Page 1

ESAB Cutmaster® 80

PLASMA CUTTING SYSTEM

SL60 1Torch™

Operating

Manual

Art # A-12768_AB

80

Revision: AB Issue Date: April 15, 2015 Manual No.: 0-5378

400V

esab.com.br

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new ESAB product. We are proud to have you as our customer and will strive to

provide you with the best service and reliability in the industry. This product is backed by our extensive

warranty and world-wide service network. To locate your nearest distributor or service agency, visit us on

the web at www.esab.com.br.

This Operating Manual has been designed to instruct you on the correct use and operation of your ESAB

product. Your satisfaction with this product and its safe operation is our ultimate concern. Therefore please

take the time to read the entire manual, especially the Safety Precautions. They will help you to avoid potential

hazards that may exist when working with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

ESAB is a Global Brand of manual and automation Plasma Cutting Products.

We distinguish ourselves from our competition through market-leading, dependable products that have stood

the test of time. We pride ourselves on technical innovation, competitive prices, excellent delivery, superior

customer service and technical support, together with excellence in sales and marketing expertise.

Above all, we are committed to developing technologically advanced products to achieve a safer working

environment within the welding industry.

Page 3

WARNING

!

Read and understand this entire Manual and your employer’s safety practices before installing, operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement,

the Manufacturer assumes no liability for its use.

Plasma Cutting Power Supply

ESAB Cutmaster® 80 with SL60 1Torch™

Operating Manual Number 0-5378

Published by:

ESAB

2800 Airport Rd.

Denton, TX 76208

www.esab.com.br

Copyright 2015 by ESAB

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any

loss or damage caused by any error or omission in this Manual, whether such error

results from negligence, accident, or any other cause.

Original Publication Date: April 15, 2015

Revision Date: April 15, 2015

Record the following information for Warranty purposes:

Where Purchased:_______________________________ ________________

Purchase Date:__________________________________ ________________

Power Supply Serial #:___________________________ ________________

Torch Serial #:___________________________________ ________________

i

Page 4

Be sure this information reaches the operator.

You can get extra copies through your supplier.

CAUTION

These INSTRUCTIONS are for experienced operators. If you are not fully familiar

with the principles of operation and safe practices for arc welding and cutting equipment, we urge you to read our booklet, “Precautions and Safe Practices for Arc

Welding, Cutting, and Gouging,” Form 52-529. Do NOT permit untrained persons to

install, operate, or maintain this equipment. Do NOT attempt to install or operate this

equipment until you have read and fully understand these instructions. If you do not

fully understand these instructions, contact your supplier for further information. Be

sure to read the Safety Precautions before installing or operating this equipment.

USER RESPONSIBILITY

This equipment will perform in conformity with the description thereof contained in this manual and accompanying labels and/or inserts when installed, operated, maintained and repaired in accordance with the

instructions provided. This equipment must be checked periodically. Malfunctioning or poorly maintained equipment should not be used. Parts that are broken, missing, worn, distorted or contaminated should be replaced

immediately. Should such repair or replacement become necessary, the manufacturer recommends that a telephone or written request for service advice be made to the Authorized Distributor from whom it was purchased.

This equipment or any of its parts should not be altered without the prior written approval of the manufacturer. The user of this equipment shall have the sole responsibility for any malfunction which results from

improper use, faulty maintenance, damage, improper repair or alteration by anyone other than the manufacturer or a service facility designated by the manufacturer.

!

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR

OPERATING.

PROTECT YOURSELF AND OTHERS!

Page 5

TABLE OF CONTENTS

SECTION 1: SAFETY ............................................................................................................................ 1-1

1.0 Safety Precautions ................................................................................................ 1-1

SECTION 2 SYSTEM: INTRODUCTION ................................................................................................ 2-1

2.01 How To Use This Manual ....................................................................................... 2-1

2.02 Equipment Identification ....................................................................................... 2-1

2.03 Receipt Of Equipment ........................................................................................... 2-1

2.04 Power Supply Specifications ................................................................................. 2-2

2.05 Input Wiring Specifications .................................................................................... 2-3

2.06 Power Supply Features ......................................................................................... 2-4

SECTION 2 TORCH: INTRODUCTION ...................................................................................................2T-1

2T.01 Scope of Manual ..................................................................................................2T-1

2T.02 General Description .............................................................................................2T-1

2T.03 Specifications .....................................................................................................2T-1

2T.04 Options And Accessories ......................................................................................2T-2

2T.05 Introduction to Plasma .........................................................................................2T-2

SECTION 3 SYSTEM: INSTALLATION ................................................................................................... 3-1

3.01 Unpacking ............................................................................................................ 3-1

3.02 Lifting Options ...................................................................................................... 3-1

3.03 Opening the Contactor Cover ................................................................................ 3-1

3.04 Primary Input Power Connections ......................................................................... 3-1

3.05 Gas Connections ................................................................................................... 3-2

SECTION 3 TORCH: INSTALLATION ...................................................................................................3T-1

3T.01 Torch Connections ...............................................................................................3T-1

3T.02 Setting Up Mechanical Torch ................................................................................3T-1

SECTION 4 SYSTEM: OPERATION ...................................................................................................... 4-1

4.01 Front Panel Controls / Features ............................................................................. 4-1

4.02 Preparations for Operation .................................................................................... 4-2

SECTION 4 TORCH: OPERATION .........................................................................................................4T-1

4T.01 Torch Parts Selection ...........................................................................................4T-1

4T.02 Cut Quality ...........................................................................................................4T-1

4T.03 General Cutting Information .................................................................................4T-2

4T.04 Hand Torch Operation ..........................................................................................4T-3

4T.05 Gouging ............................................................................................................... 4T-6

4T.06 Mechanized Torch Operation ................................................................................4T-6

4T.07 Parts Selection for Manual and Mechanized Torch Cutting ....................................4T-8

4T.08 Recommended Cutting Speeds for Mechanized Torch With Exposed Tip ...............4T-9

4T.09 Recommended Cutting Speeds for Mechanized Torch With Shielded Tip .............4T-12

PATENT INFORMATION ....................................................................................................................4T-16

Page 6

TABLE OF CONTENTS

SECTION 5 SYSTEM: SERVICE ............................................................................................................ 5-1

5.01 General Maintenance ............................................................................................ 5-1

5.02 Maintenance Schedule ......................................................................................... 5-2

5.03 Common Faults..................................................................................................... 5-2

5.04 Fault Indicator ....................................................................................................... 5-3

5.05 Basic Troubleshooting Guide ................................................................................. 5-4

5.06 Power Supply Basic Parts Replacement ................................................................ 5-6

SECTION 5 TORCH: SERVICE .............................................................................................................5T-1

5T.01 General Maintenance ...........................................................................................5T-1

5T.02 Inspection and Replacement of Consumable Torch Parts ......................................5T-2

SECTION 6: PARTS LISTS .................................................................................................................... 6-1

6.01 Introduction .......................................................................................................... 6-1

6.02 Ordering Information ............................................................................................. 6-1

6.03 Power Supply Replacement .................................................................................. 6-1

6.04 Replacement Power Supply Parts .......................................................................... 6-2

6.05 Options and Accessories ....................................................................................... 6-2

6.06 Replacement Parts for Hand Torch ....................................................................... 6-3

6.07 Replacement Parts - for Machine Torches with Unshielded Leads ......................... 6-4

6.08 Replacement Shielded Machine Torch Leads Assemblies ..................................... 6-6

6.09 Torch Consumable Parts (SL60) ............................................................................ 6-7

6.10 Torch Consumable Parts (SL100) .......................................................................... 6-8

APPENDIX 1: SEQUENCE OF OPERATION (BLOCK DIAGRAM) ...........................................................A-1

APPENDIX 2: DATA TAG INFORMATION .............................................................................................A-2

APPENDIX 3: TORCH PIN - OUT DIAGRAMS ...................................................................................... A-3

APPENDIX 4: TORCH CONNECTION DIAGRAMS ................................................................................A-4

APPENDIX 5: SYSTEM SCHEMATIC, 208/460V UNITS .......................................................................A-6

APPENDIX 6: SYSTEM SCHEMATIC, 600V UNITS ..............................................................................A-8

REVISION HISTORY ........................................................................................................................... A-10

Page 7

ESAB CUTMASTER 80

SECTION 1: SAFETY

1.0 Safety Precautions

Users of ESAB welding and plasma cutting equipment have the ultimate responsibility for ensuring

that anyone who works on or near the equipment observes all the relevant safety precautions. Safety

precautions must meet the requirements that apply to this type of welding or plasma cutting equipment.

The following recommendations should be observed in addition to the standard regulations that apply

to the workplace.

All work must be carried out by trained personnel well acquainted with the operation of the

welding or plasma cutting equipment. Incorrect operation of the equipment may lead to hazardous situations which can result in injury to the operator and damage to the equipment.

1. Anyone who uses welding or plasma cutting equipment must be familiar with:

- its operation

- location of emergency stops

- its function

- relevant safety precautions

- welding and / or plasma cutting

2. The operator must ensure that:

- no unauthorized person stationed within the working area of the equipment when it is started up.

- no one is unprotected when the arc is struck.

3. The workplace must:

- be suitable for the purpose

- be free from drafts

4. Personal safety equipment:

- Always wear recommended personal safety equipment, such as safety glasses, flame proof

clothing, safety gloves.

- Do not wear loose fitting items, such as scarves, bracelets, rings, etc., which could become

trapped or cause burns.

5. General precautions:

- Make sure the return cable is connected securely.

- Work on high voltage equipment may only be carried out by a qualified electrician.

- Appropriate fire extinguishing equipment must be clearly marked and close at hand.

- Lubrication and maintenance must not be carried out on the equipment during operation.

Dispose of electronic equipment at the recycling facility!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment and its

implementation in accordance with national law, electrical and/or electronic equipment that has reached the

end of its life must be disposed of at a recycling facility.

As the person responsible for the equipment, it is your responsibility to obtain information on approved collection stations.

For further information contact the nearest ESAB dealer.

ESAB can provide you with all necessary cutting protection and accessories.

Manual 0-5378 SAFETY

1-1

Page 8

ESAB CUTMASTER 80

WARNING

ELECTRIC SHOCK - Can kill.

- Install and earth (ground) the welding or plasma cutting unit in accordance with applicable standards.

- Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

- Insulate yourself from earth and the workpiece.

- Ensure your working stance is safe.

FUMES AND GASES - Can be dangerous to health.

- Keep your head out of the fumes.

- Use ventilation, extraction at the arc, or both, to take fumes and gases away from your

breathing zone and the general area.

ARC R AYS - Can injure eyes and burn skin.

- Protect your eyes and body. Use the correct welding / plasma cutting screen and filter

lens and wear protective clothing.

- Protect bystanders with suitable screens or curtains.

FIRE HAZARD

- Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

Arc welding and cutting can be injurious to yourself and others. Take

precautions when welding and cutting. Ask for your employer's safety

practices which should be based on manufacturers' hazard data.

NOISE - Excessive noise can damage hearing.

- Protect your ears. Use earmuffs or other hearing protection.

- Warn bystanders of the risk.

MALFUNCTION - Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

Do not use the power source for thawing frozen pipes.

WARNING

CAUTION

CAUTION

CAUTION

Class A equipment is not intended for use in residential locations

where the electrical power is provided by the public low-voltage

supply system. There may be potential difficulties in ensuring

electromagnetic compatibility of class A equipment in those locations, due to conducted as well as radiated disturbances.

This product is solely intended for metal removal. Any other use may

result in personal injury and / or equipment damage.

Read and understand the instruction manual before

installing or operating.

!

SAFETY Manual 0-5378

1-2

Page 9

ESAB CUTMASTER 80

SECTION 2 SYSTEM:

INTRODUCTION

2.01 How To Use This Manual

This Owner’s Manual applies to just specification

or part numbers listed on page i.

To ensure safe operation, read the entire manual,

including the chapter on safety instructions and warnings.

Throughout this manual, the words WARNING,

CAUTION, and NOTE may appear. Pay particular attention to the information provided under these headings.

These special annotations are easily recognized as

follows:

NOTE!

An operation, procedure, or background

information which requires additional

emphasis or is helpful in efficient operation

of the system.

CAUTION

!

!

A procedure which, if not properly followed,

may cause damage to the equipment.

WARNING

A procedure which, if not properly followed,

may cause injury to the operator or others

in the operating area.

2.02 Equipment Identification

The unit’s identification number (specification or

part number), model, and serial number usually appear on a data tag attached to the rear panel. Equipment which does not have a data tag such as torch

and cable assemblies are identified only by the specification or part number printed on loosely attached

card or the shipping container. Record these numbers

on the bottom of page i for future reference.

2.03 Receipt Of Equipment

When you receive the equipment, check it

against the invoice to make sure it is complete and

inspect the equipment for possible damage due to

shipping. If there is any damage, notify the carrier immediately to file a claim. Furnish complete information

concerning damage claims or shipping errors to the

location in your area listed in the inside back cover of

this manual.

Include all equipment identification numbers as

described above along with a full description of the

parts in error.

Move the equipment to the installation site

before un-crating the unit. Use care to avoid damaging the equipment when using bars, hammers, etc., to

un-crate the unit.

WARNING

Gives information regarding possible electrical shock injury. Warnings will be enclosed

in a box such as this.

DANGER

Means immediate hazards which, if not

avoided, will result in immediate, serious

personal injury or loss of life.

Additional copies of this manual may be purchased by contacting ESAB at the address and phone

number in your area listed on back cover of this

manual. Include the Owner’s Manual number and

equipment identification numbers.

Electronic copies of this manual can also be

downloaded at no charge in Acrobat PDF format by

going to the ESAB web site listed below

http://www. esab.com

Manual 0-5378 INTRODUCTION

2-1

Page 10

ESAB CUTMASTER 80

2.04 Power Supply Specifications

ESAB Cutmaster® 80 Power Supply Specifications

Input Power 460 VAC (414 - 506 VAC), Three Phase, 60 Hz

Input Power Cable

Output Current 30 - 80 Amps, Continuously Adjustable

Power Supply Gas

Filtering Ability

ESAB Cutmaster® 80 Power Supply Duty Cycle *

Cable for 208/230V input power includes molded plug.

Power Supply includes input cable.

Particulates to 5 Microns

Ambient Temperature

Duty Cycle Ratings @ 40° C (104° F)

Operating Range 0° - 50° C

IEC

Rating

IEC

Rating

IEC

Rating

Duty Cycle 40% 60% 100%

All Units

Current

DC Voltage

80 Amps 65 Amps 50 Amps

112 106 100

* NOTE: The duty cycle will be reduced if the primary input power (AC) is low

or the output voltage (DC) is higher than shown in this chart.

NOTE!

IEC Rating is determined as specified by the International Electro-Technical Commission. These specifications include calculating an output voltage based upon power supply rated current. To facilitate comparison

between power supplies, all manufacturers use this output voltage to determine duty cycle.

Power Supply Dimensions & Weight Ventilation Clearance Requirements

10.75"

273 mm

Art # A-07941

Art # A-07925_AB

16.375"

416 mm

6"

150 mm

24"

22.5"

43 lb / 19.5 kg

0.57 m

INTRODUCTION Manual 0-5378

2-2

610 mm

6"

150 mm

6"

150 mm

Page 11

2.05 Input Wiring Specifications

ESAB Cutmaster® 80 Power Supply Input Cable Wiring Requirements

Input voltage Freq Power Input Suggested Sizes

Volts Hz kVA I max I1eff Fuse (amps)

3 Phase 400 50/60 11.8 18 12 20 12

Line Voltages with Suggested Circuit Protection and Wire Sizes

Based on National Electric Code and Canadian Electric Code

NOTE!

Refer to Local and National Codes or local authority having jurisdiction for proper wiring requirements.

Cable size is de-rated based on the Duty Cycle of the equipment.

ESAB CUTMASTER 80

Flexible Cord

(Min. AWG)

Manual 0-5378 INTRODUCTION

2-3

Page 12

ESAB CUTMASTER 80

and Clamp

2.06 Power Supply Features

Art # A-07942

Handle and Leads Wrap

Control Panel

To rch Leads Receptacle

Work Cable

Port for Optional Automation

Interface Cable

Input Power Selection

Filter Assembly

Gas Inlet Port

Input Power Cord

Art # A-07981

INTRODUCTION Manual 0-5378

2-4

Page 13

ESAB CUTMASTER 80

SECTION 2 TORCH:

INTRODUCTION

2T.01 Scope of Manual

This manual contains descriptions, operating

instructions and maintenance procedures for the

1Torch Models SL60/Manual and SL100/Mechanized

Plasma Cutting Torches. Service of this equipment is

restricted to properly trained personnel; unqualified

personnel are strictly cautioned against attempting

repairs or adjustments not covered in this manual, at

the risk of voiding the Warranty.

Read this manual thoroughly. A complete understanding of the characteristics and capabilities of this

equipment will assure the dependable operation for

which it was designed.

2T.02 General Description

Plasma torches are similar in design to the

automotive spark plug. They consist of negative and

positive sections separated by a center insulator. Inside the torch, the pilot arc starts in the gap between

the negatively charged electrode and the positively

charged tip. Once the pilot arc has ionized the plasma

gas, the superheated column of gas flows through the

small orifice in the torch tip, which is focused on the

metal to be cut.

A single torch lead provides gas from a single

source to be used as both the plasma and secondary gas. The air flow is divided inside the torch head.

Single - gas operation provides a smaller sized torch

and inexpensive operation.

NOTE!

Refer to Section "2T.05 Introduction to

Plasma", for a more detailed description of

plasma torch operation.

Refer to the Appendix Pages for additional

specifications as related to the Power Supply used.

2T.03 Specifications

A. Torch Configurations

1. Hand/Manual Torch, Models

The hand torch head is at 75° to the torch handle. The hand

torches include a torch handle and torch trigger assembly.

10.125" (257 mm)

3.75"

(95 mm)

1.17" (29 mm)

2. Mechanized Torch, Model

The standard machine torch has a positioning tube with

rack & pinch block assembly.

15.875" / 403 mm

9.285" / 236 mm

1.375" / 35 mm

1.75" /

44.5 mm

0.625" /

4.95" / 126 mm

16 mm

1.175" / 30 mm

B. Torch Leads Lengths

Hand Torches are available as follows:

• 20ft/6.1m,withATCconnectors

• 50ft/15.2m,withATCconnectors

Machine Torches are available as follows:

• 5foot/1.5m,withATCconnectors

• 10foot/3.05m,withATCconnectors

• 25foot/7.6m,withATCconnectors

• 50foot/15.2m,withATCconnectors

C. Torch Parts

Starter Cartridge, Electrode, Tip, Shield Cup

D. Parts - In - Place (PIP)

Torch Head has built - in switch

12 VDC circuit rating

Art # A-03322_AB

Art # A-02998

E. Type Cooling

Combination of ambient air and gas stream through torch.

Manual 0-5378 INTRODUCTION

2T-1

Page 14

ESAB CUTMASTER 80

F. Torch Ratings

Manual Torch Ratings

Ambient

Temperature

Duty Cycle

Maximum Current

Voltage (V

Arc Striking Voltage

Ambient

Temperature

Duty Cycle

Maximum Current

Voltage (V

Arc Striking Voltage

peak

Mechanized Torch Ratings

peak

100% @ 60 Amps @ 400 scfh

)

100% @ 100 Amps @ 400 scfh

)

G. Gas Requirements

Manual and Mechanized Torch Gas

Specifications

Gas (Plasma and Secondary)

Operating Pressure

Refer to NOTE

Maximum Input Pressure

104° F

40° C

80 Amps

500V

7kV

104° F

40° C

120 Amps

500V

7kV

Compressed Air

60 - 95 psi

4.1 - 6.5 bar

125 psi / 8.6 bar

2T.05 Introduction to Plasma

A. Plasma Gas Flow

Plasma is a gas which has been heated to an extremely high

temperature and ionized so that it becomes electrically conductive. The plasma arc cutting and gouging processes use

this plasma to transfer an electrical arc to the workpiece. The

metal to be cut or removed is melted by the heat of the arc

and then blown away.

While the goal of plasma arc cutting is separation of the

material, plasma arc gouging is used to remove metals to a

controlled depth and width.

In a Plasma Cutting Torch a cool gas enters Zone B, where a

pilot arc between the electrode and the torch tip heats and

ionizes the gas. The main cutting arc then transfers to the

workpiece through the column of plasma gas in Zone C.

_

Power

Supply

+

A

Gas Flow (Cutting and

Gouging)

300 - 500 scfh

142 - 235 lpm

WARNING

!

This torch is not to be used with oxygen

(O2).

NOTE!

Operating pressure varies with torch

model, operating amperage, and torch

leads length. Refer to gas pressure settings

charts for each model.

H. Direct Contact Hazard

For standoff tip the recommended standoff is 3/16 inches /

4.7 mm.

2T.04 Options And Accessories

For options and accessories, see section 6.

Workpiece

C

Typical Torch Head Detail

By forcing the plasma gas and electric arc through a small

orifice, the torch delivers a high concentration of heat to a small

area. The stiff, constricted plasma arc is shown in Zone C.

Direct current (DC) straight polarity is used for plasma cutting,

as shown in the illustration.

Zone A channels a secondary gas that cools the torch. This

gas also assists the high velocity plasma gas in blowing the

molten metal out of the cut allowing for a fast, slag - free cut.

B. Gas Distribution

The single gas used is internally split into plasma and secondary gases.

B

A-00002

INTRODUCTION Manual 0-5378

2T-2

Page 15

The plasma gas flows into the torch through the negative lead,

Remote Pendant

through the starter cartridge, around the electrode, and out

through the tip orifice.

The secondary gas flows down around the outside of the torch

starter cartridge, and out between the tip and shield cup around

the plasma arc.

C. Pilot Arc

When the torch is started a pilot arc is established between

the electrode and cutting tip. This pilot arc creates a path for

the main arc to transfer to the work.

D. Main Cutting Arc

DC power is also used for the main cutting arc. The negative

output is connected to the torch electrode through the torch

lead. The positive output is connected to the workpiece via

the work cable and to the torch through a pilot wire.

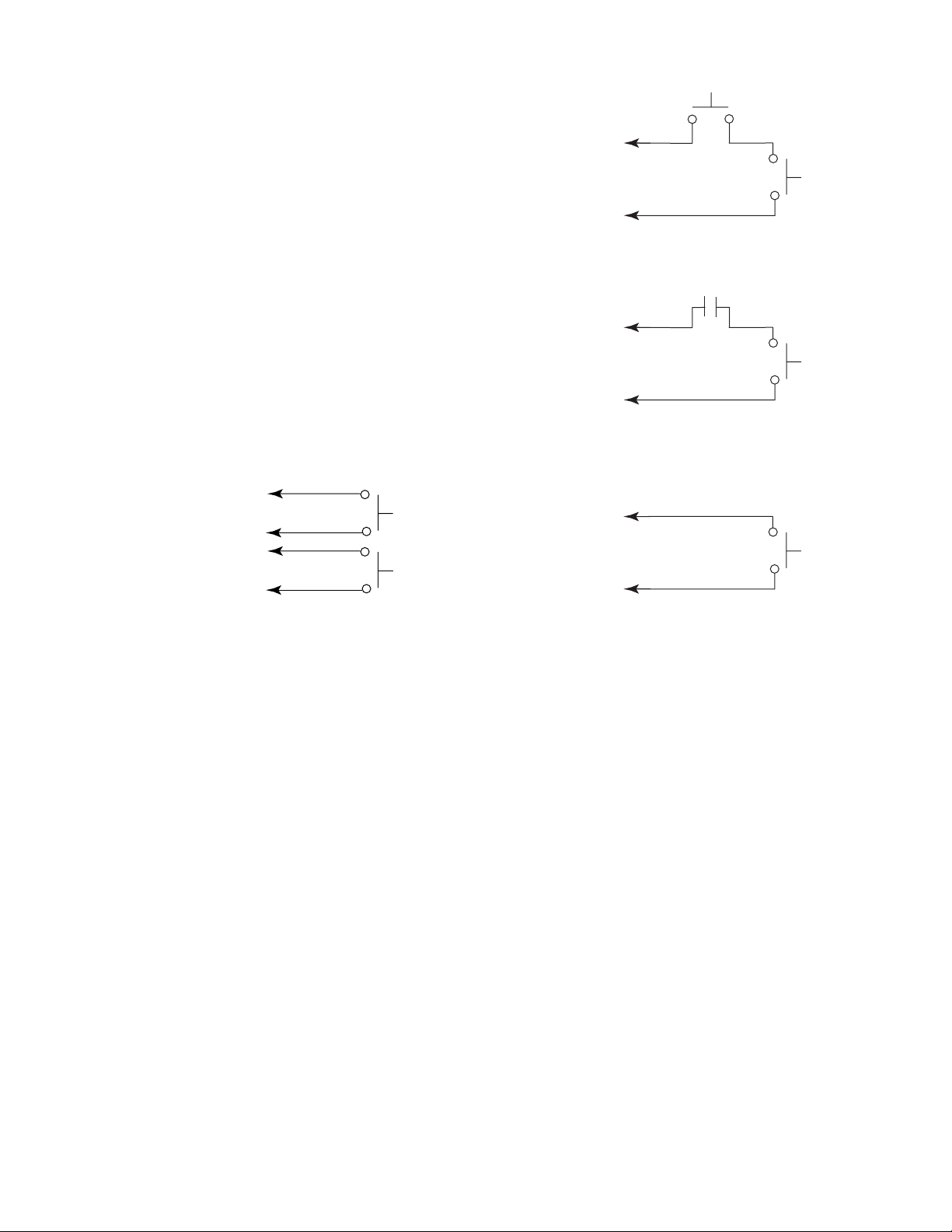

E. Parts - In - Place (PIP)

The torch includes a 'Parts - In - Place' (PIP) circuit. When the

shield cup is properly installed, it closes a switch. The torch

will not operate if this switch is open.

To Control

Torch Switch

Cable Wiring

PIP Switch

A-02997

Torch Trigger

Shield Cup

Parts - In - Place Circuit Diagram for

Hand Torch

ESAB CUTMASTER 80

To AT C

To AT C

To AT C

PIP Sw itch

CNC Start

PIP Sw itch

Automation Torch

PIP Sw itch

Parts - In - Place Circuit Diagram for

Machine Torch

Sh ield Cup

Sh ield Cup

Art # A-08168

Sh ield Cup

Manual 0-5378 INTRODUCTION

2T-3

Page 16

ESAB CUTMASTER 80

This Page Intentionally Blank

INTRODUCTION Manual 0-5378

2T-4

Page 17

SECTION 3 SYSTEM:

INSTALLATION

3.01 Unpacking

1. Use the packing lists to identify and account

for each item.

2. Inspect each item for possible shipping

damage. If damage is evident, contact your

distributor and / or shipping company before

proceeding with the installation.

3. Record Power Supply and Torch model and serial numbers, purchase date and vendor name,

in the information block at the front of this

manual.

3.02 Lifting Options

The Power Supply includes a handle for hand lifting

only. Be sure unit is lifted and transported safely and

securely.

WARNING

Do not touch live electrical parts.

!

• Onlypersonsofadequatephysicalstrength

should lift the unit.

• Liftunitbythehandles,usingtwohands.Donot

use straps for lifting.

• Useoptionalcartorsimilardeviceofadequate

capacity to move unit.

• Placeunitonaproperskidandsecureinplace

before transporting with a fork lift or other vehicle.

Disconnect input power cord before moving

unit.

WARNING

FALLING EQUIPMENT can cause serious personal injury and can damage equipment.

HANDLE is not for mechanical lifting.

ESAB CUTMASTER 80

1

2

1

2

Art# A-11478

Contactor cover

3.04 Primary Input Power Connections

CAUTION

!

The following illustration and directions are for wiring

three phase input power.

Check your power source for correct voltage before plugging in or connecting the

unit. Check the Voltage Selector at the rear

of the unit for correct setting before plugging in or connecting the unit. The primary

power source, fuse, and any extension

cords used must conform to local electrical

code and the recommended circuit protection and wiring requirements as specified in

Section 2.

Three-Phase (3ø) and Jumper Settings

Store copper jumper in spare parts box

L1

L2

L3

L4

GND

L1

L2

L3

L4

Jumper L1 -L4

Three Phase Input Power Wiring

Art # A-07983_AB

3.03 Opening the Contactor Cover

The input power cord is connected to the main contactor, the contactor is located inside a box with a snap

on cover. The cover is held in place with two or more

snap lock tabs. To remove the cover release the front

latch and tilt the cover up about ½ inch. Then squeeze

both sides of the cover and lift it straight up. See the

Primary Input Power Connections section for the necessary changes to the Contactor. Remember to replace

the Contactor Cover when the changes are complete.

Manual 0-5378 INSTALLATION

3-1

Page 18

ESAB CUTMASTER 80

Connections to Three Phase Input Power

WARNING

Disconnect input power from the power

supply and input cable before attempting

this procedure.

These instructions are for changing the input power

and or cable on the 208/230, 400, 460 VAC Power

Supply to Three - Phase input power.

1. Remove the Power Supply cover per instructions found in section 5.

2. Disconnect the original input power cable

from the main input contactor and the chassis

ground connection.

3. Loosen the through - hole protector on the

back panel of the power supply. Pull the original power cable out of the power supply.

4. Using a customer supplied four - conductor

input power cable for the voltage desired, strip

back the insulation on the individual wires.

5. Pass the cable being used through the access

opening in the back panel of the power supply.

Refer to Section 2 for power cable specifications.

CAUTION

!

The primary power source and power cable

must conform to local electrical code and

the recommended circuit protection and

wiring requirements (refer to table in Section 2).

6. Connect the wires as follows.

• SetJumperwiresonthecontactor.See

illustration.

• Green/YellowwiretoGround.

• RemainingwirestoL1,L2andL3input.It

does not matter what order these wires are

attached. See the previous illustrations.

7. With a little slack in the wires, tighten the

through - hole protector to secure the power

cable.

8. Reinstall the Power Supply cover per instructions found in section 5.

9. Connect the opposite end of individual wires to

a customer supplied plug or main disconnect.

10. Connect the input power cable (or close the

main disconnect switch) to supply power.

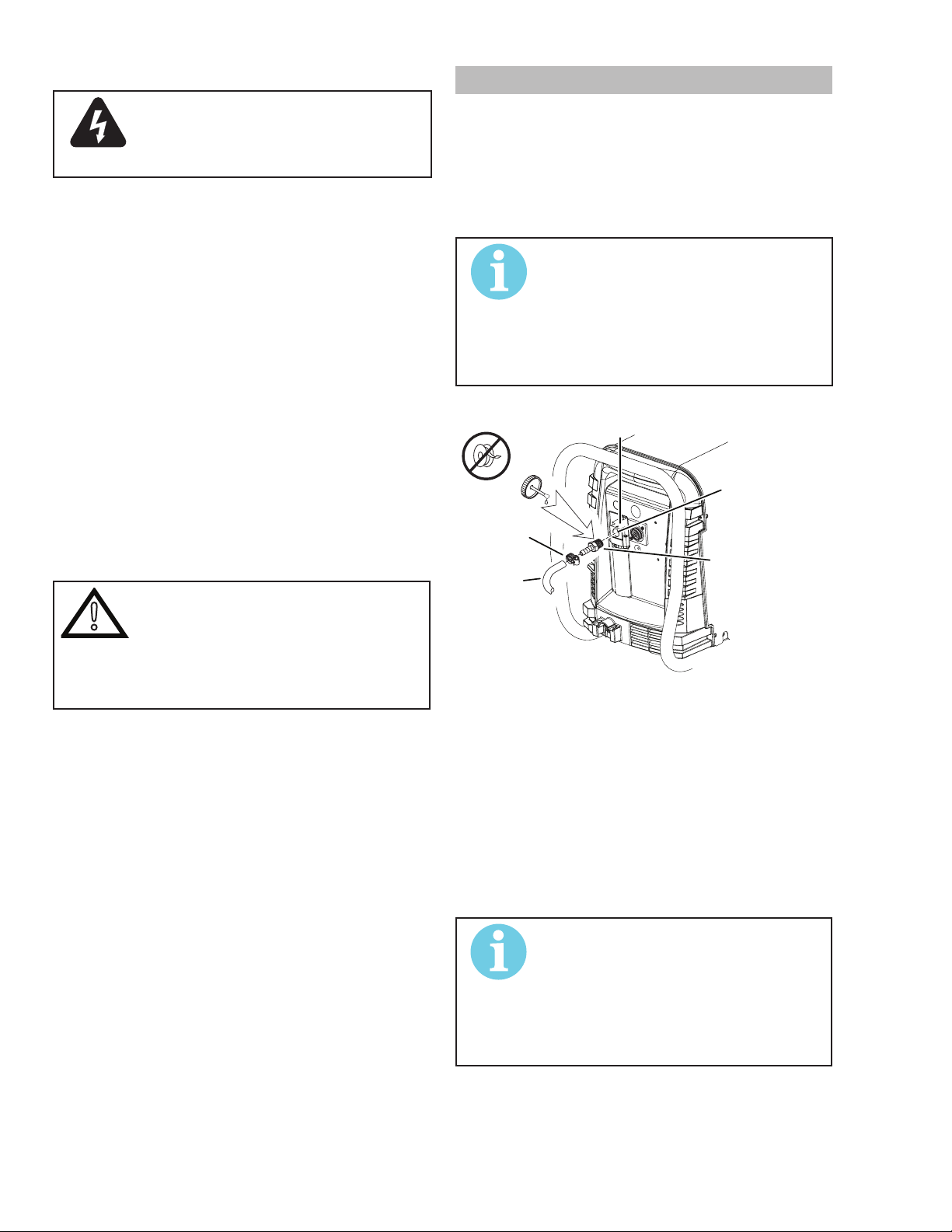

3.05 Gas Connections

Connecting Gas Supply to Unit

The connection is the same for compressed air or high

pressure cylinders. Refer to the following two subsections if an optional air line filter is to be installed.

1. Connect the air line to the inlet port. The illustration shows typical fittings as an example.

NOTE!

For a secure seal, apply thread sealant to

the fitting threads, according to manufacturer's instructions. Do not use Teflon tape

as a thread sealer, as small particles of the

tape may break off and block the small air

passages in the torch.

Regulator/Filter

Assembly

Inlet Port

Hose Clamp

1/4 NPT or ISO-R

Gas Supply

Hose

Art # A-07943

to 1/4” (6mm) Fitting

Air Connection to Inlet Port

Installing Optional Single - Stage Air Filter

An optional filter kit is recommended for improved

filtering with compressed air, to keep moisture and

debris out of the torch.

1. Attach the Single - Stage Filter Hose to the

Inlet Port.

2. Attach the Filter Assembly to the filter hose.

3. Connect the air line to the Filter. The illustration shows typical fittings as an example.

NOTE!

For a secure seal, apply thread sealant to

the fitting threads, according to the maker's

instructions. Do Not use Teflon tape as a

thread sealer, as small particles of the tape

may break off and block the small air passages in the torch. Connect as follows:

INSTALLATION Manual 0-5378

3-2

Page 19

ESAB CUTMASTER 80

Regulator/Filter

Regulator/Filter

Assembly

Inlet Port

Art # A-07944

Hose Clamp

Gas Supply

Hose

1/4 NPT to 1/4"

(6mm) Fitting

Optional Single - Stage Filter Installation

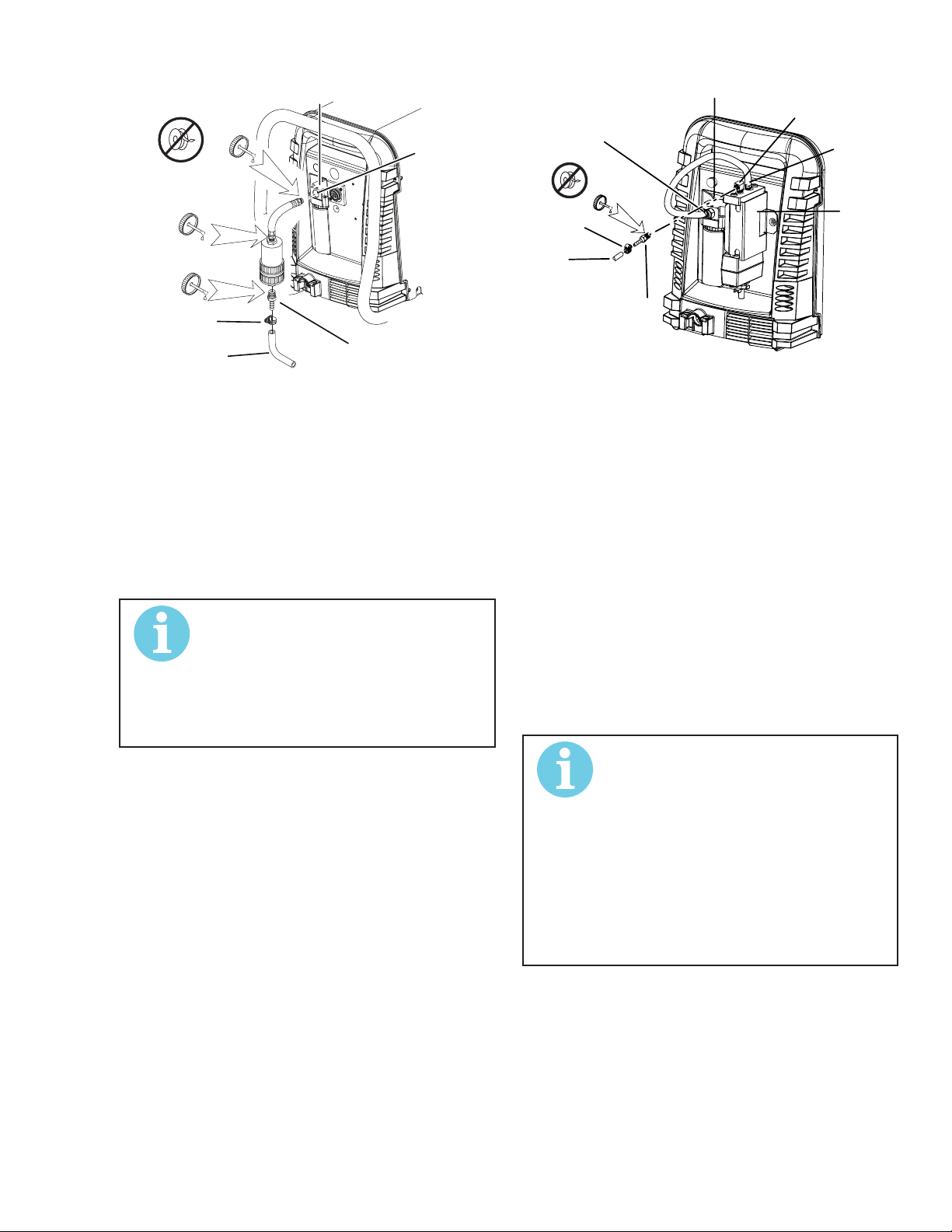

Installing Optional Two - Stage Air Filter Kit

This optional two - stage air line filter is also for use

on compressed air shop systems. Filter removes

moisture and contaminants to at least 5 microns.

Connect the air supply as follows:

1. Attach the Two Stage Filter bracket to the back

of the power supply per instructions supplied

with the filter assembly.

NOTE!

For a secure seal, apply thread sealant to

the fitting threads according to manufacturer's instructions. Do Not use Teflon tape

as a thread sealer as small particles of the

tape may break off and block the small air

passages in the torch.

2. Connect the two stage filter outlet hose to the

inlet port of the Regulator / Filter Assembly.

3. Use customer - supplied fittings to connect the

air line to the Filter. A 1/4 NPT to 1/4" hose

barbed fitting is shown as an example.

Assembly

Regulator

Input

Hose Clamp

Gas Supply

Hose

1/4 NPT to 1/4”

(6mm) Fitting

2-Stage Filter

Inlet Port (IN)

Art # A-07945_AC

Optional Two - Stage Filter Installation

Using High Pressure Air Cylinders

When using high pressure air cylinders as the air

supply:

1. Refer to the manufacturer’s specifications for

installation and maintenance procedures for

high pressure regulators.

2. Examine the cylinder valves to be sure they

are clean and free of oil, grease or any foreign

material. Briefly open each cylinder valve to

blow out any dust which may be present.

3. The cylinder must be equipped with an adjustable high - pressure regulator capable of outlet

pressures up to 100 psi (6.9 bar) maximum

and flows of at least 300 scfh (141.5 lpm).

4. Connect supply hose to the cylinder.

NOTE!

Pressure should be set at 100 psi (6.9 bar)

at the high pressure cylinder regulator.

Supply hose must be at least 1/4 inch (6

mm) I.D.

For a secure seal, apply thread sealant to

the fitting threads, according to manufacturer's instructions. Do Not use Teflon tape

as a thread sealer, as small particles of the

tape may break off and block the small air

passages in the torch.

Outlet Port

(OUT)

Two Stage

Filter

Assembly

Manual 0-5378 INSTALLATION

3-3

Page 20

ESAB CUTMASTER 80

This Page Intentionally Blank

INSTALLATION Manual 0-5378

3-4

Page 21

SECTION 3 TORCH:

INSTALLATION

3T.01 Torch Connections

If necessary, connect the torch to the Power

Supply. Connect only the ESAB model SL60 / Manual

or SL100 / Mechanical Torch to this power supply.

Maximum torch leads length is 100 feet / 30.5 m,

including extensions.

WARNING

Disconnect primary power at the source

1. Align the ATC male connector (on the torch

2. Secure the connection by turning the locking

before connecting the torch.

lead) with the female receptacle. Push the

male connector into the female receptacle.

The connectors should push together with a

small amount of pressure.

nut clockwise until it clicks. DO NOT use the

locking nut to pull the connection together. Do

not use tools to secure the connection.

ESAB CUTMASTER 80

3T.02 Setting Up Mechanical Torch

NOTE!

An adapter is required to be installed in the

power supply if converting a hand torch

system to operate a machine torch.

WARNING

Disconnect primary power at the source before disassembling the torch or torch leads

The mechanical torch includes a positioning tube

with rack and pinch block assembly.

1. Mount the torch assembly on the cutting table.

2. To obtain a clean vertical cut, use a square to

align the torch perpendicular to the surface of

the workpiece.

Pinch Block

Assembly

Art # A-07885

Connecting the Torch to the Power

Supply

3. The system is ready for operation.

Check Air Quality

To test the quality of air:

1. Put the ON / OFF switch in the ON

(up) position.

2. Put the Function Control switch in the SET

Square

Workpiece

A-02585

2

1

Mechanical Torch Set - Up

3. The proper torch parts (shield cup, tip, start

cartridge, and electrode) must be installed for

the type of operation. Refer to Section 4T.07,

Torch Parts Selection for details.

position.

3. Place a welding filter lens in front of the torch

and turn ON the air. Do not start an arc!

Any oil or moisture in the air will be visible on the lens.

Manual 0-5378 INSTALLATION

3T-1

Page 22

ESAB CUTMASTER 80

This Page Intentionally Blank

INSTALLATION Manual 0-5378

3T-2

Page 23

ESAB CUTMASTER 80

12

3

!

SECTION 4 SYSTEM:

OPERATION

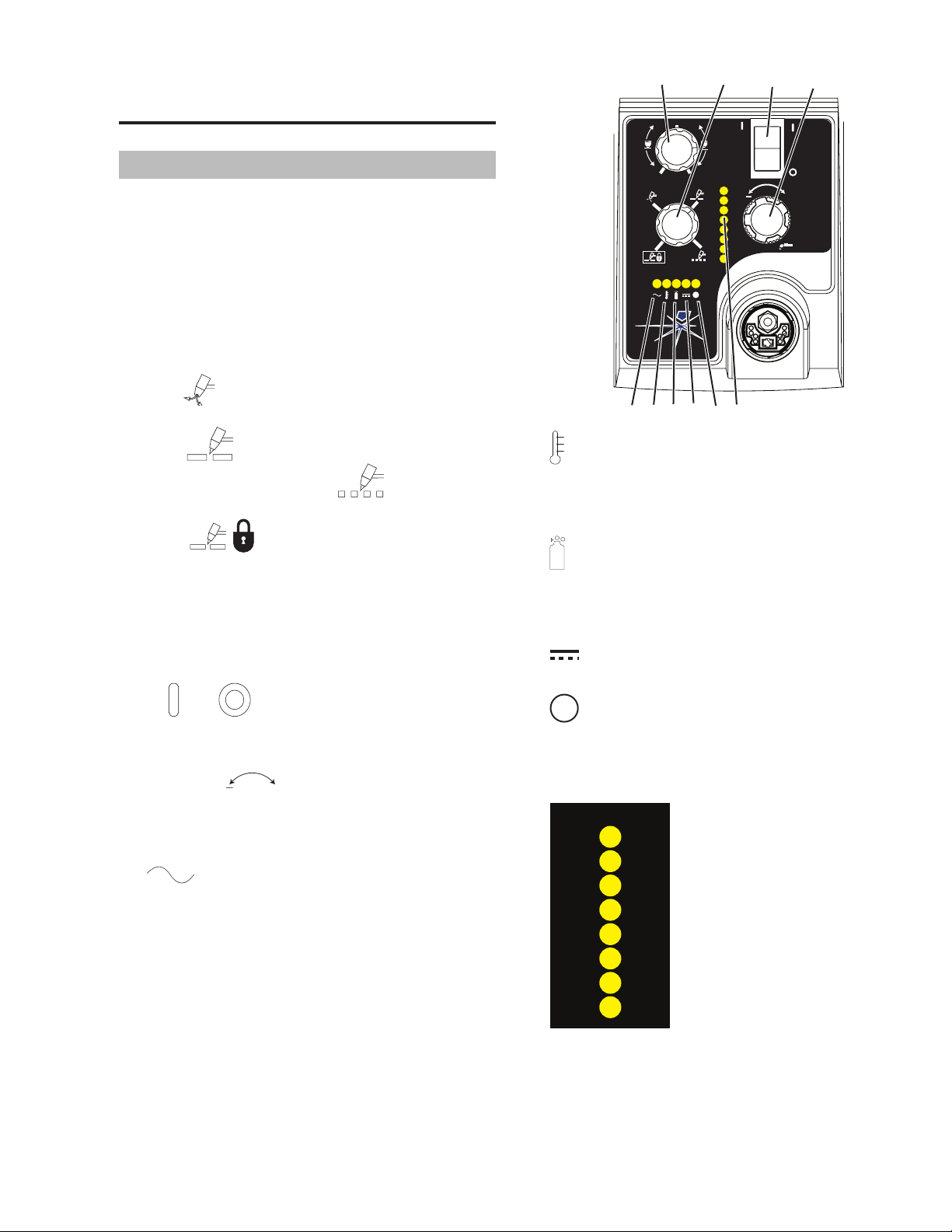

4.01 Front Panel Controls / Features

See illustration for numbering Identification

1. Output Current Control

Sets the desired output current. Output settings up to 60 Amps

may be used for drag cutting (with the torch tip contacting the

workpiece) or higher for standoff cutting.

2. Function Control

Function Control Knob; Used to select between the different

operating modes.

SET Used to purge the air through the

unit and torch and leads and to adjust gas pressure.

RUN Used for general cutting opera-

tions RAPID AUTO RESTART Allows for faster restarting of the Pilot Arc for uninterrupted cutting.

4

MAX

MIN

A

PSI BAR

MAXMAX

MINMIN

!

5

8

7

6

10

9

+

Art# A-07886

6. Temp Indicator

Indicator is normally OFF. Indicator is ON when internal

temperature exceeds normal limits. Let the unit cool before

continuing operation.

LATCH Used for longer hand held cuts. Once a

cutting arc is established, the torch switch can be released.

The cutting arc will remain ON until the torch is lifted away

from the work piece, the torch leaves the edge of the work

piece the torch switch is activated again or if one of the system

interlocks is activated.

3. ON OFF Power Switch

ON / OFF Switch controls input power to the power

supply. Up is ON, down is OFF.

4. Air/Gas Pressure Control

The Pressure

adjust the air/gas pressure. Pull the knob out to adjust and

push in to lock.

5. AC Indicator

Steady light indicates power supply is ready for operation.

Blinking light indicates unit is in protective interlock mode.

Shut unit OFF, shut OFF or disconnect input power, correct

the fault, and restart the unit. Refer to Section 5 for details.

+

Control is used in the "SET" mode to

7. Gas Indicator

Indicator is ON when minimum input gas pressure for power

supply operation is present. Minimum pressure for power

supply operation is not sufficient for torch operation.

8. DC Indicator

Indicator is ON when DC output circuit is active.

9.

Fault Error Indicator

Indicator is ON when Fault circuit is active. See section 5 for

explanations of fault lights.

10. Pressure Indicators

PSI BAR

MAX MAX

90 6.3

85 5.9

80

75

70

65

MINMIN

The Indicators will illuminate according to the pressure set by

the Pressure Control Knob (number 4).

5.5

5.2

4.8

4.5

Art # A-08170

Manual 0-5378 OPERATON

4-1

Page 24

ESAB CUTMASTER 80

Art # A-04509

1

2

4.02 Preparations for Operation

At the start of each operating session:

WARNING

Disconnect primary power at the source

before assembling or disassembling power

supply, torch parts, or torch and leads assemblies.

Torch Parts Selection

Check the torch for proper assembly and appropriate torch

parts. The torch parts must correspond with the type of operation, and with the amperage output of this Power Supply

(80 amps maximum). Refer to Section 4T.07 and following for

torch parts selection.

Torch Connection

Check that the torch is properly connected. Only ESAB model

SL60 / Manual or SL100 / Mechanical Torches may be connected to this Power Supply. See Section 3T of this manual.

Check Primary Input Power Source

1. Check the power source for proper input voltage. Make sure the input power source meets

the power requirements for the unit per Section 2, Specifications.

2. Connect the input power cable (or close the

main disconnect switch) to supply power to

the system.

Air Source

Ensure source meets requirements (refer to Section 2). Check

connections and turn air supply ON.

Power ON

Place the Power Supply ON / OFF switch to the ON (up) position.

AC indicator turns ON. Gas indicator turns ON

if there is sufficient gas pressure for power supply operation

and the cooling fans turn ON.

NOTE!

Minimum pressure for power supply

operation is lower than minimum for torch

operation.

The cooling fans will turn ON as soon as

the unit is turned ON. After the unit is idle

for ten (10) minutes the fans will turn OFF.

The fans will come back ON as soon as the

torch switch (Start Signal) is activated or if

the unit is turned off, then turned ON again.

If an over temperature condition occurs, the

fans will continue to run while the condition

exists and for a ten (10) minute period once

the condition is cleared.

Set Operating Pressure

1. Place the Power Supply Function Control knob

to the SET position. Gas will flow.

2. For Standoff cutting, adjust gas pressure from

70 - 85 psi / 4.8 - 5.9 bar (LED's in center of

control panel). Refer to the Standoff chart for

pressure setting details.

Connect Work Cable

Clamp the work cable to the workpiece or cutting table. The

area must be free from oil, paint and rust. Connect only to

the main part of the workpiece; do not connect to the part to

be cut off.

OPERATION Manual 0-5378

4-2

MIN

MAX

A

PSI BAR

MAXMAX

MINMIN

!

+

Art# A-07946

Page 25

ESAB CUTMASTER 80

STANDOFF

ESAB Cutmaster® 80 Gas Pressure Settings

Leads

Length

Up to 25'

(7.6 m)

Each additional

25' (7.6 m)

SL60

(Hand Torch)

75 psi

5.2 bar

Add 5 psi

0.4 bar

SL100

(Mechanized Torch)

75 psi

5.2 bar

Add 5 psi

0.4 bar

3. For Drag cutting, adjust gas pressure from

75 - 95 psi / 5.2 - 6.5 bar (LED's in center of

control panel). Refer to the Drag Cutting chart

for pressure setting details.

DRAG

ESAB Cutmaster® 80 Gas Pressure

Settings

Leads Length

Up to 25'

(7.6 m)

Each additional

25' (7.6 m)

SL60

(Hand Torch)

80 psi

5.5 bar

Add 5 psi

0.4 bar

Cutting Operation

When the torch leaves the workpiece during cutting operations

with the Function Control Knob in the RUN position, there is

a brief delay in restarting the pilot arc. With the knob in the

RAPID AUTO RESTART position, when the torch leaves the

workpiece the pilot arc restarts instantly, and the cutting arc

restarts instantly when the pilot arc contacts the workpiece.

(Use the 'Rapid Auto Restart' position when cutting expanded

metal or gratings, or in gouging or trimming operations when

an uninterrupted restart is desired). And with the knob in the

LATCH position the main cutting arc will be maintained after

the torch switch is released.

Typical Cutting Speeds

Cutting speeds vary according to torch output amperage, the

type of material being cut, and operator skill. Refer to Section

4T.08 and following for greater details.

Output current setting or cutting speeds may be reduced to

allow slower cutting when following a line, or using a template

or cutting guide while still producing cuts of excellent quality.

Postflow

Release the trigger to stop the cutting arc. Gas continues to

flow for approximately 20 seconds. During post - flow, if the

user moves the trigger release to the rear and presses the trigger, the pilot arc starts. The main arc transfers to the workpiece

if the torch tip is within transfer distance to the workpiece.

Select Current Output Level

1. Place the Function Control Knob in one of the

three operating positions available:

RUN ,

RAPID AUTO RESTART

or LATCH . Gas flow stops.

2. Set the output current to desired amperage

with the Output Current Control Knob.

Shutdown

Turn the ON / OFF switch to OFF (down). All

Power Supply indicators shut OFF. Unplug the input power cord

or disconnect input power. Power is removed from the system.

Manual 0-5378 OPERATON

4-3

Page 26

ESAB CUTMASTER 80

This Page Intentionally Blank

OPERATION Manual 0-5378

4-4

Page 27

ESAB CUTMASTER 80

Kerf Width

Cut Surface

Bevel Angle

Top Edge

Rounding

Cut Surface

Drag Lines

Dross

Build-Up

Top

Spatter

A-00007

SECTION 4 TORCH:

OPERATION

4T.01 Torch Parts Selection

Depending on the type of operation to be done

determines the torch parts to be used.

Type of operation:

Drag cutting, standoff cutting or gouging

Torch parts:

Shield Cup, Cutting Tip, Electrode and Starter Cartridge

NOTE!

Refer to Section 4T.07 and following for additional information on torch parts.

Change the torch parts for a different operation

as follows:

WARNING

Disconnect primary power at the source

before assembling or disassembling power

supply, torch parts, or torch and leads assemblies.

NOTE!

The shield cup holds the tip and starter

cartridge in place. Position the torch with

the shield cup facing upward to keep these

parts from falling out when the cup is

removed.

1. Unscrew and remove the shield cup assembly

from the torch head.

2. Remove the Electrode by pulling it straight out

of the Torch Head.

3. Install the replacement Electrode by pushing it

straight into the torch head until it clicks.

4. Install the starter cartridge and desired tip for

the operation into the torch head.

5. Hand tighten the shield cup assembly until it

is seated on the torch head. If resistance is

felt when installing the cup, check the threads

before proceeding.

4T.02 Cut Quality

NOTE!

Cut quality depends heavily on setup and

parameters such as torch standoff, alignment with the workpiece, cutting speed,

gas pressures, and operator ability.

Cut quality requirements differ depending on

application. For instance, nitride build - up and bevel

angle may be major factors when the surface will be

welded after cutting. Dross - free cutting is important

when finish cut quality is desired to avoid a secondary

cleaning operation. The following cut quality characteristics are illustrated in the following figure:

Torch Head

Electrode

Start Cartridge

Tip

Shield Cup

Cut Surface

Nitride Build - Up

Bevel Angle

A-03510_AB

Torch Parts (Drag Shield Cap & Shield

Cup Body Shown)

Manual 0-5378 OPERATION

Cut Quality Characteristics

The desired or specified condition (smooth or rough) of the

face of the cut.

Nitride deposits can be left on the surface of the cut when

nitrogen is present in the plasma gas stream. These buildups

may create difficulties if the material is to be welded after the

cutting process.

The angle between the surface of the cut edge and a plane

perpendicular to the surface of the plate. A perfectly perpendicular cut would result in a 0° bevel angle.

4T-1

Page 28

ESAB CUTMASTER 80

Right Side

Cut Angle

Left Side

Cut Angle

A-00512

Top - Edge Rounding

Rounding on the top edge of a cut due to wearing from the

initial contact of the plasma arc on the workpiece.

Bottom Dross Buildup

Molten material which is not blown out of the cut area and

resolidifies on the plate. Excessive dross may require secondary cleanup operations after cutting.

Kerf Width

The width of the cut (or the width of material removed during

the cut).

Top Spatter (Dross)

Top spatter or dross on the top of the cut caused by slow travel

speed, excess cutting height, or cutting tip whose orifice has

become elongated.

4T.03 General Cutting Information

WARNING

!

Disconnect primary power at the source

before disassembling the power supply,

torch, or torch leads.

Frequently review the Important Safety

Precautions at the front of this manual. Be

sure the operator is equipped with proper

gloves, clothing, eye and ear protection.

Make sure no part of the operator’s body

comes into contact with the workpiece

while the torch is activated.

CAUTION

!

Sparks from the cutting process can cause

damage to coated, painted, and other surfaces such as glass, plastic and metal.

NOTE!

Handle torch leads with care and protect

them from damage.

Piloting

Piloting is harder on parts life than actual cutting because the

pilot arc is directed from the electrode to the tip rather than

to a workpiece. Whenever possible, avoid excessive pilot arc

time to improve parts life.

Edge Starting

For edge starts, hold the torch perpendicular to the workpiece

with the front of the tip near (not touching) the edge of the

workpiece at the point where the cut is to start. When starting

at the edge of the plate, do not pause at the edge and force the

arc to "reach" for the edge of the metal. Establish the cutting

arc as quickly as possible.

Direction of Cut

In the torches, the plasma gas stream swirls as it leaves the

torch to maintain a smooth column of gas. This swirl effect

results in one side of a cut being more square than the other.

Viewed along the direction of travel, the right side of the cut is

more square than the left.

Side Characteristics Of Cut

To make a square - edged cut along an inside diameter of a

circle, the torch should move counterclockwise around the

circle. To keep the square edge along an outside diameter cut,

the torch should travel in a clockwise direction.

Dross

When dross is present on carbon steel, it is commonly referred

to as either “high speed, slow speed, or top dross”. Dross present on top of the plate is normally caused by too great a torch

to plate distance. "Top dross" is normally very easy to remove

and can often be wiped off with a welding glove. "Slow speed

dross" is normally present on the bottom edge of the plate.

It can vary from a light to heavy bead, but does not adhere

tightly to the cut edge, and can be easily scraped off. "High

speed dross" usually forms a narrow bead along the bottom

of the cut edge and is very difficult to remove. When cutting a

troublesome steel, it is sometimes useful to reduce the cutting

speed to produce "slow speed dross". Any resultant cleanup

can be accomplished by scraping, not grinding.

Torch Standoff

Improper standoff (the distance between the torch tip and

workpiece) can adversely affect tip life as well as shield cup

life. Standoff may also significantly affect the bevel angle.

Reducing standoff will generally result in a more square cut.

OPERATION Manual 0-5378

4T-2

Page 29

4T.04 Hand Torch Operation

A-00024_AB

Shield Cup

Torch

Standoff Distance

1/8" - 3/8" (3 - 9mm)

A-02986

Trigger

Trigger Release

3

4

Art # A-03383

Tr igger

2

1

Tr igger Release

Standoff Cutting With Hand Torch

NOTE!

For best performance and parts life, always

use the correct parts for the type of operation.

1. The torch can be comfortably held in one hand

or steadied with two hands. Position the hand

to press the Trigger on the torch handle. With

the hand torch, the hand may be positioned

close to the torch head for maximum control or

near the back end for maximum heat protection. Choose the holding technique that feels

most comfortable and allows good control and

movement.

NOTE!

The tip should never come in contact with

the workpiece except during drag cutting

operations.

2. Depending on the cutting operation, do one of

the following:

a. For edge starts, hold the torch perpendicu-

lar to the workpiece with the front of the tip

on the edge of the workpiece at the point

where the cut is to start.

b. For standoff cutting, hold the torch 1/8 -

3/8 in (3-9 mm) from the workpiece as

shown below.

ESAB CUTMASTER 80

5. Bring the torch within transfer distance to the

work. The main arc will transfer to the work,

and the pilot arc will shut OFF.

NOTE!

The gas preflow and postflow are a characteristic of the power supply and not a

function of the torch.

Standoff Distance

3. Hold the torch away from your body.

4. Slide the trigger release toward the back of the

torch handle while simultaneously squeezing

the trigger. The pilot arc will start.

Manual 0-5378 OPERATION

6. Cut as usual. Simply release the trigger assembly to stop cutting.

7. Follow normal recommended cutting practices

as provided in the power supply operator's

manual.

NOTE!

When the shield cup is properly installed,

there is a slight gap between the shield cup

and the torch handle. Gas vents through

this gap as part of normal operation. Do

not attempt to force the shield cup to close

this gap. Forcing the shield cup against

the torch head or torch handle can damage

components.

8. For a consistent standoff height from the

workpiece, install the standoff guide by sliding

it onto the torch shield cup. Install the guide

4T-3

Page 30

ESAB CUTMASTER 80

A-03539

Non-Conductive

Straight Edge

Cutting Guide

A-02986

Trigger

Trigger Release

with the legs at the sides of the shield cup

body to maintain good visibility of the cutting

arc. During operation, position the legs of the

standoff guide against the workpiece.

Shield Cup

Standoff Guide

Torch Tip

Workpiece

Art # A-04034

Shield Cup With Straight Edge

The drag shield cup can be used with a non conductive straight

edge to make straight cuts by hand.

WARNING

The straight edge must be non-conductive.

tion. Choose the holding technique that feels

most comfortable and allows good control and

movement.

3. Keep the torch in contact with the workpiece

during the cutting cycle.

4. Hold the torch away from your body.

5. Slide the trigger release toward the back of the

torch handle while simultaneously squeezing

the trigger. The pilot arc will start.

6. Bring the torch within transfer distance to the

work. The main arc will transfer to the work,

and the pilot arc will shut OFF.

NOTE!

The gas preflow and postflow are a characteristic of the power supply and not a

function of the torch.

Tr igger

Using Drag Shield Cup With Straight

Edge

The crown shield cup functions best when cutting 3/16 inch

(4.7 mm) solid metal with relatively smooth surface.

Drag Cutting With a Hand Torch

Drag cutting works best on metal 1/4" (6 mm) thick or less.

NOTE!

For best parts performance and life, always

use the correct parts for the type of operation.

1. Install the drag cutting tip and set the output

current.

2. The torch can be comfortably held in one hand

or steadied with two hands. Position the hand

to press the Trigger on the torch handle. With

the hand torch, the hand may be positioned

close to the torch head for maximum control or

near the back end for maximum heat protec-

1

2

Tr igger Release

3

4

Art # A-03383

7. Cut as usual. Simply release the trigger assembly to stop cutting.

8. Follow normal recommended cutting practices

as provided in the power supply operator's

manual.

OPERATION Manual 0-5378

4T-4

Page 31

ESAB CUTMASTER 80

A-02986

Trigger

Trigger Release

NOTE!

When the shield cup is properly installed,

there is a slight gap between the shield cup

and the torch handle. Gas vents through

this gap as part of normal operation. Do

not attempt to force the shield cup to close

this gap. Forcing the shield cup against

the torch head or torch handle can damage

components.

Piercing With Hand Torch

1. The torch can be comfortably held in one hand

or steadied with two hands. Position the hand

to press the Trigger on the torch handle. With

the hand torch, the hand may be positioned

close to the torch head for maximum control or near the back end for maximum heat

protection. Choose the technique that feels

most comfortable and allows good control and

movement.

NOTE!

The tip should never come in contact with

the workpiece except during drag cutting

operations.

2. Angle the torch slightly to direct blowback

particles away from the torch tip (and operator)

rather than directly back into it until the pierce

is complete.

3. In a portion of the unwanted metal start the

pierce off the cutting line and then continue

the cut onto the line. Hold the torch perpendicular to the workpiece after the pierce is

complete.

4. Hold the torch away from your body.

5. Slide the trigger release toward the back of the

torch handle while simultaneously squeezing

the trigger. The pilot arc will start.

and the pilot arc will shut OFF.

NOTE!

The gas preflow and postflow are a characteristic of the power supply and not a

function of the torch.

When the shield cup is properly installed,

there is a slight gap between the shield cup

and the torch handle. Gas vents through

this gap as part of normal operation. Do

not attempt to force the shield cup to close

this gap. Forcing the shield cup against

the torch head or torch handle can damage

components.

7. Clean spatter and scale from the shield cup

and the tip as soon as possible. Spraying the

shield cup in anti - spatter compound will

minimize the amount of scale which adheres

to it.

Cutting speed depends on material, thickness,

and the operator’s ability to accurately follow the

desired cut line. The following factors may have an

impact on system performance:

• Torchpartswear

• Airquality

• Linevoltageuctuations

• Torchstandoffheight

• Properworkcableconnection

6. Bring the torch within transfer distance to the

work. The main arc will transfer to the work,

Manual 0-5378 OPERATION

4T-5

Page 32

ESAB CUTMASTER 80

35°

Workpiece

Torch Head

Standoff Height

A-00941_AB

4T.05 Gouging

WARNING

!

!

Gouging Parameters

Gouging performance depends on parameters such as torch

travel speed, current level, lead angle (the angle between the

torch and workpiece), and the distance between the torch tip

and workpiece (standoff).

!

Be sure the operator is equipped with

proper gloves, clothing, eye and ear protection and that all safety precautions at the

front of this manual have been followed.

Make sure no part of the operator’s body

comes in contact with the workpiece when

the torch is activated.

Disconnect primary power to the system

before disassembling the torch, leads, or

power supply.

CAUTION

Sparks from plasma gouging can cause

damage to coated, painted or other surfaces such as glass, plastic, and metal.

Check torch parts. The torch parts must

correspond with the type of operation. Refer

to Section 4T.07, Torch Parts Selection.

CAUTION

Touching the torch tip or shield cup to the

work surface will cause excessive parts

wear.

Gouging Angle and Standoff Distance

Standoff Distance

The tip to work distance affects gouge quality and depth.

Standoff distance of 1/8 - 1/4 inch (3 - 6 mm) allows for

smooth, consistent metal removal. Smaller standoff distances

may result in a severance cut rather than a gouge. Standoff

distances greater than 1/4 inch (6 mm) may result in minimal

metal removal or loss of transferred main arc.

Slag Buildup

Slag generated by gouging on materials such as carbon and

stainless steels, nickels, and alloyed steels, can be removed

easily in most cases. Slag does not obstruct the gouging process if it accumulates to the side of the gouge path. However,

slag build - up can cause inconsistencies and irregular metal

removal if large amounts of material build up in front of the

arc. The build - up is most often a result of improper travel

speed, lead angle, or standoff height.

Torch Travel Speed

NOTE!

Refer to Appendix Pages for additional

information as related to the Power Supply

used.

Optimum torch travel speed is dependent on current setting,

lead angle, and mode of operation (hand or machine torch).

Current Setting

Current settings depend on torch travel speed, mode of operation (hand or machine torch), and the amount of material to

be removed.

Lead Angle

The angle between the torch and workpiece depends on the

output current setting and torch travel speed. The recommended lead angle is 35°. At a lead angle greater than 45°

the molten metal will not be blown out of the gouge and may

be blown back onto the torch. If the lead angle is too small

(less than 35°), less material may be removed, requiring more

passes. In some applications, such as removing welds or

working with light metal, this may be desirable.

4T.06 Mechanized Torch Operation

Cutting With Mechanized Torch

The mechanized torch can be activated by remote control

pendant or by a remote interface device such as CNC.

1. To start a cut at the plate edge, position the

center of the torch along the edge of the plate.

Travel Speed

Proper travel speed is indicated by the trail of the arc which

is seen below the plate. The arc can be one of the following:

OPERATION Manual 0-5378

4T-6

Page 33

ESAB CUTMASTER 80

Standoff Distance

Straight Arc

Trailing Arc

Leading Arc

Direction of Torch Travel

A-02586

1. Straight Arc

A straight arc is perpendicular to the workpiece surface.

This arc is generally recommended for the best cut using

air plasma on stainless or aluminum.

2. Leading Arc

The leading arc is directed in the same direction as torch

travel. A five degree leading arc is generally recommended

for air plasma on mild steel.

3. Trailing Arc

The trailing arc is directed in the opposite direction as

torch travel.

Piercing With Machine Torch

To pierce with a machine torch, the arc should be started with

the torch positioned as high as possible above the plate while

allowing the arc to transfer and pierce. This standoff helps

avoid having molten metal blow back onto the front end of

the torch.

When operating with a cutting machine, a pierce or dwell time

is required. Torch travel should not be enabled until the arc

penetrates the bottom of the plate. As motion begins, torch

standoff should be reduced to the recommended 1/8 - 1/4

inch (3-6 mm) distance for optimum speed and cut quality.

Clean spatter and scale from the shield cup and the tip as

soon as possible. Spraying or dipping the shield cup in anti

- spatter compound will minimize the amount of scale which

adheres to it.

For optimum smooth surface quality, the travel speed should

be adjusted so that only the leading edge of the arc column

produces the cut. If the travel speed is too slow, a rough cut

will be produced as the arc moves from side to side in search

of metal for transfer.

Travel speed also affects the bevel angle of a cut. When cutting

in a circle or around a corner, slowing down the travel speed

will result in a squarer cut. The power source output should

be reduced also. Refer to the appropriate Control Module

Operating Manual for any Corner Slowdown adjustments that

may be required.

Manual 0-5378 OPERATION

Mechanized Torch Operation

4T-7

Page 34

ESAB CUTMASTER 80

4T.07 Parts Selection for Manual and Mechanized Torch Cutting

Start

Cartridge

9-8213

DRAG TIP

CUTTING

40A

CUTTING

50-60A

CUTTING

Tips:

20A 9-8205

30A 9-8206

40A 9-8207

60A 9-8252

DRAG SHIELD

CUTTING

Tip:

40A 9-8208

STANDOFF

CUTTING

DRAG SHIELD

CUTTING

Tips:

50-55A 9-8209

60A 9-8210

STANDOFF

CUTTING

Shield

Cup Body,

9-8237

Shield Cup

9-8218

O-Ring No. 8-3488

Shield

Cup Body,

9-8237

Shield Cup

9-8218

O-Ring No. 8-3488

Shield

Cup Body,

9-8237

Shield Cup

9-8218

Shield Cap, Deflector

9-8243

Shield Cap, Drag

40A 9-8244

Shield Cap, Deflector

9-8243

Standoff Guide

9-8251

Shield Cap, Drag

50-60A 9-8235

Shield Cap, Deflector

9-8243

Standoff Guide

9-8281

Electrode

9-8215

Art # A-12790_AA

DRAG SHIELD

CUTTING

70-120A

CUTTING

80A 9-8211

90/100A 9-8212

Tips:

70A 9-8231

120A 9-8253

STANDOFF CUTTING

40-120A

GOUGING

Tips:

Tip Gouging A 9-8225 (40 Amps Max.)

Tip Gouging B 9-8226 (50 - 100 Amps)

Tip Gouging C 9-8227 (60 - 120 Amps)

Tip Gouging D 9-8228 (60 - 120 Amps)

Tip Gouging E 9-8254 (60 - 120 Amps)

O-Ring No. 8-3488

Shield

Cup Body,

9-8237

Shield Cup

9-8218

Shield

Cup Body,

9-8237

Shield Cap, Drag

70-100A 9-8236

Shield Cap, Deflector

9-8243

Standoff Guide

9-8281

Shield Cap, Gouging

9-8241

NOTE

ESAB CutMaster 60 uses 60A and less

ESAB CutMaster 80 uses 80A and less

ESAB CutMaster 100 uses 100A and less

ESAB CutMaster 120 uses 120A and less

OPERATION Manual 0-5378

4T-8

Page 35

ESAB CUTMASTER 80

4T.08 Recommended Cutting Speeds for Mechanized Torch With Exposed Tip

Type Torch: SL60 With Exposed Tip Type Material: Mild Steel

Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch

Thickness Tip Output Amperage Speed (Per Minute) Standoff Plasma Gas Press Flow (CFH) Pierce Pierce Height

Inches mm (Cat. No.) Volts(VDC) (Amps) Inches Meters Inches mm psi* bar Plasma Total** Delay (Sec) Inches mm

0.036 0.9 9-8208 104 40 340 8.64 0.19 4.8 70 4.8 55 170 0.00 0.2 5.1

0.06 1.5 9-8208 108 40 250 6.35 0.19 4.8 70 4.8 55 170 0.10 0.2 5.1

0.075 1.9 9-8208 108 40 190 4.83 0.19 4.8 70 4.8 55 170 0.30 0.2 5.1

0.135 3.4 9-8208 110 40 105 2.67 0.19 4.8 70 4.8 55 170 0.40 0.2 5.1

0.188 4.8 9-8208 113 40 60 1.52 0.19 4.8 70 4.8 55 170 0.60 0.2 5.1

0.25 6.4 9-8208 111 40 40 1.02 0.19 4.8 70 4.8 55 170 1.00 0.2 5.1

0.375 9.5 9-8208 124 40 21 0.53 0.19 4.8 70 4.8 55 170 NR NR NR

0.500 12.7 9-8208 123 40 11 0.28 0.19 4.8 70 4.8 55 170 NR NR NR

0.625 15.9 9-8208 137 40 7 0.18 0.19 4.8 70 4.8 55 170 NR NR NR

Type Torch: SL60 With Exposed Tip Type Material: Stainless Steel

Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch

Thickness Tip Output Amperage Speed (Per Minute) Standoff Plasma Gas Press Flow (CFH) Pierce Pierce Height

Inches mm (Cat. No.) Volts(VDC) (Amps) Inches Meters Inches mm psi* bar Plasma Total** Delay (Sec) Inches mm

0.036 0.9 9-8208 103 40 355 9.02 0.125 3.2 70 4.8 55 170 0.00 0.2 5.1

0.05 1.3 9-8208 98 40 310 7.87 0.125 3.2 70 4.8 55 170 0.00 0.2 5.1

0.06 1.5 9-8208 98 40 240 6.10 0.125 3.2 70 4.8 55 170 0.10 0.2 5.1

0.078 2.0 9-8208 100 40 125 3.18 0.125 3.2 70 4.8 55 170 0.30 0.2 5.1

0.135 3.4 9-8208 120 40 30 0.76 0.187 4.8 70 4.8 55 170 0.40 0.2 5.1

0.188 4.8 9-8208 124 40 20 0.51 0.187 4.8 70 4.8 55 170 0.60 0.2 5.1

0.25 6.4 9-8208 122 40 15 0.38 0.187 4.8 70 4.8 55 170 1.00 0.2 5.1

0.375 9.5 9-8208 126 40 10 0.25 0.187 4.8 70 4.8 55 170 NR NR NR

Type Torch: SL60 With Exposed Tip Type Material: Aluminum

Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch

Thickness Tip Output Amperage Speed (Per Minute) Standoff Plasma Gas Press Flow (CFH) Pierce Pierce Height

Inches mm (Cat. No.) Volts(VDC) (Amps) Inches Meters Inches mm psi* bar Plasma Total** Delay (Sec) Inches mm

0.032 0.8 9-8208 110 40 440 11.18 0.187 4.8 70 4.8 55 170 0.00 0.2 5.1

0.051 1.3 9-8208 109 40 350 8.89 0.187 4.8 70 4.8 55 170 0.10 0.2 5.1

0.064 1.6 9-8208 112 40 250 6.35 0.187 4.8 70 4.8 55 170 0.10 0.2 5.1

0.079 2.0 9-8208 112 40 200 5.08 0.19 4.8 70 4.8 55 170 0.30 0.2 5.1

0.125 3.2 9-8208 118 40 100 2.54 0.19 4.8 70 4.8 55 170 0.40 0.2 5.1

0.188 4.8 9-8208 120 40 98 2.49 0.187 4.8 70 4.8 55 170 0.60 0.2 5.1

0.250 6.4 9-8208 123 40 50 1.27 0.187 4.8 70 4.8 55 170 1.00 0.2 5.1

0.375 9.5 9-8208 134 40 16 0.41 0.187 4.8 70 4.8 55 170 NR NR NR

Manual 0-5378 OPERATION

4T-9

Page 36

ESAB CUTMASTER 80

Type Torch: SL60 With Exposed Tip Type Material: Mild Steel

Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch

Thickness Tip Output Amperage Speed (Per Minute) Standoff Plasma Gas Press Flow (CFH) Pierce Pierce Height

Inches mm (Cat. No.) Volts(VDC) (Amps) Inches Meters Inches mm psi* bar Plasma Total** Delay (Sec) Inches mm

0.060 1.5 9-8210 110 60 290 7.37 0.19 4.8 75 5.2 90 245 0.00 0.19 4.8

0.075 1.9 9-8210 120 60 285 7.24 0.19 4.8 75 5.2 90 245 0.10 0.19 4.8

0.120 3.0 9-8210 120 60 180 4.57 0.19 4.8 75 5.2 90 245 0.10 0.19 4.8

0.135 3.4 9-8210 119 60 170 4.32 0.19 4.8 75 5.2 90 245 0.10 0.19 4.8