Page 1

MEK 2

Service manual

0740 800 094

020531

Page 2

LIST OF CONTENTS Page

READ THIS FIRST 2..................................

COMPONENT DESCRIPTION 4........................

CONNECTION DIAGRAM 5............................

DESCRIPTION OF OPERATION 6......................

1 Power supply 7.........................................

2 2--stroke / 4--stroke 8....................................

3 Start / Stop 8...........................................

4 Current relay, Creep start / Normal start 9..................

5 Motor driving / braking 10..................................

6 Tachometer input 1 1......................................

7 Burn--back time 1 1.......................................

8 Wire feed speed 1 1.......................................

9 Gas valve 12............................................

10 Activation, contactor 12...................................

11 Processor 12............................................

TECHNICAL DATA 13..................................

MAINTENANCE 13....................................

SETTING THE WIRE FEED PRESSURE 14...............

CONTROL PANEL AND CONNECTIONS 15..............

ACCESSORIES 16.....................................

SPARE PARTS LIST 17.................................

NOTES 24............................................

READ THIS FIRST

Maintenance and repair work should be performed by an experienced person, and electrical

work only by a trained electrician. Use only recommended replacement parts.

This service manual is intended for use by technicians with electrical/electronic training for

help in connection with fault--tracing and repair .

Use the connection diagram as a form of index for the d escription of operation. The circuit

board is divided into numbered blocks, which are described individually in more detail in

the description of operation. All component names in the connection diagram are listed in

the component description.

This manual contains details of all design changes that have been made up to and including

May 2002.

The MEK 2 is designed and tested in accordance with international and European

standard IEC/EN 60974--1 and EN 50199.

On completion of service or repair work, it is the responsibility of the person(s) etc.

performing the work to ensure that the product does not depart from the requirements

of the above standard.

Rights reserved to alter specifications without notice.

cmek2de1

-- 2 --

Page 3

WARNING !

STATIC ELECTRICITY can damage circuit

boards and electronic components.

SSSS Observe precautions for handling electrostatic

sensitive devices.

ESD

SSSS Use proper static--proof bags and boxes.

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and

the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use ear defenders or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

WARNING!

Rotating parts can cause injury, take great care

-- 3 --cmek2de1

Page 4

COMPONENT DESCRIPTION

This component description refers to the connection diagram. In the description of operation

on page 7 there is a more detailed description of the components and their function.

AP01 Main circuit board with control electronics.

C01 Capacitor 0.1 ←F 125 VAC, decoupling.

G01 Tachogenerator, incorporated in motor M01.

M01 Motor, rated voltage 24 V.

R3 Potentiometer, for setting the burn--back time.

RP01 Potentiometer, 10 kτ, for setting the wire feed speed.

SW1 Switch, 2/4--stroke changeover.

SW2 Switch, creep start ON/OFF

XP01 23--pole connector, for connection to the welding power unit.

XP02 Terminal for welding current connection from the power unit.

XS01 -- XS09 Sleeve connectors.

YV01 Solenoid valve

cmek2de1

-- 4 --

Page 5

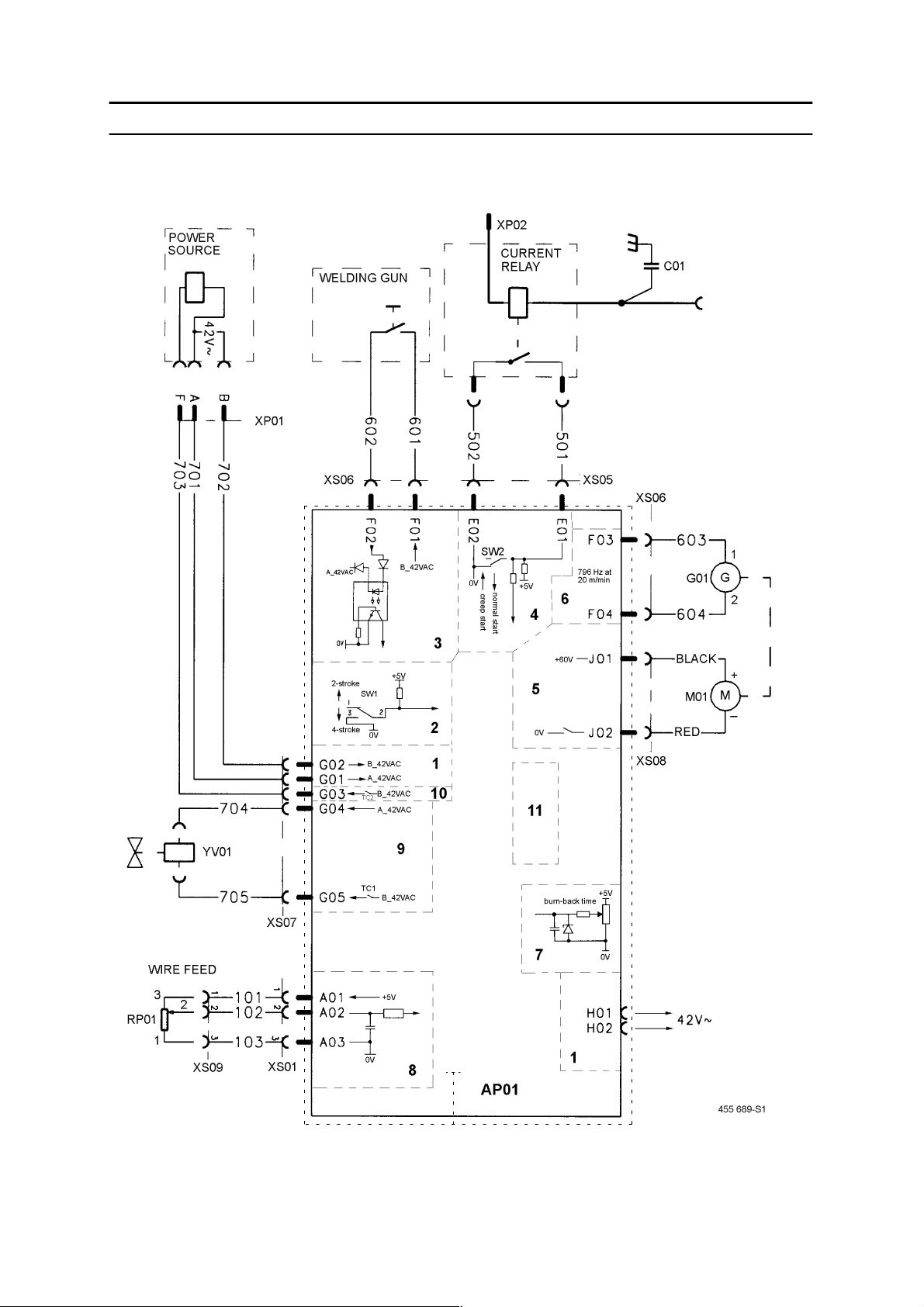

CONNECTION DIAGRAM MEK 2

The numerals 1 -- 11 refer to the description of operation.

R3

0V

cmek2e01

-- 5 --cmek2de1

Page 6

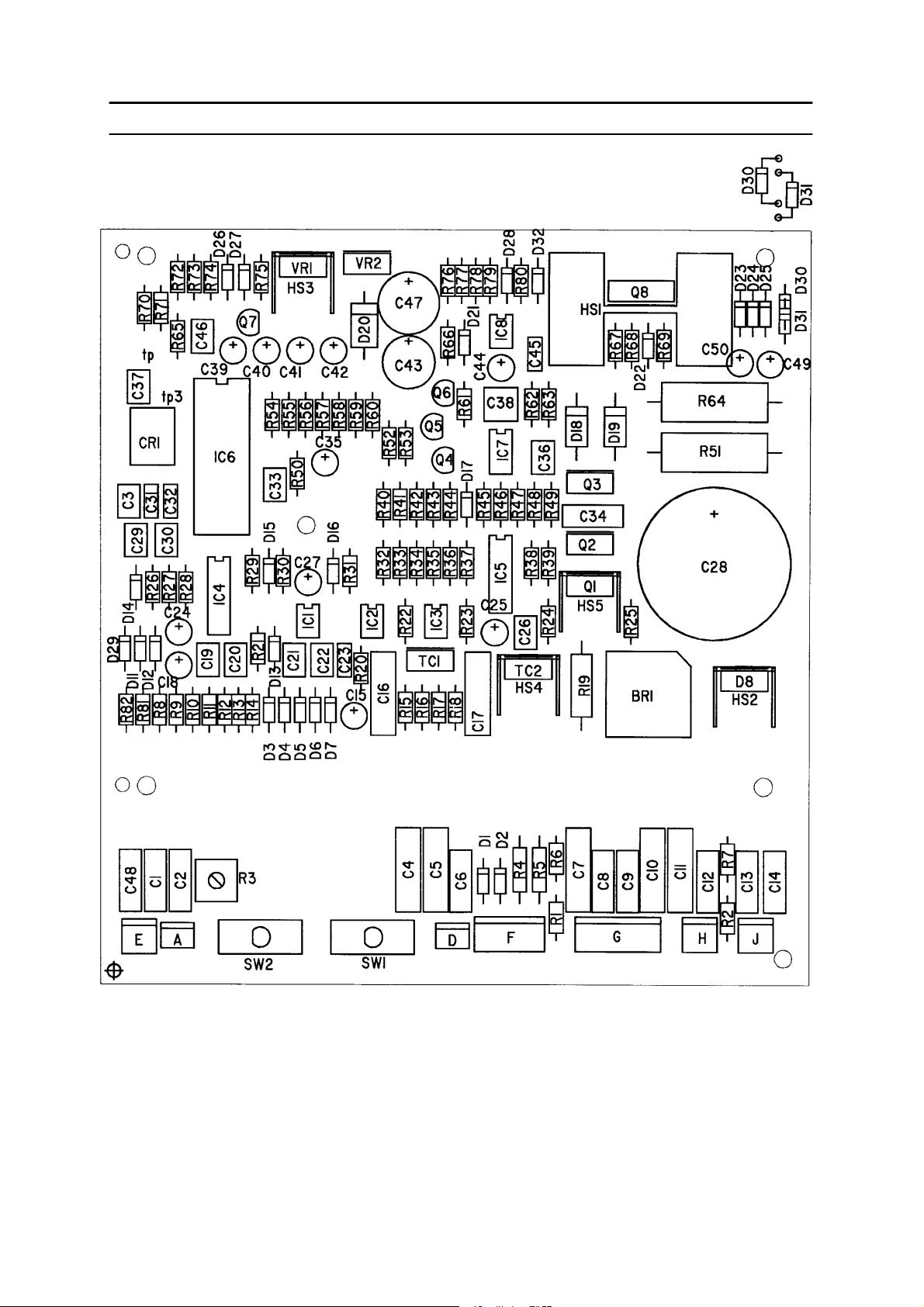

DESCRIPTION OF OPERATION

Component positions, circuit board AP01

cmek2de1

cmek2e02

-- 6 --

Page 7

Sections1to11belowrefertothediagramonpage5.

The circuit board is screened by a metal casing, connected to 0 V in the wire feed unit.

1 Power supply

The feeder obtains a 42 V supply from the control power supply tr ansformer in the

power unit via contact XP01. Its power demand at maximum load is 3.5 A.

42 V AC is used for the welding torch trigger switch and as the power supply to the

gas solenoid valve and the main contactor. In addition, 42 V is also available on

contacts H01 and H02.

cmek2e09

Rectifier BR1 rectifies the 42 V supply to 60 V. Capacitor C28 smooths the voltage,

which then supplies the wire feeder motor.

Transistor Q8 is a pre--regulator which reduces the voltage from 60 V to 20 V. Q8 is

current--limited to about 200 mA. If the 20 V supply drops below 13 V, the wire

feed unit stops.

VR1 and VR2 are 5 V and 15 V voltage regulators respectively.

-- 7 --cmek2de1

Page 8

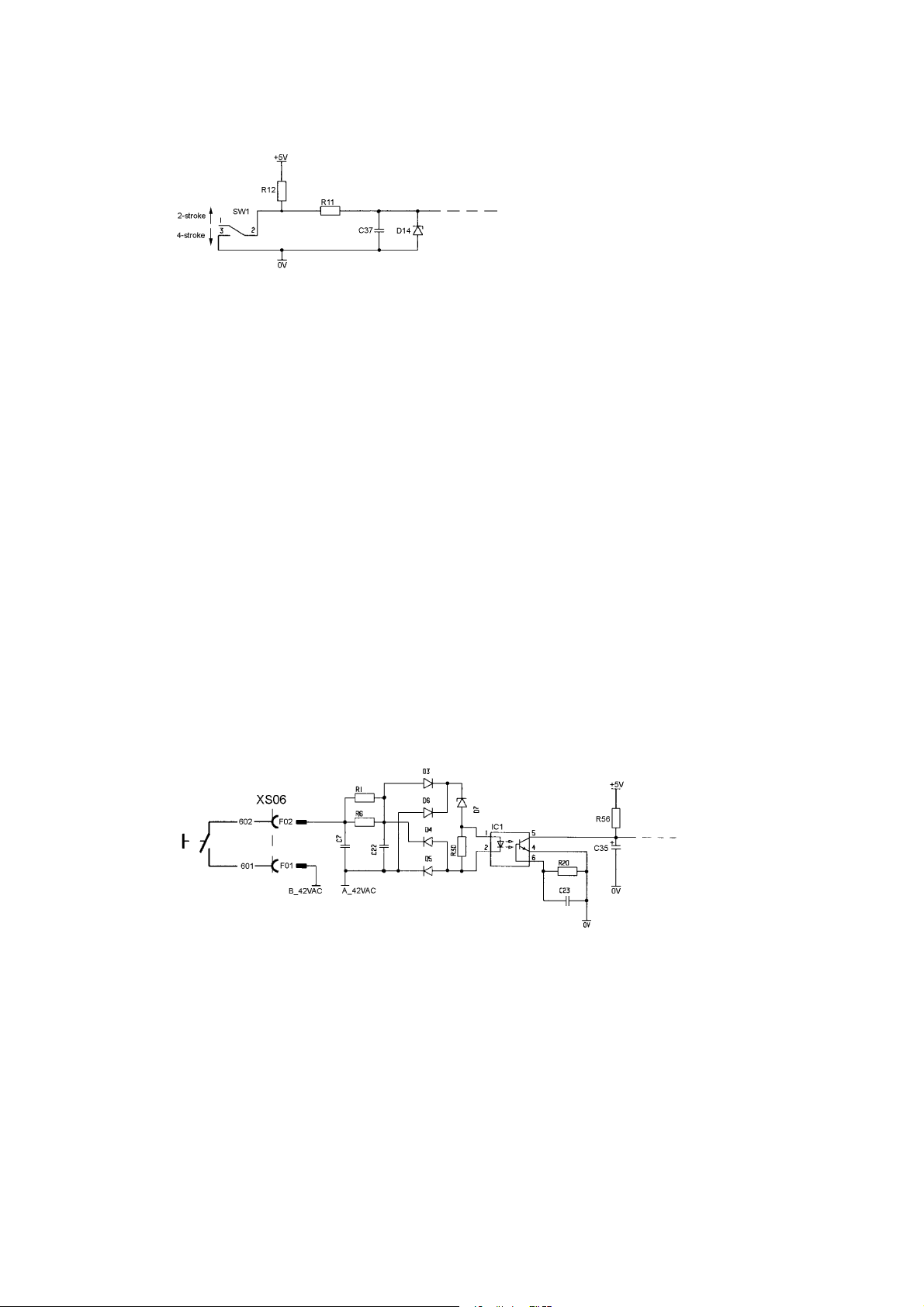

2 2--stroke / 4--stroke

2--STROKE

When SW1 is open, the unit operates in 2--stroke mode. Operating the trigger on the

welding torch starts the motor, opens the gas valve and energises the power unit

contactor.

Releasing the trigger stops the motor, de--energises the contactor and closes the gas

valve. If burn--back is in operation, welding ceases when the burn--back time has

elapsed.

4--STROKE

When SW1 is closed, the unit operates in 4--stroke mode. Operating the trigger on

the welding torch opens the gas valve: releasing the trigger then starts the motor and

energises the power unit contactor.

cmek2e08

Operating the trigger switch for a second time stops the motor and de--energises the

contactor in the power unit: releasing the switch then closes the gas solenoid valve.

If burn--back is in operation, welding ceases when the burn--back time has elapsed..

3 Start / Stop

The welding torch switch is supplied with 42 V AC. Closing the switch activates

optocoupler IC1, causing the voltage across C35 to go low.

cmek2e07

cmek2de1

-- 8 --

Page 9

4 Current relay, Creep start / Normal start

The current relay is activated when the welding current exceeds 20 A.

Creep start means that the motor runs at 1.9 m/minute until the current relay

operates, after which the speed increases to the set speed. If the current relay does

not operate within one second after starting, the m otor speed increases to the set

speed in any case.

Selector switch SW2 on the circuit board selects Creep Start On/Off. Closing the

switch on to the 0 V rail disengages creep start.

cmek2e03

-- 9 --cmek2de1

Page 10

5 Motor driving / braking

cmek2e12

DRIVING

The motor is powered from the smoothed +60 V supply. Motor speed is controlled

by pulse width modulation of transistor Q1. The pulse frequency is 12 kHz, and the

maximum on--time is 97% of the pulse cycle time. During the pulse spaces, the

motor current freewheels through diode D8.

At 24 V motor supply voltage, the wire feed rollers’ speed is 160 r/min. A wire feed

speed of 20 m/min. requires a roller speed of 212 r/min.

Resistor R19 produces a voltage drop proportional to the motor current. If the

current exceeds 7 A, IC5:2 turns off the gate pulses to Q1. When the current falls,

Q1 conducts again at the next gate pulse.

BRAKING

When the motor starts, capacitor C43 charges up via diode D28: the voltage is

limited to 15 V by zener diode D21. When the motor is to brake, the L ED in

optocoupler IC8 lights, causing the transistor in IC8 to conduct and discharge

capacitor C43 (15 V) to the gate of transistor Q3. The transistor conducts and

short--circuits the motor voltage through resistors R51 and R64, which limit the

current to about 20 A.

cmek2de1

-- 1 0 --

Page 11

6 Tachometer input

Tachometer G01 is fitted in the motor casing. Tachometer output frequency is

796 Hz for a wire feed speed of 20 meters per minute.

Comparator IC4:2 converts the sine wave signal from the tachometer to a square

wave at the same frequency.

7 Burn --back time

cmek2e06

The burn --back time is the time from when motor braking starts until the main

contactor in the power unit opens. It can be adjusted between 0 and 0.5 seconds by

potentiometer R3, which is mounted on the circuit board.

8 Wire feed speed

The wire feed speed range is from 1.9 to 20 meters per minute.

A 5 V reference voltage signal at connection A02 represents a speed of 20 m/minute.

cmek2e05

cmek2e04

-- 1 1 --cmek2de1

Page 12

9 Gas valve

The gas valve is connected to board contacts G04 and G05. The valve is energised

via triac TC1.

10 Activation, contacto r

cmek2e11

The start signal to the power unit is connected to board contact G03. The contactor

is energised via triac TC2.

11 Processor

The processor incorporates EPROM memory in which the machine’s program is

stored.

The processor monitors the wire feed speed. If the speed deviates from the set speed

by more than 1.5 m/minute for more than five seconds, wire feed will be stopped..

cmek2e10

cmek2de1

-- 1 2 --

Page 13

TECHNICAL DATA

Power supply 42 V 50 -- 60 Hz

Power requirement 150 VA

Feed speed 1.9 -- 20 m/min

Pistol connection EURO

Max. diameter of wire bobbin 300 mm

Weight 15 kg

Dimensions (l x w x h) 645 x 240 x 480 mm

WARNING

There is a risk of tipping if the MEK 4 is fitted with a counterbalance arm. Secure the

equipment, especially if used on an uneven or sloping surface.

Limit the angle of rotation of the wire feed cabinet using the straps supplied.

When moving the equipment, do NOT pull on the torch.

MAINTENANCE

Regular maintenance is important in ensuring safe and reliable operation.

S The feed unit

Clean and replace the wearing parts in the feed mechanism at regular intervals.

Do not set too high a pressure on the pressure rollers, as this can cause abnormal wear of

the pressure rollers,. the feed rollers and wire guide. Instructions for setting the wire feed

pressure are on page 14.

S The pistol

Blow the wire guide clean with compressed air at regular intervals and clean the gas

nozzle.

-- 1 3 --cmek2de1

Page 14

SETTING THE WIRE FEED PRESSURE

Start by checking that the wire can run freely through the wire liner, and then adjust the

pressure of the wire feed rollers. It is important that the pressure is not too high.

Figure 1 Figure 2

To check for correct feed pressure, feed the wire out against a piece of insulating material,

such as a piece of wood.

With the pistol held about 5 mm from the wood (Figure 1), the drive rollers should slip.

With the pistol held further away from the wood (about 50 mm, as shown in Figure 2), the

wire should continue to feed out, bending as it does so.

cmek2de1

-- 1 4 --

Page 15

CONTROL PANEL AND CONNECTIONS

1. Cooling water connections

(only --883 model).

2. Gas connection.

3. Connector for control cable from the

power unit.

4. Connector for welding current cable from

the power unit.

5. Potentiometer, wire feed speed 1.9 -- 20

meter per minute.

6. Cooling water connections to/from the

welding gun (only --883 model).

7. Strap securing points. The strap must be

used to secure the wire feed unit to the

power unit during transport.

8. Hole for fitting wire liner from the ESAB

Marathon Pac.

9. Welding gun connector.

10. Selector switch, 2/4--stroke mode.

11. Selector switch, creep start On/Off.

12. Potentiometer, burn--back time, 0 -- 0.5 seconds.

13. Brake hub.

The hub is adjusted when delivered, if readjustment is required, follow the instructions

below.

Adjust the braking power by means of the two screws (springs) inside the hub.

Turn the adjustment screws clockwise to reduce the braking power.

Adjust the brake hub so that wire is slightly slack when wire feed stops.

S = Adjustment screws

cmek0p05

-- 1 5 --cmek2de1

Page 16

ACCESSORIES

Item

no.

Ordering no. Denomination

1 469 789-- 880 Lifting eye

2 469 836-- 880

2 469 836-- 885 Connection set, 1.7 meter. When connected to LAX 380W

469 836-- 881 Connection set, 8 meter. When connected to LAX 320/380

469 836-- 886 Connection set, 8 meter. When connected to LAX 380W

4 469 786-- 880 T rolley

5 156 654-- 883 Guide pin (included in LAX)

6 469 792-- 881 Counter balance device and mast

7 469 967-- 880 W ater connection set

8 455 410-- 001 Adapter for 5 kg bobbin

9 0156 746 880 Mast

10 0456 693 880 Counter balance device, sprung coil

11 0457 341 880 Hose reinforcement bracket

Connection set, 1.7 meter. When connected to LAX

320/380

cmek2de1

cmek2p02

-- 1 6 --

Page 17

MEK

2E

dit

ion

Spare parts list

020531

Valid for serial no. 510 --xxx--xxxx to serial no. 826--xxx--xxxx

Ordering numbers for MEK 2

0455 590 881 MEK 2 Without water connection

0455 590 883 MEK 2 With water connection

Spare parts are to be ordered through the nearest ESAB agency as per the list on the back of the

cover. Kindly indicate type of unit, serial number, denominations and ordering numbers according to

the spare parts list.

Maintenance and repair work should be performed by an experienced person, and electrical work only

by a trained electrician. Use only recommended spare parts.

-- 1 7 --bm17s11a

Page 18

MEK

2E

dit

ion

Item

Qty Ordering no. Denomination Notes

101a 1 0455 693 001 Cover

101b 1 0456 352 001 Plate With text

102 1 0467 176 001 Handle

103 4 0192 230 105 Cover

104 1 0192 230 112 Cover

105 1 0469 959 001 Side cover

106 4 0467 695 001 Rubber foot

107 2 0469 823 001 Hook

108 2 0369 561 002 Clamp

109 2 0369 561 001 Lock

110 1 0469 960 001 Side cover

111 1 0192 562 104 Cage nut M5

020531

112a -- Chassis Replaced by item 112b

112b 1 0469 779 880 Chassis New design, fits all versions of MEK 4

113 1 0146 967 881 Brake hub

114 1 0416 236 001 Plate

115 1 0192 230 104 Cover

-- 1 8 --bm17s11a

Page 19

MEK

2E

dit

ion

020531

-- 1 9 --bm17s11a

Page 20

MEK

2E

dit

ion

020531

C = component designation in the circuit diagram

Item Qty Ordering no. Denomination Notes C

201 1 0321 475 882 Knob

202 1 0469 776 001 Cover

203 1 0193 260 092 Cover For 3--pole connector

204 1 0193 260 062 Connector 3-- pole XS07, XS08,

205 1 0191 870 616 Potentiometer 10 kτ RP01, RP02,

206 1 0368 543 005 Pin socket 23-- pole XP01

14 0323 945 004 Pin

XS09, XS10

RP03, RP04

207 1 0190 315 106 Hose L=2x0.65metre, D=16/9.5mm reinforced PVC.

208a 1 0365 803 008 Quick connector Female, red

1 0365 803 009 Quick connector Female, blue

-- -- 0365 803 001 Quick connector Male

208b 1 0365 803 008 Quick connector Female, red Beforeser.no. ... 649 ....

1 0365 803 009 Quick connector Female, blue Beforeser.no. ... 649 ....

208b 1 0365 803 011 Quick connector Female, red Fromser.no. ... 649 ....

1 0365 803 012 Quick connector Female, blue Fromser.no. ... 649 ....

-- -- 0365 803 013 Quick connector Male Fromser.no. ... 649 ....

209 1 0367 149 001 Quick connector Male, the nut is not included

1 Nut M10

-- 0365 803 002 Quick connector Female

210 1 0456 496 001 Hose L=0.33metre, D=9/5mm, reinforced PVC.

211 1 0193 054 002 Solenoid valve YV01

212 1 0456 496 001 Hose L=0.22metre, D=9/5mm, reinforced PVC

213 1 0160 609 881 Welding current connector XP02

214 1 0455 599 880 Busbar With insulation.

215 1 0192 915 013 Capacitor PME 271 0.1 ←F 250 V, without cable lugs C01

216 1 Screw M10x20

217 1 Spring washer ⊘ 20/10.2x1.1

218 1 Washer ⊘ 24/13x2

To be ordered per metre.

To be ordered per metre.

To be ordered per metre.

The picture on the opposite page does not show

the real shape of the busbar.

219 1 0455 517 001 Cover (bottom box) From ser. no. 826 . . . . . . Length = 317mm

220 1 0486 283 880 Circuit board AP01

221 1 0455 518 001 Box (top box) From ser. no. 826 . . . . . . Length = 317mm

222 1 0455 519 001 Cover Fromser.no. 514 ... ....

223 1 0193 260 062 Connector 3-- pole XS01

1 0193 260 091 Cover For 3--pole connector

2 0193 260 150 Connector 2--pole XS05, XS08

2 0193 260 180 Cover For 2--pole connector

1 0193 260 152 Connector 4--pole XS06

1 0193 260 182 Cover For 4--pole connector

1 0193 260 153 Connector 5--pole XS07

1 0193 260 183 Cover For 5--pole connector

224 3 0455 661 019 Plastic rivet Fromser.no.514 ... .... to514718 ....

225 3 0193 517 342 Screw Plastic Fromser.no. 514718 ....

226 3 0194 019 001 Spacer Plastic Fromser.no. 514718 ....

232 1 0458 918 880 Front flange with PC board Current relay

When a cover with another length is replaced

also item 221 must be replaced.

When a box with another length is replaced also

item 219 must be replaced. With this box items

228, 225 and 226 must be used.

-- 2 0 --bm17s11a

Page 21

MEK

2E

dit

ion

020531

-- 2 1 --bm17s11a

Page 22

MEK

2E

dit

ion

020531

C = component designation in the circuit diagram

Item Qty Ordering no. Denomination Notes C

-- -- 0455 890 881 Feed unit Complete, contains items 301 -- 332

300 1 0469 833 880 Pressure arm (W) Complete, contains items 301 -- 305

301 1 0455 053 880 Geared adapter (W)

302 1 0369 728 001 Pressure roller (W)

0466 262 001 Pressure roller (W) (A) Knurled

303 1 Locking washer SGA D8

304 1 Holder

305 1 Shaft

306 1 0455 896 001 Spring

308 1 0455 597 001 Drive unit With tachometer M01, G01

309 1 0215 701 007 Locking washer Included in item 308

310 1 0191 496 114 Key Included in item 308

311 1 0466 074 001 Inlet nozzle (W)

312 1 0367 528 001 Pin bolt

313 1 0368 749 880 Pressure transducer

314 2 0368 750 001 Insulating sleeve

315a 1 0455 894 001 Insert tube (W) (A) For Al wire, must be used together with item

315b 1 0455 889 001 Insert tube (W) Steel, must be used together with item 316b

316a 1 0455 885 001 Outlet nozzle (W) (A) Must be used together with item 315a

316b 1 0455 886 001 Outlet nozzle (W) Must be used together with item 315b

317 1 0455 882 001 Current sleeve

318 1 0455 883 001 Spacer sleeve ⊘ 16/8.2x0.9

319 1 Washer ⊘ 16/8.4x1.5

320 1 Screw M8x20

321 1 0455 881 001 Protection plate

322 1 0215 201 202 O--ring

323 1 0455 898 001 Screw (M5x12)

324 1 Screw M4x12

325 2 Screw M3x16

326 1 0193 104 002 Washer

327 1 0369 557 001 Feed roller (W) (A) (V)For ⊘ 0.6 -- 0.8 mm Fe, Ss and cored wire

1 0369 557 002 Feed roller (W) (A) (V)For ⊘ 0.8 -- 1.0 mm Fe, Ss and cored wire

1 0369 557 003 Feed roller (W) (V)For ⊘ 1.0 -- 1.2 mm Fe, Ss and cored wire

1 0369 557 007 Feed roller (W) (A) (V)For ⊘ 1.2 -- 1.6 mm Fe, Ss and cored wire

1 0369 557 010 Feed roller (W) (A) (V)For ⊘ 1.2 mm x 2 Fe, Ss and cored wire

1 0369 557 013 Feed roller (W) (A) (V)For ⊘ 1.4 --1.6 mm Fe, Ss and cored wire

1 0369 557 004 Feed roller (W) (A) (K)(V) For ⊘1.0 -- 1.2 / 1.4 -- 1.6 mm cored wire

1 0369 557 005 Feed roller (W) (A) (K)(V) For ⊘1.4--1.6 / (2.0-- 2.4) mm cored wire

1 0369 557 006 Feed roller (W) (A) (U) For ⊘ 1.0 -- 1.2 mm Al wire

1 0369 557 008 Feed roller (W) (A) (U) For ⊘ 1.6 mm Al wire

1 0369 557 011 Feed roller (W) (A) (U) For ⊘ 0,8 -- 0,9 mm Al wire

328 1 0369 716 001 Geared adapter (W)

316a

Delivered from machine no. XXX 647 XXX

Delivered from machine no. XXX 647 XXX

329 1 0455 893 001 Shaft

330 1 0455 884 001 Gear housing

331 3 Screw M6x16

332 1 0332 351 013 Drive shaft with pinion Included in item 308

(W) = wear part (A) = accessory (K) = knurled rollers (V) = V--groove (U) = U--groove

-- 2 2 --bm17s11a

Page 23

MEK

2E

dit

ion

020531

-- 2 3 --bm17s11a

Page 24

NOTES

-- 2 4 --notes

Page 25

-- 2 5 --notes

Page 26

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna--Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 726 80 05

THE CZECH REPUBLIC

ESAB VAMBERK s.r.o.

Prague

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Copenhagen--Valby

Tel:+4536300111

Fax:+4536304003

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel:+33130755500

Fax:+33130755524

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 204

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

HUNGARY

ESAB Kft

Budapest

Tel:+3612044182

Fax:+3612044186

ITALY

ESAB Saldatura S.p.A.

Mesero (Mi)

Tel:+3902979681

Fax:+390297289181

THE NETHERLANDS

ESAB Nederland B.V.

Utrecht

Tel: +31 30 248 59 22

Fax: +31 30 248 52 60

NORWAY

AS ESAB

Larvik

Tel:+4733121000

Fax:+4733115203

POLAND

ESAB Sp.z.o.o

Warszaw

Tel: +48 22 813 99 63

Fax: +48 22 813 98 81

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 1 837 1527

Fax: +351 1 859 1277

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel:+421744882426

Fax:+421744888741

SPAIN

ESAB Ibérica S.A.

Alcobendas (Madrid)

Tel: +34 91 623 11 00

Fax: +34 91 661 51 83

SWEDEN

ESAB Sverige AB

Gothenburg

Tel:+4631509500

Fax:+4631509222

ESAB International AB

Gothenburg

Tel:+4631509000

Fax:+4631509360

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem--MG

Tel: +55 31 333 43 33

Fax: +55 31 361 31 51

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 44 58

Asia/Pacific

AUSTRALIA

ESAB Australia Pty Ltd

Ermington

Tel: +61 2 9647 1232

Fax: +61 2 9748 1685

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 6539 7124

Fax: +86 21 6543 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. Esabindo Pratama

Jakarta

Tel: +62 21 460 01 88

Fax: +62 21 461 29 29

MALAYSIA

ESAB (Malaysia) Snd Bhd

Selangor

Tel: +60 3 703 36 15

Fax: +60 3 703 35 52

SINGAPORE

ESAB Singapore Pte Ltd

Singapore

Tel: +65 861 43 22

Fax: +65 861 31 95

ESAB Asia/Pacific Pte Ltd

Singapore

Tel: +65 861 74 42

Fax: +65 863 08 39

SOUTH KOREA

ESAB SeAH Corporation

Kyung--Nam

Tel: +82 551 289 81 11

Fax: +82 551 289 88 63

UNITED ARAB EMIRATES

ESAB Middle East

Dubai

Tel: +971 4 338 88 29

Fax: +971 4 338 87 29

Representative offices

BULGARIA

ESAB Representative Office

Sofia

Tel/Fax: +359 2 974 42 88

EGYPT

ESAB Egypt

Dokki--Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

ROMANIA

ESAB Representative Office

Bucharest

Tel/Fax: +40 1 322 36 74

RUSSIA--CIS

ESAB Representative Office

Moscow

Tel: +7 095 937 98 20

Fax: +7 095 937 95 80

ESAB Representative Office

St Petersburg

Tel: +7 812 325 43 62

Fax: +7 812 325 66 85

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.com

ESAB AB

SE-- 695 81 LAXÅ

SWEDEN

Phone +46 584 81 000

Fax +46 584 123 08

www.esab.com

020314

Loading...

Loading...