Page 1

INSTRUCTIONS for

F-15-075-A

April, 1995

DIGIPULSE AUTOMATIC

MICROPROCESSOR CONTROL

DIGIPULSE

AUTOMATIC

MICROPROCESSOR

CONTROL

P/N 31990

FOR AUTOMATED MECHANIZED MIG

WELDING

SPECIFICATIONS

Input Power Required ....................... 7 Amp., 115 vac, 1ph, 50/60 Hz

Wire Feed Speed Range .................. 20-999 in/min (.5-25.2 m/min)

Wire Sizes Preprogrammed ............. 023-in. (.7 mm), .030-in. (.76 mm),

.035-in. (.9 mm), .045-in (1.2 mm)

and .063 (1.6 mm)

Wire type (mat.) Preprogrammed .... 1. Carbon Steel, 2. Alternate Steel,

3. 4043 Alum., 4. 5356 Alum.

5 . Stainless Steel, 6. Silicon Bronze,

and 7. thru 10. reserved for

custom applications

Dimensions ....................................... 15.5-in. (394 mm) h,

13.0-in. (330 mm) w,

8-in. (200 mm) d

Weight ............................................... 20 lbs (9.1 kg)

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of

operation and safe practices for electric welding equipment, we urge you to read our booklet, “Precautions and Safe Practices for Electric Welding and Cutting,” Form 52-529. Do NOT permit untrained

persons to install, operate, or maintain this equipment. Do NOT attempt to install or operate this equipment until you have read and fully understand these instructions. If you do not fully understand these

instructions, contact your supplier for further information. Be sure to read the Safety Precautions on

page 3 and 4 before installing or operating this equipment.

Be sure this information reaches the operator.

You can get extra copies through your supplier.

Page 2

CONTACTS

Specifications ...................................................................................................................................................................... 1

Safety Precautions ........................................................................................................................................................... 3/4

Features/Benefits ................................................................................................................................................................ 5

I. INSTALLATION ............................................................................................................................................................. 5

A. Equipment Supplied ................................................................................................................................................. 5

B. Required Accessories .............................................................................................................................................. 5

C. Optional Accessories ................................................................................................................................................ 6

II. OPERATING INSTRUCTIONS ..................................................................................................................................... 7

A. Power Supply Welding Controls ................................................................................................... Refer to F-15-014

B. Digipulse Front Panel Control Functions ................................................................................................................. 9

C. Inside Panel Controls ............................................................................................................................................. 12

III. SETTING UP PROGRAM PARAMETERS ................................................................................................................. 15

A. General Welding Program Data ............................................................................................................................. 15

B. Preliminary Power Supply Checks ......................................................................................................................... 15

C. Program Control Parameters for Short/Spray Pulse Welding

Process Modes (Includes Hot Start Adjustment Procedures) ................................................................................ 15

D. Programming Your Own Pulse Parameters in optional Teach Mode.

Graphs—19) ........................................................................................................................................................... 17

E. Custom Program Development Procedures (Includes Customer

Development Chart ................................................................................................................................................ 21

IV. WELDING OPERATION

A. Pulse/Spray/Short Arc Wire Speed Recommendations ......................................................................................... 21

B. Welding Sequence for Teach Pulse or Spray or Short Arc Mode .......................................................................... 22

V. TROUBLESHOOTING ................................................................................................................................................ 23

VI. REPLACEMENT PARTS DATA .................................................................................................................................. 27

Figure 1 - Digipulse Interconnection Diagram .............................................................................................................. 8

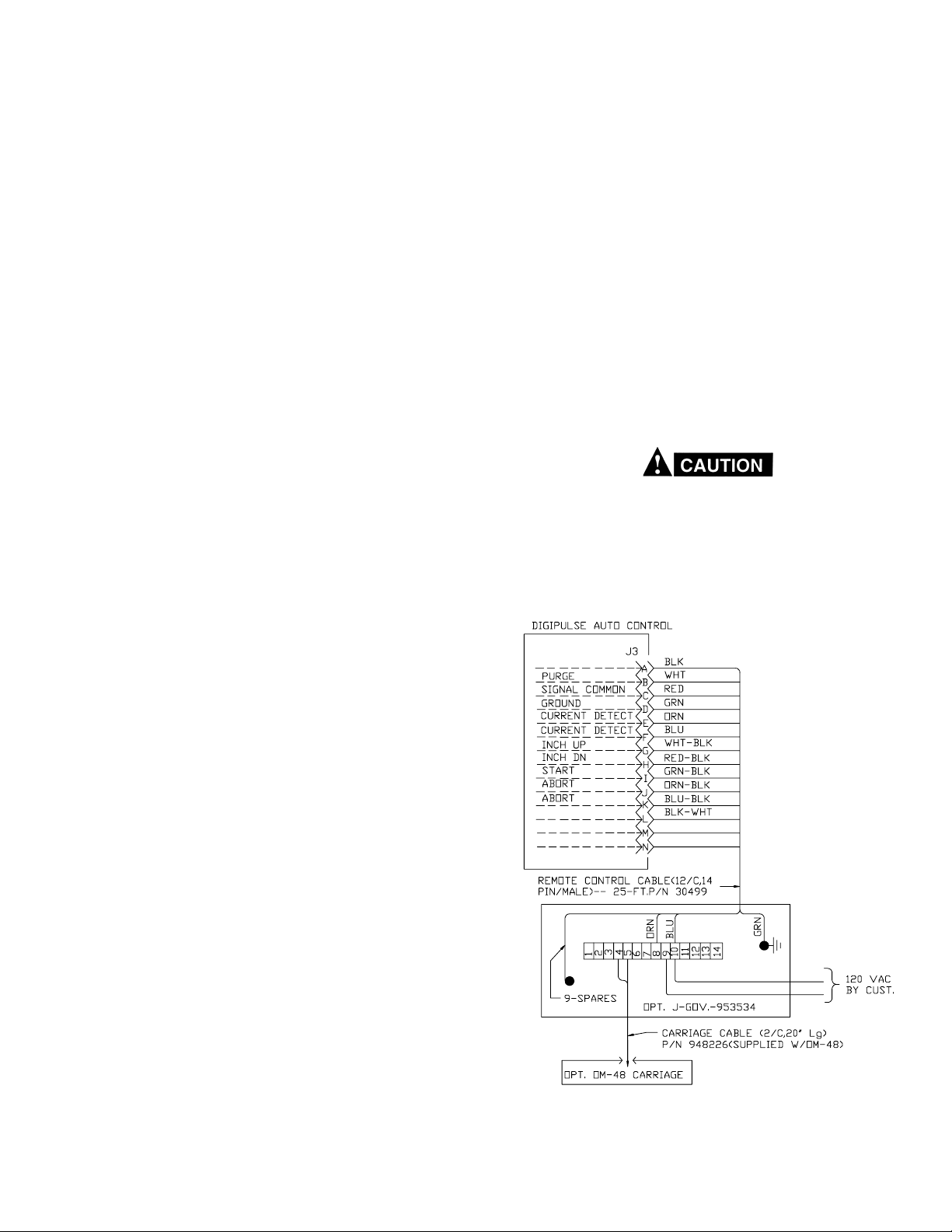

Figure 1A, OM-48 J-Governor Carriage Hookup .......................................................................................................... 9

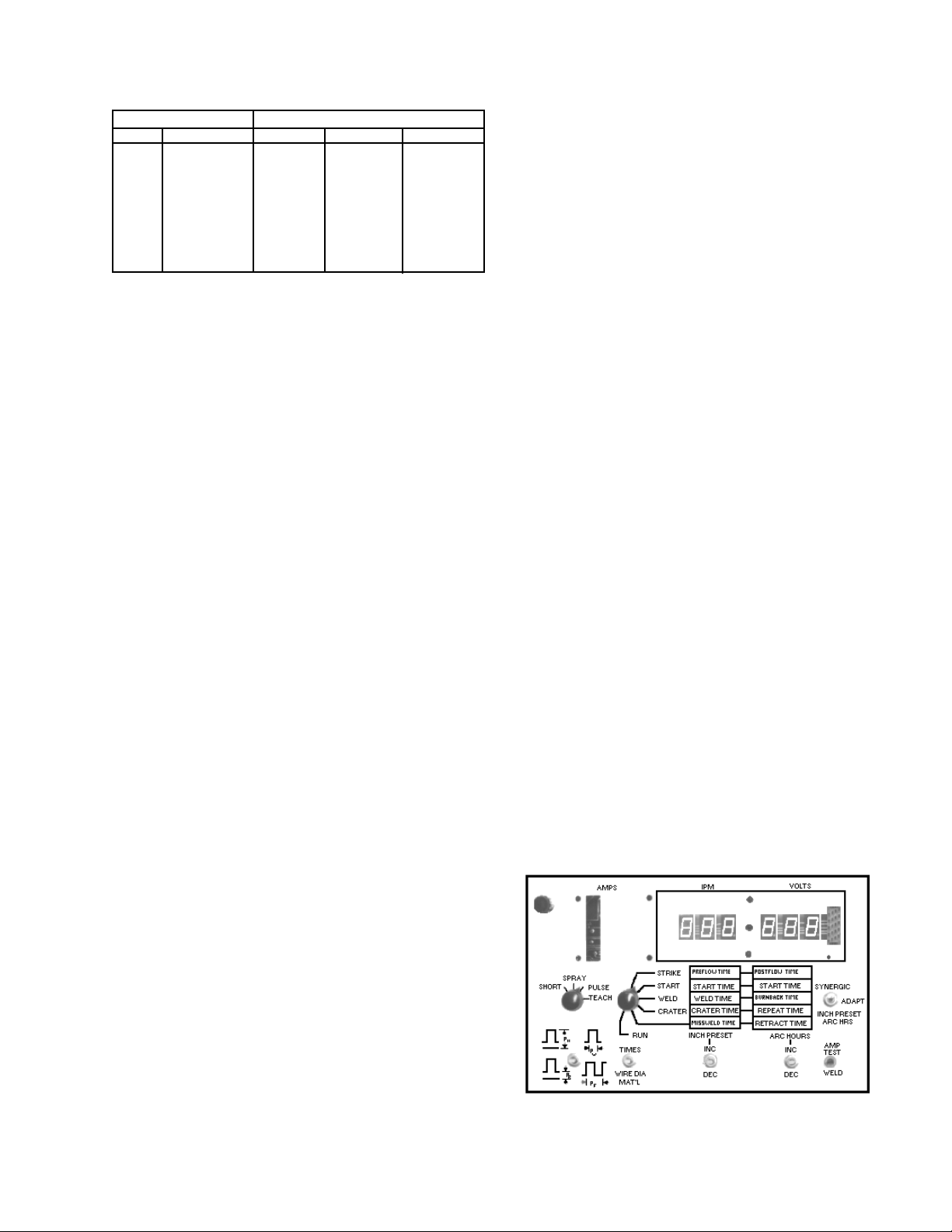

Figure 2 - Front Panel Controls ..................................................................................................................................... 9

Figure 3 - Inside Panel Controls ................................................................................................................................. 10

Figure 4 - Typical Time Parameter Set-up ................................................................................................................. 16

Figure 5 - Pulse Wave Description ............................................................................................................................. 18

Figure 6 - Teach Set-up On Inside Panel .................................................................................................................... 18

Figure 7 - Typical Welding Conditions Sequence Per Schedule ................................................................................ 23

Figure 8 - Control Assy. ............................................................................................................................................... 26

Figure 9 - Inside Control Panel ................................................................................................................................... 27

Figure 10 - Inner Cabinet Components....................................................................................................................... 27

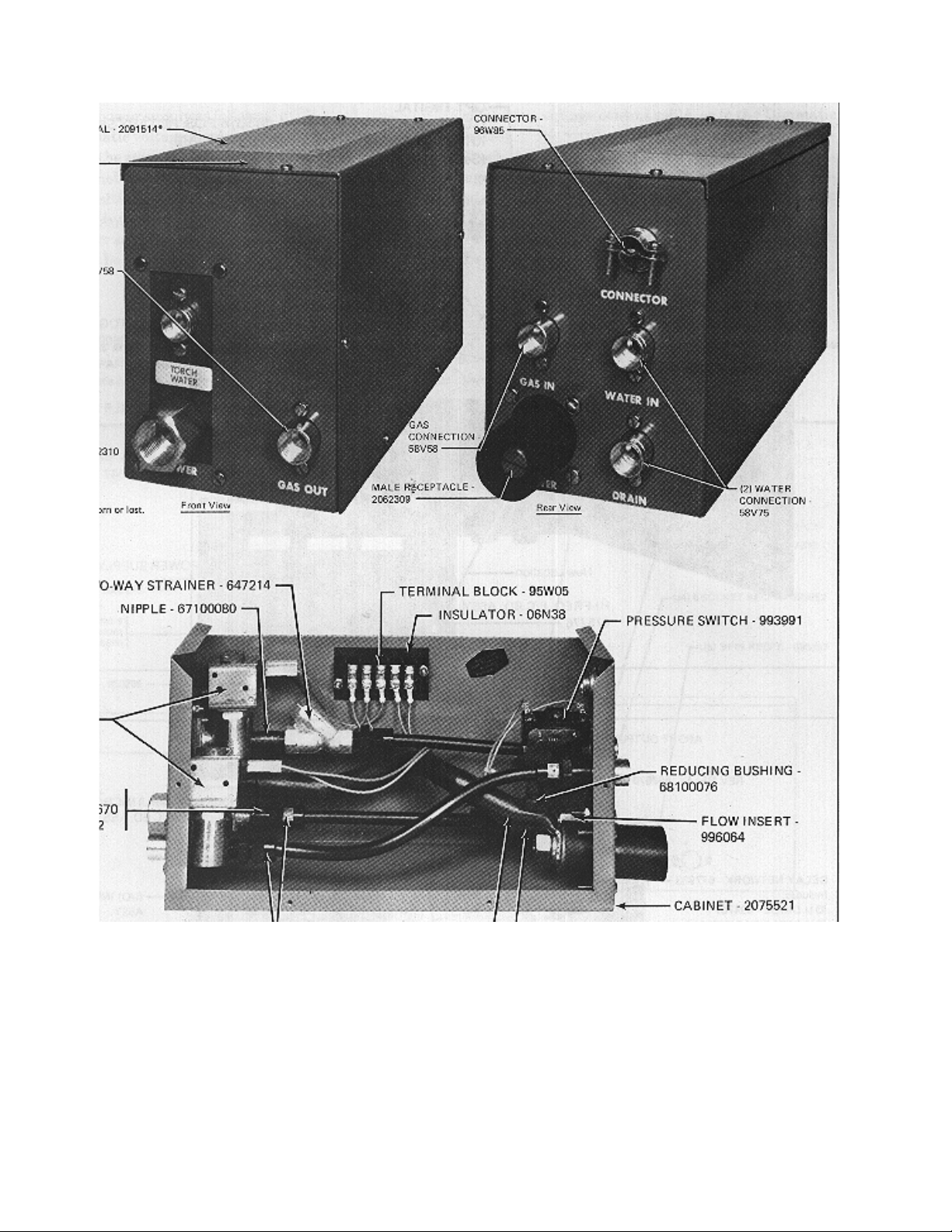

Figure 11 - Optional Plumbing Box ............................................................................................................................. 28

Figure 12 - Schematic Diagram - Digipulse Automatic ............................................................................................... 29

Figure 13 - Wiring Diagram - Sheet 1 of 2 .................................................................................................................. 30

Figure 13A - Wiring Diagram - Sheet 2 of 2 ................................................................................................................ 31

TABLES

Table I. - Feed rolls, feed roll kit and outlet guides ....................................................................................................... 6

Table II. - Recommended Shielding Gases ................................................................................................................ 15

Table III. - Typical “Short Arc” Wire Speed Ranges ..................................................................................................... 21

Table IV. - Typical “Spray Arc” Wire Speed Ranges .................................................................................................... 21

Table V. - Typical “Pulse Arc” Wire Speed Ranges ..................................................................................................... 21

2

Page 3

345

Page 4

Page 5

FEATURES/BENEFITS

The Digipulse Automatic is a unique, state-of-the-art pulse

welding control that combines a microcomputer with inverter power technology to provide a welder friendly system for automatic mechanized mig welding operations.

Matched with an EH-10A digital welding head, it can be

directly interfaced with the J- Governor/OM-48 carriage

and the mig plumbing box for use in fixture builder applications.

n The control stores four selectable mig welding sched-

ules -- Short Arc, Spray Arc, Pulse Arc and optional

Teach Pulse Arc that can save control setup time and

improve productivity. By presetting three of your most

common welding requirements --wire type, diameter

and wire feed speed, the microcomputer automatically

provides the correct arc length (for synergic operation)

or arc voltage (for adaptive operation) for a stable welding condition. All you have to do is switch weldments

and select the appropriate schedule for that particular

job.

n Eight presettable welding condition parameters per

schedule in sequence, including, Preflow, Strike, Start,

Weld, Crater, Anti-Stick (Burnback), Postflow and Wire

Retract. Total weld condition presettability means improved weld quality and production.

n The control is preprogrammed for six standard mate-

rials and five standard wire sizes and the computer

calculates all other welding parameters to produce

ultra-high quality performance and results.

n An optional field installed Teach mode is available and

is used to develop a complete set of synergic pulsedmig parameters for any weldable alloy quickly and easily.

n Operate in the logic mode of your choice, Synergic or

Adaptive. In the Synergic logic mode, the arc length

changes with tip to work distance while frequency remains constant. Conversely, in the Adaptive logic

mode, the arc length does not change with tip to work

distance while frequency constantly varies.

n Other standard features include:

- Sure Start Interlock...To assure troublefree starts, the

control has an interlock circuit which will not allow wire

feed to initiate unless the power supply contactor is

closed and STRIKE voltage is present.

- Presettable STRIKE Time...Assures safe consistent

starts. If for any reason the Strike Time is exceeded

(wire does not feed or misses the work) the control will

automatically shut down and flash the preset STRIKE

TIME in the VOLTS display window.

- Arc Detector Circuit...Senses that both Welding Voltage and Amperage are present to facilitate transfer from

Strike to Start condition parameters, and also provide a

signal to initiate travel of a carriage or fixture.

- Automatic Controlled Shutdown . To assure that all welding is performed only at the preset parameters, control

will automatically shutdown in the rare event that either

voltage or wire feed speed cannot be maintained during the welding sequence. The control will always sequence through a controlled shutdown including dynamic motor brake, anti-stick and postflow. Simultaneously, the cause is indicated by a flashing VOLTS or

IPM display.

- Remote Control Capabilities...To provide easy interfacing with fixtures, the control incorporates remote Start/

Stop and Wire Inch Capabilities which can be controlled

by switches or relays at a central control panel.

- Single or Repeat Timed Weld Capabilities...Because

the control incorporates a Repeat weld timer, adjustable up to 999 cycles (16.5 seconds), the Digipulse offers more than conventional continuous seam, or Single

Times welding capabilities. It can also be preset for

Repeat Timed skip or stitch welding applications.

- Individual Digital Meters Provide Large 1/2-in. Display

of Voltage And Wire Feed Speed IPM...After the arc is

struck, the meters automatically transfer from preset to

display of actual VOLTS and IPM for each welding condition as the control sequences through the preset welding sequence.

- Arc Hours Readout...This unique feature provides a direct measure of productivity by accumulating and displaying, upon command, actual welding Arc Hours.

- Automatic Adaptive Anti-Stick or Manual Burnback Time

Feature...A patented adaptive anti-stick circuit automatically adjusts the same amount of wire burnback, regardless of wire size, speed or voltage. Or, you can

manually preset a Burnback Time to specifically suit a

specialized application.

- Missweld Time...depending on the criticality of the weld,

this feature allows you to preset the number of cycles

of arc time that can reasonably be missed during a welding condition and still produce an acceptable weld. If

more than the allowable number of arc cycles are

missed, the unit will shutdown/abort and flash the preset Missweld Time cycles in the IPM display window.

- Wire Retract Feature...Provides the ability to preset a

Wire Retract time which will assure that the wire is well

removed from the work area and not subject to possible postweld bending due to contact with the workpiece

or fixture.

- Independent Presettable Cold Wire Inch...To reduce

down time for reloading welding wire, the cold wire Inch

speed can be independently adjusted (up to 999 ipm)

without affecting any of the other preset welding conditions.

- Circuit Protection...Resettable circuit breaker for 115

VAC, 50 or 60 HZ input power minimizes down time

and maintenance.

- Unique Diagnostic Set-up/Test Circuit...Provides the

ability to totally test the control electronics as well as

run it through a complete timed sequence of preset weld

conditions without actually welding.

I. INSTALLATION

A. EQUIPMENT SUPPLIED

The following Digipulse Automatic control;

1. Digipulse Automatic Control P/N 31990.

B. EQUIPMENT REQUIRED

1. One of the following three-phase Digipulse InverterType Power Sources:

a. Digipulse 450i cvcc for 230/460-volt, 60 Hz service P/N

31120, covered in booklet F-15-014.

b. Digipulse 450i cvcc for 575-volt, 60 Hz service P/N

31238, covered in booklets F-15-014 and Supplement

F-15-015.

Page 6

c. Digipulse 450i cvcc for 50 Hz. service P/N 31690, cov-

ered in booklets F-15-014 and Supplement F-15-039.

2. EH-10A Digital Welding Head (20-999 IPM). The welding

head is composed of three basic units; a wire feed motortachometer unit, a gear reduction unit, and the accessory

support assembly. This control is only usable with an EH10A Digital Welding Head, and either of two versions (following) are available for use.

a. Two Roll Drive EH-10A Head - P/N 600416. This head

provides wire feed speeds from 20-999 IPM using a

40:1 gear reduction ratio, and a two-roll accessory support wire drive. The motor-tachometer power and control leads are provided by a pair of 52 inch long cables

connected to a 5-pin amphenol. For further information

refer to booklet L12-873.

b. Four Roll Drive EH-10A Head - P/N 600417. This head

is the same as P/N 600416, except that it incorporates

a four-roll accessory support wire drive assembly. For

further information, refer to booklets F-12-873 and F12-821.

NOTE: If the motor direction is to be changed, interchange

the blue and grey wires on the reversing relay terminals R-9 and R-7 respectively.

b. ST-21M Water-Cooled Mechanized Torch (for currents

up to 600 amps.) P/N 690509, or--

c. MT-500M Air-Cooled Torch (for currents up to 500 amps)

P/N 17705.

5. Power Supply Control Cable (J1) Assembly. One of the

following control cables is required to connect the Digipulse Control to the power supply as shown on Interconnection Diagram Fig. 1. Each assembly consists of a 19conductor cable with a 19-pin amphenol plug on each end:

30-ft. long assembly, P/N 30780,

60-ft. long assembly, P/N 30781.

6. Torch Voltage Pickup Lead (J6) Assy. (3-pin, 1/c), P/N

680847. Required to connect the control to the power lug

on the torch (or the accessory support) to provide a positive arc voltage feedback to the control for reliable arc starting and arc stability.

7. Gas Regulation. Shielding gas regulator/flowmeter and

fitted hose to bring gas from flowmeter to a plumbing box

or connection block.

R-5007 Regulator/Flowmeter, P/N 998124.

Heavy-Duty Gas Hose, P/N 19416 (12-1/2-ft.), or P/N

19415 (25- ft.).

Gas Hose Coupling, for connecting additional 5/8 - 18

(R.H.) hoses together, P/N 11N17.

3. Feed Rolls. The 2-Roll Drive comes equipped with a pressure roll but NOT a feed roll. Select the proper feed roll

from Table 1 for the wire size and type to be used. To convert the 2-Roll to 4-Roll Drive; order optional 4-Roll Drive

Accessory Support, P/N 600216, and the appropriate kit

listed in Table 1.

Table 1

Wire/Size Two Roll Drive Four Roll Drive Outlet

in. (mm) Feed Roll Feed Roll Kit* Guide

Soft

.030 (.8) 2075304 (U) 999320 (U) 29N13**

.035 (.9) 2075304 (U) 999321 (U) 29N13**

3/64 (1.2) 2075301 (U)† 999322 (U) 29N13**

1/16 (1.6) 2075298 (U) 999323 (U) 29N13**

Hard

.023 (.6) 17998 (V) — 999745 (c)

.030 (.8) 2075300 (V) 999325 (V) 993860 (a)

.035 (.9) 2075303 (V) 999326 (V) 993860 (a)

.045 (1.2) 2075302 (V) 999327 (V) 39N15 (b)

.052 (1.4) 2075330 (V) 999328 (V) 39N15 (b)

.063,1/16(1.6) 2075299 (V) 999329 (V) 39N15 (b)

Cored Hard

.035 (.9) 19761 (Serr.) - 993860 (a)

.045 (1.2) 19761 (Serr.) 999330 (Serr.) 39N15 (b)

.052 (1.4) 2075261 (Serr.) 999331 (Serr.) 39N15 (b)

.063,1/16(1.6) 2075261 (Serr.) 999332 (Serr.) 39N15 (b)

U = U-groove, V = V-groove, Serr. = serrated

(a) Includes replaceable sleeve (995651).

(b) Includes replaceable sleeve (995692).“

(c) Requires guide bushing 17997.

* Includes a center wire guide and 2 upper and 2 lower feed rolls.

** Requires outlet guide as follows: For .030/.035 wire use 993902, For 3/64 wire use

05N57, For 1/16 wire use 12N57.

† Recommended U-Groove Pressure Roll 2075346 be used.

4. Welding Torch. A mechanized mig welding torch having

a rated capacity suitable for the welding application, such

as ESAB:

a. St-12 Water-Cooled Torch (for currents up to 700

amps) P/N 46V59, or--

8. Water Cooling Requirements. When using a water cooled

torch (ST-12 and ST-21M), the following are required to

supply and drain the cooling water:

Water Hose, 12-1/2 ft. P/N 40V76--or,

Water Hose, 25-ft., P/N 406196.

Water (In/Out) Adaptor (Connects 5/8 - 18 (L.H.) hose to

1/4 NPT), P/N 11N16.

Water Hose Coupling (Connect 5/8 - 18 hose together), P/

N 11N18.

C. OPTIONAL ACCESSORIES

1. Digipulse Automatic Teach Kit, P/N 35636. This field-

installed kit adds pulse-teach functions that allow the operator to set pulse height (PH), - width (PW), - frequency

(PF) and - background current (PB) to a unique pulse-weld

condition. One complete set of “teach” pulse functions can

be developed and stored (in Material Codes 11 thru 15) for

each of the following weld conditions; Strike, Start, Weld

and Crater of any weldable alloy. The kit’s installation instructions are covered in booklet F-15-232, and the operating instructions are covered in this booklet.

2. Digital D.C. Ammeter Kit, P/N 679111. This kit permits

direct visual indication of welding current up to 999 amps

d.c., and is available as a field installed option. The kit is

designed for easy bolt-on/plug-in installation and consists

of an LED Display P/C Board (P/N 675284), and Ammeter

Control P/C Board (P/N 675334), and assorted mounting

hardware--for installation refer to booklet F-14-220.

3. Plumbing Box Control Cable (J5) Assembly; 4-1/2-ft.

long, P/N 948273, or 25-ft P/N 678037. This cable pro-

vides connections to energize solenoid valves for gas

shielding and water cooling (if connected) during the

preflow, welding, and postflow cycles. It also provides an

interlock to a pressure switch in the water line which will

shutdown the control if the supply to a water-cooled torch

is inadequate. The assembly is a 6-conductor cable with a

6-pin amphenol to self-lead wire connections.

6

Page 7

4. Motor-Tachometer Extension Cable (J2) Assembly, P/

N 996808. This assembly allows you to extend the weld-

ing head location using a 25-ft., 6-conductor cable (1-conductor not used) with a 5-pin amphenol plug (which connects to the control's J2 receptacle) and a 5-pin amphenol

receptacle (which connects to the EH-10's plug).

5. Remote Control Cable (J3) Assembly; 25-ft. long, P/N

30499. This assembly allows you to connect remote con-

trol functions (as shown on Fig. 1) such as Up/Down coldwire Inching, Welding Start-Stop, Weld Abort Output signal (to shutdown a carriage or fixture drive mechanism),

Weld Current Detector signal (to initiate a carriage or fixture drive mechanism), and a Purge/Reset (to “purge” the

shielding gas line of the torch, or to “reset” the welding

sequence after an abort shutdown occurs). The cable assembly consists of a 25-ft., 12 conductor cable with a 14pin male amphenol plug on one end and self-lead wire

connections at the other end.

6. Reel/Spindle Support, P/N 634288. This support arm is

utilized to mount either wire spools or coils. Will mount to

any fixture or to the OM-48 carriage when the required

support adaptor P/N 996498 is used.

7. Spindle Assy., P/N 948259. Mounts to Item 6 above and

is used for 12-in. diam. spools.

ter-cooled torch operation is to be used with the plumbing box, the jumper splice (between J5-E and -F) must

be disconnected because these pin locations will be

connected across the water pressure switch in the

plumbing box. Also note that pressure switch is factory

connected for normally- closed (N/C) operation, and must

be reconnected for normally- open (N/O) operation as

shown in Fig. 1.

13.OM-48 Carriage/J-Governor Packages. The OM-48 is

available in two different speed ranges, P/N 01E52 with a

43- 112 IPM travel speed range and P/N 01E54 with a 2 56 IPM speed range. Both packages include a solid state

J-Governor for speed control. The Remote Control Cable,

Item I-C-5 is required to connect the control to the J-Governor. Carriage track is not provided with the OM-48 packages but, is available in ten foot (10') lengths under P/N

38V16. An optional J-Governor digital travel speed meter

P/N 14292 is available as a special customer order. Refer

to Figure 1-A for OM-48/J-Gov. wiring hook-up.

II. OPERATING INSTRUCTIONS

8. H.D. Spoke-Type Wire Reel, P/N 19V89. Mounts to item

6 above and is used for 65 lb. coils.

9. Spool Enclosure Kit, P/N 600240, covers and protects

12-in. spools from dust and moisture.

10.Wire Wiper. The wire wiper effectively cleans and lubricates the welding wire as it is being fed, thus providing

smoother wire feeding and longer conduit life. A complete

wiping assembly consists of a Felt Wiper (P/N 598537,

Pkg. of 10) and one of the Wiper Holders following:

a. Wiper Holder, P/N 598763, screws into the optional wire

straightener.

b. Wiper Holder, P/N 598764, screws on to the accessory

support's inlet wire guide.

11.WC-9 Coolant Recirculator, P/N 33540 (F-15-140), is

used for water cooled torch operation and is designed to

be “free standing” in a convenient location near the torch.

A four-gallon capacity tank provides 1.0 gal/min @ 50 psi,

115/230 volts, 50/60 Hertz, 1 phase input. Since the cooler

is designed to run continuously during a welding operation, never connect it to a power supply or wire feeder that

uses a solenoid controlled water supply that opens and

closes with each operation of the welding contactor -- the

cooling efficiency of the unit will be hampered and the starting winding in the pump motor may burn out.

12.Plumbing Box, P/N 677261. The plumbing box assembly

contains the solenoid valves which provide shielding gas

and cooling water control. It is also equipped with a pressure switch in the water line which (if connected) will shut

down the welding operation when the water supply is

inadequate.u The Plumbing Box Control Cable, Item I-C-3

is required to connect the control to the Plumbing Box.

Refer to Figure 1 for Plumbing Box wiring hook-up.

Never, under any circumstances, operate the power supply with the cover removed. In addition to the safety hazard, improper cooling may cause damage to internal components. Keep side panels closed when unit is energized.

Also make sure you are adequately protected before you

start welding - welding helmet, gloves, eye and ear protection should always be worn.

K

As shipped from the factory, the digipulse control is wired

for air-cooled torch operation and this is provided by an

insulated jumper splice connection between pins J5-E & F of the control's plumbing Box receptacle J5. When wa-

Fig. 1A, OM-48/J-Gov. Carriage Hookup

7

Page 8

NOTES:

1. Both output welding cable leads (torch and work) must be a minimum size of No. 4/0 welding cable (nothing smaller), and both leads should be

kept as close to the same length as possible — with neither lead exceeding 50-ft. in length. Also, both cables must be run next to each other and

tywrapped every couple of feet to minimize cable reactance.

2. If wire feed runs backwards, reverse motor direction as follows: In the control, disconnect the blue wire (RLY-7) from T1-5 and connect it to T16; disconnect orange wire (RLY-9) from T1-6 and connect it to T1-5.

3. As shipped from the factory, the Digipulse control is wired for air-cooled torch operation and this is provided by an insulated jumper splice

connection between pins J5-E and -F of the control’s plumbing box receptacle J5. When water-cooled torch operation is to be used with the

plumbing box, the jumper splice (between J5-E and -F) must be disconnected because these pins will be connected across the water

pressure switch in the plumbing box. Also note that the pressure switch is factory-connected for normally-closed (NC) operation, and must

be reconnected for normally-open (NO) operation as shown above and in the schematic and detail wiring diagrams.

Figure 1 - Interconnection Diagram

8

Page 9

Do not allow metal-to-metal contact between the wire

feeder chassis and a metal surface connected in any way

to a welding ground. With such contact, a poor welding

ground connection may create a difference in potential

that sends part of the welding current through the safety

ground wiring in the control cable and wire feeder, resulting in burnout of that wiring and/or damage to wire

feeder circuitry. If the safety ground burns out, the operator may be exposed to 115V. shock hazard.

A. POWER SUPPLY WELDING CONTROLS

For detailed information regarding the power supply welding

controls, refer to F-15-014.

B. DIGIPULSE FRONT PANEL CONTROL FUNCTIONS

For location of front panel control features, refer to Figure 2 following:

1. Power Switch. Pulling-out the mushroom-style red button

of this switch turns power on into the control as indicated

5c

(Ref)

Key

Lock

5a

6

DIGIPULSE AUTOMATIC

MICROPROCESSOR CONTROL

a. Prior to starting the welding sequence, it actuates

the gas solenoid and lets you “purge” the shielding gas

line of the torch. At the same time, the IPM and VOLTS

windows will also display the preset times (in cycles)

for gas preflow and gas postflow respectively.

b. After starting the welding sequence -- if an abort

“shutdown” condition occurs (indicated by flashing digital

display), the Purge/Reset rocker can be actuated and

the control will automatically “reset”.

3. Inch-Up-Down Rocker. This switch is used to “cold inch”

the wire, up or down, at a preset speed which is programmed from the inside control panel (see II-C-4).

IMPORTANT: Cold inching is only possible when the weld

Start-Stop rocker switch is in its “stop” (or

off) position.

4. Start-Stop Rocker. This two position (no neutral) switch

initiates the welding sequence when placed in its START

position; and, depending on the type of welding -- Continuous Seam or Timed, terminates the welding sequence

in its STOP position as follows.

a. Continuous Seam welding applications. The “stop” sig-

nal does not immediately terminate the welding sequence, it only terminates the weld condition parameter. The sequence then transfers to the remaining condition parameters (crater fill, burnback, postflow/retract).

b. Single or Repeat “Timed” welding applications. Although

the “stop signal” is not normally used for timed-welds,

you may wish to prematurely terminate a burn thru or

unstable weld condition. When the “stop” is used; all

welding action (including crater-fill) will terminate, except burnback and postflow/retract.

5b

7

1

2

3 4

Fig. 2 Front Panel Controls

by the illuminated display windows. To turn power off, simply push-in red button and the display windows and control will deenergize.

NOTE: Immediately after the control is turned on a num-

ber will appear in the IPM window (e.g. 3) and

another number will appear in the VOLTS window, and these numbers will only be displayed

for 1-second. This information identifies the EProm “program” used in your control. The number shown in the VOLTS window will be in decimal form (e.g.,.1,.2,.3 etc.).

2. Gas Purge/Reset Rocker. A momentary “on” switch, this

rocker provides a dual function when actuated.

5. Digital Readout Windows. Three individual 3- digit windows labeled AMPS (optional ammeter), IPM and VOLTS

are provided to display actual welding current, preset or

actual welding parameters (wire feed speed and welding

voltage) and time parameters as follows:

a. AMP Digital Readout. This window is normally blank

unless the optional Ammeter Kit is provided to monitor

actual welding current. When installed, the window displays d.c. current (AMPS) in a range from 0-999 amperes in one amp increments.

b. IPM Digital Readout. This window is primarily used to

display wire feed sped (IPM) for each of the four “welding conditions” (Strike, Start, Weld, and Crater) during

a typical welding sequence. Depending on the position

of the inside “condition” selector switch functionally defined in II-C, the IPM window displays actual and/or preset wire feed speed in a range from 20 to 999 inches-

per-minute, in one-inch increments, for each weld condition in the program sequence.

l With power turned ON, but not welding, the IPM

window will “continuously” read the Preset wire

speed setting. When the arc is struck, the IPM window will then continuously read the Actual welding

wire speed as the weld conditions cycle thru the

welding sequence.

In addition to the above, and using the “Condition” and “Time/

Wire Dia.-Material” selector controls on the inner panel func-

9

Page 10

4

1

6

2

7

Figure 3 - Inside Panel Controls

tionally defined in II-C, this window can also display the following programmed times:

- PREFLOW. Shielding gas time from 0 to 999 cycles (16.5

sec.) in one cycle increments (60 cycles per second).

- START TIME. Start time duration is factory preset at 6

cycles, and can be increased up to 999 cycles, in one cycle

increments.

- WELD TIME. Weld condition duration for “timed-welding”

(must be set to zero for Continuous-Seam Welding), from

1 to 999 cycles, in one cycle increments.

- CRATER TIME. Crater fill duration, from 1 to 999 cycles, in

one cycle increments.

- MISSWELD TIME. Presets the number of cycles of arc

time that can reasonably be missed (from 1 to 999 cycles)

during the WELD condition and still produce an acceptable weld. If the number of missed cycles match the preset cycles, the unit will abort. Since the number of missed

cycles to be preset is based upon many variables, the required setting for a given application obviously involved

good judgment and technique. As an example, to set up a

critical 45 cycle spot weld, you might want to preset no

more than 5 cycles of missweld arc time. Be careful not to

make the missweld time to short, otherwise nuisance aborts

will occur. If this feature is not desired, preset the time for

zero cycles.

- INCH. Cold wire inch sped from 50 to 999 inches-perminute, in one inch increments.

- a code number indicates a type of MATERIAL which is

programmed for various welding wire applications, as follows: code #1 indicates Carbon Steel, #2 is Alternate Steel,

#3 is 4043 Aluminum, #4 is 5356 Aluminum, #5 is 308 Stainless, #6 is Silicon Bronze. (Additional Material code num-

bers 7 thru 10, are reserved for custom applications.)

- if provided, Ph indicates PULSE HEIGHT which is displayed

as a “reference voltage” setting, from 0.1 to 10 (in 0.1 volt

increments), that controls or establishes the amplitude of

the pulse peak (in teach option only).

3

5a

- if provided, Pb indicates PULSE BACKGROUND which is

displayed as a “reference current” setting, from 15 to 100

(in one ampere increments), that establishes the approximate background current in pulse applications (in teach

option only).

c. Volts Digital Readout. In a typical weld sequence, with

power “on” but not welding, this window will selectively

display an arbitrary number (100) that represents a programmed arc length in the “synergic” mode*, or a computed arc voltage in the “adaptive” mode* for each of

the four “welding conditions” (Strike, Start, Weld, and

Crater). When the arc is struck, the VOLTS window will

continuously display actual welding voltage in a range

from 12 to 50 vdc in one-tenth (0.1) volt increments.

* In the “synergic” mode , the control will automati-

cally select and display an appropriate “arc length”

integer for a given wire type, size, feed rate and gas

shielding. An arbitrary number, represented by the

integer 100, is the normalized value for all applications programmed in the control, and this figure will

be displayed in the VOLTS window during setup (not

welding). This value (set @ 100) can be readjusted,

within a range from 0 to 200, to fine-tune the operating arc length of the selected welding condition.

By reducing the number below 100 (minimum 0),

you will reduce the arc length. Conversely, by increasing this value above 100 (maximum 200) you

can increase the arc length. After the arc is struck,

the number will be replaced by the actual welding

arc voltage.

The Digipulse can also operate in the adaptive mode,

where the arc is continuously monitored by a closed

loop feedback circuit and the machine modulates

5b

10

Page 11

its output to maintain a given voltage for

preprogrammed data. In the adaptive mode, a computed arc voltage (unique to your preprogrammed

welding selection) will be displayed in the VOLTS

window before welding. Once the arc is struck, the

control will measure the actual welding voltage and

change the output of the power supply to maintain

the precalculated voltage setting. In this manner,

the power supply automatically compensates for

variations in stickout or weld joint geometry. Further, all of the precalculated arc voltages programmed in the control can be readjusted +/- 10

volts to “fine-tune” the welding arc.

In addition to the above, and using the inside “Condition” and

“Time/Wire Dia.-Material” selector controls (functionally defined in II-C), this window can also display the following programmed times.

- POSTFLOW. Controls time for gas postflow after the arc

extinguishes form 0 to 999 cycles.

- STRIKE TIME. Preset time period allowed, for the wire to

come down and hit the plate during the Strike Condition. If

the wire does not strike the plate within the allowed time

period, the control will automatically shutdown, and flash

the “strike time” in the VOLTS display window. Simultaneously, it also provides an abort output signal to stop carriage or fixture travel. Time range is factory preset for a

minimum of 20 cyclesl and can be increased in one cycle

increments.

played as a “frequency (Hertz) reference” setting, from 25

to 909* pulse cycles per second, that establishes the approximate pulse frequency required for the wire feed speed

set on the control (in teach option only).

* Please note that the maximum Pulse Frequency is de-

pendent on the “pulse width” - the narrower the width,

the higher the maximum frequency; and the wider the

width, the lower the maximum frequency.

6. Welding Condition (LED) Lights. These lights are labeled

START, WELD, and CRATER, and they energize individually as the welding program sequences through each of

these weld conditions. Prior to the Start, and after the Crater Conditions, none of these lights will be “on”.

7. Reset Circuit Breaker. A seven (7) ampere circuit breaker

provides protection to the 115 volt control circuit and the

wire feed motor. If an overload occurs, the breaker will trip

and suspend all operation. To restore service, simply depress the breaker button on the front panel.

C. INSIDE PANEL CONTROLS

For location of inside panel controls, see. Fig. 3.

1. Short (arc), Spray (arc), Pulse, optional Teach Mode

Schedule Selector. This four-position rotary switch allows

you to select the welding process mode you wish to use-non-pulsed mig Short or Spray Arc, or Pulsed mig spray

arc, and/or Teach mode (with teach option only) for “selfdeveloped” Synergic Pulsed mig spray arc applications.

l

The strike time setting is dependent upon the “strike

IPM setting”. The lower the speed, the longer the strike

time needs to be, otherwise nuisance shutdowns will

occur.

- BURNBACK TIME. Manually adjustable burnback time period which when preset will over-ride the automatic adaptive anti-stick feature. This time period can be set in one

cycle increments. When set to “zero”, the Automatic Adaptive Anti-Stick feature will be operational.

- REPEAT TIME (or Pause Time). Time period preset between timed- welds from 1 to 999 cycles, in one cycle increments.

- RETRACT TIME. After the postflow cycle, the wire feed

motor will reverse for automatic wire retract for a preset

time period. A setting of 10 to 30 cycles is recommended

to prevent excessive withdrawal of the wire into the contact tip. If a normal stop is desired, preset this time for zero

cycles.

- ARC HOURS. Selectable display (record) of accumulative

welding time in one tenth of an hour increments. After 99.9

hours it will automatically return to zero.

- a pair of numbers represent WIRE DIA. sizes which are

programmed for selection as follows: #23 represents .023''

dia., and #30 is .030'' dia.; #35 is .035'' dia., #45 is .045''

dia. hard (3/64'' dia. soft) and #63 is .063'' (1/16'') dia.

- if provided, Pw indicates PULSE WIDTH which is displayed

as a “reference time” setting, from 1.0 to 10 (in one-tenth

millisecond increments), that measures or establishes the

width of pulse duration (in teach option only).

- if provided, Pf indicates PULSE FREQUENCY which is dis-

In the Short, Spray, or Pulse schedule modes, the operator must code the control to select any one of the

“preprogrammed” welding wire “Materials” and wire “Diameters”, and then set the desired wire feed speed (IPM)

for each of the four weld conditions (Strike, Start, Weld,

and Crater) required for the weldment--the control automatically provides the computed arc voltage parameters

to produce the necessary output for the process/conditions

selected.

The optional Teach schedule mode is used in conjunction

with the Teach Pulse Parameter switch (item C-7), and it

allows the operator to develop and store one complete set

of customized “pulsed-mig” parameters. These parameters

include a wire feed speed (ipm) and a Pulse Frequency

(PF) setting for each of the four weld conditions (Strike,

Start, Weld, and Crater) needed. The remaining teach parameters that must be programmed include a Pulse Background (PB) a Pulse Height (PH) and a Pulse Width (PW),

and these parameters are common to all four conditions.

The set-up procedure for using the “teach mode” is more

fully described in Section III-D of this booklet.

2. Condition Selector. This six-position rotary switch is used

to select two sets of parameters, Welding and Timing for

each of the available welding schedules (Short Arc, Spray

Arc, Pulse, or Teach).

a. Welding Parameters. The selector's primary function,

when used with the appropriate Inc./Dec. toggle, allows

you to preset and display (see II-B-5-b & c) the wire

feed speed (IPM) and computed arc voltage (VOLTS)

“weld” parameters for its first-four positions labeled --

11

Page 12

STRIKE, START, WELD, and CRATER. The fifth position of this selector has “no” label, but is the required

position used for presetting the Missweld and Retract

Time features. The sixth position of this selector, labeled

RUN, is the normal operating setting used after the control is fully programmed and ready for use. The IPM

and VOLTS l parameters, for each of the following “welding” conditions, are preset or adjusted using the INC./

DEC. toggle located directly below their respective digital

window displays.

- STRIKE. This condition sets the desired approach

speed of the wire before striking the workpiece, and

displays the computed voltagel needed to control

the short-circuit current for arc initiation.

- START. This condition can be used to set an appropriate wire speed and display the computed

l

voltage

parameter to create a “hot-start” to help

stabilize the arc (for its preset time) prior to the weld

cycle.

- WELD. This condition sets the desired wire speed

and displays the computed arc voltage

l

used dur-

ing the actual weld cycle.

- CRATER. This condition allows you to set a higher

or lower weld speed and/or displayed computed

arc voltagel (for a preset time period), depending

on the welding condition needed, to regulate the

weld termination size or crater-fill appearance at

the end of the weld.

l

In all Process modes (Short, Spray, or Pulse)

except Teach, the microprocessor “automatically” provides the correct arc voltage (in the

adaptive mode) or arc length/frequency (in synergic mode) for each welding combination -- for

additional information regarding the Adaptive

versus Synergic modes of operation, refer to

Section II-C-4.

b. Time Parameters. The secondary function of this se-

lector is to setup the “Time” parameters, located within

the charts adjacent to each of the weld conditions. These

“times” are preset by using the Times/Wire Dia.-Material selector (following).

3. Times-Wire Dia./Material Selector. This two-position, momentary “on”, toggle must be actuated in order to preset or

change the following parameters, or welding setups:

a. Access the “Time” Functions. This position actuates

the “timed-parameters” for the sequences shown in the

chart beneath each digital display window. These se-

quences are preselected by positioning the Condition Selector to the pair of time-parameters to be

programmed from its Strike, Start, Weld, and Crater

settings. To check or observe the time settings, actu-

ate the TIMES (up) position; and to set or change the

settings, simultaneously operate the INC./DEC. toggle

switch directly below the parameter (chart) being set -the time setting in cycles will appear in its digital display. The timed- parameters which can be programmed

in each display window are shown in Fig. 3, and were

previously described in Section II-B-5- b (IPM window)

and Section II-B-5-c (VOLTS window).

b. Access the WIRE DIA/MATERIAL mode (down posi-

tion) to select one of the welding conditions

preprogrammed into the control, as follows:

To select the type of wire MATERIAL, actuate the INC

position of the Inc/Dec switch below the IPM window

(while holding the Wire Dia/Mat'l key down) until the

desired code number for your “material selection” appears in the IPM window, and these material codes follow: #1 is carbon steel, #2 is alternate steel, #3 is 4043

aluminum, #4 is 5356 aluminum, #5 is 308 stainless,

#6 is silicon bronze. (Additional Material codes 7 thru

10, are reserved for custom applications.)

Now select the Wire DIA. size to be used, by actuat-

ing the INC position of the Inc/Dec switch below the

VOLTS window (while holding the Wire Dia/Mat'l key

down) until the desired pair of numbers for your “wire

size selection” appears in the VOLTS window, and these

wire diameter numbers follow: #23 is .023" dia., #30 is

.030" dia., #35 is .035" dia., #45 is .045" dia. hard

(3/64" dia. soft), and #63 is .063" (1/16" dia.).

NOTE: Accessing the WIRE DIA/MAT'L selector key “dur-

ing an actual weld,” allows you to check the factory- preset numbers that determine the quality

of starts (hot, cold, etc.) for your preset welding

condition. These numbers are preset to provide

optimum starting characteristics required for

most welding applications. This is a diagnostic

tool available to the experienced operator or serviceman and need not be activated during a normal operation unless you are experiencing weld

starting problems, or weld condition (speed and/

or voltage) aborting problems. It must also be

noted that only the speed (IPM) condition can be

checked when a unit is operating in the “synergic mode” (the VOLTS window will always displayed the number “100” and cannot be adjusted;

however, in the “adaptive mode” both speed and

voltage conditions can be checked and adjusted.

The factory-set “starting condition” is represented by numbers that are displayed, on command, in the digital IPM and VOLTS windows. For

good welds and starts, these numbers should

be in a range from 105 to 115 (with 110 being the

norm) in the IPM window (synergic and adaptive

mode), and from 90 to 100 (with 95 being the

norm) in the VOLTS window (adaptive mode

only). If your weld starts are not acceptable,

please refer Section III-C-10-b for a simple adjustment procedure that will enhance good starting.

4. Synergic-Adaptive-Inch Preset/Arc Hours Selector. This

switch provides three essential functions; depending on

the toggle-positions selected as follows:

a. The “toggle-down” location is a momentary on position

for checking or presetting a cold-wire INCH parameter

(50-999 ipm), or to monitor and reset the accumulated

ARC HOURS (welding) time. These features are only

functional when the control is in its non-welding mode.

To check or monitor this data, you must place the Con-

12

Page 13

dition selector switch in its RUN setting and toggle-down

the Inch Preset/A.H. function--the data will be displayed

in the IPM and VOLTS windows respectively. To set or

“zero” the data, place the Condition selector in its RUN

setting & actuate the Inch Preset/A.H. position while

simultaneously operating the Inc./Dec. switch below the

function being adjusted--this data will be displayed in

the appropriate IPM and/or VOLTS window.

b. The “toggle-center” location is a maintained ON posi-

tion for operating the control in the ADAPTIVE* logic

mode. The Adaptive logic utilizes a closed loop feedback system that continuously modifies the output to

maintain a constant arc voltage. The “adaptive operation” works as follows:

Pulse Arc Welding: Adaptive welding is a synergic relationship programmed into the weld control which will

calculate and display the proper arc voltage for a given

wire feed speed and material setting (see graph). As

the wire feed speed increases the control will automatically increase the pulse frequency to maintain the arc

voltage set in the control VOLTS window. Changes in

tip to work will not affect arc length.

voltage is set-up by the weld control program and

changes in tip to work will effect arc length. The voltage

can be read during welding and increased accordingly

to obtain a stable welding condition based on the wire

feed speed used. If the wire feed speed is changed,

the program will calculate the new voltage necessary

to maintain a stable arc.

* Please note that either type of logic (adaptive or syn-

ergic) can be used in the “preprogrammed” material

codes; however, only the synergic logic can be used

in the optional “Teach” process mode.

5. Inc/Dec Toggle Switches. These two control toggles are

used to preset or change the individual welding “Condition” parameters required for the selected “Process” mode

(Short, Spray, Pulse, and Teach). The switches are spring

loaded, center-return toggles which must be operated (Inc

or Dec) to actuate their indicated functions as follows:

Spray Arc and Short Arc: In this mode the machine

will control the power supply to maintain the arc voltage

set-up in the volts window of the control. Changes in tip

to work will not change arc length. The voltage can be

preset before welding and changed during welding to

obtain a stable welding condition based on the wire feed

speed used. If the wire feed speed is changed then the

program will calculate the new voltage necessary to

maintain a stable arc.

c. The “toggle-up” location is a maintained ON position

for operating the control in the SYNERGIC* logic mode.

The Synergic program logic provides the weld process

modes with fixed operating parameters that follow

preprogrammed relationships. The “synergic operation”

works as follows:

Arc Length Will Not Change

with Tip to Work Distance

Arc Volts

Frequency Changes

with Tip to Work Distance

Wire Feed (ipm)

Pulse Arc Welding: Synergic welding is a relationship

of pulse frequency and wire feed speed (see graph)

programmed into the weld control. As the wire feed

speed increases the control will automatically increase

the pulse frequency to maintain stable weld performance. Changes in welding current (heat) can be completed by increasing or decreasing the IPM switch without readjusting voltage. Changes in tip to work will affect arc length.

Spray Arc and Short Arc: In this mode the machine

will operate like a conventional welder where an arc

Arc Length Will Change

with Tip to Work Distance

Frequency Does Not

Change

with Tip to Work Distance

or

Arc Volts

(Spray/Short)

Pulse Frequency

Wire Feed (ipm)

a. “IPM-TIME” Increase/Decrease Control. This toggle

switch is used to set and/or vary wire feed speed (IPM)

for the required “weld conditions” (Strike, Start, Weld &

Crater), and also the following: Material-type, Preflow

(time), Start Time, Weld Time, Crater Time, Missweld

Time and Inch Preset (ipm), and Pulse Height (PH) and

Pulse Background (PB) in the optional teach mode. By

setting and/or operating the appropriate Control Selectors (see C-2 and -3 above), each parameter setting

will be displayed in the digital window directly above

this toggle.

b. “VOLTS-TIME” Increase/Decrease Control. This

toggle switch is used to set and/or vary the arc voltage*

(VOLTS), for the required “weld condition” (Strike, Start,

Weld & Crater), and also the following: Wire Diameter,

Postflow (time), Strike Time, Burnback Time, Repeat

Time, Retract Time and to “zero” (dec.) the Arc Hour

accumulation, and Pulse Width (PW) and Pulse Frequency (PF) in the teach mode. By setting and/or operating the appropriate Control Selector (see C- 2 and -3,

above), each parameter setting will be displayed in the

digital window directly above this toggle.

* Please note that the term VOLTAGE denotes “arc voltage”

(in the adaptive mode) and/or “arc length” (in the synergic

mode) and is the computed value that has been

precalculated for each of the combinations programmed

into the control. And further, any of these “computed voltages” can be altered (+/- 5 volts in the adaptive mode; and

+/- 50 numerals from its midrange value of 100 in the synergic mode) to fine tune each welding condition (Strike,

Start, Weld, & Crater).

13

Page 14

However, when a condition (e.g.: the Strike Condition) is

altered, the computed value is altered for all other

precalculated wire size/type combinations available in that

condition--the computed values for the remaining conditions (Start, Weld, Crater) are not affected unless they also

are altered. Therefore, when you plan to use a new com-

bination (a different wire size and/or type), it is suggested that the control be “reset” to provide the correct

computed value for the new program combination as follows:

Adaptive Mode. To reset the computed arc voltage value

for a given wire size and type, make sure the control's

Power switch is “on” and the unit is not in a welding mode,

then decrease the arc voltage key until the number in the

VOLTS window stops. This number is 5 volts below the

computed or midrange value. To establish the computed

value, add 5 (volts) to the displayed number using the increase (INC) portion of the Volts Inc./Dec. key.

Synergic Mode. Resetting the computed value in this

mode is much simpler--remember that the computed or

midrange value is the arbitrary numeral 100 (this number

represents a precalculated “arc length/frequency” based

on the wire feed speed of the programmed wire size and

type). Therefore, if the number appearing in the VOLTS

display window is any numeral between 50 and 150 (other

than 100) simply use the appropriate Inc./Dec. key to reset the condition to the numeral 100.

6. Amp Test-Weld Switch. This two-position toggle switch

provides the following functions:

a. The WELD position is the normal and required setting

for all schedule welding operations.

b. The AMP TEST position is only used to provide a con-

venient way of “test-sequencing” all of the program parameters to either diagnose a problem, or to demonstrate the control without actually striking a welding arc.

The test can be set up with the control operated in any

of its preprogrammed schedule modes (Short, Spray or

Pulse) that have a complete set of actual welding parameters preset, except for the “Missweld” time which

must be set to “zero”--otherwise an abort will occur.

With this accomplished, make sure that the welding wire

is clear of the workpiece/weldment and then open up

the accessory support (on the welding head) to release

pressure on the wire feed roll. Now place the Start-Stop

rocker switch (on the front panel) to its START position,

and the control will sequence thru the programmed

Preflow-time and enter the Strike condition--Remem-

ber that open-circuit or welding voltage is present

on the welding wire during the test sequence.

Make sure that the Strike Time is set long enough to

give you ample time to operate the “Amp” test toggle (a

setting of 200 cycles is recommended for the Strike

time).

During the Strike condition; you must actuate the “Amps”

toggle to its TEST position, to simulate closure of the

arc/current detection circuitry that verifies the arc has

initiated. This action automatically allows you to enter

the timed Start condition, and the subsequent Weld,

Crater, etc., conditions to evaluate and/or demonstrate

the welding sequence.

7. Teach Pulse Parameter Selector PH, PW, PB, PF (in

“teach” kit only). This momentary two-position switch is

only operative when the process (Short/Spray/Pulse/Teach)

control selector is placed in the Teach mode position (see

Item II-C-1). When the Teach Parameter switch is actuated, it allows you to program one complete set of customized (self-developed) pulsed- spray arc mig parameters. The subsequent teach parameter settings for Pulse

Height (PH) and Pulse Background (PB) are displayed in

the IPM window (and described in Section II-B-5-b); and

Pulse width (PW) and Pulse Frequency (PF) are displayed

in the VOLTS window (previously described in Section IIB-5-C). Please note that a Pulse Frequency (PF) parameter must be programmed for each wire feed speed (ipm)

setting selected for use in each of the four welding conditions (Strike, Start, Weld, and Crater). The remaining teach

parameters PH, PB, and PW are common to all four weld

conditions, and therefore only need to be programmed once

(for example, in the Strike mode). The set-up procedure

for the “teach mode” is fully covered in Section III-D.

III. SETTING UP PROGRAM PARAMETERS

A. GENERAL WELDING PROGRAM DATA

Four sets of welding (schedule) mode parameters can be preset in the Digipulse control: one each for the standard SHORT

arc, standard SPRAY arc and one for the PULSE (spray) arc

schedule modes using any one of the “preprogrammed” wire

material/diameters parameters; and one for the optional Teach

(pulse) schedule mode, which incorporates the customer's

“self- developed” pulsed welding parameters.

Because of the distinct differences between the

“preprogrammed” welding parameters (for the Short/Spray/

Pulse schedule modes) and the “self- developed” welding parameters (for the pulsed Teach schedule mode), the specific

“set-up procedures” for Short/Spray/Pulse control parameters

are covered in Section C, and the optional Teach control parameters in Section D following.

Since proper gas shielding is extremely important in conventional and pulsed welding applications, we have also provided

a list of recommended shielding gases (Table II-following) suggested for use with the wire material preprogrammed in this

control--however, you may find other combinations that are

equally successful.

B. PRELIMINARY POWER SUPPLY CHECKS

Before programming the control, make sure that the

power supply is properly set-up as follows:

- Check the rear panel of the power supply to make sure

that only the “Digipulse control cable” is connected. The

remaining “stick control receptacle/cable” must be dis-

connected.

- Depending on the welding process mode programmed on

the control, set the power supply INDUCTOR control pot

as follows:

14

Page 15

Table II

Recommended Shielding Gas

Wire Material Welding Arc Mode

Code # Type Short Arc Spray Arc Pulse Arc

1 Carbon Steel CO

2 Alternate Stl. C-25 Stargon/C-8 Stargon/C-5

3 4043 Aluminum - Argon Argon

4 5356 Aluminum - Argon Argon

5 308 Stainless A1025 1%/2%O

6 Silicon Bronze - Argon Argon

7*

8*

9*

10*

* These codes are reserved for custom applications.

/C25 C-5/C- 8 C- 5

2

Pulse SS

2

For SHORT ARC mode, set Inductance @ 12 O'clock position and adjust for best performance when welding.

For PULSE and SPRAY ARC and TEACH modes set Inductance @ MINIMUM.

C. PROGRAM CONTROL PARAMETERS FOR SHORT/

SPRAY/PULSE WELDING PROCESS MODES

The following procedures represent a typical example of how

to set up one of the many “preprogrammed” welding material

conditions available in this control, and that these procedures

can be used in each schedule mode--Short, Spray, and Pulse.

The only difference(s) between each “schedule mode” will,

or may, be the Wire Material and/or Wire Diameter used, the

IPM wire feed speed setting for each weld condition (Strike,

Start, Weld and Crater), the pair of Time parameters for each

weld condition, and the shielding gas used--the control automatically provides the required arc voltage for each weld condition, and even this parameter (voltage) can be fine-tuned

as described following.

1. Pull the POWER switch button to its “out” position to energize the control for programming.

2. On the inside panel, set the SHORT-SPRAY-PULSE mode

selector switch to the “process” you wish to preset.

3. Make sure the inside Amp Test toggled switch is in its WELD

position.

4. Select the type of Wire Material and Wire Diameter to be

used as follows. Depress and hold the WIRE DIA./MATERIAL toggle switch in its “down” position and simultaneously

preset each of the following:

a. Set the STRIKE “wire feed speed” (IPM) by operating

the “left” Inc./Dec. toggle until the desired setting appears in the IPM display window. Notice that this parameter setting will start at zero and immediately jump

to 20 and then rapidly increase (1 ipm at a time) until

the desired setting is reached. If you overshoot the

planned setting, simply “bump” the DEC position of the

left toggle to obtain the exact IPM setting.

b. As mentioned previously, after the welding condition in

items 4 and 5-a (above) have been preset, the microcomputer automatically sets a preprogrammed arc voltage (in the adaptive mode) or arc length/frequency (in

the synergic mode) for the STRIKE condition will be

displayed in the VOLTS window. If this precalculated

valuel (voltage or frequency) does not provide a stable

condition it can be fine-tuned by using the “right” Inc./

Dec. toggle switch--as described in Section II-C-5-b.

l

If the existing welding condition is altered (fine tuned),

it is suggested that each time a new wire size/type is

used that you reset the control to set up the original

computed (mid-range) arc voltage/frequency values as

described in Section II-C-5-b.

c. Leave the rotary selector in the “STRIKE” position to

set the PREFLOW and POSTFLOW “time” parameters

(as shown in Fig. 4). Actuate the “Times-Wire Dia./Mat.”

toggle switch to its TIMES (cycle) position, and observe

that the existing numbers shown in the IPM and VOLTS

windows will change--the new parameters being the pair

of “time” functions in the chart(s) adjacent to the selected condition (in this case, the pre- and postflow data).

To reset or change these “Time” parameters (see Fig. 4);

actuate and hold the TIMES toggle position, while simultaneously operating the appropriate INC./DEC. toggle switch

below each of the time parameters being set. The preset

time intervals will be displayed in their respective IPM and

VOLTS digital windows.

6. Reposition the rotary Condition selector to the START position and program the following:

a. Set the START “wire feed speed” (IPM) using the same

procedure outlined in III-C-5-a.

b. The subsequent “arc voltage” or “arc length/frequency”

for the START condition will be set as outlined in III-C5-b.

a. Operate (increase or decrease) the “left” Inc./Dec. toggle

switch (beneath the IPM window) until the desired MATERIAL numeral (1-carbon steel, 2-alternate steel, 34043 aluminum, 4-5356 aluminum, 5-stainless steel,

6-silicon bronze) appears in the IPM display window.

b. Now, operate (increase or decrease) the “right” Inc./

Dec. toggle switch until the desired WIRE DIA. numeral

(#23 for .023", #30 for .030" dia., #35 for .035" dia., #45

for .045" dia., or #63 for .063" dia.) appears in the VOLTS

display window.

5. Place the rotary Condition selector to the STRIKE position

and program the following:

Figure 4, Typical Time Parameter Set Up

15

Page 16

c. Leave the rotary selector in the START position and set

the START TIME and STRIKE TIME parameters using

the procedures outlined in III-C-5-c.

7. Reposition the rotary Condition selector to the WELD position and program the following:

a. Set the WELD “wire feed speed” (IPM) using the same

procedure outlined in III-C-5-a.“

b. The subsequent “arc voltage” or “arc length/frequency”

for the WELD condition will be set as outlined in III-C-5b.

c. Leave the rotary selector in the WELD position and set

the WELD TIME and BURNBACK TIME parameters

using the procedures outlined in III-C-5-c, and also the

following:

(1) “WELD TIME” setting requirements for:

(a) Continuous Seam Welding--set time to

“zero”.

(b) Single Time Weld without carriage travel (cus-

tomer must deenergize the arc detection output

signal)--set time from 1 up to 999 cycles.

(c) Single Time Weld with carriage travel (the Arc

Detector Circuit provides a signal to initiate travel

of a carriage, or fixture)--set time from 1 up to

999 cycles.

(d) Repeat Timed Weld (same as c) except that the

elapsed time between welds is preset in the REPEAT TIME PARAMETERS.

(2) “BURNBACK TIME” setting requirements:

(a) If automatic adaptive anti-stick is desired--set

time to “zero”.

(b) If manual burnback (anti-stick) is needed--set

time required from 1 cycle on up.

8. Reposition the rotary Condition selector to the CRATER

position and program the following:

a. Set the CRATER “wire feed speed” (IPM) using the same

procedures outlined in III-C-5-a.

b. The subsequent “arc voltage” or “arc length/frequency”

for the CRATER condition will be set as outlined in IIIC-5-b.“

c. Leave the rotary selector in the CRATER position and

set the CRATER TIMEl and REPEAT TIMEll parameters using the procedures outlined in III-C-5-c.

l

If the Weld and Crater conditions are both “Timed”;

simply preset the appropriate time desired for each

condition - 1 up to 999 cycles for Weld, and 1 up to 999

cycles for Crater.

If the Weld condition is a Continuous Seam weld, the

CRATER condition can either be “Timed” or skipped

completely. If Crater Fill is desired; enter from 1 to 999

cycle in the Crater Time parameter. If Crater fill is not

desired; simply enter “zero” in the Crater Time parameter, and this sequence will be skipped after the STOP

switch terminates the Weld condition sequence.

ll

Repeat Time--if repeat “timed weld” are not used, set

this time to “zero”. If repeat welds are desired, the

cycles set will control the elapsed time between the

“Timed” weld parameters.

9. Reposition the rotary Condition selector to the “blank” position, and program the following:

a. Set the MISSWELD TIME

l

and RETRACT TIME pa-

rameters using the procedures outlined in III-C-5-c.

l

The Missweld time cycle only monitors the WELD Condition. If not desired, set Missweld Time to “zero”.

10.Reposition the rotary Condition selector to the RUN position to perform the following operations:

a. To check or preset a cold-wire INCH parameter (50-

999ipm), or to monitor or “zero” the accumulated ARC

HOURS (welding) time. (These features are only functional in a non-welding mode.) To check or monitor

this data, you must place the Condition Selector switch

in its RUN setting and actuating the Inch Preset/Arc

Hrs. switch position*--the “data” will be displayed in the

IPM and VOLTS windows respectively. To set or “zero”

the data, place the Condition Selector in its RUN setting and actuate the Inch Preset/Arc Hrs. switch position* while simultaneously operating the Inc/Dec switch

below the function being adjusted--this data will be displayed in the appropriate IPM and/or VOLTS window.

* This momentary switch position (Arc Hrs/Inch Preset)

is part of the SYNERGIC-ADAPTIVE-ARC HRS/INCH

PRESET switch (covered in Section II-C-4). After the

control is fully programmed, the operator must set either the SYNERGIC or ADAPTIVE position to determine

the “program logic” that the control will utilize for the

programmed schedule sequence.

In the synergic mode, the control selects an appropriate arc length, based on weld mode (short, pulse or

spray), for a given wire type, size and feed rate. The

pulse frequency in pulse mode remains constant regardless of torch manipulation. This pulse logic offers

many advantages to the welder particularly where joint

geometry cause rapid changes in torch stickout resulting in unstable puddle conditions.

In the adaptive mode, the control varies the frequency

during pulse welding to maintain a constant arc voltage regardless of changes in torch stickout or angle.

This logic is very useful where joint geometry is clean.

b. The RUN position is the “normal operating setting” used

when the control is fully programmed and ready to be

weld- tested, and if necessary readjusted. If your weld

starts are not acceptable, refer to the following “Hot Start”

adjustment procedures that will enhance starting.

Hot Start Adjustment Procedures

As mentioned earlier in the italicized “Note” following Section

II-C-3-b, the control is preset at the factory to provide the optimum starting characteristic for most welding conditions. However, due to factors such as inaccurate parameters (for a given

wire type and size), welding technique, shielding gas, or wire

feed speed, you may have to readjust the factory-set starting

characteristics to provide the best arc starts possible. To do

this, it is necessary to readjust the factory-set calibrations to

provide a hot start characteristic in which the initial starting

voltage (open- circuit voltage) will be slightly higher than ac-

16

Page 17

tual welding voltage (arc voltage) and speed which initially is

somewhat lower than the selected wire feed speed desired.

To set-up the control to provide this, do the following:

Program the welding condition you need in the IPM (wire feed

speed) and VOLTS( arc voltage) windows, and fine-tune these

parameters until you have the welding arc desired. Do not at

this point concern yourself with the “arc starts”, this follows.

If after the welding condition is fine-tuned you find that the arc

starts are unsatisfactory, proceed as follows:

(1) During an actual weld, actuate and hold the Wire Dia/

Mat'l. key position and observe the numbers displayed

in the IPM and VOLTS windows.

Remember that only the speed (IPM) condition can

be checked when a unit is operating in the “synergic

mode” (the VOLTS window will always display the number “100” and cannot be adjusted); however, in the

“adaptive mode” both speed and voltage conditions

can be checked and adjusted.

(2) For proper starts, the number in the IPM window should

be in the range from 105 to 115. If it is not, adjust the

Inc/Dec toggle (below the IPM window) until the displayed number reads 110.

(3) Similarly, the number in the VOLTS window should be

in the range of 90 to 100. Again, if it is not, adjust the

Inc/Dec toggle (below the VOLTS window) until the

displayed number reads 95.

(4) These adjustments to the control should now provide

good arc starts to a legitimate welding condition.

(5) A good “rule-of-thumb” to follow whenever you set up

a new welding condition and you experience unstable

starts, is to simply check the start characteristic numbers (while welding) to make sure they are within the

ranges described in the preceding steps.

If you continue experiencing problems, refer to Troubleshooting procedures.

The following instructions assume that the operator is familiar with “pulse-mig” welding and the effects of pulse variables

with respect to arc performance.

The Pulse Height, Width, and Background parameter settings

(derived from the appropriate pulse parameter graphs) need

only be set once, in the STRIKE condition, because they are

common to all other weld conditions (START, WELD and CRATER). The Pulse Frequency parameter setting (also derived

from the appropriate graph examples) must be programmed

for each wire feed speed set in the IPM window for each weld

condition (Strike, Start, Weld & Crater). The metal transfer

and arc characteristics are defined by pulse height (PH), width

(PW) and background current (PB). These parameters, shown

in Figure 5, must be developed for each wire type, diameter,

shielding gas, and stickout. To maintain the proper arc characteristics once an appropriate pulse height, width and background have been established, the pulse frequency should

be the only parameter requiring readjustment with changes

in wire feed speed to maintain a stable arc condition. The

“teach” mode operates in the synergic logic “only” (not

adaptive), and only one wire feed speed and its respective

pulse frequency setting can be programmed in each weld

condition (Strike, Start, Weld, and Crater). Changes in wire

feed speed will require a manual adjustment to the pulse

frequency to maintain stable metal transfer. Since the op-

erator selects pulse parameters at a given point, the control

will not assume values at other wire feed speeds.

For the inexperienced operator, use the following graphs to

assist in pulse parameter set-up. These graphs will provide

you with pulse parameters used in the preprogrammed codes

(1-6). To obtain specific arc characteristics these parameters

can be set- up and changed in the teach mode. The following

procedure will achieve a reasonable starting point for pulse

welding in each “weld condition” (Strike, Start, Weld, and Crater).

1. Pull the POWER switch button, on the front panel, “out” to

energize the control.

2. Make sure the Amp-Test toggle switch (Item 2, Fig. 6) is in

WELD position.

D. PROGRAMMING YOUR OWN PULSE PARAMETERS IN

TEACH MODE (with Teach option kit).

The “teach” mode program is designed to allow the operator

to develop and store one set of customized Pulsed mig parameters* for wire types which have not been preprogrammed

in this control (for example; titanium, inconel, monel, etc.). In

some instances the preprogrammed carbon steel or stainless steel parameters may be inadequate, and the “teach”

mode can then be used to further refine those particular arc

characteristics.

* You may wish to permanently incorporate your “selfdeveloped” conditions in codes 7 thru 10 which are reserved for custom applications. If so, you can specialorder a custom E-PROM, from ESAB, that will include your

teach conditions along with the other preprogrammed

applications. In order to do this, you will have to provide

the necessary welding condition development parameters

outlined in Section E following.

Figure 5 - Pulse Wave Description

3. Set the Process control selector (Item 1, Fig. 6) in its

TEACH position.

17

Page 18

The selected Teach position automatically sets-up the control for Synergic pulse operation (and disables voluntary

selection of synergic/adaptive logic using toggle switch Item

3, Fig 6). At the same time, it “enables” the optional Pulse

Parameter program switch (Item 5, Fig. 6) to be operative

for programming the teach-pulse functions described following.

b. Using the pulse parameter graph(s), shown following