Page 1

Crossbow Operation

Quick Start Guide

Refer to Crossbow Instruction Manual

for detailed operating instructions.

Article Number: 0560956424

Revision Date: April 30, 2015

Revision Number: 00

Language: ENG

Page 2

CROSSBOW QUICK-START GUIDE

1

Procedure to create a new program from the Shape Library and load into temporary Run Memory.

Start from the Main Menu (pictured below).

If the control is not showing the Main Menu

(pictured above), press [ESC] key until the

Main Menu is reached.

Create Program From Library

Select desired shape

using Arrow Keys.

Press [F6] LIBRARY.

Make selection by

pressing [Enter].

Page 3

BASIC OPERATION

Type desired dimensions

on number pad, press [Enter]

to finish each entry.

Press [F6] APPLY to preview

part.

When finished, press [ESC].

The part is stored in temporary

Run Memory. The part can

be cut immediately by going

directly to procedure 5, “Run the

Program”.

Page 4

CROSSBOW QUICK-START GUIDE

2

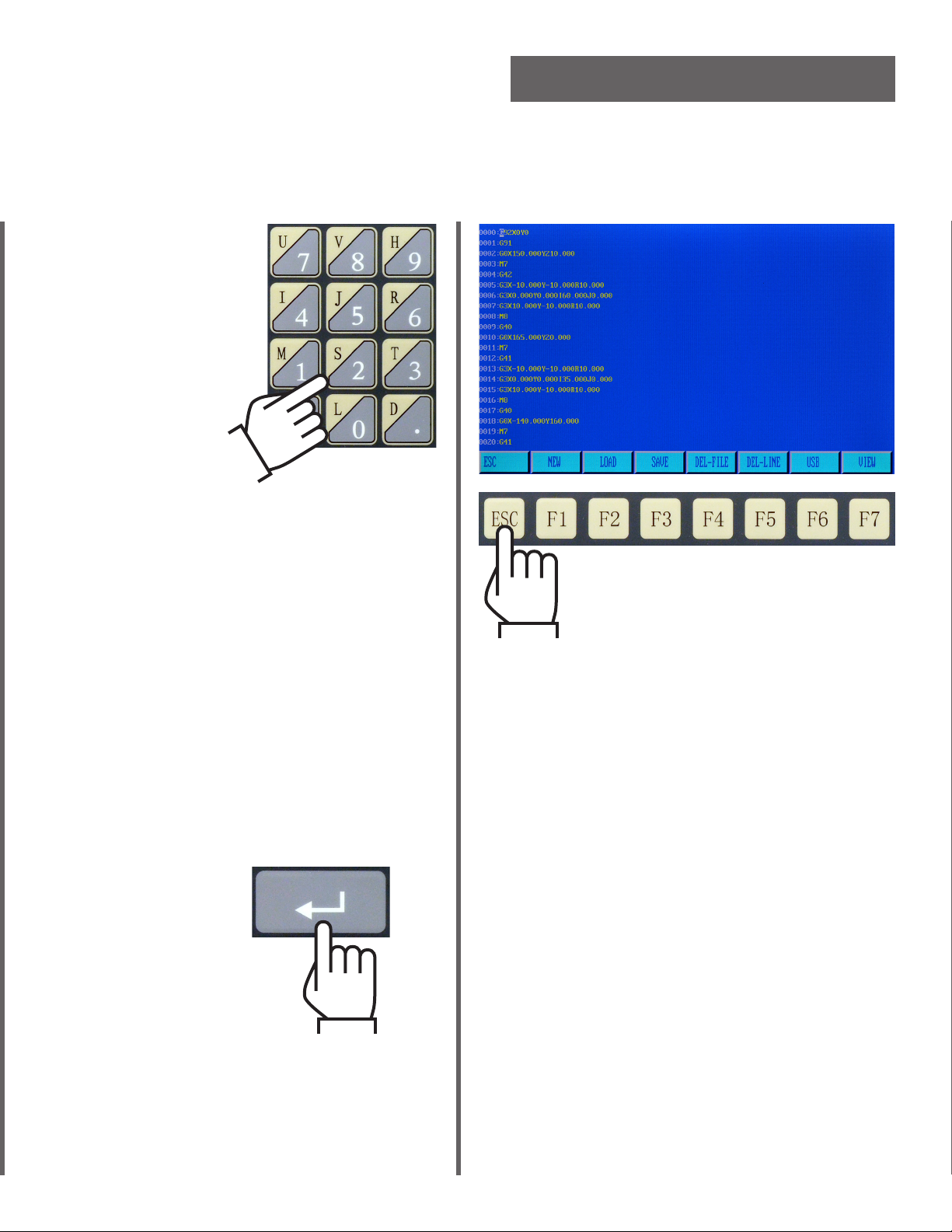

Procedure to store a program from temporary Run Memory into permanent Internal Storage.

Save the Program

Press [F3] EDIT.

Verify part is correct, then press

[F7] VIEW again to close the

preview window.

Press [F7] VIEW to preview

program.

Press [F3] SAVE.

Page 5

Type file name on

number pad.

BASIC OPERATION

File Naming:

The program name and extension should not

exceed 12 characters.

It is recommended to use a file name with

numbers only, up to 7 characters, plus “.TXT”

as the extension.

Be sure to use an extension, or the control

may be unable to recall the file.

When finished,

press [Enter].

When finished, press [ESC] to

return to main menu.

The file will be saved to permanent

Internal Storage.

Page 6

CROSSBOW QUICK-START GUIDE

3

Procedure to recall a program from permanent Internal Storage into temporary Run Memory.

Load Program from Memory

Press [F3] EDIT.

Use up and down arrow keys

to highlight name of desired

program.

Press [F2] LOAD.

Press [Enter] to select

desired program.

The selected program is opened in the editor.

Page 7

BASIC OPERATION

Press [F7] VIEW to preview

program.

When finished, press [ESC].

The part is stored in temporary

Run Memory.

Press [F7] VIEW again to

turn off preview.

Page 8

CROSSBOW QUICK-START GUIDE

4

Procedure to load a program from a USB disk onto the Crossbow CNC.

Load Program from USB

Press [F3] EDIT.

Press [F1] LOAD.

The contents of the USB disk are read and

displayed. If an error occurs, check the USB

drive and re-format if necessary.

USB disks used with the Crossbow must be

formatted as “FAT” or “FAT32” file systems.

Press [F6] USB.

Page 9

BASIC OPERATION

Use up and down arrow keys

to highlight name of desired

program.

Press [Enter] to select

desired program.

The selected program is opened in the editor.

Press [F3] SAVE to

store program in

permanent Internal

Storage.

To run the program directly from

USB drive without storing in

memory, press [ESC]. The part is

stored in temporary Run Memory.

Page 10

CROSSBOW QUICK-START GUIDE

5

Procedure to execute a program that has been loaded into temporary Run Memory.

Run the Program

Press [F1] AUTO.

Press [F4] PREVIEW

again to return to

Automatic Mode menu.

Press [F4] PREVIEW to

verify the correct part

is loaded.

If part looks correct, then proceed.

Switch Drive Enable to OFF.

Manually position the torch to the starting

point.

Make sure the plasma or oxy-fuel torch is

set up correctly, with proper consumables.

Switch Drive Enable to ON.

Page 11

BASIC OPERATION

Press [F] key to adjust

cutting speed (Feed rate).

Type desired speed on

number pad, then press

[Enter].

When ready

Press [START].

To interrupt program,

press [STOP].

Speed must be entered as four digits. To enter

45 inches per minute, enter 0045.

OPTION: Press [X] key to

enable DRY RUN mode if

you wish to run the program with out cutting.

Press [ESC] once to abandon

program and return to Auto Mode

menu.

Press [ESC] again to quit Auto

Mode and return to main menu.

Page 12

CROSSBOW QUICK-START GUIDE

6

Procedure to set control for using plasma torch.

Press [F4] SETUP.

Setup To Cut with Plasma

Use number keypad to

change PLASMA / OXYFUEL parameter to “1”.

Press [F5] CONTROL.

Press [F7] SAVE to store the new

parameters. Failure to press save

will cause any changes to be lost.

Page 13

Press [F4] PLASMA.

BASIC OPERATION

Below are recommended initial settings for

PLASMA parameters. Set PIERCE TIME and

FIRST PIERCE TIME depending on meterial

thickness. Refer to plasma torch manual for

recommended settings.

FIND INITIAL HEIGHT 1

IHS LOGIC 0

IHS AFTER PAUSE 0

INITIAL HEIGHT TIMER 00.50

TORCHUP TIME 001.00

TORCHDN TIME 000.00

USE ARC-ON SIGNAL 1

MAX TIME FOR ARC-ON 12.0

PIERCE TIME 0.50

FIRST PIERCE TIME 0.50

WATER INJECTION 0

NUM FOR PIERCE TIMER 1

AHC CORNER DISTANCE 00010

AHC-OFF LOOK AHEAD 02.0

ARC VOLTAGE DELAY 00.5

ARC ON M ORDER 12

ARC OFF M ORDER 13

Use up and down arrow keys

to navigate parameters.

Use number keypad to

change parameters as

required.

Press [F7] SAVE.

Continue immediately with the following

procedure to cut a part with plasma.

Page 14

CROSSBOW QUICK-START GUIDE

7

Procedure to cut a part using plasma torch.

Cut with Plasma

Press [F1] AUTO.

Press [F4] PREVIEW

again to return to

Automatic Mode menu.

Press [F4] PREVIEW to

verify the correct part

is loaded.

Press [F5] KERF to

set the kerf width.

Page 15

Type desired Kerf

width using number

pad, then press [Enter].

BASIC OPERATION

Switch Drive Enable to OFF.

Make sure the plasma torch is set up correctly,

with proper consumables.

Manually position the torch at the desired

starting position over the plate.

Press [F] key to adjust

cutting speed (Feedrate).

Type desired Speed

using number pad,

then press [Enter].

Switch Drive Enable to ON.

When ready

Press [START].

After torch begins to cut, use

“S-Up” and “S-Down” keys to

adjust the cutting height. The

Automatic Height Control will

maintain the new height.

Page 16

CROSSBOW QUICK-START GUIDE

8

Procedure to set control for using oxy-fuel torch.

Press [F4] SETUP.

Setup To Cut with Oxy-Fuel Torch

Use number keypad to

change PLASMA / OXYFUEL parameter to “0”.

Press [F5] CONTROL.

Press [F7] SAVE to store the new

parameters. Failure to press save

will cause any changes to be lost.

Page 17

BASIC OPERATION

Below are recommended initial settings for

FLAME parameters. Set PREHEAT TIME and

PIERCE TIME as needed.

IGNITE TIME 00.00

PREHEAT TIME 100.00

TORCHUP TIME(M70) 000.00

TORCHDN TIME(M71) 000.00

PIERCEUP HIGH(M72) 000.00

PIERCEDN HIGH(M73) 000.00

PIERCE TIME 000.00

CUT-OXY BLEED DELAY 00.50

USE HIGH-PREHEAT M24 0

GAS ON M ORDER 10

LEAVE PREHEATS ON 0

Use up and down arrow keys

to navigate parameters.

Use number keypad to

change parameters as

required.

Press [F3] FLAME.

Press [F7] SAVE.

Continue immediately with the following

procedure to cut a part with Oxy-Fuel.

Page 18

CROSSBOW QUICK-START GUIDE

9

Procedure to cut a part using oxy-fuel torch.

Cut with Oxy-Fuel

Press [F1] AUTO.

Press [F4] PREVIEW

again to return to

Automatic Mode menu.

Press [F4] PREVIEW to

verify the correct part

is loaded.

Press [F5] KERF to

set the kerf width.

Page 19

Type desired Kerf

width using number

pad, then press [Enter].

BASIC OPERATION

Switch Drive Enable to OFF.

Make sure the oxy-fuel torch is set up correctly, with proper consumables, flame is lit, and

adjusted properly.

Manually position the torch at the desired

starting position over the plate.

Press [F] key to adjust

cutting speed (Feedrate).

Type desired Speed

using number pad,

then press [Enter].

Switch Drive Enable to ON.

When ready

Press [START].

Press [G] key (CONTINUE) to

override Preheat Timer, turn

on cutting oxygen, and startthe Pierce Time.

While cutting, use “S-Up” and

“S-Down” keys to adjust the

cutting height as required.

Page 20

Customer // Technical Support

(843) 664-4405

(800) ESAB-123 (372-2123)

ESAB Welding and Cutting Products

PO BOX 100545 Ebenezer Road

Florence, SC 29501-0545

http://www.esab.com

ESAB Cutting Systems – Canada

6010 Tomken Road

Mississauga, Ontario Canada L5T 1X9

Phone: (905) 670-0220

Fax: (905) 670-4879

ESAB Cutting Systems GMBH

Robert-Bosch-Strasse 20

Pos tf ac h 1128

D-61184 Karben 1

Phone 011-49-6039-400

Fax 011-49-6039-403-02

http://www.esab.de

Loading...

Loading...