GB

A6 Mastertrac

A6 TFE2

Instruction manual

Valid for serial no. 7090449 468 101 GB 2007--07--12

ESAB AB, Welding Equipment, 695 81 Laxå, Sweden, declares under sole responsibility that the au-

L

tomatic welding machine A6 Mastertrac (A6 TFE2) from serial number 709 xxx xxxx (2007 week 09)

is designed and tested in conformity with the published standards in accordance with the conditions in

the directives (98/37/EC) and (2004/108/EC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- ------------------------------------

axå 2007--02--21

Kent Eimbrodt

Global Director

Equipment and Automation

DECLARATION OF CONFORMITY

-- 2 --

1SAFETY 4...........................................................

2 INTRODUCTION 6...................................................

2.1 General 6..................................................................

2.2 Welding method 6...........................................................

2.3 Horizontal Welding or Welding on an Inclined Plane 6............................

2.4 Technical data 7............................................................

2.5 Main components 7.........................................................

2.6 Description of Main Components 8............................................

3 INSTALLATION 9....................................................

3.1 General 9..................................................................

3.2 Mounting 9.................................................................

3.3 Adjusting the brake hub 9....................................................

3.4 Connections 10..............................................................

4 OPERATION 11.......................................................

4.1 General 11..................................................................

4.2 Loading the welding wire 12...................................................

4.3 Changing the feed roller 13...................................................

4.4 Contact equipment for submerged--arc welding 14................................

4.5 Refilling with flux powder 15...................................................

4.6 Conversion of A6 TF (submerged--arc welding) to Twin--arc 15.....................

5 MAINTENANCE 16....................................................

5.1 General 16..................................................................

5.2 Daily 16.....................................................................

5.3 Regularly 16.................................................................

6 TROUBLESHOOTING 17..............................................

6.1 General 17..................................................................

6.2 Possible faults 17............................................................

7 ORDERING OF SP ARE P ARTS 17......................................

WEAR COMPONENTS 18.................................................

DIMENSION DRAWING 19................................................

SPARE PARTS LIST 21...................................................

Rights reserved to alter specifications without notice.

TOCe

-- 3 --

GB

1SAFETY

Users of ESAB welding equipment have the ultimate responsibility for ensuring that anyone who

works on or near the equipment observes all the relevant safety precautions. Safety precautions

must meet the requirements that apply to this type of welding equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace.

All work must be carried out by trained personnel well--acquainted with the operation of the welding

equipment. Incorrect operation of the equipment may lead to hazardous situations which can result

in injury to the operator and damage to the equipment.

1. Anyone who uses the welding equipment must be familiar with:

S its operation

S location of emergency stops

S its function

S relevant safety precautions

S welding

2. The operator must ensure that:

S no unauthorised person is stationed within the working area of the equipment when it is

started up.

S no--one is unprotected when the arc is struck

3. The workplace must:

S be suitable for the purpose

S be free from draughts

4. Personal safety equipment

S Always wear recommended personal safety equipment, such as safety glasses, flame--proof

clothing, safety gloves.

S Do not wear loose--fitting items, such as scarves, bracelets, rings, etc., which could become

trapped or cause burns.

5. General precautions

S Make sure the return cable is connected securely.

S Work on high voltage equipment may only be carried out by a qualified electrician.

S Appropriate fire extinquishing equipment must be clearly marked and close at hand.

S Lubrication and maintenance must not be carried out on the equipment during operation.

Mind the following:

S That the freewheel clutch of the gear shall be in locked position.

S That, if the operator leaves the machine, it shall be parked with blocks in front of the wheels,

in order to prevent the machine from moving unintentionally.

S Make sure that the automatic welding machine is not unstable before start.

S That the placement of the welding head and the wire reel influence the centre of gravity of

the machine.

Too high a centre of gravity means an unstable welding machine.

S That the consumption of wire and flux results in displacement of the weight distribution during

the welding.

ffa8safE

-- 4 --

GB

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to take fumes and gases away from your breathing zone

and the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use earmuffs or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

ffa8safE

-- 5 --

GB

2 INTRODUCTION

2.1 General

The A6 TFE2 automatic welding machine, with two welding heads, is mounted on

a self --propelled trolley and is designed for submerged--arc welding of butt welds.

All other uses are prohibited

The position of welding head can be set horizontally and vertically with the linear

slides. Angular movement is adjusted with the angular slide.

The automatic welding m achine is intended for use in combination with the

A2--A6 Process Controller (PEH) and ESAB’s welding power sources LAF or TAF.

2.2 Welding method

2.2.1 Submerged--arc welding

The weld bead is protected by a cover of flux during the welding.

S Submerged--arc Heavy duty

Submerged--arc heavy duty, with a ∅ 35 mm connector, which permits a load of

up to 1500 A.

This version can be equipped with feed rollers for single or twin wire welding

(twin--arc). A special knurled feed roller is available for flux--cored wire, which

guarantees even wire feed without the risk of deformation due to high feed

pressure.

S Tandem welding (submerged--arc)

For tandem welding, a welding head of type A6 TFE2 is always used, which

must be connected to 2 welding power sources and 2 control boxes of type

(A2-- A6 Process Controller).

The tandem welding head includes 2 single welding heads (A6 SF), each with its

own contact tip. Each contact tip has a maximum rated load of 1500 A.

2.3 Horizontal Welding or Welding on an Inclined Plane

The automatic welding machine is designed for horizontal welding.

A6 TFE2 is not to be used for welding on inclined planes.

Read section 5, on page 4.

ffb9d1ea

-- 6 --

GB

2.4 Technical data

A6 TFE2

Supply voltage 42 V AC

Rated load 100 % 1500 A DC/AC

Electrode dimensions:

solid single wire 3,0--6,0 mm

flux--cored wire 3,0--4,0 mm

twin wire 2x2,0--3,0 mm

Electrode feed rate, max. 4m/min

Brake drum braking torque 1,5 Nm

Speed of travel 0,1--2,0 m/min

Electrode weight, max. 2x15kg

Flux hopper capacity (Must not be filled with preheated flux) 10 l

Weight (excluding electrode and flux) 158 kg

Continuous A weighted sound pressure 68 dB

2.5 Main components

1. Carriage

2. Wire feed unit

3. Slide, manual

4. Connector

5. Motor with gear (A6 VEC)

See on page 8 for a description of the main components.

ffb9d1ea

-- 7 --

6. Flux hopper

7. Flux nozzle

GB

2.6 Description of Main Components

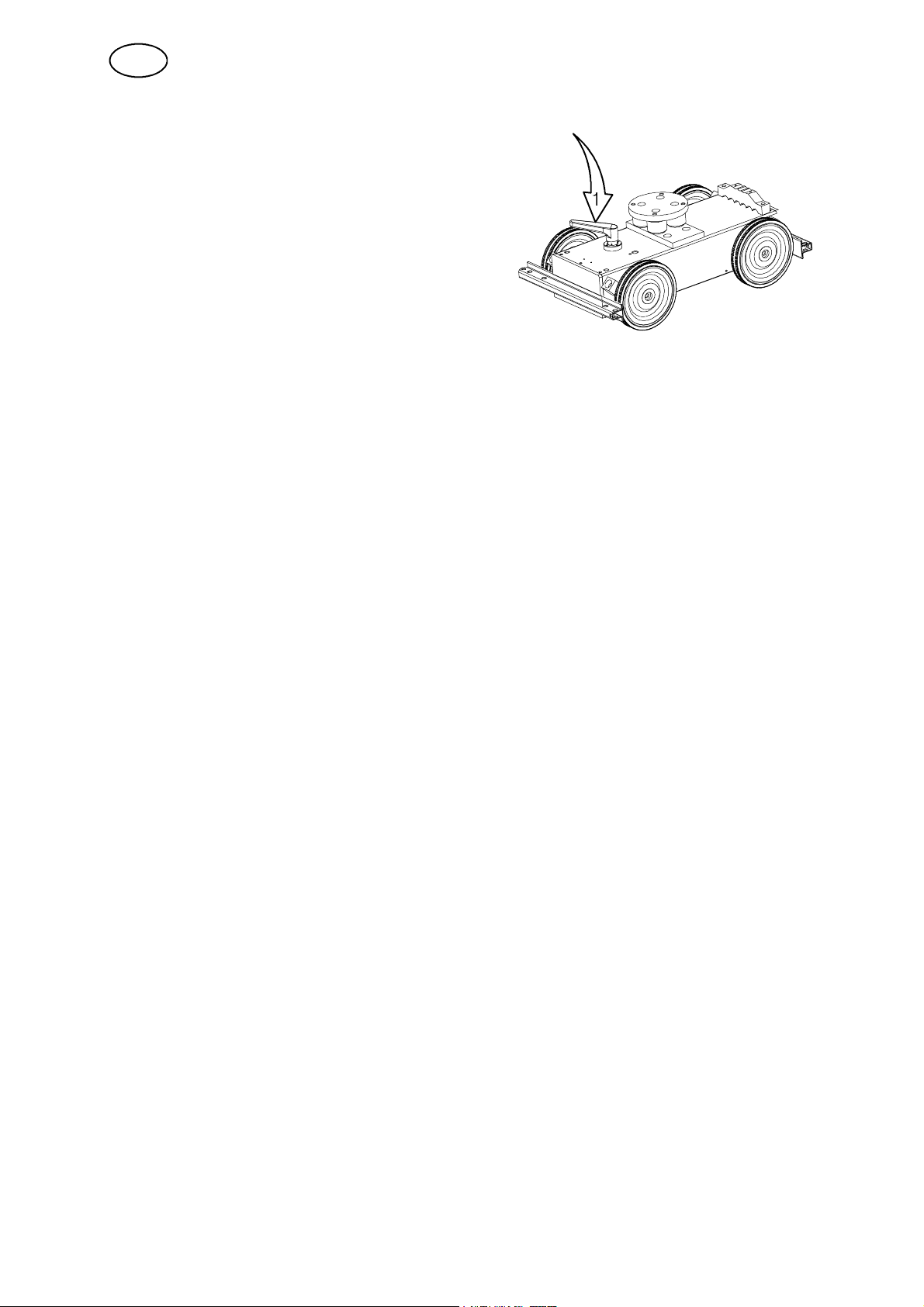

2.6.1 Carriage

The carriage is provided with 4--wheel drive.

The carriage can be secured by way of the

locking lever (1).

2.6.2 Wire Feed Unit

The unit is used for guiding and feeding the welding wire down into the connector.

2.6.3 Manual Slides

The horizontal and vertical position of the welding head is adjusted by way of linear

slides. The angular motion can be freely adjusted using the rotary slide.

2.6.4 Connector

Transfers welding current to the wire during welding.

2.6.5 Motor with gear (A6 VEC)

The motor is used for feeding the welding wire.

For more information regarding the A6 VEC see instruction manual 0443 393 xxx.

2.6.6 Flux Hopper / Flux Tube / Flux nozzle

The flux is filled into the flux hopper and is then transferred to the workpiece through

the flux tube and the flux nozzle.

The amount of flux to be dropped down is controlled by way of the flux valve fitted to

the flux hopper.

See “Refilling with flux on page 15.

ffb9d1ea

-- 8 --

GB

3 INSTALLATION

3.1 General

The installation must be executed by a professional.

WARNING

Rotating parts can cause injury, take great care.

3.2 Mounting

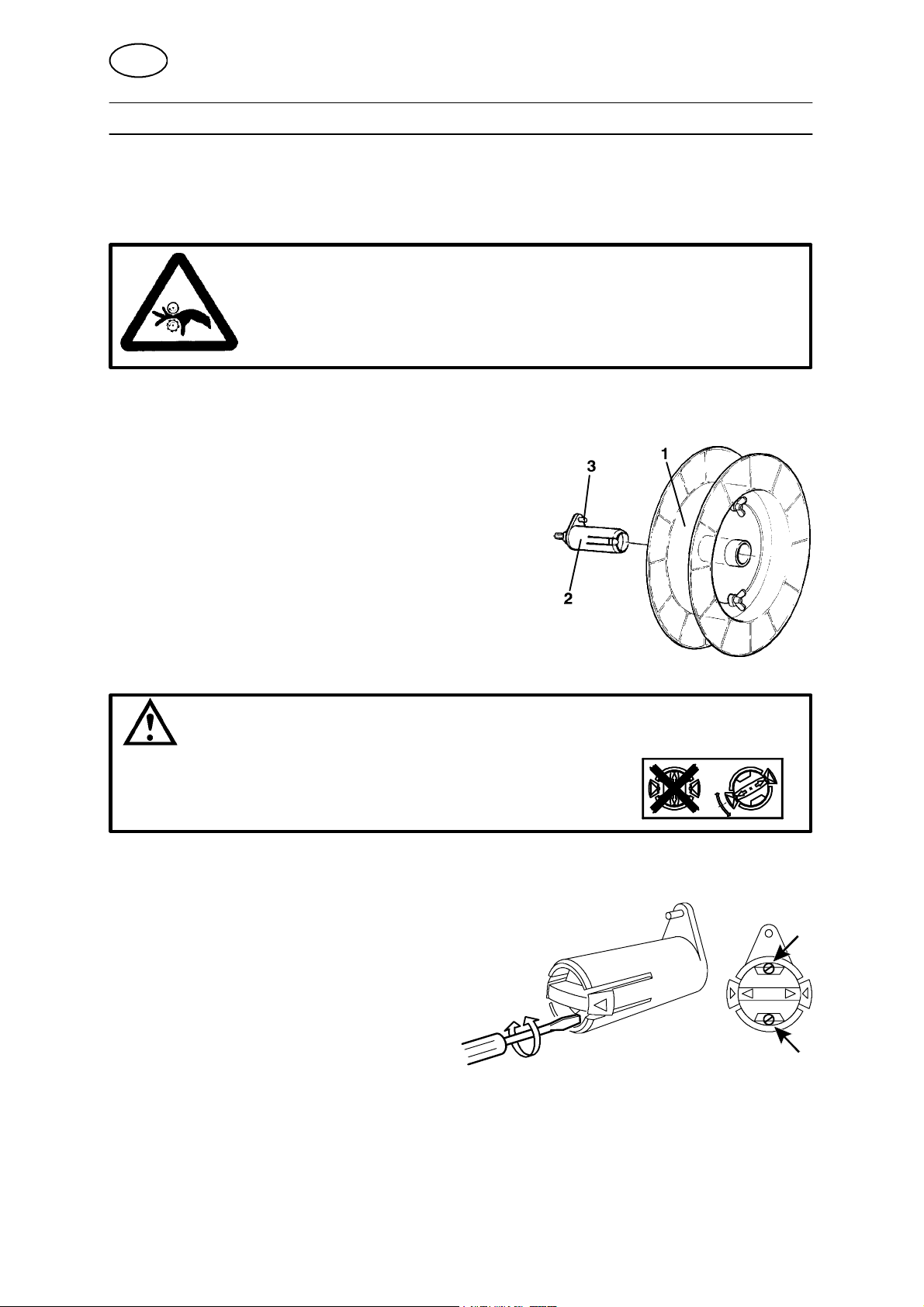

3.2.1 Wire drum (Accessories)

Wire drum (1) is mounted on the brake hub (2).

S Check that the carrier (3) is pointing upwards.

NOTE! The maximum angle for the wire bobbin is 25°.

At extreme angles, wear will occur on the brake hub

locking mechanism and the wire bobbin will slide off

the brake hub.

WARNING

To prevent the r eel sliding off the hub:

S

Lock the reel in place by turning the red knob as shown

on the warning label attached next to the hub.

3.3 Adjusting the brake hub

The brake hub is adjusted when delivered, if readjustment

is required, follow the instructions below. Adjust the brake

hub so that wire is slightly slack when wire feed stops.

S Adjusting the braking torque:

S Turn the r ed handle to the locked

position.

S Insert a screwdriver into the springs in the hub.

Turn the springs clockwise to reduce the braking torque

Turn the springs anticlockwise to increase the braking torque.

NB: Turn both springs through the same amount.

ffb9i1ea

-- 9 --

GB

3.4 Connections

3.4.1 General

S TheA2--A6ProcessController(PEH) is to be connected by a qualified person.

S For the connection of A6 GMD, see instruction manual 0443 403 xxx.

S For the connection of A6 PAK, see instruction manual 0443 405 xxx.

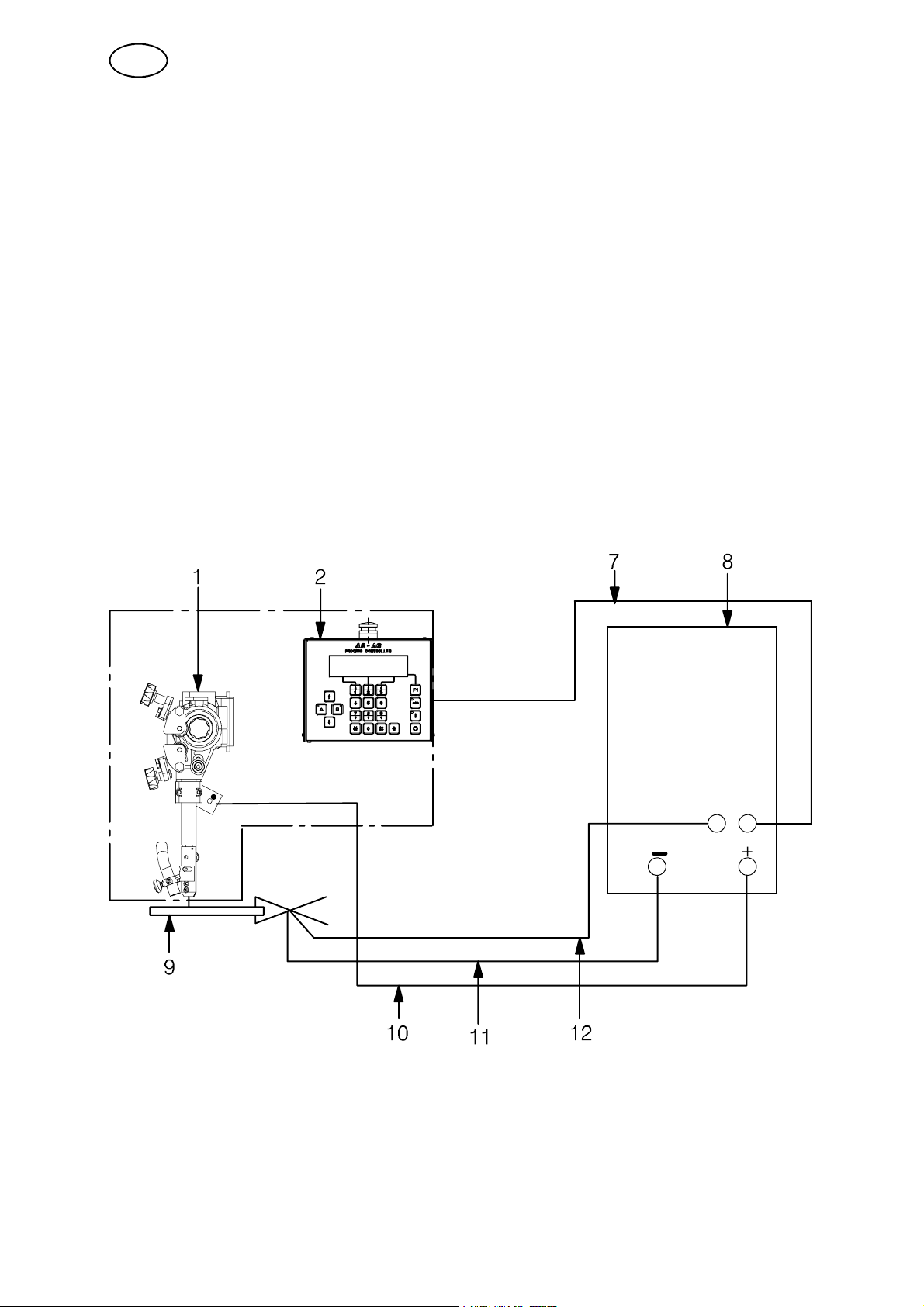

3.4.2 Submerged arc weldin g (SAW)

1. Connect the control cable (7) between the power source (8) and the control box

A2--A6 Process Controller (2).

2. Connect the return cable (11) between the power source (8) and work piece (9).

3. Connect the welding cable (10) between the power source (8) and the automatic

welding machine (1).

4. Connect the measurement cable (12) between the power source (8) and

workpiece (9).

ffb9i1ea

-- 1 0 --

GB

4 OPERATION

4.1 General

Caution:

Have you read and understood the safety information ?

You must not operate the machine before then !

General safety regulations for the handling of the equipment can be found on

page 4. Read through before you start using the equipment!

S Select wire type and flux powder or shielding gas so that the weld m aterial is as

close as possible to the analysis of the base metal.

Select wire size and welding data in accordance with the values recommended

by the welding materials supplier.

S Thorough preparation of the weld surfaces is necessary to achieve a good weld.

NOTE! The width of the weld joint gap must be uniform.

S To minimise the risk of heat crack formation, the width of the weld must be

greater than the penetration depth.

S Always carry out a test weld with the same joint type and sheet thickness as the

production work piece.

S For control and adjustment of the automatic welding machine and welding power

supply, see the instruction manual for the A2--A6 Process Controller (PEH).

S The trolley can be moved manually after disengaging the disengagement lever,

see the diagram on page 8.

S When changing consumables, see table on page 18.

ffb9o1ea

-- 1 1 --

GB

4.2 Loading the welding wire

1. Mount the wire drum according to the instructions on page 9.

2. Check that feed roller (1) and contact jaw or contact tip (3) are of the correct

dimension for the selected wire size.

3. For A6 TF (Twin):

S Feed the wire through the wire guide (8).

4. When welding with fine wire:

S Feed the wire through the fine Wire feed unit (6).

Ensure that the straightener is correctly adjusted so that the wire emerges

straight out through the contact jaws or contact tip (3).

5. Pull the end of the wire through the straightener (2).

S For a wire diameter greater than 2 mm; straighten out 0.5 m of wire and feed

it by hand down through the straightener.

6. Locate the end of the wire in the feed roller (1) groove.

7. Set the wire tension on the feed roller with the knob (4).

S Note! Do not tension more than is required to achieve an even feed.

8. Feed the wire forward 30 mm by pressing on the control box

A2--A6 Process Controller (PEH).

9. Direct the wire by adjusting the knob (5).

S Always use a guide tube (7) to ensure even feed of fine wire (1.6 -- 2.5 mm).

ffb9o1ea

-- 1 2 --

GB

4.3 Changing the feed roller

Single wire

S Release the knobs (3 ) and (4).

S Release the hand wheel (2).

S Change the feed roller (1).

They are marked with their respective wire sizes.

Twin wire (Twin--arc)

S Change the feed roller (1) with twin grooves in the same way as for single wire.

NOTE! The pressure roller (5) m ust also be changed. A special curved pressure

roller for twin wire replaces the standard pressure roller for single wire.

S Assemble the pressure roller with special stub shaft

(order no. 0146 253 001).

Flux--cored wire for knurled rollers (Accessories)

S Change the feed roller (1) and pressure roller (5) as a pair for the wire size to be

used.

NOTE! A special stub shaft is required for the pressure roller

(order no. 0212 901 101).

S Tighten the pressure screw (4) with moderate pressure to ensure that the

flux--cored wire does not deform.

ffb9o1ea

-- 1 3 --

GB

4.4 Contact equipment for submerged--arc welding

For single wire 3.0 -- 6.0 mm. Heavy duty (D35)

S Use the straightener (3), connector (1) D35 with

contact jaws (2).

S Assemble one contact jaw with the M5 bolts provided,

in the fixed contact tip (a).

S Assemble the other contact jaw in the free half of the

two--piece connector (b) under the bolt (8) and tighten

down hard to ensure that a good contact is achieved between

the contact jaws and the wire.

For flux--co red wire 1.6 mm -- 4.0 mm (D20 and D35) (Accessories)

If contact jaws ( D35) are used, the contact jaws must not be tightened down to

hard in order to ensure that the flux-- cored wire is not distorted.

S Ensure that good contact is achieved with the wire.

Adjustment of the wire for tandem welding

The distance between the first and second wires must not be so great that the

slag has time to solidify between the wires.

S Ensure that good flux coverage is achieved between the first and second

wires.

Fortwinwires2x2.0--3.0Heavy Twin (D35) (Accessories)

S Use the straightener (3), connector (1) D35 with

contact jaws (2).

S Assemble the first contact jaw with the M5 bolts supplied,

in the fixed connector (a).

S Assemble the other contact jaw in the free half of the

two--piece connector (b) under the bolt (8) and tighten down

hard to ensure that a good contact is a chieved between the

contact jaws and the wire.

ffb9o1ea

-- 1 4 --

GB

Fortwinwires2x1.2--2.0mm,LightTwin(D35)(Accesso ries)

S Use the straightener (3), connector (1) D35 with twin

adapter (9) and 2 contact tips (2) (M6 threads) and

separate fine wire straightener (4) with two guide tubes (6).

For twin wires < 1.6 mm, a guide spiral, inserted into each

guide tube, is used.

S Assemble the twin adapter (9) for M6 contact tips (2) with the

M5 bolts in the fixed half of the two-- piece connector (1).

S Assemble the clamp (7) with guide tube (6) in the M12 hole

on the standard straightener (3). The guide tube should bottom

on the twin adapter (9) for the contact tip (2).

S Tighten the contact tip (2) with a key to ensure that a good

contact is achieved.

S If necessary, cut the guide tube (6) to length so that the feed

roller (5) runs freely.

Adjustment of the wires for Twin-- arc welding:

S Position the wires in the joint so as to achieve optimal weld quality by rotating the

connector.

The two wires can be rotated so that they are positioned one after the other

along the line of the joint, or in any position up to 90_ across the joint, i.e. one

wire on each side of the joint.

4.5 Refilling with flux powder

1. Close the flux valve (1) on the flux hopper.

2. Remove the cyclone on the flux recovery unit, if fitted.

3. Fill with flux powder.

NOTE! The flux powder must be dry. Where possible

avoid using agglomerating flux powder outdoors and

in damp environments.

4. Position the flux tube so that it does not become

kinked.

5. Adjust the height of the flux nozzle above the weld so

that the correct amount of flux is delivered.

Flux coverage should be sufficient so that penetration

of the arc does not occur.

4.6 Conversion of A6 TF (submerged--arc welding) to Twin--arc

S Assemble in accordance with the instructions accompanying the conversion kit.

ffb9o1ea

-- 1 5 --

GB

5 MAINTENANCE

5.1 General

Note:

All warranty undertakings given by the supplier cease to apply if the customer

attempts to rectify any faults on the machine during the warranty period.

NB! Before doing any kind of maintenance work, make sure the mains is

disconnected.

For the maintenance of the A2--A6 Process Controller (PEH), see the instruction

manual 0443 745 xxx.

5.2 Daily

S Clean flux and dirt off moving parts of the welding machine.

S Check that the contact tip and all electrical cables are connected.

S Check that all bolted joints are tight and that guides and drive rollers are not

worn or damaged.

S Check the brake hub braking torque. It should not be so low, that the wire reel

continues to rotate when wire feed is stopped and it should not be so great that

the feed rollers slip. As a guide, the braking torque for a 30 kg wire reel should

be 1,5 Nm.

To adjust the braking torque see on page 9.

5.3 Regularly

S Check the wire feed motor brushes

once every three months.

Replace when they are worn

downto6mm.

S Eximine the slides and lubricate if

they bind.

S Inspect the wire guides, drive

rollers and contact tip on the wire

feed unit. Replace any worn or damaged

components, (see spare parts list on page 21).

S If the carriage travel becomes

jerky, check that hte chain is correctly tensioned. Tension the chain if necessary.

S To tension the chain undo the nut (*1) and turn the cam, then tighten the nut.

ffb9u1ea

-- 1 6 --

GB

6 TROUBLESHOOTING

6.1 General

Equipment

S Instruction manual for control box A2--A6 Process Controller (PEH),

ordering number 0443 745 xxx.

S Operating manual for m otor with gear A6 VEC, ordering number 0443 393 xxx.

Check

S that the power supply is connected for the correct mains supply

S that all three phases are supplying the correct voltage (phase sequence is not

important)

S that welding cables and connections are not damaged

S that the controls are correctly set

S that the mains supply is disconnected before starting repairs

6.2 Possible faults

1. Symptom Current and voltage readings show large fluctuations.

Cause 1 .1 Contact jaws or nozzle are worn or wrong size.

Action Replace contact jaws or nozzle.

Cause 1 .2 Feed roller pressure is inadequate.

Action Increase pressure on feed rollers.

2. Symptom Wire feed is irregular.

Cause 2 .1 Pressure on feed rollers incorrectly set.

Action Pressure on feed rollers incorrectly set.

Cause 2 .2 Feed rollers wrong size.

Action Replace feed rollers.

Cause 2 .3 Grooves in feed rollers are worn.

Action Replace feed rollers.

3. Symptom Welding cables overheating.

Cause 3 .1 Poor electrical connection.

Action Clean and tighten all electrical connections.

Cause 3 .2 Cross--sectional area of welding cables too small.

Action Use cables with a larger cross-- section or use parallel cables.

7 ORDERING OF SPARE PARTS

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as designation and spare part number as shown in the spare parts list on page 21.

This will simplify dispatch and ensure you get the right part.

ffb9f1ea

-- 1 7 --

Wear components

Feed rollers

SAW tubular wire

Part no D (mm)

0146 024 880 0,8--1,6

0146 024 881 2,0--4,0

Pressure rollers

SAW tubular wire

Part no D (mm)

0146 025 880 0,8--1,6

0146 025 881 2,0--4,0

Contact jaws

SAW HD (D35)

Part no D (mm)

0265 900 880 3,0

0265 900 882 4,0

0265 900 883 5,0

0265 900 884 6,0

dfa8s11a

-- 1 8 --

Dimension drawing

ffb9dim

-- 1 9 --

sida

-- 2 0 --

Spare parts list

Edition 2007--07--12

Ordering no. Denomination Notes

0334 191 882 Automatic welding machine A6 TFE2

-- 2 1 --

spareFram

Item

Qty Ordering no. Denomination Notes

no.

0334191882 Automatic welding machine A6 TFE2

3 2 0443741880 Control box PEH, see separate manual

6 2 0146967880 Brake hub

7 1 0334457880 Wire guide

8 1 0334184001 Plate

10 1 0147639881 Wire straightener (left mounted) D35

11 2 0334170001 Clamping ring

13 2 0417959880 Contact jaw tube L=220

14 1 0334183881 Carriage

15 2 0334171001 Plate

17 1 0147639880 Wire straightener (right mounted) D35

18 1 0334294001 Bracket

19 1 0148487880 Bracket for fluxhopper

20 1 0147649881 Flux hopper 10 l

21 4 0154465880 Manual Slide L=90

23 1 0145063906 Motor with gear A6 VEC (156:1), see separate manual

24 2 0456490880 Motor cable 1.6 m

25 2 0218810183 Insulated hand wheel

26 1 0334172001 Gear bracket

27 1 0334180880 Reel holder

29 1 0334177001 Plate

31 8 0278300180 Insulator 2000 V

32 1 0334168881 Column

33 1 0145063896 Motor with gear A6 VEC (156:1), see separate manual

34 1 0334297881 Box holder

35 1 0334179001 Plate

36 1 0334185887 Box girder beam complete

40 1 0153491001 Branching tube

42 0443383001 Flux hose D32/25

43 1 0153299880 Flux nozzle

57 1 0334709001 Spacer

80 2 0457713001 Bar

90 2 0456504881 Cable (arc--voltage) 1,7m

f334191s

-- 2 2 --

f334191s

-- 2 3 --

Item

no.

Qty Ordering no. Denomination Notes

0147639880 Straightener (right mounted)

1 1 0156449001 Clamp

4 1 0215503601 Insulating sleeve

5 1 0156530001 Clamp half D35

6 2 0212900001 Spacer screw

7 4 0215201209 Sealing, O--ring D11.3x2.4

8 2 0218400801 Pressure roller arm

9 1 0218810181 Handwheel, insulated

10 1 0218810182 Handwheel, insulated

11 3 0332408001 Stub shaft

13 3 0153148880 Pressure roller

14 1 0415498001 Pressure roller, upper

15 2 0212902601 Spacer screw

16 1 0415499001 Pressure roller, lower

19 2 0219501013 Spring washer D18.1/10.2

28 1 0156531001 Clamp half D35

30 1 0212 601110 Nut M10

f147639s

-- 2 4 --

Item

Qty Orderingno. Denomination Remarks

0147639881 Straightener (left mounted)

1 1 0156449001 Clamp

4 1 0215503601 Insulating sleeve

5 1 0156530001 Clamp half D35

6 2 0212900001 Spacer screw

7 4 0215201209 Sealing, O--ring D11.3x2.4

8 2 0218400801 Pressure roller arm

9 1 0218810181 Handwheel, insulated

10 1 0218810182 Handwheel, insulated

11 3 0332408001 Stub shaft

13 3 0153148880 Pressure roller

14 1 0415498001 Pressure roller, upper

15 2 0212902601 Spacer screw

16 1 0415499001 Pressure roller, lower

19 2 0219501013 Spring washer D18.1/10.2

28 1 0156531001 Clamp half D35

30 1 0212601110 Nut M10

f147639s

-- 2 5 --

Item

Qty Ordering no. Denomination Notes

no.

0417959880 Contact jaw tube L = 220 mm

1 1 0443344880 Contact tube L = 220 mm

4 1 0443372001 Fitting bolt

5 4 0219504307 Cup s pring d20/10.2, T=1.1

6 1 0417979001 Ring

f417959s

-- 2 6 --

Item no.

Qty Ordering no. Denomination Notes

0334183881 Carriage

1 2 0334295880 Handle

2 2 0449205880 Guide arm

5 4 0229202280 Wheel

7 4 0219501013 Spring washer d18,1/10,2

8 1 0334198880 Front shaft with sprocket

12 4 0334264001 Flange bearing unit

15 1 0218201502 Chain 1/2”x4,88

16 1 0218201602 Chain lock simple 1/2”x4,88

17 1 0334160001 Stub shaft

20 1 0334163880 Sprocket

21 1 0334162880 Sprocket

22 1 0334161001 Exenter

23 1 0334197880 Rear shaft with sprocket

24 1 0334267880 Cover

25 1 0334265880 Motorgear

31 2 0215701019 Grooved ring d25x1,2

32 1 0334189001 Gear wheel

36 1 0321220001 Grommet

38 1 0456491880 Motor cable 1,7m

43 1 0333630001 Adjustable locking arm

44 1 0211102940 Roll pin d3x28

45 1 0215701016 Grooved ring d20

46 1 0334196001 Bushing

48 1 0334192880 Excenter

52 1 0221307001 Steel ball 7,94 mm

53 14 0219501101 Spring plate d8/3,2x0,3

63 4 0278300180 Insulator (a6)

f334183s

-- 2 7 --

Item

Qty Ordering no. Denomination Notes

no.

0147649881 Flux Hopper 10l

1 1 0154007001 Flux hopper

2 1 0148837001 Window (a6 flux hopper)

3 1 0147645001 Mounting

6 1 0153347880 Flux valve

7 1 0215201232 Sealing, O--ring 69,2x5,7

13 1 0020301780 Flux strainer

14 1 0443383002 Flux hose L=500

f147649s

-- 2 8 --

Item

Qty Orderingno. Denomination Remarks

0154465880 Slide, manually operated L=90

1 1 0154464001 Slide frame

6 1 0154463880 Carriage with slide rails

7 6 0190509485 Stop screw M10x10

8 1 0154458001 End piece

10 2 0211102957 Roll pin D5x20

11 1 0154461001 Lead screw

16 1 0190531201 Ball bearing SKF 3201

17 1 0154456001 Lock nut

18 1 0154457001 Ball bearing cap

22 1 0334537001 Handle crank

23 1 0211102938 Roll pin D3x20

f154465s

-- 2 9 --

Item

Qty Ordering no. Denomination Notes

no.

0153299880 Flux nozzle complete

1 1 0153290002 Holder for flux pipe

2 1 0153296001 Flux pipe, bent

3 1 0153425001 Wheel

f153299s

-- 3 0 --

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna--Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 745 11 28

THE CZECH REPUBLIC

ESAB VAMBERK s.r.o.

Vamberk

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Herlev

Tel:+4536300111

Fax:+4536304003

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel:+33130755500

Fax:+33130755524

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 218

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

HUNGARY

ESAB Kft

Budapest

Tel:+3612044182

Fax:+3612044186

ITALY

ESAB Saldatura S.p.A.

Mesero (Mi)

Tel:+3902979681

Fax:+390297289181

THE NETHERLANDS

ESAB Nederland B.V.

Amersfoort

Tel: +31 33 422 35 55

Fax: +31 33 422 35 44

NORWAY

AS ESAB

Larvik

Tel:+4733121000

Fax:+4733115203

POLAND

ESAB Sp.zo.o.

Katowice

Tel: +48 32 351 11 00

Fax: +48 32 351 11 20

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 8 310 960

Fax: +351 1 859 1277

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel:+421744882426

Fax:+421744888741

SPAIN

ESAB Ibérica S.A.

Alcalá de Henares (MADRID)

Tel: +34 91 878 3600

Fax: +34 91 802 3461

SWEDEN

ESAB Sverige AB

Gothenburg

Tel:+4631509500

Fax:+4631509222

ESAB international AB

Gothenburg

Tel:+4631509000

Fax:+4631509360

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem--MG

Tel: +55 31 2191 4333

Fax: +55 31 2191 4440

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 57 48

Asia/Pacific

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 5308 9922

Fax: +86 21 6566 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. ESABindo Pratama

Jakarta

Tel: +62 21 460 0188

Fax: +62 21 461 2929

JAPAN

ESAB Japan

Tokyo

Tel: +81 3 5296 7371

Fax:+81352968080

MALAYSIA

ESAB (Malaysia) Snd Bhd

Selangor

Tel: +60 3 8027 9869

Fax:+60380274754

SINGAPORE

ESAB Asia/Pacific Pte Ltd

Singapore

Tel:+6568614322

Fax: +65 6861 31 95

SOUTH KOREA

ESAB SeAH Corporation

Kyungnam

Tel: +82 55 269 8170

Fax: +82 55 289 8864

UNITED ARAB EMIRATES

ESAB Middle East FZE

Dubai

Tel: +971 4 887 21 11

Fax: +971 4 887 22 63

Representative offices

BULGARIA

ESAB Representative Office

Sofia

Tel/Fax: +359 2 974 42 88

EGYPT

ESAB Egypt

Dokki--Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

ROMANIA

ESAB Representative Office

Bucharest

Tel/Fax: +40 1 322 36 74

RUSSIA

LLC ESAB

Moscow

Tel: +7 095 543 9281

Fax: +7 095 543 9280

LLC ESAB

St Petersburg

Tel: +7 812 336 7080

Fax: +7 812 336 7060

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.com

ESAB AB

SE-- 695 81 LAXÅ

SWEDEN

Phone +46 584 81 000

www.esab.com

070514

Loading...

Loading...