Page 1

INSTRUCTIONS for

F-15-240-A

April, 1997

DIGIMATIC II

FOUR SCHEDULE

MICROPROCESSOR

CONTROL

P/N 35635

FOR AUTOMATED MECHANIZED

MIG WELDING

SPECIFICATIONS

Input Power Required 7A., 115 volts, 50/60 Hz, 1 ph

Height 15.5-in. (394mm)

Depth 8-in. (200mm)

Width 13-in. (330mm)

Weight (approx.) 20-lbs. (9.1kg)

This manual provides complete instructions for the Digimatic II starting with Serial No. AF-I511029.

FEATURES/BENEFITS

n Presettable Wire Feed Speed (IPM) and Voltage

n Patented Microprocessor Controlled Closed Loop

F-15-240-A

n Four Presettable Welding Schedules...Unlike the

original single- schedule Digimatic II, this unit

allows you to preset up to four (4) completely

(VOLTS) ...Provides ability to easily and accurately preset the exact welding parameters desired, before the welding sequence begins!

System ...Provides most accurate means of maintaining wire feed speed (amperage) and welding

voltage. The microprocessor compensates for

deviations in ambient temperature, primary voltage fluctuation and changes in arc dynamics or

wire feed force conditions, to assure that preset

parameters are maintained.

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation

and safe practices for electric welding equipment, we urge you to read our booklet, "Precautions and Safe

Practices for Arc Welding, Cutting and Gouging," Form 52-529. Do NOT permit untrained persons to install,

operate, or maintain this equipment. Do NOT attempt to install or operate this equipment until you have read and

fully understand these instructions, contact your supplier for further information. Be sure to read the SAFETY

PRECAUTIONS on page 3 and 4 before installing or operating this equipment.

different welding schedules that can save control

setup time and improve productivity. By preset-

ting four of your most common welding require-

ments, all you have to do is switch weldments and

select the appropriate schedule for that particular

job.

n Eight Presettable Conditions Per Schedule...In

sequence, including, PREFLOW, STRIKE, START,

WELD, CRATER, ANTI-STICK (Burnback), POST-

FLOW and WIRE RETRACT. Total weld condition

presettability means improved weld quality and

productivity.

Be sure this information reaches the operator.

You can get extra copies through your supplier.

Page 2

USER RESPONSIBILITY

This equipment will perform in conformity with the description thereof contained in this manual and accompanying

labels and/or inserts when installed, operated, maintained and repaired in accordance with the instructions provided. This equipment must be checked periodically. Defective equipment should not be used. Parts that are

broken, missing, worn, distorted or contaminated should be replaced immediately. Should such repair or replacement become necessary, the manufacturer recommends that a telephone or written request for service advice be

made to the Authorized Distributor from whom purchased.

This equipment or any of its parts should not be altered without the prior written approval of the manufacturer. The

user of this equipment shall have the sole responsibility for any malfunction which results from improper use, faulty

maintenance, damage, improper repair or alteration by anyone other than the manufacturer or a service facility

designated by the manufacturer.

TABLE OF CONTENTS

Specifications ........................................................................................................................................................ 1

Features/Benefits ............................................................................................................................................... 1/5

Safety Precautions ............................................................................................................................................. 3/4

I. INSTALLATION ................................................................................................................................................ 5

A. Required Equipment ..................................................................................................................................... 5

B. Optional Accessories .................................................................................................................................... 6

C. Mount/Connect Equipment ............................................................................................................................ 8

II. CONTROL FUNCTIONS .................................................................................................................................. 8

A. Front Panel Controls ..................................................................................................................................... 8

B. Inside Panel Controls .................................................................................................................................. 10

C. Additional Program Controls ....................................................................................................................... 12

III.PRESETTING WELDING SCHEDULES ........................................................................................................ 12

IV. WELDING SEQUENCE ................................................................................................................................ 14

V. TROUBLESHOOTING.................................................................................................................................... 15

VI. REPLACEMENT PARTS DATA .................................................................................................................... 19

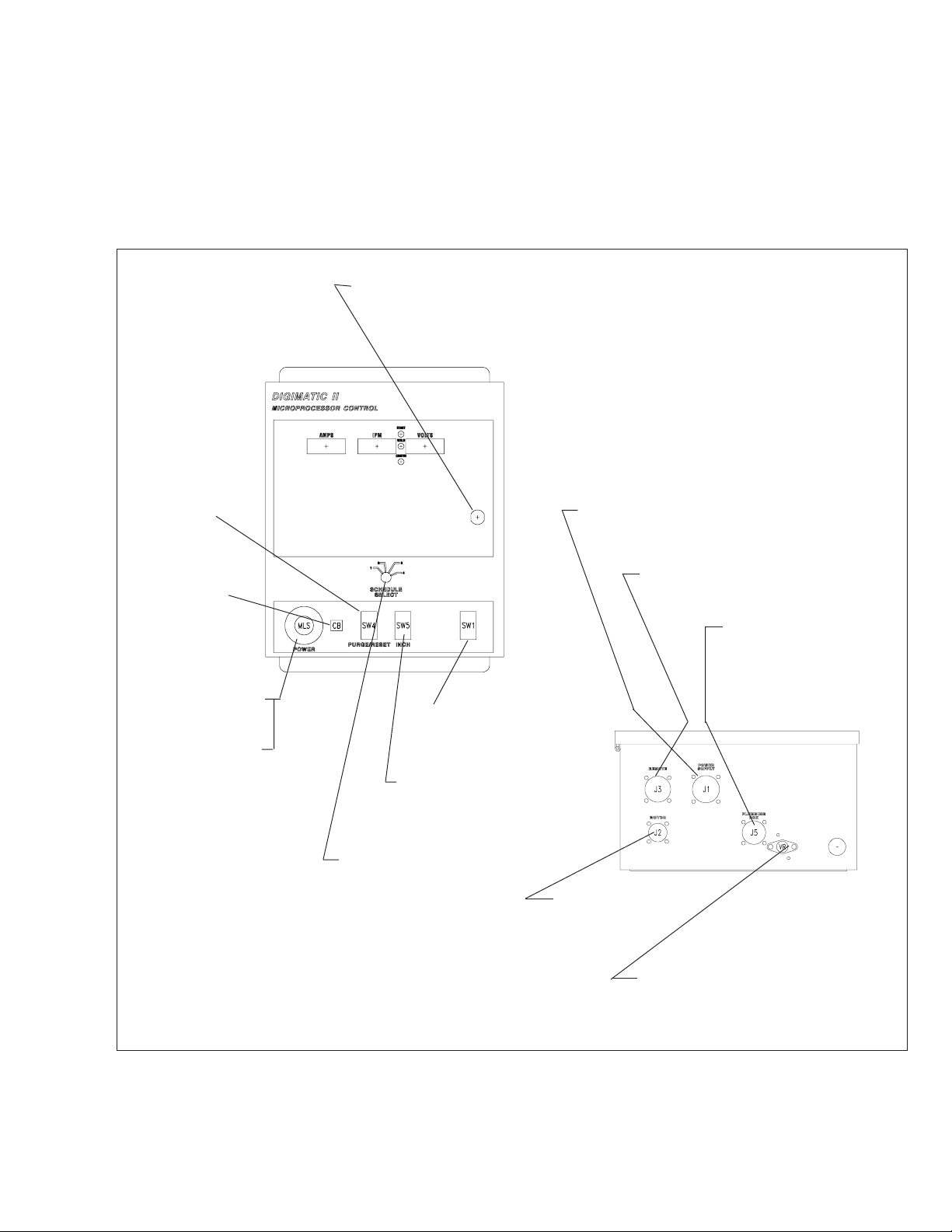

Figure 1 - Interconnection Diagram .................................................................................................................. 7

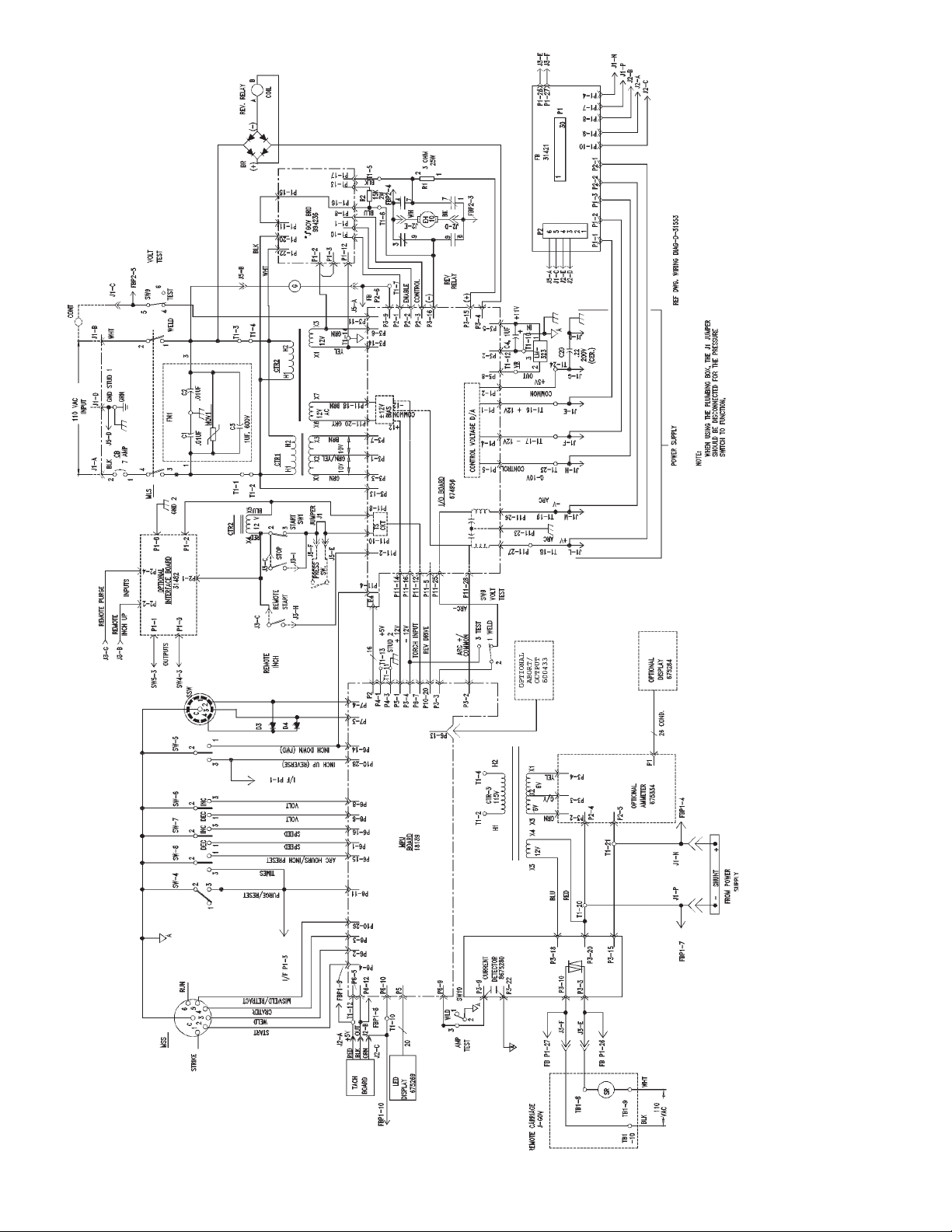

Figure 2 - Front Panel Controls ........................................................................................................................ 8

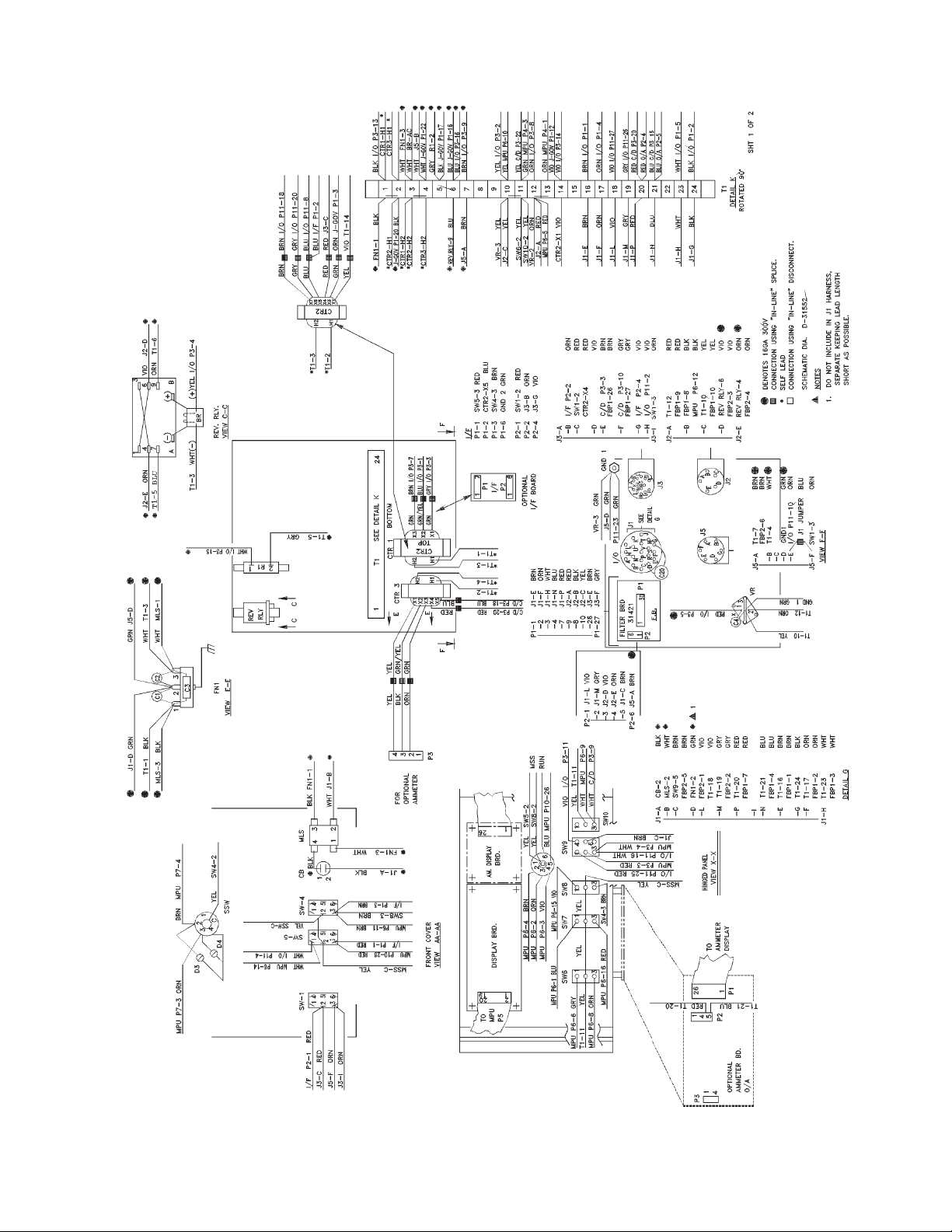

Figure 3 - Inside Panel Controls ...................................................................................................................... 11

Figure 4 - MPU Dip Switch Location ................................................................................................................ 12

Figure 4-A - Typical Time Parameter Setup .................................................................................................... 12

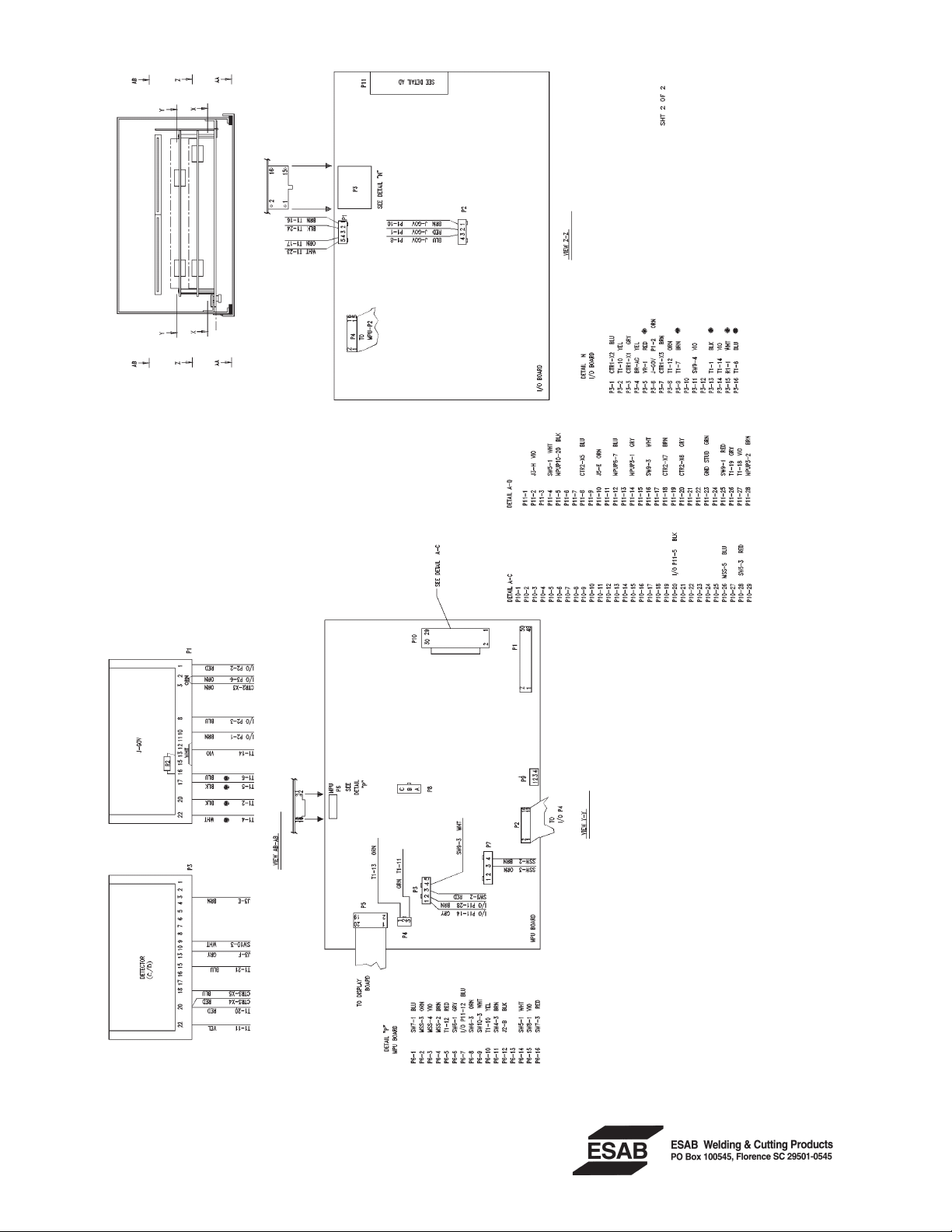

Figure 5 - Typical Weld Condition Sequence Per Schedule ............................................................................ 15

Figure 6 - Sequential Troubleshooting Flow Diagram ...................................................................................... 18

Figure 7 - Control Assy. Replacement Parts/External ..................................................................................... 19

Figure 8, 9 - Control Assy. Replacement Parts/Internal ................................................................................... 20

Figure 10 - Plumbing Box Replacement Parts ................................................................................................. 21

Figure 11 - Control Schematic Diagram .......................................................................................................... 22

Figure 12, 13 - Control Wiring Diagrams .................................................................................................... 23/24

2

Page 3

SAFETY PRECAUTIONS

WARNING: These Safety Precautions are for

your protection. They summarize precautionary information from the references listed in

Additional Safety Information section. Before

performing any installation or operating procedures, be

sure to read and follow the safety precautions listed below

as well as all other manuals, material safety data sheets,

labels, etc. Failure to observe Safety Precautions can result

in injury or death.

PROTECT YOURSELF AND OTHERS

Some welding, cutting, and gouging

processes are noisy and require ear

protection. The arc, like the sun, emits

ultraviolet (UV) and other radiation and

can injure skin and eyes. Hot metal can cause burns.

Training in the proper use of the processes and equipment is essential to prevent accidents. Therefore:

1. Always wear safety glasses with side shields in any work

area, even if welding helmets, face shields, and goggles

are also required.

2. Use a face shield fitted with the correct filter and cover

plates to protect your eyes, face, neck, and ears from

sparks and rays of the arc when operating or observing

operations. Warn bystanders not to watch the arc and

not to expose themselves to the rays of the electric-arc

or hot metal.

3. Wear flameproof gauntlet type gloves, heavy long-sleeve

shirt, cuffless trousers, high-topped shoes, and a welding helmet or cap for hair protection, to protect against

arc rays and hot sparks or hot metal. A flameproof apron

may also be desirable as protection against radiated

heat and sparks.

4. Hot sparks or metal can lodge in rolled up sleeves,

trouser cuffs, or pockets. Sleeves and collars should be

kept buttoned, and open pockets eliminated from the

front of clothing

5. Protect other personnel from arc rays and hot sparks

with a suitable non-flammable partition or curtains.

6. Use goggles over safety glasses when chipping slag or

grinding. Chipped slag may be hot and can fly far.

Bystanders should also wear goggles over safety glasses.

FIRES AND EXPLOSIONS -- Heat from

flames and arcs can start fires. Hot slag

or sparks can also cause fires and explosions. Therefore:

1. Remove all combustible materials well away from the

work area or cover the materials with a protective nonflammable covering. Combustible materials include wood,

cloth, sawdust, liquid and gas fuels, solvents, paints and

coatings, paper, etc.

2. Hot sparks or hot metal can fall through cracks or

crevices in floors or wall openings and cause a hidden

smoldering fire or fires on the floor below. Make certain

that such openings are protected from hot sparks and

metal.“

3. Do not weld, cut or perform other hot work until the

workpiece has been completely cleaned so that there

are no substances on the workpiece which might produce flammable or toxic vapors. Do not do hot work on

closed containers. They may explode.

4. Have fire extinguishing equipment handy for instant use,

such as a garden hose, water pail, sand bucket, or

portable fire extinguisher. Be sure you are trained in its

use.

5. Do not use equipment beyond its ratings. For example,

overloaded welding cable can overheat and create a fire

hazard.

6. After completing operations, inspect the work area to

make certain there are no hot sparks or hot metal which

could cause a later fire. Use fire watchers when necessary.

7. For additional information, refer to NFPA Standard 51B,

"Fire Prevention in Use of Cutting and Welding Pro-

--

cesses", available from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

ELECTRICAL SHOCK -- Contact with live

electrical parts and ground can cause

severe injury or death. DO NOT use AC

welding current in damp areas, if movement is confined, or if there is danger of

falling.

1. Be sure the power source frame (chassis) is connected

to the ground system of the input power.

2. Connect the workpiece to a good electrical ground.

3. Connect the work cable to the workpiece. A poor or

missing connection can expose you or others to a fatal

shock.

4. Use well-maintained equipment. Replace worn or damaged cables.

5. Keep everything dry, including clothing, work area, cables,

torch/electrode holder, and power source.

6. Make sure that all parts of your body are insulated from

work and from ground.

7. Do not stand directly on metal or the earth while working

in tight quarters or a damp area; stand on dry boards or

an insulating platform and wear rubber-soled shoes.

8. Put on dry, hole-free gloves before turning on the power.

9. Turn off the power before removing your gloves.

10. Refer to ANSI/ASC Standard Z49.1 (listed on next page)

for specific grounding recommendations. Do not mistake

the work lead for a ground cable.

ELECTRIC AND MAGNETIC FIELDS —

May be dangerous. Electric current flowing through any conductor causes localized Electric and Magnetic Fields

(EMF). Welding and cutting current creates EMF around welding cables and

welding machines. Therefore:

1. Welders having pacemakers should consult their physician before welding. EMF may interfere with some pacemakers.

2. Exposure to EMF may have other health effects which are

unknown.

3. Welders should use the following procedures to minimize

exposure to EMF:

A. Route the electrode and work cables together. Secure

them with tape when possible.

B. Never coil the torch or work cable around your body.

C. Do not place your body between the torch and work

cables. Route cables on the same side of your body.

D. Connect the work cable to the workpiece as close as

possible to the area being welded.

E. Keep welding power source and cables as far away

from your body as possible.

3

11/95

Page 4

FUMES AND GASES -- Fumes and

gases, can cause discomfort or harm,

particularly in confined spaces. Do

not breathe fumes and gases. Shielding gases can cause asphyxiation.

Therefore:

1. Always provide adequate ventilation in the work area by

natural or mechanical means. Do not weld, cut, or gouge

on materials such as galvanized steel, stainless steel,

copper, zinc, lead, beryllium, or cadmium unless positive

mechanical ventilation is provided. Do not breathe fumes

from these materials.

2. Do not operate near degreasing and spraying operations. The heat or arc rays can react with chlorinated

hydrocarbon vapors to form phosgene, a highly toxic

gas, and other irritant gases.

3. If you develop momentary eye, nose, or throat irritation

while operating, this is an indication that ventilation is not

adequate. Stop work and take necessary steps to improve ventilation in the work area. Do not continue to

operate if physical discomfort persists.

4. Refer to ANSI/ASC Standard Z49.1 (see listing below)

for specific ventilation recommendations.

CYLINDER HANDLING -- Cylinders, if

mishandled, can rupture and violently

release gas. Sudden rupture of cylinder, valve, or relief device can injure or

kill. Therefore:

1. Use the proper gas for the process and use the proper

pressure reducing regulator designed to operate from

the compressed gas cylinder. Do not use adaptors.

Maintain hoses and fittings in good condition. Follow

manufacturer's operating instructions for mounting regulator to a compressed gas cylinder.

2. Always secure cylinders in an upright position by chain

or strap to suitable hand trucks, undercarriages, benches,

walls, post, or racks. Never secure cylinders to work

tables or fixtures where they may become part of an

electrical circuit.

3. When not in use, keep cylinder valves closed. Have

valve protection cap in place if regulator is not connected. Secure and move cylinders by using suitable

hand trucks. Avoid rough handling of cylinders.

4. Locate cylinders away from heat, sparks, and flames.

Never strike an arc on a cylinder.

5. For additional information, refer to CGA Standard P-1,

"Precautions for Safe Handling of Compressed Gases in

Cylinders", which is available from Compressed Gas

Association, 1235 Jefferson Davis Highway, Arlington,

VA 22202.

EQUIPMENT MAINTENANCE -- Faulty or improperly maintained equipment can cause

injury or death. Therefore:

perform any electrical work unless you are qualified to

perform such work.

2. Before performing any maintenance work inside a power

source, disconnect the power source from the incoming

electrical power.

3. Maintain cables, grounding wire, connections, power cord,

and power supply in safe working order. Do not operate

any equipment in faulty condition.

4. Do not abuse any equipment or accessories. Keep

equipment away from heat sources such as furnaces, wet

conditions such as water puddles, oil or grease, corrosive

atmospheres and inclement weather.

5. Keep all safety devices and cabinet covers in position and

in good repair.

6. Use equipment only for its intended purpose. Do not

modify it in any manner.

ADDITIONAL SAFETY INFORMATION -- For

more information on safe practices for electric arc welding and cutting equipment, ask

your supplier for a copy of "Precautions and

Safe Practices for Arc Welding, Cutting and

Gouging", Form 52-529.

The following publications, which are available from the

American Welding Society, 550 N.W. LeJuene Road, Miami,

FL 33126, are recommended to you:

1. ANSI/ASC Z49.1 - "Safety in Welding and Cutting"

2. AWS C5.1 - "Recommended Practices for Plasma Arc

Welding"

3. AWS C5.2 - "Recommended Practices for Plasma Arc

Cutting"

4. AWS C5.3 - "Recommended Practices for Air Carbon Arc

Gouging and Cutting"

5. AWS C5.5 - "Recommended Practices for Gas Tungsten

Arc Welding“

6. AWS C5.6 - "Recommended Practices for Gas Metal Arc

Welding"“

7. AWS SP - "Safe Practices" - Reprint, Welding Handbook.

8. ANSI/AWS F4.1, "Recommended Safe Practices for Welding and Cutting of Containers That Have Held Hazardous

Substances."

This symbol appearing throughout this manual

means Attention! Be Alert! Your safety is

involved.

The following definitions apply to DANGER, WARNING,

CAUTION found throughout this manual:

Used to call attention to immediate hazards which, if not avoided, will result in

immediate, serious personal injury or loss

of life.

Used to call attention to potential hazards which could result in personal injury

or loss of life.

1. Always have qualified personnel perform the installation, troubleshooting, and maintenance work. Do not

Used to call attention to hazards which

could result in minor personal injury.

4

Page 5

n Sure Start Interlock...To assure troublefree starts,

the Digimatic II has an interlock circuit which will

not allow wire feed to initiate unless the power

source contactor is closed and STRIKE voltage is

present.

n Presettable STRIKE Time...Assures safe consis-

tent starts. If for any reason the Strike Time is

exceeded (wire does not feed or misses the work)

the Digimatic II will automatically shut down and

flash the preset STRIKE TIME in the VOLTS display window.

n Arc Detector Circuit...Senses that both Welding

Voltage and Amperage are present to facilitate

transfer from Strike to Start condition parameters, and also provide a signal to initiate travel of

a carriage or fixture.

n Automatic Controlled Shutdown ...To assure

that all welding is performed only at the preset

parameters, Digimatic II will automatically shutdown in the rare event that either voltage or wire

feed speed cannot be maintained during the welding sequence.

n The Digimatic II will always sequence through a

controlled shutdown including dynamic motor

brake, anti-stick and postflow. Simultaneously,

the cause is indicated by a flashing VOLTS or IPM

display.

n Automatic Adaptive Anti-Stick or Manual Burn-

back Time Feature...The adaptive anti-stick feature automatically adjusts the same amount of

wire burnback, regardless of wire size, speed or

voltage. Or, you can manually preset a Burnback

Time to specifically suit a specialized application.

n Missweld Time...depending on the criticality of

the weld, this feature allows you to preset the

number of cycles of arc time that can reasonably

be missed during a welding condition and still

produce an acceptable weld. If more than the

allowable number of arc cycles are missed, the

unit will shutdown/abort and flash the preset

Missweld Time cycles in the IPM display window.

n Wire Retract Feature...Provides the ability to pre-

set a Wire Retract time which will assure that the

wire is well removed from the work area and not

subject to possible postweld bending due to contact with the workpiece or fixture.

n Independent Presettable Cold Wire Inch...To re-

duce down time for reloading welding wire, the

Digimatic II cold wire Inch speed can be independently adjusted (up to 999 ipm) without affecting

any of the other preset welding conditions.

n Circuit Protection...Resettable circuit breaker for

115 VAC, 50 or 60 HZ input power minimizes down

time and maintenance.

n Remote Control Capabilities...To provide easy

interfacing with fixtures, the Digimatic II incorporates remote Start/Stop and Wire Inch Capabilities which can be controlled by switches or relays at a central control panel.

n Single or Repeat Timed Weld Capabilities ...Be-

cause the Digimatic II incorporates a Repeat weld

timer, adjustable up to 999 cycles (16.5 seconds),

the Digimatic II offers more than conventional

continuous seam, or Single Times welding capabilities. It can also be preset for Repeat Timed

skip or stitch welding applications.

n Individual Digital Meters Provide Large 1/2-in.

Display of Voltage And Wire Feed Speed

IPM...After the arc is struck, the meters automatically transfer from preset to display of actual

VOLTS and IPM for each welding condition as the

Digimatic II sequences through the preset welding sequence.

n Arc Hours Readout...This unique feature pro-

vides a direct measure of productivity by accumulating and displaying, upon command, actual

welding Arc Hours.

n Unique Diagnostic Set-up/Test Circuit...Provides

the ability to totally test the Digimatic II electronics as well as run it through a complete timed

sequence of preset weld conditions without actually welding.

I. INSTALLATION

A. EQUIPMENT REQUIRED

1. Digimatic II Four-Schedule Control Assy. P/N

35635.

2. EH-10A Digital Welding Head (20-999 IPM). The

welding head is composed of three basic units; a wire

feed motor- tachometer unit, a gear reduction unit,

and the accessory support assembly. This control (4schedule) is only usable with a EH-10A Digital Welding Head, and either of two welding head (following)

are available for use. The wire sizes accommodated

are:

Hard .................................. .030 -1/8-in. (.8 - 3.2mm)

Soft ................................. .030 - 3/32-in. (.8 - 2.4mm)

Flux Core........................ .045 - 1/8-in. (1.2 - 3.2mm)

5

Page 6

a. Two Roll Drive EH-10A Head - P/N 600416.

This head provides wire feed speeds from 20 999 IPM using a 40:1 gear reduction ratio, and a

two-roll accessory support wire drive. The motortachometer power and control leads are provided

by a pair of 52 inch long cables connected to a 5pin amphenol. For further information refer to

booklet F-12-873.

a. R-5007 Argon Regulator/Flowmeter, P/N 998124.

b. Heavy Duty Gas Hose, P/N 19416 (12-1/2-ft.), or

P/N 19415 (25-ft.).

c. Gas Hose Coupling, P/N 11N17.

8. Water Cooling Requirements. When using a water

cooled torch (ST-16 and ST-21), the following are

required to supply and drain the cooling water:

b. Four Roll Drive E-10A Head - P/N 600417. This

head is the same as P/N 600416, except that it

incorporates a four- roll accessory support wire

drive assembly. For further information, refer to

booklets F-12-873 and F-12-821.

NOTE: If the motor direction is to be changed, inter-

change the blue and orange wires on T1-5 and

T1-6 positions on the terminal strip.

3. Feed Rolls. Select the proper feed roll, for the wire

size to be used, from the data provided in booklets F12-873 and F-12-821.

4. Constant Voltage Power Source. In order to use

the Digimatic II Control, it must be operated with

C.V. power sources designed with electronically

controlled arc voltage regulation, such as:

ESAB 452 cv, P/N 36000

ESAB 652 cvcc, P/N 36004

ESAB SVI-450i cvcc, P/N 31950

5. Welding Torch. A mechanized mig welding torch

having a rated capacity suitable for the welding application, such as:

a. ST-16 Water-Cooled Torch (for currents up to 600

amps) P/N 997498, or

b. ST-21M Water-Cooled Mechanized Torch (for cur-

rents up to 600 amps.) P/N 690509.

6. Power Source Control Cable (J1) Assembly.

Depending on the type of power source used (transformer- rectifier/SCR, or inverter), one of the following control cables is required.

a. 19-conductor control cable with 19-pin amphenol

plug each end order one of the following cables:

P/N 30686, 6-ft. long assembly.

P/N 30780, 30-ft. long assembly.

P/N 30781, 60-ft. long assembly.

7. Shielding Gas Regulation. A gas regulator/flowmeter and fitted hose are required to bring gas to the

torch, such as:

a. Water Hose, 12-1/2-foot, P/N 40V76or,

b. Water Hose, 25-foot, P/N 406196.

c. Water (In/Out) Adaptor (Connects hose to 1/4

NPT), P/N 11N16.

d. Water Hose Coupling, P/N 11N18.

B. OPTIONAL ACCESSORIES

1. Digital D.C. Ammeter Kit, P/N 679111. This kit

permits direct visual indication of welding current up

to 999 amps d.c., and is available as a field

installed option. The kit is designed for easy snapon/plug-in installation and consists of an LED Display P/C Board (P/N 675284), an Ammeter Control

P/C Board (P/N 675334), and assorted mounting

hardwarefor installation refer to booklet F-14-220.

2. Remote Control Cable (J3) Assembly; 25-ft. lg.,

P/N 30499. This cable assembly is used in conjunc-

tion with optional Interface Board Assembly, P/N

31482, and/or Abort/Output Board Assembly, P/N

600433. The combination provides remote wire inch-

ing, purge, start-stop, current detecting, and abort

output functions. See Fig. 9 for mounting location of

the board assemblies. The cable assembly is a 12conductor cable with a 14-pin amphenol plug on one

end and self-lead wire connections at the other end

for customer hook-up .

3. Plumbing Box Control Cable (J5) Assembly;

4 1/2-ft. lg. P/N 948273, or 25-ft. lg. P/N 678037.

This cable provides connections to energize solenoid valves for gas shielding and water cooling (if

connected) during the preflow, welding and postflow

cycles. It also provides as interlock to a pressure

switch in the water line which will shutdown the

control if the supply to a water-cooled torch is inadequate. This assembly is a 6-conductor cable with a

6-pin amphenol to self-lead wire connections.

4. Motor-Tachometer Extension Cable Assembly, P/N 996808. This assembly allows you to ex-

tend the welding head location using a 25-foot, 6

conductor cable (1-conductor not used) with a 5pin amphenol plug (which connects to the controls

J2 receptacle) and an 5-pin amphenol receptacle

(which connects to the EH-10s plug).

6

Page 7

DIGIMATIC II CONTROL

POWER SOURCE CONTROL

CABLE ASSYS. (19C., PIN)

30-FT. - 30780

60-FT. - 30781

To be used with Optional Interface Board

31482 and/or Abort Output Board 600433.

POWER

SOURCE

NOTES:

1. Both output welding cable leads (torch and work) must be a minimum size of No. 4/0 welding cable (nothing smaller), and both leads should

be kept as close to the same length as possible with neither lead exceeding 50-ft. in length. Also, both cables must be run next to each

other and tywrapped every couple of feet to minimize cable reactance.

2. If wire feed runs backwards, reverse motor direction as follows: in the control, disconnect the blue wire (RLY-7) from T1-5 and connect it to

T1-6; disconnect orange wire (RLY-9) from T1-6 and connect it to T1-5.

3. As shipped from the factory, the control is wired for air-cooled torch operation and this is provided by an insulated jumper splice connection

between pins J5-E and -F of the controls plumbing box receptacle J5. When water-cooled torch operation is to be used with the plumbing box,

the jumper splice (between J5-E and -F) must be disconnected because these pins will be connected across the water pressure switch in the

plumbing box. Also note that the pressure switch is factory-connected for normally-closed (NC) operation, and must be reconnected for

normally-open (NO) operation as shown above and in the schematic and detail wiring diagrams.

Figure 1 - Interconnection Diagram

7

Page 8

5. Gas and Water Solenoid Valves, P/N 636386.

Used to control flow of shielding gas and cooling

water.

6. Reel/Spindle Support, P/N 634288. This support

arm is utilized to mount either wire spools or coils. Will

mount to any fixture or to the OM-48 carriage when

the required support adaptor P/N 996498 is used.

7. Spindle Assy., P/N 948259. Mounts to Item 6 above

and is used for 12-in. diam. spools.

8. H.D. Spoke-Type Wire Reel, P/N 19V89. Mounts to

Item 6 above and is used for 65 lb coils.

A

A

7

6b

A

6a

A

6c

9. Spool Enclosure Kit, P/N 600240, covers and

protects 12-in. spools from dust and moisture.

10. WC-9 Coolant Circulator, P/N 33540 For use with

water cooled torches such as the ST-21. A fourgallon tank provides 1.0 gal/min. at 50 psi pump

capacity, using 115 volts, 50/60 Hz input.

11. Plumbing Box, P/N 677261 (for ESAB Water

Cooled Torches)

Plumbing Box, P/N 34749 (for other Water Cooled

Torches

The plumbing box assembly contains the solenoid

valves which provide shielding gas and cooling water

control. It is also equipped with a pressure switch in the

water line which (if connected) will shut down the

welding operation when the water supply is inadequate (see Fig. 1).

C. MOUNTING/CONNECTING THE EQUIP-

MENT

Since the operating controls are mounted on and

inside the Digimatic front panel, the box should be

located so that the meters and controls are within

easy reach of the operator. The control can be

mounted on a side-beam carriage or other vertical

surface by using the mounting holes provided.

For complete Interconnection Diagram of the

Digimatic II Control with all required and/or optional

related accessories, see Figure 1.

II. CONTROL FUNCTIONS

A. FRONT PANEL CONTROLS

For location of control features refer to Fig. 2.

1. Power Switch. Pulling-out the mushroom-style

red button of this switch turns power on in the control

as indicated by the illuminated display windows. To

turn power off, simply push-in the red button and the

display windows and control will deenergize.

A

1

A

8

Figure 2 - Front Panel Controls

A

2

A

4

NOTE: Immediately after the control is turned on,

a number (e.g.:3) will appear in the IPM read

and will only be displayed for 1-second.

This information identifies the current program (E-PROM) used in your control. When

a Program is changed, the new E-PROM will

automatically indicate a 2,3, etc. to identify

the program number being used. If a revision is made to an existing program, a decimal number .1,.2,.3, etc. indicating the

numerical revision will also appear in the

VOLTS readout window simultaneously.

2. Gas Purge/Reset Rocker. A momentary on switch,

this rocker provides a dual function when actuated.

a. Prior to starting the welding sequence, it

actuates the gas solenoid and lets you purge

the shielding gas line of the torch. At the same

time, the IPM and VOLTS windows will also display the preset times (in cycles) for gas preflow

and gas postflow respectively.

b. After starting the welding sequenceif an abort

shutdown condition occurs (indicated by flashing digital display), the Purge/Reset rocker

can be actuated and the control will automatically

reset for a new start.

8

A

3

A

5

Page 9

3. Schedule Select Switch. This four-position rotary

switch allows you to program and select Schedule

No. 1 and program (using the Condition Selector,

section II-B-1) a complete welding sequence for a

particular application. All of the remaining schedules

(No. 2, No. 3 or No. 4) can be programmed in the

same manner for each different welding application.

4. Inch Up-Down Rocker. This switch is used to cold

inch the wire, up or down, as a preset speed which

you have programmed on the inside panel (II-B-2-b).

IMPORTANT: Cold inching is only possible when the

weld Start-Stop rocker switch is in its

stop (or off) position.

5. Start-Stop Rocker. This two-position (no neutral)

switch initiates the welding sequence when placed in

its START position; and, depending on the type of

weldingSeam or Timed, terminates the welding

sequence in its STOP position as follows (for typical

setup procedures, refer to Section IV-F):

minute, in one-inch increments for each weld condition in the program sequence.

* With power turned ON, but not welding, the IPM

window will continuously read the Preset STRIKE

Condition wire speed setting. When the arc is struck,

the IPM window will then continuously read the Actual

welding wire speed as the weld conditions cycle thru

the welding sequence.

In addition to the above, and using the Condition and

Time selector controls on the inner panel (functionally

defined in II-B), this window can also display the following programmed times:

- PREFLOW. Shielding gas time from 0 to 999 cycles,

(16.5 sec.) in one cycle increments (60 cycles per

second).

- START TIME. Start time duration is factory preset at

6 cycles, and can be increased up to 999 cycles, in

one cycle increments.

a. Seam welding applications. The stop signal does

not immediately terminate the welding sequence.

It only terminates the weld condition. The sequence then transfers to the remaining conditions (crater fill, burnback, postflow/retract).

b. Single or Repeat T imed welding applications.

Although the stop signal is not normally used for

timed-welds, you may wish to prematurely terminate a burn-thru or unstable weld condition. When

the stop is used; all welding action (including

craterfill) will terminate, except burnback and

postflow/retract).

6. Digital Readout Windows. Three individual 3- digit

windows labeled AMPS (optional ammeter), IPM and

VOLTS are provided to display actual welding current, preset or actual welding parameters (wire feed

speed and welding voltage) and time parameters as

follows:

a. AMP Digital Readout. This window is normally

blank unless the optional Ammeter Kit is provided

to monitor actual welding current. When installed,

the window displays D.C. current (AMPS) in a

range from 0 - 999 amperes in one amp increments.

b. IPM Digital Readout. This window is primarily

used to display wire feed speed (IPM) for each of

the four welding conditions (Strike, Start, Weld,

and Crater) during a typical welding sequence.

Depending on the position of the inside condition

selector switch (functionally defined in II-B); the

IPM window displays actual and/or preset wire

feed speed in a range from 20 to 999 inches-per-

- WELD TIME. Weld condition duration for timedwelding (must be set to zero for Continuous-Seam

Welding), from 1 to 999 cycles, in one cycle

increments.

- CRATER TIME. Crater fill duration, from 1 to 999

cycles, in one cycle increments.

- MISSWELD TIME. Presets the number of cycles of

arc time that can reasonably be missed (from 1 up to

999 cycles) during the WELD condition and still produce an acceptable weld. If the number of missed

cycles match the preset cycles, the unit will abort.

Since the number of missed cycles to be preset

is based upon many variables, the required setting

for a given application obviously involves good judgment and technique. As an example, to set up a

critical 45 cycle spot weld, you might want to preset no

more than 5 cycles of missweld arc time. Be careful

not to make the missweld time too short, otherwise

nuisance aborts will occur. If this feature is not

desired, preset the time for zero cycles.

- INCH PRESET. Cold wire inch speed from 50 to 999

inches-per- minute, in one inch increments.

c. VOLTS Digital Readout. This window is primarily

used to display arc voltage (VOLTS) for each of the

four welding conditions (Strike, Start, Weld, and

Crater) during a typical welding sequence. Depending on the position of the inside Condition Selector

switch (functionally defined II-B); the VOLTS window displays actual and/or preset arc voltage range

from 12 to 50 vdc, in one-tenth (0.1) volt increments, for each weld condition in the program

sequence.

9

Page 10

* With the power turned ON, but not welding, the VOLTS

window will continuously read the Preset STRIKE

condition voltage setting. When the arc is struck, the

VOLTS window will then continuously read the Actual

welding voltage as the weld conditions cycle thru the

welding sequence.

In addition to the above, and using the inside "Condition"

and "Time" selector controls (functionally defined in IIB), this window can also display the following programmed

times:

Start, and after the Crater Conditions, none of

these lights will be on .

8. Reset Circuit Breaker. A seven (7) ampere circuit

breaker provides protection to the 115 volt control

circuit and the wire feed motor. If an overload occurs,

the breaker will trip and suspend all operation. To

restore service, simply depress the breaker button

on the front panel.

B. INSIDE PANEL CONTROLS

- POSTFLOW. Controls time for gas postflow after

the arc extinguishes from 0 to 999 cycles.

- STRIKE TIME. Preset time period allowed for the wire

to come down and hit the plate. If the wire does not

strike the plate within the allowed time period, the

Digimatic will automatically shutdown, and flash the

strike time in the VOLTS display window. Simultaneously, if optional abort output board is installed, it

also provides an abort output signal to stop carriage

or fixture travel. Time range is factory preset for a

minimum of 20 cycles and can be increased in one

cycle increments.

* The strike time setting is dependent upon the strike

IPM setting. The lower the speed, the longer the strike

time needs to be, otherwise nuisance shutdowns will

occur.

- BURNBACK TIME. Manually adjustable burnback time

period which when preset will override the automatic

adaptive anti-stick feature. This time period can be set

in one cycle increments. When set to zero , the

Automatic Adaptive Anti-Stick feature will be operational.

- REPEAT TIME (or Pause Time). Time period preset

between timed-welds from 1 to 999 cycles, in one

cycle increments.

- RETRACT TIME. At the end of the burnback sequence and during the postflow cycle, the wire feed

motor will reverse for automatic wire retract for a

preset time period. A setting of 5 to 10 cycles is

recommended to prevent excessive withdrawal of

the wire into the contact tip. If a normal stop is

desired, preset this time for zero cycles.

- ARC HOURS. Selectable display (record) of accumulative welding time in one tenth of an hour increments.

After 99.9 hours it will automatically return to zero.

7. Welding Condition (LED) Lights. These lights are

labeled START, WELD, and CRATER, and they energize individually as the welding program sequences

through each of these weld conditions. Prior to the

For location of internal control features, refer to Fig. 3

1. Condition Selector. This six-position rotary switch

is used to select two sets of parameters, Welding

and Timing, for each of the four available schedules:

a. Weld Parameters. The selectors primary func-

tion, when used with the appropriate Inc./Dec.

toggle, allows you to preset and display (see II-A6-b & c) the wire feed speed (IPM) and voltage

(VOLTS) weld parameters for its first-four positions labeled STRIKE, START, WELD, and

CRATER. The fifth position of this selector is

used for presetting the Missweld and Retract

Time. The sixth position of this selector, labeled

RUN, is the normal operating setting used after

the control is programmed and ready for use. The

IPM and VOLTS parameters, for each of the

following welding conditions, are preset using the

INC./DEC. toggle located directly.

- STRIKE. This condition sets the desired approach speed of the wire before striking the

workpiece, and the open-circuit voltage (on 452 cv

and 642 cvcc) needed to control the short-circuit

current for arc initiation.

- START. This condition can be used to set an appropriate wire speed and voltage parameter to create a

hot-start to help stabilize the arc (for its preset time)

prior to the weld cycle.

- WELD. This condition sets the desired wire speed

and voltage used during the actual weld cycle.

- CRATER. This condition allows you to set a higher or

lower weld speed and/or voltage (for a preset time

period), depending on the welding condition needed,

to regulate the weld termination size or craterfill

appearance at the end of the weld.

b. Time Parameters. The secondary function of this

selector is to setup the Time parameters located

within the charts adjacent to each of the weld

conditions. These times are preset by using the

Times/A.H.-Inch Selector (following).

10

Page 11

B

B

1

4

B

2

B

3a

B

3b

the data, simultaneously operate the INC/DEC

toggle switch directly below the function being set.

The cold-inch parameter will appear in the IPM

window, and the arc-hours time will be shown in

the VOLTS window.

3. Inc./Dec. Toggle Switches. A control toggle (two

position, momentary on ) is provided below the IPM

and VOLTS digital display windows. These two toggles

are used to preset the individual welding condition

and time-sequence parameters desired for the

welding operation, as follows:

a. IPM-TIME Increase/Decrease Control. This

toggle switch is used to set and/or vary wire feed

speed (IPM) for the required weld conditions , and

also the following; Preflow (time), Start Time,

Weld Time, Crater Time, Missweld Time and Inch

Preset (ipm). By setting and/or operating the appropriate Control Selectors (see B-1 and -2, above),

each parameter setting will be displayed in the

digital window directly above this toggle.

Figure 3 - Inside Panel Controls

2. Times/Arc Hours-Inch Preset Selector. This two

position, momentary on , toggle must be actuated in

order to preset or change the following parameters:

a. Time Functions. This position actuates the times-

parameters f o r t h e s e q u e n c e s s hown in the chart

beneath each digital display window. These sequences are preselected by positioning the Condition Selector to the pair of time-parameters to be

programmed from its Strike, Start, Weld, and Crater settings. To check or observe the time settings,

actuate the TIMES position; and to set or change

the settings, simultaneously operate the INC/DEC

toggle switch directly below the parameter (chart)

being setthe time setting in cycles will appear in

its digital display. The times-parameters which can

be programmed in each display window are shown

in Figure 3, and were previously described in Section II-A-6-b (IPM window) and Section II-A-6-c

(VOLTS window).

b. Arc Hours-Inch Preset Function. This switch

position operates in the same manner as the Times

function position; except that it only actuates the

programs to preset the Cold-Inch speed parameter

and to monitor or reset the accumulative Arc-Hours

(welding) time. These functions are preselected by

positioning the Condition Selector to its Run

setting. To check or monitor these parameters

actuate the A.H.- INCH position; and to set or zero

b. VOLTS-TIME Increase/Decrease Control. This

toggle switch is used to set and/or vary the arc

voltage (VOLTS) for the required weld conditions

, and also the following; Postflow (time), Strike

Time, Burnback Time, Repeat Time, Retract Time

and to zero (dec.) the Arc Hour accumulation. By

setting and/or operating the appropriate Control

Selector (see B-1 and -2 above), each parameter

setting will be displayed in the digital window

directly above this toggle.

4. TEST Toggle SwitchAMPS and VOLTS. As

the title implies, these two toggles simply provide a

convenient way of test-sequencing all of the program

parameters to either diagnose a problem or to demonstrate the control assembly without actually striking a welding arc. A complete set of actual weld

parameters must be preset for this test except for the

following: all voltage conditions and missweld time

parameters must be set to zerootherwise an abort

will occur.

To do this, place the two-position "Volts" toggle into

its TEST positionthe WELD position being the

location for normal operation. The Volts-Test position does two things: first, it safely disconnects the

actual contactor circuit in the power supply; and

second, it provides a 12-volt signal to simulate the arc

voltage required to sequence the welding cycle.

With this accomplished; open up the accessory support to release wire feed pressure, and place the

Start- Stop rocker on the front panel into its START

position, and the control will sequence thru the

programmedPreflow time and enter the Strike condition.

11

Page 12

Make sure that the Strike time is set long enough to

give you ample time to operate the Amp test toggle

a setting of 200 cycles is recommended for Strike

time.

During the Strike condition; you must actuate the

momentary "Amps" toggle to its TEST position, to

simulate closure of the arc/current detection circuitry

that verifies the arc has initiated. This action automatically allows you to enter the timed Start condition,

and the subsequent Weld, Crater, etc., conditions to

evaluate and/or demonstrate the welding sequence.

NOTE: The momentary WELD position of the Amps

toggle has no significance in the Test procedures. The normal spring-return center position, and/or its toggled Weld position essentially perform the same function.

C. ADDITIONAL PROGRAM CONTROLS

A. Pull the Power button out to energize the control, and

then place the Schedule Select switch to position No.

1. The control is now ready to accept Schedule No.

1 welding sequence program as described in steps

B thru I following:

B. Unlock the front panel door of the control cabinet to

gain access to the inside panel controls.

C. Make sure the Test-Volts and Amps toggle switches

are in the WELD position.

D. Place the rotary Condition selector switch to the

Strike position, and program each of the following

(see Sect. II-A-6-b, -c and II-B-1,-2):

1. Set the STRIKE wire feed speed (IPM) by operating the INC./DEC. toggle directly below the

IPM digital display, and the desired setting will

appear in its window.

The MPU (microprocessor) board incorporates an

integral 4-rocker/position dip switch (see Fig. 4)

that is primarily used for internal program functions. Switch positions No. 1, No. 2, No. 3 and No. 4

are factory-set in the open (or off) position and

must never be changed.

ROCKER DIP SWITCH

Figure 4 - MPU Dip Switch Location

2. Set the STRIKE open-circuit voltage requirement (VOLTS) by operating the INC./DEC. toggle

directly below the VOLTS digital display, and

the desired setting will appear in its window.

3. Leave the rotary selector switch in the STRIKE

position to set the PREFLOW and POSTFLOW

Time parameters (as shown in Fig. 4A). Actuate

the Times/A.H.-INCH toggle switch to its TIMES

(Cycle) position, and observe that the existing

numbers shown in the IPM and VOLTS windows

will changethe new parameters being the pair

of time functions in the chart(s) adjacent to the

selected condition (in this case, the pre- and

postflow data).

III. PRESETTING THE WELD SCHEDULE(S)

Remember, the front panel SCHEDULE SELECT

switch allows you to preset a complete and different

welding program for each of the four (4) available

schedules. To preset a typical schedule, do the

following.

Figure 4-A - Typical Time Parameter Set Up

To reset or change these Time parameters (see

Fig. 4A); actuate and hold the TIMES toggle position, while simultaneously operating the appropriate INC./DEC. toggle switch below each of the

12

Page 13

time parameters being set. The preset time intervals will be displayed in their respective IPM and

VOLTS digital windows.

E. Reposition the rotary Condition Selector switch to the

Start position, and program the following:

1. Set the START wire feed speed (IPM) and arc

voltage (VOLTS) parameters using the procedures outlined in III-D-1 and -2.

2. Leave the rotary selector in the START position to

set the START TIME and STRIKE TIME parameters and use the procedure outline in III-D-3.

F. Reposition the rotary Condition Selector switch to the

Weld position, and program the following:

1. Set the WELD wire feed speed (IPM) and arc

voltage (VOLTS) parameters using the procedures outlines in III-D-1, and -2.

2. Leave the rotary selector in the WELD position to

set the WELD TIME and BURNBACK TIME parameters and use the procedures outlined in III-D3, and also the following:

a. WELD TIME setting requirements for:

(1) Continuous Seam Weldingset time to

zero .

(2) Single Time Weld without carriage travel

(customer must deenergize the arc detection output signal)set time from 1 up

to 999 cycles.

(3) Single Time Weld with carriage travel (the

Arc Detector Circuit provides a signal to

initiate travel of a carriage, or fixture)set

time from 1 up to 999 cycles.

(4) Repeat Timed Weld (same as 3) except

that the elapsed time between welds is

preset in the REPEAT TIME parameters.

b. BURNBACK TIME setting requirements:

(1) If automatic adaptive anti-stick is desired

set time to zero.

(2) If manual burnback (anti-stick) is needed

set time required from 1 cycle on up.

G. Reposition the rotary Condition Selector switch to the

Crater position, and program the following:

1. Set the CRATER wire feed speed (IPM) and arc

voltage (VOLTS) parameters using procedures outlined in III-D-1 and -2.

2. Leave the rotary selector switch in the CRATER

position to set the CRATER TIME and REPEAT

TIME parameters and use the procedure outlined

in III-D-3.

* If the Weld Crater conditions are both Timed;

simply preset the appropriate time desired for each

condition - .1 up to 99.9 seconds for Weld, and .1

up to 99.6 seconds for Crater.

If Crater Fill is desired; enter from 1 to 999 cycle in the

Crater Time parameter. If Crater Fill is not desired;

simply enter zero in the Crater Time parameter, and

this sequence will be skipped after the STOP switch

terminates the Weld condition sequence.

** Repeat Timeif repeat timed welds are not used,

set this time to zero . If repeat welds are desired,

the cycles set will control the elapsed time between the Timed weld parameters.

H. Reposition the rotary Condition Selector switch to the

blank position, and program the following:

1. Set the MISSWELD TIME* and RETRACT TIME

parameters using the procedures outlined in III-D-

3. *The Missweld cycle only monitors the WELD

Condition. If not desired, set Missweld Time to

zero .

I. Reposition the rotary Condition Selector switch to the

RUN position for the following operations:

1. This is the normal operating setting used when the

control is fully programmed and ready-for-use.

As mentioned earlier in the Note following Section

II-B-2-b, the control is preset at the factory to

provide the optimum starting characteristic for most

welding conditions. However, due to factors such

as differences between various power sources

welding technique, shielding gas, power source

slope and/or response, you may have to readjust

the factory-set starting characteristics to provide the best arc starts possible. To do this, it is

necessary to readjust the factory-set condition to

provide a hot start characteristic in which the initial

starting voltage (open-circuit voltage) will be slightly

higher than actual welding voltage (arc voltage)

and speed which initially is somewhat lower than

the selected wire feed speed desired.

To set-up the control to provide this, do the following:

a. Program the welding condition you need in the

IPM (wire feed speed) and VOLTS (arc voltage)

windows, and fine-tune these parameters until

you have the welding arc desired - Do not at this

point concern yourself with the arc starts , this

follows.

b. If after the welding condition is fine-tuned you

find that the arc starts are unsatisfactory,

proceed as follows:

13

Page 14

(1) During an actual weld, depress and hold the

Arc Hours/Inch Preset toggle position

and observe the numbers displayed in the

IPM and VOLTS windows.

(2) For proper starts, the number in the

IPM window should be in the range from

105 to 115. If it is not, adjust the Inc/Dec

toggle (below the IPM window) until the

displayed number reads 110.

(3) Similarly, the number in the VOLTS win-

dow should be in the range of 90 to 100.

Again, if it is not, adjust the Inc/Dec toggle

(below the VOLTS window) until the displayed number reads 95.

(4) These adjustments to the control should

now provide good arc starts to a viable

welding condition.

(5) A good rule-of-thumb to follow whenever

you set up a new welding condition and

you experience unstable starts, is to simply check the start characteristic numbers (while welding) to make sure they

are within the ranges described in the

preceding steps.

2. Set the cold wire INCH wire feed speed and monitor

or reset (zero) the ARC HOURS by actuating Arc

Hours-Inch Preset toggle switch position, while operating the appropriate INC./DEC. toggle below

their respective charts. The preset cold-inch wire

feed speed, and accumulated arc hour usage will be

displayed in the appropriate IPM/VOLTS digital

windows.

NOTE: Upon completion of Schedule No. 1, if more

than one schedule is desired, place the

SCHEDULE SELECT switch to each of the

remaining positions (No. 2, No. 3 and No. 4) and

preset a different welding sequence program in

the same manner as Schedule No. 1.

IV. WELDING SEQUENCE

After the desired parameters have been weld-tested

and satisfactory results achieved, the preset condition can be lock-in by securing the front panel door

to the cabinet with a lock. None of the welding

parameters can be altered once the cover is closed.

To operate the preset welding schedule do the

following (a typical welding sequence is shown in

Fig. 5):

A. Pull the Power switch button out to energize the

control. (For one second, the IPM and VOLTS will

display an identification program number for the MPU

printed circuit board in your control.)

B. Operate the GAS PURGE switch to purge the

shielding gas line of the torch.

C. Place the SCHEDULE SELECT switch to the desired

schedule No. 1, No. 2, No, 3, or No. 4.

D. Operate the cold wire UP/DOWN INCH switch to

position the wire above the workpiece.

E. You are now ready to weld in the selected schedule.

Place the Start-Stop switch in its START position,

and the control will automatically sequence thru

Preflow, Strike, Start (also initiates arc detector carriage drive signal), and into the Weld condition

programmed.

F. To stop welding, proceed as follows:

1. For continuous seamwelds, simply operate the

STOP switch (or a remotely actuated stop

button or micro switch), and all welding will

cease except Crater-Fill, Burnback, Postflow and

Retract.

2. For single "Timed" weld setup, the control will

automatically provide an orderly sequenced shut

down; however, in order to start another weld, you

must press the Stop switch (panel or remote)

and then reoperate the Start position to reinitiate

the preset sequence.

3. For repeat "Timed" weld setups, the control will

automatically continue to cycle through its preset weld on and weld off sequence, until the

Digimatics Stop (or remote stop device) is operated.

4. The control can, or will, also shutdown as a result

of the following:

a. If preset Strike Time or Missweld Time is

exceeded, and /or preset wire feed speed or

arc voltage parameters cannot be maintained,

the Digimatic will shutdown and simultaneously indicate the cause by flashing a digital

display in the IPM or VOLTS window.

(1) If the Strike Time parameter was exceeded,

its preset time-interval will flash in the

VOLTS WINDOWand you may have to

preset a little more time.

(2) If the Missweld time cycles was exceeded,

its preset time will flash in the IPM window

and the unit will abort/shutdown make

sure that all parameters accurately reflect

the welding application.

14

Page 15

WELD MODE STARTS

WELD TIMER STARTS IF PROGRAMMED

WELD PARAMETERS ARE MAINTAINED

MISSWELD TIME STARTS

MONITORING

ARC DETECTOR

START TIMER BEGINS

START MODE INITIATED

PREFLOW TIMES OUT

CONTACTOR ON

MOTOR STARTS AT

STRIKE IPM SETTING

STRIKE TIMER STARTS

TIMIMG

START SW OPERATED

PREFLOW STARTS

PREFLOW

PURGE COLD INCH PRESET

MOTOR STOPS REVERSING

WIRE RETRACT ENDS

POSTFLOW TIMER STARTS

START TIMER

TIMES OUT

WIRE HITS

WORKPIECE

STRIKE START

CRATER TIME STARTS

CRATER PARAMETERS

MAINTAINED

STOP SW OPERATED

WELD TIMER TIMES

OUT IF SCHEDULED

MISSWELD TIME

ENDS

TIME

WELD

MISSWELD

AUTOMATIC OR

MANUAL ANTI-STICK

TIMER STARTS

DYNAMIC BRAKE

APPLIED

CRATER TIMER

TIMES OUT

ANTI-STICK TIMER TIMES OUT

CONTACTOR DROPS OUT

CRATER

POSTFLOW TIMES OUT

ANTI-STICK

Figure 5 - Typical Welding Conditions Sequence Per Schedule

REPEAT TIMER

STARTS IF

SET.

IF NOT WELD

CYCLE IS OVER

MOTOR

REVERSES

FOR WIRE

RETRACT

POSTFLOW

RETRACT

REPEAT

TIMER

STOPS &

NEW

WELD

BEGINS

REPEAT

(3) If the wire feed speed (IPM) and/or arc

voltage (VOLTS) parameters cannot be

maintained in any of the welding conditions (Strike, Start, Weld, or Crater), the

flashing display will only signal the original

preset Strike parameter(s).

b. In order to restart an abort shutdown, simply

depress the Gas Purge/Reset rocker switch

to clear the abort, and then repress the Start

rocker switch to start a new weld.

V. TROUBLESHOOTING

Listed below are a number of trouble symptoms,

each followed by the checks or action suggested to

determine the cause. Listing of checks and/or actions is in most probable order, but is not necessarily 100% exhaustive. In addition to the following

troubleshooting symptoms/checks, we have also

provided a Sequential Troubleshooting Flow Diagram (Fig. 6) which can be very useful in your

diagnosis.

Always follow this general rule: Do not replace a

printed circuit (PC) board until you have made all

the preceding checks. Always put the Power switch

in off position before removing or installing a PC

board. Take great care not to grasp or pull on

components when removing a PC board. If a printed

circuit (PC) board is determined to be the problem,

check with your ESAB supplier for a trade-in on a

new PC board. Supply the distributor with the part

number of the PC board as well as the serial number

of the wire feeder. Do not attempt to repair the PC

board yourself. Warranty on a PC board will be null

and void if repaired by customer or an unauthorized

repair shop.

A. General

1. Check interconnection between digimatic control and

power supply. Make sure that the contactor and

voltage control switches are placed in the Remote

position.

2. Energize the power supply and the control.

3. Immediately after the control is turned on , a number

(e.g.:3) will appear in the IPM readout window and will

only be displayed for 1-second. This number identifies the current program (E-Proms) used in your

control. When a Program is changed, the new EProms will automatically identify the new program

number being used. If a revision is made to an

existing program a decimal number .1,.2,.3,etc. indicating the numerical revision will also appear in the

VOLTS readout window simultaneously.

4. After the one (1) second delay; the preset Weld

parameters, corresponding to the position of the

Condition selector switch, will be displayed in the

IPM/ VOLTS windows. With the switch in its normal

Run position the STRIKE parameters will initially

be displayed.

5. It is also important to set the STRIKE time long

enough to provide adequate time for the current

detector to energize before the Strike timer times

out. If the Strike timer times out the unit will abort and

the preset Strike time parameters will flash in the

VOLTS window.

15

Page 16

6. If the control is not functioning properly (or as described above); for example, the numbers that appear in one or both of the display windows are

meaningless (all zeros, eights, decimals, etc.), or

are completely incorrect in relation to your settings,

- the memory must be cleared. This condition might

occur after a bad lightning storm, extremely bad

power line surges, etc. To clear the memory, do the

following:

a. Turn off the units 110-volt Power switch.

b. Using one hand, hold both of the Inc./Dec. toggle

switches in their INC position while reapplying 110volt power with the other hand.

c. Almost immediately after the Power has been

turned On, release the Inc./Dec. toggle switches

to the neutral (spring-return center) position and

each of the windows should display one zero,

indicating a successful reset or clearing has taken

place.

7. You can now enter the desired information as

described in this booklet.

B. No preset numbers, or meaningless numbers,

appear in display windows.

carriage drive(s), drill motor, hot plates, etc.) also

derive their 115-volt power from the same power

supply as the Digimatic control. Do NOT connect

auxiliary equipment to the 115-volt duplex receptacle

on the power supply. If problem still exists, call for

factory assistance.

C. Motor does not run.

1. Check to make sure all required (and/or optional)

accessories are correctly assembled as described in

Section I.

2. Make sure that plug P2 is securely connected to

receptacle P2 on the I/O Board, and then release the

clapper arm (pressure roll) on the Accessory Support

Assembly.

a. Operate the Start Switch (arc voltage of 10 volts or

more must be present) and the motor shaft/feed

roll should turn. If motor doesnt run, release start

switch and;

b. Operate the INCH switch. If the motor inches , but

will not operate from the start switch, check the

start switch circuit componentsswitch, plug,

receptacle, etc.

1. Make sure the LED Display board harness/plug

is plugged into the P5 receptacle on the MPU board.

2. Check that 110 vac is available across terminals T11 and T1-3, if present;

3. Check for (+) 5 volts between terminals T1-12 and

T1-10; if voltage is present, replace the MPU board.

If voltage is not present, check the voltage

regulator (VR). The voltage regulator is located on

the bottom of the control box.

4. Check the input and output voltage of the regulator

VR as follows:

The input should be approx. 11 volts, as measured

across capacitor C4 (between T1-10 and VR-1)

located on the VR socket. If voltage is not present

check the output of transformer CTR-1. It should read

10 volts AC from the center tap (Grn/Yel) to both of

the green windings taps. If CTR-1 good, but the input

to VR is still not present, check plug P3 per the

schematic diagram. If no opens or shorts are found

and input is still missing (to VR)replace I/O board.

If input to VR is present, but output is missing

replace VR. If numbers still do not appear in windowsreplace I/O and/or MPU boards.

c. If motor will not turn using either of the above

switches, replace the J governor board. If motor

still refuses to run, replace the I/O and MPU

boards respectively.

D. Motor runs backwards.

1. Reverse blue and orange wires on T1-5 and T1-6.

E. Motor runs, but not at right speed.

1. Check tachometer assembly mounted on the end of

EH-10 wire feed motor.

2. Make sure the tach disc is securely fastened to the

motor shaft and that the strobe markings are not

scratched. Check that the disc is properly centered in

the strobe pickup on the p.c. board.

3. If all items in step 2 are in order, and motor speed is

still incorrect, replaced MPU board.

F. Arc VOLTS display reads zero after TS is oper-

ated.

1. Check that the 5-pin plug is securely connected to the

P3 receptacle on the MPU board.

5. If all microprocessor memory is lost, it may be due to

low (sagging) line voltage or excessive line voltage

drops. This may occur if auxiliary equipment (such as

2. If no reading is displayed, check for arc voltage

feedback between terminals T1-18 and T1-19 (test

points TP1 and TP2, respectively, on I/O board). This

16

Page 17

voltage signal should correspond to that shown on

the power supply voltmeter.

3. If voltage still reads zero, but power supply indicates

a potential, trace the voltage pickup wiring from

the power supply to digimatic. If wiring is correct

and problem persist, proceed to step 4.

4. Disconnect the P3 plug from its MPU board socket

and, using a meter check for +/-12 volt power supply

output between plug pins P3-1 and P3-2 (for +12 v.),

and between plug pins P3-4 and P3-2 (for -12

v.) respectively. If voltage is present, replace the

MPU board.

G. Control Shut Down - either present VOLTS or IPM

displays will flash. The control will flash the

parameter, VOLTS or IPM, that cannot be maintained.

If this condition occurs, the respective servos need

to be checked and, if necessary, readjusted as

follows:

NOTE: The servo checking/setting procedure for the

Digimatic II control contained herein is different

from all previous Digimatic controls. Therefore, you do not need to adjust the voltage

servo trimpot or speed servo trimpot on the I/

O p.c. board - these trimpots are factory-set

and sealed, and should never be adjusted (as

was required of older Digimatics).

1. This symptom can occur as a result of the either or

all of the following; the Speed and Voltage servo

adjustments are incorrect and the conditions "set "

may not be maintainable. To check and, if necessary,

readjust the servos - proceed as follows.

Open the pressure roll clapper (so as not to feed wire),

toggle-down the Arc Hrs/Inch Preset switch position,

and either place the weld Start/Stop switch in START

position or toggle down the INCH switch. Check the

number in the IPM window - it may appear unsteady

but readable and should be about 110.

If it is higher or lower, use the Inc/Dec toggle (below

the IPM window) to adjust the number to 110 - while

"holding" the A.H.\Inch Preset as mentioned above

and while the wire feed motor is running.

If the speed servo cannot be adjusted at all, the

problem may be in the J-Governor, and/or I/O, and/or

MPU p.c. boards which must be replaced as required.

4. If a Voltage abort had occurred (VOLTS window

flashing), check and/or adjust the voltage servo as

follows:

This is a two-man operation. Set a welding condition

which closely corresponds to your welding application

and the proper speed (ipm) for a given wire size, and

then place the Weld switch in Start position and strike

a welding arc. While welding, toggle-down the Arc

Hrs./Inch Preset switch position and read the

number displayed in the VOLTS window, it may

appear unsteady but readable and should be 95.

If the number is not in the 90-100 range, use the Inc./

Dec toggle (below the VOLTS window) to adjust the

number to 95 - while holding the toggle position

mentioned above and while welding.

5. If the voltage servo cannot be adjusted, check

for proper operation of the power supply as follows:

NOTE: Prior to checking the servos, make sure the

control is connected to a suitable power source

in order to obtain the necessary o.c.v. (open

circuit voltage); otherwise, the motor will not

run.

2. The Speed and Voltage servos in this control

are simultaneously checked and displayed by depressing and holding the Arc Hrs./Inch Preset switch

(on inside panel) in its "down" position during an

actual weld and the wire feed motor running. The

speed servo number is displayed in the left (IPM)

window and should be about 110, and the right

(VOLTS) window will display the voltage servo number. This number will between 90 and 100* for the

actual welding condition.

* Voltage servo setting below 95 will normally provide

hot arc starts; whereas, setting over 100 will not.

3. If a Speed abort had occurred (IPM window flashing),

check and/or adjust the speed servo as follows:

a. Set the Digimatic voltage display to zero (this

setting will override the servo).

b. Place the Panel/Remote switch on the power sup-

ply in PANEL position.

c. Make a weld by controlling the arc voltage directly

from the power supply potentiometer.

d. If a weld can be made with good control over power

supply voltage; a problem exists either in the interconnecting voltage control cable, or in the Digimatic

control.

e. Check the control wires in the interconnecting

voltage control cable for continuity between the

appropriate terminals in the power supply and

Digimatic using the schematic diagrams.

f. If continuity is correct, replace the I/O board and/ or

the MPU board.

17

Page 18

IMPORTANT: In addition to the Welding Condition Sequence Diagram (Figure 5) and the Trouble Symptom/checks described

in Section V, the Sequential Troubleshooting Flow Diagram (Figure 6) can be very useful in diagnosing your problem.

Before using the Flow Diagram, make sure the Digimatic Control is connected to a suitable ESAB power source designed for

electronically controlled arc voltage regulation (see Section 1-A-4). The power supply much be setup for "remote" operation, and

the control preset and energized to provide the desired welding condition parameters.

If you wish to troubleshoot the Digimatic Control without using a power source, two TEST toggle switches labeled "Amps" and

"Volts", on the inside control panel provide a convenient way to "test-sequence" all of the welding condition parameters without

actually striking an arc. To do this, the control must be connected to an external 120 VAC power source (by customer),

preset all "arc voltage" condition parameters to zero (0) cycles, and preset the "Strike-Time" parameter to at least 150

cycles. The extended strike-time period is necessary to allow enough time to manually simulate an arc detection signal by

momentarily actuating the "Amp" toggle TEST position. Now, place the "Volts" toggle to its TEST position, and release the

clapper on the accessory support to remove wire feed pressure. With this accomplished, follow the Flow Diagram instruction

sequence until the weld condition is into the Strike-Time sequence. During this time period you must actuate the "Amps-Test"

toggle (to simulate arc detection), otherwise the strike-time will time out and the control will abort as shown in the diagram. If

done correctly, the unit will automatically continue through the remaining welding sequences.

(START)

1. START Sw. or Harness is Defective.

2. Defective MPU

3. Opt. Water Pressure Sw. is not closed.

No

Operate

Start Sw.

Yes

Are

Pre/Post

Flow Numbers

Displayed

Yes

Has

Pre-Flow

Timed

Out

Yes

1. P. S. Provides Strike Voltage.

2. Wire Feeds (n) Preset Strike IPM. n

3. Strike Timing Starts.

4. Strike Parameters Are Displayed.

No

1. Post-Flow Starts.

2. Pre-/Post-Flow Parameters Displayed.

3. Motor Starts Retract. C

A

1. Crater Parameters Are Displayed.

2. Crater Timing Starts.

3. Opt. Carriage Travel Stop.

Is

Crater time

Up

Ú

Is

Post-/

Flow (Retract)

Time Up

No

Yes

No

Continue

Crater

Cycle

Retract

Time

Yes

Is

Up

No

Wire

Retract

Has

Strike Timer

Timed

Out

Yes

Unit Will Abort

And Strike Time

Will Flash

No

Has

Missweld

Timed

Out

Yes

Unit Will Abort

And Missweld Time

Will Flash in IPM

No

1. Curr. Detector Signal Picks-up l

2. Start Parameters Are Displayed

3. Start Timing Begins

4. Carriage Drive Signal Provided.

1.Weld Parameter Are Displayed

2. Weld Cycle Start For:

Timed Weld

Weld time

No

Has

Wire Hit

Workpiece

Yes

Is

Start time

Up

Yes

Continuous Seam

Is

Up

No

Yes

Weld in

Progress

Stop Sw.

Operated

No

Yes

No

Is

Is

Repeat

Time Set

*

Yes

Is

Repeat Time

Up

NOTES

Motor will not feed unless an arc voltage of at least 10 volts is fed back