safety interlocks.Never bypass safety interlocks.

• Follow lock

Follow lock----out procedures.

Follow lockFollow lock

Establish and adhere to preventive maintenance.

Establish and adhere to preventive maintenance.

Establish and adhere to preventive maintenance. Establish and adhere to preventive maintenance.

A composite program can be established from

A composite program can be established from

A composite program can be established from A composite program can be established from

recommended schedules.

recommended schedules.

recommended schedules.recommended schedules.

Avoid leaving test equ

Avoid leaving test equipment or hand tools on

Avoid leaving test equAvoid leaving test equ

machine. Severe electrical or mechanical damage

machine. Severe electrical or mechanical damage

machine. Severe electrical or mechanical damage machine. Severe electrical or mechanical damage

could occur to equipment or machine.

could occur to equipment or machine.

could occur to equipment or machine.could occur to equipment or machine.

Extreme caution should be used when probing

Extreme caution should be used when probing

Extreme caution should be used when probing Extreme caution should be used when probing

circuitry with an oscilloscope or voltmeter.

circuitry with an oscilloscope or voltmeter.

circuitry with an oscilloscope or voltmeter. circuitry with an oscilloscope or voltmeter.

Integrated circuits are susceptible to over volta

Integrated circuits are susceptible to over voltage

Integrated circuits are susceptible to over voltaIntegrated circuits are susceptible to over volta

damage. Power off before using test probes to

damage. Power off before using test probes to

damage. Power off before using test probes to damage. Power off before using test probes to

prevent accidental shorting of components.

prevent accidental shorting of components.

prevent accidental shorting of components.prevent accidental shorting of components.

All circuit boards securely seated in sockets, all

All circuit boards securely seated in sockets, all

All circuit boards securely seated in sockets, all All circuit boards securely seated in sockets, all

cables properly connected, all cabinets closed and

cables properly connected, all cabinets closed and

cables properly connected, all cabinets closed and cables properly connected, all cabinets closed and

locked, all guards and covers replaced before

locked, all guards and covers replaced before

locked, all guards and covers replaced before locked, all guards and covers replaced before

power is turned

power is turned on.

power is turnedpower is turned

ystem component.

ystem component.ystem component.

out procedures.

out procedures.out procedures.

on.

on. on.

or servicing plasma torch. supplies before touching or servicing plasma torch.

ace worn or damaged

ace worn or damaged ace worn or damaged

ipment or hand tools on

ipment or hand tools on ipment or hand tools on

, cutting table or

, cutting table or , cutting table or

ge

ge ge

WARNING

Hazardous voltages. Electric shock

EtchArc-1125 Power Source 1-8

SECTION 1 Safety

1.8 Safety References -- Regulations, Standards, Guidelines

1.8.1 Domestic

The following recognized publications on safety in welding and cutting

operations are recommended. These publications have been prepared

to protect persons from injury or illness and to protect property from

damage, which could result from unsafe practices. Although some of

these publications are not related specifically to this type of industrial

cutting apparatus, the principles of safety apply equally.

• “Precautions and Safe Practices in Welding and Cutting with

Oxygen-Fuel Gas Equipment,” Form 2035. ESAB Cutting

Systems.

• “Precautions and Safe Practices for Electric Welding and Cutting,”

Form 52-529. ESAB Cutting Systems.

• “Safety in Welding and Cutting” - ANSI Z 49.1, American Welding

Society, 2501 NW 7th Street, Miami, Florida, 33125.

• “Recommended Safe Practices for Shielded Gases for Welding and

Plasma Arc Cutting” - AWS C5.10-94, American Welding Society.

• “Recommended Practices for Plasma Arc Welding” - AWS C5.1,

American Welding Society.

• “Recommended Practices for Arc Cutting” - AWS C5.2, American

Welding Society.

• “Safe Practices” - AWS SP, American Welding Society.

• “Standard for Fire Protection in Use of Cutting and Welding

Procedures” - NFPA 51B, National Fire Protection Association, 60

Batterymarch Street, Boston, Massachusetts, 02110.

• “Standard for Installation and Operation of Oxygen - Fuel Gas

Systems for Welding and Cutting” - NFPA 51, National Fire

Protection Association.

• “Safety Precautions for Oxygen, Nitrogen, Argon, Helium, Carbon

Dioxide, Hydrogen, and Acetylene,” Form 3499. ESAB Cutting

Systems. Obtainable through your ESAB representative or local

distributor.

• "Design and Installation of Oxygen Piping Systems," Form 5110.

ESAB Cutting Systems.

• “Precautions for Safe Handling of Compressed Gases in

Cylinders”, CGA Standard P-1, Compressed Gas Association.

Literature applicable to safe practices in welding and cutting with

gaseous materials is also available from the Compressed Gas

Association, Inc., 500 Fifth Ave., New York, NY 10036.

EtchArc-1125 Power Source 1-9

SECTION 1 Safety

1.8.2 International

Accident Prevention

VBG 1 General Provisions

VDE Regulations

VBG 4 Electrical Equipment and operating

Equipment

VBG 15 Welding, Cutting and related working

methods

VBG 48 Shot Blasting Works

VBG 61 Gases

VBG 62 Oxygen

VBG 87 Operating liquid jet cutting machines

VBG 93 Laser beams, accident prevention and

Electro-technology

VBG 121 Noise

VDE 0100 Erection of power installations with normal

VDE0113 Electrical equipment of industrial machines

VDE 0837 Radiation safety of laser products; users

VDE 0837-

50

voltages up to 1000 volts

guide (DIN EN 60825)

Specification for laser guards

TRAC Technical Rules for Acetylene and Carbide Stores

TRAC-204 Acetylene lines

TRG Technical Rules for Pressure gases

EtchArc-1125 Power Source 1-10

TRAC-206 Acetylene cylinder battery systems

TRAC-207 Safety devices

TRG 100 General regulations for pressure gases

TRG 101 Pressure gases

TRG 102 Technical gas mixtures

TRG 104 Pressure gases; alterative use of

compressed gas tanks

SECTION 1 Safety

DIN Standards

DIN EN ISO Harmonized Standards

DIN 2310

Part 1

DIN 2310

Part 2

DIN 2310

Part 4

DIN 2310

Part 5

DIN 4844

Part 1

DIN EN

292/1 and 2

DIN EN 559 Hoses for welding, cutting and allied

DIN EN 560 Hose connections and hose couplings for

DIN EN 561 Gas welding equipment hose couplings

Thermal cutting; terminology and

nomenclature

Thermal cutting; determination of quality of cut

faces

Thermal cutting; arc plasma cutting; process

principles, quality, dimensional tolerances

Thermal cutting; laser beam cutting of metallic

materials; process principles

Safety markings (DIN EN 7287)

Safety of machinery

processes

equipment for welding, cutting and allied

processes

DIN EN

626-1

DIN EN

848-1

DIN EN

1829

DIN EN

9013

DIN EN

12584

DIN EN

12626

DIN EN

28206

DIN EN

31252

DIN EN

31553

DIN EN

60204-1

DIN EN

60825

DIN EN 999 Arrangement of protection devices

Safety of machines, reduction of risks to

health

Single spindle vertical milling machines

High pressure water jet machines

Thermal cutting, oxygen cutting, process

principles, dimensional tolerances

Imperfections in oxy/fuel flame cuts, laser

beam cuts and plasma

Laser processing machines

Acceptance testing for oxygen cutting

machines

Laser Equipment

Laser and laser related equipment

Electrical equipment of machines

Radiation safety of laser products

VDI Guidelines

EtchArc-1125 Power Source 1-11

VDI 2906 Quality of cut faces on metallic workpieces;

abrasive water jet cutting and arc plasma

cutting

VDI 2084 Room air; Technical systems for welding

workshops

SECTION 1 Safety

This page intentionally left blank.

EtchArc-1125 Power Source 1-12

SECTION 2 System Description

2 Introduction

2.1 Overview

The EtchArc Plasma Marker is a constricted arc low

amperage plasma marking torch. It marks at

speeds between 100 and 500 ipm.

The plasma marking process is similar to the

plasma cutting process. However, rather than

piercing through the plate, the low amperage

plasma arc merely cuts the surface of the plate

material between .0002 and .005 deep. Voltage

height control maintains a constant torch standoff

for consistent, high speed, accurate pattern layout.

When the EtchArc Plasma Marker is used in

conjunction with ESAB’s Vision CNC, Dynamic

Current Control is used to precisely control width

and depth of marks by proportionally ramping

current up and down as the machine accelerates

and decelerates. This minimizes pitting at the

beginning, corners, and end of the mark.

Accurate positioning of the layout lines and marks

depends on using the automatic marker offsets

executed by the CNC during Automatic Mode.

However, the marker can be used manually for

testing and setup.

In automatic operation, the part program controls:

All of these steps can be performed by the operator

for manual operation.

The EtchArc-1125 Plasma Marking Power Supply

consists of a modified PCM-1125 capable of

supplying up to 35 amperes. Modifications include

an added argon solenoid, pressure switch, gas

connections, marker control board and cable

connection. Unused manual controls were

removed or disconnected from the PCM-1125.

• machine motion

• offsets torch

• turns on automatic height control

• fires the torch and begins marking.

The marking torch has only three consumable parts:

the electrode, nozzle and shield cup. Argon cut gas

provides long electrode and nozzle life.

EtchArc-1125 Plasma Marking System 2-1

SECTION 2 System Description

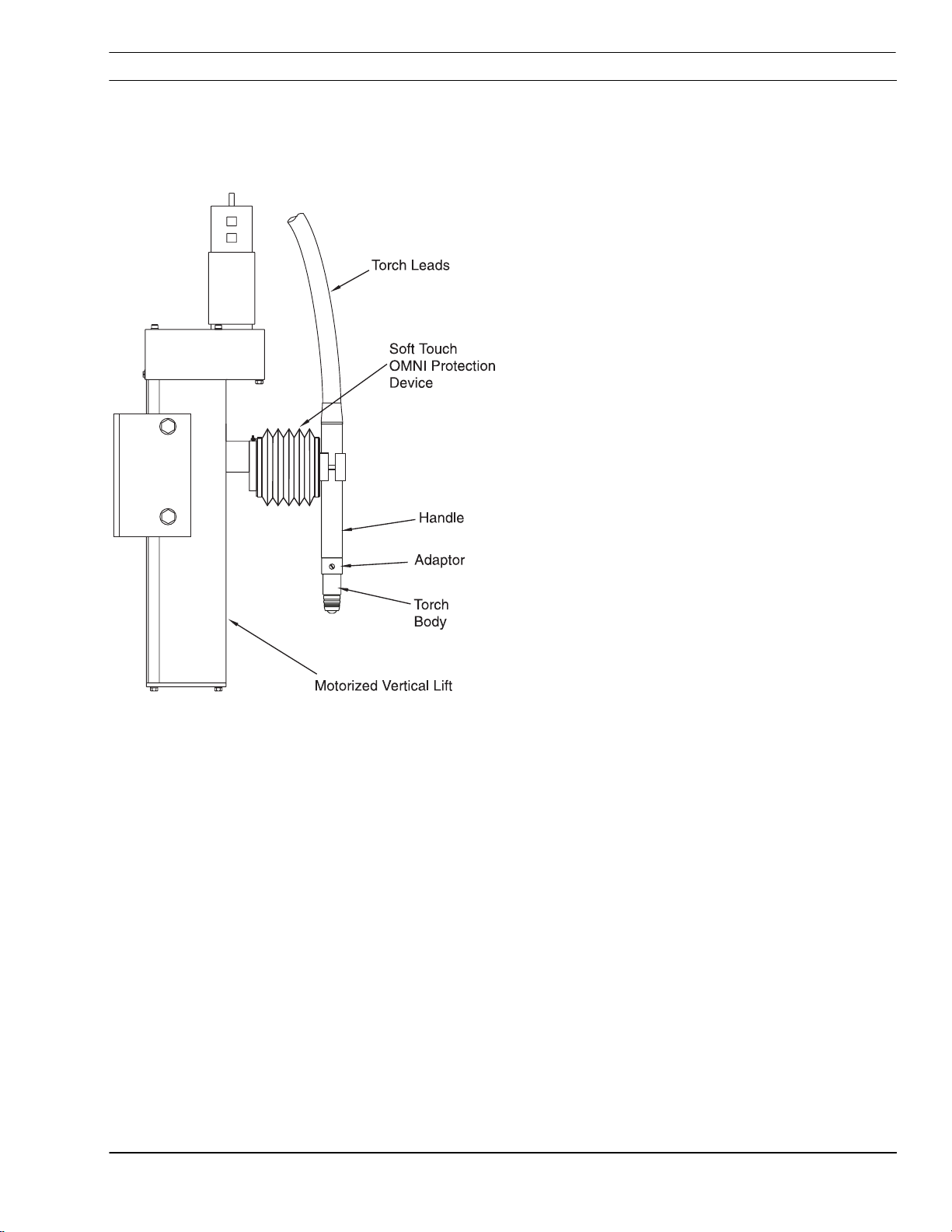

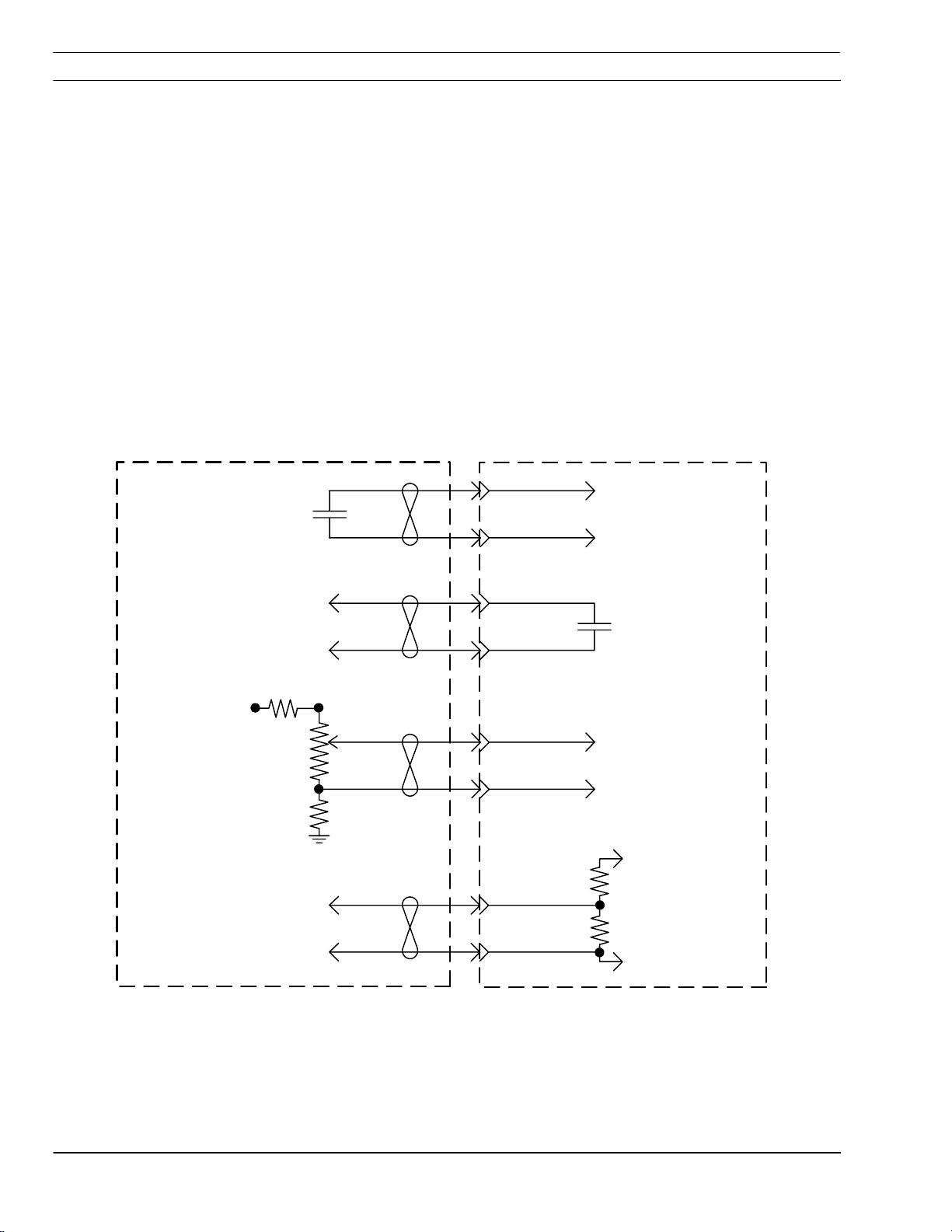

2.1.1 Interconnecting Diagram

EEEE

ttttcccc

hhhh

AAAA

rrrr

cccc

2

F

9

10

3

B

4

1

7

8

5

12

6

15

13

16

11

14

F

EtchArc----1125 Front Connections

EtchArcEtchArc

1125 Front Connections

1125 Front Connections1125 Front Connections

B

EtchArc

EtchArc----1125 Back Connections

EtchArcEtchArc

1125 Back Connections

1125 Back Connections1125 Back Connections

EtchArc

1 Vision CNC (relay box) 9 Air Regulator

2 CNC Control Cable 10 Air Supply Hose

3 Argon Gas Hose to torch 11 Argon Supply Hose

4 Work Cable 12 Primary Power Cable

5 Torch Bundle 13 Argon Gas Supply

6 Marking Torch 14 Compressed Air Supply

7 Work Piece

8 Earth Ground

15

16 Wall disconnect

EtchArc-1125 Plasma Marking System 2-2

Fused Disconnect (mounted on

machine, used when EtchArc-1125

has been mounted on the machine)

SECTION 2 System Description

2.2 System Description

2.2.1 EtchArc Systems

Includes power supply, torch and necessary cables

and hoses.

19 ft. (5.8 m) P/N 0560989772

25 ft. (7.6 m) P/N 0560989773

40 ft. (12.2 m) P/N 0560989774

50 ft. (15.2 m) P/N 0560989775

2.2.2 EtchArc-1125 Power Supply

208/230 V, 50/60Hz, 1 or 3 phase

208/230 V, 50/60Hz, 1 or 3 phase P/N 0588000967

208/230 V, 50/60Hz, 1 or 3 phase208/230 V, 50/60Hz, 1 or 3 phase

460 V, 50/60 Hz, 3 phase

460 V, 50/60 Hz, 3 phase P/N 0588000949

460 V, 50/60 Hz, 3 phase460 V, 50/60 Hz, 3 phase

575 V, 60 Hz, 3 p

575 V, 60 Hz, 3 phase

575 V, 60 Hz, 3 p575 V, 60 Hz, 3 p

Rated Inputs

Rated Inputs Rated Outputs

Rated InputsRated Inputs

hase P/N 0588000966

hasehase

Rated Outputs

Rated OutputsRated Outputs

Phases

Phases Volts

PhasesPhases

Volts Amps

VoltsVolts

1

3

Amps

AmpsAmps

Power

Power Power

Factor

Factor

FactorFactor

Duty Cycle

Duty Cycle

Duty CycleDuty Cycle

Output Amps*

Output Amps*

Output Amps* Output Amps*

@ 120 VDC

@ 120 VDC

@ 120 VDC@ 120 VDC

Open Circuit

Open Circuit

Open Circuit Open Circuit

Voltage

Voltage

VoltageVoltage

Power

64

208

73% 100% 35* 280 VDC

55

58

230

73% 100% 35* 270 VDC

55

208 28 100% 100% 35* 285 VDC

230 25 100% 100% 35* 275 VDC

460 14 100% 100% 35* 285 VDC

575 11 100% 100% 35* 260 VDC

* Output amperage is limited by the marker control

board (P/N 38138) to 35 amperes.

EtchArc-1125 Plasma Marking System 2-3

SECTION 2 System Description

2.2.3 PM60 Plasma Marker Torch Assembly

P/N 0560988474

Gas

Gas Dual (Argon and Air)

GasGas

Cooled

Cooled Air

CooledCooled

Amperes

Amperes Variable -- 35 Amperes Maximum

AmperesAmperes

2.2.4 PM60 Torch Lead Assembly

2.2.5 Option

Remote Arc Starter

Remote Arc Starter

Remote Arc StarterRemote Arc Starter

(Required if torch lead to exceed 50 ft.)

19 Ft.

19 Ft.

19 Ft.19 Ft.

25 ft.

25 ft. P/N 0560986664

25 ft.25 ft.

40 ft.

40 ft. P/N 0560987587

40 ft.40 ft.

50 ft.

50 ft. P/N 0560986685

50 ft.50 ft.

P/N 0560988947

P/N 0558002819

EtchArc-1125 Plasma Marking System 2-4

SECTION 3 Installation

3 Installation

Electric Shock Can Kill!

WARNING

!

Ensure primary power source is off

Ensure primary power source is off

Ensure primary power source is off Ensure primary power source is off

and disconnected before making any

and disconnected before making any

and disconnected before making any and disconnected before making any

electrical connections.

electrical connections.

electrical connections. electrical connections.

Only a qualified technician should

Only a qualified technician should

Only a qualified technician should Only a qualified technician should

install and service this equipment.

install and service this equipment.

install and service this equipment. install and service this equipment.

CAUTION

!

Ensure Your EtchArc-1125 is

being supplied with the

appropriate power.

This equipment comes in 208/230

VAC 1-phase, 208/230 VAC 3-phase,

460 VAC 3-phase and 575 VAC 3phase. Connecting to incorrect

power could damage your machine.

EtchArc-1125 Plasma Marking System 3-1

SECTION 3 Installation

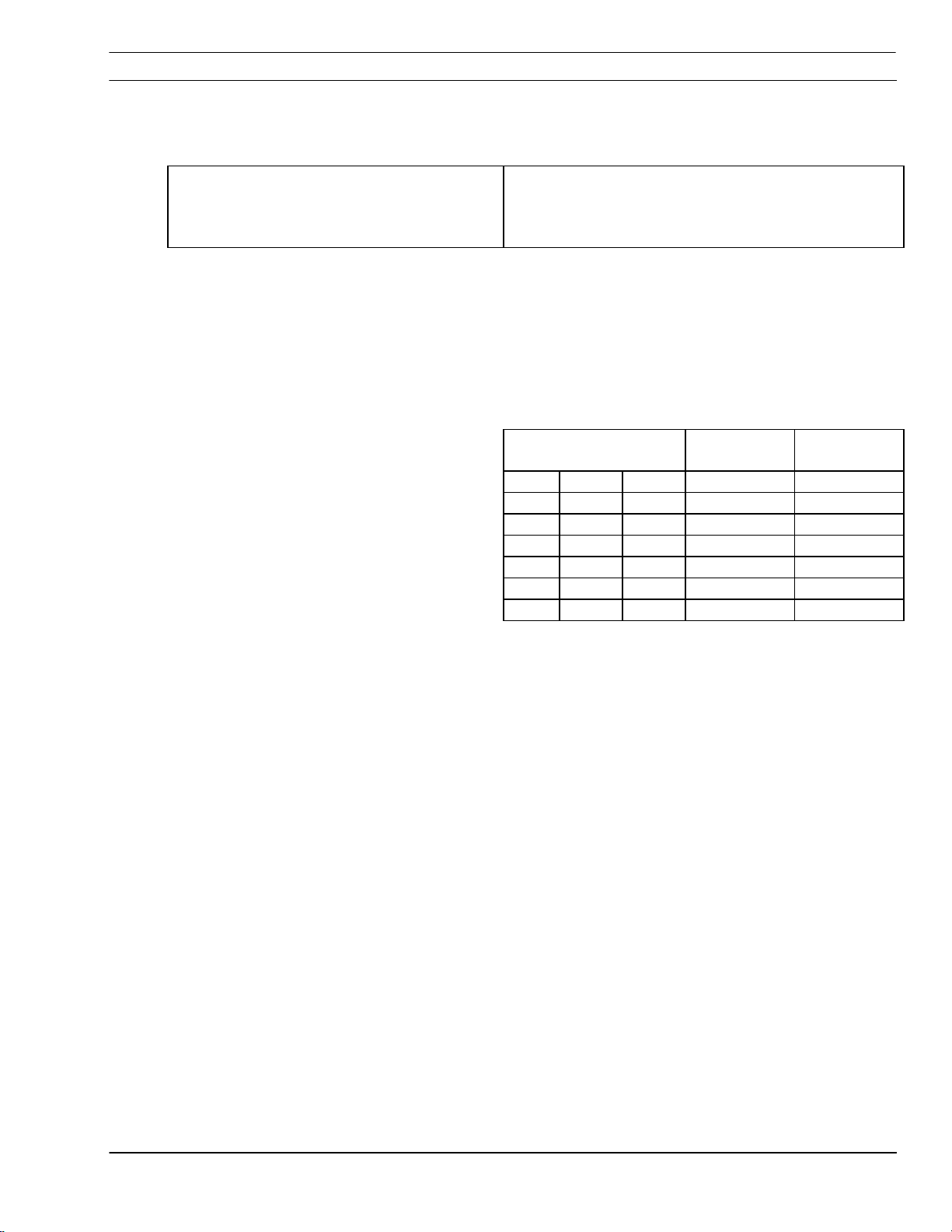

3.1 Interface

The EtchArc Plasma Marker system interfaces with

any cutting machine controller via the standard ESP

open interface. This interface provides an

amphenol connector for linking the appropriate

control wiring.

The schematic below illustrates interfacing with an

EtchArc and ESAB Vision or ESAB Series 2000

CNC. The customer must provide the external

requirements shown below when interfacing with a

control other than these types.

External

Requirements

Start signal (Close

contacts to start

arc)

ESP Interface

Plug (J2)

J2-N

J2-M

EtchArc-1125

Power Supply

Start signal to

power supply

Arc ON signal to

CNC

Current control

signal (Variable

DC Voltage)

Vmax = 3.5 V

Vmin = 0.3 V

Voltage divider

signal to voltage

height control

(+)

(-)

J2-I

J2-G

J2-L

J2-J

J2-C

J2-H

ESP Interface

Contact closes

when arc starts

(+)

3.5 V = 35 A

0.3 V = 3.0 A

(-)

Work

20:1

Electrode

EtchArc-1125 Plasma Marking System 3-2

SECTION 3 Installation

3.2 Requirements

Electrical Input Requirements

Rated primary input @ 35A / 120V output:

A fused breaker (either on the cutting machine

Recommended sizes for input conductors and

• 208/230VAC, 1 Phase 64/58A, 50/60 Hz.

• 208/230/400/575 VAC, 3 Phase

28/25/16/11A, 50/60 Hz.

gantry or wall mounted) is required to disconnect

power to the EtchArc-125 power supply. A

machine mounted disconnect should be used when

the power supply is mounted on the cutting

machine.

line fuses:

Rated Input Input & Gnd

Conductor

Volts Amps Phase CU/AWG Amps

208 64 1 No. 4 90

230 58 1 No. 4 90

208 28 3 No. 10 50

230 25 3 No. 10 40

400 16 3 No. 10 25

575 11 3 No. 10 20

Fuse Size

Gas Supply Requirements

Argon 100 psi (¼ NPT)

99.999% Pure

Service Air 100 psi (¼ NPT)

Clean, dry, oil-free

EtchArc-1125 Plasma Marking System 3-3

SECTION 3 Installation

3.3 Connections to the EtchArc-1125

3.3.1 Back

Shield Gas (Air)

Primary Power

Plasma Gas

(Argon)

There are 3 input lines to connect to the power

supply. These are made to the back of the unit

• Shield Gas

• Plasma Gas

• Primary power

Shield Gas

Shield Gas

Shield GasShield Gas

Prefiltered (clean and dry) Air) customer supplied,

90 to 150 PSI max. ¼ NPT

Plasma Gas

Plasma Gas

Plasma GasPlasma Gas

99.999% purity, 100 PSI, ¼ NPT

Primary Power

Primary Power

Primary PowerPrimary Power

3 prong plug used on

the single phase

208/230 VAC EtchArc-

1125

Red lead terminated and

not used on the

1-phase EtchArc-1125

Inside the 3 prong plug

208/230 VAC unit is supplied with a 3-prong plug

on a 10 ft. power cable when used as a single

phase EtchArc power supply. If used as a 3-phase

unit, disassemble plug and discard. Un-tape red

lead and connect.

The EtchArc 460 and 575 VAC power supplies are

3-phase and must be hard wired into the wall

disconnect box.

EtchArc-1125 Plasma Marking System 3-4

SECTION 3 Installation

3.3.2 Converting a 230 VAC power supply to 208 VAC

D2 D1

TB5-2

TB5-1 Gray Lead

TB3

The EtchArc-1125 is factory wired for 1-phase 230

volts AC. If using 208 VAC, the EtchArc must be

reconnected as follows before connecting to your

input primary power.

A. Remove cover from the EtchArc Power

Supply.

B. Locate output bridge (D2) and TB3 on left

side towards the front panel.

C. Disconnect X2 and X3 leads from these two

locations and interchange wire connections.

D. Move X2 from D2-3 to TB3.

E. Move X3 lead that was on TB3 to D2-3.

F. Locate the input bridge (IBR) and TB5

terminal block on the left side towards the

rear panel.

G. Disconnect gray lead from TB5-2 and

reconnect to TB5-1

TB5-2 to TB5-1

EtchArc-1125 Plasma Marking System 3-5

SECTION 3 Installation

3.3.3 Torch Lead Connections to EtchArc-1125

Torch Lead Bundle

Torch Lead

Connections

Shield Gas Hose/

Plasma Arc Lead

Argon Hose (Cut Gas)

Pilot Arc Cable

The torch lead bundle consists of;

one hose for the plasma gas,

one cable for the pilot arc current,

and one combination gas hose and cable for the

shield gas/plasma current. (The current conductor

is inside the air shield gas hose).

The torch lead to torch connections are covered in

section 3.3.4

Torch Lead Connection Access Panel

Remove the torch lead connection access panel to

connect the shield gas and pilot arc cable.

EtchArc-1125 Plasma Marking System 3-6

SECTION 3 Installation

Pilot Arc

Connection

Shield Gas

Connection

Connect pilot arc cable and shield gas hose. (The

plasma arc connection is made when the shield

gas hose is threaded into the bulkhead fitting.)

Connect plasma gas hose the bulkhead.

Replace access panel.

Plasma Gas Connection (Argon)

EtchArc-1125 Plasma Marking System 3-7

SECTION 3 Installation

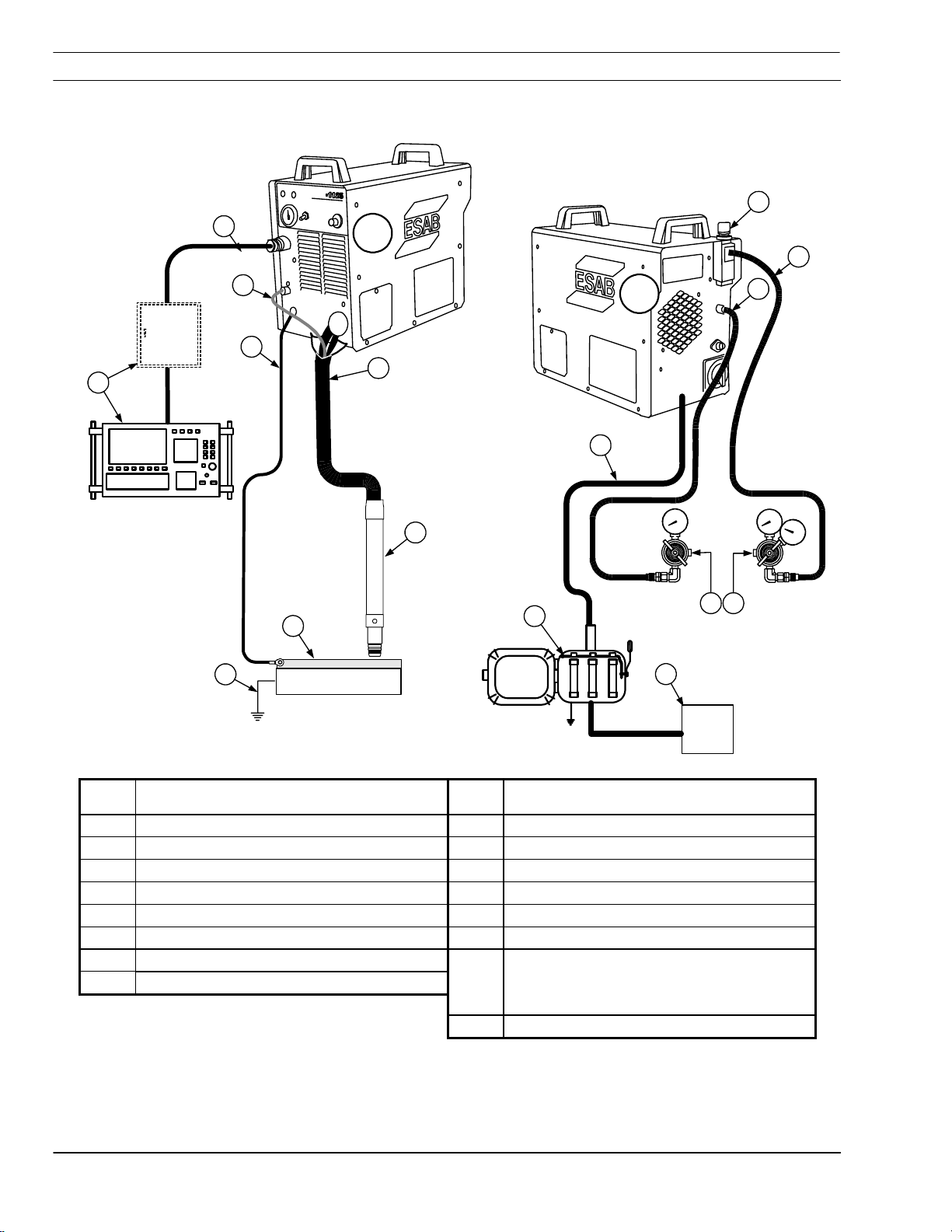

3.3.4 Torch Bundle To Torch

Handle adapter removed for illustration

Pilot Arc ShieldGas/

Plasma Gas

1 ½” dia. heat shrink

Power

The torch has three connection points.

• Shield Gas (Air)/Plasma Arc

• Pilot Arc

• Plasma Gas

Procedure

A). Unscrew handle from marker torch. Slide two

(2) pieces of black heat shrink (provided— 1 ½ dia)

onto the torch bundle.

B). Slide the torch handle on the torch bundle far

enough to allow access to connection points. This

may require a slight back and forth twisting motion

of the handle.

EtchArc-1125 Plasma Marking System 3-8

SECTION 3 Installation

2

C). Shield Gas/Power Connection

Shield Gas/Power Connection

Shield Gas/Power Connection Shield Gas/Power Connection

• Slide two (2) pieces of clear ¾ KYNAR heat

shrink on to the air/power connection of the

1

torch body as shown.

• Tighten the Air/Power Hose to the torch

2

connection.

1

• Position 1 piece or heatshrink over the

air/power connection so that all metal is covered

and shrink into place.

• Repeat procedure with the second piece of

heatshrink.

Shield

Gas/Plasma

Arc

EtchArc-1125 Plasma Marking System 3-9

SECTION 3 Installation

4

3

Cut Gas (Argon)

D. Cut Gas hose connection

Cut Gas hose connection

Cut Gas hose connectionCut Gas hose connection

• Assemble 2 pieces of ½ X 3 of Kynar

heatshrink on to the argon hose .

3

4

• Trim argon hose to length.

• Position cut gas hose clamp on to argon hose

about 1 to 2 inches past end of hose as shown.

• Slip hose on barbed fitting of torch body.

• Position clamp over barb and hose with

oreientation of clamp ears as shown .

10

• Position 1 piece of heatshrink over clamp and

hose.

• Shrink into place. Repeat.

10

EtchArc-1125 Plasma Marking System 3-10

SECTION 3 Installation

7

6

E. Pilot Arc Connection

Pilot Arc Connection

Pilot Arc ConnectionPilot Arc Connection

• Remove H.F. connector from pilot arc

5

cable and place on arc wire of torch body to

determine pilot arc cable length.

• Trim, strip and re-tin end of pilot arc cable.

5

• Remove from torch body and reassemble

cable connector to pilot arc cable.

• Tighten set screw.

• Place 2 -- 3 long pieces of 3/8 diameter

Kynar heatshrink onto pilot arc cable .

6

7

• Assemble H.F. connector to body and tighten

setscrew.

• Position 1 piece of heatshrink over the

connector and shrink in place. Repeat

Pilot Arc

EtchArc-1125 Plasma Marking System 3-11

SECTION 3 Installation

H). Using a slight back and forth twisting motion,

slide the torch handle to the torch body handle

adapter.

I). Remove screw from torch handle adapter

J). Holding torch handle stationary, thread handle

adapter into handle.

Do not rotate handle or torch body

CAUTION

to thread into adapter. This may

twist the bundle components inside

Hold handle stationary.

Do not rotate.

Rotate torch adapter to

thread into sleeve

handle and damage torch.

Hold torch body

stationary. Do not

rotate

EtchArc-1125 Plasma Marking System 3-12

SECTION 3 Installation

K). Replace screw.

L). Position 1 ½ diameter heat shrink over the end

of the torch handle as shown and shrink with heat

until tight. Shrink one piece in place. Slide second

into position and shrink with heat.

Torch

Bundle

Heat shrink Torch

Handle

EtchArc-1125 Plasma Marking System 3-13

SECTION 3 Installation

This page intentionally left blank.

EtchArc-1125 Plasma Marking System 3-14

SECTION 4 Operation

4 Operation --Setup

4.1 EtchArc-1125 Setup

The ETCHARC-1125 control panel should be set

properly before the marking operation. Check the

following items:

GAS TEST - Place this switch in the OPERATE

POWER

PRESSURE

(70 psig)

CNC

AIR

FAULT

EtchArc-1125

GAS

TEST

OPERATE

10

5

CURRENT

CONTROL

15

A

0

20

25

30

35 MAX

position for normal operation. TEST position

energizes the gas solenoids to allow presetting of

the argon and air gases.

CURRENT CONTROL - The Current Control knob

can be left in any position. This potentiometer is

normally disconnected for remote current control.

(Plasma Marking current is controlled by the cutting

machine CNC.) If the control does not support

remote current, the current control potentiometer

can be reconnected. (Wiring Diagrams in Section 6)

POWER - The Power On lamp should be on.

FAULT - The Fault lamp should be off.

ARGON

WORK

TORCH

EtchArc-1125 Plasma Marking System 4-1

SECTION 4 Operation

4.2 Gas Setup

Test/Operate Switch

Air Pressure

Gage

Air Pressure Regulator

Argon Pressure Gauge

Argon Pressure

Regulator

The plasma marking system uses two compressed

gases for operation. Compressed air is used for

electrode cooling and shield gas, argon is used as

plasma gas. The plasma gas constricts the arc as it

exits through the nozzle orifice. The shield gas

creates a secondary shield around the arc and

improves torch cooling.

Before operating the system, check gas pressure

settings for both compressed gases.

A. Set the Test/Operate switch to the TEST

position to energize the solenoid valves for both

compressed air and argon.

B. Adjust the air pressure regulator on the rear of

the unit while observing the pressure gauge on

the front of the unit. Set pressure to 90 PSI

while the air is flowing.

C. The argon pressure is adjusted at the separate

regulator panel mounted to the cutting machine.

While the argon is flowing, set the pressure to

75 psi.

D. When finished adjusting gas pressures, set the

TEST/OPERATE switch back to the OPERATE

position.

EtchArc-1125 Plasma Marking System 4-2

SECTION 4 Operation

4.3 CNC Setup

Standoff

Initial Height

Plasma Travel

Delay

Marker Remote

Current

The EtchArc plasma marker may be interfaced to

any cutting machine CNC. The following

parameters may or may not be supported by your

interface. Before plasma marking, check these

parameters, or their equivalents, at the machine

control:

On the Vision CNC, this parameter adjusts the

actual cutting height (or arc voltage) the torch will

maintain after the arc has started.

Sets the distance the torch will be raised after

sensing the plate. When VHC is turned on, the

torch will lower to the plate, then retract this

distance before starting the arc.

Sets the length of time the machine will remain

motionless after the arc strikes. Set to zero for the

plasma marking process.

This parameter sets the marking current in

amperes.

These parameters are preset when using SDP*

marker files.

*The Vision family of CNCs allows the user to store

multiple process parameter files. The files, called

SDP files (ScheidDatenPaket = Cutting data

package), contain all the same information that can

be manually adjusted on the process parameter

screen. (See your programming manuals for more

information)

EtchArc-1125 Plasma Marking System 4-3

SECTION 4 Operation

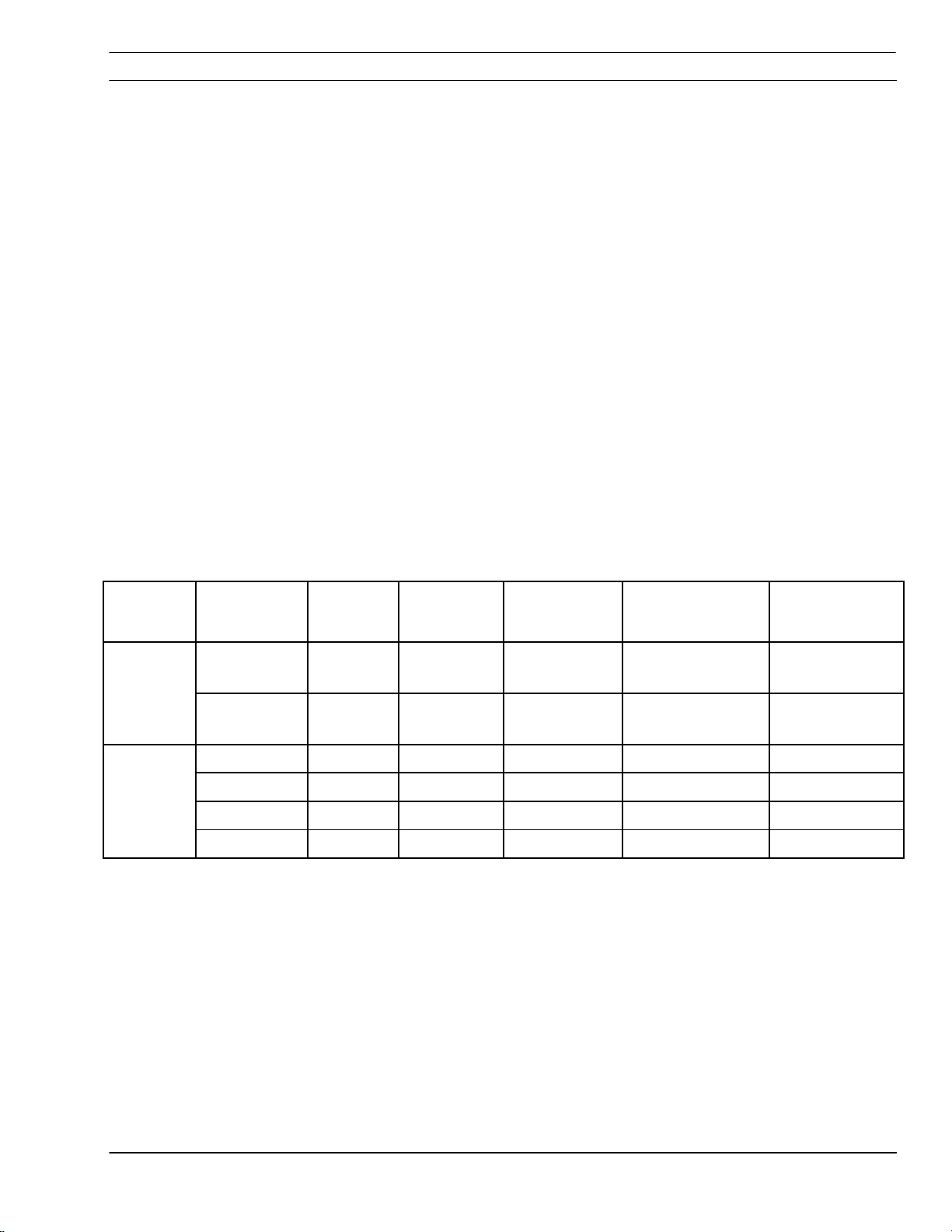

4.4 Process Data

The EtchArc Plasma Marker can produce marked

lines in a wide range of widths and depths, ranging

from poor to excellent quality. It can also operate

over a wide range of speeds. The operator must

balance these two factors based on the

requirements for a specific job.

The following pages provide process data for the six

different amperage settings. Each page shows the

setup parameters for that amperage and a chart

with marking speed range. From the chart, the

operator should select the speed setting based on

the quality of mark that can be accepted.

EtchArc-1125 Plasma Marking System 4-4

SECTION 4 Operation

10 Amp Marking

Electrode

2237857

Nozzle

56996876

CURRENT:

NOZZLE:

MATERIAL:

PLASMA GAS:

SHIELD GAS:

PIERCE HEIGHT:

ARC VOLTAGE:

10 Amps

.030 PN: 56996876

CARBON STEEL

ARGON @ 75 PSI (5 bar)

AIR @ 90 PSI (6 bar)

.125 (3 mm)

66

Shield Cup

2237859

Travel Plasma

Speed Mark

inch/min mm/min Width Depth Quality

100 2540 .040-.050 .0013 FAIR

200 5080 .040-.050 .0005 GOOD

300 7620 .040-.050 .0004 GOOD

400 10160 .040-.050 .0004 EXCELLENT

500 12700 .040-.050 .0003 EXCELLENT

Notes

1. Corner current set for 5 Amps in machine MIP.

2. Slow travel speeds usually have top spatter on mark edges.

3. Width and depth of mark will vary slightly depending on measuring methods. This information is for

estimated results.

EtchArc-1125 Plasma Marking System 4-5

SECTION 4 Operation

15 Amp Marking

Electrode

2237857

Nozzle

56996876

CURRENT:

NOZZLE:

MATERIAL:

PLASMA GAS:

SHIELD GAS:

PIERCE HEIGHT:

ARC VOLTAGE:

15 Amps

.030 PN: 56996876

CARBON STEEL

ARGON @ 75 PSI (5 bar)

AIR @ 90 PSI (6 bar)

.125 (3 mm)

66

Shield Cup

2237859

Travel Plasma

Speed Mark

inch/min mm/min Width Depth Quality

100 2540 .040-.050 .0043 POOR

200 5080 .040-.050 .0021 FAIR

300 7620 .040-.050 .0013 GOOD

400 10160 .040-.050 .0003 EXCELLENT

500 12700 .040-.050 .0002 EXCELLENT

Notes

1. Corner current set for 5 Amps in machine MIP.

2. Slow travel speeds usually have top spatter on mark edges.

3. Width and depth of mark will vary slightly depending on measuring methods. This information is for

estimated results.

EtchArc-1125 Plasma Marking System 4-6

SECTION 4 Operation

20 Amp Marking

CURRENT:

20 Amps

Electrode

2237857

Nozzle

56996876

NOZZLE:

MATERIAL:

PLASMA GAS:

SHIELD GAS:

PIERCE HEIGHT:

ARC VOLTAGE:

.030 PN: 56996876

CARBON STEEL

ARGON @ 75 PSI (5 bar)

AIR @ 90 PSI (6 bar)

.125 (3 mm)

66

Shield Cup

2237859

Travel Plasma

Speed Mark

inch/min mm/min Width Depth Quality

200 5080 .040-.050 .0028 POOR

300 7620 .040-.050 .0011 FAIR

400 10160 .040-.050 .0008 GOOD

500 12700 .040-.050 .0002 GOOD

Notes

1. Corner current set for 5 Amps in machine MIP.

2. Slow travel speeds usually have top spatter on mark edges.

3. Width and depth of mark will vary slightly depending on measuring methods. This information is for

estimated results.

EtchArc-1125 Plasma Marking System 4-7

SECTION 4 Operation

25 Amp Marking

Electrode

2237857

Nozzle

56996876

CURRENT:

NOZZLE:

MATERIAL:

PLASMA GAS:

SHIELD GAS:

PIERCE HEIGHT:

ARC VOLTAGE:

25 Amps

040 PN: 2237858

CARBON STEEL

ARGON @ 75 PSI (5 bar)

AIR @ 90 PSI (6 bar)

.125 (3 mm)

66

Shield Cup

2237859

Travel Plasma

Speed Mark

inch/min mm/min Width Depth Quality

200 5080 .050-.060 .0051 POOR

300 7620 .050-.060 .0034 FAIR

400 10160 .050-.060 .0032 GOOD

500 12700 .050-.060 .0014 GOOD

Notes

1. Corner current set for 5 Amps in machine MIP.

2. Slow travel speeds usually have top spatter on mark edges.

3. Width and depth of mark will vary slightly depending on measuring methods. This information is for

estimated results.

EtchArc-1125 Plasma Marking System 4-8

SECTION 4 Operation

30 Amp Marking

Electrode

2237857

Nozzle

2237858

CURRENT:

NOZZLE:

MATERIAL:

PLASMA GAS:

SHIELD GAS:

PIERCE HEIGHT:

ARC VOLTAGE:

30 Amps

.040 PN: 2237858

CARBON STEEL

ARGON @ 75 PSI (5 bar)

AIR @ 90 PSI (6 bar)

.125 (3 mm)

66

Shield Cup

2237859

Travel Plasma

Speed Mark

inch/min mm/min Width Depth Quality

200 5080 .050-.060 .0033 POOR

300 7620 .050-.060 .0030 FAIR

400 10160 .050"-.060 .0023 FAIR

500 12700 .050-.060 .0029 GOOD

Notes

1. Corner current set for 5 Amps in machine MIP.

2. Slow travel speeds usually have top spatter on mark edges.

3. Width and depth of mark will vary slightly depending on measuring methods. This information is for

estimated results.

EtchArc-1125 Plasma Marking System 4-9

SECTION 4 Operation

35 Amp Marking

Electrode

2237857

Nozzle

2237858

CURRENT:

NOZZLE:

MATERIAL:

PLASMA GAS:

SHIELD GAS:

PIERCE HEIGHT:

ARC VOLTAGE:

35 Amps

.040 PN: 2237858

CARBON STEEL

ARGON @ 75 PSI (5 bar)

AIR @ 90 PSI (6 bar)

.125 (3 mm)

66

Shield Cup

2237859

Travel Plasma

Speed Mark

inch/min mm/min Width Depth Quality

300 7620 .050-.060 .0012 POOR

400 10160 .050-.060 .0024 FAIR

500 12700 .050-.060 .0032 FAIR

Notes

1. Corner current set for 5 Amps in machine MIP.

2. Slow travel speeds usually have top spatter on mark edges.

3. Width and depth of mark will vary slightly depending on measuring methods. This information is for

estimated results.

EtchArc-1125 Plasma Marking System 4-10

SECTION 5 Maintenance

5 Maintenance

The Plasma Marking System consists of an

EtchArc-1125 plasma power supply, the marking

torch and argon supply.

Electric Shock Can Kill or Injure!

WARNING

!

Ensure the wall disconnect switch (or Circuit

breaker) is open before removing cover or

doing maintenance.

Electric Shock Can Kill!

WARNING

!

Ensure power supply power switch is OFF

before servicing the PM-60 EtchArc Torch.

EtchArc-1125 Plasma Marking System 5-1

SECTION 5 Maintenance

5.1 Routine Maintenance

CAUTION

!

The following routine maintenance should be

performed on the plasma marker system.

Compressed Air May Displace Debris

Causing Eye Injuries.

Always wear approved safety eye and face

protection whenever using compressed air to

clean equipment. Dust and debris can be

deflected back towards the face, possibly

resulting in a serious eye injury. Ensure

others nearby are protected also.

CAUTION

Water And Oil Contaminants in

Compressed Air May Damage Power

Supply Components.

Shop air occasionally contains accumulated

oil or water. Before using compressed shop

air to clean the interior of the power supply,

redirect the first air blast away from power

supply.

• Inspect the supply hoses, torch leads, ground

cable and interface cables for damage or wear

weekly.

• Inspect and clean the EtchArc-1125 monthly.

The unit can be blown out using a clean, dry

gas source, such as compressed air or

nitrogen.

• Occasionally drain all water from beneath the

air filter-regulator.

EtchArc-1125 Plasma Marking System 5-2

SECTION 5 Maintenance

Flow Switch

The Flow Switch (P/N 951202) may need to be

cleaned if excessive contamination is found in the

air supply.

Flow Switch Location

Piston Plug

Spring

Piston

Flow Switch Body

Note: The flow switch can be disassembled and

cleaned without extraction from the power supply.

1) Turn Off power supply

2) Remove piston plug

3) Remove the spring. Use care when handling

spring to prevent distortion.

4) Remove the piston.

5) Clean all parts with warm water and a mild

detergent. Allow parts to dry thoroughly before

reassembly.

6) Reassemble switch in reverse order.

EtchArc-1125 Plasma Marking System 5-3

SECTION 5 Maintenance

This page intentionally left blank.

This page intentionally left blank.

This page intentionally left blank.This page intentionally left blank.

EtchArc-1125 Plasma Marking System 5-4

SECTION 6 Troubleshooting

6 Troubleshooting

WARNING

!

WARNING

!

Electric Shock Can Kill!

Ensure that all primary power to the

machine has been externally

disconnected.